8831c9049acf0c2a09ef43ff76ff6790.ppt

- Количество слайдов: 85

Review for Exam 1 This exam will be administered Tuesday, September 27, 2016 in this room—you will have the entire period— 80 min.

Exam Structure b 80 multiple choice worth 100% b Bring: pencils, erasure, 5 -function calculator, orange scantron sheet b Exam is closed-notes, closed-books, closed -neighbors

Chapters covered b 1, 4, 3, 6, 15, 16, 7 b No supplements to any of these chapters

Chapter 1 b Name some activities of operations managers • Organizing work, selecting and innovating processes, arranging layouts, locating facilities, designing jobs, measuring performance, controlling quality, scheduling work, managing inventory, planning production b Is the Japanese success in Manufacturing a cultural one? • No. Witness what Matsushita did with Motorola’s Quasar

Activities in Operations Management include all but…. b Organizing work b Controlling quality b Selecting processes b Controlling finances b Scheduling work

Operations at a Bank b Processing funds b Providing checks b Cashing checks b Preparing monthly statements b Reconciling statements b Approving loans b Loaning money b Tracking loan payments

Operations at a retail store b Purchasing goods b Stocking goods b Selling goods b Tracking inventory b Scheduling workers b Laying out the store b Locating the store b Forecasting demand

Operations at hospital b Preparing rooms b Scheduling doctors, nurses, operating rooms b Processing paperwork b Ordering supplies b Billing customers b Caring for patients b Maintaining the facility

Operations at a cable TV company b Taking orders b Installing equipment b Maintaining equipment b Staying on the “air” b Scheduling work b Processing statements b Processing payments

Productivity is what exactly? b Output/Input • Measured in $$$ b The most common measure of competitiveness of a country b Government reports measure CHANGES IN PRODUCTIVITY from month to month

Name some trends in OM b Intense Competition b Global markets b Importance of Strategy b Product variety and mass customization b More services b Emphasis on quality b Flexibility b Advances in technology b Worker involvement

Name some barriers to entry of new enterprises b Economies of Scale b Access to customers and suppliers b The capital investment required b Learning curves b {Which of these would cause the cost to manufacture an airliner to decline from $300 M to $30 M as the manufacturer proceeds from the 1 st to the 10 th airplane? ? }

More Chapter 1 b Would you say that cheap labor rates are the strongest motivation for plant location? b Whose hourly wage rates are substantially higher than ours? b Operations have been likened to a _____ process b The purpose is to add _____, more ____ than you add cost.

Chapter 1 b _____ is the most common measure of competitiveness of a country. b a) Operations b b) Process b c) Productivity b d) E-commerce b e) Positioning

How important is a country’s competitiveness? b Somewhat b Not very b Not at all b Very important, if you value standard of living

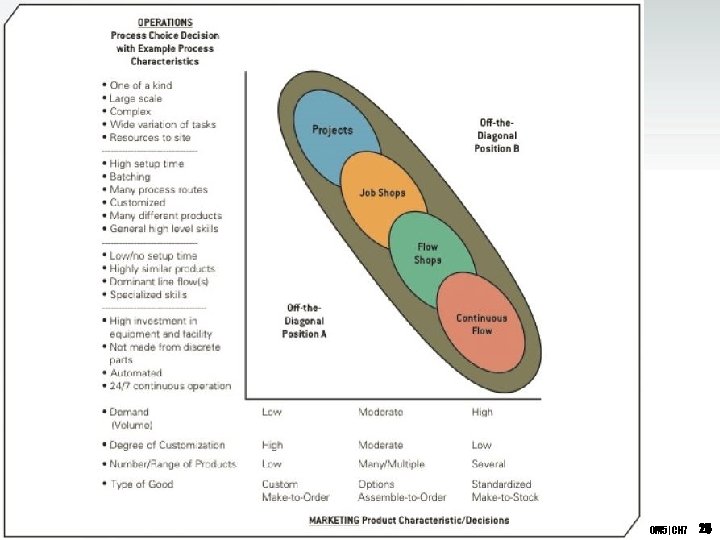

Operations Strategy b Primary tasks, core competencies, order qualifiers--define these b Name five competitive priorities b Today the focus in not on functions but _____ b Name four PROCESS (OPERATIONS) types – project, job shop, flow shop (mass production, ) continuous flow (continuous production) b Which of these are low-volume, which are high volume

Operations Strategy b What is meant by a core competence • A process that aligns with the way you add value in the marketplace b What is meant by • make to order • make to stock • assemble to order Which is custom, which is governed by a few options, which is standardized

Competing On Cost b Eliminate all waste b Invest in • updated facilities & equipment • streamlining operations • training & development b Examples • Walmart • Southwest Airlines © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Ch 2 - 3

Competing On Quality Please the customer • Understand customer attitudes toward and expectations of quality • Example – Ritz-Carlton Hotels © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Ch 2 - 4

Competing On Flexibility b Produce wide variety of products b Introduce new products quickly b Modify existing products quickly b Respond to customer needs b Example • Anderson Windows • Custom Foot Shoe Store • National Bicycle Industrial company © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Ch 2 - 5

Competing On Speed b Fast moves b Fast adaptations b Tight linkages b Example: Dell b Another example: Walmart’s cross-docking © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Ch 2 - 6

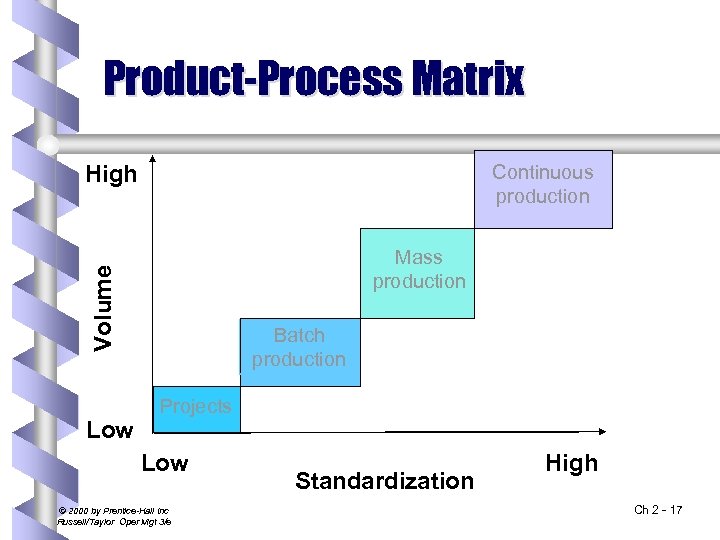

Product-Process Matrix Continuous production High Volume Mass production Low Batch production Projects Low © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Standardization High Ch 2 - 17

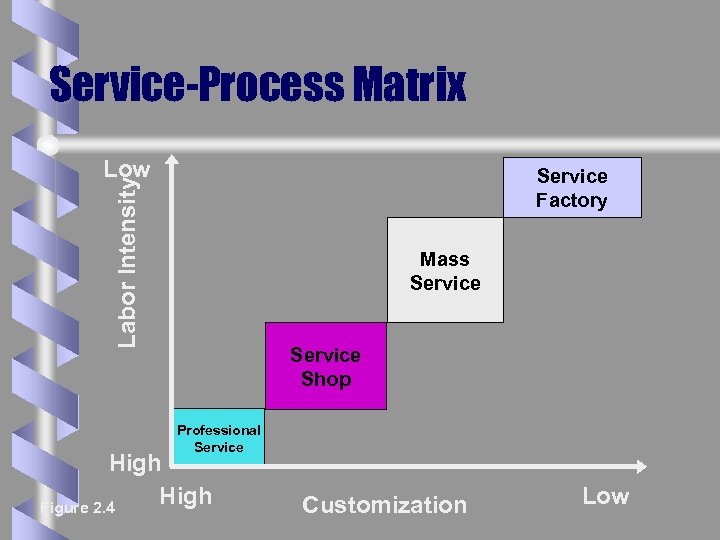

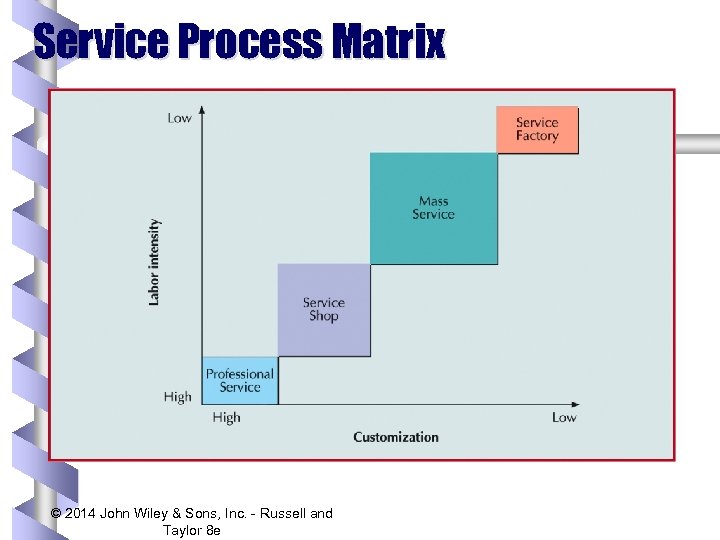

Service Operations b There are four types • Professional service, service shop, mass service, service factory • Schema coordinates are labor intensity and customization

Service-Process Matrix Low Labor Intensity Service Factory Mass Service Shop Professional Service High Figure 2. 4 Customization Low

Exhibit Copyright © 2016 Cengage Learning. All Rights Reserved. May not be scanned, copied or duplicated, or posted to a publicly accessible website, in whole or in part. OM 5| CH 7 25

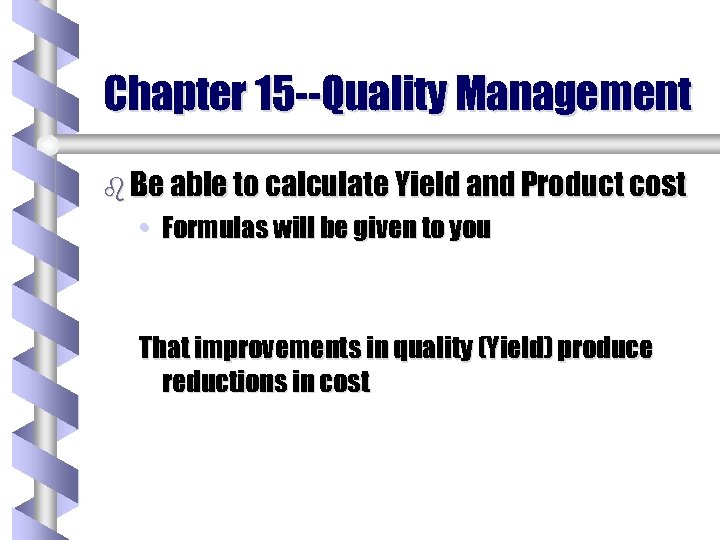

Chapter 15 --Quality Management b Be able to calculate Yield and Product cost • Formulas will be given to you That improvements in quality (Yield) produce reductions in cost

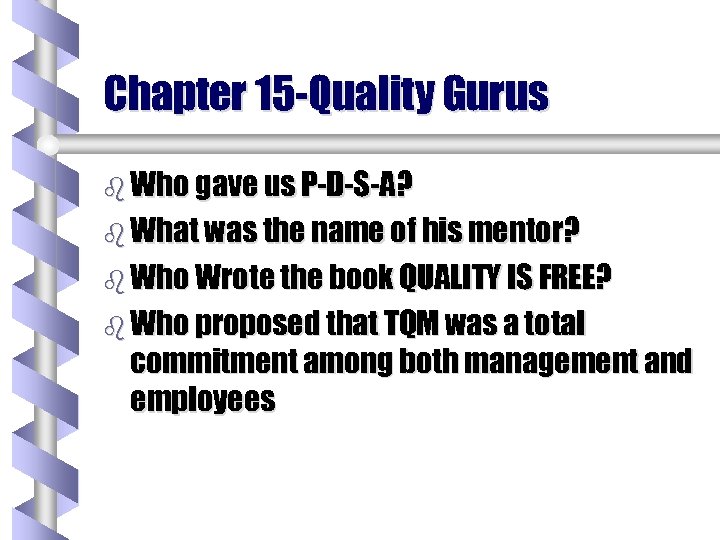

Chapter 15 -Quality Gurus b Who gave us P-D-S-A? b What was the name of his mentor? b Who Wrote the book QUALITY IS FREE? b Who proposed that TQM was a total commitment among both management and employees

Name the first five of Deming’s 14 points b Maintain constancy of purpose b Adopt a philosophy of prevention b Eliminate the need for inspection b Select a few suppliers b Constantly improve the production process

TQM b Relation to continuous process improvement b Who defines quality? ? b Who provides the leadership for quality? b Is quality a strategic issue? b To what extent is quality a worker vs. a managerial issue?

Measures of Quality b b b b b FOR PRODUCTS Performance Features Reliability Conformance Durability Serviceability Aesthetics Safety Other b b b b FOR SERVICES Timeliness Completeness Courtesy Consistency Accuracy Convenience Responsiveness

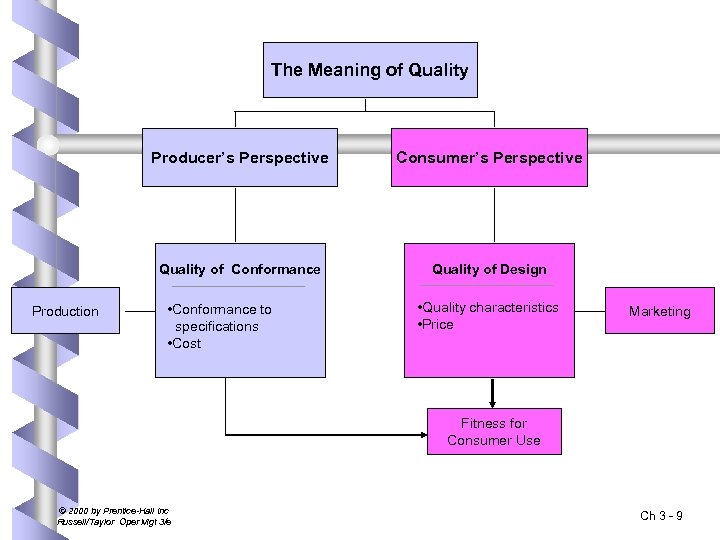

The Meaning of Quality Producer’s Perspective Quality of Conformance Production Consumer’s Perspective Quality of Design • Conformance to specifications • Cost • Quality characteristics • Price Marketing Fitness for Consumer Use © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Ch 3 - 9

Strategic Implications Of TQM b Quality is key to effective strategy b Clear strategic goal, vision, mission b High quality goals b Operational plans & policies b Feedback mechanism b Strong leadership © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Ch 3 - 16

DMAIC – what does it stand for? b Define b Measure b Analyze b Improve b Control

DMAIC is a methodology for… b Lean systems b Six sigma b Business process re-engineering b Statistical quality control charts

Which of the following endeavors to reduct process variability? b Lean systems b Six sigma b Business process re-engineering b Statistical quality control charts

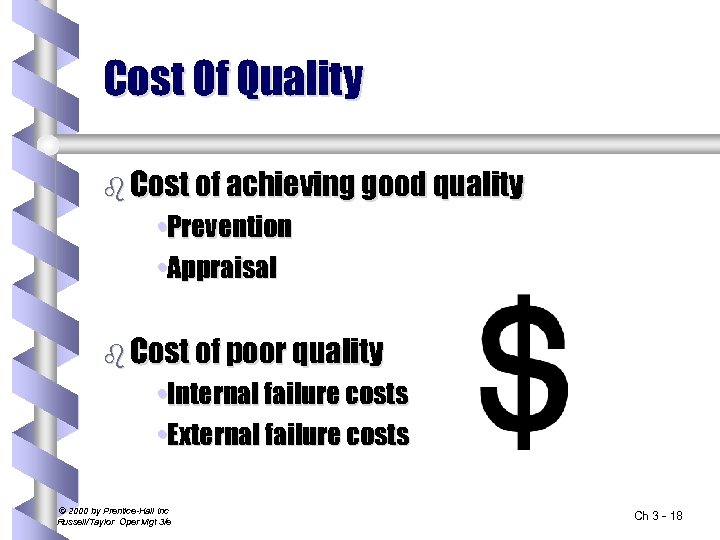

Cost Of Quality b Cost of achieving good quality • Prevention • Appraisal b Cost of poor quality • Internal failure costs • External failure costs © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Ch 3 - 18

Companies underestimate their failure costs b Because these are harder to measure b Crosby says these amount to 20 -30% of annual revenues, whereas the costs of good quality are roughly 3 -4% of annual revenues

Seven Quality Control Tools 1. Pareto analysis 2. Flowcharts 3. Check sheets 4. Histograms 5. Scatter diagrams 6. Control charts 7. Fishbone diagram © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Ch 3 - 37

Chapter 16 --Statistical Process Control b Be able to construct p-charts, c-charts • For attributes b Be able to construct xbar charts, R-charts • For variables

Variation b Common Causes • Variation inherent in a process • Can be eliminated only through improvements in the system b Special Causes – it is visible on a control chart • Variation due to identifiable factors • Can be modified through operator or management action © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Ch 4 - 4

Types Of Data b Attribute data – Product characteristic evaluated with a discrete choice – Good/bad, yes/no b Variable data – Product characteristic that can be measured – Length, size, weight, height, time, velocity © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Ch 4 - 5

Control Charts b Graph establishing process control limits b Charts for attributes • p charts and c charts b Charts for variables • Mean (X-bar), Range (R-bar) © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Ch 4 - 8

The x-bar chart is based on which probability distribution? b Exponential distribution b Binomial distribution b Normal distribution b Beta distribution b Poisson distribution

Typically control limits of control charts represent ____ sigma limits b 2 b 3 b 4 b 5 b 6

Six sigma means what in terms of defects b 35, 000 defects PMO b 3. 4 defects PMO b PMO stands for….

Chapter 6—Product & Process Design b Design for manufacture b Design for assembly b Design for environment b Design for maintenance b Design for Robustness

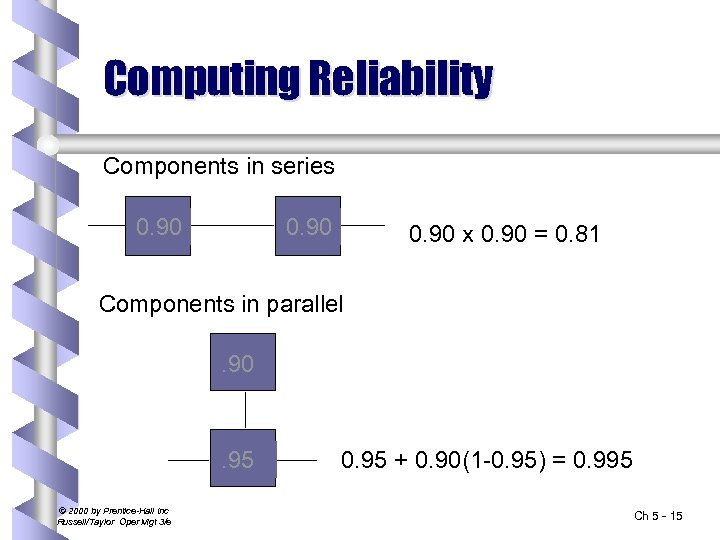

Computing Reliability Components in series 0. 90 x 0. 90 = 0. 81 Components in parallel. 90 . 95 © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e 0. 95 + 0. 90(1 -0. 95) = 0. 995 Ch 5 - 15

A technique for improving the design of a product vis-à-vis b Customer requirements b Comparing competitions’ products, is called______ b Benchmarking b Taking apart the competitions’ products, is called______ b Reverse Engineering

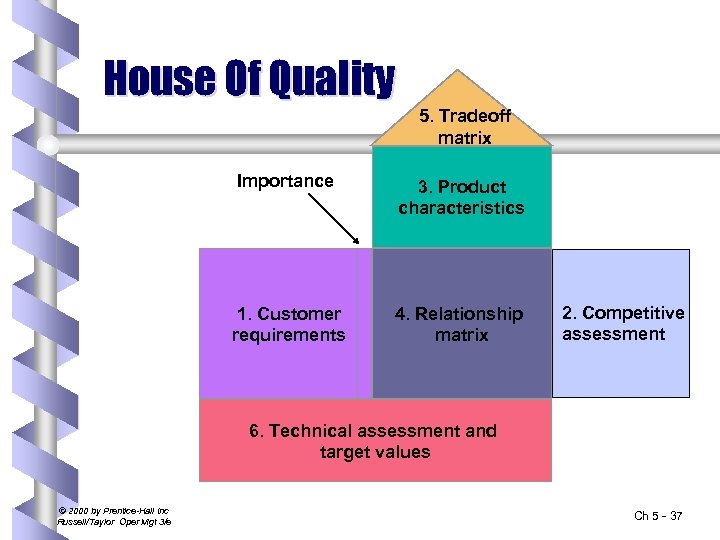

House Of Quality 5. Tradeoff matrix Importance 3. Product characteristics 1. Customer requirements 4. Relationship matrix 2. Competitive assessment 6. Technical assessment and target values © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Ch 5 - 37

Measures of Design Quality include b Number of component parts and product options b % of standard parts b Use of existing manufacturing processes b Cost of first production run b Cost of engineering changes during the first six months b Total product cost b Total product sales b Sustainable development

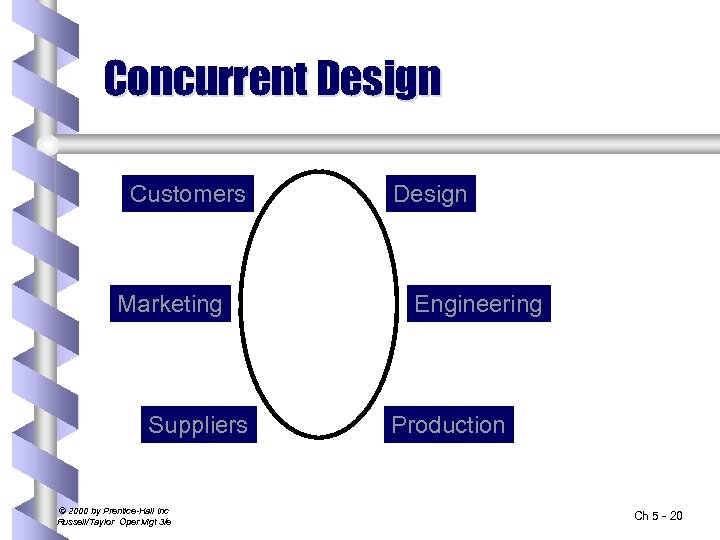

Concurrent Design Customers Marketing Suppliers © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Design Engineering Production Ch 5 - 20

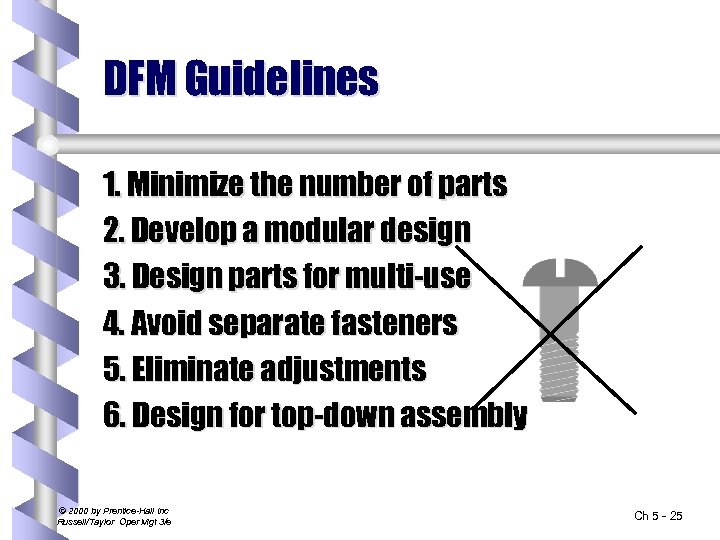

DFM Guidelines 1. Minimize the number of parts 2. Develop a modular design 3. Design parts for multi-use 4. Avoid separate fasteners 5. Eliminate adjustments 6. Design for top-down assembly © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Ch 5 - 25

Service Design

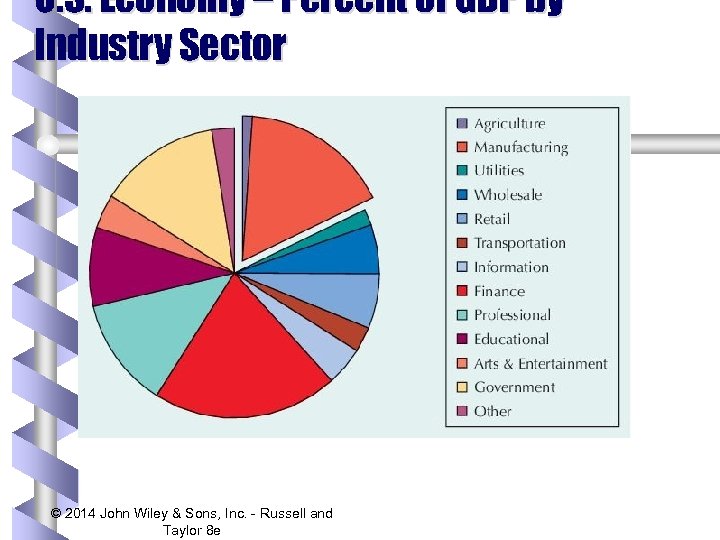

U. S. Economy – Percent of GDP by Industry Sector © 2014 John Wiley & Sons, Inc. - Russell and Taylor 8 e

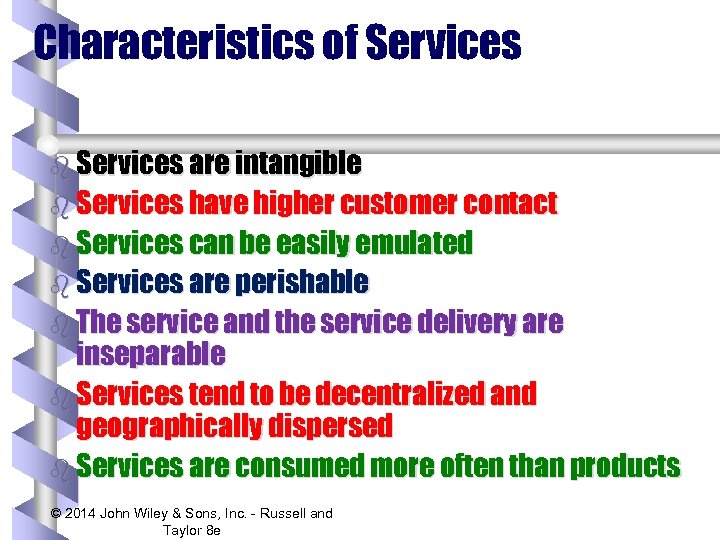

Characteristics of Services b Services are intangible b Services have higher customer contact b Services can be easily emulated b Services are perishable b The service and the service delivery are inseparable b Services tend to be decentralized and geographically dispersed b Services are consumed more often than products © 2014 John Wiley & Sons, Inc. - Russell and Taylor 8 e

Service Process Matrix © 2014 John Wiley & Sons, Inc. - Russell and Taylor 8 e

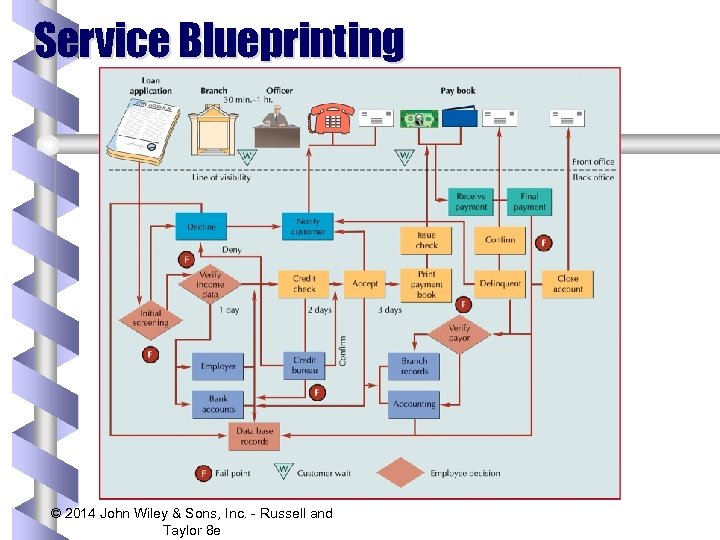

Service Blueprinting © 2014 John Wiley & Sons, Inc. - Russell and Taylor 8 e

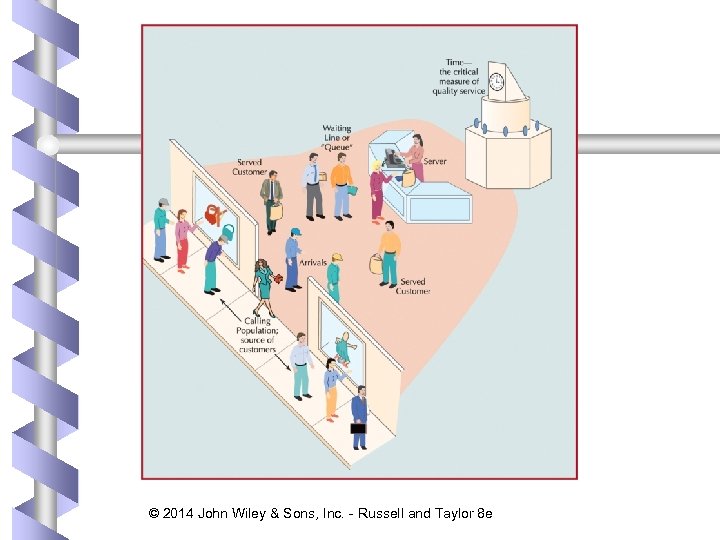

Elements of Waiting Line Analysis b Operating characteristics • average values for characteristics that describe performance of waiting line system b Queue • a single waiting line b Waiting line system • consists of arrivals, servers, and waiting line structure b Calling population • source of customers; infinite or finite © 2014 John Wiley & Sons, Inc. - Russell and Taylor 8 e

© 2014 John Wiley & Sons, Inc. - Russell and Taylor 8 e

Elements of Waiting Line Analysis b Arrival rate (λ) b Service time (μ) b b Service Rate = 1/service time * units change if any Service rate and arrival rate must be in the same units Service rate must be higher than arrival rate (λ < μ) Queue discipline b Infinite queue b b • frequency at which customers arrive at a waiting line according to a probability distribution, usually Poisson • time required to serve a customer, usually described by negative exponential distribution • order in which customers are served • FCFS, LIFO, EDD, SPT • can be of any length; length of a finite queue is limited © 2014 John Wiley & Sons, Inc. - Russell and Taylor 8 e

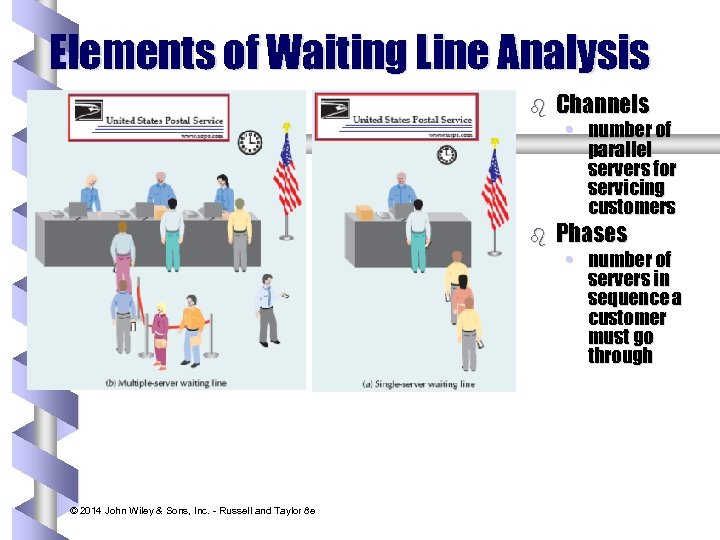

Elements of Waiting Line Analysis b b © 2014 John Wiley & Sons, Inc. - Russell and Taylor 8 e Channels Phases • number of parallel servers for servicing customers • number of servers in sequence a customer must go through

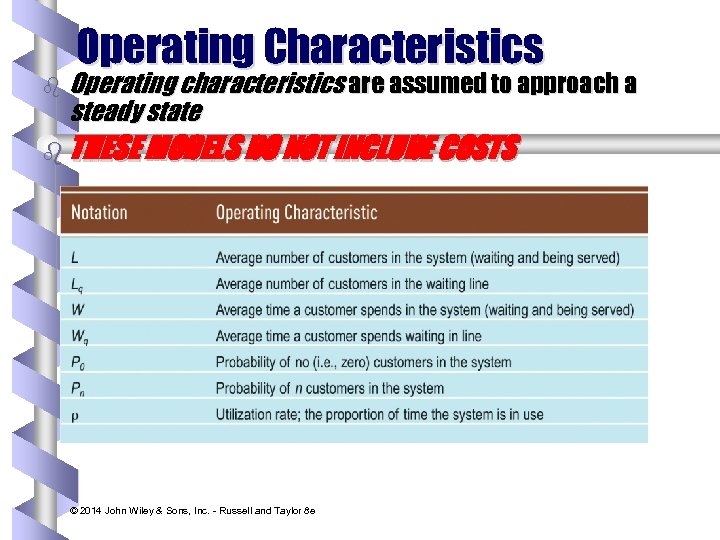

Operating Characteristics b Operating characteristics are assumed to approach a steady state b THESE MODELS DO NOT INCLUDE COSTS © 2014 John Wiley & Sons, Inc. - Russell and Taylor 8 e

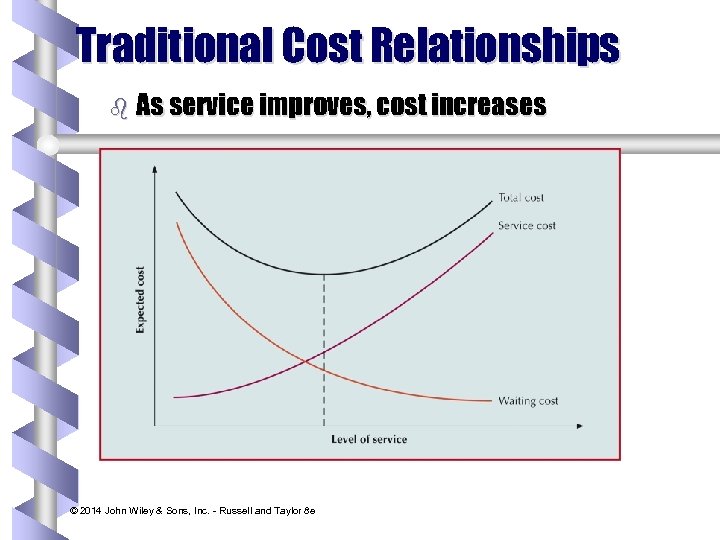

Traditional Cost Relationships b As service improves, cost increases © 2014 John Wiley & Sons, Inc. - Russell and Taylor 8 e

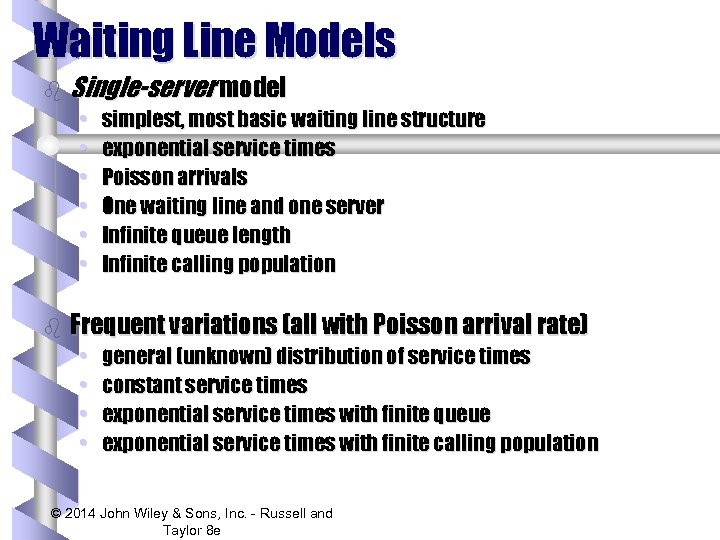

Waiting Line Models b Single-server model • • • b simplest, most basic waiting line structure exponential service times Poisson arrivals One waiting line and one server Infinite queue length Infinite calling population Frequent variations (all with Poisson arrival rate) • • general (unknown) distribution of service times constant service times exponential service times with finite queue exponential service times with finite calling population © 2014 John Wiley & Sons, Inc. - Russell and Taylor 8 e

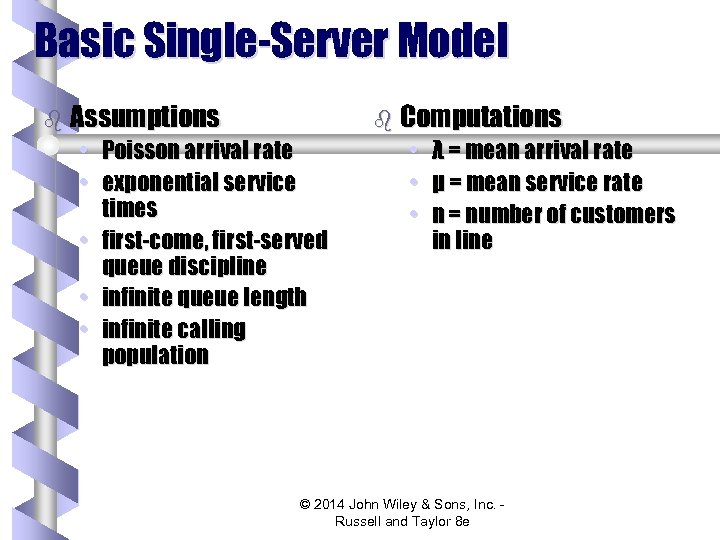

Basic Single-Server Model b Assumptions • • b Computations Poisson arrival rate exponential service times • first-come, first-served queue discipline • infinite queue length • infinite calling population • • • λ = mean arrival rate μ = mean service rate n = number of customers in line © 2014 John Wiley & Sons, Inc. Russell and Taylor 8 e

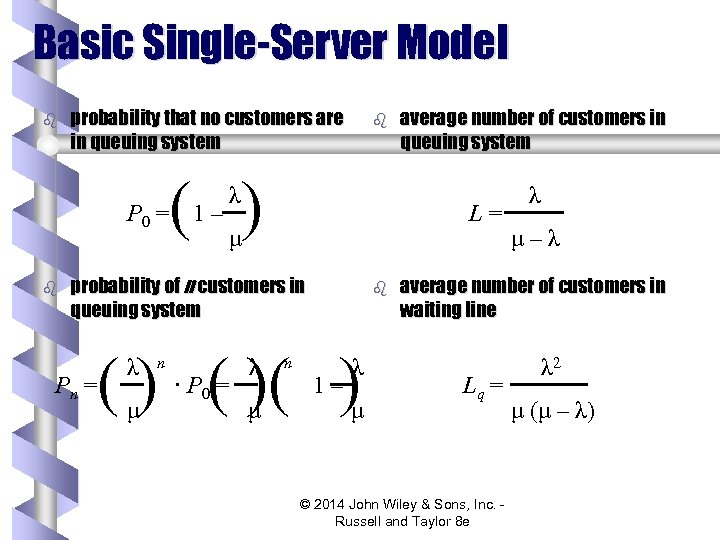

Basic Single-Server Model b probability that no customers are in queuing system b ( ) P 0 = b 1– λ L= μ probability of n customers in queuing system b ( )( ) Pn = λ μ n ∙ P 0 = λ μ average number of customers in queuing system n 1– λ μ–λ average number of customers in waiting line Lq = © 2014 John Wiley & Sons, Inc. Russell and Taylor 8 e λ 2 μ (μ – λ)

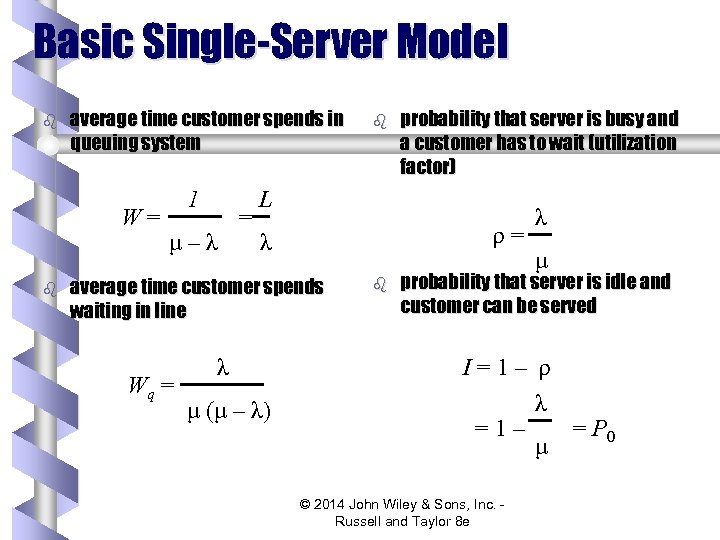

Basic Single-Server Model b average time customer spends in queuing system W= b 1 μ–λ = probability that server is busy and a customer has to wait (utilization factor) L ρ= λ average time customer spends waiting in line Wq = b λ μ (μ – λ) b λ μ probability that server is idle and customer can be served I=1– ρ λ =1– = P 0 μ © 2014 John Wiley & Sons, Inc. Russell and Taylor 8 e

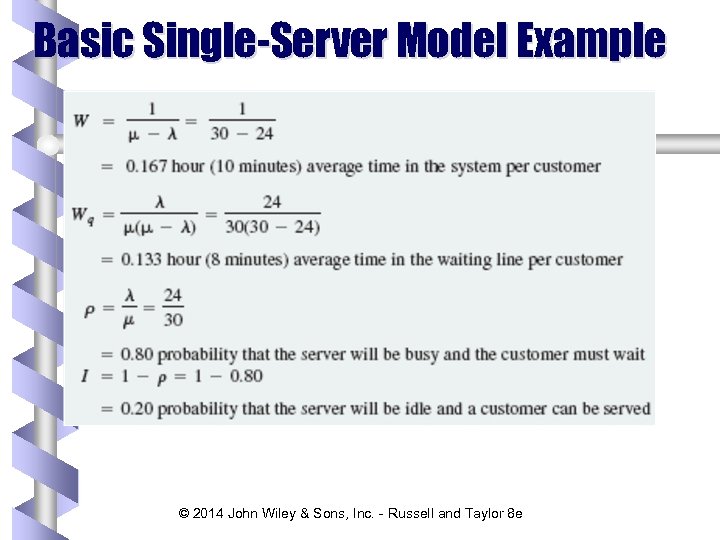

Basic Single-Server Model Example l = 24 µ = 30 P 0 = L= Lq = © 2014 John Wiley & Sons, Inc. - Russell and Taylor 8 e

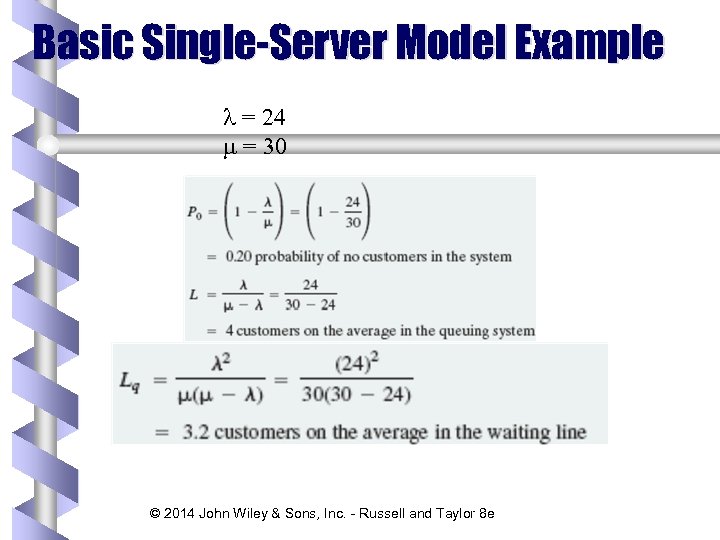

Basic Single-Server Model Example l = 24 m = 30 © 2014 John Wiley & Sons, Inc. - Russell and Taylor 8 e

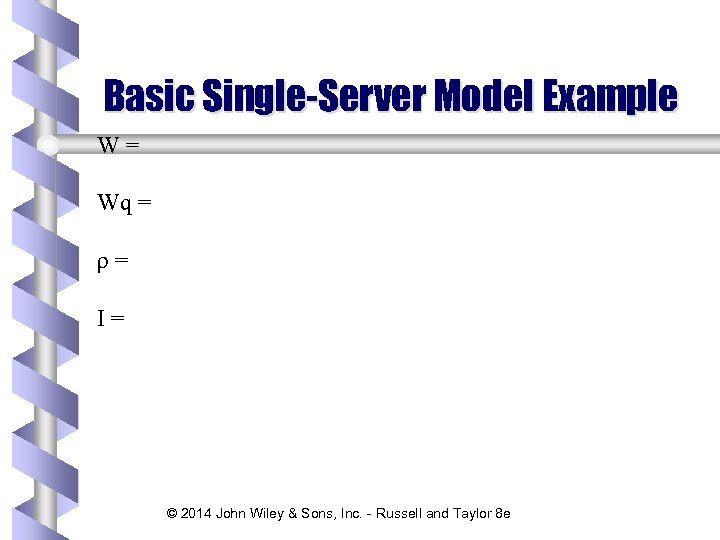

Basic Single-Server Model Example W= Wq = ρ= I= © 2014 John Wiley & Sons, Inc. - Russell and Taylor 8 e

Basic Single-Server Model Example © 2014 John Wiley & Sons, Inc. - Russell and Taylor 8 e

Chapter 6—Processes, Technologies & Capacity b Michael Hammer—eliminate _______? ? b Handoffs b Make work _____ again b Whole b Make processes _______ b Simple

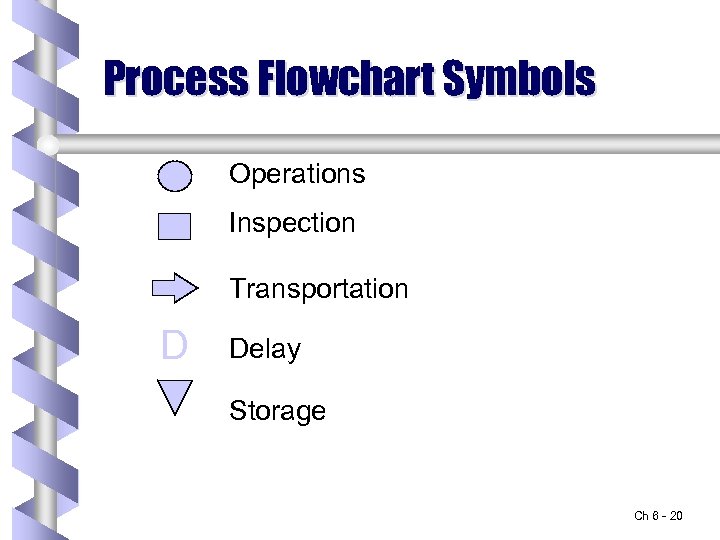

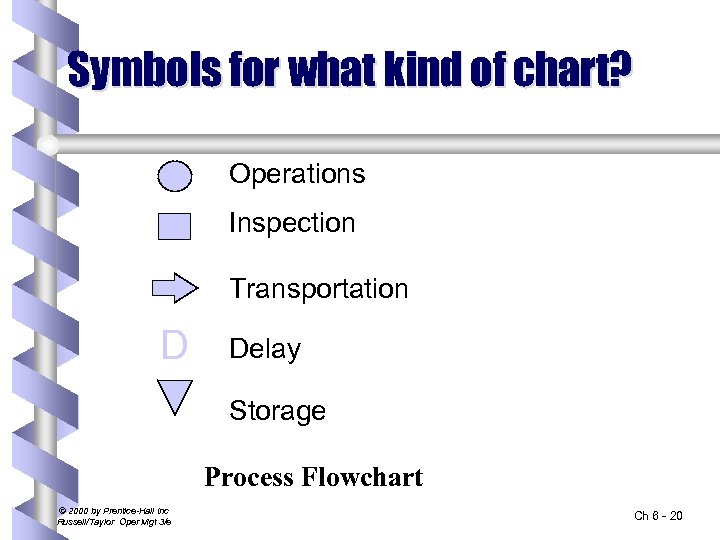

Process Flowchart Symbols Operations Inspection Transportation D Delay Storage Ch 6 - 20

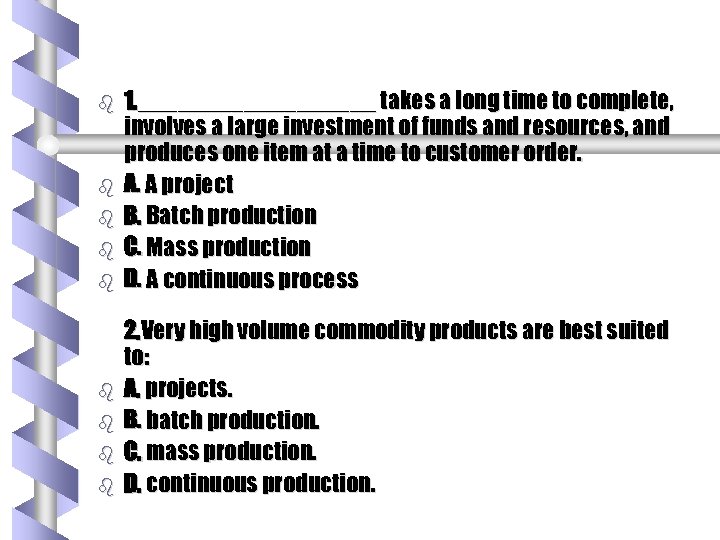

b b b b b 1. _________ takes a long time to complete, involves a large investment of funds and resources, and produces one item at a time to customer order. A. A project B. Batch production C. Mass production D. A continuous process 2. Very high volume commodity products are best suited to: A. projects. B. batch production. C. mass production. D. continuous production.

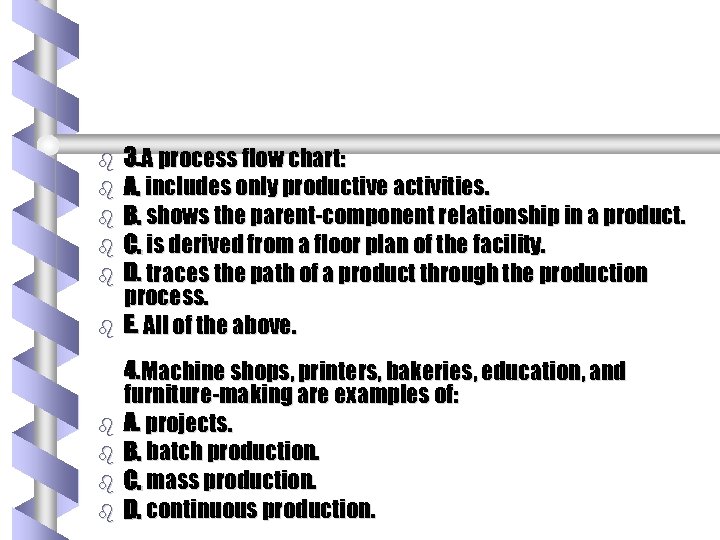

b b b b b 3. A process flow chart: A. includes only productive activities. B. shows the parent-component relationship in a product. C. is derived from a floor plan of the facility. D. traces the path of a product through the production process. E. All of the above. 4. Machine shops, printers, bakeries, education, and furniture-making are examples of: A. projects. B. batch production. C. mass production. D. continuous production.

The focus of operations today is not on functions, but _____ b Processes

Which of the following refers to dismantling a competitor’s product? b Dismantling a competitor’s product in order to improve one’s own product • • Cluster charting Benchmarking Reverse engineering Concurrent design

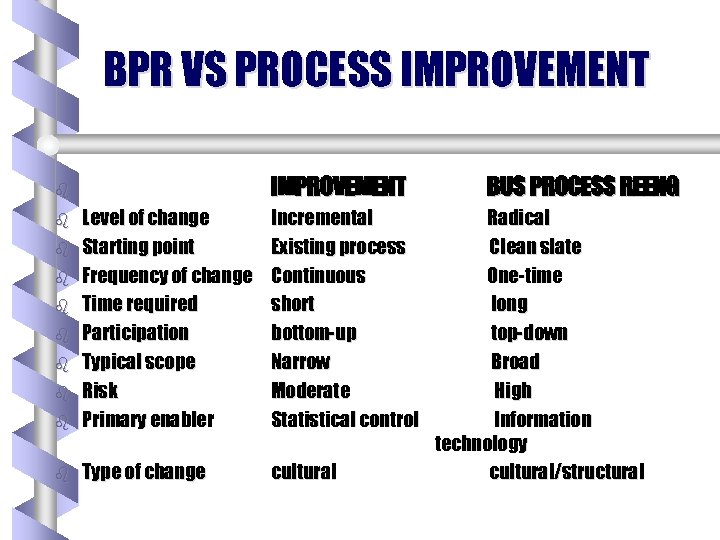

BPR VS PROCESS IMPROVEMENT b b Level of change Starting point Frequency of change Time required Participation Typical scope Risk Primary enabler Incremental Existing process Continuous short bottom-up Narrow Moderate Statistical control b Type of change cultural b b b b BUS PROCESS REENG Radical Clean slate One-time long top-down Broad High Information technology cultural/structural

Disadvantages of handoffs b allow for inventory buildup between workers, stations b add delays--transit times, wait times b require more people b make work too simple and boring b require supervision

What are byproducts of shortened cycle times? b Faster to market b Larger market share as a result b More responsive to the customer b More flexible b In some cases even lower cost

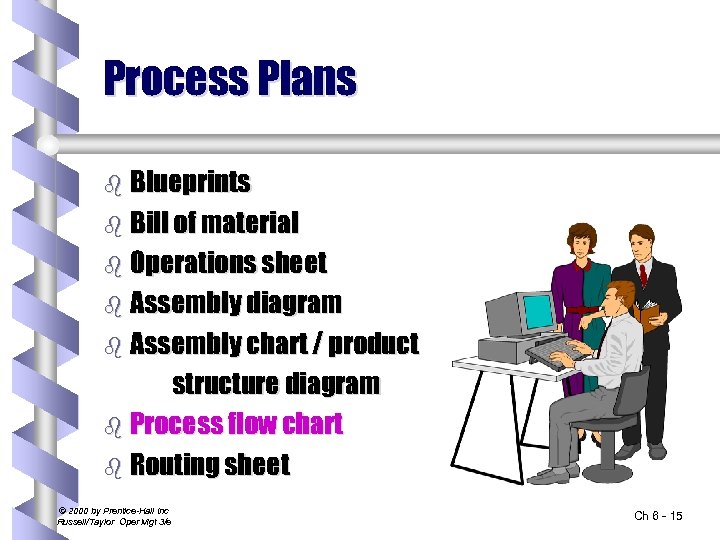

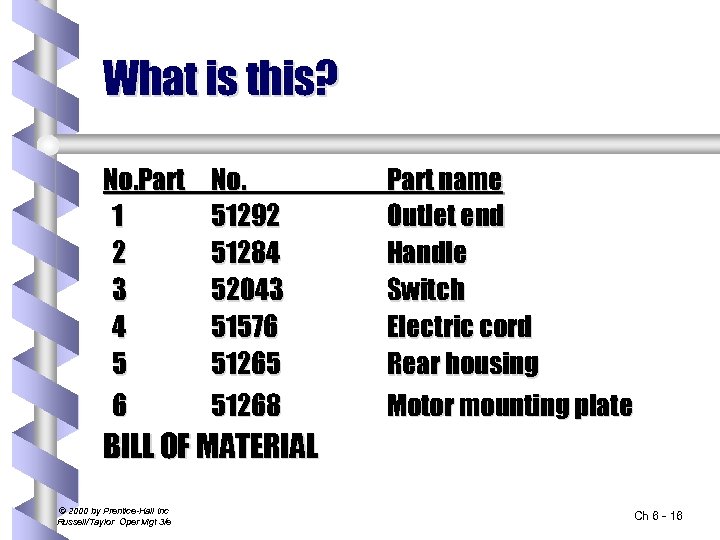

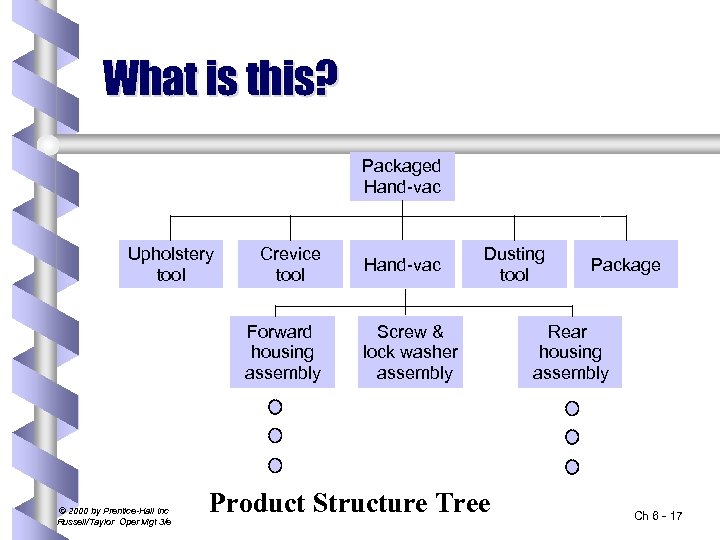

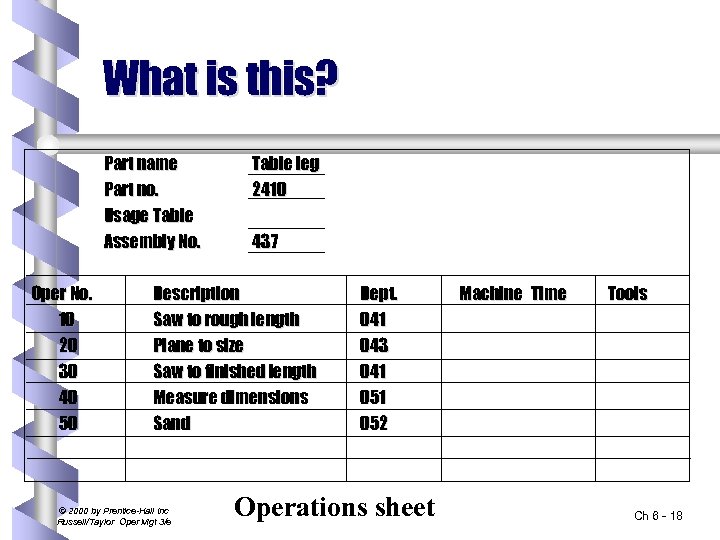

Process Plans b Blueprints b Bill of material b Operations sheet b Assembly diagram b Assembly chart / product structure diagram b Process flow chart b Routing sheet © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Ch 6 - 15

What is this? No. Part 1 2 3 4 5 6 No. 51292 51284 52043 51576 51265 51268 Part name Outlet end Handle Switch Electric cord Rear housing Motor mounting plate BILL OF MATERIAL © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Ch 6 - 16

What is this? Packaged Hand-vac Upholstery tool Crevice tool Forward housing assembly © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Hand-vac Dusting tool Screw & lock washer assembly Product Structure Tree Package Rear housing assembly Ch 6 - 17

What is this? Part name Part no. Usage Table Assembly No. Oper No. 10 20 30 40 50 Table leg 2410 437 Description Saw to rough length Plane to size Saw to finished length Measure dimensions Sand © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Dept. 041 043 041 052 Operations sheet Machine Time Tools Ch 6 - 18

Symbols for what kind of chart? Operations Inspection Transportation D Delay Storage Process Flowchart © 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e Ch 6 - 20

8831c9049acf0c2a09ef43ff76ff6790.ppt