7855d821f7b179f1d1ce60536cff5ae1.ppt

- Количество слайдов: 61

RF Pick, Pack & Ship for XA COM Including Release 2 Features/Functions Jim Simunek, Sr. Business Consultant, Cistech, Inc. Jim. Simunek@cistech. net

RF Pick, Pack & Ship for XA COM Including Release 2 Features/Functions Jim Simunek, Sr. Business Consultant, Cistech, Inc. Jim. Simunek@cistech. net

Overview • Use RF gun to stage COM orders for shipment – No need to key items/quantities picked on ‘green screen’ • Control File for ‘tailoring’ • Office functions to: – Assign Pick Lists to pickers – Status orders being picked – Clear RF flags (in case a signal gets dropped) – Ship non-container orders

Overview • Use RF gun to stage COM orders for shipment – No need to key items/quantities picked on ‘green screen’ • Control File for ‘tailoring’ • Office functions to: – Assign Pick Lists to pickers – Status orders being picked – Clear RF flags (in case a signal gets dropped) – Ship non-container orders

Existing Features • Handles both regular and stock pick lists • Recognizes Discrete Allocations • Will switch to kit component pick lists from primary pick list if there are kit items on the primary pick list • Can containerize pick (Control File setting - all orders or none) • Handles consolidated pick lists

Existing Features • Handles both regular and stock pick lists • Recognizes Discrete Allocations • Will switch to kit component pick lists from primary pick list if there are kit items on the primary pick list • Can containerize pick (Control File setting - all orders or none) • Handles consolidated pick lists

Release 2 Enhancements • Re-structure RF Environment Control Maintenance into groupings • Employee Assignment to specific pick lists (Control File setting) • Allow F 5 prompt from Enter Pick List at RF – Display pick lists available for picking at RF (this will allow pick list print too) • Allow entry of item, turnaround, or UPC from RF • When displaying pick list items, display them in pick list order • Item Substitution during picking (Control File setting) • Serial number entry (Control File Setting)

Release 2 Enhancements • Re-structure RF Environment Control Maintenance into groupings • Employee Assignment to specific pick lists (Control File setting) • Allow F 5 prompt from Enter Pick List at RF – Display pick lists available for picking at RF (this will allow pick list print too) • Allow entry of item, turnaround, or UPC from RF • When displaying pick list items, display them in pick list order • Item Substitution during picking (Control File setting) • Serial number entry (Control File Setting)

List of Enhancements • Allow entry of Carrier information from RF (Control File setting) • Allow packing list print prior to shipping, from RF • Automatic shipment create for UPS, Fed Ex or DHL without requiring containerization • Allow F 2 return from Location Rescan/Verify

List of Enhancements • Allow entry of Carrier information from RF (Control File setting) • Allow packing list print prior to shipping, from RF • Automatic shipment create for UPS, Fed Ex or DHL without requiring containerization • Allow F 2 return from Location Rescan/Verify

R 7 Only Enhancements • Incorporate new R 7 XA user exits needed to make the product work less invasively with XA • Incorporate the XA 7 ability to provide insufficient inventory messaging at the warehouse level

R 7 Only Enhancements • Incorporate new R 7 XA user exits needed to make the product work less invasively with XA • Incorporate the XA 7 ability to provide insufficient inventory messaging at the warehouse level

File Set-up

File Set-up

Control File • Containerize shipments (must use XA screens to ship the container) • Interfaces to UPS, Fed Ex and DHL • Use the feature to assign Pick Lists to Employees • Guided Picking – Un-Guided picking will ask for enter/scan of: • Item Number • UPC Number (User Exit in case UPC not stored in ‘Alternate Item Number’ field of Item Master/Revision) • Turnaround Number – Guided Picking will display the next number to be picked on the RF gun

Control File • Containerize shipments (must use XA screens to ship the container) • Interfaces to UPS, Fed Ex and DHL • Use the feature to assign Pick Lists to Employees • Guided Picking – Un-Guided picking will ask for enter/scan of: • Item Number • UPC Number (User Exit in case UPC not stored in ‘Alternate Item Number’ field of Item Master/Revision) • Turnaround Number – Guided Picking will display the next number to be picked on the RF gun

Control File • Separate Manager Approvals for either over pick quantity or under pick quantity • Item Re-scan verification • Item Substitutions • Default pick location to Item Balance Default Location • Block display on the RF gun of items waiting inspection or under QC quarantine • Warning or Error notification to the RF Gun when inventory in a location will go negative

Control File • Separate Manager Approvals for either over pick quantity or under pick quantity • Item Re-scan verification • Item Substitutions • Default pick location to Item Balance Default Location • Block display on the RF gun of items waiting inspection or under QC quarantine • Warning or Error notification to the RF Gun when inventory in a location will go negative

Control File • Automatic print of Packing List at Pick Order Verification • Ability to print Shipping Labels at Pick Order Verification – Default Label has Ship name/address from CO and CO number, PO number and label count (i. e. ‘ 1 of 3’) – User Exit and API allow use of your own label • Enter Carrier information from RF gun – – Pro Number Truck/Trailer number Weight & Cubes Separate setting in Employee Defaults

Control File • Automatic print of Packing List at Pick Order Verification • Ability to print Shipping Labels at Pick Order Verification – Default Label has Ship name/address from CO and CO number, PO number and label count (i. e. ‘ 1 of 3’) – User Exit and API allow use of your own label • Enter Carrier information from RF gun – – Pro Number Truck/Trailer number Weight & Cubes Separate setting in Employee Defaults

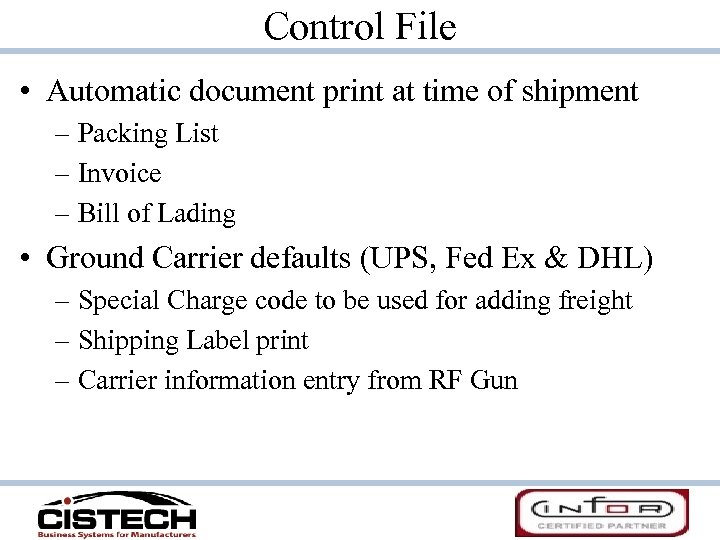

Control File • Automatic document print at time of shipment – Packing List – Invoice – Bill of Lading • Ground Carrier defaults (UPS, Fed Ex & DHL) – Special Charge code to be used for adding freight – Shipping Label print – Carrier information entry from RF Gun

Control File • Automatic document print at time of shipment – Packing List – Invoice – Bill of Lading • Ground Carrier defaults (UPS, Fed Ex & DHL) – Special Charge code to be used for adding freight – Shipping Label print – Carrier information entry from RF Gun

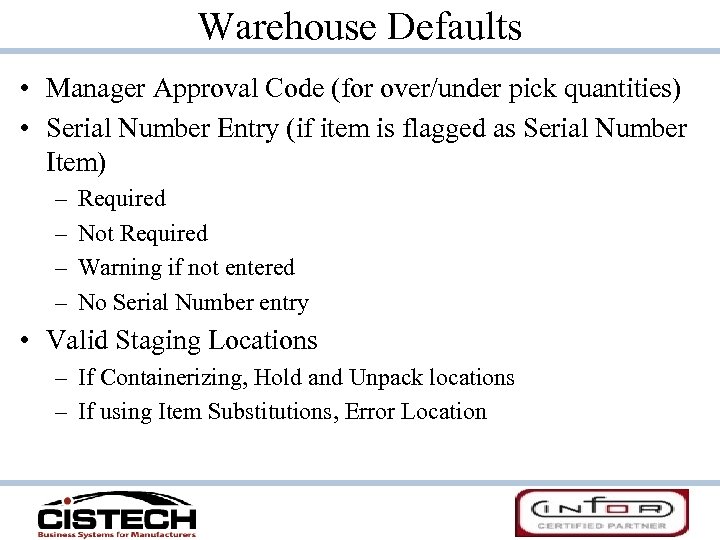

Warehouse Defaults • Manager Approval Code (for over/under pick quantities) • Serial Number Entry (if item is flagged as Serial Number Item) – – Required Not Required Warning if not entered No Serial Number entry • Valid Staging Locations – If Containerizing, Hold and Unpack locations – If using Item Substitutions, Error Location

Warehouse Defaults • Manager Approval Code (for over/under pick quantities) • Serial Number Entry (if item is flagged as Serial Number Item) – – Required Not Required Warning if not entered No Serial Number entry • Valid Staging Locations – If Containerizing, Hold and Unpack locations – If using Item Substitutions, Error Location

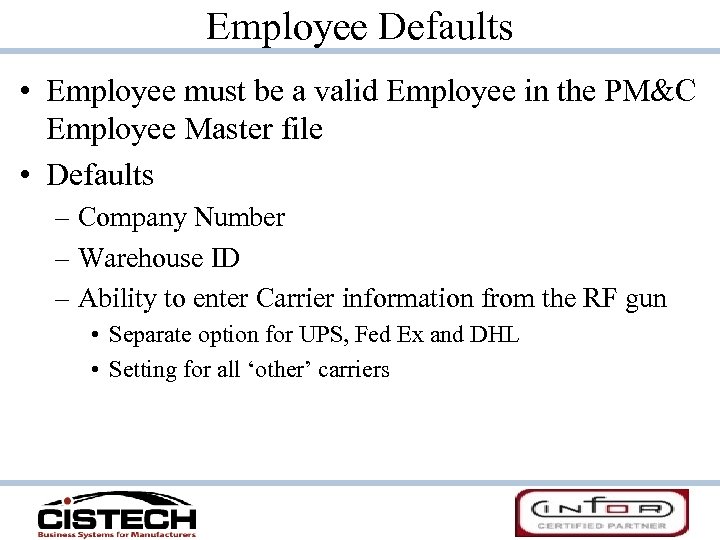

Employee Defaults • Employee must be a valid Employee in the PM&C Employee Master file • Defaults – Company Number – Warehouse ID – Ability to enter Carrier information from the RF gun • Separate option for UPS, Fed Ex and DHL • Setting for all ‘other’ carriers

Employee Defaults • Employee must be a valid Employee in the PM&C Employee Master file • Defaults – Company Number – Warehouse ID – Ability to enter Carrier information from the RF gun • Separate option for UPS, Fed Ex and DHL • Setting for all ‘other’ carriers

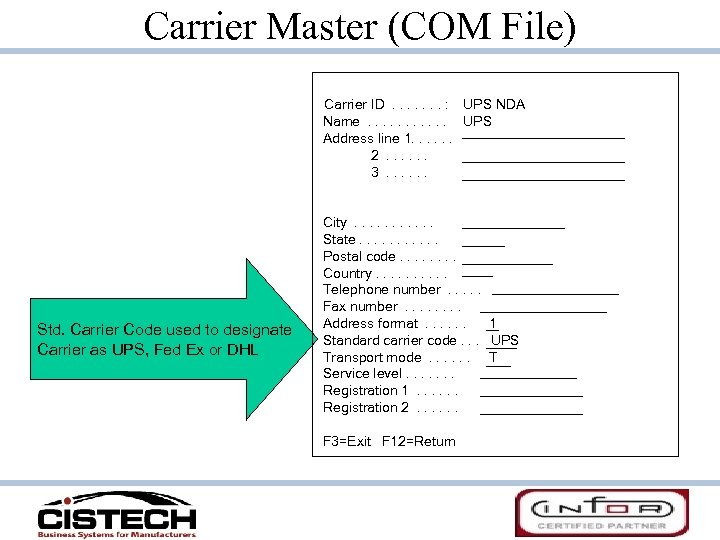

Carrier Master (COM File) Carrier ID. . . . : UPS NDA Name. . . UPS Address line 1. . . 2. . . 3. . . Std. Carrier Code used to designate Carrier as UPS, Fed Ex or DHL City. . . State. . . Postal code. . . . Country. . Telephone number. . . Fax number. . . . Address format. . . 1 Standard carrier code. . . UPS Transport mode. . . T Service level. . . . Registration 1. . . Registration 2. . . F 3=Exit F 12=Return

Carrier Master (COM File) Carrier ID. . . . : UPS NDA Name. . . UPS Address line 1. . . 2. . . 3. . . Std. Carrier Code used to designate Carrier as UPS, Fed Ex or DHL City. . . State. . . Postal code. . . . Country. . Telephone number. . . Fax number. . . . Address format. . . 1 Standard carrier code. . . UPS Transport mode. . . T Service level. . . . Registration 1. . . Registration 2. . . F 3=Exit F 12=Return

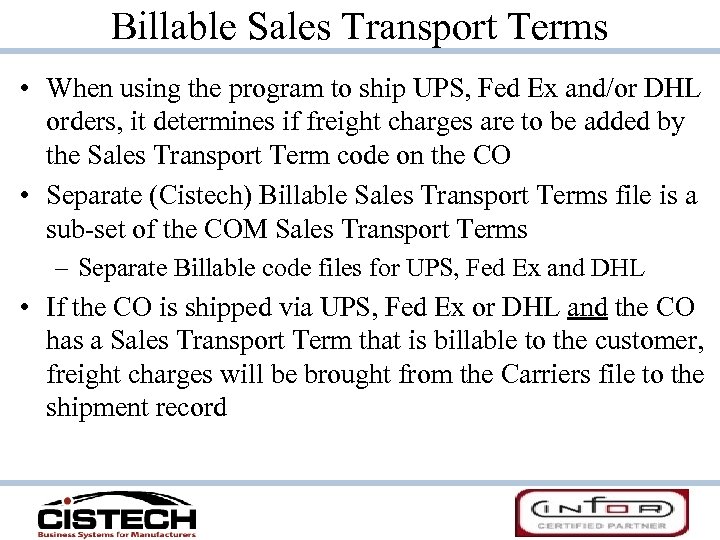

Billable Sales Transport Terms • When using the program to ship UPS, Fed Ex and/or DHL orders, it determines if freight charges are to be added by the Sales Transport Term code on the CO • Separate (Cistech) Billable Sales Transport Terms file is a sub-set of the COM Sales Transport Terms – Separate Billable code files for UPS, Fed Ex and DHL • If the CO is shipped via UPS, Fed Ex or DHL and the CO has a Sales Transport Term that is billable to the customer, freight charges will be brought from the Carriers file to the shipment record

Billable Sales Transport Terms • When using the program to ship UPS, Fed Ex and/or DHL orders, it determines if freight charges are to be added by the Sales Transport Term code on the CO • Separate (Cistech) Billable Sales Transport Terms file is a sub-set of the COM Sales Transport Terms – Separate Billable code files for UPS, Fed Ex and DHL • If the CO is shipped via UPS, Fed Ex or DHL and the CO has a Sales Transport Term that is billable to the customer, freight charges will be brought from the Carriers file to the shipment record

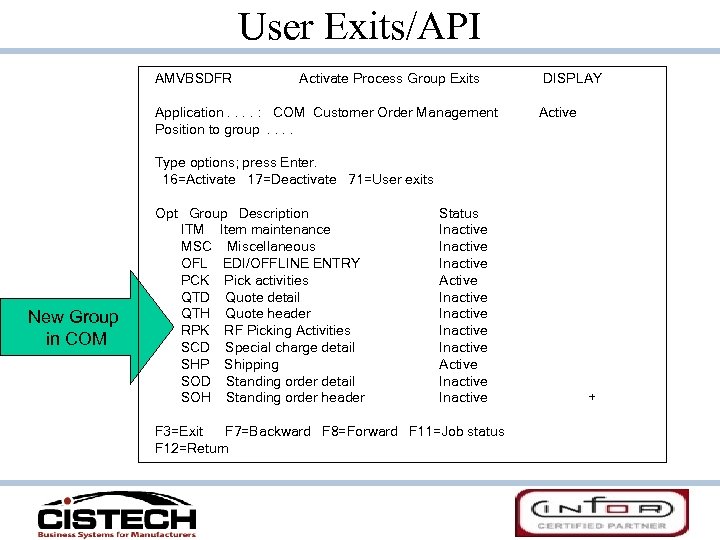

User Exits/API AMVBSDFR Activate Process Group Exits Application. . : COM Customer Order Management Position to group. . DISPLAY Active Type options; press Enter. 16=Activate 17=Deactivate 71=User exits New Group in COM Opt Group Description ITM Item maintenance MSC Miscellaneous OFL EDI/OFFLINE ENTRY PCK Pick activities QTD Quote detail QTH Quote header RPK RF Picking Activities SCD Special charge detail SHP Shipping SOD Standing order detail SOH Standing order header Status Inactive Inactive Active Inactive F 3=Exit F 7=Backward F 8=Forward F 11=Job status F 12=Return +

User Exits/API AMVBSDFR Activate Process Group Exits Application. . : COM Customer Order Management Position to group. . DISPLAY Active Type options; press Enter. 16=Activate 17=Deactivate 71=User exits New Group in COM Opt Group Description ITM Item maintenance MSC Miscellaneous OFL EDI/OFFLINE ENTRY PCK Pick activities QTD Quote detail QTH Quote header RPK RF Picking Activities SCD Special charge detail SHP Shipping SOD Standing order detail SOH Standing order header Status Inactive Inactive Active Inactive F 3=Exit F 7=Backward F 8=Forward F 11=Job status F 12=Return +

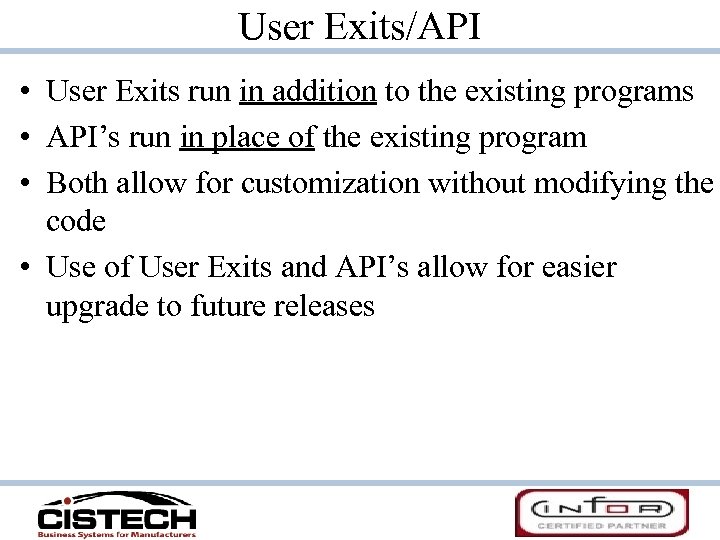

User Exits/API • User Exits run in addition to the existing programs • API’s run in place of the existing program • Both allow for customization without modifying the code • Use of User Exits and API’s allow for easier upgrade to future releases

User Exits/API • User Exits run in addition to the existing programs • API’s run in place of the existing program • Both allow for customization without modifying the code • Use of User Exits and API’s allow for easier upgrade to future releases

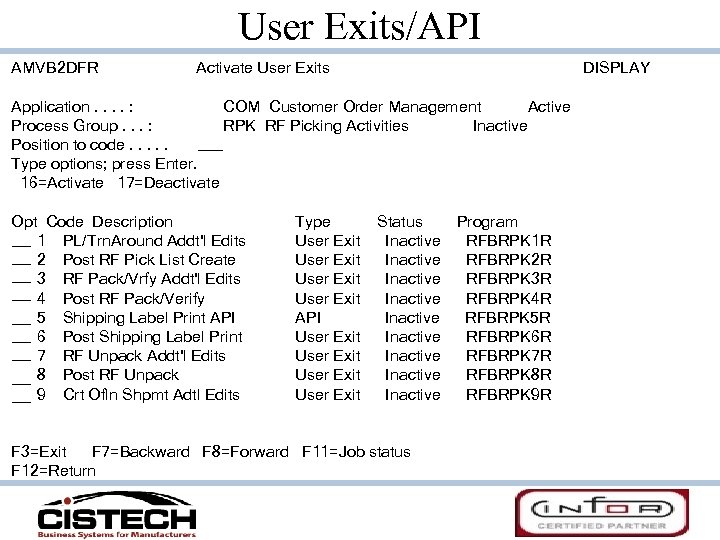

User Exits/API AMVB 2 DFR Activate User Exits DISPLAY Application. . : COM Customer Order Management Active Process Group. . . : RPK RF Picking Activities Inactive Position to code. . . Type options; press Enter. 16=Activate 17=Deactivate Opt Code Description 1 PL/Trn. Around Addt'l Edits 2 Post RF Pick List Create 3 RF Pack/Vrfy Addt'l Edits 4 Post RF Pack/Verify 5 Shipping Label Print API 6 Post Shipping Label Print 7 RF Unpack Addt'l Edits 8 Post RF Unpack 9 Crt Ofln Shpmt Adtl Edits Type User Exit API User Exit Status Inactive Inactive Inactive F 3=Exit F 7=Backward F 8=Forward F 11=Job status F 12=Return Program RFBRPK 1 R RFBRPK 2 R RFBRPK 3 R RFBRPK 4 R RFBRPK 5 R RFBRPK 6 R RFBRPK 7 R RFBRPK 8 R RFBRPK 9 R

User Exits/API AMVB 2 DFR Activate User Exits DISPLAY Application. . : COM Customer Order Management Active Process Group. . . : RPK RF Picking Activities Inactive Position to code. . . Type options; press Enter. 16=Activate 17=Deactivate Opt Code Description 1 PL/Trn. Around Addt'l Edits 2 Post RF Pick List Create 3 RF Pack/Vrfy Addt'l Edits 4 Post RF Pack/Verify 5 Shipping Label Print API 6 Post Shipping Label Print 7 RF Unpack Addt'l Edits 8 Post RF Unpack 9 Crt Ofln Shpmt Adtl Edits Type User Exit API User Exit Status Inactive Inactive Inactive F 3=Exit F 7=Backward F 8=Forward F 11=Job status F 12=Return Program RFBRPK 1 R RFBRPK 2 R RFBRPK 3 R RFBRPK 4 R RFBRPK 5 R RFBRPK 6 R RFBRPK 7 R RFBRPK 8 R RFBRPK 9 R

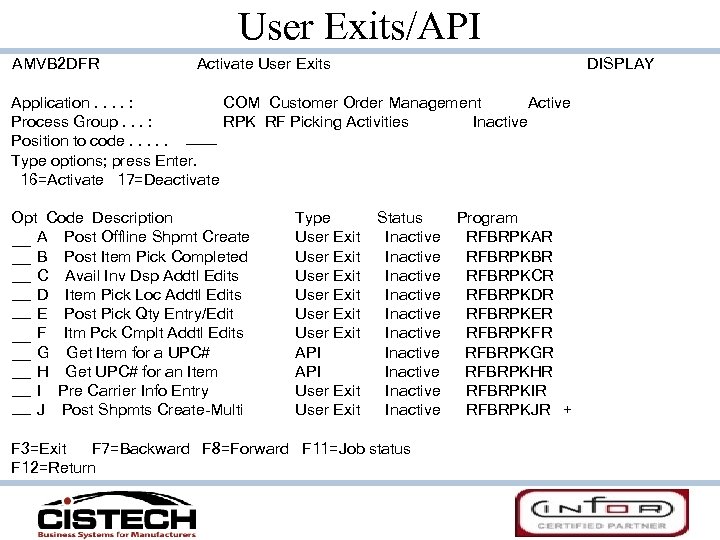

User Exits/API AMVB 2 DFR Activate User Exits DISPLAY Application. . : COM Customer Order Management Active Process Group. . . : RPK RF Picking Activities Inactive Position to code. . . Type options; press Enter. 16=Activate 17=Deactivate Opt Code Description A Post Offline Shpmt Create B Post Item Pick Completed C Avail Inv Dsp Addtl Edits D Item Pick Loc Addtl Edits E Post Pick Qty Entry/Edit F Itm Pck Cmplt Addtl Edits G Get Item for a UPC# H Get UPC# for an Item I Pre Carrier Info Entry J Post Shpmts Create-Multi Type User Exit User Exit API User Exit Status Inactive Inactive Inactive F 3=Exit F 7=Backward F 8=Forward F 11=Job status F 12=Return Program RFBRPKAR RFBRPKBR RFBRPKCR RFBRPKDR RFBRPKER RFBRPKFR RFBRPKGR RFBRPKHR RFBRPKIR RFBRPKJR +

User Exits/API AMVB 2 DFR Activate User Exits DISPLAY Application. . : COM Customer Order Management Active Process Group. . . : RPK RF Picking Activities Inactive Position to code. . . Type options; press Enter. 16=Activate 17=Deactivate Opt Code Description A Post Offline Shpmt Create B Post Item Pick Completed C Avail Inv Dsp Addtl Edits D Item Pick Loc Addtl Edits E Post Pick Qty Entry/Edit F Itm Pck Cmplt Addtl Edits G Get Item for a UPC# H Get UPC# for an Item I Pre Carrier Info Entry J Post Shpmts Create-Multi Type User Exit User Exit API User Exit Status Inactive Inactive Inactive F 3=Exit F 7=Backward F 8=Forward F 11=Job status F 12=Return Program RFBRPKAR RFBRPKBR RFBRPKCR RFBRPKDR RFBRPKER RFBRPKFR RFBRPKGR RFBRPKHR RFBRPKIR RFBRPKJR +

Order Picking

Order Picking

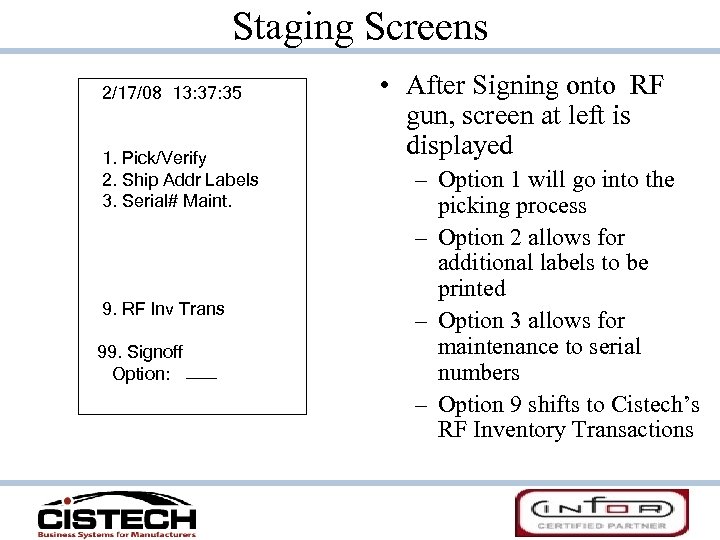

Staging Screens 2/17/08 13: 37: 35 1. Pick/Verify 2. Ship Addr Labels 3. Serial# Maint. 9. RF Inv Trans 99. Signoff Option: • After Signing onto RF gun, screen at left is displayed – Option 1 will go into the picking process – Option 2 allows for additional labels to be printed – Option 3 allows for maintenance to serial numbers – Option 9 shifts to Cistech’s RF Inventory Transactions

Staging Screens 2/17/08 13: 37: 35 1. Pick/Verify 2. Ship Addr Labels 3. Serial# Maint. 9. RF Inv Trans 99. Signoff Option: • After Signing onto RF gun, screen at left is displayed – Option 1 will go into the picking process – Option 2 allows for additional labels to be printed – Option 3 allows for maintenance to serial numbers – Option 9 shifts to Cistech’s RF Inventory Transactions

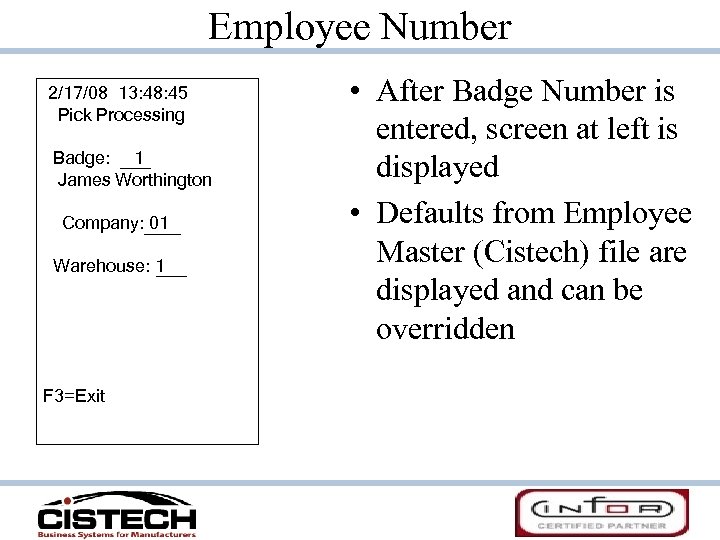

Employee Number 2/17/08 13: 48: 45 Pick Processing Badge: 1 James Worthington Company: 01 Warehouse: 1 F 3=Exit • After Badge Number is entered, screen at left is displayed • Defaults from Employee Master (Cistech) file are displayed and can be overridden

Employee Number 2/17/08 13: 48: 45 Pick Processing Badge: 1 James Worthington Company: 01 Warehouse: 1 F 3=Exit • After Badge Number is entered, screen at left is displayed • Defaults from Employee Master (Cistech) file are displayed and can be overridden

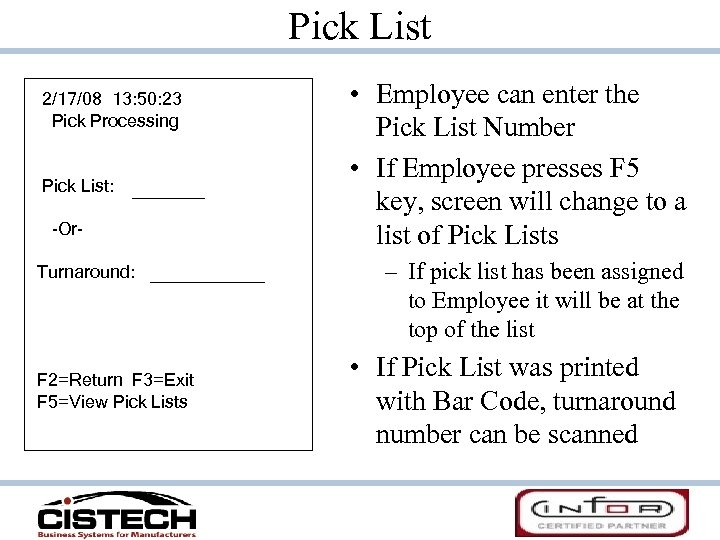

Pick List 2/17/08 13: 50: 23 Pick Processing Pick List: -Or. Turnaround: F 2=Return F 3=Exit F 5=View Pick Lists • Employee can enter the Pick List Number • If Employee presses F 5 key, screen will change to a list of Pick Lists – If pick list has been assigned to Employee it will be at the top of the list • If Pick List was printed with Bar Code, turnaround number can be scanned

Pick List 2/17/08 13: 50: 23 Pick Processing Pick List: -Or. Turnaround: F 2=Return F 3=Exit F 5=View Pick Lists • Employee can enter the Pick List Number • If Employee presses F 5 key, screen will change to a list of Pick Lists – If pick list has been assigned to Employee it will be at the top of the list • If Pick List was printed with Bar Code, turnaround number can be scanned

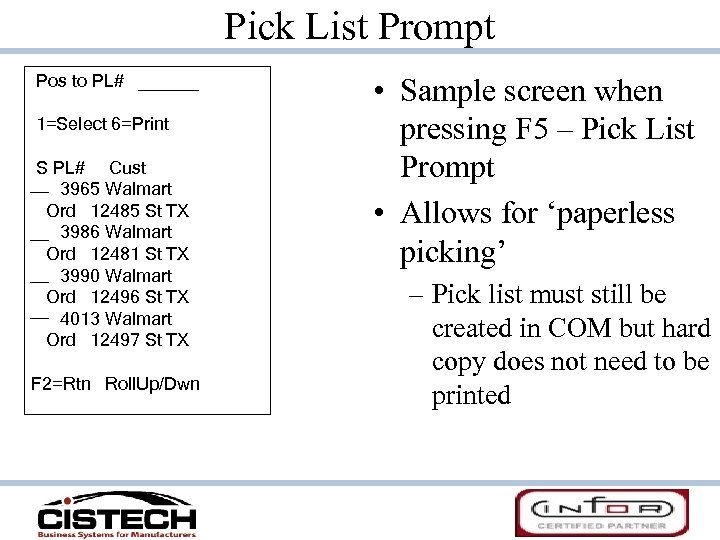

Pick List Prompt Pos to PL# 1=Select 6=Print S PL# Cust 3965 Walmart Ord 12485 St TX 3986 Walmart Ord 12481 St TX 3990 Walmart Ord 12496 St TX 4013 Walmart Ord 12497 St TX F 2=Rtn Roll. Up/Dwn • Sample screen when pressing F 5 – Pick List Prompt • Allows for ‘paperless picking’ – Pick list must still be created in COM but hard copy does not need to be printed

Pick List Prompt Pos to PL# 1=Select 6=Print S PL# Cust 3965 Walmart Ord 12485 St TX 3986 Walmart Ord 12481 St TX 3990 Walmart Ord 12496 St TX 4013 Walmart Ord 12497 St TX F 2=Rtn Roll. Up/Dwn • Sample screen when pressing F 5 – Pick List Prompt • Allows for ‘paperless picking’ – Pick list must still be created in COM but hard copy does not need to be printed

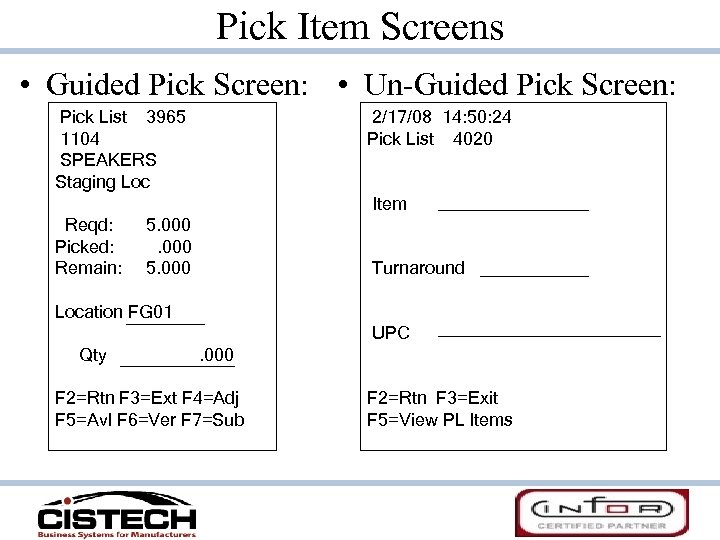

Pick Item Screens • Guided Pick Screen: • Un-Guided Pick Screen: Pick List 3965 1104 SPEAKERS Staging Loc 2/17/08 14: 50: 24 Pick List 4020 Item Reqd: Picked: Remain: 5. 000 Turnaround Location FG 01 UPC Qty . 000 F 2=Rtn F 3=Ext F 4=Adj F 5=Avl F 6=Ver F 7=Sub F 2=Rtn F 3=Exit F 5=View PL Items

Pick Item Screens • Guided Pick Screen: • Un-Guided Pick Screen: Pick List 3965 1104 SPEAKERS Staging Loc 2/17/08 14: 50: 24 Pick List 4020 Item Reqd: Picked: Remain: 5. 000 Turnaround Location FG 01 UPC Qty . 000 F 2=Rtn F 3=Ext F 4=Adj F 5=Avl F 6=Ver F 7=Sub F 2=Rtn F 3=Exit F 5=View PL Items

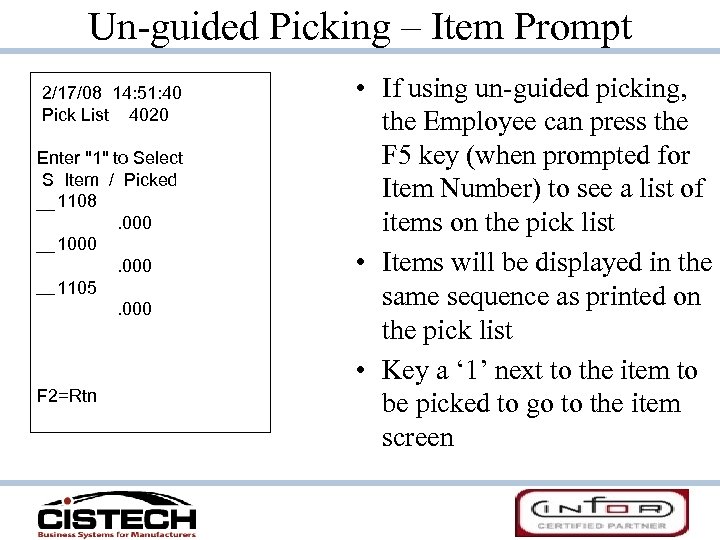

Un-guided Picking – Item Prompt 2/17/08 14: 51: 40 Pick List 4020 Enter "1" to Select S Item / Picked 1108. 000 1000. 000 1105. 000 F 2=Rtn • If using un-guided picking, the Employee can press the F 5 key (when prompted for Item Number) to see a list of items on the pick list • Items will be displayed in the same sequence as printed on the pick list • Key a ‘ 1’ next to the item to be picked to go to the item screen

Un-guided Picking – Item Prompt 2/17/08 14: 51: 40 Pick List 4020 Enter "1" to Select S Item / Picked 1108. 000 1000. 000 1105. 000 F 2=Rtn • If using un-guided picking, the Employee can press the F 5 key (when prompted for Item Number) to see a list of items on the pick list • Items will be displayed in the same sequence as printed on the pick list • Key a ‘ 1’ next to the item to be picked to go to the item screen

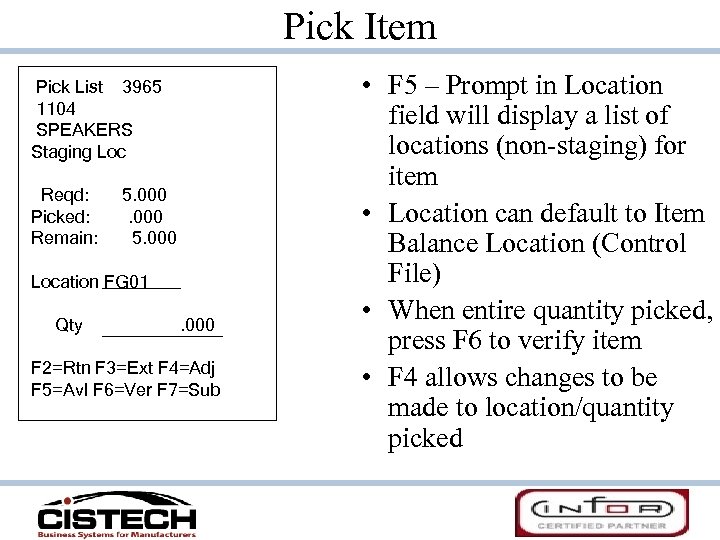

Pick Item Pick List 3965 1104 SPEAKERS Staging Loc Reqd: Picked: Remain: 5. 000 Location FG 01 Qty . 000 F 2=Rtn F 3=Ext F 4=Adj F 5=Avl F 6=Ver F 7=Sub • F 5 – Prompt in Location field will display a list of locations (non-staging) for item • Location can default to Item Balance Location (Control File) • When entire quantity picked, press F 6 to verify item • F 4 allows changes to be made to location/quantity picked

Pick Item Pick List 3965 1104 SPEAKERS Staging Loc Reqd: Picked: Remain: 5. 000 Location FG 01 Qty . 000 F 2=Rtn F 3=Ext F 4=Adj F 5=Avl F 6=Ver F 7=Sub • F 5 – Prompt in Location field will display a list of locations (non-staging) for item • Location can default to Item Balance Location (Control File) • When entire quantity picked, press F 6 to verify item • F 4 allows changes to be made to location/quantity picked

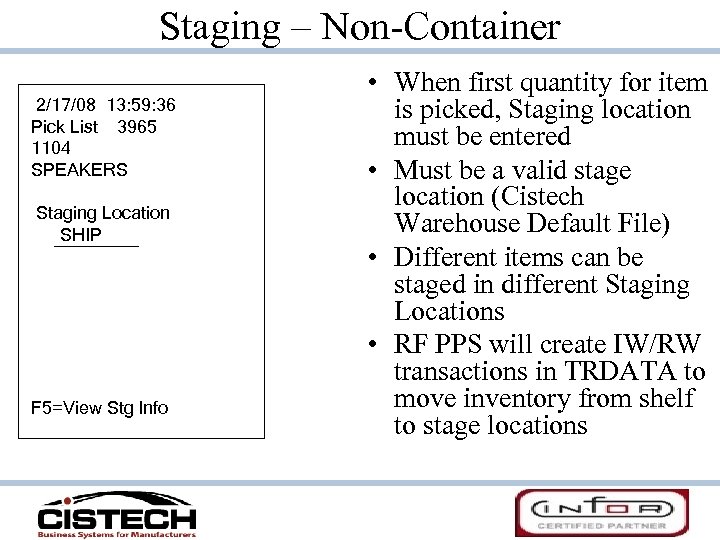

Staging – Non-Container 2/17/08 13: 59: 36 Pick List 3965 1104 SPEAKERS Staging Location SHIP F 5=View Stg Info • When first quantity for item is picked, Staging location must be entered • Must be a valid stage location (Cistech Warehouse Default File) • Different items can be staged in different Staging Locations • RF PPS will create IW/RW transactions in TRDATA to move inventory from shelf to stage locations

Staging – Non-Container 2/17/08 13: 59: 36 Pick List 3965 1104 SPEAKERS Staging Location SHIP F 5=View Stg Info • When first quantity for item is picked, Staging location must be entered • Must be a valid stage location (Cistech Warehouse Default File) • Different items can be staged in different Staging Locations • RF PPS will create IW/RW transactions in TRDATA to move inventory from shelf to stage locations

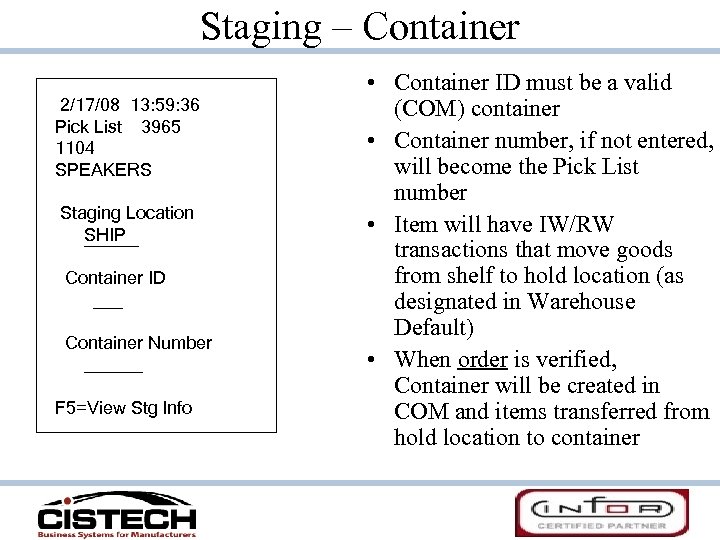

Staging – Container 2/17/08 13: 59: 36 Pick List 3965 1104 SPEAKERS Staging Location SHIP Container ID ___ Container Number ______ F 5=View Stg Info • Container ID must be a valid (COM) container • Container number, if not entered, will become the Pick List number • Item will have IW/RW transactions that move goods from shelf to hold location (as designated in Warehouse Default) • When order is verified, Container will be created in COM and items transferred from hold location to container

Staging – Container 2/17/08 13: 59: 36 Pick List 3965 1104 SPEAKERS Staging Location SHIP Container ID ___ Container Number ______ F 5=View Stg Info • Container ID must be a valid (COM) container • Container number, if not entered, will become the Pick List number • Item will have IW/RW transactions that move goods from shelf to hold location (as designated in Warehouse Default) • When order is verified, Container will be created in COM and items transferred from hold location to container

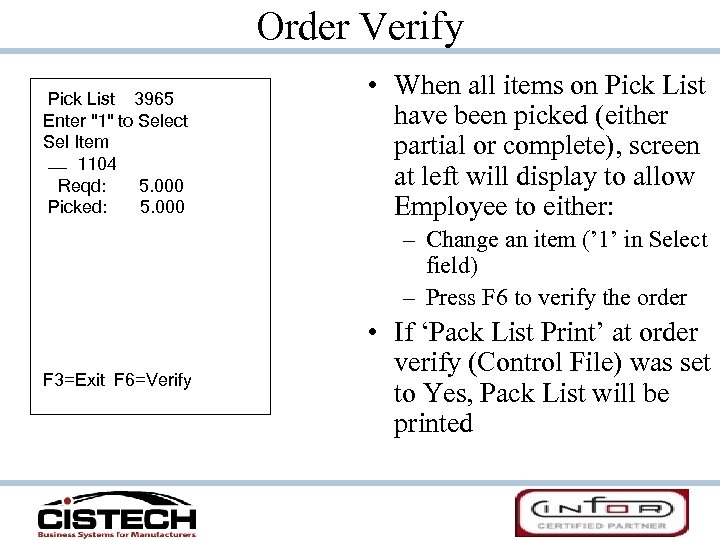

Order Verify Pick List 3965 Enter "1" to Select Sel Item 1104 Reqd: 5. 000 Picked: 5. 000 • When all items on Pick List have been picked (either partial or complete), screen at left will display to allow Employee to either: – Change an item (’ 1’ in Select field) – Press F 6 to verify the order F 3=Exit F 6=Verify • If ‘Pack List Print’ at order verify (Control File) was set to Yes, Pack List will be printed

Order Verify Pick List 3965 Enter "1" to Select Sel Item 1104 Reqd: 5. 000 Picked: 5. 000 • When all items on Pick List have been picked (either partial or complete), screen at left will display to allow Employee to either: – Change an item (’ 1’ in Select field) – Press F 6 to verify the order F 3=Exit F 6=Verify • If ‘Pack List Print’ at order verify (Control File) was set to Yes, Pack List will be printed

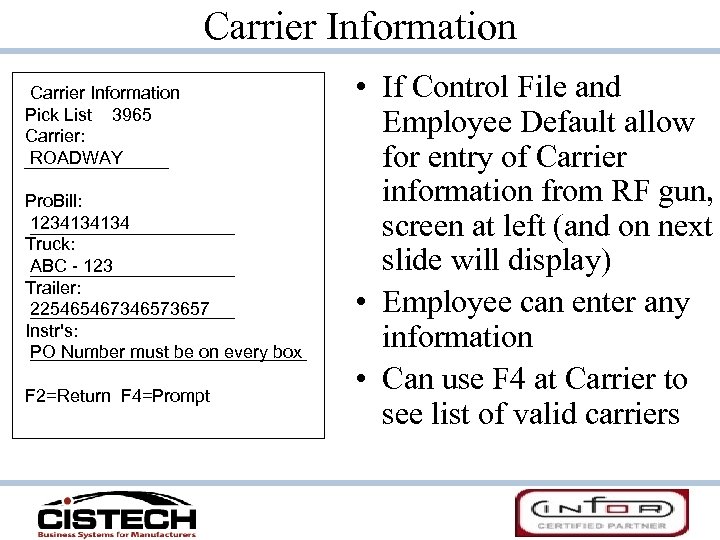

Carrier Information Pick List 3965 Carrier: ROADWAY Pro. Bill: 1234134134 Truck: ABC - 123 Trailer: 225465467346573657 Instr's: PO Number must be on every box F 2=Return F 4=Prompt • If Control File and Employee Default allow for entry of Carrier information from RF gun, screen at left (and on next slide will display) • Employee can enter any information • Can use F 4 at Carrier to see list of valid carriers

Carrier Information Pick List 3965 Carrier: ROADWAY Pro. Bill: 1234134134 Truck: ABC - 123 Trailer: 225465467346573657 Instr's: PO Number must be on every box F 2=Return F 4=Prompt • If Control File and Employee Default allow for entry of Carrier information from RF gun, screen at left (and on next slide will display) • Employee can enter any information • Can use F 4 at Carrier to see list of valid carriers

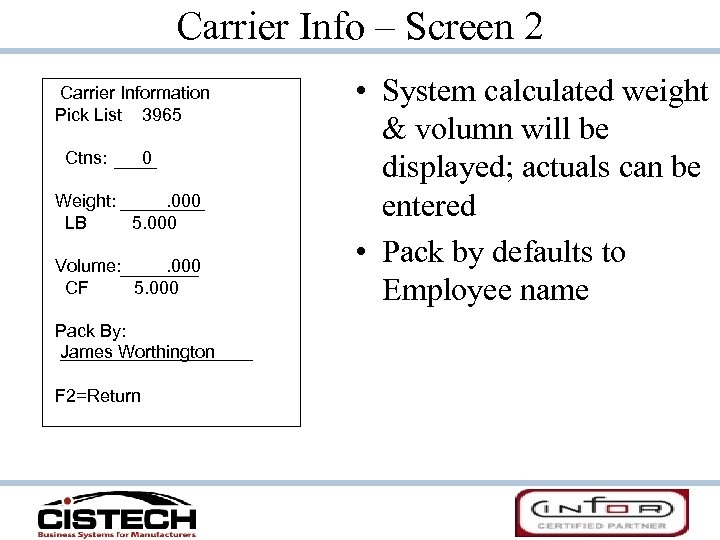

Carrier Info – Screen 2 Carrier Information Pick List 3965 Ctns: 0 Weight: . 000 LB 5. 000 Volume: . 000 CF 5. 000 Pack By: James Worthington F 2=Return • System calculated weight & volumn will be displayed; actuals can be entered • Pack by defaults to Employee name

Carrier Info – Screen 2 Carrier Information Pick List 3965 Ctns: 0 Weight: . 000 LB 5. 000 Volume: . 000 CF 5. 000 Pack By: James Worthington F 2=Return • System calculated weight & volumn will be displayed; actuals can be entered • Pack by defaults to Employee name

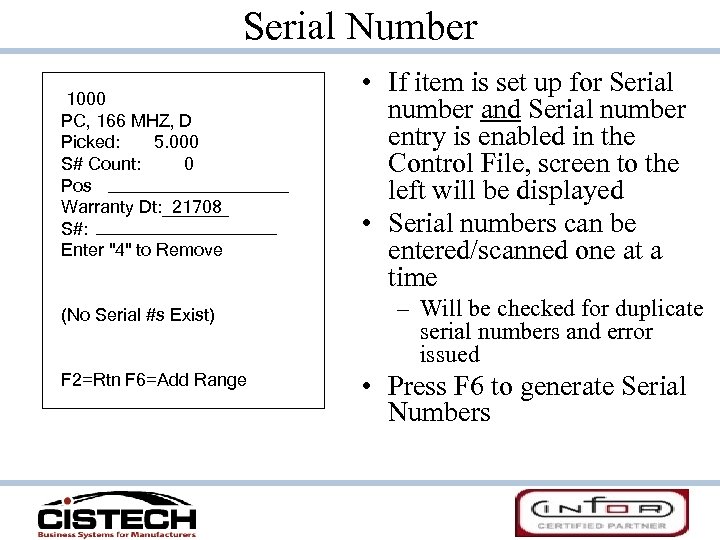

Serial Number 1000 PC, 166 MHZ, D Picked: 5. 000 S# Count: 0 Pos Warranty Dt: 21708 S#: Enter "4" to Remove (No Serial #s Exist) F 2=Rtn F 6=Add Range • If item is set up for Serial number and Serial number entry is enabled in the Control File, screen to the left will be displayed • Serial numbers can be entered/scanned one at a time – Will be checked for duplicate serial numbers and error issued • Press F 6 to generate Serial Numbers

Serial Number 1000 PC, 166 MHZ, D Picked: 5. 000 S# Count: 0 Pos Warranty Dt: 21708 S#: Enter "4" to Remove (No Serial #s Exist) F 2=Rtn F 6=Add Range • If item is set up for Serial number and Serial number entry is enabled in the Control File, screen to the left will be displayed • Serial numbers can be entered/scanned one at a time – Will be checked for duplicate serial numbers and error issued • Press F 6 to generate Serial Numbers

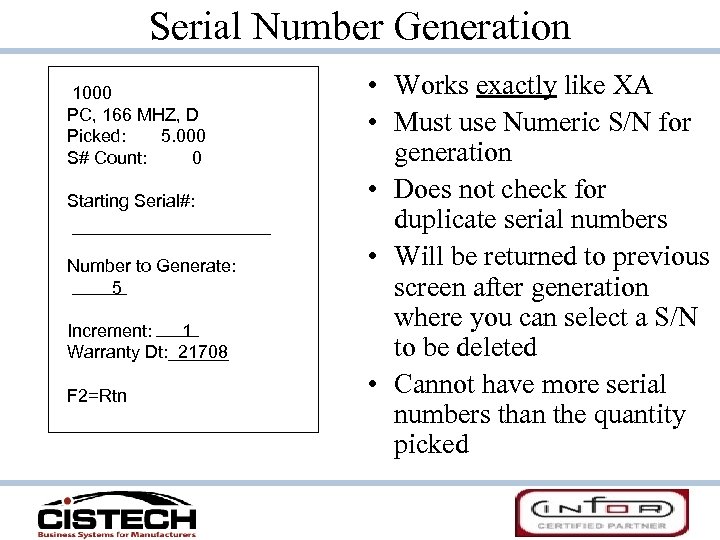

Serial Number Generation 1000 PC, 166 MHZ, D Picked: 5. 000 S# Count: 0 Starting Serial#: Number to Generate: 5 Increment: 1 Warranty Dt: 21708 F 2=Rtn • Works exactly like XA • Must use Numeric S/N for generation • Does not check for duplicate serial numbers • Will be returned to previous screen after generation where you can select a S/N to be deleted • Cannot have more serial numbers than the quantity picked

Serial Number Generation 1000 PC, 166 MHZ, D Picked: 5. 000 S# Count: 0 Starting Serial#: Number to Generate: 5 Increment: 1 Warranty Dt: 21708 F 2=Rtn • Works exactly like XA • Must use Numeric S/N for generation • Does not check for duplicate serial numbers • Will be returned to previous screen after generation where you can select a S/N to be deleted • Cannot have more serial numbers than the quantity picked

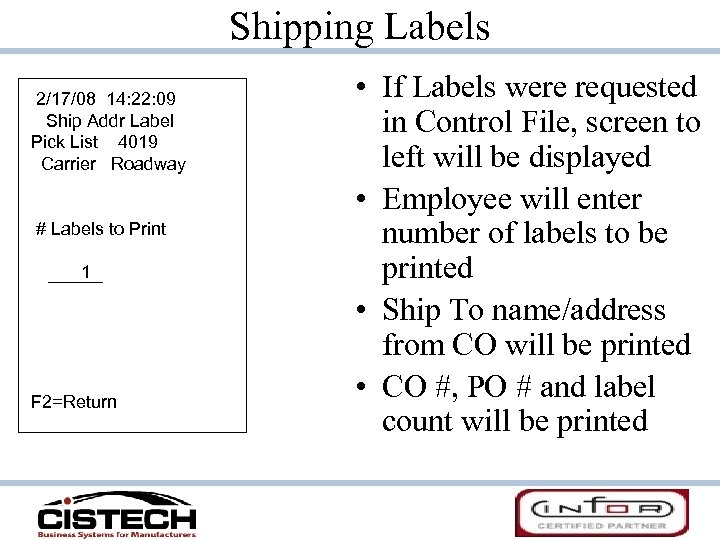

Shipping Labels 2/17/08 14: 22: 09 Ship Addr Label Pick List 4019 Carrier Roadway # Labels to Print 1 F 2=Return • If Labels were requested in Control File, screen to left will be displayed • Employee will enter number of labels to be printed • Ship To name/address from CO will be printed • CO #, PO # and label count will be printed

Shipping Labels 2/17/08 14: 22: 09 Ship Addr Label Pick List 4019 Carrier Roadway # Labels to Print 1 F 2=Return • If Labels were requested in Control File, screen to left will be displayed • Employee will enter number of labels to be printed • Ship To name/address from CO will be printed • CO #, PO # and label count will be printed

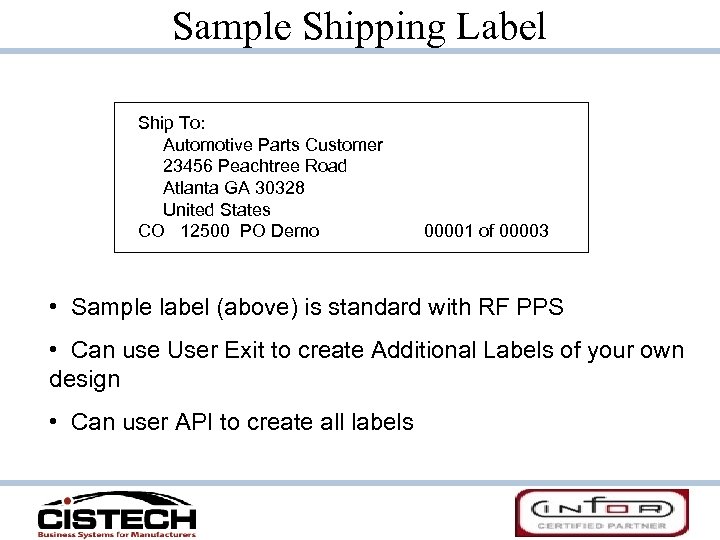

Sample Shipping Label Ship To: Automotive Parts Customer 23456 Peachtree Road Atlanta GA 30328 United States CO 12500 PO Demo 00001 of 00003 • Sample label (above) is standard with RF PPS • Can use User Exit to create Additional Labels of your own design • Can user API to create all labels

Sample Shipping Label Ship To: Automotive Parts Customer 23456 Peachtree Road Atlanta GA 30328 United States CO 12500 PO Demo 00001 of 00003 • Sample label (above) is standard with RF PPS • Can use User Exit to create Additional Labels of your own design • Can user API to create all labels

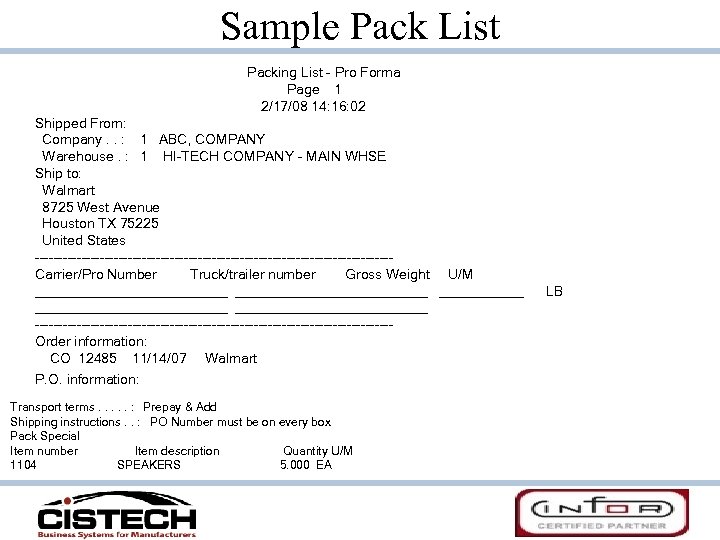

Sample Pack List Packing List - Pro Forma Page 1 2/17/08 14: 16: 02 Shipped From: Company. . : 1 ABC, COMPANY Warehouse. : 1 HI-TECH COMPANY - MAIN WHSE Ship to: Walmart 8725 West Avenue Houston TX 75225 United States --------------------------------------Carrier/Pro Number Truck/trailer number Gross Weight U/M _________________________ _____________ --------------------------------------Order information: CO 12485 11/14/07 Walmart P. O. information: Transport terms. . . : Prepay & Add Shipping instructions. . : PO Number must be on every box Pack Special Item number Item description Quantity U/M 1104 SPEAKERS 5. 000 EA LB

Sample Pack List Packing List - Pro Forma Page 1 2/17/08 14: 16: 02 Shipped From: Company. . : 1 ABC, COMPANY Warehouse. : 1 HI-TECH COMPANY - MAIN WHSE Ship to: Walmart 8725 West Avenue Houston TX 75225 United States --------------------------------------Carrier/Pro Number Truck/trailer number Gross Weight U/M _________________________ _____________ --------------------------------------Order information: CO 12485 11/14/07 Walmart P. O. information: Transport terms. . . : Prepay & Add Shipping instructions. . : PO Number must be on every box Pack Special Item number Item description Quantity U/M 1104 SPEAKERS 5. 000 EA LB

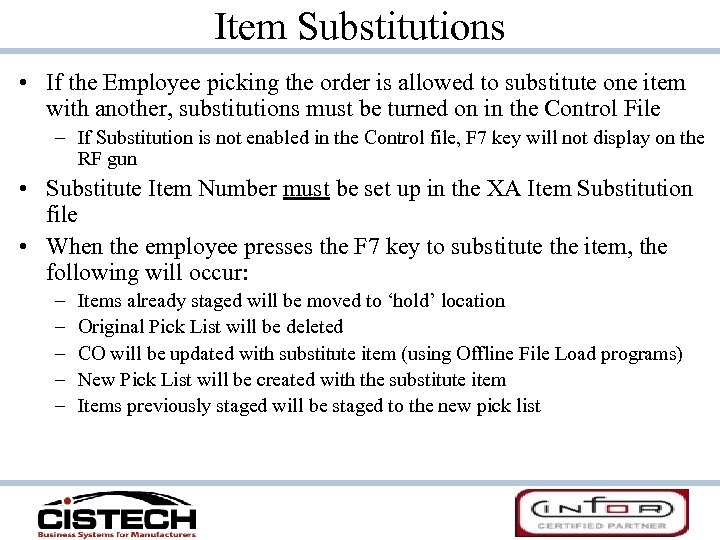

Item Substitutions • If the Employee picking the order is allowed to substitute one item with another, substitutions must be turned on in the Control File – If Substitution is not enabled in the Control file, F 7 key will not display on the RF gun • Substitute Item Number must be set up in the XA Item Substitution file • When the employee presses the F 7 key to substitute the item, the following will occur: – – – Items already staged will be moved to ‘hold’ location Original Pick List will be deleted CO will be updated with substitute item (using Offline File Load programs) New Pick List will be created with the substitute item Items previously staged will be staged to the new pick list

Item Substitutions • If the Employee picking the order is allowed to substitute one item with another, substitutions must be turned on in the Control File – If Substitution is not enabled in the Control file, F 7 key will not display on the RF gun • Substitute Item Number must be set up in the XA Item Substitution file • When the employee presses the F 7 key to substitute the item, the following will occur: – – – Items already staged will be moved to ‘hold’ location Original Pick List will be deleted CO will be updated with substitute item (using Offline File Load programs) New Pick List will be created with the substitute item Items previously staged will be staged to the new pick list

Office Functions

Office Functions

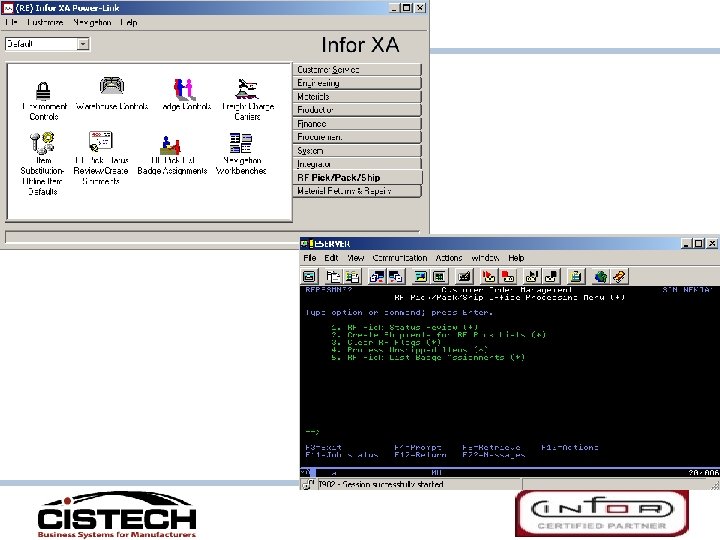

Office Functions • Use Office functions to: – Assign Pick Lists to Employees – See orders currently being picked (un-verified) – See orders staged but not shipped (verified) – Clear RF flags from item • Necessary if RF gun loses signal, RF lock will remain on item preventing access to the item – Ship staged orders (non-container)

Office Functions • Use Office functions to: – Assign Pick Lists to Employees – See orders currently being picked (un-verified) – See orders staged but not shipped (verified) – Clear RF flags from item • Necessary if RF gun loses signal, RF lock will remain on item preventing access to the item – Ship staged orders (non-container)

Office Functions • In Release 6, all Office Functions are in Green Screen • In Release 7, Office Functions can be performed in either Green Screen or Power. Link

Office Functions • In Release 6, all Office Functions are in Green Screen • In Release 7, Office Functions can be performed in either Green Screen or Power. Link

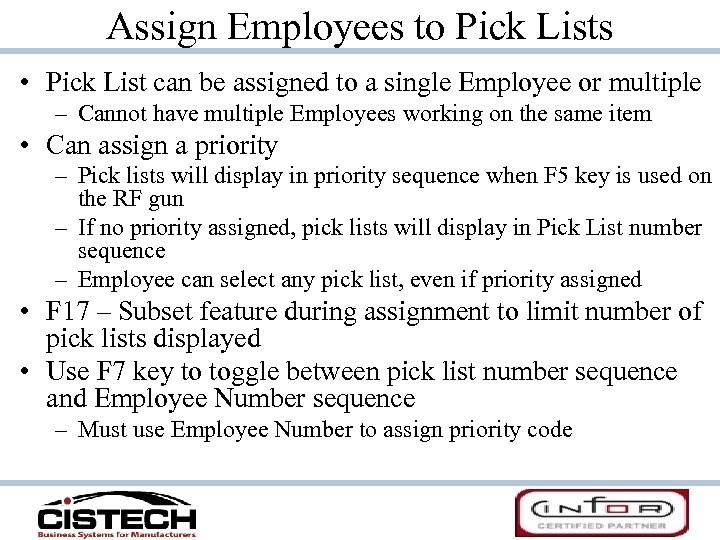

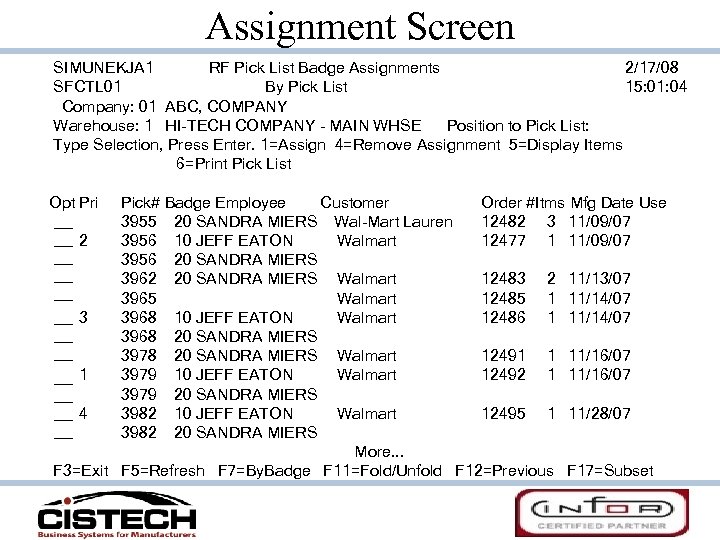

Assign Employees to Pick Lists • Pick List can be assigned to a single Employee or multiple – Cannot have multiple Employees working on the same item • Can assign a priority – Pick lists will display in priority sequence when F 5 key is used on the RF gun – If no priority assigned, pick lists will display in Pick List number sequence – Employee can select any pick list, even if priority assigned • F 17 – Subset feature during assignment to limit number of pick lists displayed • Use F 7 key to toggle between pick list number sequence and Employee Number sequence – Must use Employee Number to assign priority code

Assign Employees to Pick Lists • Pick List can be assigned to a single Employee or multiple – Cannot have multiple Employees working on the same item • Can assign a priority – Pick lists will display in priority sequence when F 5 key is used on the RF gun – If no priority assigned, pick lists will display in Pick List number sequence – Employee can select any pick list, even if priority assigned • F 17 – Subset feature during assignment to limit number of pick lists displayed • Use F 7 key to toggle between pick list number sequence and Employee Number sequence – Must use Employee Number to assign priority code

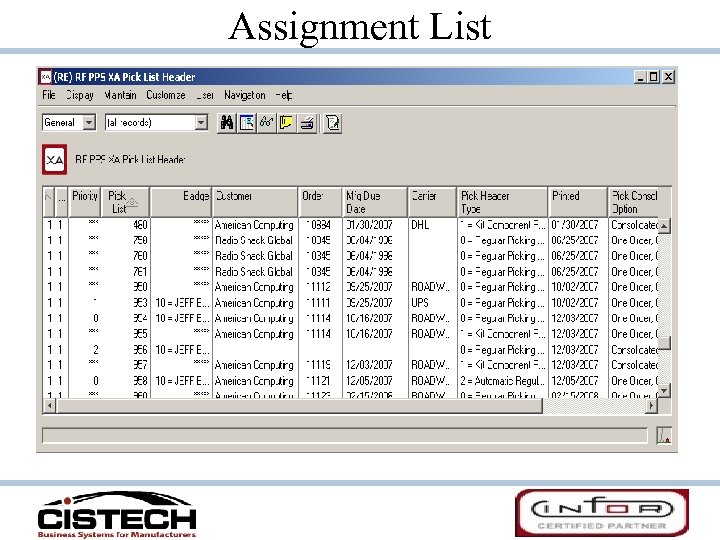

Assignment Screen SIMUNEKJA 1 RF Pick List Badge Assignments 2/17/08 SFCTL 01 By Pick List 15: 01: 04 Company: 01 ABC, COMPANY Warehouse: 1 HI-TECH COMPANY - MAIN WHSE Position to Pick List: Type Selection, Press Enter. 1=Assign 4=Remove Assignment 5=Display Items 6=Print Pick List Opt Pri Pick# Badge Employee Customer Order #Itms Mfg Date Use 3955 20 SANDRA MIERS Wal-Mart Lauren 12482 3 11/09/07 2 3956 10 JEFF EATON Walmart 12477 1 11/09/07 3956 20 SANDRA MIERS 3962 20 SANDRA MIERS Walmart 12483 2 11/13/07 3965 Walmart 12485 1 11/14/07 3 3968 10 JEFF EATON Walmart 12486 1 11/14/07 3968 20 SANDRA MIERS 3978 20 SANDRA MIERS Walmart 12491 1 11/16/07 1 3979 10 JEFF EATON Walmart 12492 1 11/16/07 3979 20 SANDRA MIERS 4 3982 10 JEFF EATON Walmart 12495 1 11/28/07 3982 20 SANDRA MIERS More. . . F 3=Exit F 5=Refresh F 7=By. Badge F 11=Fold/Unfold F 12=Previous F 17=Subset

Assignment Screen SIMUNEKJA 1 RF Pick List Badge Assignments 2/17/08 SFCTL 01 By Pick List 15: 01: 04 Company: 01 ABC, COMPANY Warehouse: 1 HI-TECH COMPANY - MAIN WHSE Position to Pick List: Type Selection, Press Enter. 1=Assign 4=Remove Assignment 5=Display Items 6=Print Pick List Opt Pri Pick# Badge Employee Customer Order #Itms Mfg Date Use 3955 20 SANDRA MIERS Wal-Mart Lauren 12482 3 11/09/07 2 3956 10 JEFF EATON Walmart 12477 1 11/09/07 3956 20 SANDRA MIERS 3962 20 SANDRA MIERS Walmart 12483 2 11/13/07 3965 Walmart 12485 1 11/14/07 3 3968 10 JEFF EATON Walmart 12486 1 11/14/07 3968 20 SANDRA MIERS 3978 20 SANDRA MIERS Walmart 12491 1 11/16/07 1 3979 10 JEFF EATON Walmart 12492 1 11/16/07 3979 20 SANDRA MIERS 4 3982 10 JEFF EATON Walmart 12495 1 11/28/07 3982 20 SANDRA MIERS More. . . F 3=Exit F 5=Refresh F 7=By. Badge F 11=Fold/Unfold F 12=Previous F 17=Subset

Assignment List

Assignment List

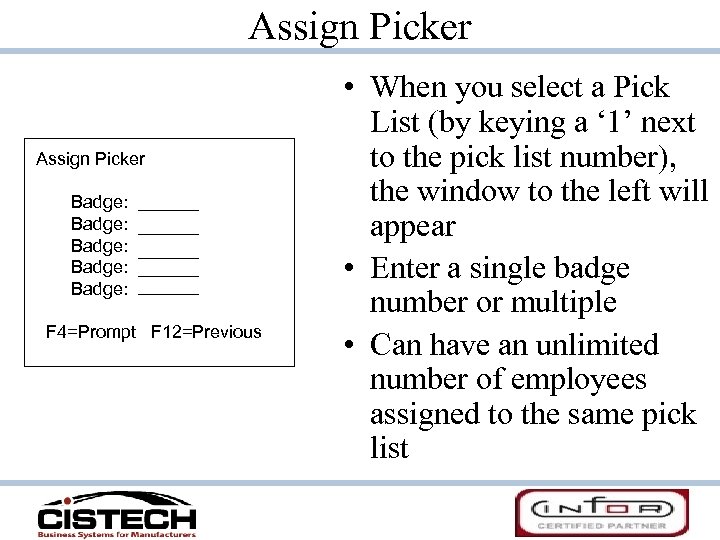

Assign Picker Badge: Badge: F 4=Prompt F 12=Previous • When you select a Pick List (by keying a ‘ 1’ next to the pick list number), the window to the left will appear • Enter a single badge number or multiple • Can have an unlimited number of employees assigned to the same pick list

Assign Picker Badge: Badge: F 4=Prompt F 12=Previous • When you select a Pick List (by keying a ‘ 1’ next to the pick list number), the window to the left will appear • Enter a single badge number or multiple • Can have an unlimited number of employees assigned to the same pick list

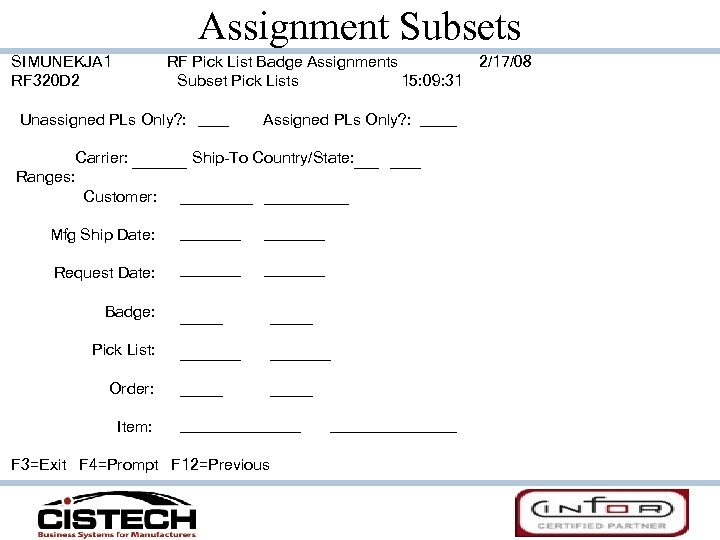

Assignment Subsets SIMUNEKJA 1 RF 320 D 2 RF Pick List Badge Assignments 2/17/08 Subset Pick Lists 15: 09: 31 Unassigned PLs Only? : Carrier: Ranges: Customer: Assigned PLs Only? : Ship-To Country/State: Mfg Ship Date: Request Date: Badge: Pick List: Order: Item: F 3=Exit F 4=Prompt F 12=Previous

Assignment Subsets SIMUNEKJA 1 RF 320 D 2 RF Pick List Badge Assignments 2/17/08 Subset Pick Lists 15: 09: 31 Unassigned PLs Only? : Carrier: Ranges: Customer: Assigned PLs Only? : Ship-To Country/State: Mfg Ship Date: Request Date: Badge: Pick List: Order: Item: F 3=Exit F 4=Prompt F 12=Previous

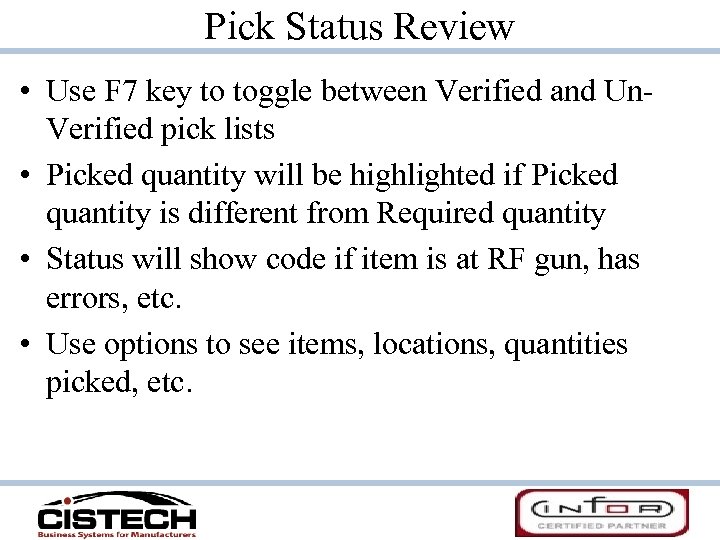

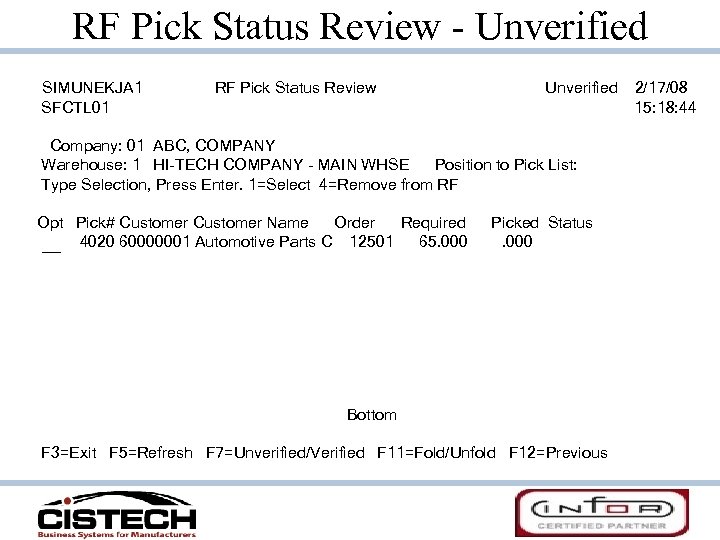

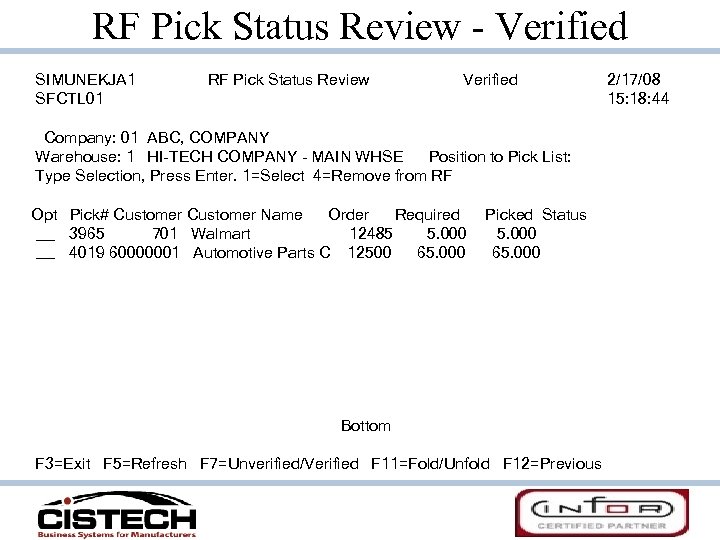

Pick Status Review • Use F 7 key to toggle between Verified and Un. Verified pick lists • Picked quantity will be highlighted if Picked quantity is different from Required quantity • Status will show code if item is at RF gun, has errors, etc. • Use options to see items, locations, quantities picked, etc.

Pick Status Review • Use F 7 key to toggle between Verified and Un. Verified pick lists • Picked quantity will be highlighted if Picked quantity is different from Required quantity • Status will show code if item is at RF gun, has errors, etc. • Use options to see items, locations, quantities picked, etc.

RF Pick Status Review - Unverified SIMUNEKJA 1 SFCTL 01 RF Pick Status Review Unverified Company: 01 ABC, COMPANY Warehouse: 1 HI-TECH COMPANY - MAIN WHSE Position to Pick List: Type Selection, Press Enter. 1=Select 4=Remove from RF Opt Pick# Customer Name Order Required 4020 60000001 Automotive Parts C 12501 65. 000 Picked Status. 000 Bottom F 3=Exit F 5=Refresh F 7=Unverified/Verified F 11=Fold/Unfold F 12=Previous 2/17/08 15: 18: 44

RF Pick Status Review - Unverified SIMUNEKJA 1 SFCTL 01 RF Pick Status Review Unverified Company: 01 ABC, COMPANY Warehouse: 1 HI-TECH COMPANY - MAIN WHSE Position to Pick List: Type Selection, Press Enter. 1=Select 4=Remove from RF Opt Pick# Customer Name Order Required 4020 60000001 Automotive Parts C 12501 65. 000 Picked Status. 000 Bottom F 3=Exit F 5=Refresh F 7=Unverified/Verified F 11=Fold/Unfold F 12=Previous 2/17/08 15: 18: 44

RF Pick Status Review - Verified SIMUNEKJA 1 SFCTL 01 RF Pick Status Review Verified Company: 01 ABC, COMPANY Warehouse: 1 HI-TECH COMPANY - MAIN WHSE Position to Pick List: Type Selection, Press Enter. 1=Select 4=Remove from RF Opt Pick# Customer Name Order Required 3965 701 Walmart 12485 5. 000 4019 60000001 Automotive Parts C 12500 65. 000 Picked Status 5. 000 65. 000 Bottom F 3=Exit F 5=Refresh F 7=Unverified/Verified F 11=Fold/Unfold F 12=Previous 2/17/08 15: 18: 44

RF Pick Status Review - Verified SIMUNEKJA 1 SFCTL 01 RF Pick Status Review Verified Company: 01 ABC, COMPANY Warehouse: 1 HI-TECH COMPANY - MAIN WHSE Position to Pick List: Type Selection, Press Enter. 1=Select 4=Remove from RF Opt Pick# Customer Name Order Required 3965 701 Walmart 12485 5. 000 4019 60000001 Automotive Parts C 12500 65. 000 Picked Status 5. 000 65. 000 Bottom F 3=Exit F 5=Refresh F 7=Unverified/Verified F 11=Fold/Unfold F 12=Previous 2/17/08 15: 18: 44

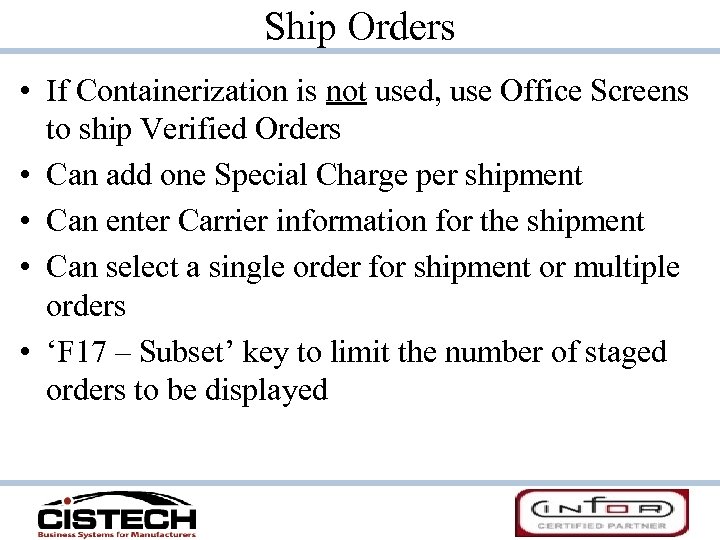

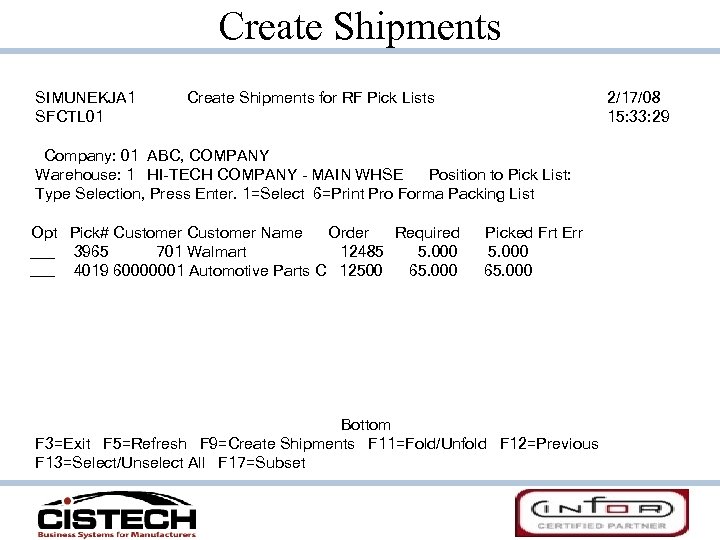

Ship Orders • If Containerization is not used, use Office Screens to ship Verified Orders • Can add one Special Charge per shipment • Can enter Carrier information for the shipment • Can select a single order for shipment or multiple orders • ‘F 17 – Subset’ key to limit the number of staged orders to be displayed

Ship Orders • If Containerization is not used, use Office Screens to ship Verified Orders • Can add one Special Charge per shipment • Can enter Carrier information for the shipment • Can select a single order for shipment or multiple orders • ‘F 17 – Subset’ key to limit the number of staged orders to be displayed

Create Shipments SIMUNEKJA 1 SFCTL 01 Create Shipments for RF Pick Lists 2/17/08 15: 33: 29 Company: 01 ABC, COMPANY Warehouse: 1 HI-TECH COMPANY - MAIN WHSE Position to Pick List: Type Selection, Press Enter. 1=Select 6=Print Pro Forma Packing List Opt Pick# Customer Name Order Required 3965 701 Walmart 12485 5. 000 4019 60000001 Automotive Parts C 12500 65. 000 Picked Frt Err 5. 000 65. 000 Bottom F 3=Exit F 5=Refresh F 9=Create Shipments F 11=Fold/Unfold F 12=Previous F 13=Select/Unselect All F 17=Subset

Create Shipments SIMUNEKJA 1 SFCTL 01 Create Shipments for RF Pick Lists 2/17/08 15: 33: 29 Company: 01 ABC, COMPANY Warehouse: 1 HI-TECH COMPANY - MAIN WHSE Position to Pick List: Type Selection, Press Enter. 1=Select 6=Print Pro Forma Packing List Opt Pick# Customer Name Order Required 3965 701 Walmart 12485 5. 000 4019 60000001 Automotive Parts C 12500 65. 000 Picked Frt Err 5. 000 65. 000 Bottom F 3=Exit F 5=Refresh F 9=Create Shipments F 11=Fold/Unfold F 12=Previous F 13=Select/Unselect All F 17=Subset

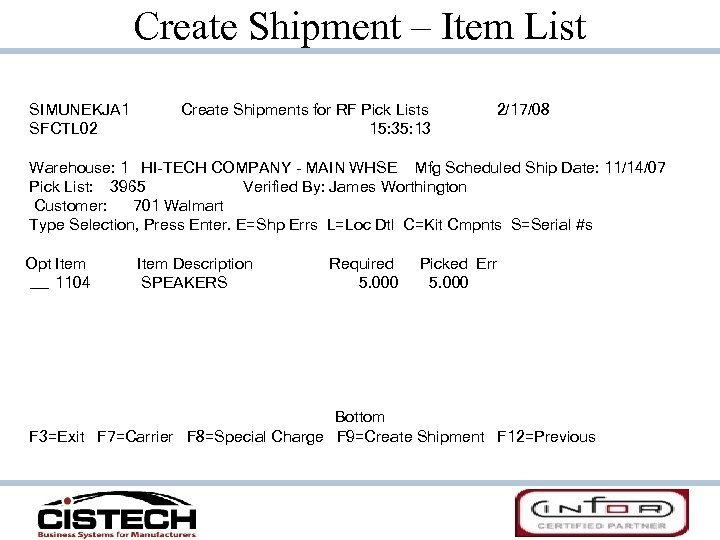

Create Shipment – Item List SIMUNEKJA 1 SFCTL 02 Create Shipments for RF Pick Lists 15: 35: 13 2/17/08 Warehouse: 1 HI-TECH COMPANY - MAIN WHSE Mfg Scheduled Ship Date: 11/14/07 Pick List: 3965 Verified By: James Worthington Customer: 701 Walmart Type Selection, Press Enter. E=Shp Errs L=Loc Dtl C=Kit Cmpnts S=Serial #s Opt Item 1104 Item Description SPEAKERS Required 5. 000 Picked Err 5. 000 Bottom F 3=Exit F 7=Carrier F 8=Special Charge F 9=Create Shipment F 12=Previous

Create Shipment – Item List SIMUNEKJA 1 SFCTL 02 Create Shipments for RF Pick Lists 15: 35: 13 2/17/08 Warehouse: 1 HI-TECH COMPANY - MAIN WHSE Mfg Scheduled Ship Date: 11/14/07 Pick List: 3965 Verified By: James Worthington Customer: 701 Walmart Type Selection, Press Enter. E=Shp Errs L=Loc Dtl C=Kit Cmpnts S=Serial #s Opt Item 1104 Item Description SPEAKERS Required 5. 000 Picked Err 5. 000 Bottom F 3=Exit F 7=Carrier F 8=Special Charge F 9=Create Shipment F 12=Previous

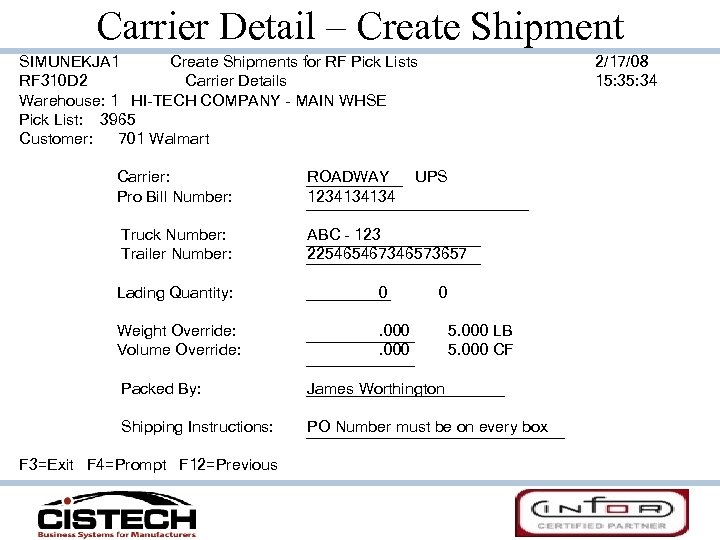

Carrier Detail – Create Shipment SIMUNEKJA 1 Create Shipments for RF Pick Lists RF 310 D 2 Carrier Details Warehouse: 1 HI-TECH COMPANY - MAIN WHSE Pick List: 3965 Customer: 701 Walmart 2/17/08 15: 34 Carrier: Pro Bill Number: ROADWAY 1234134134 UPS Truck Number: Trailer Number: ABC - 123 225465467346573657 Lading Quantity: 0 Weight Override: Volume Override: . 000 0 5. 000 LB 5. 000 CF Packed By: James Worthington Shipping Instructions: PO Number must be on every box F 3=Exit F 4=Prompt F 12=Previous

Carrier Detail – Create Shipment SIMUNEKJA 1 Create Shipments for RF Pick Lists RF 310 D 2 Carrier Details Warehouse: 1 HI-TECH COMPANY - MAIN WHSE Pick List: 3965 Customer: 701 Walmart 2/17/08 15: 34 Carrier: Pro Bill Number: ROADWAY 1234134134 UPS Truck Number: Trailer Number: ABC - 123 225465467346573657 Lading Quantity: 0 Weight Override: Volume Override: . 000 0 5. 000 LB 5. 000 CF Packed By: James Worthington Shipping Instructions: PO Number must be on every box F 3=Exit F 4=Prompt F 12=Previous

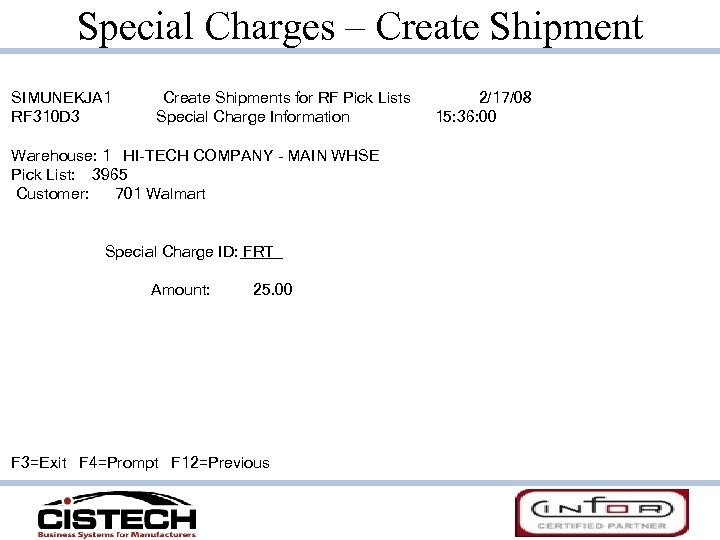

Special Charges – Create Shipment SIMUNEKJA 1 RF 310 D 3 Create Shipments for RF Pick Lists Special Charge Information Warehouse: 1 HI-TECH COMPANY - MAIN WHSE Pick List: 3965 Customer: 701 Walmart Special Charge ID: FRT Amount: 25. 00 F 3=Exit F 4=Prompt F 12=Previous 2/17/08 15: 36: 00

Special Charges – Create Shipment SIMUNEKJA 1 RF 310 D 3 Create Shipments for RF Pick Lists Special Charge Information Warehouse: 1 HI-TECH COMPANY - MAIN WHSE Pick List: 3965 Customer: 701 Walmart Special Charge ID: FRT Amount: 25. 00 F 3=Exit F 4=Prompt F 12=Previous 2/17/08 15: 36: 00

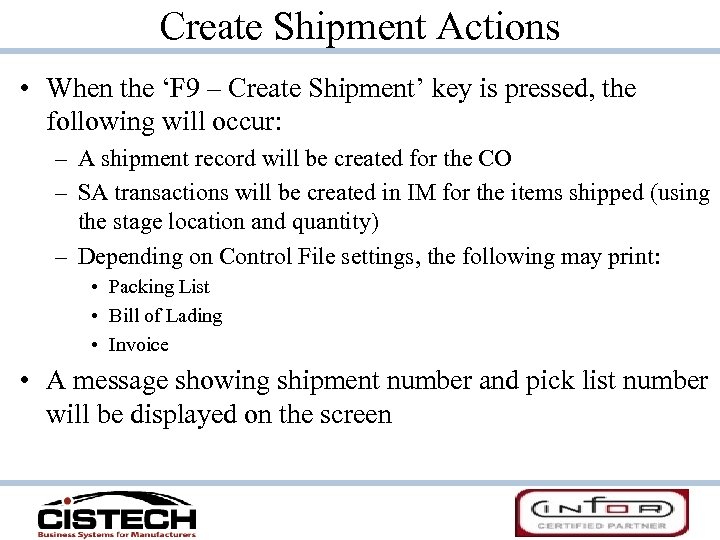

Create Shipment Actions • When the ‘F 9 – Create Shipment’ key is pressed, the following will occur: – A shipment record will be created for the CO – SA transactions will be created in IM for the items shipped (using the stage location and quantity) – Depending on Control File settings, the following may print: • Packing List • Bill of Lading • Invoice • A message showing shipment number and pick list number will be displayed on the screen

Create Shipment Actions • When the ‘F 9 – Create Shipment’ key is pressed, the following will occur: – A shipment record will be created for the CO – SA transactions will be created in IM for the items shipped (using the stage location and quantity) – Depending on Control File settings, the following may print: • Packing List • Bill of Lading • Invoice • A message showing shipment number and pick list number will be displayed on the screen

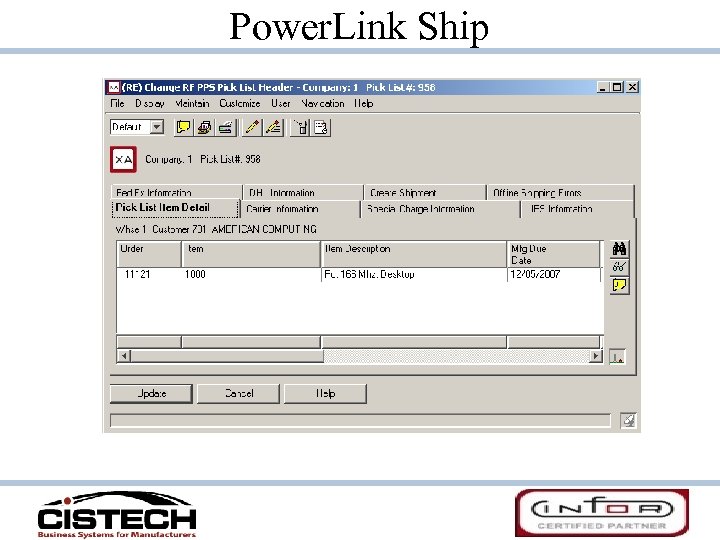

Power. Link Ship

Power. Link Ship

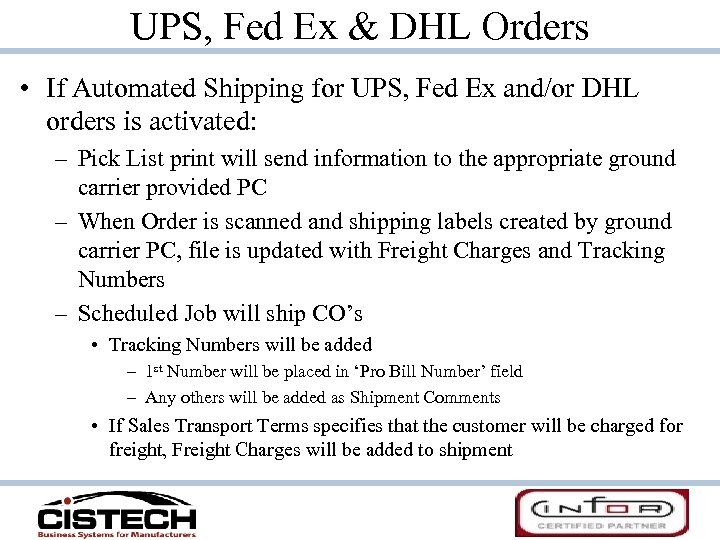

UPS, Fed Ex & DHL Orders • If Automated Shipping for UPS, Fed Ex and/or DHL orders is activated: – Pick List print will send information to the appropriate ground carrier provided PC – When Order is scanned and shipping labels created by ground carrier PC, file is updated with Freight Charges and Tracking Numbers – Scheduled Job will ship CO’s • Tracking Numbers will be added – 1 st Number will be placed in ‘Pro Bill Number’ field – Any others will be added as Shipment Comments • If Sales Transport Terms specifies that the customer will be charged for freight, Freight Charges will be added to shipment

UPS, Fed Ex & DHL Orders • If Automated Shipping for UPS, Fed Ex and/or DHL orders is activated: – Pick List print will send information to the appropriate ground carrier provided PC – When Order is scanned and shipping labels created by ground carrier PC, file is updated with Freight Charges and Tracking Numbers – Scheduled Job will ship CO’s • Tracking Numbers will be added – 1 st Number will be placed in ‘Pro Bill Number’ field – Any others will be added as Shipment Comments • If Sales Transport Terms specifies that the customer will be charged for freight, Freight Charges will be added to shipment

Summary • RF Pick/Pack/Ship is available as an RF Standalone product or can be sold as part of Cistech’s ‘RF Suite’ which includes: – IM transactions, REP transactions and IM Inquiry – Physical Inventory (interfaces with MM) – Pick/Pack/Ship • Can go completely ‘paperless’ by using Employee assignments to pick lists • Installed and implemented in 16 companies to date

Summary • RF Pick/Pack/Ship is available as an RF Standalone product or can be sold as part of Cistech’s ‘RF Suite’ which includes: – IM transactions, REP transactions and IM Inquiry – Physical Inventory (interfaces with MM) – Pick/Pack/Ship • Can go completely ‘paperless’ by using Employee assignments to pick lists • Installed and implemented in 16 companies to date

Summary • Office functions brought into Browser/Power Link is currently under development • R 2 (PPS) features greatly increased system functions – – – Employee Assignments to pick list Entry by Item Number, UPC or Turnaround Serial Number Item Substitutions UPS, Fed Ex and DHL no longer requires containerization be activated – Pack List print when order is verified

Summary • Office functions brought into Browser/Power Link is currently under development • R 2 (PPS) features greatly increased system functions – – – Employee Assignments to pick list Entry by Item Number, UPC or Turnaround Serial Number Item Substitutions UPS, Fed Ex and DHL no longer requires containerization be activated – Pack List print when order is verified

Thank You

Thank You