d02586aab3a09151a835b0c35478d438.ppt

- Количество слайдов: 55

Retro-Commissioning: A Tool for Improving HVAC Systems and Energy Cost Reduction Speaker: William Mc. Guire, P. E.

Retro-Commissioning: A Tool for Improving HVAC Systems and Energy Cost Reduction Speaker: William Mc. Guire, P. E.

AGENDA Retro-Commissioning of Existing Buildings Why Retro-Cx What is Retro-Cx ? How do you do it / what to look for Case Studies Take-Away

AGENDA Retro-Commissioning of Existing Buildings Why Retro-Cx What is Retro-Cx ? How do you do it / what to look for Case Studies Take-Away

Why Retro-Cx • Older bldgs. (Pre 1990) on average consume more energy • Antiquated control systems that don’t work • Energy saving control strategies missed in design • Neglected maintenance wasting energy and/or causing IAQ problems • System upgrades that miss the mark • Building usage / floor plans changed

Why Retro-Cx • Older bldgs. (Pre 1990) on average consume more energy • Antiquated control systems that don’t work • Energy saving control strategies missed in design • Neglected maintenance wasting energy and/or causing IAQ problems • System upgrades that miss the mark • Building usage / floor plans changed

Why Retro-Cx • Energy cost are only expected to rise • Economic outlook may prevent new construction • Employee / Community goodwill – “It’s the right thing to do” • Owners learn more about their own facilities • Benefits intended to be long lasting • Simple payback typically less than two years

Why Retro-Cx • Energy cost are only expected to rise • Economic outlook may prevent new construction • Employee / Community goodwill – “It’s the right thing to do” • Owners learn more about their own facilities • Benefits intended to be long lasting • Simple payback typically less than two years

Why Retro-Cx Leased Buildings • LEED EB / ENERGY STAR buildings may become a differentiator • High energy costs translate into increased rent cost

Why Retro-Cx Leased Buildings • LEED EB / ENERGY STAR buildings may become a differentiator • High energy costs translate into increased rent cost

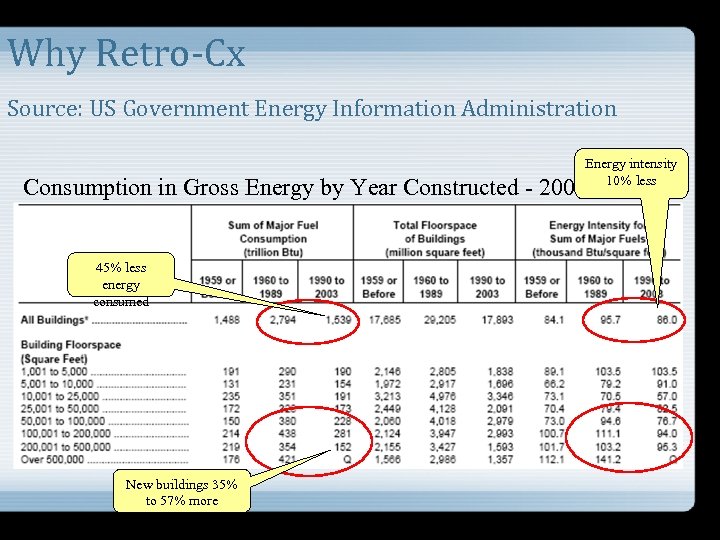

Why Retro-Cx Source: US Government Energy Information Administration Energy intensity 10% less Consumption in Gross Energy by Year Constructed - 2003 45% less energy consumed New buildings 35% to 57% more efficient

Why Retro-Cx Source: US Government Energy Information Administration Energy intensity 10% less Consumption in Gross Energy by Year Constructed - 2003 45% less energy consumed New buildings 35% to 57% more efficient

Why Retro-Cx A study by Lawrence Berkeley National Laboratory (LBNL) 2004 • • • Retro-Cx results Whole-building electricity savings range from 5% to 15% Gas savings range from 1% to 23% Payback ranged from 0. 2 to 2. 1 years The bigger the building typically the better the payback period Small buildings have opportunity as well Source: A Retro. Commissioning Guide for Building Owners PECI

Why Retro-Cx A study by Lawrence Berkeley National Laboratory (LBNL) 2004 • • • Retro-Cx results Whole-building electricity savings range from 5% to 15% Gas savings range from 1% to 23% Payback ranged from 0. 2 to 2. 1 years The bigger the building typically the better the payback period Small buildings have opportunity as well Source: A Retro. Commissioning Guide for Building Owners PECI

Why Retro-Cx Lawrence Berkeley National Laboratory (LBNL) – 2004 Value of Energy Savings $0. 11 - $0. 72/ft 2 Value of Non Energy Savings $0. 10 - $0. 45/ft 2 Non Energy: Equip Life, thermal comfort, IAQ, productivity, liability, etc.

Why Retro-Cx Lawrence Berkeley National Laboratory (LBNL) – 2004 Value of Energy Savings $0. 11 - $0. 72/ft 2 Value of Non Energy Savings $0. 10 - $0. 45/ft 2 Non Energy: Equip Life, thermal comfort, IAQ, productivity, liability, etc.

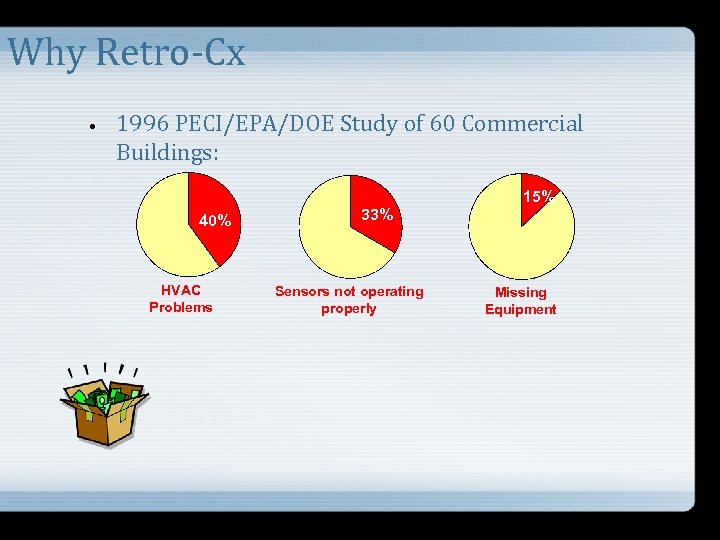

Why Retro-Cx • 1996 PECI/EPA/DOE Study of 60 Commercial Buildings: 15% 40% HVAC Problems 33% Sensors not operating properly Missing Equipment

Why Retro-Cx • 1996 PECI/EPA/DOE Study of 60 Commercial Buildings: 15% 40% HVAC Problems 33% Sensors not operating properly Missing Equipment

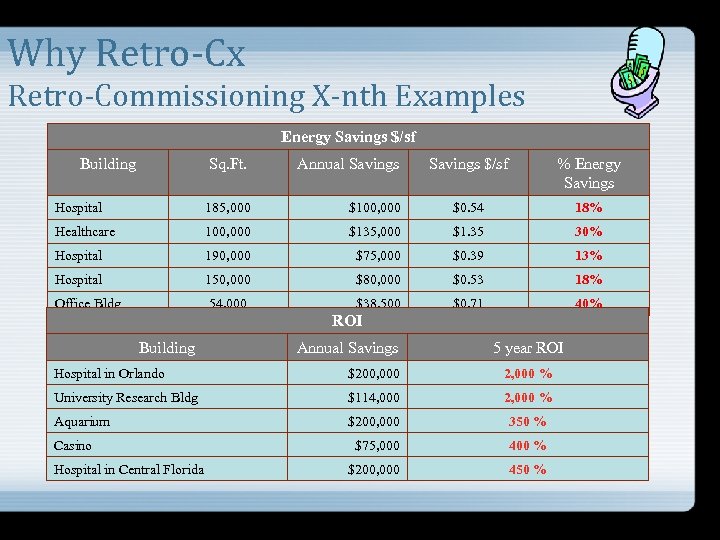

Why Retro-Cx Retro-Commissioning X-nth Examples Energy Savings $/sf Building Sq. Ft. Annual Savings $/sf % Energy Savings Hospital 185, 000 $100, 000 $0. 54 18% Healthcare 100, 000 $135, 000 $1. 35 30% Hospital 190, 000 $75, 000 $0. 39 13% Hospital 150, 000 $80, 000 $0. 53 18% Office Bldg 54, 000 $38, 500 $0. 71 40% ROI Building Annual Savings 5 year ROI Hospital in Orlando $200, 000 2, 000 % University Research Bldg $114, 000 2, 000 % Aquarium $200, 000 350 % $75, 000 400 % $200, 000 450 % Casino Hospital in Central Florida

Why Retro-Cx Retro-Commissioning X-nth Examples Energy Savings $/sf Building Sq. Ft. Annual Savings $/sf % Energy Savings Hospital 185, 000 $100, 000 $0. 54 18% Healthcare 100, 000 $135, 000 $1. 35 30% Hospital 190, 000 $75, 000 $0. 39 13% Hospital 150, 000 $80, 000 $0. 53 18% Office Bldg 54, 000 $38, 500 $0. 71 40% ROI Building Annual Savings 5 year ROI Hospital in Orlando $200, 000 2, 000 % University Research Bldg $114, 000 2, 000 % Aquarium $200, 000 350 % $75, 000 400 % $200, 000 450 % Casino Hospital in Central Florida

Retro-commissioning is “GREENER” If Retro-commissioning our existing buildings can save just 10% energy consumption • Reduce oil imports by 50%. • Almost meets Kyoto Protocol. Exploit our existing buildings, not the environment !

Retro-commissioning is “GREENER” If Retro-commissioning our existing buildings can save just 10% energy consumption • Reduce oil imports by 50%. • Almost meets Kyoto Protocol. Exploit our existing buildings, not the environment !

What is Retro. Commissioning?

What is Retro. Commissioning?

What is Retro-Cx RETRO-Commissioning is evaluating and performance testing an Existing building’s HVAC…. DISCOM Design Installation Set-up / TAB Controls / Optimization Operation Maintenance

What is Retro-Cx RETRO-Commissioning is evaluating and performance testing an Existing building’s HVAC…. DISCOM Design Installation Set-up / TAB Controls / Optimization Operation Maintenance

What is Retro-Cx • Reveals hidden deficiencies that could have been avoided by commissioning. • Highlights O&M problems that could have been avoided through better training. • Reveals hidden control system problems, lowering energy costs.

What is Retro-Cx • Reveals hidden deficiencies that could have been avoided by commissioning. • Highlights O&M problems that could have been avoided through better training. • Reveals hidden control system problems, lowering energy costs.

What is Retro-Cx is NOT an energy study! • Energy studies leave the Owner with proof of what they already suspect , something is wrong. • It provides no answers as to what to do or were to start. • Skip all the paperwork and go find the MONEY

What is Retro-Cx is NOT an energy study! • Energy studies leave the Owner with proof of what they already suspect , something is wrong. • It provides no answers as to what to do or were to start. • Skip all the paperwork and go find the MONEY

What is Retro-Cx Retro-Commissioning Defined: It’s a Tune-up, not just an ECM list PROCESS: An experienced commissioning team investigates the existing systems operation looking for equipment and systems that are not operating “properly”. RESULT: The most common HVAC discovery is even though the space temperatures are comfortable, the systems are consuming much more energy than necessary due to overcooling, over-heating, over-ventilating. Reveals hidden problems in DISCO&M. COST: Retro-commissioning’s cost is a few weeks of time for the commissioning team. The cost savings discovered usually pay back the retro-commissioning cost in months.

What is Retro-Cx Retro-Commissioning Defined: It’s a Tune-up, not just an ECM list PROCESS: An experienced commissioning team investigates the existing systems operation looking for equipment and systems that are not operating “properly”. RESULT: The most common HVAC discovery is even though the space temperatures are comfortable, the systems are consuming much more energy than necessary due to overcooling, over-heating, over-ventilating. Reveals hidden problems in DISCO&M. COST: Retro-commissioning’s cost is a few weeks of time for the commissioning team. The cost savings discovered usually pay back the retro-commissioning cost in months.

Retro. Commissioning How do you do it? Uncovering the waste in DISCO&M

Retro. Commissioning How do you do it? Uncovering the waste in DISCO&M

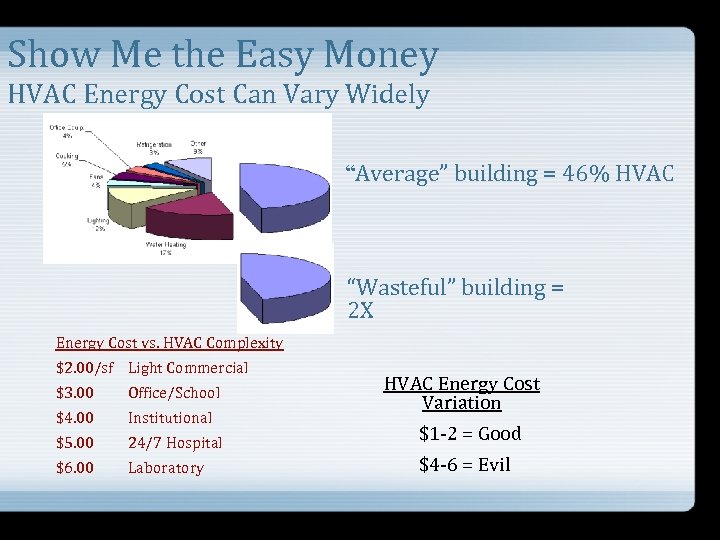

Show Me the Easy Money HVAC Energy Cost Can Vary Widely “Average” building = 46% HVAC “Wasteful” building = 2 X Energy Cost vs. HVAC Complexity $2. 00/sf Light Commercial HVAC Energy Cost Variation $3. 00 Office/School $4. 00 Institutional $5. 00 24/7 Hospital $1 -2 = Good $6. 00 Laboratory $4 -6 = Evil

Show Me the Easy Money HVAC Energy Cost Can Vary Widely “Average” building = 46% HVAC “Wasteful” building = 2 X Energy Cost vs. HVAC Complexity $2. 00/sf Light Commercial HVAC Energy Cost Variation $3. 00 Office/School $4. 00 Institutional $5. 00 24/7 Hospital $1 -2 = Good $6. 00 Laboratory $4 -6 = Evil

Where is the HVAC Energy Savings? Gas Pedal / Brake Pedal Syndrome Improper DISCO&M = energy savings opportunities HVAC systems have many combinations of gas pedal / brake pedals that could be affected by improper DISCO&M.

Where is the HVAC Energy Savings? Gas Pedal / Brake Pedal Syndrome Improper DISCO&M = energy savings opportunities HVAC systems have many combinations of gas pedal / brake pedals that could be affected by improper DISCO&M.

Where to Start? Although each building and system is unique you can start with the following: • • Interview facility personnel Review construction documents Review the controls workstation Walk the site

Where to Start? Although each building and system is unique you can start with the following: • • Interview facility personnel Review construction documents Review the controls workstation Walk the site

Where to Start? Interview facility personnel • They are a great resource as to why things are the way they are but not necessarily on how they should be • Keep them informed on what you find, it may trigger additional thoughts • If interested, train them on how the systems work

Where to Start? Interview facility personnel • They are a great resource as to why things are the way they are but not necessarily on how they should be • Keep them informed on what you find, it may trigger additional thoughts • If interested, train them on how the systems work

Where to Start? Review construction documents • Understand the design and how the systems are supposed to work – – Use the schedules and rules of thumb Sum up connected loads (air and water) Compare design installation to installed Check coil ∆Ts

Where to Start? Review construction documents • Understand the design and how the systems are supposed to work – – Use the schedules and rules of thumb Sum up connected loads (air and water) Compare design installation to installed Check coil ∆Ts

Where to Start? Review the Controls workstation and look for: – – – – – Incorrect AHU leaving air temperature set points Valve commands at 0% or 100%, or valves fighting OA Damper commands Controlling sensors like RH and CO 2 Pump / fan status on when command is off (in HAND? ) Chilled water ∆T (secondary supply & primary return) Chilled water supply temperature / set point General space temperatures System stability

Where to Start? Review the Controls workstation and look for: – – – – – Incorrect AHU leaving air temperature set points Valve commands at 0% or 100%, or valves fighting OA Damper commands Controlling sensors like RH and CO 2 Pump / fan status on when command is off (in HAND? ) Chilled water ∆T (secondary supply & primary return) Chilled water supply temperature / set point General space temperatures System stability

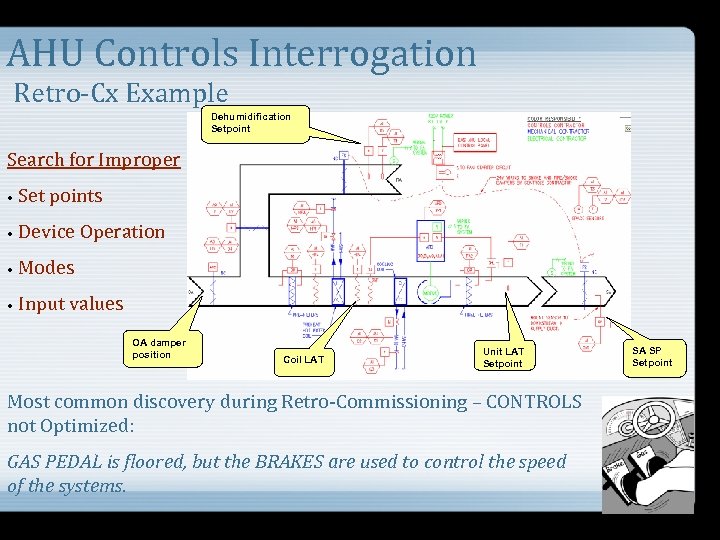

AHU Controls Interrogation Retro-Cx Example Dehumidification Setpoint Search for Improper • Set points • Device Operation • Modes • Input values OA damper position Coil LAT Unit LAT Setpoint Most common discovery during Retro-Commissioning – CONTROLS not Optimized: GAS PEDAL is floored, but the BRAKES are used to control the speed of the systems. SA SP Setpoint

AHU Controls Interrogation Retro-Cx Example Dehumidification Setpoint Search for Improper • Set points • Device Operation • Modes • Input values OA damper position Coil LAT Unit LAT Setpoint Most common discovery during Retro-Commissioning – CONTROLS not Optimized: GAS PEDAL is floored, but the BRAKES are used to control the speed of the systems. SA SP Setpoint

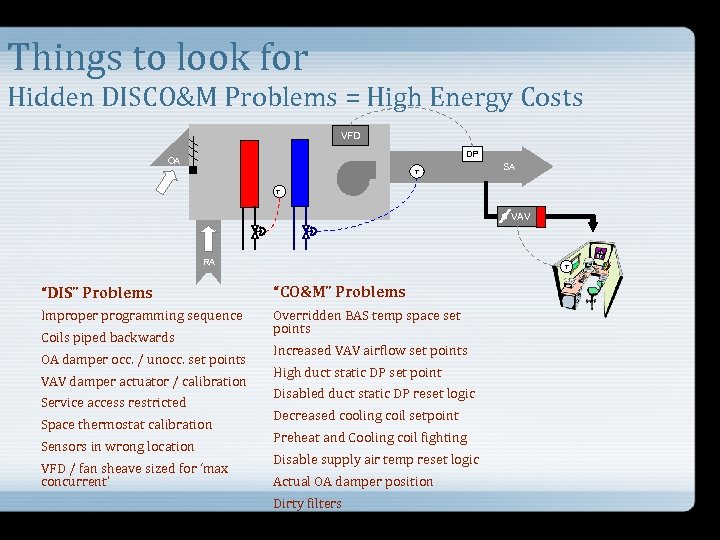

Things to look for Hidden DISCO&M Problems = High Energy Costs VFD DP OA T SA T VAV RA T “DIS” Problems “CO&M” Problems Improper programming sequence Overridden BAS temp space set points Coils piped backwards OA damper occ. / unocc. set points VAV damper actuator / calibration Service access restricted Space thermostat calibration Sensors in wrong location VFD / fan sheave sized for ‘max concurrent’ Increased VAV airflow set points High duct static DP set point Disabled duct static DP reset logic Decreased cooling coil setpoint Preheat and Cooling coil fighting Disable supply air temp reset logic Actual OA damper position Dirty filters

Things to look for Hidden DISCO&M Problems = High Energy Costs VFD DP OA T SA T VAV RA T “DIS” Problems “CO&M” Problems Improper programming sequence Overridden BAS temp space set points Coils piped backwards OA damper occ. / unocc. set points VAV damper actuator / calibration Service access restricted Space thermostat calibration Sensors in wrong location VFD / fan sheave sized for ‘max concurrent’ Increased VAV airflow set points High duct static DP set point Disabled duct static DP reset logic Decreased cooling coil setpoint Preheat and Cooling coil fighting Disable supply air temp reset logic Actual OA damper position Dirty filters

Things to look for Chiller Plants • Add / subtract logic • Incorrect set points (chiller and system) • Chillers / pumps / tower fans in manual • Condenser water control • Controlling sensor calibration • Chiller isolation valves

Things to look for Chiller Plants • Add / subtract logic • Incorrect set points (chiller and system) • Chillers / pumps / tower fans in manual • Condenser water control • Controlling sensor calibration • Chiller isolation valves

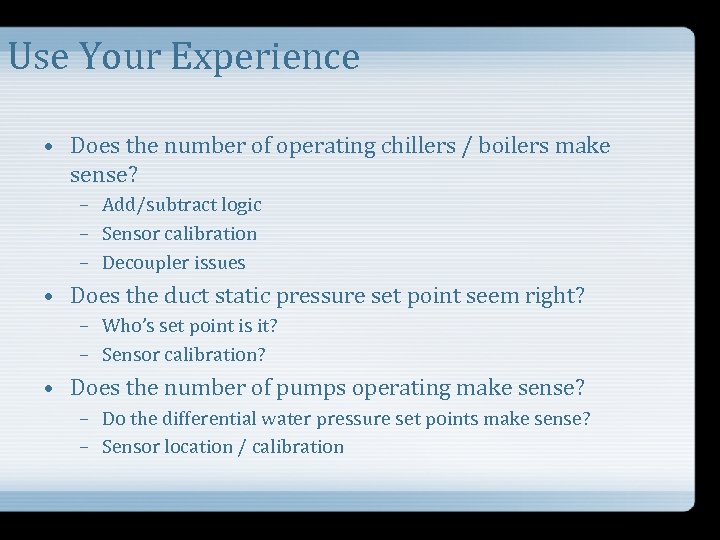

Use Your Experience • Does the number of operating chillers / boilers make sense? – Add/subtract logic – Sensor calibration – Decoupler issues • Does the duct static pressure set point seem right? – Who’s set point is it? – Sensor calibration? • Does the number of pumps operating make sense? – Do the differential water pressure set points make sense? – Sensor location / calibration

Use Your Experience • Does the number of operating chillers / boilers make sense? – Add/subtract logic – Sensor calibration – Decoupler issues • Does the duct static pressure set point seem right? – Who’s set point is it? – Sensor calibration? • Does the number of pumps operating make sense? – Do the differential water pressure set points make sense? – Sensor location / calibration

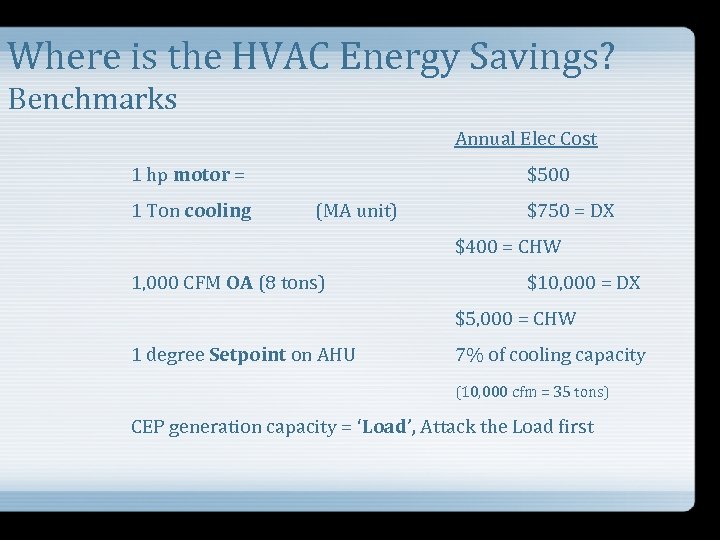

Where is the HVAC Energy Savings? Benchmarks Annual Elec Cost 1 hp motor = 1 Ton cooling $500 (MA unit) $750 = DX $400 = CHW 1, 000 CFM OA (8 tons) $10, 000 = DX $5, 000 = CHW 1 degree Setpoint on AHU 7% of cooling capacity (10, 000 cfm = 35 tons) CEP generation capacity = ‘Load’, Attack the Load first

Where is the HVAC Energy Savings? Benchmarks Annual Elec Cost 1 hp motor = 1 Ton cooling $500 (MA unit) $750 = DX $400 = CHW 1, 000 CFM OA (8 tons) $10, 000 = DX $5, 000 = CHW 1 degree Setpoint on AHU 7% of cooling capacity (10, 000 cfm = 35 tons) CEP generation capacity = ‘Load’, Attack the Load first

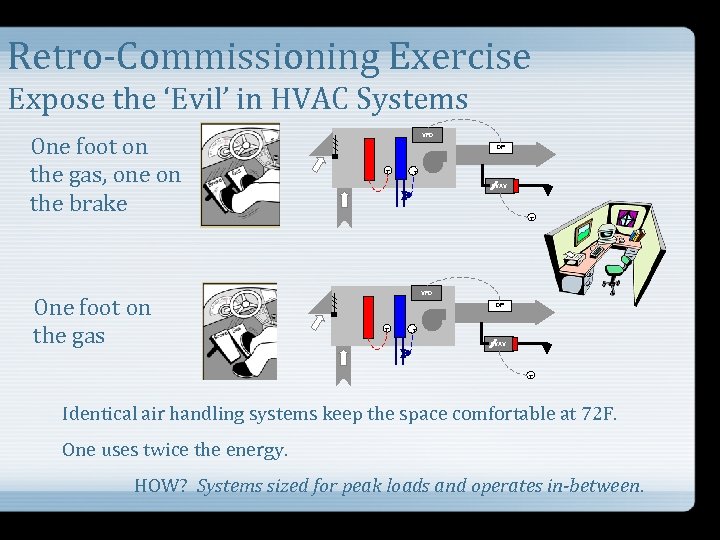

Retro-Commissioning Exercise Expose the ‘Evil’ in HVAC Systems One foot on the gas, one on the brake One foot on the gas VFD DP T T VAV T Identical air handling systems keep the space comfortable at 72 F. One uses twice the energy. HOW? Systems sized for peak loads and operates in-between.

Retro-Commissioning Exercise Expose the ‘Evil’ in HVAC Systems One foot on the gas, one on the brake One foot on the gas VFD DP T T VAV T Identical air handling systems keep the space comfortable at 72 F. One uses twice the energy. HOW? Systems sized for peak loads and operates in-between.

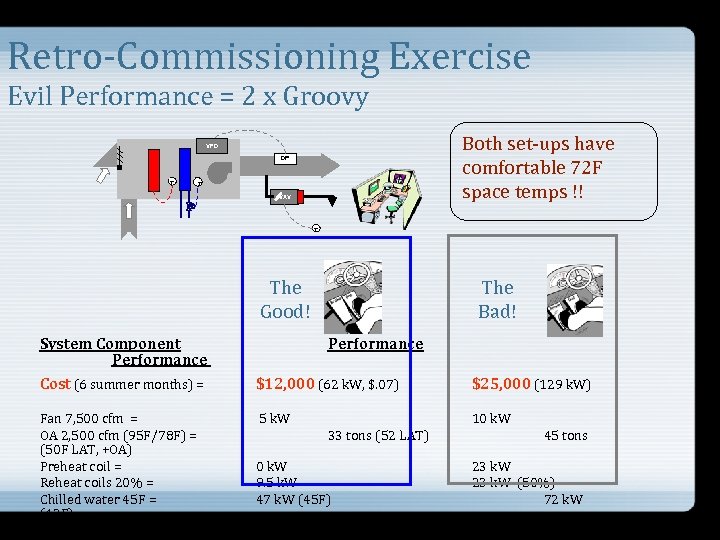

Retro-Commissioning Exercise Evil Performance = 2 x Groovy Both set-ups have comfortable 72 F space temps !! VFD DP T T VAV T The Bad! The Good! System Component Performance Cost (6 summer months) = $12, 000 (62 k. W, $. 07) $25, 000 (129 k. W) Fan 7, 500 cfm = OA 2, 500 cfm (95 F/78 F) = (50 F LAT, +OA) Preheat coil = Reheat coils 20% = Chilled water 45 F = (42 F) 5 k. W 10 k. W 33 tons (52 LAT) 0 k. W 9. 5 k. W 47 k. W (45 F) 45 tons 23 k. W (50%) 72 k. W

Retro-Commissioning Exercise Evil Performance = 2 x Groovy Both set-ups have comfortable 72 F space temps !! VFD DP T T VAV T The Bad! The Good! System Component Performance Cost (6 summer months) = $12, 000 (62 k. W, $. 07) $25, 000 (129 k. W) Fan 7, 500 cfm = OA 2, 500 cfm (95 F/78 F) = (50 F LAT, +OA) Preheat coil = Reheat coils 20% = Chilled water 45 F = (42 F) 5 k. W 10 k. W 33 tons (52 LAT) 0 k. W 9. 5 k. W 47 k. W (45 F) 45 tons 23 k. W (50%) 72 k. W

Retro. Commissioning 4 Case Studies

Retro. Commissioning 4 Case Studies

Retro. Commissioning University Biological Study DISCO&M Case. Science #1 Building “CO&M” HVAC System operators and the Controls vendor were not familiar with the basis of design.

Retro. Commissioning University Biological Study DISCO&M Case. Science #1 Building “CO&M” HVAC System operators and the Controls vendor were not familiar with the basis of design.

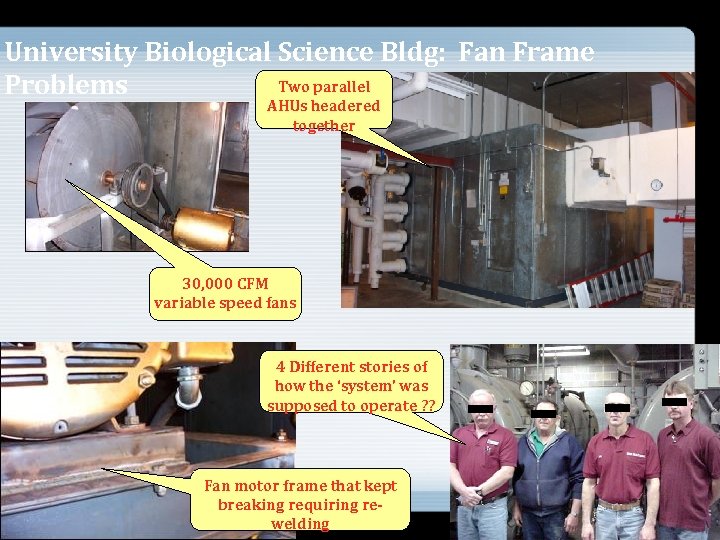

University Biological Science Bldg: Fan Frame Two parallel Problems AHUs headered together 30, 000 CFM variable speed fans 4 Different stories of how the ‘system’ was supposed to operate ? ? Fan motor frame that kept breaking requiring rewelding

University Biological Science Bldg: Fan Frame Two parallel Problems AHUs headered together 30, 000 CFM variable speed fans 4 Different stories of how the ‘system’ was supposed to operate ? ? Fan motor frame that kept breaking requiring rewelding

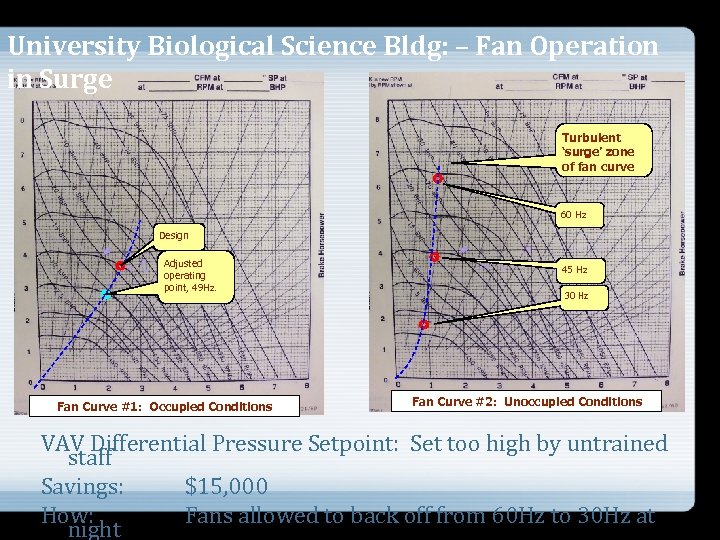

University Biological Science Bldg: – Fan Operation in Surge Turbulent ‘surge’ zone of fan curve 60 Hz Design Adjusted operating point, 49 Hz. Fan Curve #1: Occupied Conditions 45 Hz 30 Hz Fan Curve #2: Unoccupied Conditions VAV Differential Pressure Setpoint: Set too high by untrained staff Savings: $15, 000 How: Fans allowed to back off from 60 Hz to 30 Hz at night

University Biological Science Bldg: – Fan Operation in Surge Turbulent ‘surge’ zone of fan curve 60 Hz Design Adjusted operating point, 49 Hz. Fan Curve #1: Occupied Conditions 45 Hz 30 Hz Fan Curve #2: Unoccupied Conditions VAV Differential Pressure Setpoint: Set too high by untrained staff Savings: $15, 000 How: Fans allowed to back off from 60 Hz to 30 Hz at night

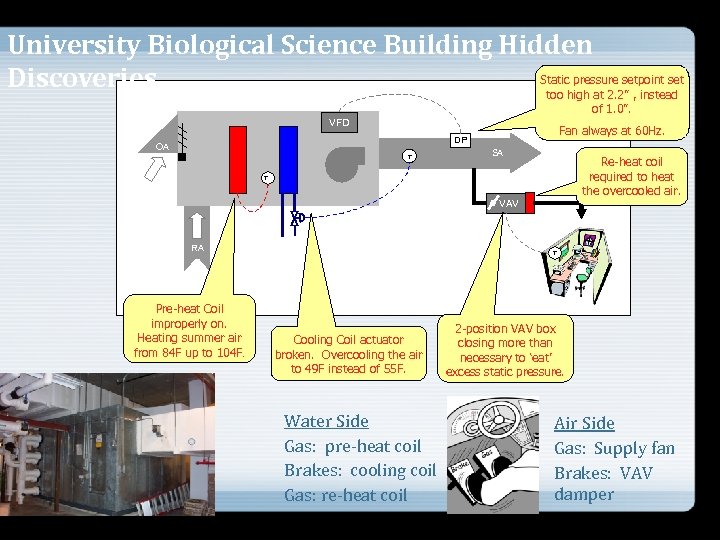

University Biological Science Building Hidden Static pressure setpoint set Discoveries too high at 2. 2” , instead of 1. 0”. VFD Fan always at 60 Hz. DP OA T SA Re-heat coil required to heat the overcooled air. T VAV RA Pre-heat Coil improperly on. Heating summer air from 84 F up to 104 F. T Cooling Coil actuator broken. Overcooling the air to 49 F instead of 55 F. Water Side Gas: pre-heat coil Brakes: cooling coil Gas: re-heat coil 2 -position VAV box closing more than necessary to ‘eat’ excess static pressure. Air Side Gas: Supply fan Brakes: VAV damper

University Biological Science Building Hidden Static pressure setpoint set Discoveries too high at 2. 2” , instead of 1. 0”. VFD Fan always at 60 Hz. DP OA T SA Re-heat coil required to heat the overcooled air. T VAV RA Pre-heat Coil improperly on. Heating summer air from 84 F up to 104 F. T Cooling Coil actuator broken. Overcooling the air to 49 F instead of 55 F. Water Side Gas: pre-heat coil Brakes: cooling coil Gas: re-heat coil 2 -position VAV box closing more than necessary to ‘eat’ excess static pressure. Air Side Gas: Supply fan Brakes: VAV damper

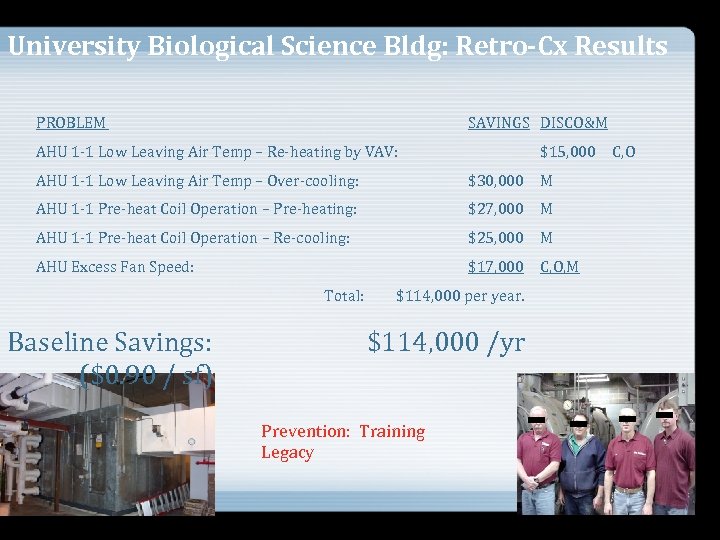

University Biological Science Bldg: Retro-Cx Results PROBLEM SAVINGS DISCO&M AHU 1 -1 Low Leaving Air Temp – Re-heating by VAV: $15, 000 AHU 1 -1 Low Leaving Air Temp – Over-cooling: $30, 000 M AHU 1 -1 Pre-heat Coil Operation – Pre-heating: $27, 000 M AHU 1 -1 Pre-heat Coil Operation – Re-cooling: $25, 000 M AHU Excess Fan Speed: $17, 000 C, O, M Total: Baseline Savings: ($0. 90 / sf) $114, 000 per year. $114, 000 /yr Prevention: Training Legacy C, O

University Biological Science Bldg: Retro-Cx Results PROBLEM SAVINGS DISCO&M AHU 1 -1 Low Leaving Air Temp – Re-heating by VAV: $15, 000 AHU 1 -1 Low Leaving Air Temp – Over-cooling: $30, 000 M AHU 1 -1 Pre-heat Coil Operation – Pre-heating: $27, 000 M AHU 1 -1 Pre-heat Coil Operation – Re-cooling: $25, 000 M AHU Excess Fan Speed: $17, 000 C, O, M Total: Baseline Savings: ($0. 90 / sf) $114, 000 per year. $114, 000 /yr Prevention: Training Legacy C, O

Retro. Commissioning DISCO&M Case Study #2 CA Research Laboratory “DSCO&M” Corporate Mandate: 10% energy savings. HVAC operators did not understand where the ‘optimized’ operating points were.

Retro. Commissioning DISCO&M Case Study #2 CA Research Laboratory “DSCO&M” Corporate Mandate: 10% energy savings. HVAC operators did not understand where the ‘optimized’ operating points were.

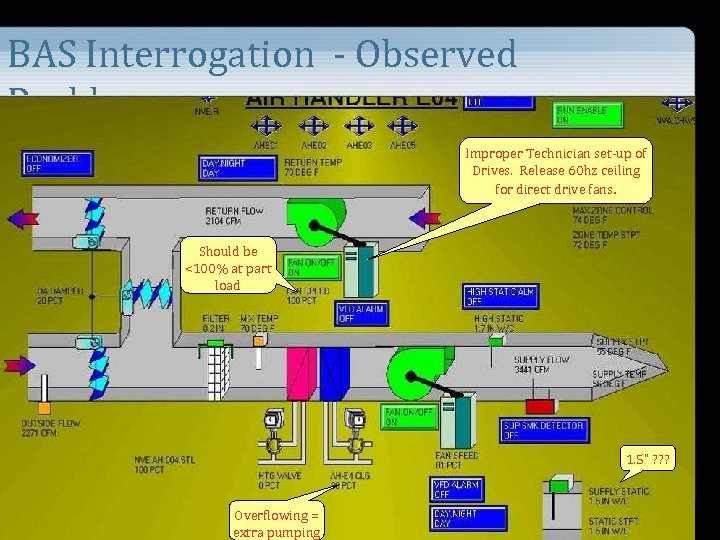

BAS Interrogation - Observed Problems Improper Technician set-up of Drives. Release 60 hz ceiling for direct drive fans. Should be <100% at part load 1. 5” ? ? ? Overflowing = extra pumping

BAS Interrogation - Observed Problems Improper Technician set-up of Drives. Release 60 hz ceiling for direct drive fans. Should be <100% at part load 1. 5” ? ? ? Overflowing = extra pumping

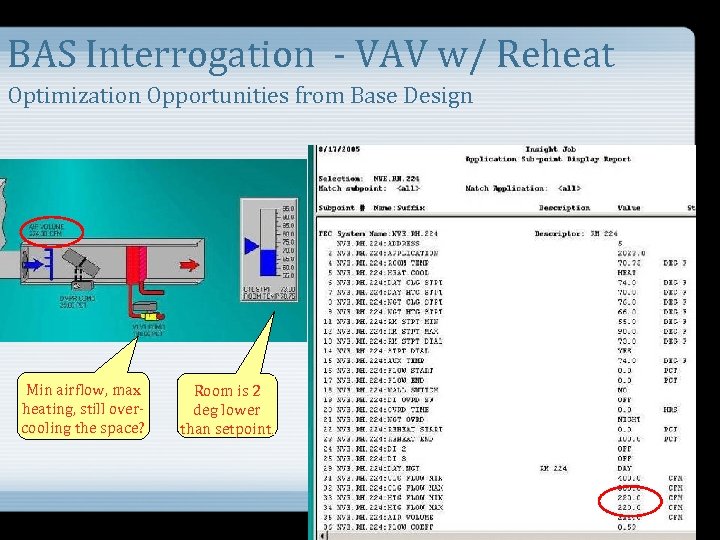

BAS Interrogation - VAV w/ Reheat Optimization Opportunities from Base Design Min airflow, max heating, still overcooling the space? Room is 2 deg lower than setpoint.

BAS Interrogation - VAV w/ Reheat Optimization Opportunities from Base Design Min airflow, max heating, still overcooling the space? Room is 2 deg lower than setpoint.

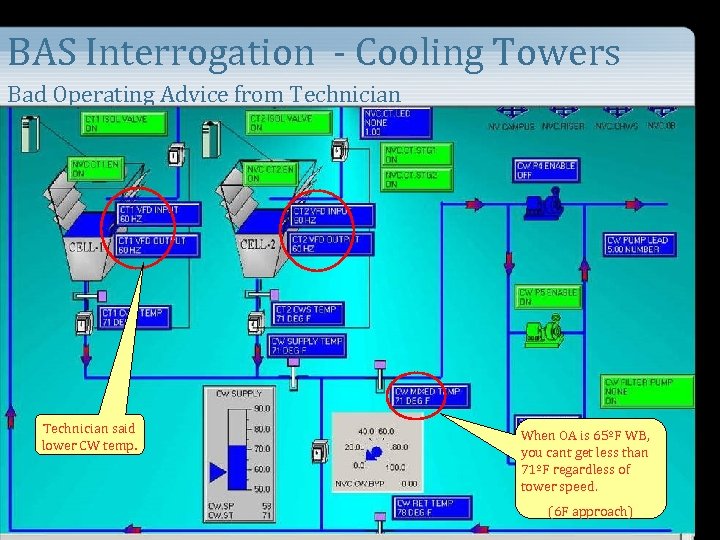

BAS Interrogation - Cooling Towers Bad Operating Advice from Technician said lower CW temp. When OA is 65ºF WB, you cant get less than 71ºF regardless of tower speed. (6 F approach)

BAS Interrogation - Cooling Towers Bad Operating Advice from Technician said lower CW temp. When OA is 65ºF WB, you cant get less than 71ºF regardless of tower speed. (6 F approach)

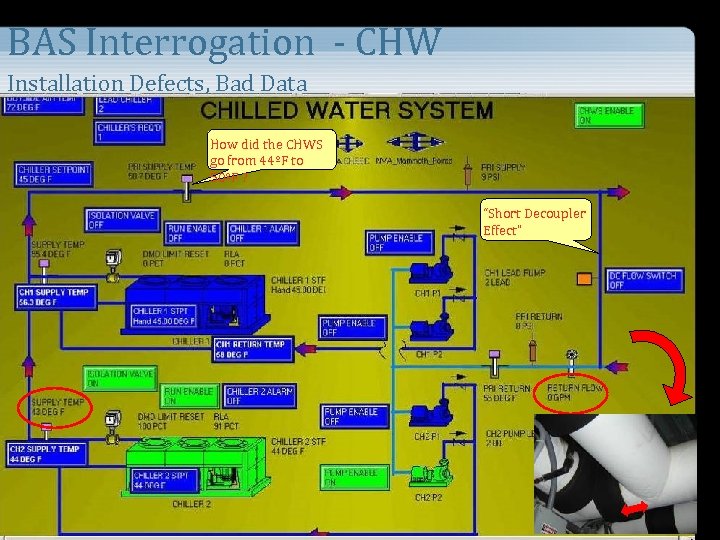

BAS Interrogation - CHW Installation Defects, Bad Data How did the CHWS go from 44ºF to 50ºF ? “Short Decoupler Effect”

BAS Interrogation - CHW Installation Defects, Bad Data How did the CHWS go from 44ºF to 50ºF ? “Short Decoupler Effect”

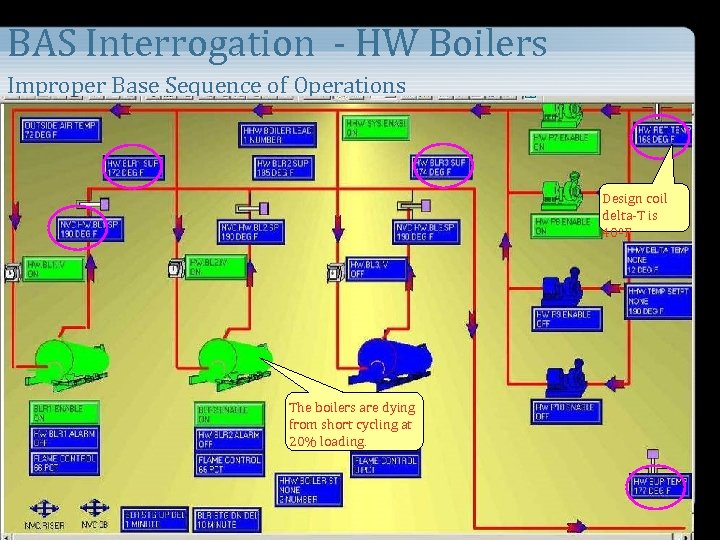

BAS Interrogation - HW Boilers Improper Base Sequence of Operations Design coil delta-T is 40ºF The boilers are dying from short cycling at 20% loading.

BAS Interrogation - HW Boilers Improper Base Sequence of Operations Design coil delta-T is 40ºF The boilers are dying from short cycling at 20% loading.

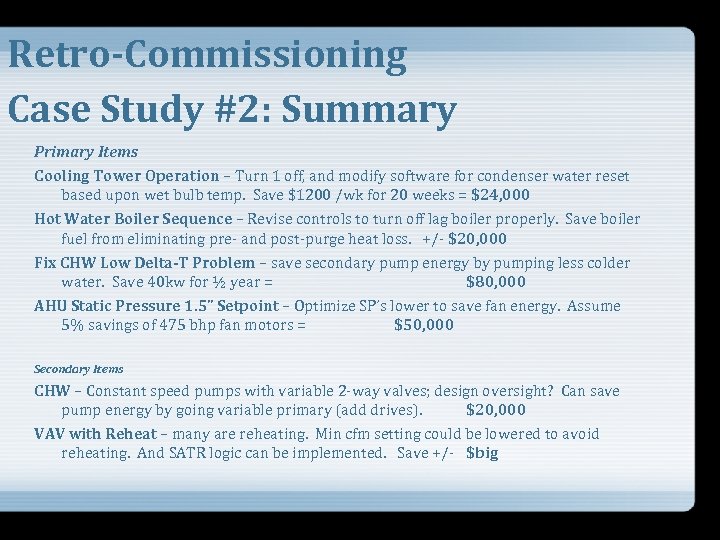

Retro-Commissioning Case Study #2: Summary Primary Items Cooling Tower Operation – Turn 1 off, and modify software for condenser water reset based upon wet bulb temp. Save $1200 /wk for 20 weeks = $24, 000 Hot Water Boiler Sequence – Revise controls to turn off lag boiler properly. Save boiler fuel from eliminating pre- and post-purge heat loss. +/- $20, 000 Fix CHW Low Delta-T Problem – save secondary pump energy by pumping less colder water. Save 40 kw for ½ year = $80, 000 AHU Static Pressure 1. 5” Setpoint – Optimize SP’s lower to save fan energy. Assume 5% savings of 475 bhp fan motors = $50, 000 Secondary Items CHW – Constant speed pumps with variable 2 -way valves; design oversight? Can save pump energy by going variable primary (add drives). $20, 000 VAV with Reheat – many are reheating. Min cfm setting could be lowered to avoid reheating. And SATR logic can be implemented. Save +/- $big

Retro-Commissioning Case Study #2: Summary Primary Items Cooling Tower Operation – Turn 1 off, and modify software for condenser water reset based upon wet bulb temp. Save $1200 /wk for 20 weeks = $24, 000 Hot Water Boiler Sequence – Revise controls to turn off lag boiler properly. Save boiler fuel from eliminating pre- and post-purge heat loss. +/- $20, 000 Fix CHW Low Delta-T Problem – save secondary pump energy by pumping less colder water. Save 40 kw for ½ year = $80, 000 AHU Static Pressure 1. 5” Setpoint – Optimize SP’s lower to save fan energy. Assume 5% savings of 475 bhp fan motors = $50, 000 Secondary Items CHW – Constant speed pumps with variable 2 -way valves; design oversight? Can save pump energy by going variable primary (add drives). $20, 000 VAV with Reheat – many are reheating. Min cfm setting could be lowered to avoid reheating. And SATR logic can be implemented. Save +/- $big

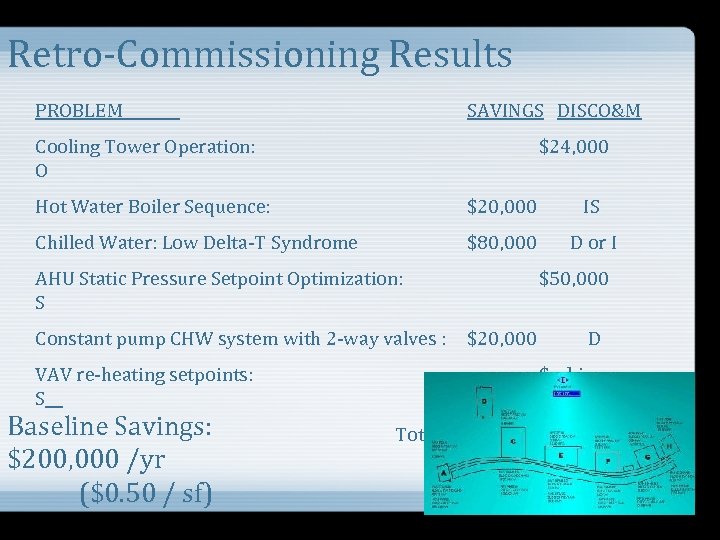

Retro-Commissioning Results PROBLEM SAVINGS DISCO&M Cooling Tower Operation: O $24, 000 Hot Water Boiler Sequence: $20, 000 IS Chilled Water: Low Delta-T Syndrome $80, 000 D or I AHU Static Pressure Setpoint Optimization: S Constant pump CHW system with 2 -way valves : VAV re-heating setpoints: S Baseline Savings: $200, 000 /yr ($0. 50 / sf) $50, 000 $20, 000 D $ big Total: $200, 000 per year.

Retro-Commissioning Results PROBLEM SAVINGS DISCO&M Cooling Tower Operation: O $24, 000 Hot Water Boiler Sequence: $20, 000 IS Chilled Water: Low Delta-T Syndrome $80, 000 D or I AHU Static Pressure Setpoint Optimization: S Constant pump CHW system with 2 -way valves : VAV re-heating setpoints: S Baseline Savings: $200, 000 /yr ($0. 50 / sf) $50, 000 $20, 000 D $ big Total: $200, 000 per year.

Retro-Commissioning DISCO&M Case Study #3 Not-For-Profit Hospital “O&M” Looking for HIDDEN CAPACITY resulting from possible improperation.

Retro-Commissioning DISCO&M Case Study #3 Not-For-Profit Hospital “O&M” Looking for HIDDEN CAPACITY resulting from possible improperation.

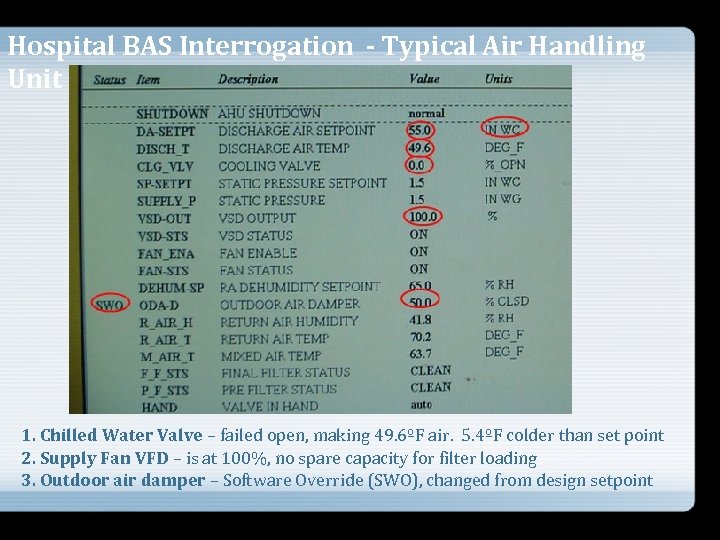

Hospital BAS Interrogation - Typical Air Handling Unit 1. Chilled Water Valve – failed open, making 49. 6ºF air. 5. 4ºF colder than set point 2. Supply Fan VFD – is at 100%, no spare capacity for filter loading 3. Outdoor air damper – Software Override (SWO), changed from design setpoint

Hospital BAS Interrogation - Typical Air Handling Unit 1. Chilled Water Valve – failed open, making 49. 6ºF air. 5. 4ºF colder than set point 2. Supply Fan VFD – is at 100%, no spare capacity for filter loading 3. Outdoor air damper – Software Override (SWO), changed from design setpoint

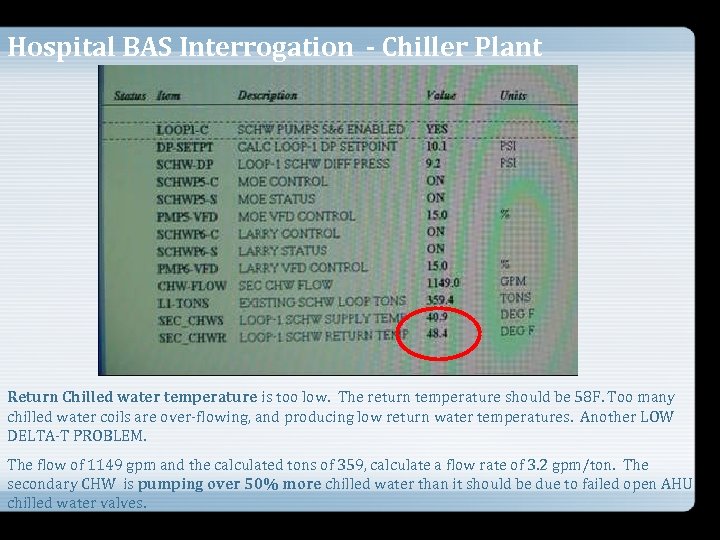

Hospital BAS Interrogation - Chiller Plant Return Chilled water temperature is too low. The return temperature should be 58 F. Too many chilled water coils are over-flowing, and producing low return water temperatures. Another LOW DELTA-T PROBLEM. The flow of 1149 gpm and the calculated tons of 359, calculate a flow rate of 3. 2 gpm/ton. The secondary CHW is pumping over 50% more chilled water than it should be due to failed open AHU chilled water valves.

Hospital BAS Interrogation - Chiller Plant Return Chilled water temperature is too low. The return temperature should be 58 F. Too many chilled water coils are over-flowing, and producing low return water temperatures. Another LOW DELTA-T PROBLEM. The flow of 1149 gpm and the calculated tons of 359, calculate a flow rate of 3. 2 gpm/ton. The secondary CHW is pumping over 50% more chilled water than it should be due to failed open AHU chilled water valves.

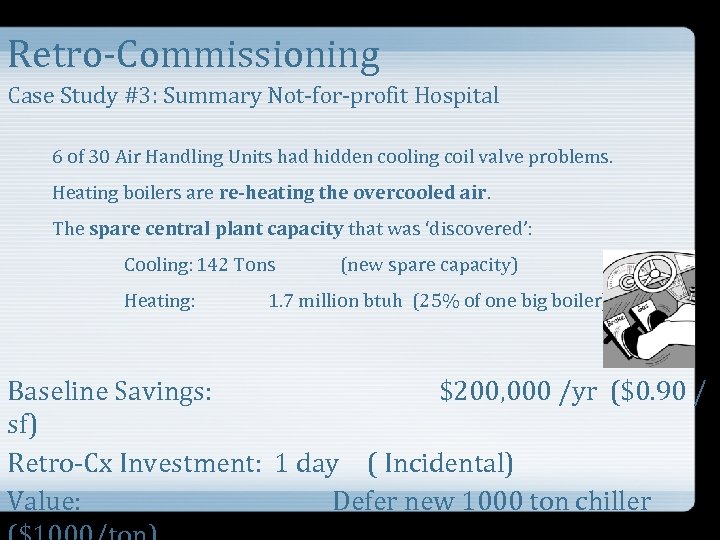

Retro-Commissioning Case Study #3: Summary Not-for-profit Hospital 6 of 30 Air Handling Units had hidden cooling coil valve problems. Heating boilers are re-heating the overcooled air. The spare central plant capacity that was ‘discovered’: Cooling: 142 Tons Heating: (new spare capacity) 1. 7 million btuh (25% of one big boiler) Baseline Savings: $200, 000 /yr ($0. 90 / sf) Retro-Cx Investment: 1 day ( Incidental) Value: Defer new 1000 ton chiller

Retro-Commissioning Case Study #3: Summary Not-for-profit Hospital 6 of 30 Air Handling Units had hidden cooling coil valve problems. Heating boilers are re-heating the overcooled air. The spare central plant capacity that was ‘discovered’: Cooling: 142 Tons Heating: (new spare capacity) 1. 7 million btuh (25% of one big boiler) Baseline Savings: $200, 000 /yr ($0. 90 / sf) Retro-Cx Investment: 1 day ( Incidental) Value: Defer new 1000 ton chiller

Retro. Commissioning DISCO&M Case For-Profit Hospital Study #4 “DISCO&M” Administration wanted energy savings. Facilities Staff did not want anyone (us) to look at their system and find potential problems – it might make them look bad.

Retro. Commissioning DISCO&M Case For-Profit Hospital Study #4 “DISCO&M” Administration wanted energy savings. Facilities Staff did not want anyone (us) to look at their system and find potential problems – it might make them look bad.

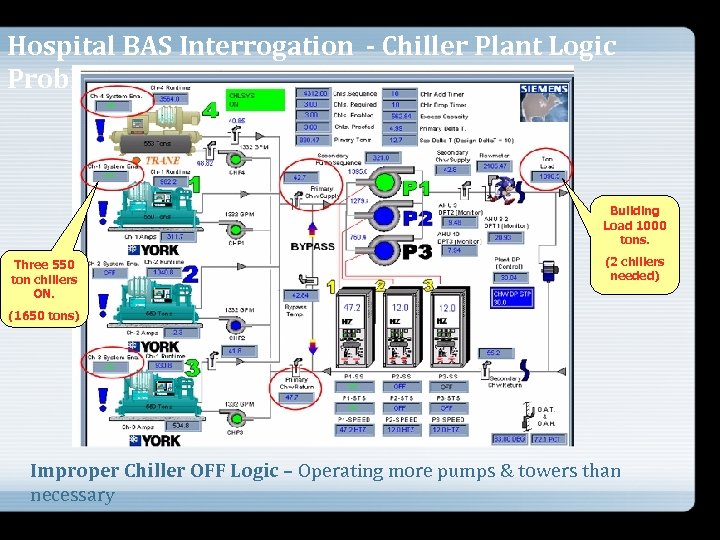

Hospital BAS Interrogation - Chiller Plant Logic Problems Building Load 1000 tons. Three 550 ton chillers ON. (2 chillers needed) (1650 tons) Improper Chiller OFF Logic – Operating more pumps & towers than necessary

Hospital BAS Interrogation - Chiller Plant Logic Problems Building Load 1000 tons. Three 550 ton chillers ON. (2 chillers needed) (1650 tons) Improper Chiller OFF Logic – Operating more pumps & towers than necessary

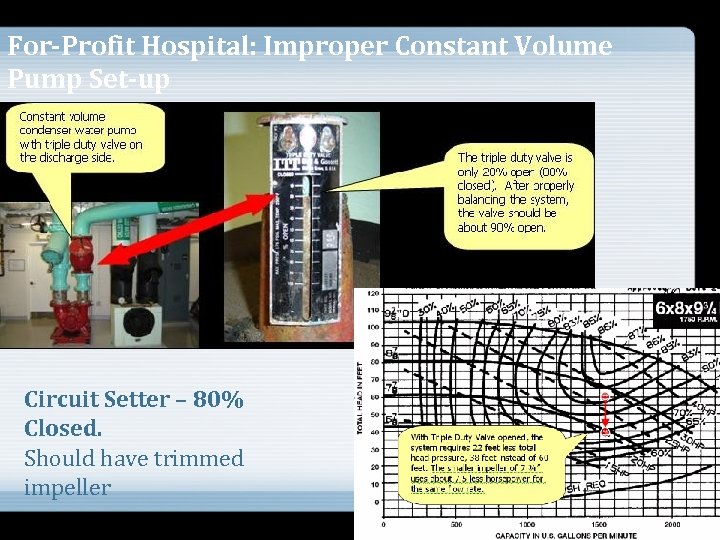

For-Profit Hospital: Improper Constant Volume Pump Set-up Circuit Setter – 80% Closed. Should have trimmed impeller

For-Profit Hospital: Improper Constant Volume Pump Set-up Circuit Setter – 80% Closed. Should have trimmed impeller

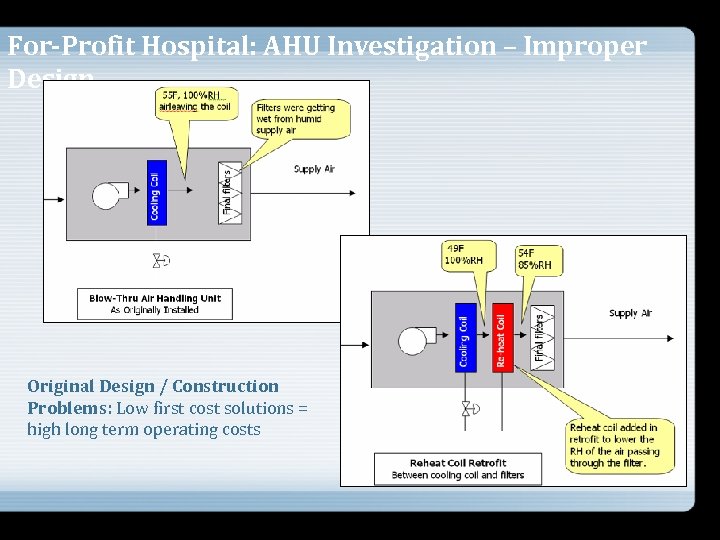

For-Profit Hospital: AHU Investigation – Improper Design Original Design / Construction Problems: Low first cost solutions = high long term operating costs

For-Profit Hospital: AHU Investigation – Improper Design Original Design / Construction Problems: Low first cost solutions = high long term operating costs

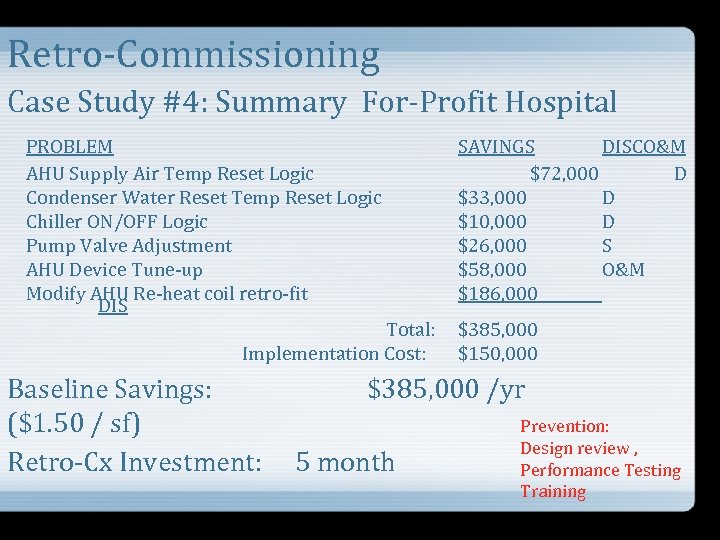

Retro-Commissioning Case Study #4: Summary For-Profit Hospital PROBLEM AHU Supply Air Temp Reset Logic Condenser Water Reset Temp Reset Logic Chiller ON/OFF Logic Pump Valve Adjustment AHU Device Tune-up Modify AHU Re-heat coil retro-fit DIS Total: Implementation Cost: Baseline Savings: ($1. 50 / sf) Retro-Cx Investment: SAVINGS DISCO&M $72, 000 D $33, 000 D $10, 000 D $26, 000 S $58, 000 O&M $186, 000 $385, 000 $150, 000 $385, 000 /yr 5 month Prevention: Design review , Performance Testing Training

Retro-Commissioning Case Study #4: Summary For-Profit Hospital PROBLEM AHU Supply Air Temp Reset Logic Condenser Water Reset Temp Reset Logic Chiller ON/OFF Logic Pump Valve Adjustment AHU Device Tune-up Modify AHU Re-heat coil retro-fit DIS Total: Implementation Cost: Baseline Savings: ($1. 50 / sf) Retro-Cx Investment: SAVINGS DISCO&M $72, 000 D $33, 000 D $10, 000 D $26, 000 S $58, 000 O&M $186, 000 $385, 000 $150, 000 $385, 000 /yr 5 month Prevention: Design review , Performance Testing Training

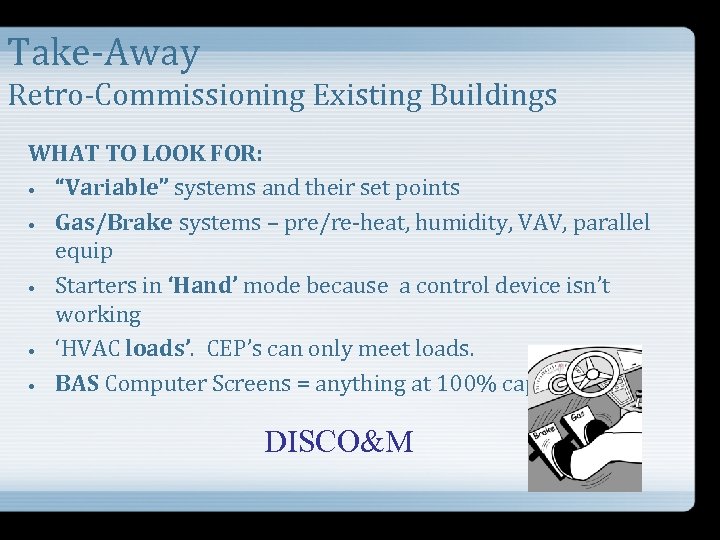

Take-Away Retro-Commissioning Existing Buildings WHAT TO LOOK FOR: • “Variable” systems and their set points • Gas/Brake systems – pre/re-heat, humidity, VAV, parallel equip • Starters in ‘Hand’ mode because a control device isn’t working • ‘HVAC loads’. CEP’s can only meet loads. • BAS Computer Screens = anything at 100% capacity DISCO&M

Take-Away Retro-Commissioning Existing Buildings WHAT TO LOOK FOR: • “Variable” systems and their set points • Gas/Brake systems – pre/re-heat, humidity, VAV, parallel equip • Starters in ‘Hand’ mode because a control device isn’t working • ‘HVAC loads’. CEP’s can only meet loads. • BAS Computer Screens = anything at 100% capacity DISCO&M

Questions?

Questions?