815f01b53e2e94e99d569d3b59d3b17c.ppt

- Количество слайдов: 41

RESEARCH AND TEACHING PLAN Presentation to: Department of Information and Decision Sciences College of Business Administration University of Texas at El Paso 1

RESEARCH AND TEACHING PLAN Presentation to: Department of Information and Decision Sciences College of Business Administration University of Texas at El Paso 1

PRESENTATION OUTLINE • Describe an “interesting” research project • Present an overview of current research and teaching interests/projects • Discuss my vision for the future 2

PRESENTATION OUTLINE • Describe an “interesting” research project • Present an overview of current research and teaching interests/projects • Discuss my vision for the future 2

“Interesting” Research Project: KABOM knowledge/activity based operations modeling With Carey Mc. Cleskey, Edgar Zapata, Russ Rhodes Advanced Projects, NASA Kennedy Space Center, FL 3

“Interesting” Research Project: KABOM knowledge/activity based operations modeling With Carey Mc. Cleskey, Edgar Zapata, Russ Rhodes Advanced Projects, NASA Kennedy Space Center, FL 3

Outline for this section • Introduction • Previous work • KABOM • Project Extensions • Project Status 4

Outline for this section • Introduction • Previous work • KABOM • Project Extensions • Project Status 4

Introduction do you know? • The cost per space shuttle flight? • During the design of shuttle, the designers expected/planned the time between flights to be: a) < 1 week b) < 1 month c) 1 - 2 months d) 3 - 4 months e) > 5 months • From the above, what is the current average time between flights? • What is the shuttle’s design reliability? 5

Introduction do you know? • The cost per space shuttle flight? • During the design of shuttle, the designers expected/planned the time between flights to be: a) < 1 week b) < 1 month c) 1 - 2 months d) 3 - 4 months e) > 5 months • From the above, what is the current average time between flights? • What is the shuttle’s design reliability? 5

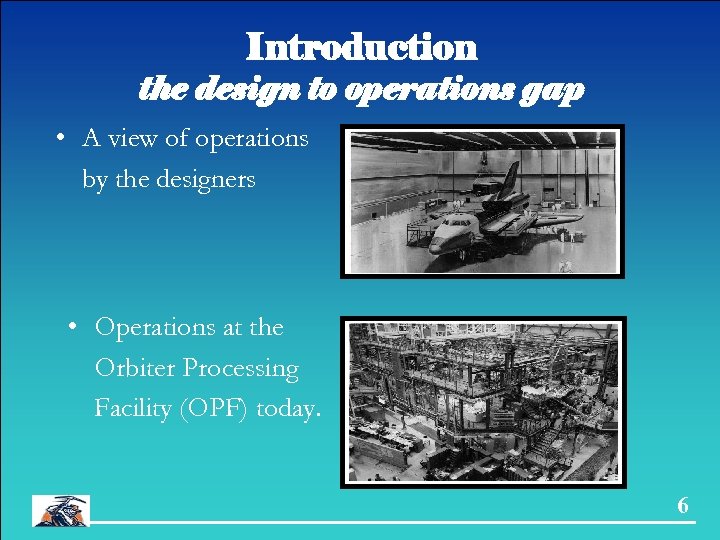

Introduction the design to operations gap • A view of operations by the designers • Operations at the Orbiter Processing Facility (OPF) today. 6

Introduction the design to operations gap • A view of operations by the designers • Operations at the Orbiter Processing Facility (OPF) today. 6

Introduction the causes • Space vehicles are complex systems • Operations was not a primary concern of designers – Design process focused on the rocket equation – Primary operations concern: how do we use existing facilities – Once the vehicle worked - up to Kennedy to make it work. • Minimizing cost was an objective (NASA’s budget has had its ups and downs), BUT it was a “myopic” view, minimize development cost or minimize manufacturing cost, seldom a total cost view. 7

Introduction the causes • Space vehicles are complex systems • Operations was not a primary concern of designers – Design process focused on the rocket equation – Primary operations concern: how do we use existing facilities – Once the vehicle worked - up to Kennedy to make it work. • Minimizing cost was an objective (NASA’s budget has had its ups and downs), BUT it was a “myopic” view, minimize development cost or minimize manufacturing cost, seldom a total cost view. 7

Introduction things are changing • NASA is changing. – Moving from a service provider to a support and monitoring entity • Space business environment is changing – Commercial launch capabilities have increased. • Facilities in old USSR, Guyana, Brazil, China, and even sea launches – Need for launches has increased, exceeding capacity – Interest in other commercial uses of space • Hilton Space Hotels? - spacehotels – The X Prize 8

Introduction things are changing • NASA is changing. – Moving from a service provider to a support and monitoring entity • Space business environment is changing – Commercial launch capabilities have increased. • Facilities in old USSR, Guyana, Brazil, China, and even sea launches – Need for launches has increased, exceeding capacity – Interest in other commercial uses of space • Hilton Space Hotels? - spacehotels – The X Prize 8

Outline for this section • Introduction • Previous work • KABOM • Project Extensions • Project Status 9

Outline for this section • Introduction • Previous work • KABOM • Project Extensions • Project Status 9

Previous work vision spaceport • Team approach > ground operations modeling – Includes NASA KSC and Ames, Lockheed Martin, Boeing, SIAC, and other related government, university, and private organizations. – My role: NASA fellow for the summers of 1998 and 1999. • Objectives: – Develop models to asses new designs: spaceport operations - life cycle costs – Educate vehicle designers on spaceport operations – Connect model to design/development models and manufacturing models 10

Previous work vision spaceport • Team approach > ground operations modeling – Includes NASA KSC and Ames, Lockheed Martin, Boeing, SIAC, and other related government, university, and private organizations. – My role: NASA fellow for the summers of 1998 and 1999. • Objectives: – Develop models to asses new designs: spaceport operations - life cycle costs – Educate vehicle designers on spaceport operations – Connect model to design/development models and manufacturing models 10

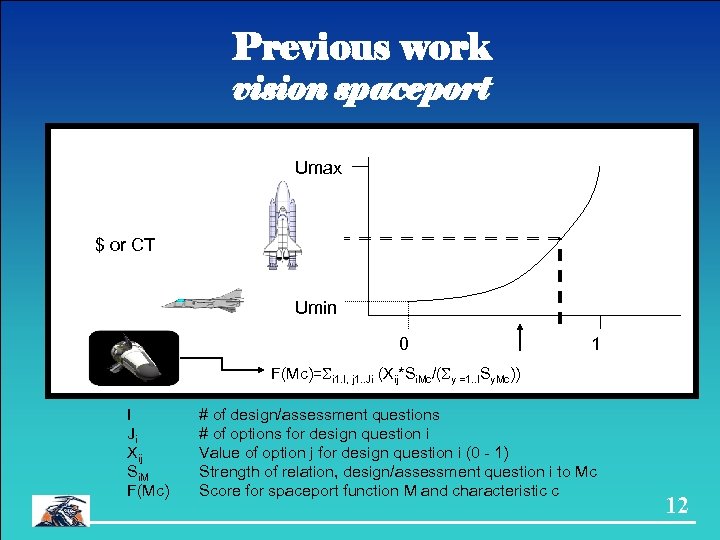

Previous work vision spaceport • First approach – Knowledge based utility functions – Mapped vehicle inputs to spaceport functions. • Functions provided sense of direction: was the design an improvement over the baseline for a function. Cost and times derived from the deviation • Developed a tool in Excel/VB: AATe. – NASA Copyright. – Used in several studies at Marshal and Langley. – Modeling approach was applied in a second tool application developed by CCT. 11

Previous work vision spaceport • First approach – Knowledge based utility functions – Mapped vehicle inputs to spaceport functions. • Functions provided sense of direction: was the design an improvement over the baseline for a function. Cost and times derived from the deviation • Developed a tool in Excel/VB: AATe. – NASA Copyright. – Used in several studies at Marshal and Langley. – Modeling approach was applied in a second tool application developed by CCT. 11

Previous work vision spaceport Umax $ or CT Umin 0 1 F(Mc)=Si 1. I, j 1. . Ji (Xij*Si. Mc/(Sy =1. . ISy. Mc)) I Ji Xij Si. M F(Mc) # of design/assessment questions # of options for design question i Value of option j for design question i (0 - 1) Strength of relation, design/assessment question i to Mc Score for spaceport function M and characteristic c 12

Previous work vision spaceport Umax $ or CT Umin 0 1 F(Mc)=Si 1. I, j 1. . Ji (Xij*Si. Mc/(Sy =1. . ISy. Mc)) I Ji Xij Si. M F(Mc) # of design/assessment questions # of options for design question i Value of option j for design question i (0 - 1) Strength of relation, design/assessment question i to Mc Score for spaceport function M and characteristic c 12

Outline for this section • Introduction • Previous work • KABOM • Project Extensions • Project Status 13

Outline for this section • Introduction • Previous work • KABOM • Project Extensions • Project Status 13

Knowledge/Activity based Operations Modeling (KABOM) • Objective: – To asses the operational requirements of a vehicle design. Determine: • Cost per flight (cost per pound) and Cycle time • Processes and Resources required – Present to vehicle designers the processes required for operation – Address limitations of the utility function approach • Dissipate effect an expert will have captures • Difficult to calibrate as inputs increase • Limited representation of reliability effect 14

Knowledge/Activity based Operations Modeling (KABOM) • Objective: – To asses the operational requirements of a vehicle design. Determine: • Cost per flight (cost per pound) and Cycle time • Processes and Resources required – Present to vehicle designers the processes required for operation – Address limitations of the utility function approach • Dissipate effect an expert will have captures • Difficult to calibrate as inputs increase • Limited representation of reliability effect 14

KABOM Basics Origins • Related to ABC models - used in manufacturing and SCM • Similar to the approach used by Christenson and Komar (1998) to model/ analyze reusable rocket engine operability • Primarily for online functions (landing, turnaround, . . ) • Model is a component of total spaceport analysis model which should capture the other spaceport modules (not in flow). – This is a subset of an LCC model that includes development, manufacturing, and operations 15

KABOM Basics Origins • Related to ABC models - used in manufacturing and SCM • Similar to the approach used by Christenson and Komar (1998) to model/ analyze reusable rocket engine operability • Primarily for online functions (landing, turnaround, . . ) • Model is a component of total spaceport analysis model which should capture the other spaceport modules (not in flow). – This is a subset of an LCC model that includes development, manufacturing, and operations 15

KABOM Basics The RLV design • The model characterizes a RLV architecture/concept by I design variables – I represents a particular option of the vehicle, for example ceramic times, ultra high density ceramics, SOFI. – The binary variable di is used to represent the inclusion of a design option; di = 1 if the design option is included in the design and di = 0 if not. 16

KABOM Basics The RLV design • The model characterizes a RLV architecture/concept by I design variables – I represents a particular option of the vehicle, for example ceramic times, ultra high density ceramics, SOFI. – The binary variable di is used to represent the inclusion of a design option; di = 1 if the design option is included in the design and di = 0 if not. 16

KABOM Basics The RLV design • This model characterizes a RLV architecture/concept by J vehicle characteristics/ operational drivers. – The vehicle characteristics J represents measures that will drive operational cost or time, for example the number of fuel cells or the area covered by a type of thermal protection. – The variable qj is used to represent the quantify of an operational driver, qj > 0 if that operational driver exists in the design and qj = 0 if not. 17

KABOM Basics The RLV design • This model characterizes a RLV architecture/concept by J vehicle characteristics/ operational drivers. – The vehicle characteristics J represents measures that will drive operational cost or time, for example the number of fuel cells or the area covered by a type of thermal protection. – The variable qj is used to represent the quantify of an operational driver, qj > 0 if that operational driver exists in the design and qj = 0 if not. 17

KABOM Basics The Activities • There are A spaceport activities. – Activities relate to one or more design variables. – The binary variable sa represents the inclusion of that activity in the activity set for that design; sa = 1 if that activity is part of the activity set and sa = 0 if it is not. – The determination of the activity set is determined by knowledge based equations. I. E. : s 3 = s 7 = 1 , if d 1 + d 12 = 2 0, otherwise 1 , if d 11 = 0 and d 123 = 1 or if q 56 > 100 0, otherwise 18

KABOM Basics The Activities • There are A spaceport activities. – Activities relate to one or more design variables. – The binary variable sa represents the inclusion of that activity in the activity set for that design; sa = 1 if that activity is part of the activity set and sa = 0 if it is not. – The determination of the activity set is determined by knowledge based equations. I. E. : s 3 = s 7 = 1 , if d 1 + d 12 = 2 0, otherwise 1 , if d 11 = 0 and d 123 = 1 or if q 56 > 100 0, otherwise 18

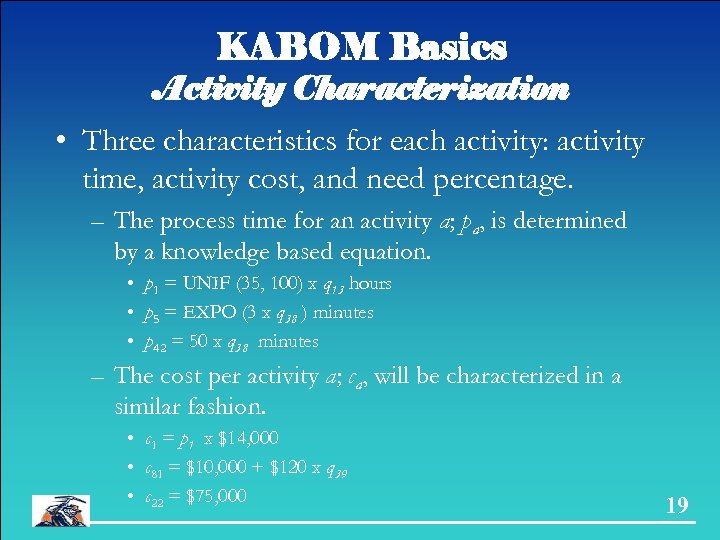

KABOM Basics Activity Characterization • Three characteristics for each activity: activity time, activity cost, and need percentage. – The process time for an activity a; pa, is determined by a knowledge based equation. • p 1 = UNIF (35, 100) x q 13 hours • p 5 = EXPO (3 x q 38 ) minutes • p 42 = 50 x q 38 minutes – The cost per activity a; ca, will be characterized in a similar fashion. • c 1 = p 1 x $14, 000 • c 81 = $10, 000 + $120 x q 39 • c 22 = $75, 000 19

KABOM Basics Activity Characterization • Three characteristics for each activity: activity time, activity cost, and need percentage. – The process time for an activity a; pa, is determined by a knowledge based equation. • p 1 = UNIF (35, 100) x q 13 hours • p 5 = EXPO (3 x q 38 ) minutes • p 42 = 50 x q 38 minutes – The cost per activity a; ca, will be characterized in a similar fashion. • c 1 = p 1 x $14, 000 • c 81 = $10, 000 + $120 x q 39 • c 22 = $75, 000 19

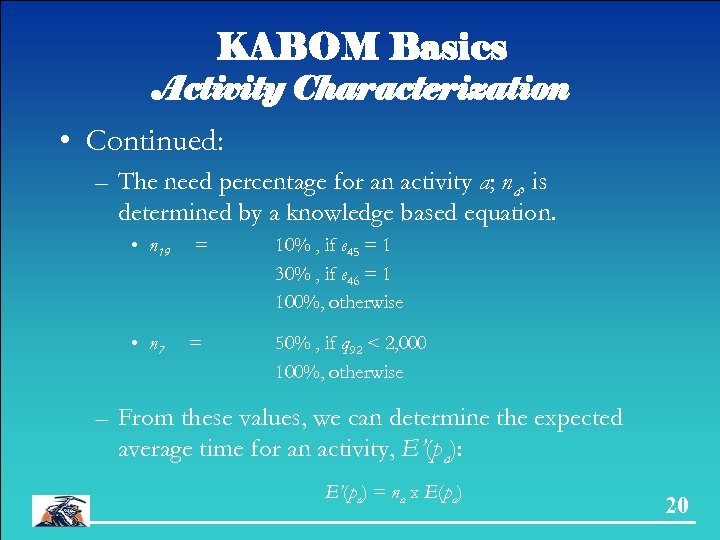

KABOM Basics Activity Characterization • Continued: – The need percentage for an activity a; na, is determined by a knowledge based equation. • n 19 • n 7 = = 10% , if e 45 = 1 30% , if e 46 = 1 100%, otherwise 50% , if q 92 < 2, 000 100%, otherwise – From these values, we can determine the expected average time for an activity, E’(pa): E’(pa) = na x E(pa) 20

KABOM Basics Activity Characterization • Continued: – The need percentage for an activity a; na, is determined by a knowledge based equation. • n 19 • n 7 = = 10% , if e 45 = 1 30% , if e 46 = 1 100%, otherwise 50% , if q 92 < 2, 000 100%, otherwise – From these values, we can determine the expected average time for an activity, E’(pa): E’(pa) = na x E(pa) 20

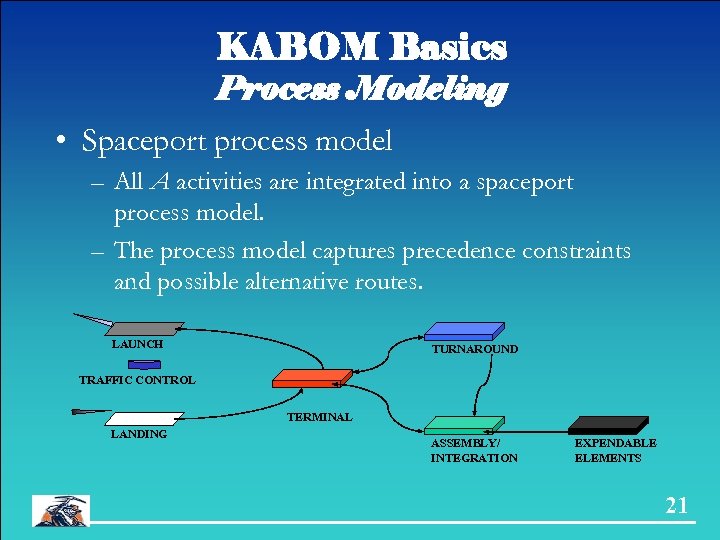

KABOM Basics Process Modeling • Spaceport process model – All A activities are integrated into a spaceport process model. – The process model captures precedence constraints and possible alternative routes. LAUNCH TURNAROUND TRAFFIC CONTROL TERMINAL LANDING ASSEMBLY/ INTEGRATION EXPENDABLE ELEMENTS 21

KABOM Basics Process Modeling • Spaceport process model – All A activities are integrated into a spaceport process model. – The process model captures precedence constraints and possible alternative routes. LAUNCH TURNAROUND TRAFFIC CONTROL TERMINAL LANDING ASSEMBLY/ INTEGRATION EXPENDABLE ELEMENTS 21

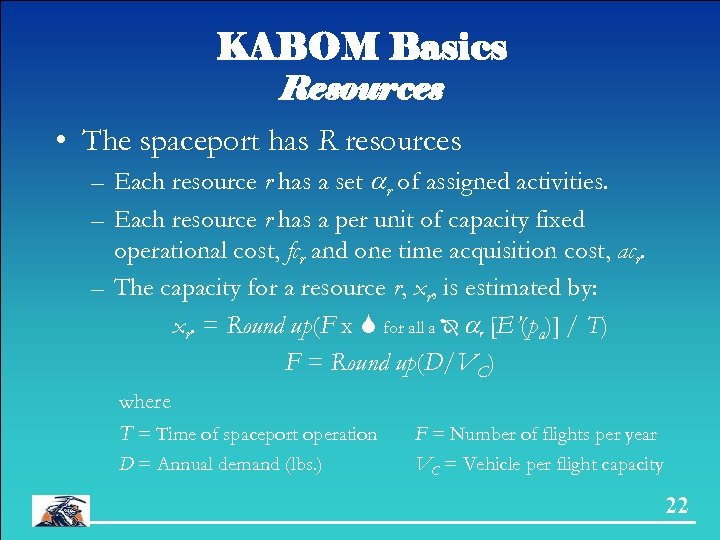

KABOM Basics Resources • The spaceport has R resources – Each resource r has a set r of assigned activities. – Each resource r has a per unit of capacity fixed operational cost, fcr and one time acquisition cost, acr. – The capacity for a resource r, xr, is estimated by: xr. = Round up(F x for all a r [E’(pa)] / T) F = Round up(D/VC) where T = Time of spaceport operation D = Annual demand (lbs. ) F = Number of flights per year VC = Vehicle per flight capacity 22

KABOM Basics Resources • The spaceport has R resources – Each resource r has a set r of assigned activities. – Each resource r has a per unit of capacity fixed operational cost, fcr and one time acquisition cost, acr. – The capacity for a resource r, xr, is estimated by: xr. = Round up(F x for all a r [E’(pa)] / T) F = Round up(D/VC) where T = Time of spaceport operation D = Annual demand (lbs. ) F = Number of flights per year VC = Vehicle per flight capacity 22

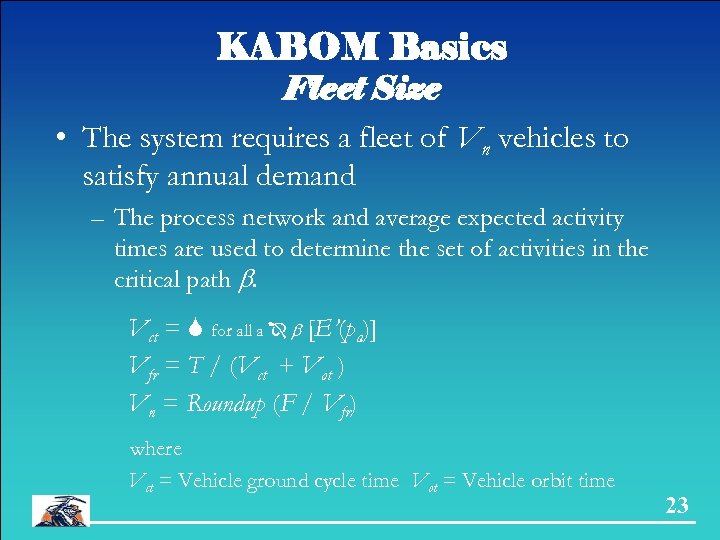

KABOM Basics Fleet Size • The system requires a fleet of Vn vehicles to satisfy annual demand – The process network and average expected activity times are used to determine the set of activities in the critical path . Vct = for all a [E’(pa)] Vfr = T / (Vct + Vot ) Vn = Roundup (F / Vfr) where Vct = Vehicle ground cycle time Vot = Vehicle orbit time 23

KABOM Basics Fleet Size • The system requires a fleet of Vn vehicles to satisfy annual demand – The process network and average expected activity times are used to determine the set of activities in the critical path . Vct = for all a [E’(pa)] Vfr = T / (Vct + Vot ) Vn = Roundup (F / Vfr) where Vct = Vehicle ground cycle time Vot = Vehicle orbit time 23

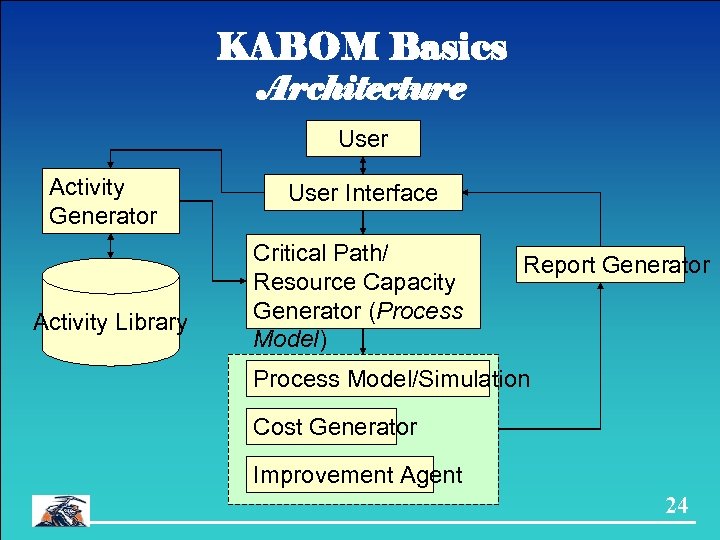

KABOM Basics Architecture User Activity Generator Activity Library User Interface Critical Path/ Resource Capacity Generator (Process Model) Report Generator Process Model/Simulation Cost Generator Improvement Agent 24

KABOM Basics Architecture User Activity Generator Activity Library User Interface Critical Path/ Resource Capacity Generator (Process Model) Report Generator Process Model/Simulation Cost Generator Improvement Agent 24

KABOM Basics Simulation Model • Why the use of simulation: – Better representation of a dynamic environment. – Estimate bottlenecks, resource utilization, queues, . . . , costs (VS Team objective 1). – Provide designers a graphical (animation) representation of their system at work. . (Team objective 2) – Allows the evaluation of scenarios. • For example, a version of the model could be developed where two types of vehicles can be modeled (I. e. Shuttle and Venture Star). 25

KABOM Basics Simulation Model • Why the use of simulation: – Better representation of a dynamic environment. – Estimate bottlenecks, resource utilization, queues, . . . , costs (VS Team objective 1). – Provide designers a graphical (animation) representation of their system at work. . (Team objective 2) – Allows the evaluation of scenarios. • For example, a version of the model could be developed where two types of vehicles can be modeled (I. e. Shuttle and Venture Star). 25

KABOM Basics Improvement Agent and Cost Calculations • Improvement Agent – Heuristic to improve total performance. • The heuristics will recommend changes to resource capacity and/or fleet size parameters. Several iterations are conducted (simulation repeated) until cost improvements are not obtained. • Cost calculations – Activity costs tracked during the simulation run. – Total costs include activity costs and resource related costs – Vehicle acquisition costs are included as an input from the designers. 26

KABOM Basics Improvement Agent and Cost Calculations • Improvement Agent – Heuristic to improve total performance. • The heuristics will recommend changes to resource capacity and/or fleet size parameters. Several iterations are conducted (simulation repeated) until cost improvements are not obtained. • Cost calculations – Activity costs tracked during the simulation run. – Total costs include activity costs and resource related costs – Vehicle acquisition costs are included as an input from the designers. 26

Outline for this section • Introduction • Previous work • KABOM • Project Extensions • Project Status 27

Outline for this section • Introduction • Previous work • KABOM • Project Extensions • Project Status 27

Project Extensions • Approach used to develop design analysis tools for manufactured products (an advanced ABC analysis) – Help product designers estimate costs/processes – Evaluate what if scenarios in a design (mfg processes) – A “real time” version of the model could estimate the effect of a new product on current system load. • • Order for “customized product” arrives Tool determines activities, costs, . . Order is added to current production schedule Decision on taking the order or how to schedule it 28

Project Extensions • Approach used to develop design analysis tools for manufactured products (an advanced ABC analysis) – Help product designers estimate costs/processes – Evaluate what if scenarios in a design (mfg processes) – A “real time” version of the model could estimate the effect of a new product on current system load. • • Order for “customized product” arrives Tool determines activities, costs, . . Order is added to current production schedule Decision on taking the order or how to schedule it 28

Outline for this section • Introduction • Previous work • KABOM • Project Extensions • Project Status 29

Outline for this section • Introduction • Previous work • KABOM • Project Extensions • Project Status 29

Project Status • A prototype was developed last summer while at KSC • Student project on a web based version of the AATe • Grant proposal - excellent evaluations, waiting for funding. 30

Project Status • A prototype was developed last summer while at KSC • Student project on a web based version of the AATe • Grant proposal - excellent evaluations, waiting for funding. 30

PRESENTATION OUTLINE • Describe an “interesting” research project • Present an overview of current research and teaching interests/projects • Discuss my vision for the future 31

PRESENTATION OUTLINE • Describe an “interesting” research project • Present an overview of current research and teaching interests/projects • Discuss my vision for the future 31

Overview Of Research/ Teaching Interests And Projects • Research – – Production Planning Supply Chain Management IS/OM/Simulation Interaction Space operations • Teaching – Games – Excel applications – Advanced POM courses/ APICS/ ERP (Future) 32

Overview Of Research/ Teaching Interests And Projects • Research – – Production Planning Supply Chain Management IS/OM/Simulation Interaction Space operations • Teaching – Games – Excel applications – Advanced POM courses/ APICS/ ERP (Future) 32

Production Planning Research • Cellular manufacturing systems – Development of tools and models to plan/schedule on systems where production resources are organized as cells and products into common families. – Work with Jeet Gupta from Ball State University – Paper in progress • Parallel Machine Scheduling with Multiple Criteria – Development of heuristics for difficult multi-criteria problems in the parallel machine setting. – Work with Jeet Gupta and Kazou Nakatani (FGCU) – Two papers accepted for publication, several in progress. 33

Production Planning Research • Cellular manufacturing systems – Development of tools and models to plan/schedule on systems where production resources are organized as cells and products into common families. – Work with Jeet Gupta from Ball State University – Paper in progress • Parallel Machine Scheduling with Multiple Criteria – Development of heuristics for difficult multi-criteria problems in the parallel machine setting. – Work with Jeet Gupta and Kazou Nakatani (FGCU) – Two papers accepted for publication, several in progress. 33

Supply Chain Management Research • Supplier Decision Making – Evaluation of the role transportation plays on supplier decision making. – Work with John Tyworth from Penn State University – One paper accepted for publication • Supply Chain Simulation – Development of simulation models for supply chain environments in order to evaluate transportation and scheduling priorities. . – Work with John Tyworth 34

Supply Chain Management Research • Supplier Decision Making – Evaluation of the role transportation plays on supplier decision making. – Work with John Tyworth from Penn State University – One paper accepted for publication • Supply Chain Simulation – Development of simulation models for supply chain environments in order to evaluate transportation and scheduling priorities. . – Work with John Tyworth 34

Interaction of IS, OM, and simulation • Supply Chain Management – Development of architecture to support “real time” DM. . – Utilizes simulation to investigate “what if” scenarios. – Work with J. Tyworth and K. Nakatani. • Project Management – Development of architecture to support Web based project management. – Utilizes simulation to evaluate the CP and effect of “what if” scenarios. – Prototype developed and tested at NASA. – Work with K. Nakatani. 35

Interaction of IS, OM, and simulation • Supply Chain Management – Development of architecture to support “real time” DM. . – Utilizes simulation to investigate “what if” scenarios. – Work with J. Tyworth and K. Nakatani. • Project Management – Development of architecture to support Web based project management. – Utilizes simulation to evaluate the CP and effect of “what if” scenarios. – Prototype developed and tested at NASA. – Work with K. Nakatani. 35

OM Games/Exercises • Development/application of class games to enhance student learning – Beer game from Jacobs web page – In-class exercises after “lecture”. • QFD - development of a QFD diagram for a business class • SPC - process simulation – JIT game with Lego/remote controlled cars (Rokenbok) 36

OM Games/Exercises • Development/application of class games to enhance student learning – Beer game from Jacobs web page – In-class exercises after “lecture”. • QFD - development of a QFD diagram for a business class • SPC - process simulation – JIT game with Lego/remote controlled cars (Rokenbok) 36

Excel Applications • Use of Excel for operations analysis – – Data analysis/ “real time” behavior graphs Queue models Forecasting Capacity Analysis • Use of Excel for quantitative methods course – Math Programming – VB front end – “Real world” application development 37

Excel Applications • Use of Excel for operations analysis – – Data analysis/ “real time” behavior graphs Queue models Forecasting Capacity Analysis • Use of Excel for quantitative methods course – Math Programming – VB front end – “Real world” application development 37

PRESENTATION OUTLINE • Describe an “interesting” research project • Present an overview of current research and teaching interests/projects • Discuss my vision for the future 38

PRESENTATION OUTLINE • Describe an “interesting” research project • Present an overview of current research and teaching interests/projects • Discuss my vision for the future 38

My vision of the future research • Continue research on all four areas – SS: applications of KABOM to manufacturing, IS/Simulation, Production Planning, SCM – Publication in leading journals, – Long term - editor of leading journal • Develop relationships with manufacturers in El Paso and Juarez. • Manufacturing-Logistics Center? - outreach program. – Foster knowledge creation in the ML field - faculty and student projects, grants, . . – Foster business 2 business partnerships/creation of new businesses – Continuing education programs? 39

My vision of the future research • Continue research on all four areas – SS: applications of KABOM to manufacturing, IS/Simulation, Production Planning, SCM – Publication in leading journals, – Long term - editor of leading journal • Develop relationships with manufacturers in El Paso and Juarez. • Manufacturing-Logistics Center? - outreach program. – Foster knowledge creation in the ML field - faculty and student projects, grants, . . – Foster business 2 business partnerships/creation of new businesses – Continuing education programs? 39

My vision of the future teaching • Teaching/POM – Continue development of teaching games • Program/curricula development – Graduate program in Manufacturing Logistics? – Integration of APICS certification into some undergraduate and graduate courses? – Revision of POM undergraduate program? – ERP integration to the POM program? • Link undergraduate POM students to faculty research projects 40

My vision of the future teaching • Teaching/POM – Continue development of teaching games • Program/curricula development – Graduate program in Manufacturing Logistics? – Integration of APICS certification into some undergraduate and graduate courses? – Revision of POM undergraduate program? – ERP integration to the POM program? • Link undergraduate POM students to faculty research projects 40

• Thanks for your time • Questions? 41

• Thanks for your time • Questions? 41