912e371b8a6add4e394c77c75d5892ab.ppt

- Количество слайдов: 23

Research Update Automated Bolting and Meshing Project - C 17018

Introduction Summary of the Project • This project aims to help contribute to ACARP and the Australian’s underground coal industry’s CM 2010 initiative in achieving production rates from a continuous miner of at least 10 metres per operating hour and 20 hours per day utilisation by 2010. • We aim to do this by developing a system integrated into a continuous miner platform that will fully automate the process of self loading and installing: 1. rib and roof Self Drilling Rock Bolts, and associated plates, washers etc. , 2. steel roof and rib mesh or other alternative roof confinement material, 3. materials handling systems needed to efficiently supply consumables at the expected rates of use. Today ACARP Funded Project C 17018 2009 2010

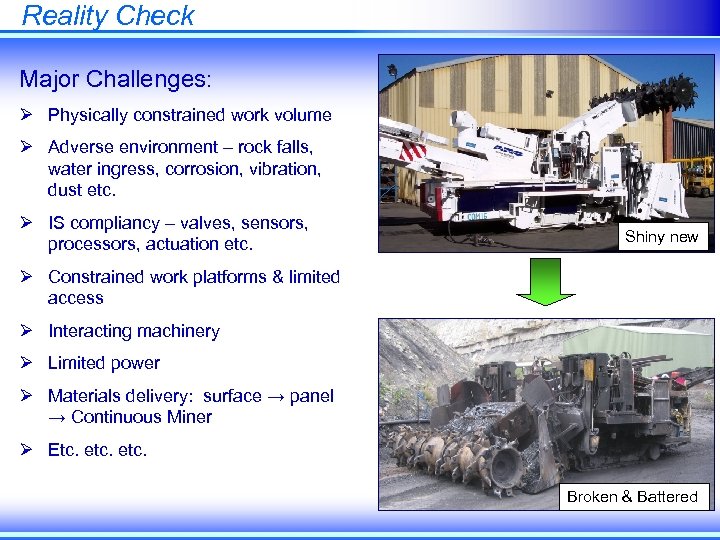

Reality Check Major Challenges: Ø Physically constrained work volume Ø Adverse environment – rock falls, water ingress, corrosion, vibration, dust etc. Ø IS compliancy – valves, sensors, processors, actuation etc. Shiny new Ø Constrained work platforms & limited access Ø Interacting machinery Ø Limited power Ø Materials delivery: surface → panel → Continuous Miner Ø Etc. etc. Broken & Battered

Background

Where do you fit something new on here without interfering with the basic operation and maintenance?

Project Outcomes The expected major benefits of this project will be: • Reduced cycle time for roof and rib support installation that will directly increase roadway development production rates; • Reduced exposure of personnel to unsupported roof, dust, noise, water, moving equipment and outburst conditions. – For LTI frequency of hand/finger injuries by employer activity, roof/rib bolting had the highest incidence at 26% followed by materials handling at 16%. For injuries causing death, there have been 107 fatalities for NSW coal mine in the past 25 years with 61% occurring at the development face and 57% related to rock falls; • Reduced manual handling injuries by improving the logistics and storage method for the loading and transportation of roof support consumables to and then within the development area and finally onto a continuous miner. • The removal of remedial and repetitive manual tasks that allows for better utilisation of mine operators elsewhere in the production process.

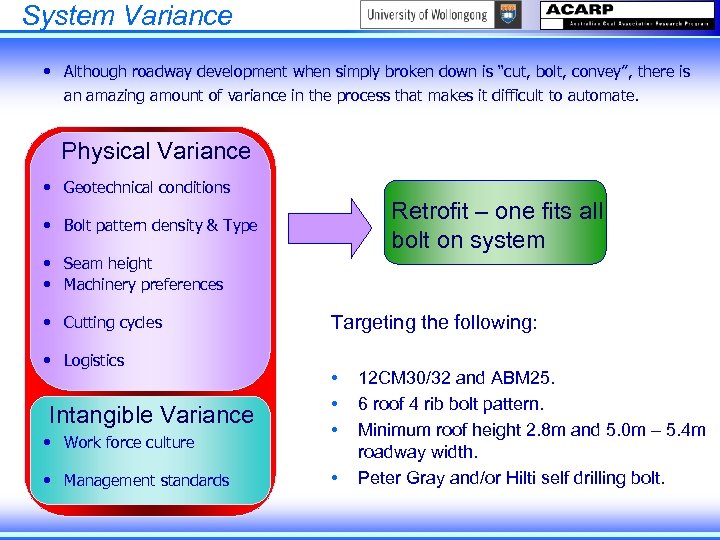

System Variance • Although roadway development when simply broken down is “cut, bolt, convey”, there is an amazing amount of variance in the process that makes it difficult to automate. Physical Variance • Geotechnical conditions Retrofit – one fits all bolt on system • Bolt pattern density & Type • Seam height • Machinery preferences • Cutting cycles • Logistics Intangible Variance • Work force culture • Management standards Targeting the following: • • 12 CM 30/32 and ABM 25. 6 roof 4 rib bolt pattern. Minimum roof height 2. 8 m and 5. 0 m – 5. 4 m roadway width. Peter Gray and/or Hilti self drilling bolt.

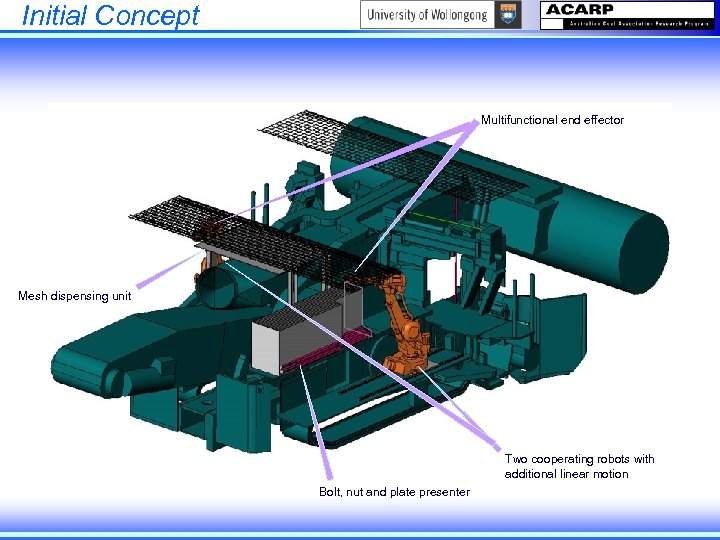

Initial Concept Multifunctional end effector Mesh dispensing unit Two cooperating robots with additional linear motion Bolt, nut and plate presenter

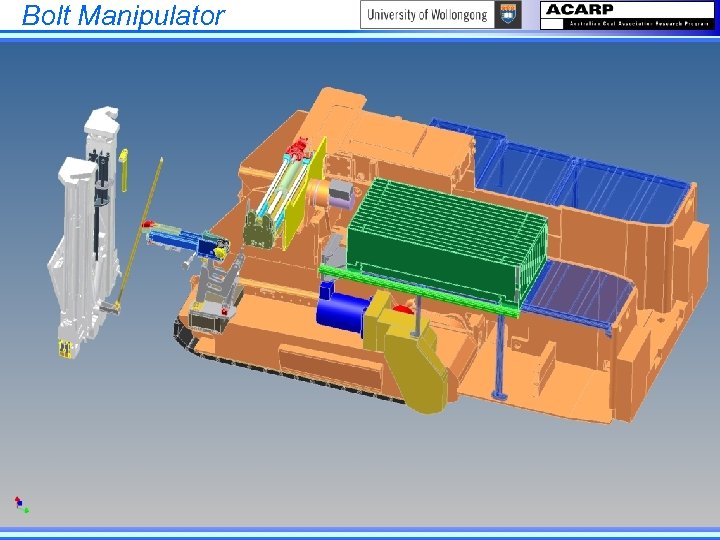

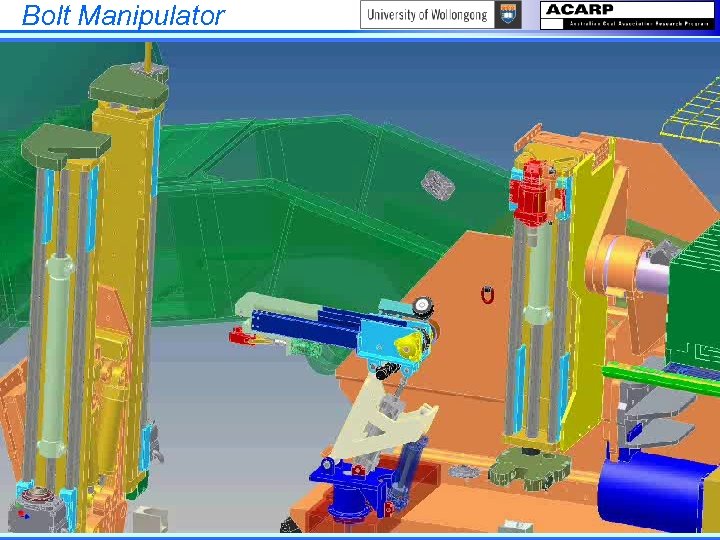

Bolt Manipulator

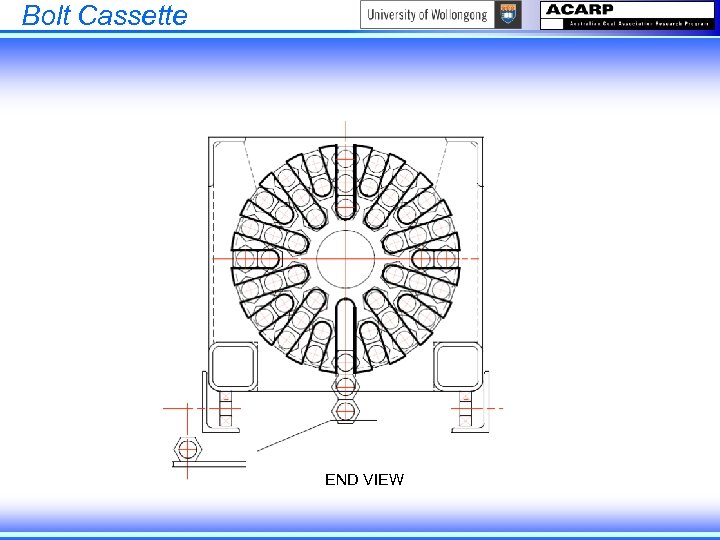

Bolt Cassette

Bolt Cassette

Bolt Cassette END VIEW

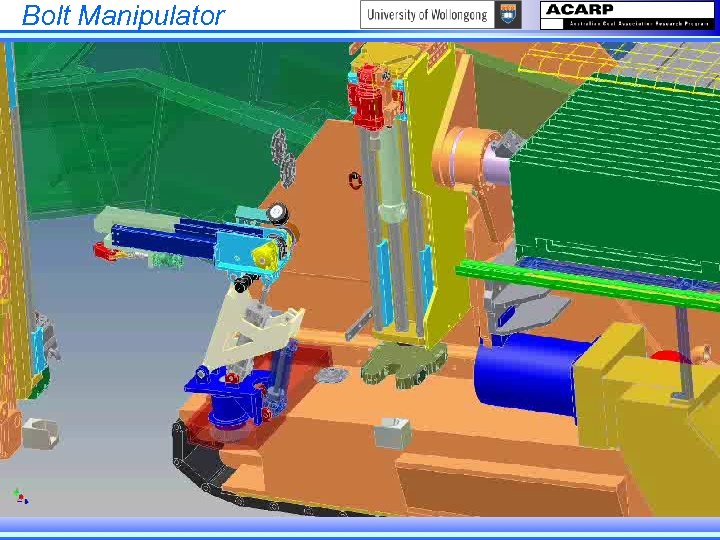

Bolt Manipulator

Bolt Manipulator

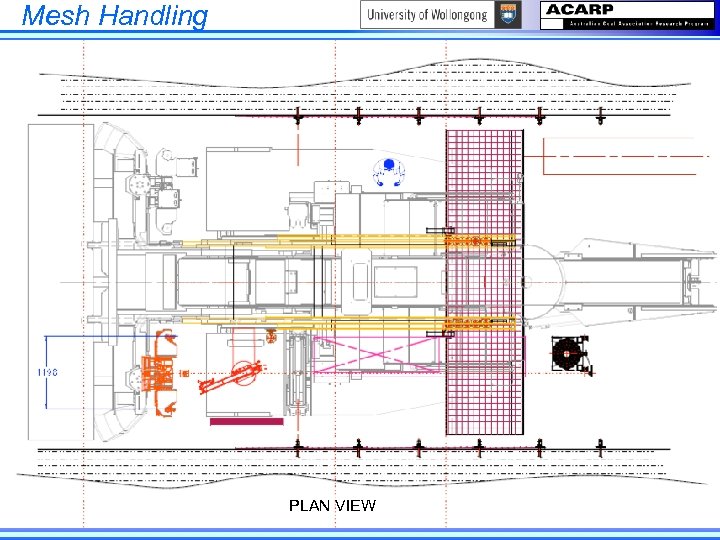

Mesh Handling PLAN VIEW

Mesh Handling PLAN VIEW SIDE VIEW

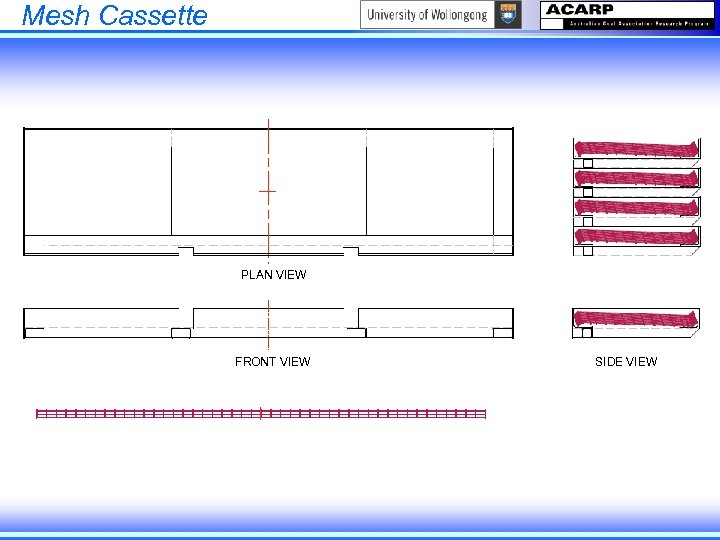

Mesh Cassette PLAN VIEW FRONT VIEW SIDE VIEW

Where to from here Year one • Shortly we should be demonstrating the automatic loading of self drilling bolts into a drilling rig. Demonstration is to be in the laboratory using a prototype manipulator currently being fabricated. Year two • Demonstration of mesh handling system. Beyond this project • Modification of prototype system for underground trials • Transfer of research over to OEM’s for commercialisation and further development.

912e371b8a6add4e394c77c75d5892ab.ppt