0a29f07841f52930a359d2a2a337ccb9.ppt

- Количество слайдов: 64

Resource Planning Chapter 15 © 2007 Pearson Education

Resource Planning Chapter 15 © 2007 Pearson Education

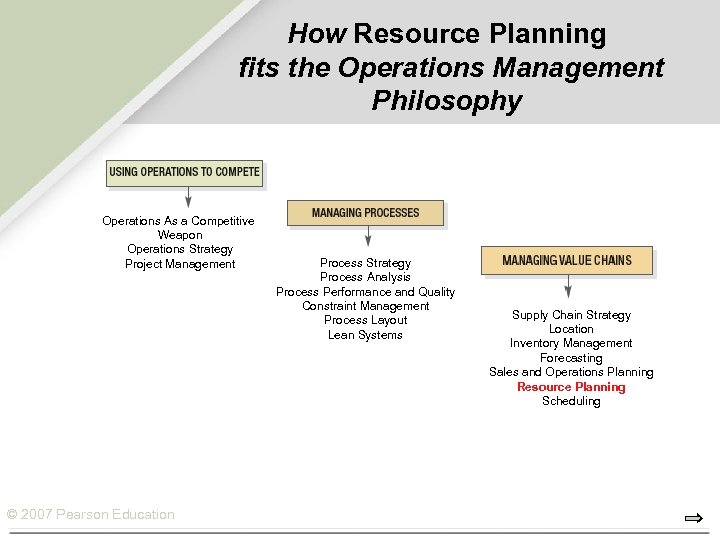

How Resource Planning fits the Operations Management Philosophy Operations As a Competitive Weapon Operations Strategy Project Management © 2007 Pearson Education Process Strategy Process Analysis Process Performance and Quality Constraint Management Process Layout Lean Systems Supply Chain Strategy Location Inventory Management Forecasting Sales and Operations Planning Resource Planning Scheduling

How Resource Planning fits the Operations Management Philosophy Operations As a Competitive Weapon Operations Strategy Project Management © 2007 Pearson Education Process Strategy Process Analysis Process Performance and Quality Constraint Management Process Layout Lean Systems Supply Chain Strategy Location Inventory Management Forecasting Sales and Operations Planning Resource Planning Scheduling

Resource Planning at Starwood Ø Starwood manages employees, equipment, and supplies at 750 hotels around the world to ensure that the needs and expectations of each and every customer are met. Ø To help forecast these needs, Starwood now uses an enterprise resource planning (ERP) system. Ø Included in the ERP system by Oracle is an electronic reservation system that profiles the preferences of guests, allowing the staff to provide a “customized” experience for each guest. Ø The ERP system schedules the hotel’s staff members, projects the amount of food, beverages, and other resources needed for the hotel’s food-service department. Ø Starwood’s ERP system also features a centralized database with accounting data, payroll, accounts payable information, general ledger and balance sheet, as well as income statements for its various properties. © 2007 Pearson Education

Resource Planning at Starwood Ø Starwood manages employees, equipment, and supplies at 750 hotels around the world to ensure that the needs and expectations of each and every customer are met. Ø To help forecast these needs, Starwood now uses an enterprise resource planning (ERP) system. Ø Included in the ERP system by Oracle is an electronic reservation system that profiles the preferences of guests, allowing the staff to provide a “customized” experience for each guest. Ø The ERP system schedules the hotel’s staff members, projects the amount of food, beverages, and other resources needed for the hotel’s food-service department. Ø Starwood’s ERP system also features a centralized database with accounting data, payroll, accounts payable information, general ledger and balance sheet, as well as income statements for its various properties. © 2007 Pearson Education

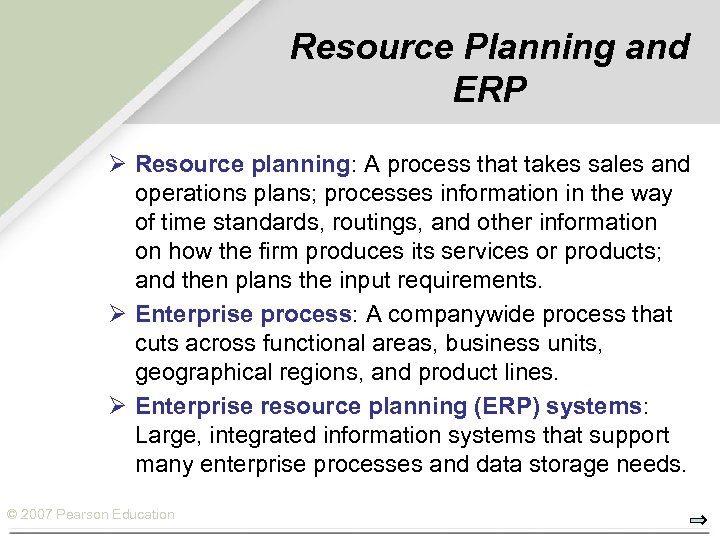

Resource Planning and ERP Ø Resource planning: A process that takes sales and operations plans; processes information in the way of time standards, routings, and other information on how the firm produces its services or products; and then plans the input requirements. Ø Enterprise process: A companywide process that cuts across functional areas, business units, geographical regions, and product lines. Ø Enterprise resource planning (ERP) systems: Large, integrated information systems that support many enterprise processes and data storage needs. © 2007 Pearson Education

Resource Planning and ERP Ø Resource planning: A process that takes sales and operations plans; processes information in the way of time standards, routings, and other information on how the firm produces its services or products; and then plans the input requirements. Ø Enterprise process: A companywide process that cuts across functional areas, business units, geographical regions, and product lines. Ø Enterprise resource planning (ERP) systems: Large, integrated information systems that support many enterprise processes and data storage needs. © 2007 Pearson Education

ERP Application Modules © 2007 Pearson Education

ERP Application Modules © 2007 Pearson Education

ERP Design Ø ERP revolves around a single comprehensive database that can be made available across the entire organization (or enterprise). Ø The database collects data and feeds them into the various modular applications (or suites). Ø As new information is entered as a transaction in one application, related information is automatically updated in the other applications. Ø The ERP system streamlines the data flows throughout the organization and provides employees with direct access to a wealth of real-time operating information. Ø ERP eliminates many of the cross-functional coordination problems older nonintegrated systems suffered from. © 2007 Pearson Education

ERP Design Ø ERP revolves around a single comprehensive database that can be made available across the entire organization (or enterprise). Ø The database collects data and feeds them into the various modular applications (or suites). Ø As new information is entered as a transaction in one application, related information is automatically updated in the other applications. Ø The ERP system streamlines the data flows throughout the organization and provides employees with direct access to a wealth of real-time operating information. Ø ERP eliminates many of the cross-functional coordination problems older nonintegrated systems suffered from. © 2007 Pearson Education

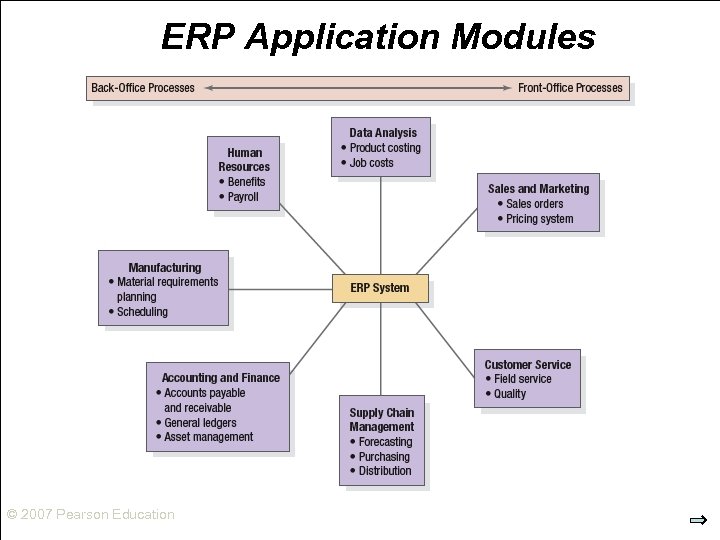

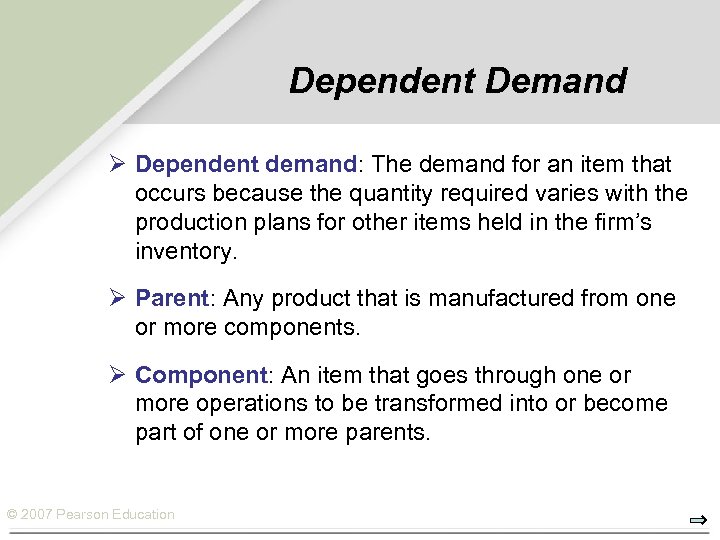

Dependent Demand Ø Dependent demand: The demand for an item that occurs because the quantity required varies with the production plans for other items held in the firm’s inventory. Ø Parent: Any product that is manufactured from one or more components. Ø Component: An item that goes through one or more operations to be transformed into or become part of one or more parents. © 2007 Pearson Education

Dependent Demand Ø Dependent demand: The demand for an item that occurs because the quantity required varies with the production plans for other items held in the firm’s inventory. Ø Parent: Any product that is manufactured from one or more components. Ø Component: An item that goes through one or more operations to be transformed into or become part of one or more parents. © 2007 Pearson Education

Lumpy Dependent Demand Resulting from Continuous Independent Demand © 2007 Pearson Education Parent Inventory (Independent) Component Demand (Dependent)

Lumpy Dependent Demand Resulting from Continuous Independent Demand © 2007 Pearson Education Parent Inventory (Independent) Component Demand (Dependent)

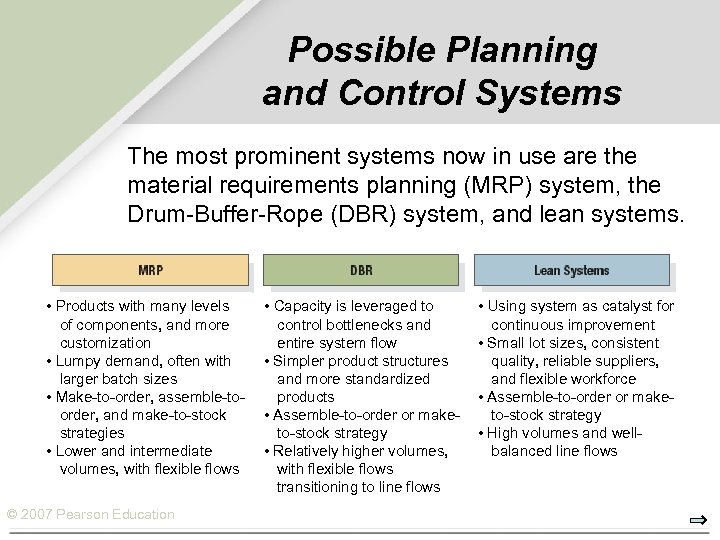

Possible Planning and Control Systems The most prominent systems now in use are the material requirements planning (MRP) system, the Drum-Buffer-Rope (DBR) system, and lean systems. • Products with many levels • Capacity is leveraged to • Using system as catalyst for of components, and more customization • Lumpy demand, often with larger batch sizes • Make-to-order, assemble-toorder, and make-to-stock strategies • Lower and intermediate volumes, with flexible flows control bottlenecks and entire system flow • Simpler product structures and more standardized products • Assemble-to-order or maketo-stock strategy • Relatively higher volumes, with flexible flows transitioning to line flows continuous improvement • Small lot sizes, consistent quality, reliable suppliers, and flexible workforce • Assemble-to-order or maketo-stock strategy • High volumes and wellbalanced line flows © 2007 Pearson Education

Possible Planning and Control Systems The most prominent systems now in use are the material requirements planning (MRP) system, the Drum-Buffer-Rope (DBR) system, and lean systems. • Products with many levels • Capacity is leveraged to • Using system as catalyst for of components, and more customization • Lumpy demand, often with larger batch sizes • Make-to-order, assemble-toorder, and make-to-stock strategies • Lower and intermediate volumes, with flexible flows control bottlenecks and entire system flow • Simpler product structures and more standardized products • Assemble-to-order or maketo-stock strategy • Relatively higher volumes, with flexible flows transitioning to line flows continuous improvement • Small lot sizes, consistent quality, reliable suppliers, and flexible workforce • Assemble-to-order or maketo-stock strategy • High volumes and wellbalanced line flows © 2007 Pearson Education

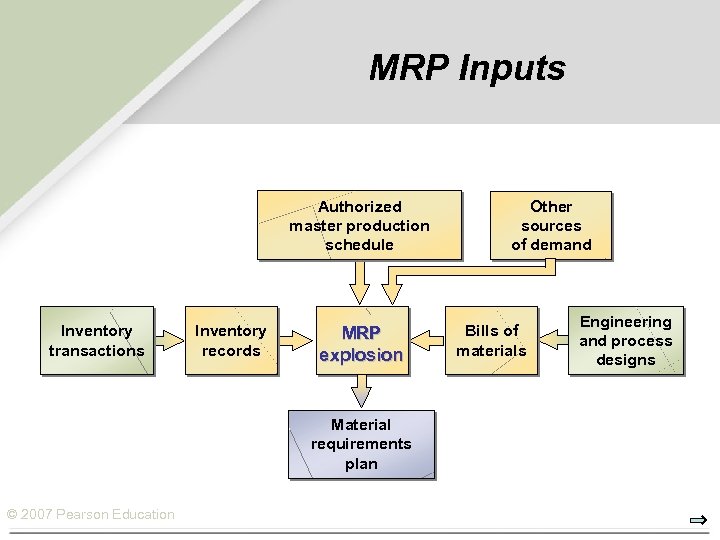

Material Requirements Planning Ø Material requirements planning (MRP): A computerized information system developed specifically to help manufacturers manage dependent demand inventory and schedule replenishment orders. Ø MRP explosion: A process that converts the requirements of various final products into a material requirements plan that specifies the replenishment schedules of all the subassemblies, components, and raw materials needed to produce final products. Ø Bill of materials (BOM): A record of all the components of an item, the parent–component relationships, and the usage quantities derived from engineering and process designs. © 2007 Pearson Education

Material Requirements Planning Ø Material requirements planning (MRP): A computerized information system developed specifically to help manufacturers manage dependent demand inventory and schedule replenishment orders. Ø MRP explosion: A process that converts the requirements of various final products into a material requirements plan that specifies the replenishment schedules of all the subassemblies, components, and raw materials needed to produce final products. Ø Bill of materials (BOM): A record of all the components of an item, the parent–component relationships, and the usage quantities derived from engineering and process designs. © 2007 Pearson Education

MRP Inputs Authorized master production schedule Inventory transactions Inventory records MRP explosion Material requirements plan © 2007 Pearson Education Other sources of demand Bills of materials Engineering and process designs

MRP Inputs Authorized master production schedule Inventory transactions Inventory records MRP explosion Material requirements plan © 2007 Pearson Education Other sources of demand Bills of materials Engineering and process designs

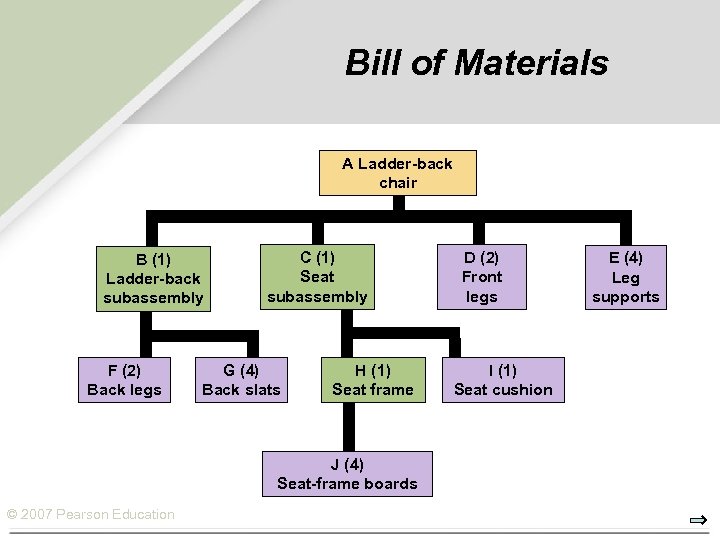

Bill of Materials Terms Ø Usage quantity: The number of units of a component that are needed to make one unit of its immediate parent. Ø Inventory items: Ø End item: The final product sold to a customer. Ø Intermediate item: An item that has at least one parent and at least one component. Ø Subassembly: An intermediate item that is assembled (as opposed to being transformed by other means) from more than one component. Ø Purchased item: An item that has one or more parents but no components because it comes from a supplier. Ø Part commonality: The degree to which a component has more than one immediate parent. © 2007 Pearson Education

Bill of Materials Terms Ø Usage quantity: The number of units of a component that are needed to make one unit of its immediate parent. Ø Inventory items: Ø End item: The final product sold to a customer. Ø Intermediate item: An item that has at least one parent and at least one component. Ø Subassembly: An intermediate item that is assembled (as opposed to being transformed by other means) from more than one component. Ø Purchased item: An item that has one or more parents but no components because it comes from a supplier. Ø Part commonality: The degree to which a component has more than one immediate parent. © 2007 Pearson Education

Bill of Materials Back slats Leg supports Back legs © 2007 Pearson Education Front legs Seat cushion Seat-frame boards A Ladder-back chair

Bill of Materials Back slats Leg supports Back legs © 2007 Pearson Education Front legs Seat cushion Seat-frame boards A Ladder-back chair

Bill of Materials A Ladder-back chair B (1) Ladder-back subassembly F (2) Back legs C (1) Seat subassembly G (4) Back slats H (1) Seat frame J (4) Seat-frame boards © 2007 Pearson Education D (2) Front legs I (1) Seat cushion E (4) Leg supports

Bill of Materials A Ladder-back chair B (1) Ladder-back subassembly F (2) Back legs C (1) Seat subassembly G (4) Back slats H (1) Seat frame J (4) Seat-frame boards © 2007 Pearson Education D (2) Front legs I (1) Seat cushion E (4) Leg supports

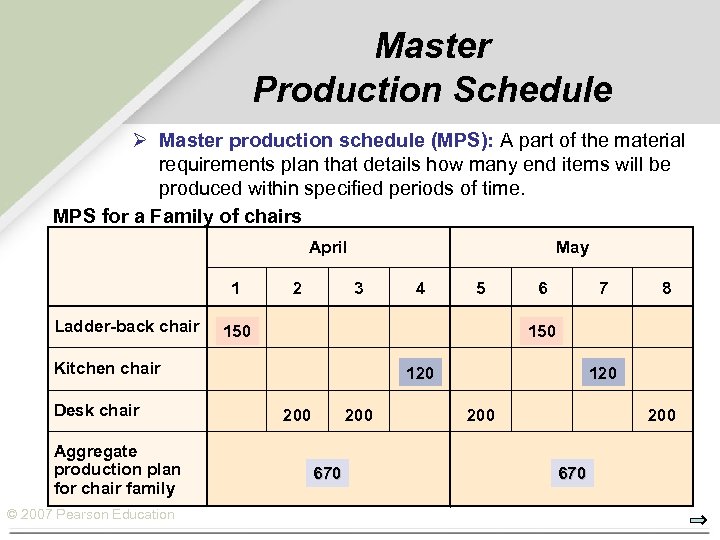

Master Production Schedule Ø Master production schedule (MPS): A part of the material requirements plan that details how many end items will be produced within specified periods of time. MPS for a Family of chairs April 1 Ladder-back chair 2 May 3 Aggregate production plan for chair family © 2007 Pearson Education 5 150 6 7 8 150 Kitchen chair Desk chair 4 120 200 200 670

Master Production Schedule Ø Master production schedule (MPS): A part of the material requirements plan that details how many end items will be produced within specified periods of time. MPS for a Family of chairs April 1 Ladder-back chair 2 May 3 Aggregate production plan for chair family © 2007 Pearson Education 5 150 6 7 8 150 Kitchen chair Desk chair 4 120 200 200 670

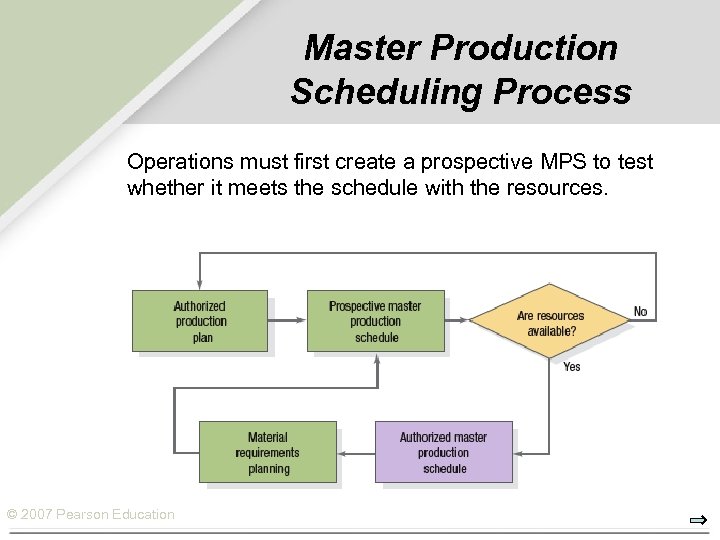

Master Production Scheduling Process Operations must first create a prospective MPS to test whether it meets the schedule with the resources. © 2007 Pearson Education

Master Production Scheduling Process Operations must first create a prospective MPS to test whether it meets the schedule with the resources. © 2007 Pearson Education

Developing a Master Production Schedule MPS for Weeks 1 & 2 Forecast is less than booked orders in week 1; projected on-hand inventory balance = 55 + 0 – 38 = 17. Forecast exceeds booked orders in week 2; projected onhand inventory balance = 17 + 0 – 30 = – 13. The shortage signals a need to schedule an MPS quantity for completion in week 2. © 2007 Pearson Education

Developing a Master Production Schedule MPS for Weeks 1 & 2 Forecast is less than booked orders in week 1; projected on-hand inventory balance = 55 + 0 – 38 = 17. Forecast exceeds booked orders in week 2; projected onhand inventory balance = 17 + 0 – 30 = – 13. The shortage signals a need to schedule an MPS quantity for completion in week 2. © 2007 Pearson Education

Available-To-Promise Inventory Ø Available-to-promise (ATP) inventory: The quantity of end items that marketing can promise to deliver on specified dates. Ø It is the difference between the customer orders already booked and the quantity that operations is planning to produce. Ø As new customer orders are accepted, the ATP inventory is reduced to reflect the commitment of the firm to ship those quantities Ø Actual inventory stays unchanged until the order is removed from inventory and shipped to the customer. © 2007 Pearson Education

Available-To-Promise Inventory Ø Available-to-promise (ATP) inventory: The quantity of end items that marketing can promise to deliver on specified dates. Ø It is the difference between the customer orders already booked and the quantity that operations is planning to produce. Ø As new customer orders are accepted, the ATP inventory is reduced to reflect the commitment of the firm to ship those quantities Ø Actual inventory stays unchanged until the order is removed from inventory and shipped to the customer. © 2007 Pearson Education

MPS Worksheet © 2007 Pearson Education

MPS Worksheet © 2007 Pearson Education

MPS Schedule with ATP Item: Ladder-back chair Order Policy: 150 units Lead Time: 1 week May April Quantity on Hand: 55 1 2 3 4 5 6 7 8 Forecast 30 30 35 35 Customer orders booked 38 27 24 8 0 0 Projected on-hand inventory 17 137 107 77 42 7 122 87 MPS quantity 0 150 0 17 91 MPS start Available-topromise (ATP) inventory 0 0 0 150 The total of customer orders booked until the next MPS receipt is 38 is 27 The total of customer orders booked until the next MPS receipt + units. 8 = ATP = 55 The ATP = 150 (MPS quantity) – 59 24 + The © 2007 Pearson Education 59 units. (on-hand) + 0 (MPS quantity) – 38 = 17. = 91 units.

MPS Schedule with ATP Item: Ladder-back chair Order Policy: 150 units Lead Time: 1 week May April Quantity on Hand: 55 1 2 3 4 5 6 7 8 Forecast 30 30 35 35 Customer orders booked 38 27 24 8 0 0 Projected on-hand inventory 17 137 107 77 42 7 122 87 MPS quantity 0 150 0 17 91 MPS start Available-topromise (ATP) inventory 0 0 0 150 The total of customer orders booked until the next MPS receipt is 38 is 27 The total of customer orders booked until the next MPS receipt + units. 8 = ATP = 55 The ATP = 150 (MPS quantity) – 59 24 + The © 2007 Pearson Education 59 units. (on-hand) + 0 (MPS quantity) – 38 = 17. = 91 units.

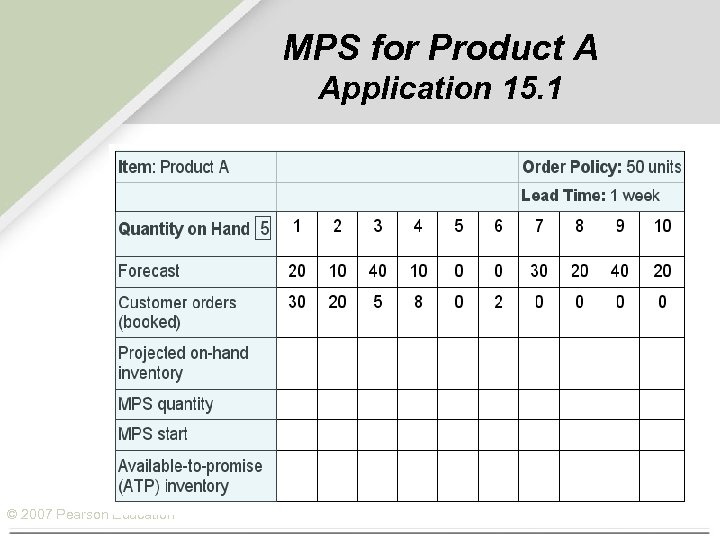

MPS for Product A Application 15. 1 © 2007 Pearson Education

MPS for Product A Application 15. 1 © 2007 Pearson Education

MPS for Product A Application 15. 1 © 2007 Pearson Education

MPS for Product A Application 15. 1 © 2007 Pearson Education

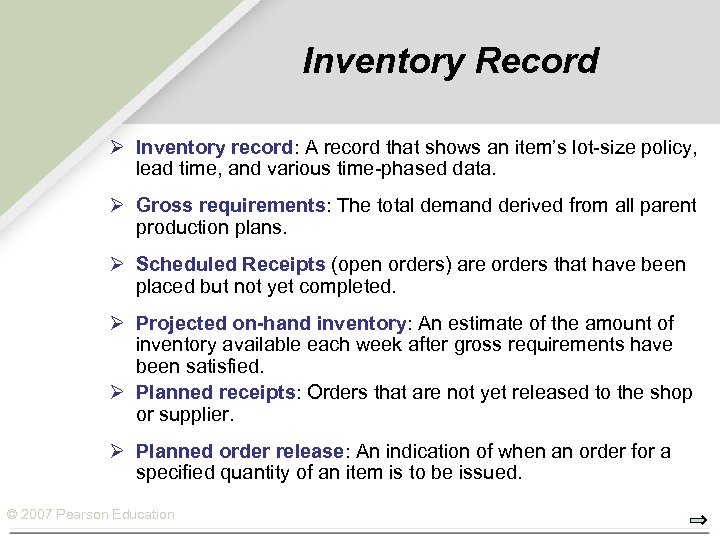

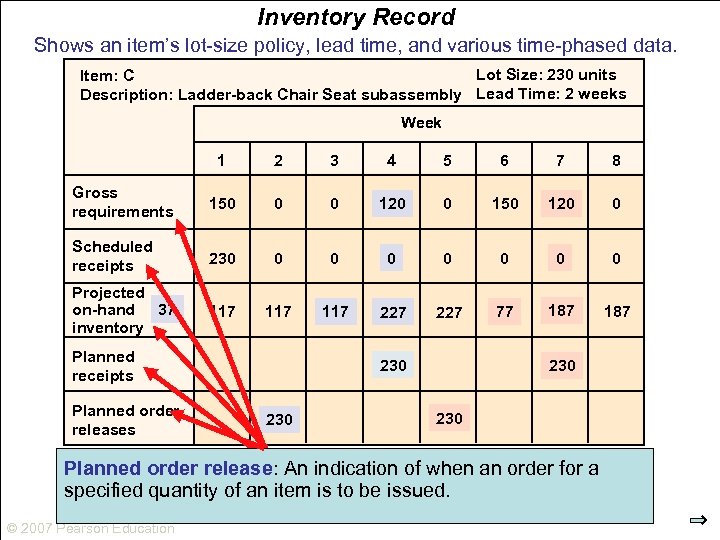

Inventory Record Ø Inventory record: A record that shows an item’s lot-size policy, lead time, and various time-phased data. Ø Gross requirements: The total demand derived from all parent production plans. Ø Scheduled Receipts (open orders) are orders that have been placed but not yet completed. Ø Projected on-hand inventory: An estimate of the amount of inventory available each week after gross requirements have been satisfied. Ø Planned receipts: Orders that are not yet released to the shop or supplier. Ø Planned order release: An indication of when an order for a specified quantity of an item is to be issued. © 2007 Pearson Education

Inventory Record Ø Inventory record: A record that shows an item’s lot-size policy, lead time, and various time-phased data. Ø Gross requirements: The total demand derived from all parent production plans. Ø Scheduled Receipts (open orders) are orders that have been placed but not yet completed. Ø Projected on-hand inventory: An estimate of the amount of inventory available each week after gross requirements have been satisfied. Ø Planned receipts: Orders that are not yet released to the shop or supplier. Ø Planned order release: An indication of when an order for a specified quantity of an item is to be issued. © 2007 Pearson Education

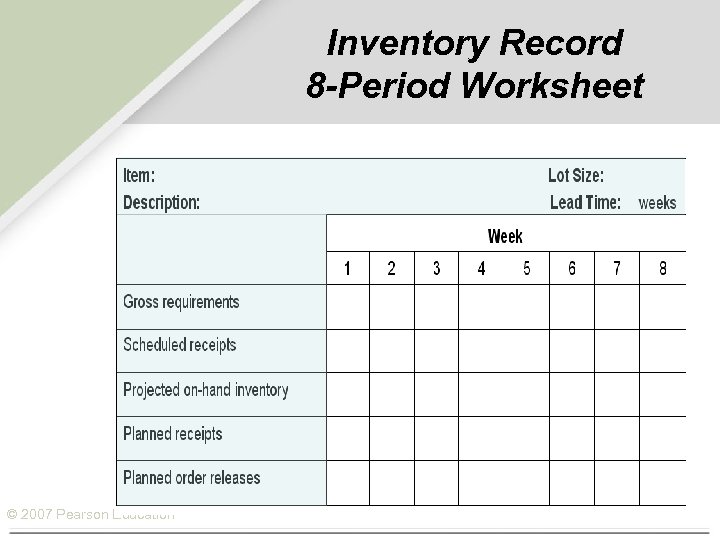

Inventory Record 8 -Period Worksheet © 2007 Pearson Education

Inventory Record 8 -Period Worksheet © 2007 Pearson Education

Inventory Record Shows an item’s lot-size policy, lead time, and various time-phased data. Lot Size: 230 units Item: C Description: Ladder-back Chair Seat subassembly Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 Projected on-hand 37 inventory 117 117 227 77 187 Planned receipts Planned order releases 230 230 Projected on-hand inventory: demandorders that of Scheduled Receipts The total An are when the amount a Gross requirements: (open orders)not yet released have been Planned order release: An that are estimate ofan from all parent Planned receipts: each week after gross requirementsfor shop Orders indication of derived order the to have inventory available placedsupplier. but plans. specified quantity of an item is to be issued. production not yet completed. or thesatisfied. been © 2007 Pearson Education

Inventory Record Shows an item’s lot-size policy, lead time, and various time-phased data. Lot Size: 230 units Item: C Description: Ladder-back Chair Seat subassembly Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 Projected on-hand 37 inventory 117 117 227 77 187 Planned receipts Planned order releases 230 230 Projected on-hand inventory: demandorders that of Scheduled Receipts The total An are when the amount a Gross requirements: (open orders)not yet released have been Planned order release: An that are estimate ofan from all parent Planned receipts: each week after gross requirementsfor shop Orders indication of derived order the to have inventory available placedsupplier. but plans. specified quantity of an item is to be issued. production not yet completed. or thesatisfied. been © 2007 Pearson Education

Lot Size: 230 units Item: C Description: Ladder-back Chair Seat subassembly Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 Projected on-hand 37 inventory 117 117 227 77 187 Planned receipts Planned order releases 230 230 The first a planned receipt in week 4, a shortage of 3 units will occur: 117 + 0 Without planned receipt lasts until week 7, when projected inventory would drop to 120+ 0– 3 0 – 120 = – 43 the planned receipt bringsplanned receipt 117 + 0 the – 77 = + units. Adding the second the balance to brings + balance to = 227 units. Offsetting 187 a 2 -week lead time puts the corresponding 230 – 120 77 + 0 + 230 – 120 = for units. The corresponding planned order release is for week 5 (or week 7 minus 2 weeks). planned order release back to week 2. © 2007 Pearson Education

Lot Size: 230 units Item: C Description: Ladder-back Chair Seat subassembly Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 Projected on-hand 37 inventory 117 117 227 77 187 Planned receipts Planned order releases 230 230 The first a planned receipt in week 4, a shortage of 3 units will occur: 117 + 0 Without planned receipt lasts until week 7, when projected inventory would drop to 120+ 0– 3 0 – 120 = – 43 the planned receipt bringsplanned receipt 117 + 0 the – 77 = + units. Adding the second the balance to brings + balance to = 227 units. Offsetting 187 a 2 -week lead time puts the corresponding 230 – 120 77 + 0 + 230 – 120 = for units. The corresponding planned order release is for week 5 (or week 7 minus 2 weeks). planned order release back to week 2. © 2007 Pearson Education

Planning Factors Ø Planning lead time: An estimate of the time between placing an order for an item and receiving the item in inventory. ØSetup time ØProcessing time ØMaterials handling time between operations ØWaiting time Ø Lot-sizing rules: A rule that determines the timing and size of order quantities. © 2007 Pearson Education

Planning Factors Ø Planning lead time: An estimate of the time between placing an order for an item and receiving the item in inventory. ØSetup time ØProcessing time ØMaterials handling time between operations ØWaiting time Ø Lot-sizing rules: A rule that determines the timing and size of order quantities. © 2007 Pearson Education

Lot Sizing Rules Fixed Order Quantity (FOQ) Ø Fixed order quantity (FOQ): A rule that maintains the same order quantity each time an order is issued. Ø Dictated by Ø Equipment capacity limits Ø Quantity discount Ø Truckload capacity Ø Minimum purchase quantity Ø EOQ © 2007 Pearson Education

Lot Sizing Rules Fixed Order Quantity (FOQ) Ø Fixed order quantity (FOQ): A rule that maintains the same order quantity each time an order is issued. Ø Dictated by Ø Equipment capacity limits Ø Quantity discount Ø Truckload capacity Ø Minimum purchase quantity Ø EOQ © 2007 Pearson Education

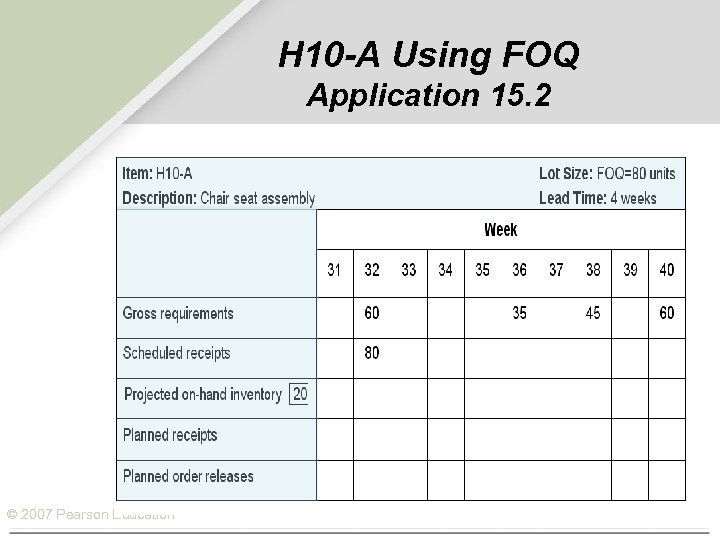

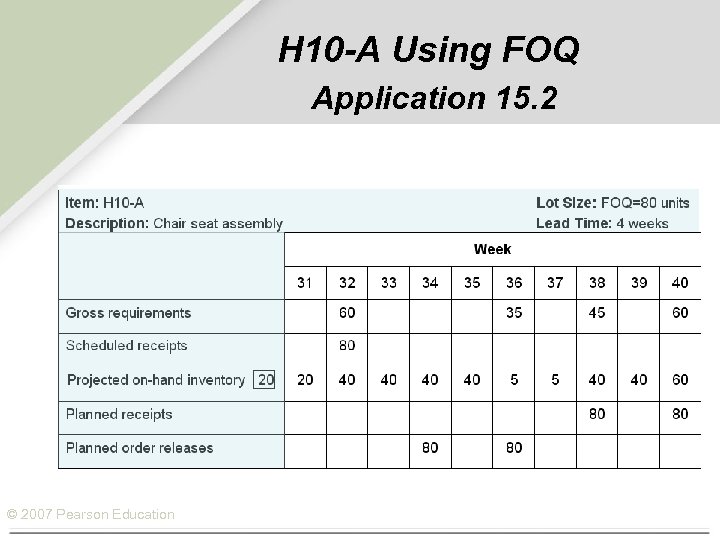

H 10 -A Using FOQ Application 15. 2 © 2007 Pearson Education

H 10 -A Using FOQ Application 15. 2 © 2007 Pearson Education

H 10 -A Using FOQ Application 15. 2 © 2007 Pearson Education

H 10 -A Using FOQ Application 15. 2 © 2007 Pearson Education

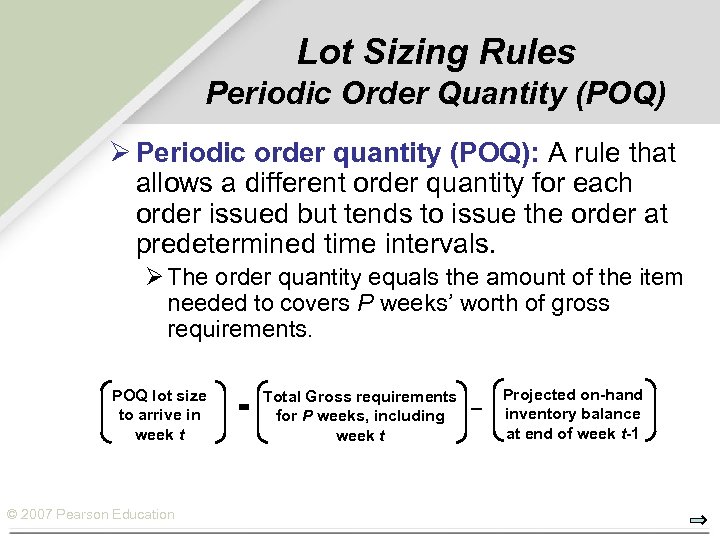

Lot Sizing Rules Periodic Order Quantity (POQ) Ø Periodic order quantity (POQ): A rule that allows a different order quantity for each order issued but tends to issue the order at predetermined time intervals. Ø The order quantity equals the amount of the item needed to covers P weeks’ worth of gross requirements. POQ lot size to arrive in week t © 2007 Pearson Education = Total Gross requirements for P weeks, including week t – Projected on-hand inventory balance at end of week t-1

Lot Sizing Rules Periodic Order Quantity (POQ) Ø Periodic order quantity (POQ): A rule that allows a different order quantity for each order issued but tends to issue the order at predetermined time intervals. Ø The order quantity equals the amount of the item needed to covers P weeks’ worth of gross requirements. POQ lot size to arrive in week t © 2007 Pearson Education = Total Gross requirements for P weeks, including week t – Projected on-hand inventory balance at end of week t-1

The POQ (P = 3) Rule for the Ladder-back Chair Seat Subassembly Item: C Description: Ladder-back Chair Seat subassembly Lot Size: P = 3 Lead Time: 2 weeks Week 1 Gross requirements 230 3 150 Scheduled receipts 2 Projected on-hand inventory 37 117 5 6 7 150 120 8 120 (120 + 150) - 117 = 153 117 Planned receipts Planned order releases © 2007 Pearson Education 4 117 150 153 0 0 120 0

The POQ (P = 3) Rule for the Ladder-back Chair Seat Subassembly Item: C Description: Ladder-back Chair Seat subassembly Lot Size: P = 3 Lead Time: 2 weeks Week 1 Gross requirements 230 3 150 Scheduled receipts 2 Projected on-hand inventory 37 117 5 6 7 150 120 8 120 (120 + 150) - 117 = 153 117 Planned receipts Planned order releases © 2007 Pearson Education 4 117 150 153 0 0 120 0

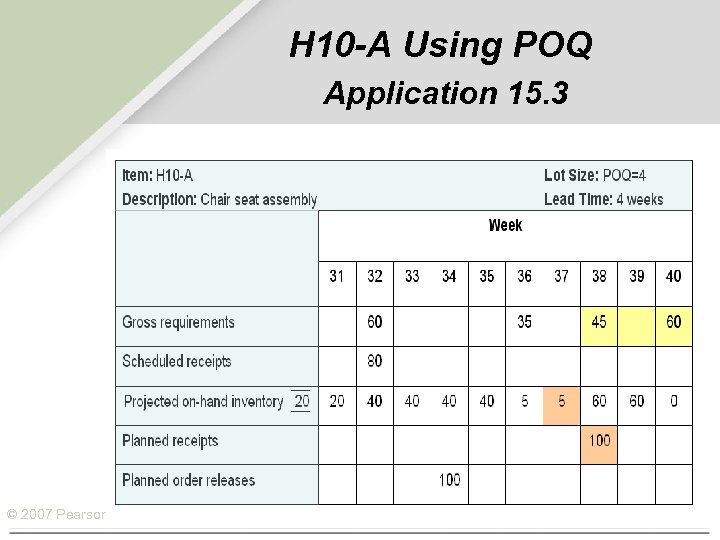

H 10 -A Using POQ Application 15. 3 © 2007 Pearson Education

H 10 -A Using POQ Application 15. 3 © 2007 Pearson Education

H 10 -A Using POQ Application 15. 3 © 2007 Pearson Education

H 10 -A Using POQ Application 15. 3 © 2007 Pearson Education

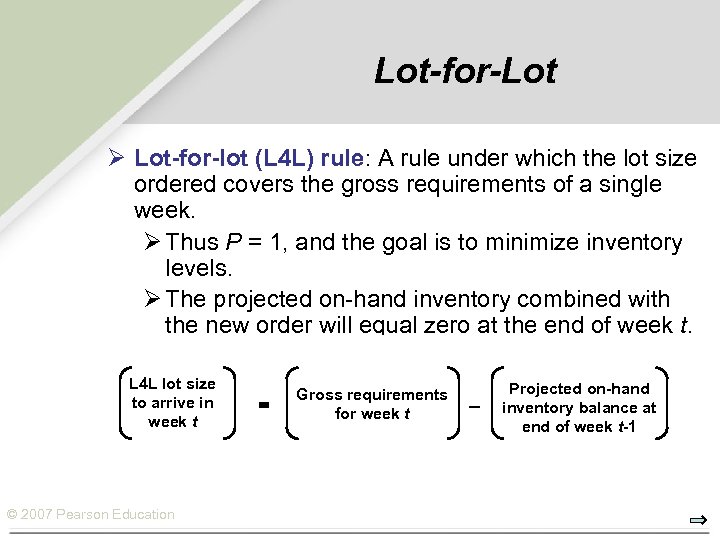

Lot-for-Lot Ø Lot-for-lot (L 4 L) rule: A rule under which the lot size ordered covers the gross requirements of a single week. Ø Thus P = 1, and the goal is to minimize inventory levels. Ø The projected on-hand inventory combined with the new order will equal zero at the end of week t. L 4 L lot size to arrive in week t © 2007 Pearson Education = Gross requirements for week t – Projected on-hand inventory balance at end of week t-1

Lot-for-Lot Ø Lot-for-lot (L 4 L) rule: A rule under which the lot size ordered covers the gross requirements of a single week. Ø Thus P = 1, and the goal is to minimize inventory levels. Ø The projected on-hand inventory combined with the new order will equal zero at the end of week t. L 4 L lot size to arrive in week t © 2007 Pearson Education = Gross requirements for week t – Projected on-hand inventory balance at end of week t-1

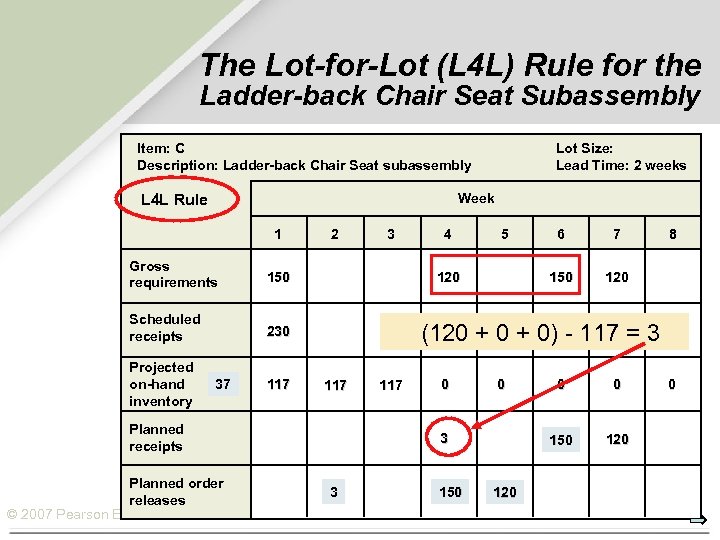

The Lot-for-Lot (L 4 L) Rule for the Ladder-back Chair Seat Subassembly Item: C Description: Ladder-back Chair Seat subassembly Week L 4 L Rule 1 Gross requirements Scheduled receipts 2 3 150 230 Projected on-hand inventory Lot Size: Lead Time: 2 weeks 37 117 5 6 7 150 120 8 120 (120 + 0) - 117 = 3 117 Planned receipts Planned order releases © 2007 Pearson Education 4 117 0 0 3 150 120 0 150 3 0 120 0

The Lot-for-Lot (L 4 L) Rule for the Ladder-back Chair Seat Subassembly Item: C Description: Ladder-back Chair Seat subassembly Week L 4 L Rule 1 Gross requirements Scheduled receipts 2 3 150 230 Projected on-hand inventory Lot Size: Lead Time: 2 weeks 37 117 5 6 7 150 120 8 120 (120 + 0) - 117 = 3 117 Planned receipts Planned order releases © 2007 Pearson Education 4 117 0 0 3 150 120 0 150 3 0 120 0

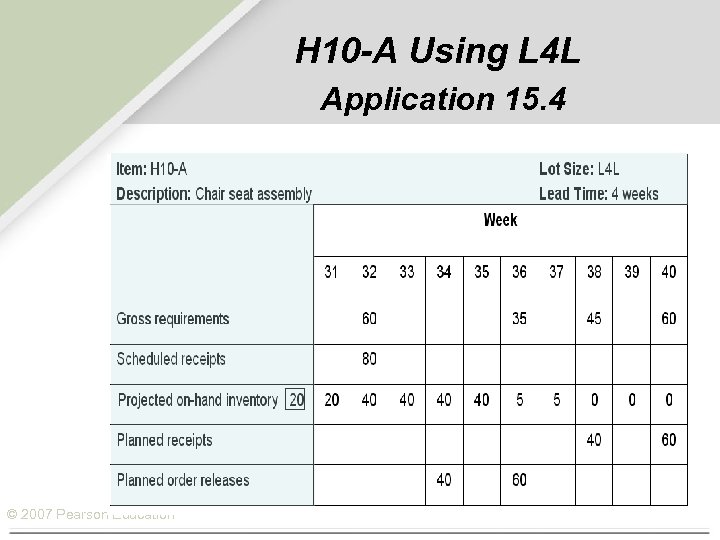

H 10 -A Using L 4 L Application 15. 4 © 2007 Pearson Education

H 10 -A Using L 4 L Application 15. 4 © 2007 Pearson Education

H 10 -A Using L 4 L Application 15. 4 © 2007 Pearson Education

H 10 -A Using L 4 L Application 15. 4 © 2007 Pearson Education

Comparing Lot-Sizing Rules Ø FOQ, POQ, and L 4 L rules affect inventory costs and setup and ordering costs. In the example, each rule took effect in week 4, when the first order was placed. Ø A comparison of projected on-hand inventory averaged over weeks 4 through 8 of the planning horizon for the ladder-back chair seat subassembly: FOQ: (227+77+187)/5 = 181 units POQ: (150+0+0+0)/5 = 60 units L 4 L: (0+0+0)/5 = 0 units Ø FOQ generates high inventory because it creates remnants. Ø POQ reduces on-hand inventory because it does a better job of matching order quantity to requirements. Ø L 4 L minimizes inventory investment but maximizes the number of orders placed. © 2007 Pearson Education

Comparing Lot-Sizing Rules Ø FOQ, POQ, and L 4 L rules affect inventory costs and setup and ordering costs. In the example, each rule took effect in week 4, when the first order was placed. Ø A comparison of projected on-hand inventory averaged over weeks 4 through 8 of the planning horizon for the ladder-back chair seat subassembly: FOQ: (227+77+187)/5 = 181 units POQ: (150+0+0+0)/5 = 60 units L 4 L: (0+0+0)/5 = 0 units Ø FOQ generates high inventory because it creates remnants. Ø POQ reduces on-hand inventory because it does a better job of matching order quantity to requirements. Ø L 4 L minimizes inventory investment but maximizes the number of orders placed. © 2007 Pearson Education

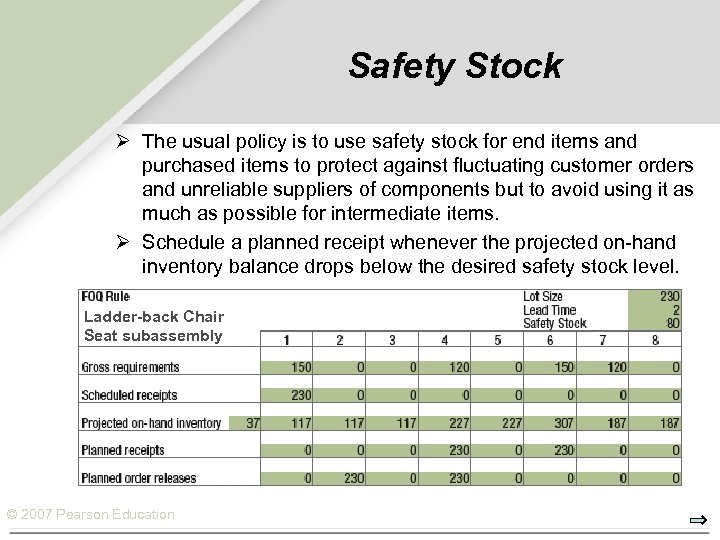

Safety Stock Ø The usual policy is to use safety stock for end items and purchased items to protect against fluctuating customer orders and unreliable suppliers of components but to avoid using it as much as possible for intermediate items. Ø Schedule a planned receipt whenever the projected on-hand inventory balance drops below the desired safety stock level. Ladder-back Chair Seat subassembly © 2007 Pearson Education

Safety Stock Ø The usual policy is to use safety stock for end items and purchased items to protect against fluctuating customer orders and unreliable suppliers of components but to avoid using it as much as possible for intermediate items. Ø Schedule a planned receipt whenever the projected on-hand inventory balance drops below the desired safety stock level. Ladder-back Chair Seat subassembly © 2007 Pearson Education

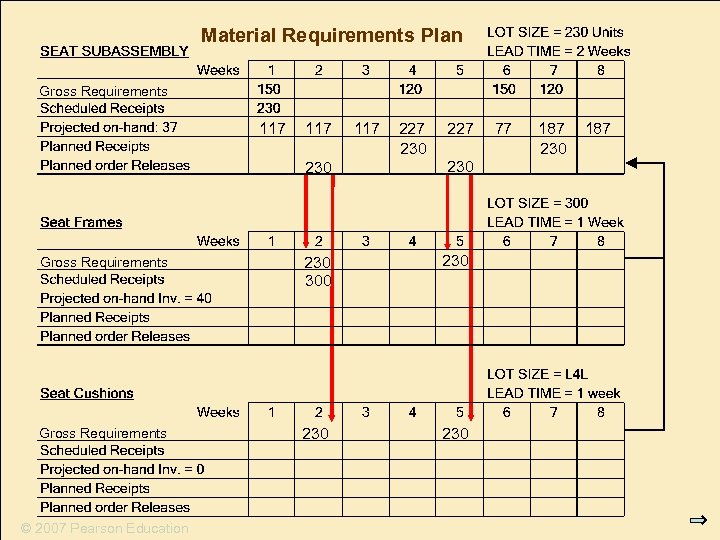

MRP translates, or explodes, the MPS and other sources of demand into the requirements needed for all of the subassemblies, components, and raw materials the firm needs to produce parent items. This process generates the material requirements plan for each component item. MRP explosion Material requirements plan Action notices · Releasing new orders · Adjusting due dates Routings and time standards Priority reports · Dispatch lists · Supplier schedules Capacity reports · Capacity requirements planning · Finite capacity scheduling · Input-output control Manufacturing resources plan Performance reports © 2007 Pearson Education Cost and price data

MRP translates, or explodes, the MPS and other sources of demand into the requirements needed for all of the subassemblies, components, and raw materials the firm needs to produce parent items. This process generates the material requirements plan for each component item. MRP explosion Material requirements plan Action notices · Releasing new orders · Adjusting due dates Routings and time standards Priority reports · Dispatch lists · Supplier schedules Capacity reports · Capacity requirements planning · Finite capacity scheduling · Input-output control Manufacturing resources plan Performance reports © 2007 Pearson Education Cost and price data

Material Requirements Plan Gross Requirements 117 117 On hand Inventory + Scheduled receipts – Gross Requirements © 2007 Pearson Education 300

Material Requirements Plan Gross Requirements 117 117 On hand Inventory + Scheduled receipts – Gross Requirements © 2007 Pearson Education 300

Material Requirements Plan Requirements Gross Requirements 117 117 227 230 117 units is insufficient to meet gross requirements of 120 for week 4, so a planned order release of 230 must be scheduled. Gross Requirements 300 Gross Requirements © 2007 Pearson Education

Material Requirements Plan Requirements Gross Requirements 117 117 227 230 117 units is insufficient to meet gross requirements of 120 for week 4, so a planned order release of 230 must be scheduled. Gross Requirements 300 Gross Requirements © 2007 Pearson Education

Material Requirements Plan Gross Requirements 117 230 117 227 230 77 units is insufficient to meet gross requirements of 150 for week 6, so a planned order release of 230 must be scheduled. Gross Requirements 300 Gross Requirements © 2007 Pearson Education 77 187 230 187

Material Requirements Plan Gross Requirements 117 230 117 227 230 77 units is insufficient to meet gross requirements of 150 for week 6, so a planned order release of 230 must be scheduled. Gross Requirements 300 Gross Requirements © 2007 Pearson Education 77 187 230 187

Material Requirements Plan Gross Requirements 117 230 117 227 230 Gross Requirements 230 300 230 Gross Requirements 230 © 2007 Pearson Education 77 187 230 187

Material Requirements Plan Gross Requirements 117 230 117 227 230 Gross Requirements 230 300 230 Gross Requirements 230 © 2007 Pearson Education 77 187 230 187

Material Requirements Plan Gross Requirements 117 117 227 230 Gross Requirements 40 230 300 110 230 110 300 110 of on-handin be scheduled previous demandweek 110 is carried from 40 40 hand plus inventory untiltominusproduction inis one. 4 and Loton 300 must 300 in receiptsweek 5 whento of 230 = start plan more needed. arrives as planned receipt in week 5. Gross Requirements © 2007 Pearson Education 230 77 187 230 187

Material Requirements Plan Gross Requirements 117 117 227 230 Gross Requirements 40 230 300 110 230 110 300 110 of on-handin be scheduled previous demandweek 110 is carried from 40 40 hand plus inventory untiltominusproduction inis one. 4 and Loton 300 must 300 in receiptsweek 5 whento of 230 = start plan more needed. arrives as planned receipt in week 5. Gross Requirements © 2007 Pearson Education 230 77 187 230 187

Material Requirements Plan Gross Requirements 117 117 227 230 Gross Requirements 40 110 180 300 The 180 in inventory is 300 + 110 - 230 next gross On-Hand for week 5 carried until the = 180 requirements. © 2007 Pearson Education 187 230 300 Gross Requirements 187 230 230 300 110 77 230 180

Material Requirements Plan Gross Requirements 117 117 227 230 Gross Requirements 40 110 180 300 The 180 in inventory is 300 + 110 - 230 next gross On-Hand for week 5 carried until the = 180 requirements. © 2007 Pearson Education 187 230 300 Gross Requirements 187 230 230 300 110 77 230 180

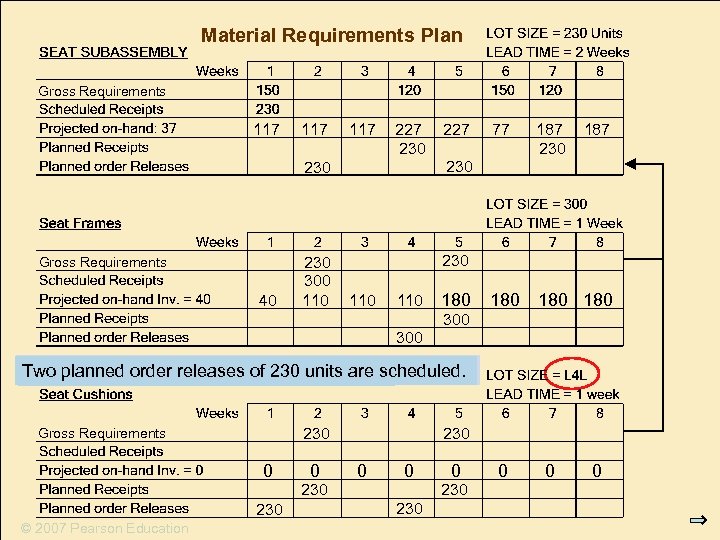

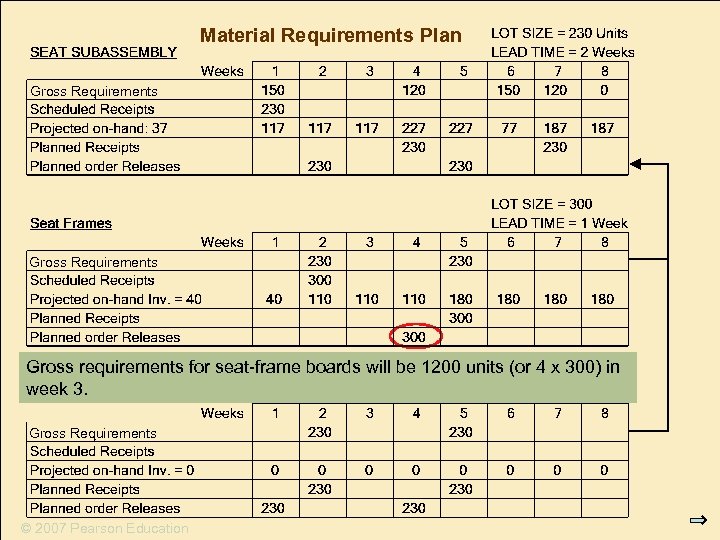

Material Requirements Plan Gross Requirements 117 117 227 230 Gross Requirements 40 187 230 230 300 110 77 230 110 300 180 180 300 Planned order releases are of 230 gross requirements. Two planned order releasessized tounits zero. Projected on-hand inventory remains at are scheduled. 230 Gross Requirements 0 0 230 230 © 2007 Pearson Education 230 0 0 0

Material Requirements Plan Gross Requirements 117 117 227 230 Gross Requirements 40 187 230 230 300 110 77 230 110 300 180 180 300 Planned order releases are of 230 gross requirements. Two planned order releasessized tounits zero. Projected on-hand inventory remains at are scheduled. 230 Gross Requirements 0 0 230 230 © 2007 Pearson Education 230 0 0 0

Material Requirements Plan Gross Requirements Gross requirements for seat-frame boards will be 1200 units (or 4 x 300) in week 3. Gross Requirements © 2007 Pearson Education

Material Requirements Plan Gross Requirements Gross requirements for seat-frame boards will be 1200 units (or 4 x 300) in week 3. Gross Requirements © 2007 Pearson Education

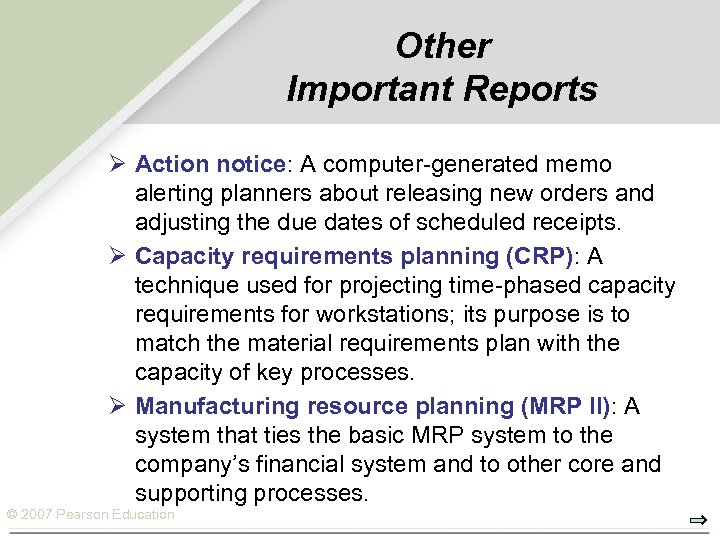

Other Important Reports Ø Action notice: A computer-generated memo alerting planners about releasing new orders and adjusting the due dates of scheduled receipts. Ø Capacity requirements planning (CRP): A technique used for projecting time-phased capacity requirements for workstations; its purpose is to match the material requirements plan with the capacity of key processes. Ø Manufacturing resource planning (MRP II): A system that ties the basic MRP system to the company’s financial system and to other core and supporting processes. © 2007 Pearson Education

Other Important Reports Ø Action notice: A computer-generated memo alerting planners about releasing new orders and adjusting the due dates of scheduled receipts. Ø Capacity requirements planning (CRP): A technique used for projecting time-phased capacity requirements for workstations; its purpose is to match the material requirements plan with the capacity of key processes. Ø Manufacturing resource planning (MRP II): A system that ties the basic MRP system to the company’s financial system and to other core and supporting processes. © 2007 Pearson Education

Item A’s MPS and BOM Application 15. 5 © 2007 Pearson Education

Item A’s MPS and BOM Application 15. 5 © 2007 Pearson Education

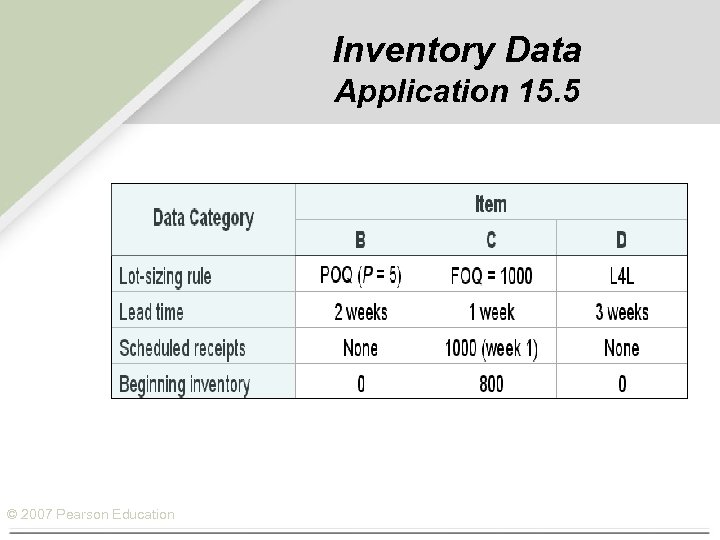

Inventory Data Application 15. 5 © 2007 Pearson Education

Inventory Data Application 15. 5 © 2007 Pearson Education

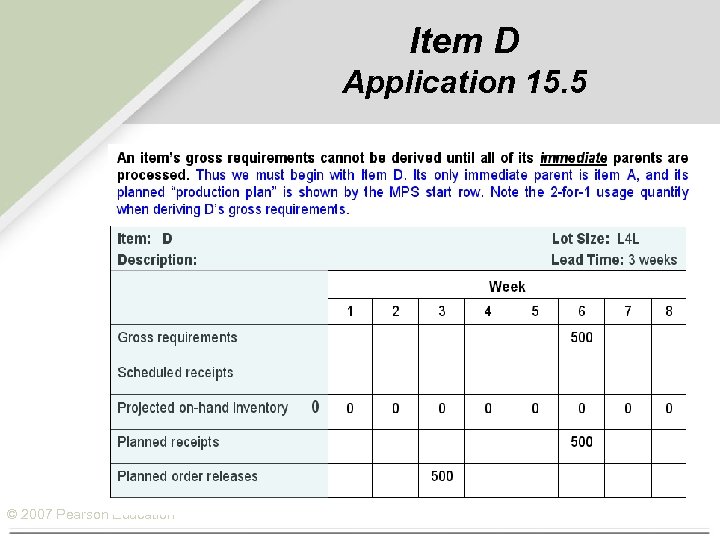

Item D Application 15. 5 © 2007 Pearson Education

Item D Application 15. 5 © 2007 Pearson Education

Item B Application 15. 5 © 2007 Pearson Education

Item B Application 15. 5 © 2007 Pearson Education

Item C Application 15. 5 © 2007 Pearson Education

Item C Application 15. 5 © 2007 Pearson Education

Drum-Buffer-Rope System Ø Drum-Buffer-Rope (DBR): A planning and control system that regulates the flow of work-in-process materials at the bottleneck or the capacity constrained resource (CCR) in a productive system. Drum-Buffer-Rope System with a Capacity Constrained Resource (CCR) Market Demand 650 units/week © 2007 Pearson Education

Drum-Buffer-Rope System Ø Drum-Buffer-Rope (DBR): A planning and control system that regulates the flow of work-in-process materials at the bottleneck or the capacity constrained resource (CCR) in a productive system. Drum-Buffer-Rope System with a Capacity Constrained Resource (CCR) Market Demand 650 units/week © 2007 Pearson Education

Drum-Buffer-Rope System in Practice Ø The U. S. Marine Corps Maintenance Center in Albany, Georgia, overhauls and repairs vehicles used by the Corps. Ø Repairs to equipment can vary tremendously at the U. S. Marine Corps Maintenance Center in Albany, Georgia. Ø The center struggled to keep up with its repairs until managers implemented the simplified form of a drum-buffer-rope system. Ø The result? Repair times fell from 167 days to just 58 days, on average. © 2007 Pearson Education

Drum-Buffer-Rope System in Practice Ø The U. S. Marine Corps Maintenance Center in Albany, Georgia, overhauls and repairs vehicles used by the Corps. Ø Repairs to equipment can vary tremendously at the U. S. Marine Corps Maintenance Center in Albany, Georgia. Ø The center struggled to keep up with its repairs until managers implemented the simplified form of a drum-buffer-rope system. Ø The result? Repair times fell from 167 days to just 58 days, on average. © 2007 Pearson Education

Resource Planning for Service Providers Ø Dependent demand for services ØRestaurant ØAirlines ØHospitals ØHotels Ø Bill of Resources: A record of a firm’s parent-component relationships and all of the materials, equipment time, staff, and other resources. © 2007 Pearson Education

Resource Planning for Service Providers Ø Dependent demand for services ØRestaurant ØAirlines ØHospitals ØHotels Ø Bill of Resources: A record of a firm’s parent-component relationships and all of the materials, equipment time, staff, and other resources. © 2007 Pearson Education

Level 1 Discharge Bill of Resources (BOR) A record of a service firm’s parent– component relationships and all of the materials, equipment time, staff, and other resources associated with them, including usage quantities. BOR for Treating an Aneurysm MD (1 hr) © 2007 Pearson Education Therapy (1 hr) Bed (24 hr) Lab (3 tests) Level 3 Postoperative care (Step down) Level 4 Postoperative care (Intensive) Level 5 Surgery Level 6 Preoperative care (Angiogram) Nurse (6 hr) Level 2 Intermediate care Level 6 Preoperative care (Angiogram) Kitchen (1 meal) Pharmacy (10 medicines) Level 7 Preoperative care (Testing)

Level 1 Discharge Bill of Resources (BOR) A record of a service firm’s parent– component relationships and all of the materials, equipment time, staff, and other resources associated with them, including usage quantities. BOR for Treating an Aneurysm MD (1 hr) © 2007 Pearson Education Therapy (1 hr) Bed (24 hr) Lab (3 tests) Level 3 Postoperative care (Step down) Level 4 Postoperative care (Intensive) Level 5 Surgery Level 6 Preoperative care (Angiogram) Nurse (6 hr) Level 2 Intermediate care Level 6 Preoperative care (Angiogram) Kitchen (1 meal) Pharmacy (10 medicines) Level 7 Preoperative care (Testing)

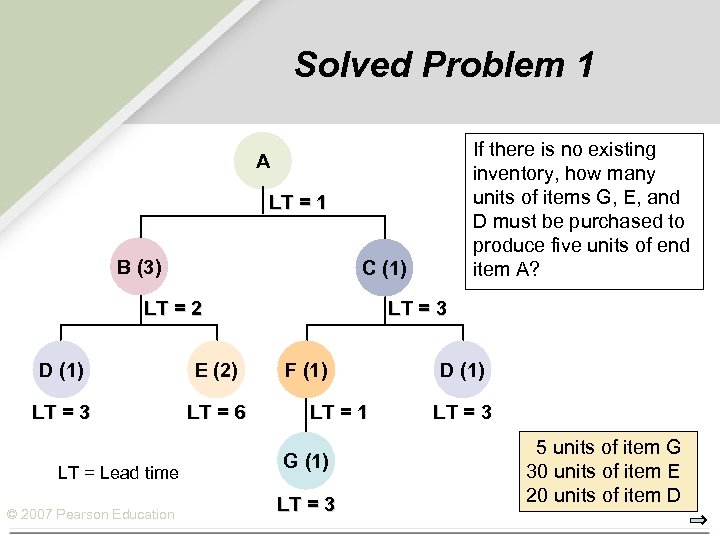

Solved Problem 1 If there is no existing inventory, how many units of items G, E, and D must be purchased to produce five units of end item A? A LT = 1 B (3) C (1) LT = 2 D (1) E (2) LT = 3 LT = 6 LT = Lead time © 2007 Pearson Education LT = 3 F (1) LT = 1 G (1) LT = 3 D (1) LT = 3 5 units of item G 30 units of item E 20 units of item D

Solved Problem 1 If there is no existing inventory, how many units of items G, E, and D must be purchased to produce five units of end item A? A LT = 1 B (3) C (1) LT = 2 D (1) E (2) LT = 3 LT = 6 LT = Lead time © 2007 Pearson Education LT = 3 F (1) LT = 1 G (1) LT = 3 D (1) LT = 3 5 units of item G 30 units of item E 20 units of item D

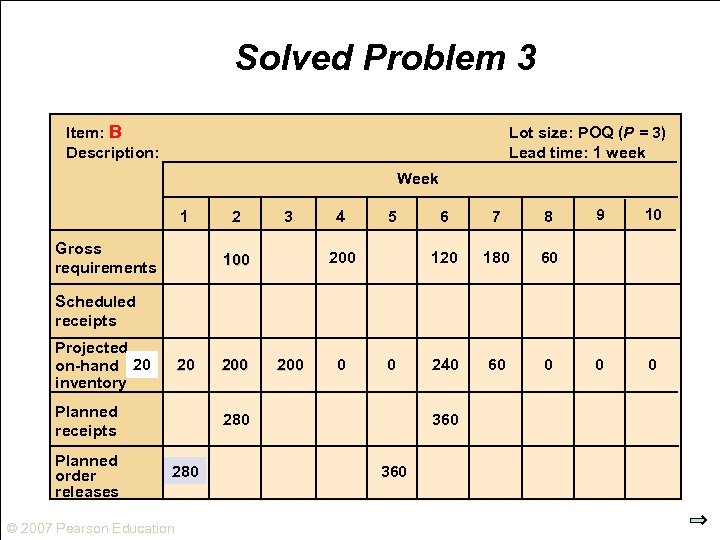

Solved Problem 3 A The MPS for product A calls for the assembly department to begin final assembly according to the following schedule: 100 units in week 2; 200 units in week 4; 120 units in week 6; 180 units in week 7; and 60 units in week 8. Develop a material requirements plan for the next eight weeks for items B, C, and D. DATA CATEGORY Lot-sizing rule Lead time Scheduled receipts Beginning (on-hand) inventory © 2007 Pearson Education B POQ (P=3) 1 week None 20 ITEM C L 4 L 2 weeks 200 (week 1) 0 LT = 2 B (1) LT = 1 D FOQ = 500 units 3 weeks None 425 C (2) LT = 2 D (1) LT = 3

Solved Problem 3 A The MPS for product A calls for the assembly department to begin final assembly according to the following schedule: 100 units in week 2; 200 units in week 4; 120 units in week 6; 180 units in week 7; and 60 units in week 8. Develop a material requirements plan for the next eight weeks for items B, C, and D. DATA CATEGORY Lot-sizing rule Lead time Scheduled receipts Beginning (on-hand) inventory © 2007 Pearson Education B POQ (P=3) 1 week None 20 ITEM C L 4 L 2 weeks 200 (week 1) 0 LT = 2 B (1) LT = 1 D FOQ = 500 units 3 weeks None 425 C (2) LT = 2 D (1) LT = 3

Solved Problem 3 Item: B Description: Lot size: POQ (P = 3) Lead time: 1 week Week 1 Gross requirements 2 3 4 5 7 8 120 200 100 6 180 60 0 10 0 0 60 240 9 Scheduled receipts Projected on-hand 20 inventory 20 Planned receipts Planned order releases 200 0 0 280 © 2007 Pearson Education 360

Solved Problem 3 Item: B Description: Lot size: POQ (P = 3) Lead time: 1 week Week 1 Gross requirements 2 3 4 5 7 8 120 200 100 6 180 60 0 10 0 0 60 240 9 Scheduled receipts Projected on-hand 20 inventory 20 Planned receipts Planned order releases 200 0 0 280 © 2007 Pearson Education 360

Solved Problem 3 Item: C Description: Lot size: L 4 L Lead time: 2 weeks Week 1 Gross requirements 2 3 200 6 7 8 240 360 0 0 240 360 120 10 0 0 120 0 9 200 Projected on-hand 0 inventory 5 400 200 Scheduled receipts 4 0 Planned receipts Planned order releases © 2007 Pearson Education 0 0 0 400 240 360 120

Solved Problem 3 Item: C Description: Lot size: L 4 L Lead time: 2 weeks Week 1 Gross requirements 2 3 200 6 7 8 240 360 0 0 240 360 120 10 0 0 120 0 9 200 Projected on-hand 0 inventory 5 400 200 Scheduled receipts 4 0 Planned receipts Planned order releases © 2007 Pearson Education 0 0 0 400 240 360 120

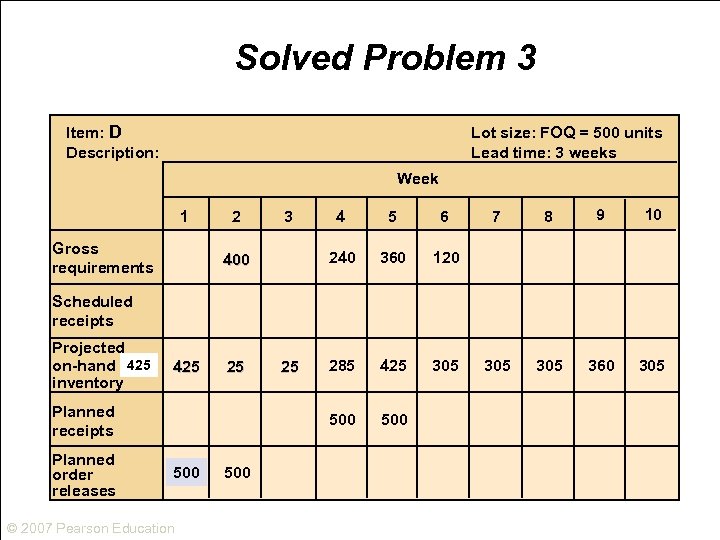

Solved Problem 3 Item: D Description: Lot size: FOQ = 500 units Lead time: 3 weeks Week 1 3 5 6 240 400 4 360 285 425 305 500 7 8 9 10 305 360 305 120 500 Gross requirements 2 Scheduled receipts Projected on-hand 425 inventory 425 25 Planned receipts Planned order releases 500 © 2007 Pearson Education 500 25

Solved Problem 3 Item: D Description: Lot size: FOQ = 500 units Lead time: 3 weeks Week 1 3 5 6 240 400 4 360 285 425 305 500 7 8 9 10 305 360 305 120 500 Gross requirements 2 Scheduled receipts Projected on-hand 425 inventory 425 25 Planned receipts Planned order releases 500 © 2007 Pearson Education 500 25