Lecture 8_Welding.pptx

- Количество слайдов: 17

Representation of welds on technical drawing THEME 8

Representation of welds on technical drawing THEME 8

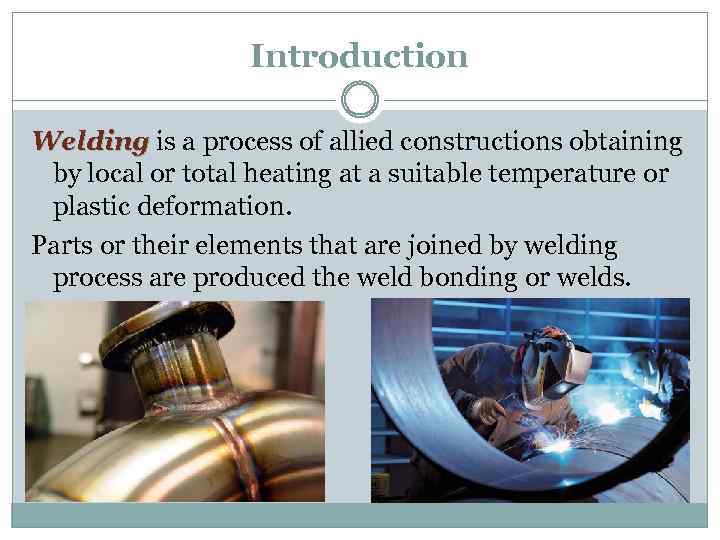

Introduction Welding is a process of allied constructions obtaining by local or total heating at a suitable temperature or plastic deformation. Parts or their elements that are joined by welding process are produced the weld bonding or welds.

Introduction Welding is a process of allied constructions obtaining by local or total heating at a suitable temperature or plastic deformation. Parts or their elements that are joined by welding process are produced the weld bonding or welds.

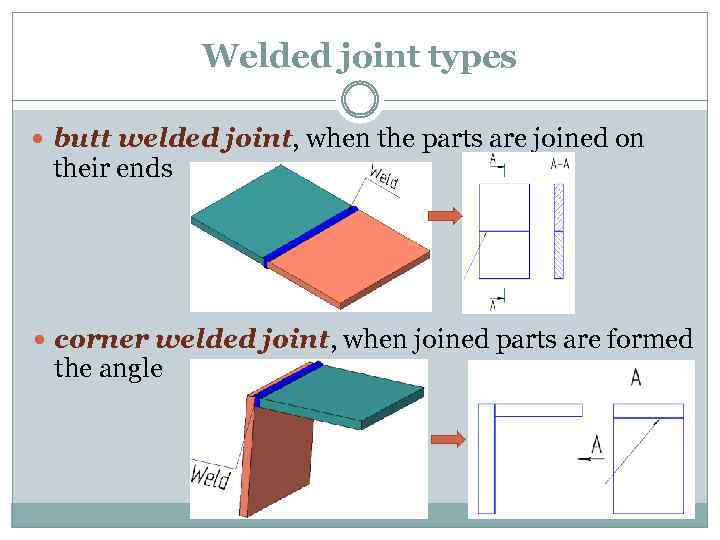

Welded joint types butt welded joint, when the parts are joined on their ends corner welded joint, when joined parts are formed the angle

Welded joint types butt welded joint, when the parts are joined on their ends corner welded joint, when joined parts are formed the angle

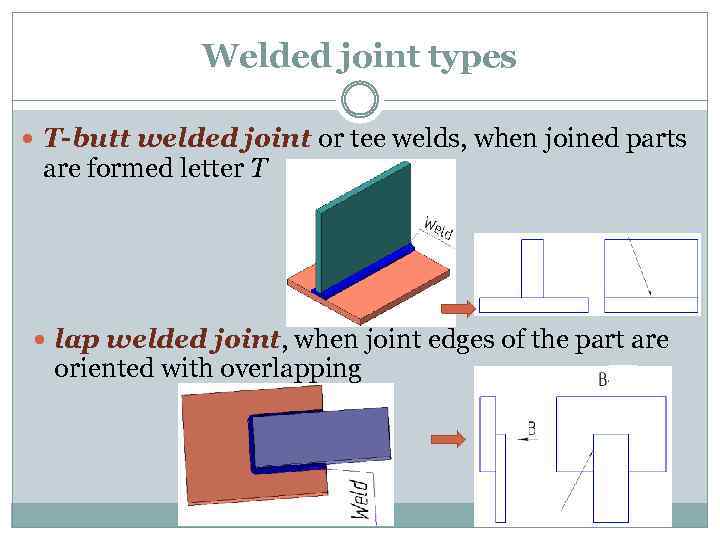

Welded joint types T-butt welded joint or tee welds, when joined parts are formed letter T lap welded joint, when joint edges of the part are oriented with overlapping

Welded joint types T-butt welded joint or tee welds, when joined parts are formed letter T lap welded joint, when joint edges of the part are oriented with overlapping

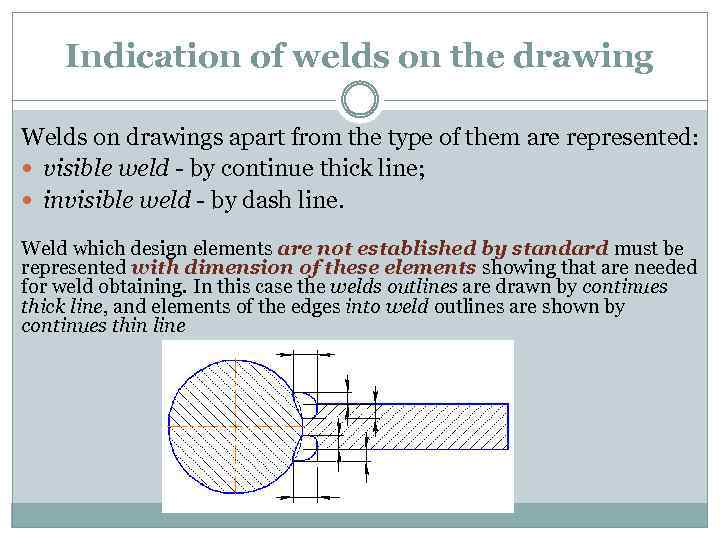

Indication of welds on the drawing Welds on drawings apart from the type of them are represented: visible weld - by continue thick line; invisible weld - by dash line. Weld which design elements are not established by standard must be represented with dimension of these elements showing that are needed for weld obtaining. In this case the welds outlines are drawn by continues thick line, and elements of the edges into weld outlines are shown by continues thin line

Indication of welds on the drawing Welds on drawings apart from the type of them are represented: visible weld - by continue thick line; invisible weld - by dash line. Weld which design elements are not established by standard must be represented with dimension of these elements showing that are needed for weld obtaining. In this case the welds outlines are drawn by continues thick line, and elements of the edges into weld outlines are shown by continues thin line

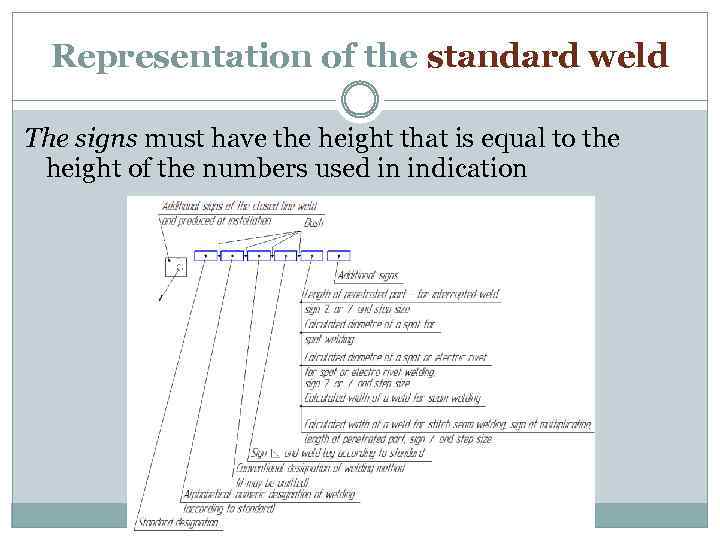

Representation of the standard weld The signs must have the height that is equal to the height of the numbers used in indication

Representation of the standard weld The signs must have the height that is equal to the height of the numbers used in indication

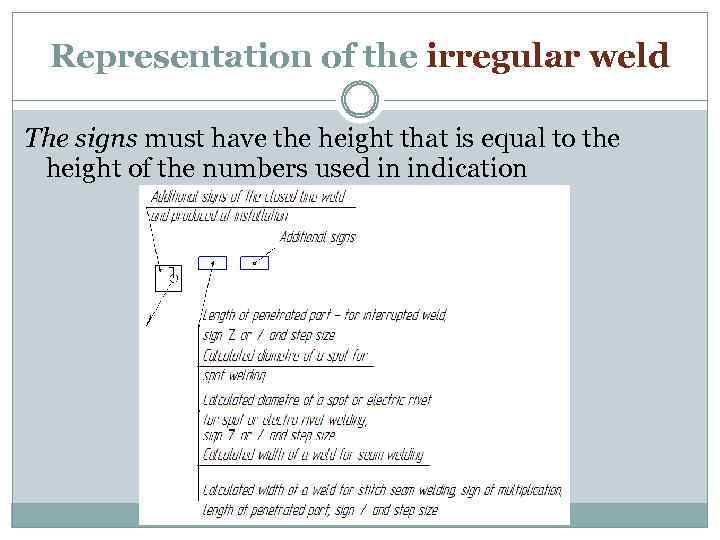

Representation of the irregular weld The signs must have the height that is equal to the height of the numbers used in indication

Representation of the irregular weld The signs must have the height that is equal to the height of the numbers used in indication

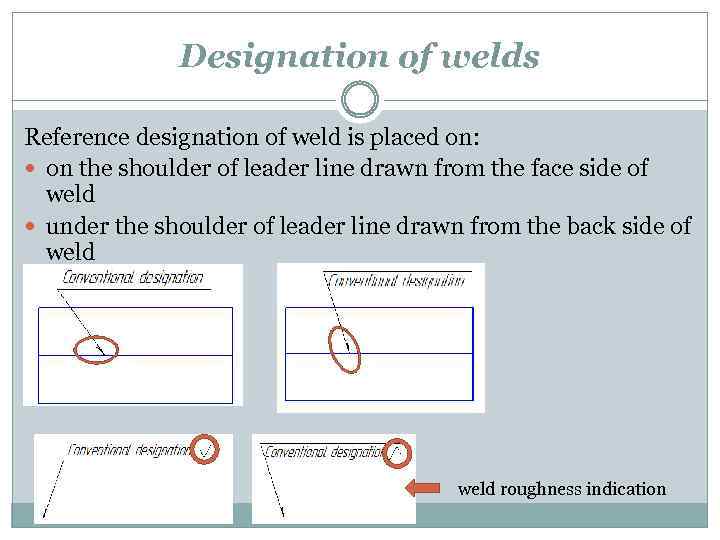

Designation of welds Reference designation of weld is placed on: on the shoulder of leader line drawn from the face side of weld under the shoulder of leader line drawn from the back side of weld roughness indication

Designation of welds Reference designation of weld is placed on: on the shoulder of leader line drawn from the face side of weld under the shoulder of leader line drawn from the back side of weld roughness indication

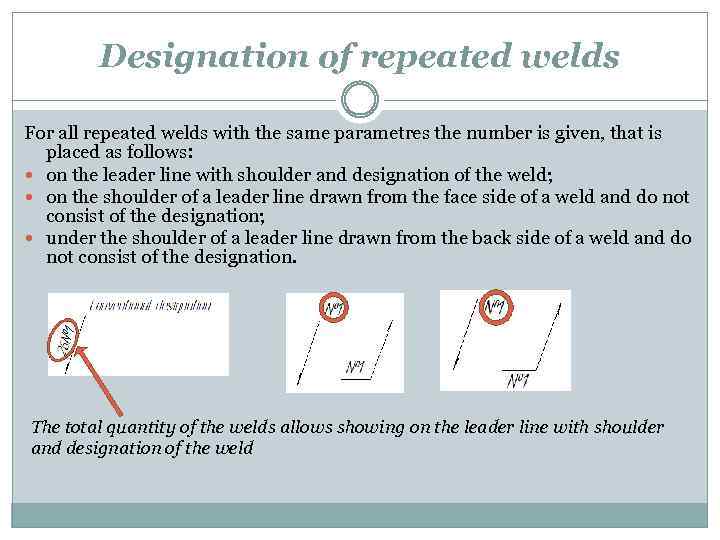

Designation of repeated welds For all repeated welds with the same parametres the number is given, that is placed as follows: on the leader line with shoulder and designation of the weld; on the shoulder of a leader line drawn from the face side of a weld and do not consist of the designation; under the shoulder of a leader line drawn from the back side of a weld and do not consist of the designation. The total quantity of the welds allows showing on the leader line with shoulder and designation of the weld

Designation of repeated welds For all repeated welds with the same parametres the number is given, that is placed as follows: on the leader line with shoulder and designation of the weld; on the shoulder of a leader line drawn from the face side of a weld and do not consist of the designation; under the shoulder of a leader line drawn from the back side of a weld and do not consist of the designation. The total quantity of the welds allows showing on the leader line with shoulder and designation of the weld

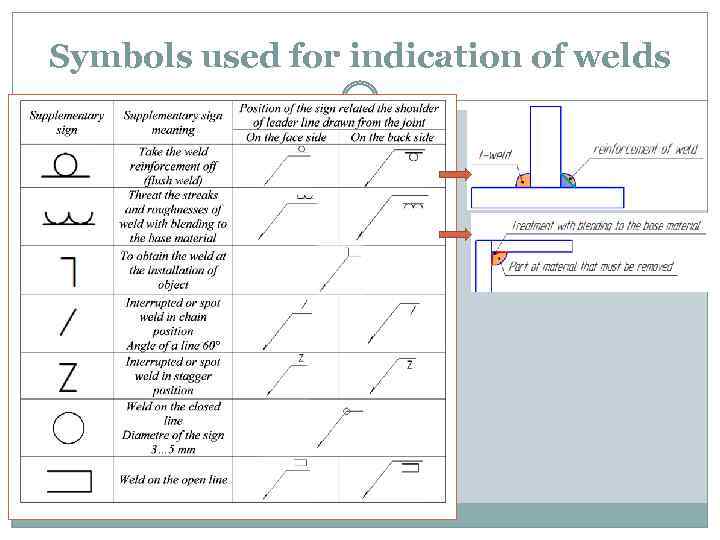

Symbols used for indication of welds

Symbols used for indication of welds

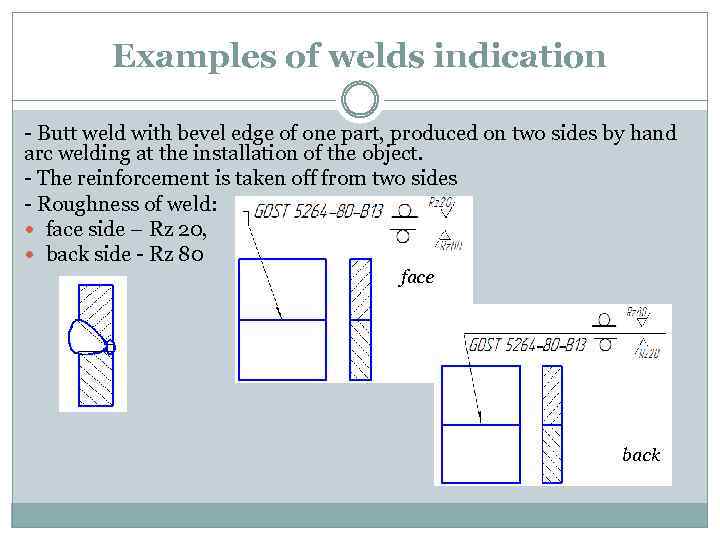

Examples of welds indication - Butt weld with bevel edge of one part, produced on two sides by hand arc welding at the installation of the object. - The reinforcement is taken off from two sides - Roughness of weld: face side – Rz 20, back side - Rz 80 face back

Examples of welds indication - Butt weld with bevel edge of one part, produced on two sides by hand arc welding at the installation of the object. - The reinforcement is taken off from two sides - Roughness of weld: face side – Rz 20, back side - Rz 80 face back

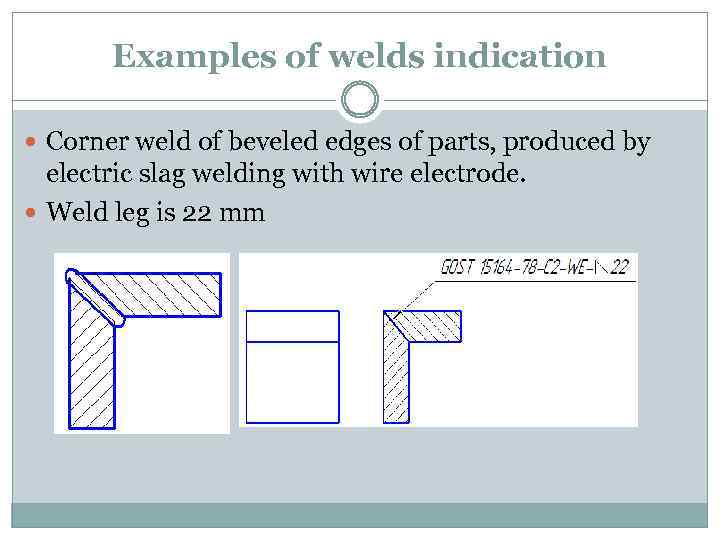

Examples of welds indication Corner weld of beveled edges of parts, produced by electric slag welding with wire electrode. Weld leg is 22 mm

Examples of welds indication Corner weld of beveled edges of parts, produced by electric slag welding with wire electrode. Weld leg is 22 mm

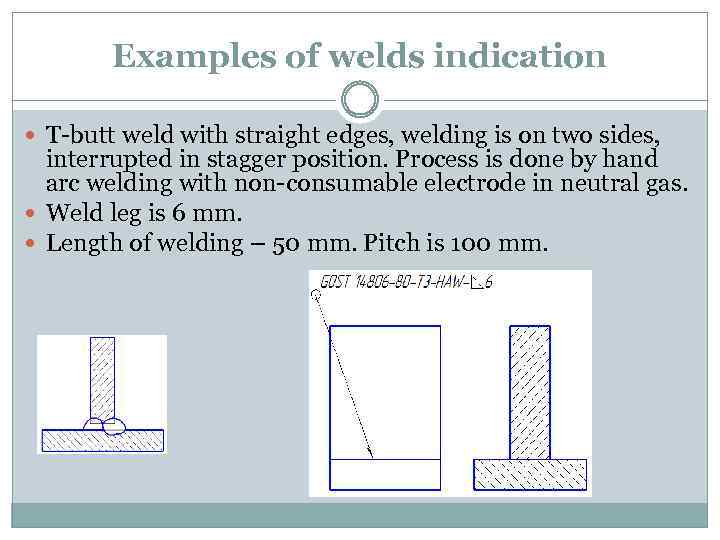

Examples of welds indication T-butt weld with straight edges, welding is on two sides, interrupted in stagger position. Process is done by hand arc welding with non-consumable electrode in neutral gas. Weld leg is 6 mm. Length of welding – 50 mm. Pitch is 100 mm.

Examples of welds indication T-butt weld with straight edges, welding is on two sides, interrupted in stagger position. Process is done by hand arc welding with non-consumable electrode in neutral gas. Weld leg is 6 mm. Length of welding – 50 mm. Pitch is 100 mm.

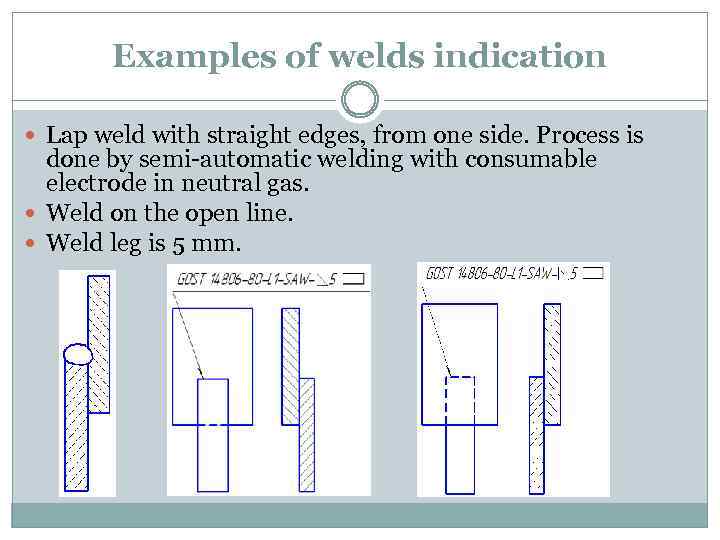

Examples of welds indication Lap weld with straight edges, from one side. Process is done by semi-automatic welding with consumable electrode in neutral gas. Weld on the open line. Weld leg is 5 mm.

Examples of welds indication Lap weld with straight edges, from one side. Process is done by semi-automatic welding with consumable electrode in neutral gas. Weld on the open line. Weld leg is 5 mm.

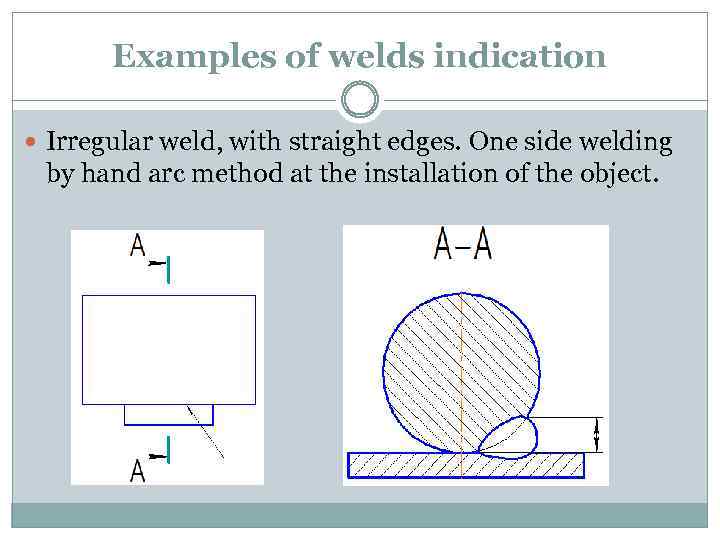

Examples of welds indication Irregular weld, with straight edges. One side welding by hand arc method at the installation of the object.

Examples of welds indication Irregular weld, with straight edges. One side welding by hand arc method at the installation of the object.

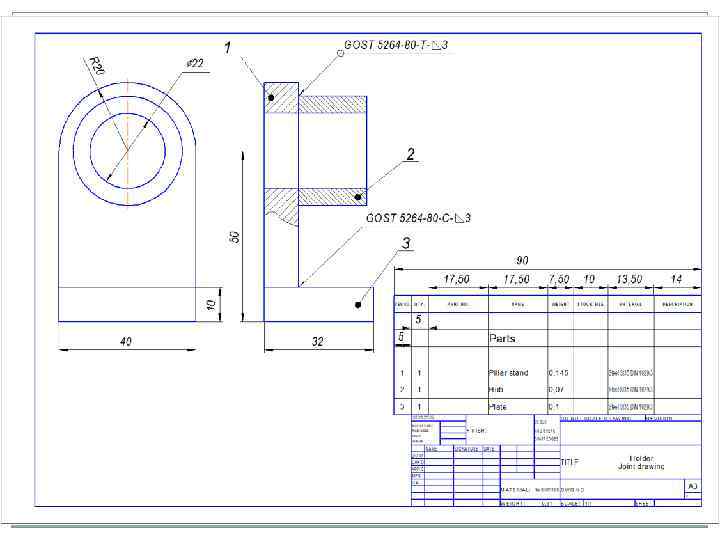

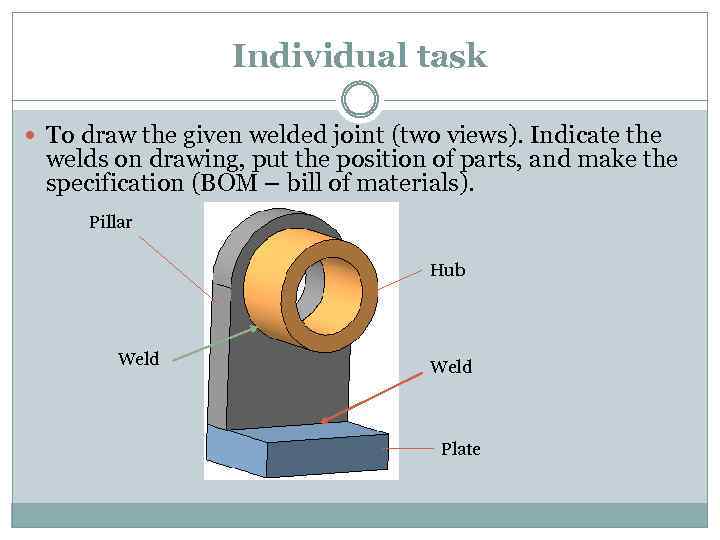

Individual task To draw the given welded joint (two views). Indicate the welds on drawing, put the position of parts, and make the specification (BOM – bill of materials). Pillar Hub Weld Plate

Individual task To draw the given welded joint (two views). Indicate the welds on drawing, put the position of parts, and make the specification (BOM – bill of materials). Pillar Hub Weld Plate