3d3b1db154dcd662ffa09b786612236a.ppt

- Количество слайдов: 44

RFID Branko Zebec Regional Marketing Manager July - 2006

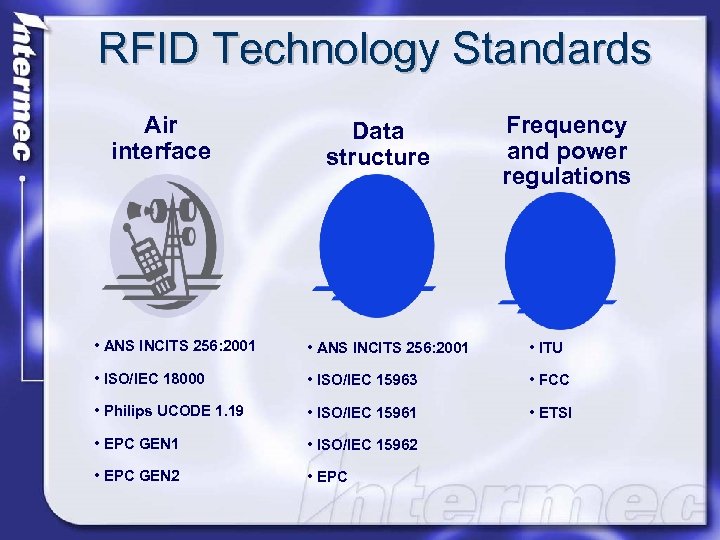

RFID Technology Standards Air interface Data structure Frequency and power regulations • ANS INCITS 256: 2001 • ITU • ISO/IEC 18000 • ISO/IEC 15963 • FCC • Philips UCODE 1. 19 • ISO/IEC 15961 • ETSI • EPC GEN 1 • ISO/IEC 15962 • EPC GEN 2 • EPC

Air interface standards

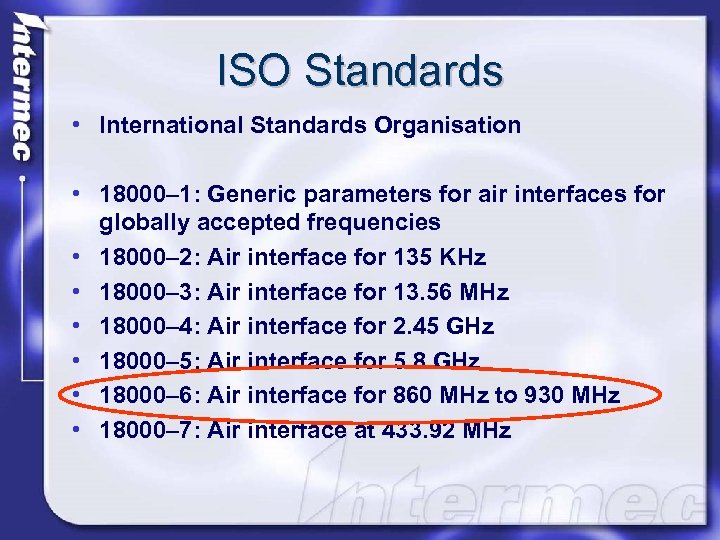

ISO Standards • International Standards Organisation • 18000– 1: Generic parameters for air interfaces for globally accepted frequencies • 18000– 2: Air interface for 135 KHz • 18000– 3: Air interface for 13. 56 MHz • 18000– 4: Air interface for 2. 45 GHz • 18000– 5: Air interface for 5. 8 GHz • 18000– 6: Air interface for 860 MHz to 930 MHz • 18000– 7: Air interface at 433. 92 MHz

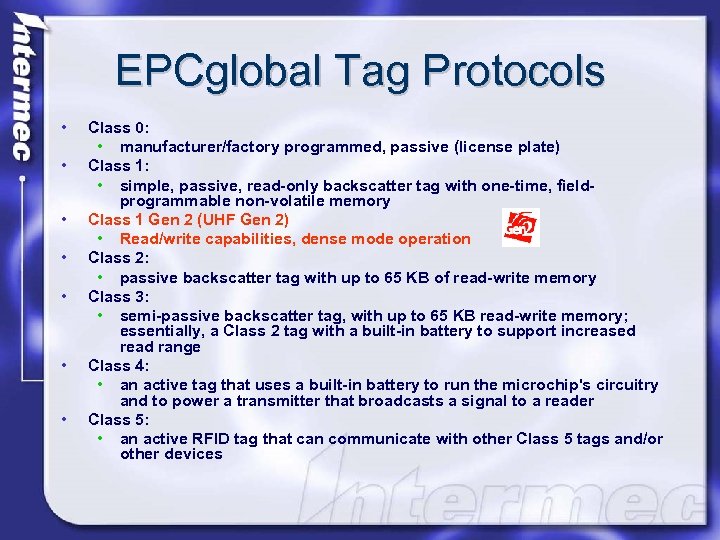

EPCglobal Tag Protocols • • Class 0: • manufacturer/factory programmed, passive (license plate) Class 1: • simple, passive, read-only backscatter tag with one-time, fieldprogrammable non-volatile memory Class 1 Gen 2 (UHF Gen 2) • Read/write capabilities, dense mode operation Class 2: • passive backscatter tag with up to 65 KB of read-write memory Class 3: • semi-passive backscatter tag, with up to 65 KB read-write memory; essentially, a Class 2 tag with a built-in battery to support increased read range Class 4: • an active tag that uses a built-in battery to run the microchip's circuitry and to power a transmitter that broadcasts a signal to a reader Class 5: • an active RFID tag that can communicate with other Class 5 tags and/or other devices

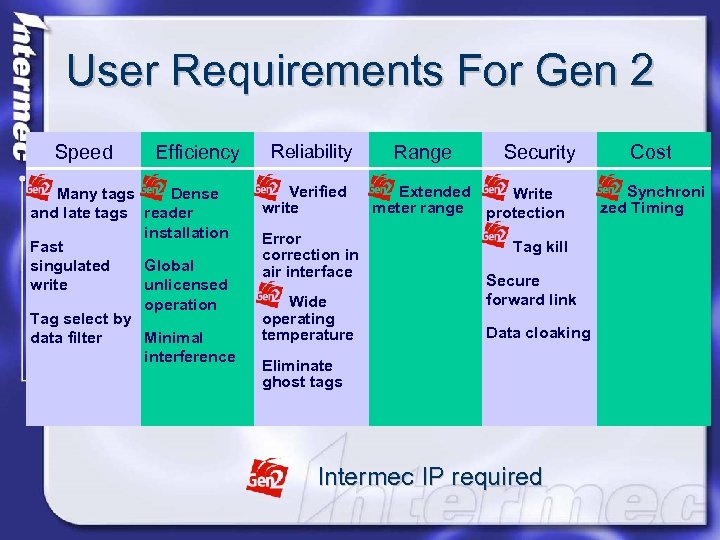

User Requirements For Gen 2 Speed Efficiency Many tags Dense and late tags reader installation Fast singulated Global write unlicensed operation Tag select by data filter Minimal interference Reliability Verified write Error correction in air interface Wide operating temperature Range Security Extended Write meter range protection Tag kill Secure forward link Data cloaking Eliminate ghost tags Intermec IP required Cost Synchroni zed Timing

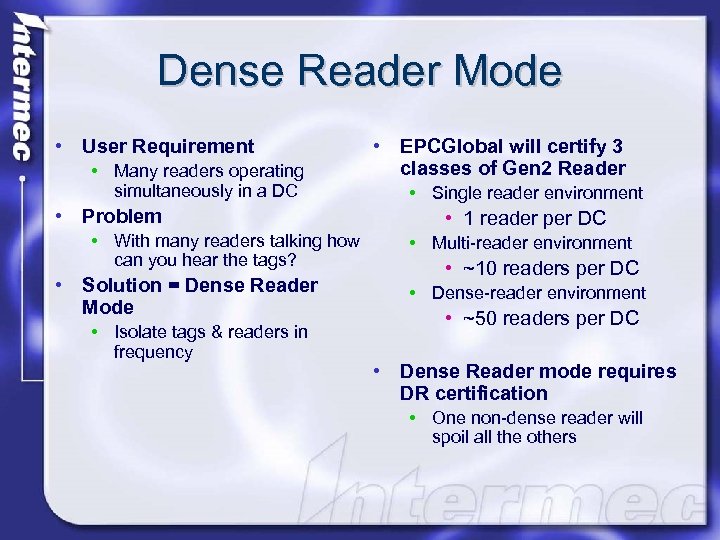

Dense Reader Mode • User Requirement • Many readers operating simultaneously in a DC • Problem • With many readers talking how can you hear the tags? • Solution = Dense Reader Mode • Isolate tags & readers in frequency • EPCGlobal will certify 3 classes of Gen 2 Reader • Single reader environment • 1 reader per DC • Multi-reader environment • ~10 readers per DC • Dense-reader environment • ~50 readers per DC • Dense Reader mode requires DR certification • One non-dense reader will spoil all the others

Data Structure

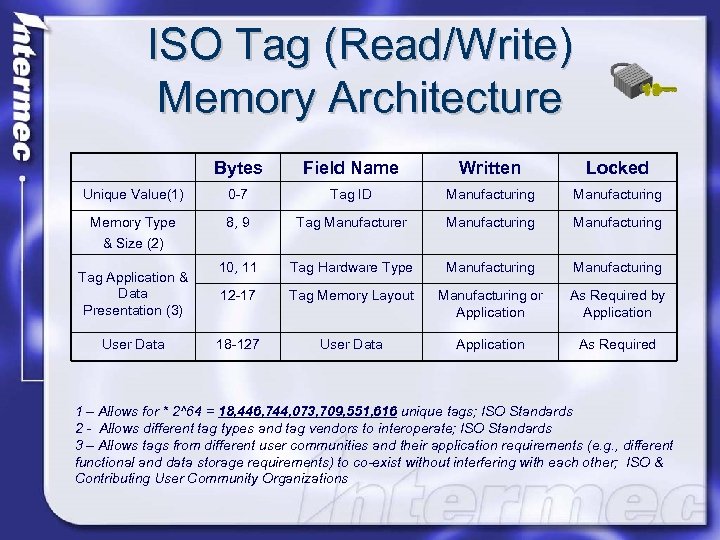

ISO Tag (Read/Write) Memory Architecture Bytes Field Name Written Locked Unique Value(1) 0 -7 Tag ID Manufacturing Memory Type & Size (2) 8, 9 Tag Manufacturer Manufacturing 10, 11 Tag Hardware Type Manufacturing 12 -17 Tag Memory Layout Manufacturing or Application As Required by Application 18 -127 User Data Application As Required Tag Application & Data Presentation (3) User Data 1 – Allows for * 2^64 = 18, 446, 744, 073, 709, 551, 616 unique tags; ISO Standards 2 - Allows different tag types and tag vendors to interoperate; ISO Standards 3 – Allows tags from different user communities and their application requirements (e. g. , different functional and data storage requirements) to co-exist without interfering with each other; ISO & Contributing User Community Organizations

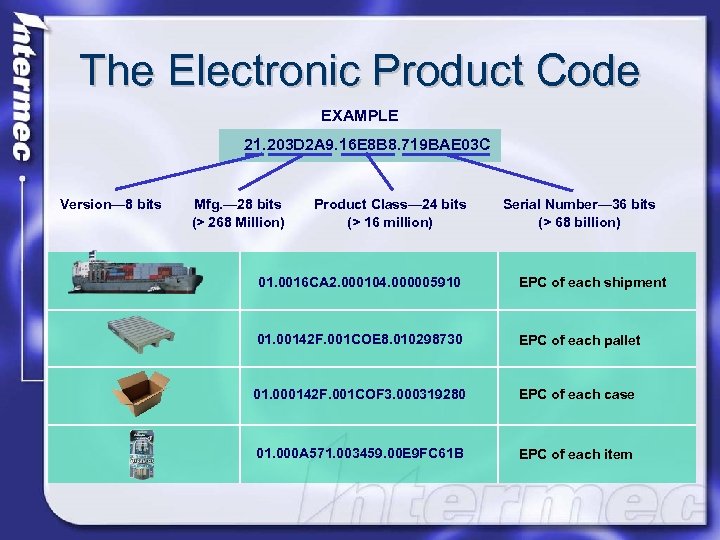

The Electronic Product Code EXAMPLE 21. 203 D 2 A 9. 16 E 8 B 8. 719 BAE 03 C Version— 8 bits Mfg. — 28 bits (> 268 Million) Product Class— 24 bits (> 16 million) Serial Number— 36 bits (> 68 billion) 01. 0016 CA 2. 000104. 000005910 EPC of each shipment 01. 00142 F. 001 COE 8. 010298730 EPC of each pallet 01. 000142 F. 001 COF 3. 000319280 EPC of each case 01. 000 A 571. 003459. 00 E 9 FC 61 B EPC of each item

Frequency & Power Regulations

ITU Regulations

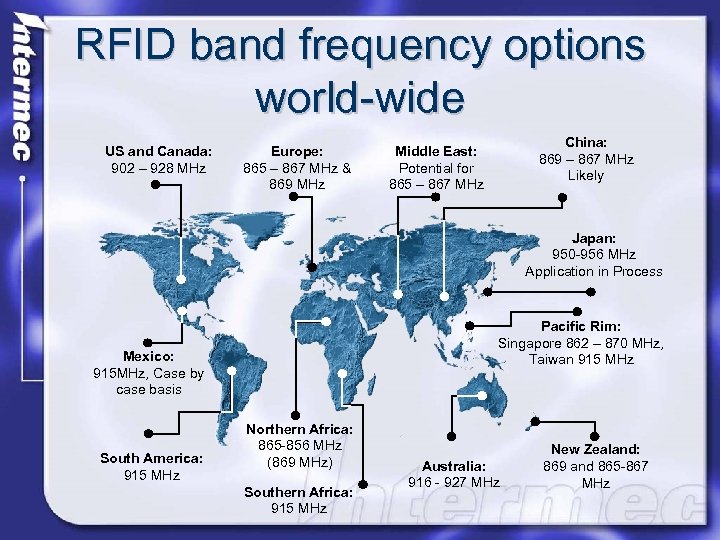

RFID band frequency options world-wide US and Canada: 902 – 928 MHz Europe: 865 – 867 MHz & 869 MHz China: 869 – 867 MHz Likely Middle East: Potential for 865 – 867 MHz Japan: 950 -956 MHz Application in Process Pacific Rim: Singapore 862 – 870 MHz, Taiwan 915 MHz Mexico: 915 MHz, Case by case basis South America: 915 MHz Northern Africa: 865 -856 MHz (869 MHz) Southern Africa: 915 MHz Australia: 916 - 927 MHz New Zealand: 869 and 865 -867 MHz

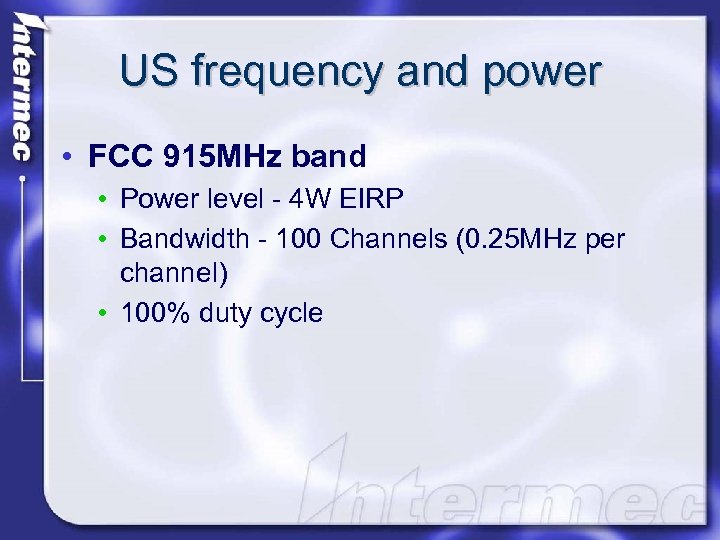

US frequency and power • FCC 915 MHz band • Power level - 4 W EIRP • Bandwidth - 100 Channels (0. 25 MHz per channel) • 100% duty cycle

European power regulations & restrictions • ETSI EN 300 220 -1 • At 869 MHz - no greater than 0. 5 W ( <500 m. W) ERP • 1 channel (0. 25 MHz) • 10% Duty Cycle per hour, per transmitter (6 minutes of continuous transmission per hour) • Accepted everywhere in Europe except Italy • ETSI EN 302 208 • • At 865 -7 MHz - 2 W of ERP 10 Channels (0. 25 MHz) 100% duty cycle Requires individual Country acceptance • So far, Germany, Finland, Denmark, Iceland, Switzerland, Czech, Malta and UK

RFID Products & Technologies

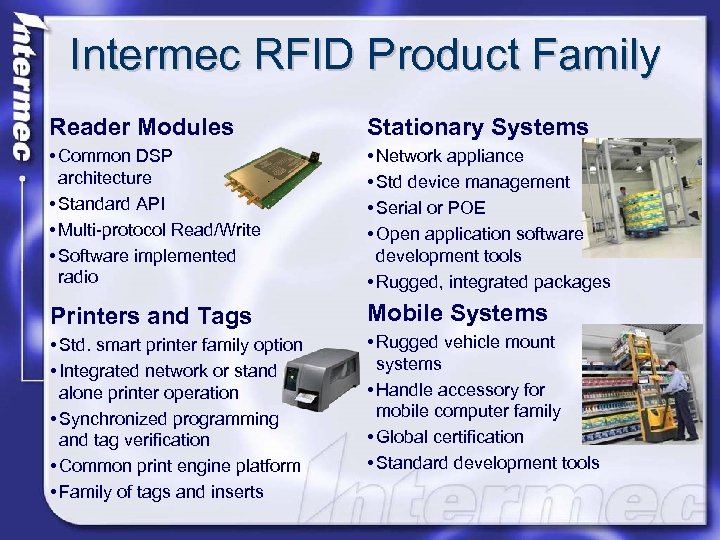

Intermec RFID Product Family Reader Modules Stationary Systems • Common DSP architecture • Standard API • Multi-protocol Read/Write • Software implemented radio • Network appliance • Std device management • Serial or POE • Open application software development tools • Rugged, integrated packages Printers and Tags Mobile Systems • Std. smart printer family option • Integrated network or stand alone printer operation • Synchronized programming and tag verification • Common print engine platform • Family of tags and inserts • Rugged vehicle mount systems • Handle accessory for mobile computer family • Global certification • Standard development tools

IF 4 Serial RFID Reader • • Designed to use external edge server architecture • RFID ADC scanner for adding RFID to existing PLC • Four antenna input capability • RS 232 connection • Qualified reader/tag system performance • Software radio provides multi -protocol capability • Meets RFID global regulations • EPC Global Gen 2 capable and download upgradeable to ISO 18000 -6 c Applications • Access control • Portal – pallet tag • Conveyor – carton tag IF 4 Benefits • Ability to deploy real-world RFID systems! • Lowers cost to maintain RFID • Lowers cost to implement RFID

IF 5 Network Appliance RFID Reader • Intelligent on-board edge • Applications server – Linux OS • Portal – pallet and carton tag • Four antenna input • Conveyor – carton and item capability tag • Self-powered sensor/control interfaces • Ethernet or 802. 11 interfaces IF 5 • Qualified reader/tag system performance Benefits • Software radio provides • Lower risk associated multi-protocol capability implementing RFID while • Meets RFID global increasing system response! regulations • Deploy real-world RFID • EPC Global Gen 2 capable • IBM, Oracle, SAP: full and download upgradeable support for the future! to ISO 18000 -6 c

IF 1 Integrated RFID Reader • Installation cost savings antenna and reader in one package • Designed to use external edge server architecture • RS 232 or wired Ethernet • DC or Power over Ethernet • Qualified reader/tag system performance • Software radio provides multi-protocol capability • EPC Global Gen 2 capable and download upgradeable to ISO 18000 -6 c • Includes dense reader operation • Applications • • Outdoor – vehicle control Access control Portal – pallet tag Conveyor – carton tag Jul-06 IF 1 Benefits • Clean installation (fewer parts and cables) • Lowers cost to implement and maintain RFID • Reads tags at wide angles for greater reliability

IV 7 Vehicle Mounted RFID Reader • Intermec’s legendary rugged • Applications design • Work in process • RS 232 connectivity to vehicle • Pallet R/W tag mounted computer • Replenishment IV 7 • Easy to use tool set resides • Shelf ID tag on VMT • Order staging • Four antenna input capability • Cross docking • Software radio provides multi • Door and Driver ID -protocol capability tags • Meets RFID global Benefits • Forklift - lower cost offering than regulations portals • EPC Global Gen 2 capable • Works with existing applications! and download upgradeable • More picks per day! to ISO 18000 -6 c • Includes DR operation • Lowers cost to implement and maintain RFID

RFID Antennas • RFID Antennas Now Listed on Intermec Website • Sales Data Sheets Now Available on Website

IP 4 Industrial Mobile RFID Reader • Accessory provides RFID upgrade capability • Reads and programs tags • Self-contained RFID accessory • All HHC functions are maintained • Easy omni-directional data collection • Software radio provides multi-protocol capability • EPC Global Gen 2 capable and download upgradeable to ISO 18000 -6 c • Applications • • Item level tracking Picking IP 4 Shipping & receiving Maintenance & field service • Any “exception” handling Benefits • Snap-on upgrade for Color 700 users, esp. DSD • Supervisors and inventory takers can perform their job faster • Utilize existing applications, preserving software investment

Easy. Coder® PM 4 i Printer with RFID • Multiple RFID options • Gen 2 and ISO 915 MHz or 869 MHz • EPC Gen 1 (Class 1 only) • Applications • WIP labels • Pick/pack/shipping labels • Cross-docking labels • Metal industrial printer • Strong connectivity. • Ethernet, USB & Serial Std. • Optional 802. 11 b/g, Dual serial, Parallel. Benefits PM 4 i • Multi-purpose RFID printer • Offer Gen 2 “slap-and-ship” product now! • Smart printer with stand • Oracle WMS and SAP AII-ready alone capabilities • Works with existing applications! • Easy Host connectivity to • Guaranteed system performance ERP & WMS systems.

RFID Value Added Features

Intermec RFID Middleware Partners • IBM – Web. Sphere RFID Device Infrastructure (WRDI) • Oracle – Sensor Management • SAP – Auto-ID Infrastructure (AII) • Sun – RFID Event Manager • Cisco – AON RFID, RFID Network Ready • Microsoft – Device Service Provider Infrastructure (DSPI) • BEA – RFTag. Aware • Others: Globe Ranger, RFCode, Reva Systems, …

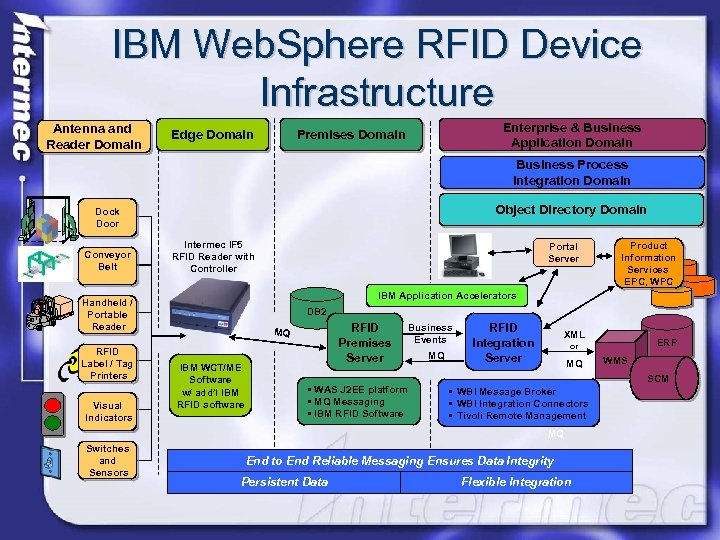

IBM Web. Sphere RFID Device Infrastructure Antenna and Reader Domain Edge Domain Enterprise & Business Application Domain Premises Domain Business Process Integration Domain Object Directory Domain Dock Door Conveyor Belt Intermec IF 5 RFID Reader with Controller Visual Indicators Switches and Sensors Product Information Services EPC, WPC IBM Application Accelerators Handheld / Portable Reader RFID Label / Tag Printers Portal Server DB 2 RFID Premises Server MQ IBM WCT/ME Software w/ add’l IBM RFID software § WAS J 2 EE platform § MQ Messaging § IBM RFID Software Business Events MQ RFID Integration Server XML MQ WMS SCM § WBI Message Broker § WBI Integration Connectors § Tivoli Remote Management XML MQ End to End Reliable Messaging Ensures Data Integrity Persistent Data ERP or Flexible Integration

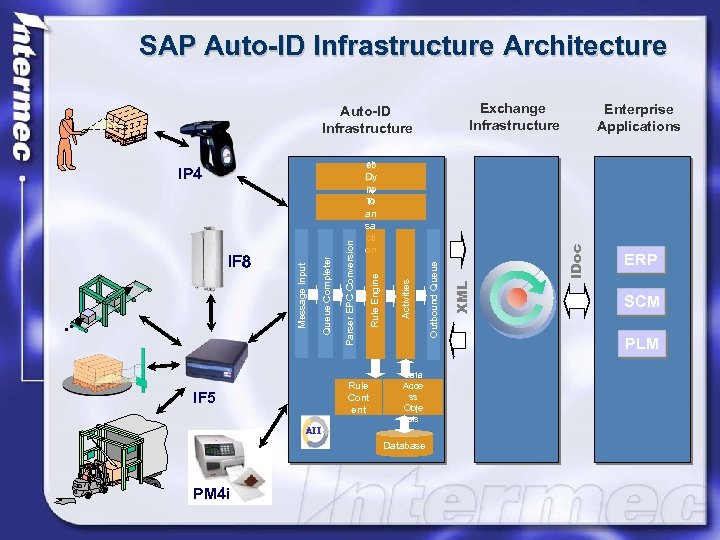

SAP Auto-ID Infrastructure Architecture Exchange Infrastructure Auto-ID Infrastructure Rule Cont ent IF 5 Data Acce ss Obje cts AII Database PM 4 i IDoc XML Outbound Queue Activities Rule Engine Parser EPC Conversion Queue Completer IF 8 Message Input IP 4 W eb M Dy ob np ile ro Tr an sa cti on Enterprise Applications ERP SCM PLM

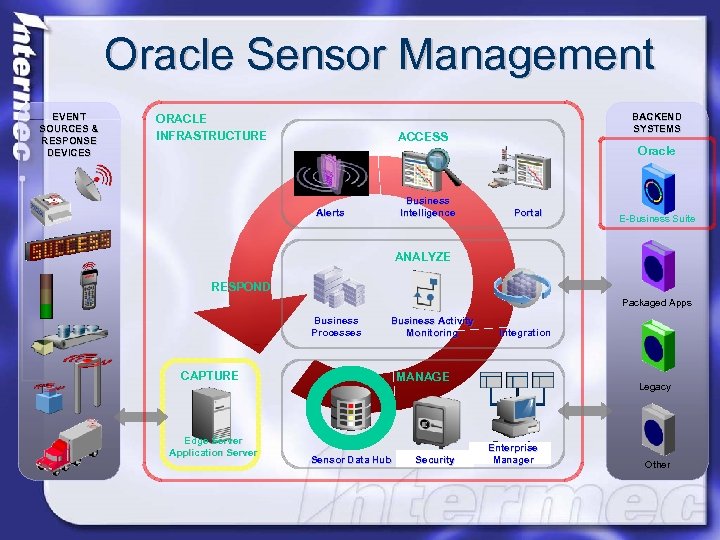

Oracle Sensor Management EVENT SOURCES & RESPONSE DEVICES ORACLE INFRASTRUCTURE BACKEND SYSTEMS ACCESS Oracle Business Intelligence Alerts Portal E-Business Suite ANALYZE RESPOND Packaged Apps Business Processes Business Activity Monitoring CAPTURE Edge Server Application Server Integration MANAGE Sensor Data Hub Security Legacy Enterprise Manager Other

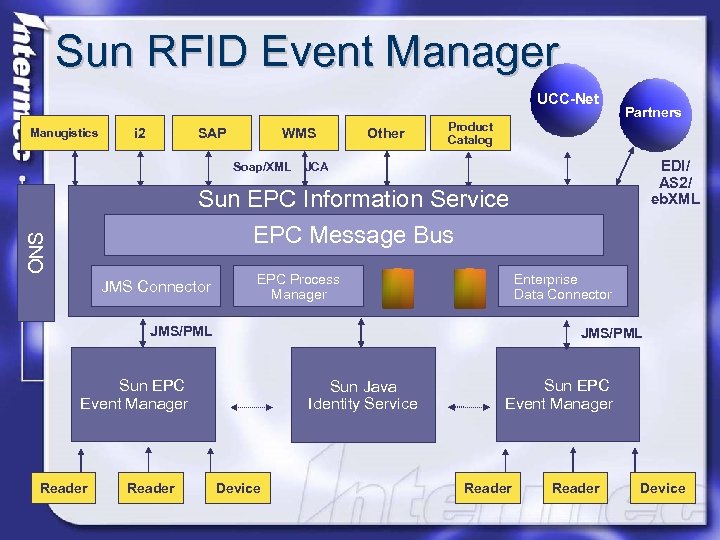

Sun RFID Event Manager UCC-Net Manugistics i 2 SAP WMS Soap/XML Other Product Catalog Partners EDI/ AS 2/ eb. XML JCA Sun EPC Information Service ONS EPC Message Bus JMS Connector EPC Process Manager Enterprise Data Connector JMS/PML Sun EPC Event Manager Reader Sun Java Identity Service Device Sun EPC Event Manager Reader Device

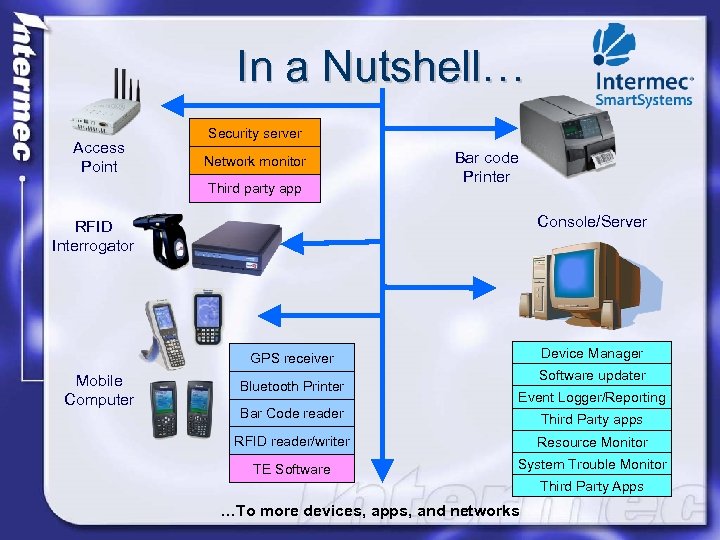

In a Nutshell… Access Point Security server Network monitor Third party app Bar code Printer Console/Server RFID Interrogator Device Manager GPS receiver Mobile Computer Bluetooth Printer Software updater Event Logger/Reporting Bar Code reader Third Party apps RFID reader/writer Resource Monitor TE Software System Trouble Monitor Third Party Apps …To more devices, apps, and networks

Intermec Developers Library • • The right tool makes for a better fit IDL Objectives: Make it easier to develop for Intermec devices Enable developers to focus on the business logic Ensure software investment protection

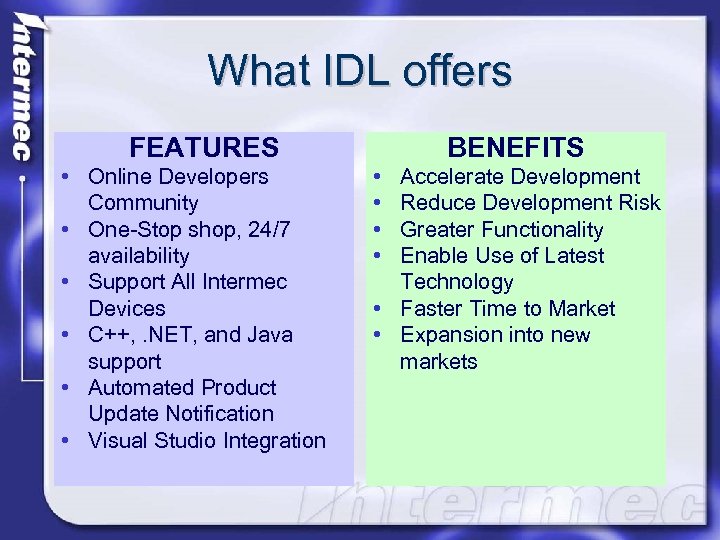

What IDL offers FEATURES • Online Developers Community • One-Stop shop, 24/7 availability • Support All Intermec Devices • C++, . NET, and Java support • Automated Product Update Notification • Visual Studio Integration BENEFITS • • Accelerate Development Reduce Development Risk Greater Functionality Enable Use of Latest Technology • Faster Time to Market • Expansion into new markets

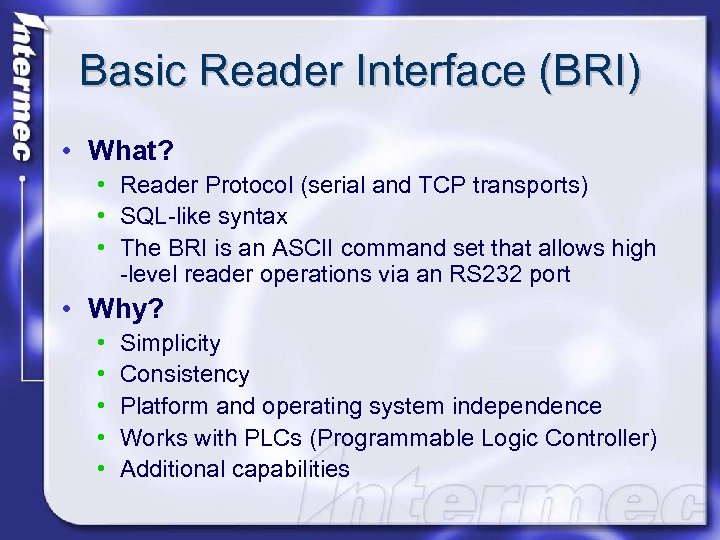

Basic Reader Interface (BRI) • What? • Reader Protocol (serial and TCP transports) • SQL-like syntax • The BRI is an ASCII command set that allows high -level reader operations via an RS 232 port • Why? • • • Simplicity Consistency Platform and operating system independence Works with PLCs (Programmable Logic Controller) Additional capabilities

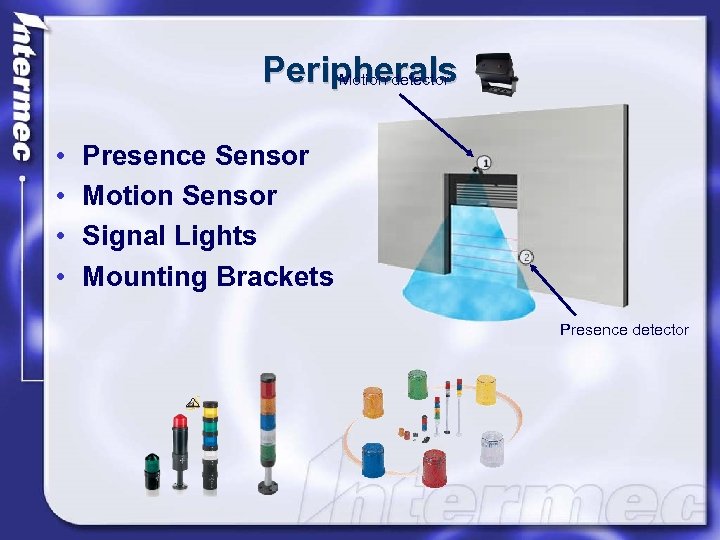

Peripherals Motion detector • • Presence Sensor Motion Sensor Signal Lights Mounting Brackets Presence detector

RFID Certified CCX compliant 802. 11 radio in IF 5 IM 5 module certified used in IF 5, IF 4, IV 7 & PM 4 i XMLReady™ for Oracle® Mobile Supply Chain Application/ Oracle Warehouse Management. IF 5 first Gen 2 RFID reader certified to operate with the SAP Auto-ID Infrastructure (SAP AII), IF 5 first device to meet test criteria in testing by an independent testing facility for interoperability with the Cisco RFID Solution

RFID Status Review July 2006 Intermec Confidential

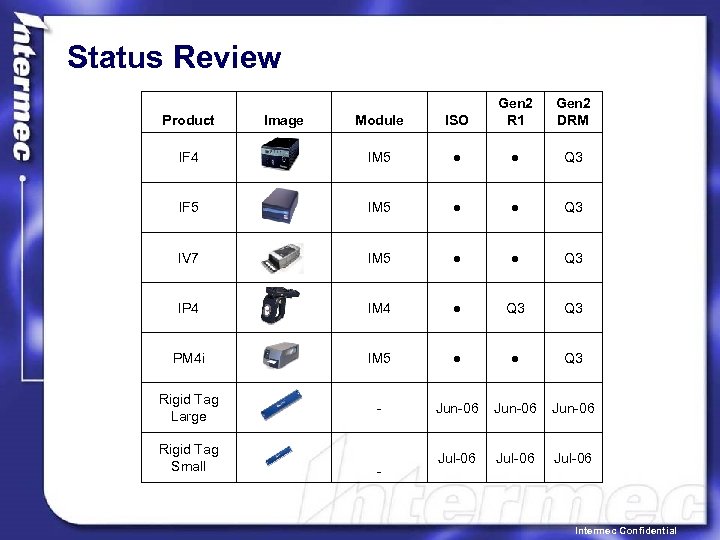

Status Review Module ISO Gen 2 R 1 IF 4 IM 5 ● ● Q 3 IF 5 IM 5 ● ● Q 3 IV 7 IM 5 ● ● Q 3 IP 4 IM 4 ● Q 3 PM 4 i IM 5 ● ● Q 3 Rigid Tag Large - Jun-06 Jul-06 Product Rigid Tag Small Image - Gen 2 DRM Intermec Confidential

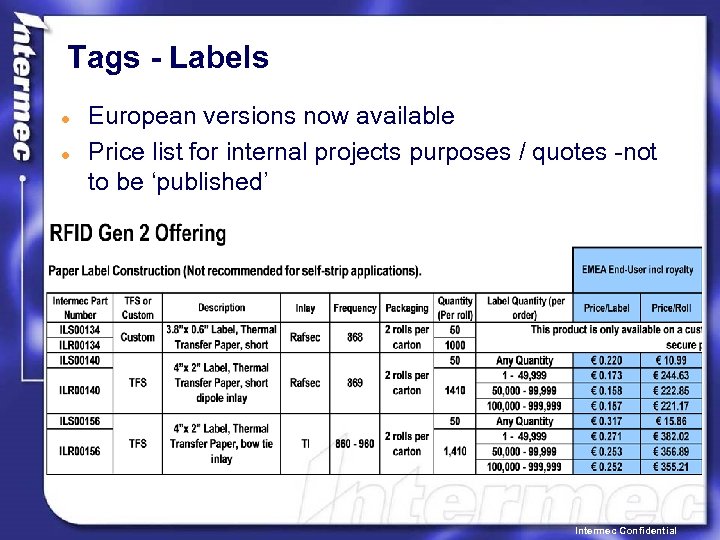

Tags - Labels l l European versions now available Price list for internal projects purposes / quotes -not to be ‘published’ Intermec Confidential

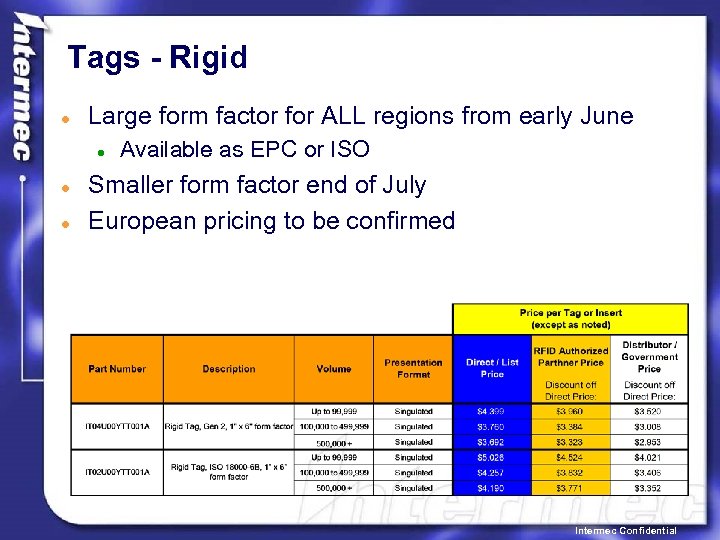

Tags - Rigid l Large form factor for ALL regions from early June l l l Available as EPC or ISO Smaller form factor end of July European pricing to be confirmed Intermec Confidential

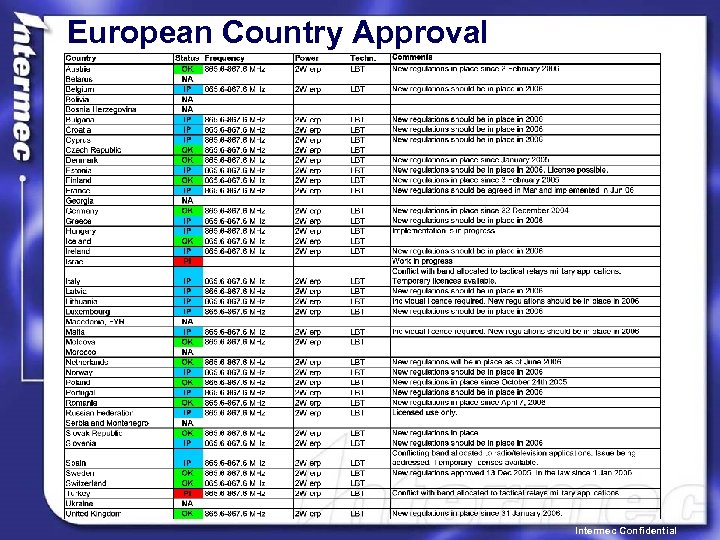

European Country Approval Intermec Confidential

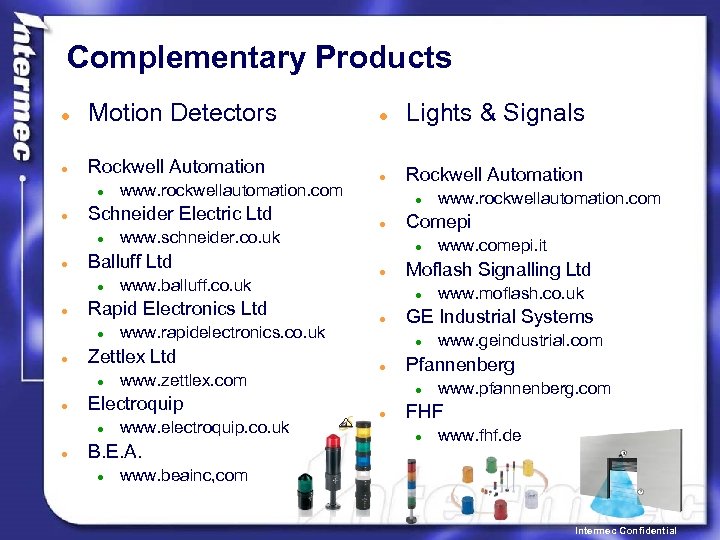

Complementary Products l Motion Detectors l Rockwell Automation l l Schneider Electric Ltd l l www. zettlex. com Electroquip l l www. rapidelectronics. co. uk Zettlex Ltd l l www. balluff. co. uk Rapid Electronics Ltd l l www. schneider. co. uk Balluff Ltd l l www. rockwellautomation. com www. electroquip. co. uk B. E. A. l l Lights & Signals l Rockwell Automation l l Comepi l l www. geindustrial. com Pfannenberg l l www. moflash. co. uk GE Industrial Systems l l www. comepi. it Moflash Signalling Ltd l l www. rockwellautomation. com www. pfannenberg. com FHF l www. fhf. de www. beainc, com Intermec Confidential

Demo 0123 4567 8910

Thank You

3d3b1db154dcd662ffa09b786612236a.ppt