3a123a226deb228f17df0b645795d5b2.ppt

- Количество слайдов: 49

RM Technology Platform The European consolidation of Rapid Manufacturing

RM Technology Platform The European consolidation of Rapid Manufacturing

What is it? • A community of European stakeholders finding RM relevant to survive • “Stakeholders” can be companies, universities or branch organisations 2

What is it? • A community of European stakeholders finding RM relevant to survive • “Stakeholders” can be companies, universities or branch organisations 2

Why do we need a RM-platform? • Create strong European economy with RM • RM is fragmented • There is not yet a central info place for peoples on RM 3

Why do we need a RM-platform? • Create strong European economy with RM • RM is fragmented • There is not yet a central info place for peoples on RM 3

What is considered here as RM RM is making functional end products “directly” from CAD using Additive Layer Manufacturing technologies • In particular for “smaller” volumes or one-off products • It avoids investments of tooling • Currently hardly any dedicated RM technologies or machines; only “RP+” • Also called Additive Layer Manufacturing (ALM), Direct Manufacturing, Direct Fabrication or Digital Manufacturing 4

What is considered here as RM RM is making functional end products “directly” from CAD using Additive Layer Manufacturing technologies • In particular for “smaller” volumes or one-off products • It avoids investments of tooling • Currently hardly any dedicated RM technologies or machines; only “RP+” • Also called Additive Layer Manufacturing (ALM), Direct Manufacturing, Direct Fabrication or Digital Manufacturing 4

How it all started • Nextrama • 5

How it all started • Nextrama • 5

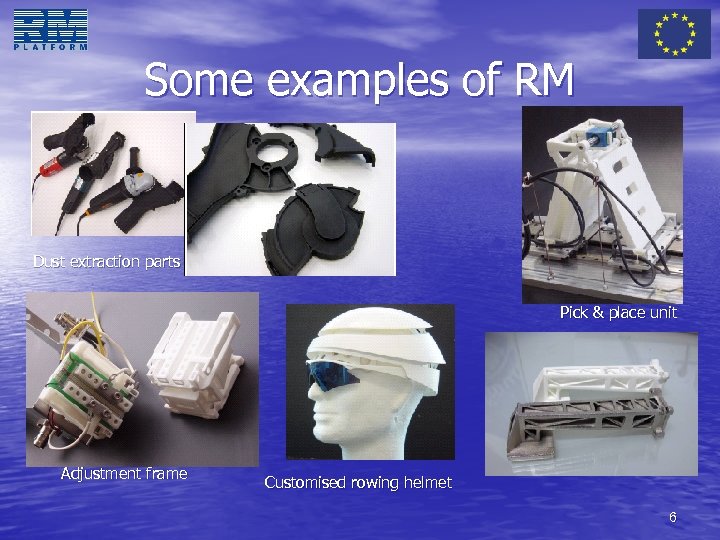

Some examples of RM Dust extraction parts Pick & place unit Adjustment frame Customised rowing helmet 6

Some examples of RM Dust extraction parts Pick & place unit Adjustment frame Customised rowing helmet 6

Some examples of RM Inserts Camera support 7

Some examples of RM Inserts Camera support 7

Some examples of RM Direction indicator 8

Some examples of RM Direction indicator 8

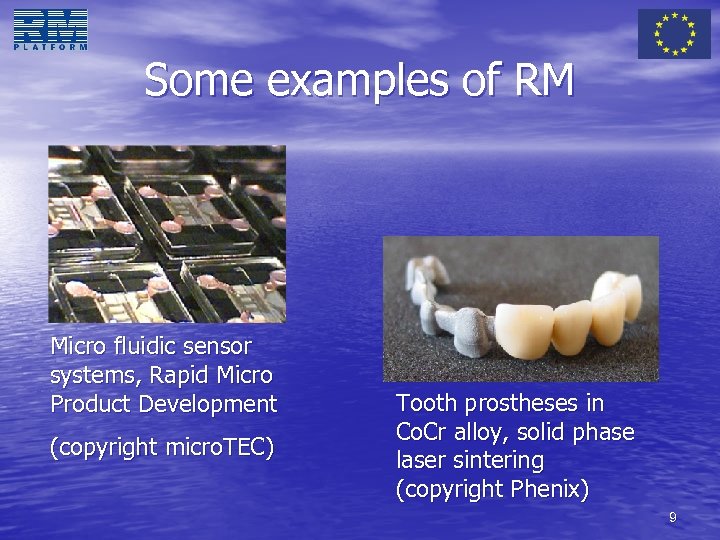

Some examples of RM Micro fluidic sensor systems, Rapid Micro Product Development (copyright micro. TEC) Tooth prostheses in Co. Cr alloy, solid phase laser sintering (copyright Phenix) 9

Some examples of RM Micro fluidic sensor systems, Rapid Micro Product Development (copyright micro. TEC) Tooth prostheses in Co. Cr alloy, solid phase laser sintering (copyright Phenix) 9

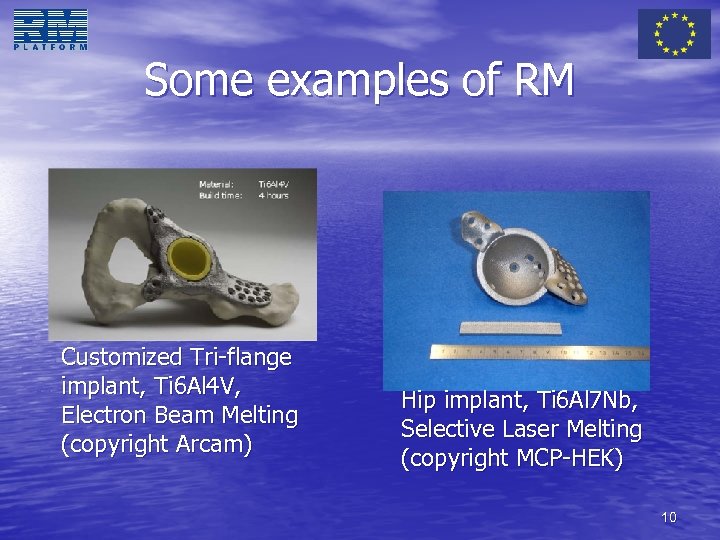

Some examples of RM Customized Tri-flange implant, Ti 6 Al 4 V, Electron Beam Melting (copyright Arcam) Hip implant, Ti 6 Al 7 Nb, Selective Laser Melting (copyright MCP-HEK) 10

Some examples of RM Customized Tri-flange implant, Ti 6 Al 4 V, Electron Beam Melting (copyright Arcam) Hip implant, Ti 6 Al 7 Nb, Selective Laser Melting (copyright MCP-HEK) 10

RM platform objective To achieve European industrial growth & sustainability by a coherent strategy, condensed research, dissemination and exploitation of Rapid Manufacturing 11

RM platform objective To achieve European industrial growth & sustainability by a coherent strategy, condensed research, dissemination and exploitation of Rapid Manufacturing 11

How to achieve this? • Consolidating on European level • Achieving a coherent Vision on RM-future • Achieving the required research topics (SRA) • Making a roadmap for RM • Providing to EC for possible adoption in FP 7 • Creating consortium with the BEST parties • Initiate activities like projects; bilateral, (inter) national, funded or not 12

How to achieve this? • Consolidating on European level • Achieving a coherent Vision on RM-future • Achieving the required research topics (SRA) • Making a roadmap for RM • Providing to EC for possible adoption in FP 7 • Creating consortium with the BEST parties • Initiate activities like projects; bilateral, (inter) national, funded or not 12

Platform also useful because • RM research and applications up to now fragmented, no coordination • Joined approach key to success • Together strong – To create business for companies in Europe – To compete against other regions – To apply for national, regional or EC funding 13

Platform also useful because • RM research and applications up to now fragmented, no coordination • Joined approach key to success • Together strong – To create business for companies in Europe – To compete against other regions – To apply for national, regional or EC funding 13

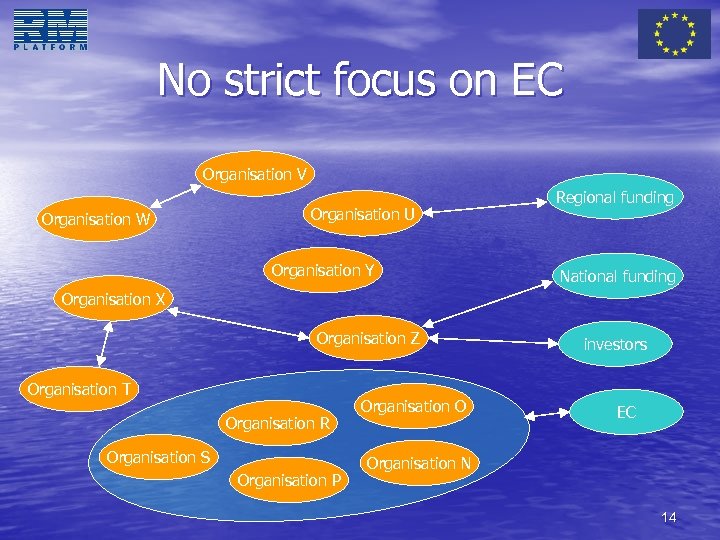

No strict focus on EC Organisation V Organisation W Organisation U Organisation Y Regional funding National funding Organisation X Organisation Z Organisation T Organisation R Organisation S Organisation P Organisation O investors EC Organisation N 14

No strict focus on EC Organisation V Organisation W Organisation U Organisation Y Regional funding National funding Organisation X Organisation Z Organisation T Organisation R Organisation S Organisation P Organisation O investors EC Organisation N 14

Figures per Nov ‘ 06 • 145 stakeholders – 92 from industry; 63% • 22 countries; great geographical balance • Expanding continuously…. . • No doubt this is a “critical mass”… 15

Figures per Nov ‘ 06 • 145 stakeholders – 92 from industry; 63% • 22 countries; great geographical balance • Expanding continuously…. . • No doubt this is a “critical mass”… 15

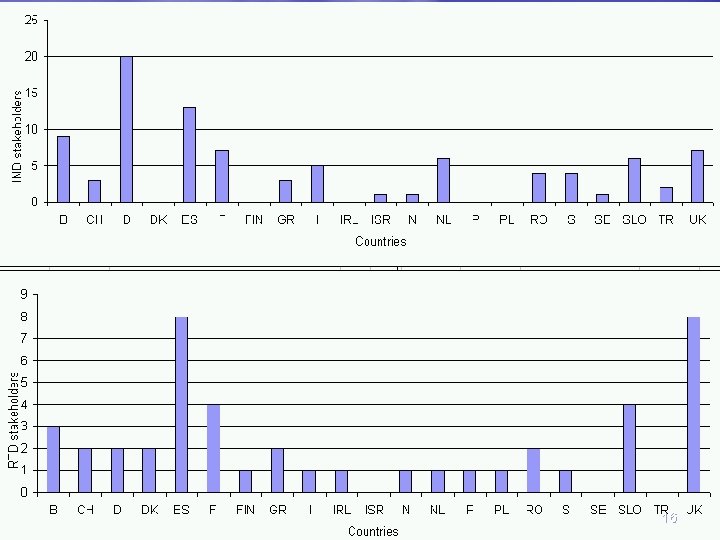

16

16

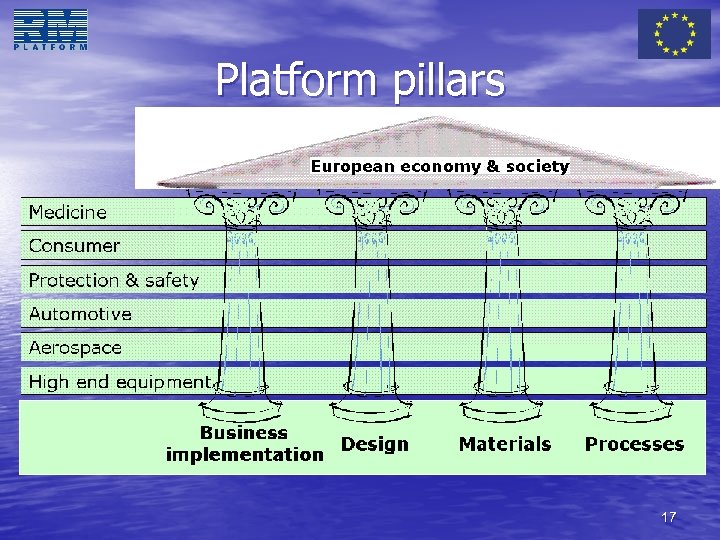

Platform pillars 17

Platform pillars 17

Highlights Vision paper • Potential impact • Business implementation • Design • Materials • Processes 18

Highlights Vision paper • Potential impact • Business implementation • Design • Materials • Processes 18

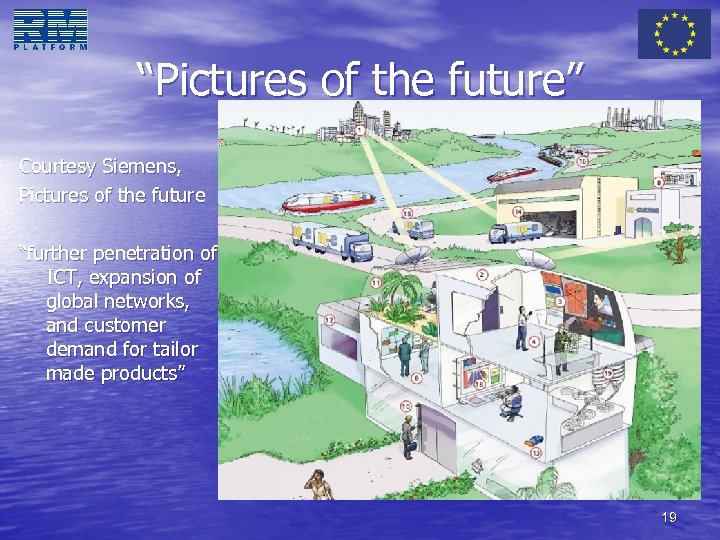

“Pictures of the future” Courtesy Siemens, Pictures of the future “further penetration of ICT, expansion of global networks, and customer demand for tailor made products” 19

“Pictures of the future” Courtesy Siemens, Pictures of the future “further penetration of ICT, expansion of global networks, and customer demand for tailor made products” 19

Potential impact • Mega-trends: – Demand for individualization of products increases (mass customisation) – Products become more complex and life cycles shorten (pressure on cost and time-to-market – Customer-oriented services as selling argument – Environmental issues get more attention • As a result: – Mass production is moving outside Europe – Risk of tooling investment becomes show-stopper – Growth in niche markets and services 20

Potential impact • Mega-trends: – Demand for individualization of products increases (mass customisation) – Products become more complex and life cycles shorten (pressure on cost and time-to-market – Customer-oriented services as selling argument – Environmental issues get more attention • As a result: – Mass production is moving outside Europe – Risk of tooling investment becomes show-stopper – Growth in niche markets and services 20

Potential impact • Solution: Rapid Manufacturing! – No investment risk for tooling – Perfect for mass customisation – Minimum time-to-market – Minimum waste – Knowledge based rather than labour based • Still more expensive, just like every emerging technology 21

Potential impact • Solution: Rapid Manufacturing! – No investment risk for tooling – Perfect for mass customisation – Minimum time-to-market – Minimum waste – Knowledge based rather than labour based • Still more expensive, just like every emerging technology 21

Potential impact “new industrial revolution in the digital age” “customer-oriented service-based manufacturing” 22

Potential impact “new industrial revolution in the digital age” “customer-oriented service-based manufacturing” 22

Potential impact • Economic impact – Reduction of cost and time, particularly for limited volumes – Risk management for investment and stock – Localized production minimizes logistics effort – Enhanced service dimension in business – Most importantly, new sales through niche, customized and new products 23

Potential impact • Economic impact – Reduction of cost and time, particularly for limited volumes – Risk management for investment and stock – Localized production minimizes logistics effort – Enhanced service dimension in business – Most importantly, new sales through niche, customized and new products 23

Potential impact • Social impact – People can co-design products to their specific needs – Applications help the growing group of elderly & disabled people – Good for the environment; minimum energy consumption, reduced waste and pollution – Again: the quality of life is key term 24

Potential impact • Social impact – People can co-design products to their specific needs – Applications help the growing group of elderly & disabled people – Good for the environment; minimum energy consumption, reduced waste and pollution – Again: the quality of life is key term 24

Potential impact • EU policies are met • Sustainability • Quality of life • Employment • Environment • Industry must come into action • Top level support, integration in strategies • Cover complete supply chain • Integrate in market development & commercialisation • Create awareness, acceptance & adoption of RM 25

Potential impact • EU policies are met • Sustainability • Quality of life • Employment • Environment • Industry must come into action • Top level support, integration in strategies • Cover complete supply chain • Integrate in market development & commercialisation • Create awareness, acceptance & adoption of RM 25

Business implementation • Looking at the complete manufacturing picture rather than focussing solely at processes, material or design • Mass production including resulting mass consumption has shaped our society • RM does not fit within these standard thinking patterns and processes • The total realisation chain will be affected 26

Business implementation • Looking at the complete manufacturing picture rather than focussing solely at processes, material or design • Mass production including resulting mass consumption has shaped our society • RM does not fit within these standard thinking patterns and processes • The total realisation chain will be affected 26

Business implementation • Vision on medium term – Costs of manufacturing – Implementation aspects – Education and skills programs for RM 27

Business implementation • Vision on medium term – Costs of manufacturing – Implementation aspects – Education and skills programs for RM 27

Business implementation • Vision on 2020 – RM beginning to become mainstream process – Centre on improvements to business processes, quality, the impact on local manufacturing & effects on skills & employment • Zero waste manufacturing • Quality standards • Stockless manufacturing • Location and distribution • Value Chain • Integration of RM with existing manufacturing • Fuzzy logic interface 28

Business implementation • Vision on 2020 – RM beginning to become mainstream process – Centre on improvements to business processes, quality, the impact on local manufacturing & effects on skills & employment • Zero waste manufacturing • Quality standards • Stockless manufacturing • Location and distribution • Value Chain • Integration of RM with existing manufacturing • Fuzzy logic interface 28

Design • Design will change dramatically. . • Lead times / time-to-market gets shorter • # of product variants is rising • Complexity of design is rising • Responsibilities of the designer increase • Need support of VR-FEM & automated design • Unlimited geometrical freedom • Integration of functionalities by material variations • No assembly required 29

Design • Design will change dramatically. . • Lead times / time-to-market gets shorter • # of product variants is rising • Complexity of design is rising • Responsibilities of the designer increase • Need support of VR-FEM & automated design • Unlimited geometrical freedom • Integration of functionalities by material variations • No assembly required 29

Design • Vision on medium term • Supporting software for macro textures & textile replacements in 3 D format • Experimental CAD system for Functionally Graded Materials (FGM) • E-learning programs to fully exploit the opportunities for RM • Integration of CAD, VR and FEM to support designers • Experimental 3 D Webcam for 3 D low-level geometry scanning • Experimental topological optimisation for automatic geometry optimisation • Computational inspection of RM parts for First Time Right • Cost price calculation comparing conventional with RM 30

Design • Vision on medium term • Supporting software for macro textures & textile replacements in 3 D format • Experimental CAD system for Functionally Graded Materials (FGM) • E-learning programs to fully exploit the opportunities for RM • Integration of CAD, VR and FEM to support designers • Experimental 3 D Webcam for 3 D low-level geometry scanning • Experimental topological optimisation for automatic geometry optimisation • Computational inspection of RM parts for First Time Right • Cost price calculation comparing conventional with RM 30

Design • Vision on 2020 • Free feature modelling CAD system • Product specific CAD systems • CAD for Functionally graded materials • E-learning programs • Integration of CAD, VR and FEM • CAD systems with hybrid kernels • 3 D Webcam for 3 D low-level geometry scanning • Topological optimisation • Multi objective & disciplinary optimisation • Dummy proof design systems • Computational inspection of RM parts • Technologies for capturing user characteristics 31

Design • Vision on 2020 • Free feature modelling CAD system • Product specific CAD systems • CAD for Functionally graded materials • E-learning programs • Integration of CAD, VR and FEM • CAD systems with hybrid kernels • 3 D Webcam for 3 D low-level geometry scanning • Topological optimisation • Multi objective & disciplinary optimisation • Dummy proof design systems • Computational inspection of RM parts • Technologies for capturing user characteristics 31

Materials • Materials development is main driver for RM • It is yet limiting factor for R&D • Only few technologies to use per material • Mainly few main players rule it all 32

Materials • Materials development is main driver for RM • It is yet limiting factor for R&D • Only few technologies to use per material • Mainly few main players rule it all 32

Materials • Vision on medium term • New methods for substitution of classic materials • Prediction of the short and long term behaviour • Implementation of new energy sources • Investigation into the densification mechanisms • New purpose materials with unique selling point • Increase of industrial use of RM technologies • Integration into conventional production • Systematic approach to enable standardisation 33

Materials • Vision on medium term • New methods for substitution of classic materials • Prediction of the short and long term behaviour • Implementation of new energy sources • Investigation into the densification mechanisms • New purpose materials with unique selling point • Increase of industrial use of RM technologies • Integration into conventional production • Systematic approach to enable standardisation 33

Materials • Vision on 2020 • New generation of materials will be developed • Supplementation of wide range stable materials • Processes linked with unique material properties • Operating system for the cost control of material’s choice will be established • Decision methods will assist planning, visualisation and simulation of RM material applications 34

Materials • Vision on 2020 • New generation of materials will be developed • Supplementation of wide range stable materials • Processes linked with unique material properties • Operating system for the cost control of material’s choice will be established • Decision methods will assist planning, visualisation and simulation of RM material applications 34

Processes • Specific advantages over conventional – Any complex shape can be made – Costs independent from complexity (. . ) – Multi materials/components without assembly – Changes to geometry affected immediately – Especially interesting for limited volumes 35

Processes • Specific advantages over conventional – Any complex shape can be made – Costs independent from complexity (. . ) – Multi materials/components without assembly – Changes to geometry affected immediately – Especially interesting for limited volumes 35

Processes • Vision on medium term • First introduced in several niche markets • Improvement into 100% solid material density • Economic manufacture (speed, cost) • Incorporation of nano-engineered materials • Use of high melting point alloys • Human spare parts in process • Sufficient and capable employment 36

Processes • Vision on medium term • First introduced in several niche markets • Improvement into 100% solid material density • Economic manufacture (speed, cost) • Incorporation of nano-engineered materials • Use of high melting point alloys • Human spare parts in process • Sufficient and capable employment 36

Processes • Vision on 2020 • Wider RM-use, complementary to mass production • Cutting edge applications in medical area • RM to be an appealing manufacturing technology • Cutting edge applications with nano materials • Large scale implementation of RM systems 37

Processes • Vision on 2020 • Wider RM-use, complementary to mass production • Cutting edge applications in medical area • RM to be an appealing manufacturing technology • Cutting edge applications with nano materials • Large scale implementation of RM systems 37

Status per Nov ‘ 06 • Commitment of broad range of end user industries • Commitment from high level RTDs • Good feedback from EC regarding WP contribution • Website up & running • Presented during events & meetings • Publications to inform public • Vision paper ready • SRA ready 38

Status per Nov ‘ 06 • Commitment of broad range of end user industries • Commitment from high level RTDs • Good feedback from EC regarding WP contribution • Website up & running • Presented during events & meetings • Publications to inform public • Vision paper ready • SRA ready 38

Milestones 2006 • January: invitation of EC to set up platform • February: first meeting • June: agreement on Vision paper • October: agreement on SRA • November Tuesday 28 th: open RM event • December: FP 7 opens its gates…… 39

Milestones 2006 • January: invitation of EC to set up platform • February: first meeting • June: agreement on Vision paper • October: agreement on SRA • November Tuesday 28 th: open RM event • December: FP 7 opens its gates…… 39

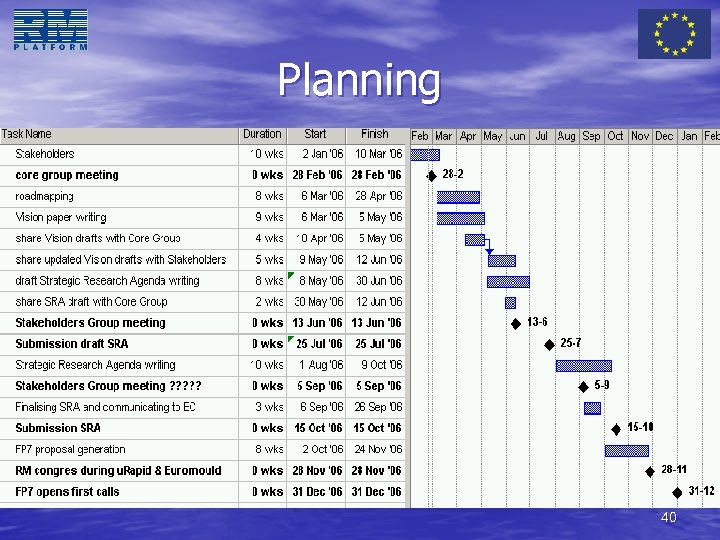

Planning 40

Planning 40

www. rm-platform. com • Home of RM platform stakeholders • To stimulate industry, and also RTD's • Central desk for all kind of RM info – Independent – Free of charge – European wide – Strict focus on RM, so no RP or RT or HSM 41

www. rm-platform. com • Home of RM platform stakeholders • To stimulate industry, and also RTD's • Central desk for all kind of RM info – Independent – Free of charge – European wide – Strict focus on RM, so no RP or RT or HSM 41

www. rm-platform. com 42

www. rm-platform. com 42

Coordination • The platform is managed by TNO and Fraunhofer-Gesellschaft • Website moderated also by micro. TEC and U Wolverhampton Frits Feenstra, Anton Gerrits, Rudolf Meyer, Andrea Reinhardt, Tahar Laoui 43

Coordination • The platform is managed by TNO and Fraunhofer-Gesellschaft • Website moderated also by micro. TEC and U Wolverhampton Frits Feenstra, Anton Gerrits, Rudolf Meyer, Andrea Reinhardt, Tahar Laoui 43

What to find • Public area – Platform objective and info – Papers, case studies, publications, presentations • These to be provided by YOU!! – Links to events, magazines and organisations active in RM • Restricted area (stakeholders) – Vision paper, SRA, minutes, presentations, planning – Stakeholders info sheets & contact data 44

What to find • Public area – Platform objective and info – Papers, case studies, publications, presentations • These to be provided by YOU!! – Links to events, magazines and organisations active in RM • Restricted area (stakeholders) – Vision paper, SRA, minutes, presentations, planning – Stakeholders info sheets & contact data 44

Who can join the Link area • Organisations active with RM • AND uploaded 1+ item to prove this – Paper, case study, publication, presentation 45

Who can join the Link area • Organisations active with RM • AND uploaded 1+ item to prove this – Paper, case study, publication, presentation 45

Who can benefit • OEM’s, end users, industry, consultancy • Companies active in RM – process, material, software, service bureaus • RTD’s – universities, students, research institutions • Dissemination organisms – branch organisations, magazines, conferences 46

Who can benefit • OEM’s, end users, industry, consultancy • Companies active in RM – process, material, software, service bureaus • RTD’s – universities, students, research institutions • Dissemination organisms – branch organisations, magazines, conferences 46

Newsletter • Quarterly update of the new RM info available on the website – Events – Papers – case studies – publications – other interesting documents Subscribe at www. rm-platform. com 47

Newsletter • Quarterly update of the new RM info available on the website – Events – Papers – case studies – publications – other interesting documents Subscribe at www. rm-platform. com 47

RM platform “conference” • During u. Rapid, day before Euromould – Tuesday morning of November 28 th • Objective – To inform “Europe” about the SRA – To expose the project initiatives – To inform industry and get them on board • Good to combine with u. Rapid & Euromould!! 48

RM platform “conference” • During u. Rapid, day before Euromould – Tuesday morning of November 28 th • Objective – To inform “Europe” about the SRA – To expose the project initiatives – To inform industry and get them on board • Good to combine with u. Rapid & Euromould!! 48

Interested? www. rm-platform. com info@rm-platform. com 49

Interested? www. rm-platform. com info@rm-platform. com 49