bc2ee317bb445d0ab874139f5f2cffd5.ppt

- Количество слайдов: 71

Reporting on I&C Status & Recommendations to the IAEA on NPP I&C IAEA TWG-NPPIC meeting, Vienna, May 20 -22 2009 Dr. Davide Roverso Manager COSS OECD Halden Reactor Project Institute for energy technology (IFE) NORWAY

Reporting on I&C Status & Recommendations to the IAEA on NPP I&C IAEA TWG-NPPIC meeting, Vienna, May 20 -22 2009 Dr. Davide Roverso Manager COSS OECD Halden Reactor Project Institute for energy technology (IFE) NORWAY

Nuclear installations in Norway • The Institute for energy technology, , operates two research reactors, the only nuclear installations in Norway • Halden Boiling Water Reactor (HBWR) • 20 MW, used for research on fuel and materials • High burn-up, water chemistry, stress corrosion cracking, . . . • JEEP II Reactor – Kjeller • 2 MW, used for basic physics research, • Neutron source for Neutron Activation Analysis (NAA) • Nanomaterials, silisium doping, . . . 2

Nuclear installations in Norway • The Institute for energy technology, , operates two research reactors, the only nuclear installations in Norway • Halden Boiling Water Reactor (HBWR) • 20 MW, used for research on fuel and materials • High burn-up, water chemistry, stress corrosion cracking, . . . • JEEP II Reactor – Kjeller • 2 MW, used for basic physics research, • Neutron source for Neutron Activation Analysis (NAA) • Nanomaterials, silisium doping, . . . 2

NPP I&C Activities • Most NPP I&C activities at IFE are conducted as part of the OECD Halden Reactor Project (HRP) • International co-operative effort affiliated to OECD NEA in Paris • Project established in 1958 (50 years’ celebrated in 2008) • Jointly funded by its Members: • 18 countries • > 100 nuclear organisations world wide • Hosted and run by IFE, Norway • Participant types • Utilities, Vendors, Licensing Authorities and R&D centres 3

NPP I&C Activities • Most NPP I&C activities at IFE are conducted as part of the OECD Halden Reactor Project (HRP) • International co-operative effort affiliated to OECD NEA in Paris • Project established in 1958 (50 years’ celebrated in 2008) • Jointly funded by its Members: • 18 countries • > 100 nuclear organisations world wide • Hosted and run by IFE, Norway • Participant types • Utilities, Vendors, Licensing Authorities and R&D centres 3

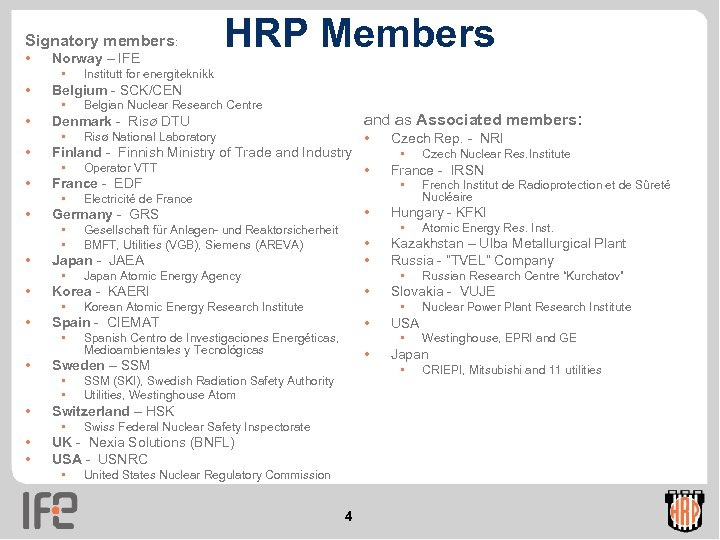

Signatory members: • Norway – IFE • • Swiss Federal Nuclear Safety Inspectorate UK - Nexia Solutions (BNFL) USA - USNRC • United States Nuclear Regulatory Commission 4 Nuclear Power Plant Research Institute USA Westinghouse, EPRI and GE Japan • SSM (SKI), Swedish Radiation Safety Authority Utilities, Westinghouse Atom Russian Research Centre “Kurchatov” Slovakia - VUJE • Spanish Centro de Investigaciones Energéticas, Medioambientales y Tecnológicas Atomic Energy Res. Inst. Kazakhstan – Ulba Metallurgical Plant Russia - “TVEL” Company • Korean Atomic Energy Research Institute French Institut de Radioprotection et de Sûreté Nucléaire Hungary - KFKI • Japan Atomic Energy Agency Switzerland – HSK • • • Czech Nuclear Res. Institute France - IRSN • Gesellschaft für Anlagen- und Reaktorsicherheit BMFT, Utilities (VGB), Siemens (AREVA) Sweden – SSM • • Spain - CIEMAT • Czech Rep. - NRI • Electricité de France Korea - KAERI • • • Japan - JAEA • • Operator VTT Germany - GRS • • • Risø National Laboratory France - EDF • • and as Associated members: Finland - Finnish Ministry of Trade and Industry • • Belgian Nuclear Research Centre Denmark - Risø DTU • • Institutt for energiteknikk Belgium - SCK/CEN • • HRP Members CRIEPI, Mitsubishi and 11 utilities

Signatory members: • Norway – IFE • • Swiss Federal Nuclear Safety Inspectorate UK - Nexia Solutions (BNFL) USA - USNRC • United States Nuclear Regulatory Commission 4 Nuclear Power Plant Research Institute USA Westinghouse, EPRI and GE Japan • SSM (SKI), Swedish Radiation Safety Authority Utilities, Westinghouse Atom Russian Research Centre “Kurchatov” Slovakia - VUJE • Spanish Centro de Investigaciones Energéticas, Medioambientales y Tecnológicas Atomic Energy Res. Inst. Kazakhstan – Ulba Metallurgical Plant Russia - “TVEL” Company • Korean Atomic Energy Research Institute French Institut de Radioprotection et de Sûreté Nucléaire Hungary - KFKI • Japan Atomic Energy Agency Switzerland – HSK • • • Czech Nuclear Res. Institute France - IRSN • Gesellschaft für Anlagen- und Reaktorsicherheit BMFT, Utilities (VGB), Siemens (AREVA) Sweden – SSM • • Spain - CIEMAT • Czech Rep. - NRI • Electricité de France Korea - KAERI • • • Japan - JAEA • • Operator VTT Germany - GRS • • • Risø National Laboratory France - EDF • • and as Associated members: Finland - Finnish Ministry of Trade and Industry • • Belgian Nuclear Research Centre Denmark - Risø DTU • • Institutt for energiteknikk Belgium - SCK/CEN • • HRP Members CRIEPI, Mitsubishi and 11 utilities

HRP Activity Sectors • Nuclear Safety and Reliability • Operation of Halden BWR • Fuel and Materials technology research • 140 employees • Safety MTO – Man Technology and Organization • • • Human performance and reliability Control room technology Virtual Reality (VR) technology Operator Support Systems Software Systems Dependability 85 employees I&C 5

HRP Activity Sectors • Nuclear Safety and Reliability • Operation of Halden BWR • Fuel and Materials technology research • 140 employees • Safety MTO – Man Technology and Organization • • • Human performance and reliability Control room technology Virtual Reality (VR) technology Operator Support Systems Software Systems Dependability 85 employees I&C 5

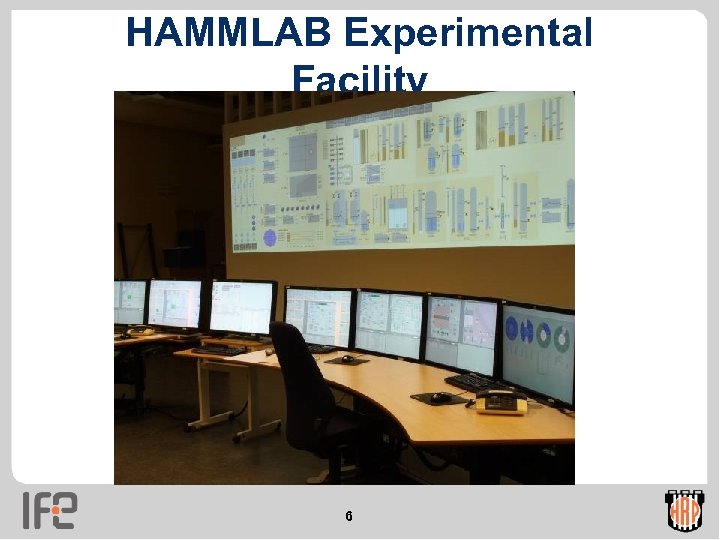

HAMMLAB Experimental Facility 6

HAMMLAB Experimental Facility 6

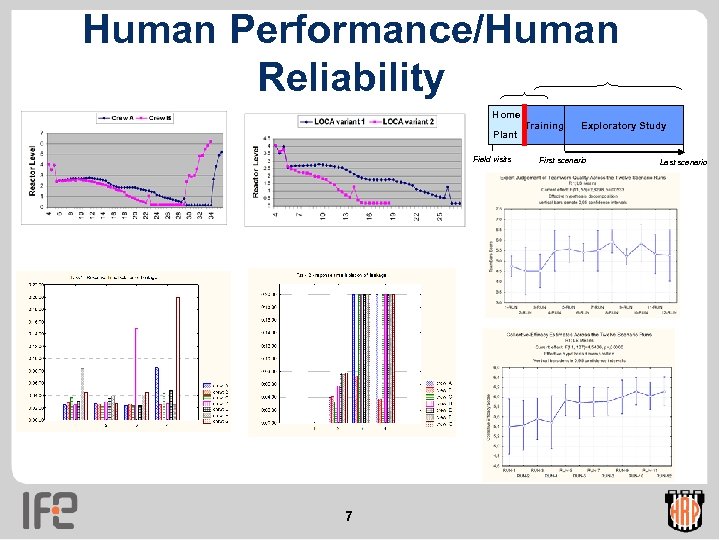

Human Performance/Human Reliability Home Plant Field visits 7 Training Exploratory Study First scenario Last scenario

Human Performance/Human Reliability Home Plant Field visits 7 Training Exploratory Study First scenario Last scenario

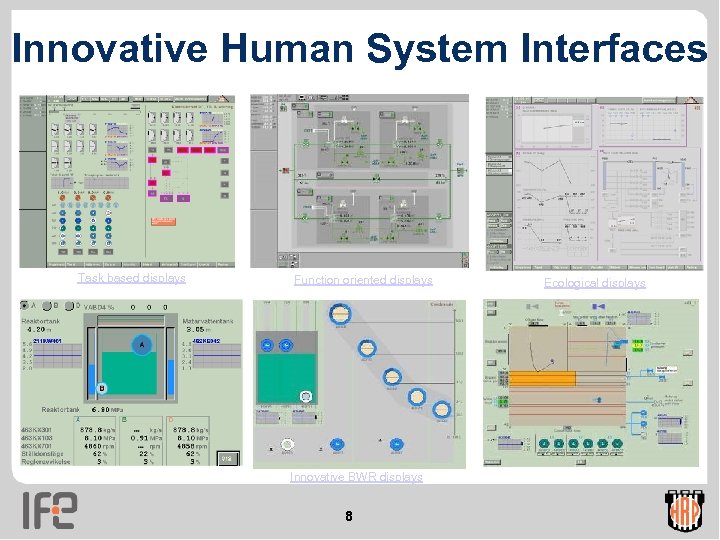

Innovative Human System Interfaces Task based displays Function oriented displays Innovative BWR displays 8 Ecological displays

Innovative Human System Interfaces Task based displays Function oriented displays Innovative BWR displays 8 Ecological displays

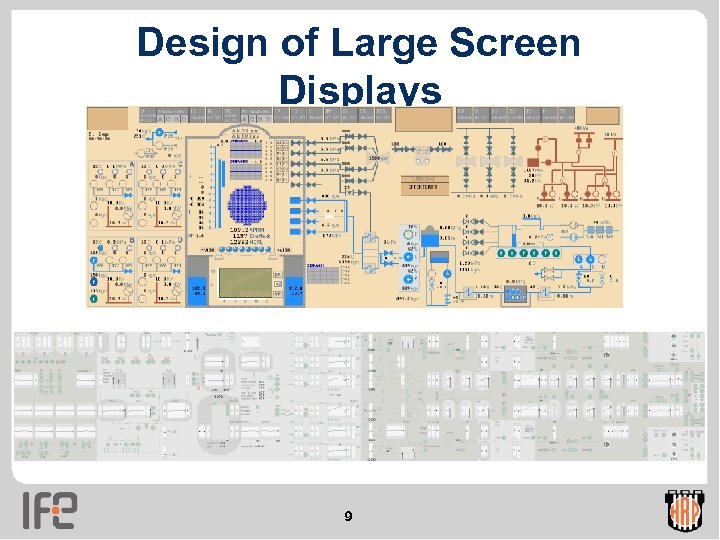

Design of Large Screen Displays 9

Design of Large Screen Displays 9

Mixed Reality for Design, Planning & Training 10

Mixed Reality for Design, Planning & Training 10

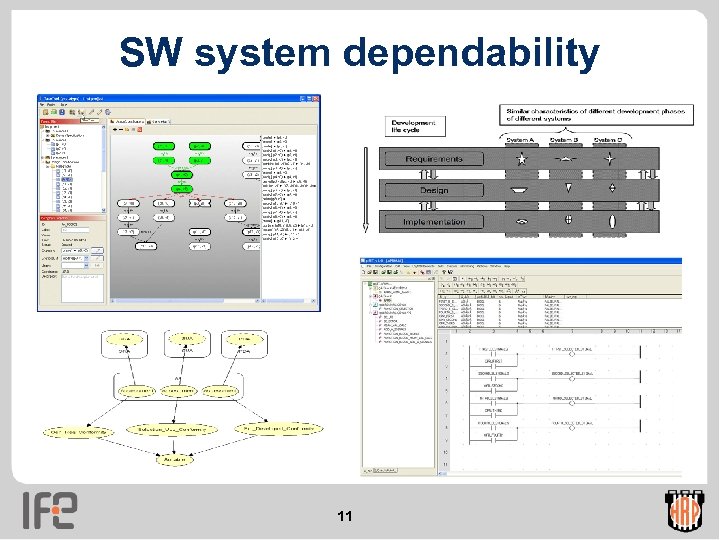

SW system dependability 11

SW system dependability 11

Computerised Operation Support Computerised Procedures Knowledge Management Simulator technology Work Processes Advanced Alarm Systems Function Allocation Performance Monitoring Core Monitoring and Simulation Condition Monitoring Prognostics Virtual Sensing 12

Computerised Operation Support Computerised Procedures Knowledge Management Simulator technology Work Processes Advanced Alarm Systems Function Allocation Performance Monitoring Core Monitoring and Simulation Condition Monitoring Prognostics Virtual Sensing 12

Highlights • • • Large-scale Signal Validation Vision-based Diagnostics Cable Monitoring Mímir Framework & Toolbox Prognostics • Recommendations to the IAEA TWG-NPPIC • HOLMUG 2009 13

Highlights • • • Large-scale Signal Validation Vision-based Diagnostics Cable Monitoring Mímir Framework & Toolbox Prognostics • Recommendations to the IAEA TWG-NPPIC • HOLMUG 2009 13

Large-scale Signal Validation • Increase the applicability of signal validation and diagnostic tools • Method needed for supporting monitoring of a large number of signals • Signal grouping + Ensemble of models • Each model handles a small group of signals Mario Hoffmann, Giulio Gola 14

Large-scale Signal Validation • Increase the applicability of signal validation and diagnostic tools • Method needed for supporting monitoring of a large number of signals • Signal grouping + Ensemble of models • Each model handles a small group of signals Mario Hoffmann, Giulio Gola 14

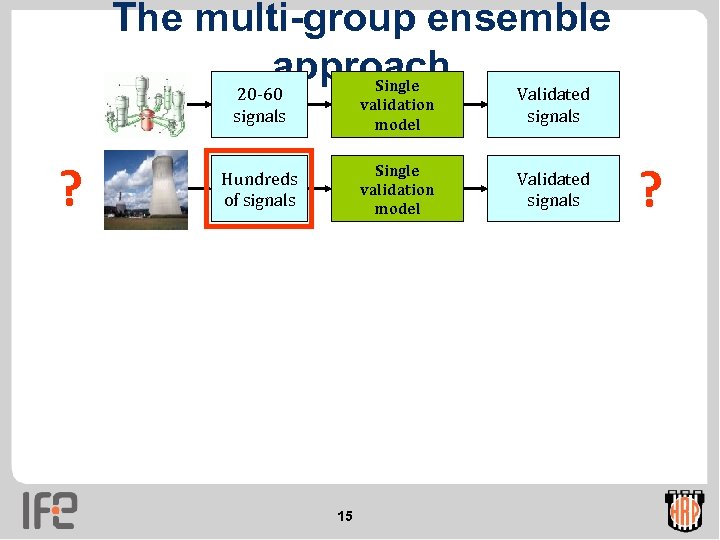

The multi-group ensemble approach 20 -60 signals ? Single validation model Validated signals Hundreds of signals Single validation model Validated signals 15 ?

The multi-group ensemble approach 20 -60 signals ? Single validation model Validated signals Hundreds of signals Single validation model Validated signals 15 ?

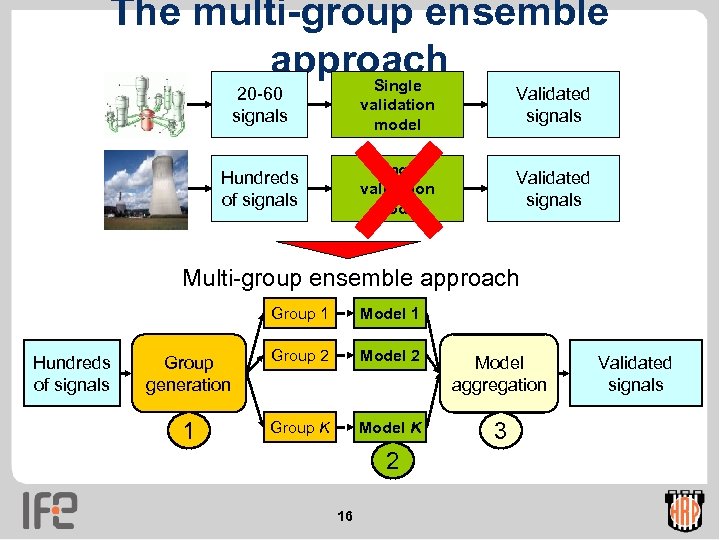

The multi-group ensemble approach 20 -60 signals Single validation model Validated signals Hundreds of signals Single validation model Validated signals Multi-group ensemble approach Group 1 Hundreds of signals Model 1 Group generation Group 2 Model aggregation 1 Group K Model K 3 2 16 Validated signals

The multi-group ensemble approach 20 -60 signals Single validation model Validated signals Hundreds of signals Single validation model Validated signals Multi-group ensemble approach Group 1 Hundreds of signals Model 1 Group generation Group 2 Model aggregation 1 Group K Model K 3 2 16 Validated signals

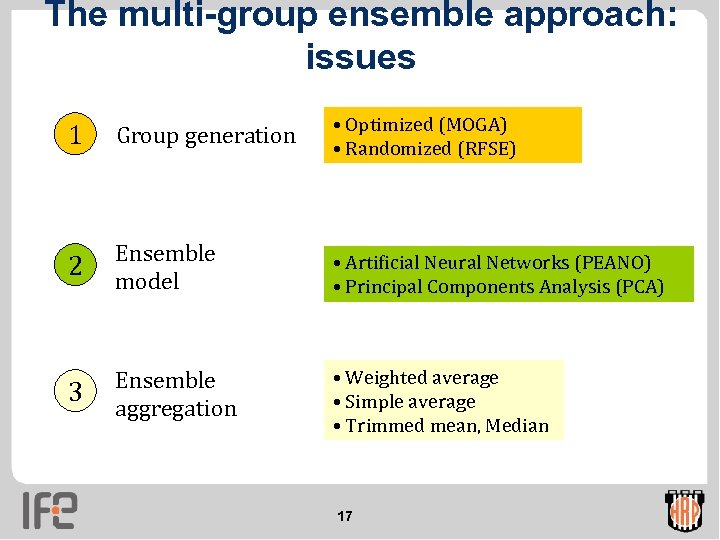

The multi-group ensemble approach: issues 1 Group generation • Optimized (MOGA) • Randomized (RFSE) 2 Ensemble model • Artificial Neural Networks (PEANO) • Principal Components Analysis (PCA) 3 Ensemble aggregation • Weighted average • Simple average • Trimmed mean, Median 17

The multi-group ensemble approach: issues 1 Group generation • Optimized (MOGA) • Randomized (RFSE) 2 Ensemble model • Artificial Neural Networks (PEANO) • Principal Components Analysis (PCA) 3 Ensemble aggregation • Weighted average • Simple average • Trimmed mean, Median 17

Applications 1) 84 signals from Oskarshamn BWR 2) 215 signals from Loviisa PWR 3) 920 simulated signals Forsmark-3 BWR (HAMBO) 18

Applications 1) 84 signals from Oskarshamn BWR 2) 215 signals from Loviisa PWR 3) 920 simulated signals Forsmark-3 BWR (HAMBO) 18

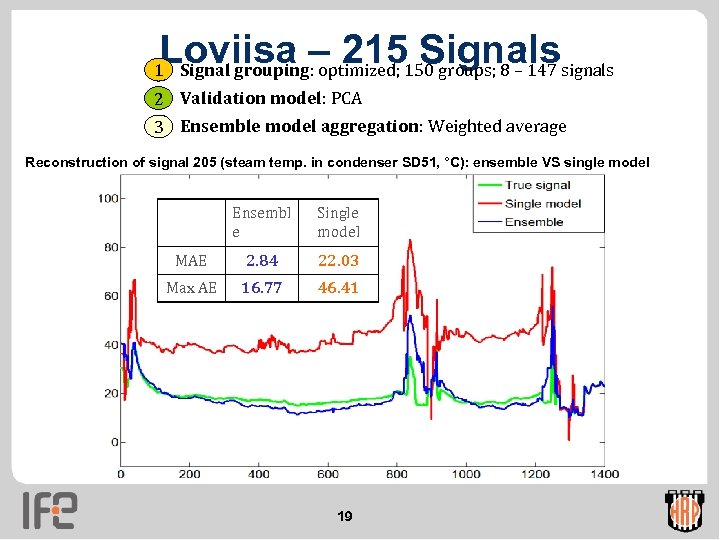

Loviisa – 215150 groups; 8 – 147 signals Signal grouping: optimized; 1 2 Validation model: PCA 3 Ensemble model aggregation: Weighted average Reconstruction of signal 205 (steam temp. in condenser SD 51, °C): ensemble VS single model Ensembl e Single model MAE 2. 84 22. 03 Max AE 16. 77 46. 41 19

Loviisa – 215150 groups; 8 – 147 signals Signal grouping: optimized; 1 2 Validation model: PCA 3 Ensemble model aggregation: Weighted average Reconstruction of signal 205 (steam temp. in condenser SD 51, °C): ensemble VS single model Ensembl e Single model MAE 2. 84 22. 03 Max AE 16. 77 46. 41 19

Ongoing work • Verification of the proposed procedure on 802 measured signals from Oskarshamn BWR • Implementation of a randomized-wrapper grouping technique • Implementation of the final grouping scheme in the PEANO signal validation system • Within 2009 Giulio Gola 20

Ongoing work • Verification of the proposed procedure on 802 measured signals from Oskarshamn BWR • Implementation of a randomized-wrapper grouping technique • Implementation of the final grouping scheme in the PEANO signal validation system • Within 2009 Giulio Gola 20

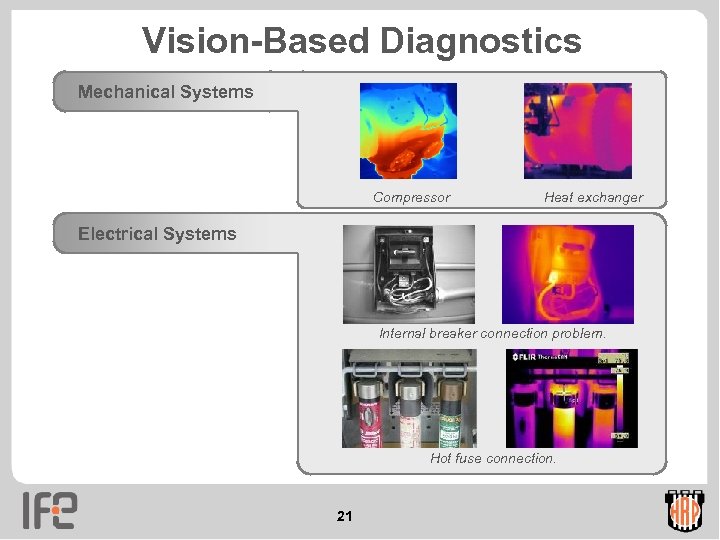

Vision-Based Diagnostics Mechanical Systems Compressor Heat exchanger Electrical Systems Internal breaker connection problem. Hot fuse connection. 21

Vision-Based Diagnostics Mechanical Systems Compressor Heat exchanger Electrical Systems Internal breaker connection problem. Hot fuse connection. 21

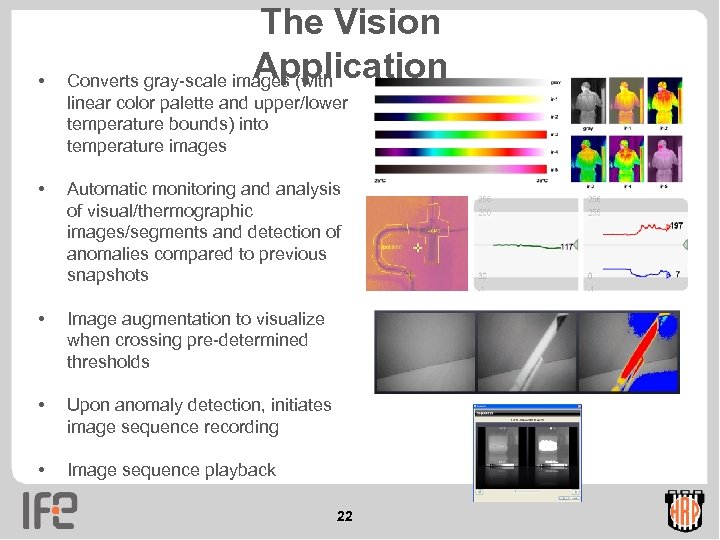

• The Vision Application Converts gray-scale images (with linear color palette and upper/lower temperature bounds) into temperature images • Automatic monitoring and analysis of visual/thermographic images/segments and detection of anomalies compared to previous snapshots • Image augmentation to visualize when crossing pre-determined thresholds • Upon anomaly detection, initiates image sequence recording • Image sequence playback 22

• The Vision Application Converts gray-scale images (with linear color palette and upper/lower temperature bounds) into temperature images • Automatic monitoring and analysis of visual/thermographic images/segments and detection of anomalies compared to previous snapshots • Image augmentation to visualize when crossing pre-determined thresholds • Upon anomaly detection, initiates image sequence recording • Image sequence playback 22

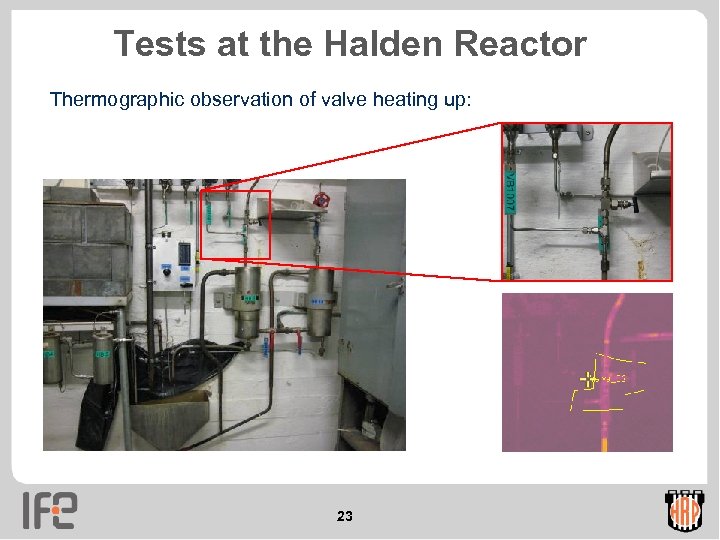

Tests at the Halden Reactor Thermographic observation of valve heating up: 23

Tests at the Halden Reactor Thermographic observation of valve heating up: 23

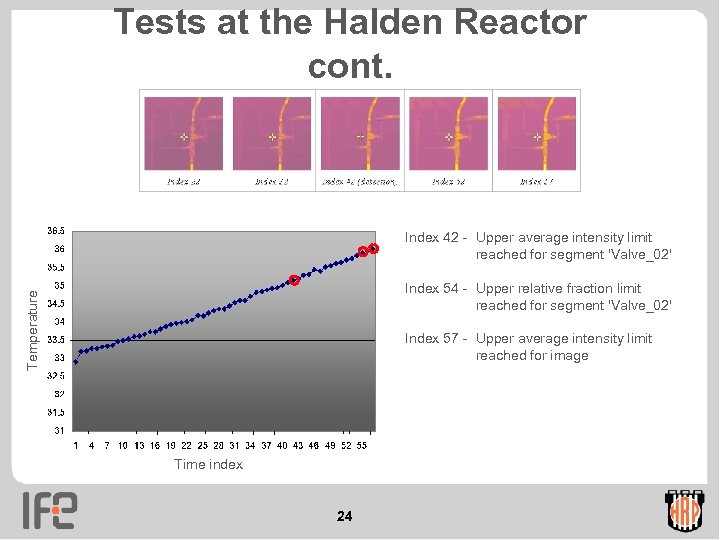

Tests at the Halden Reactor cont. Index 42 - Upper average intensity limit reached for segment 'Valve_02' Temperature Index 54 - Upper relative fraction limit reached for segment 'Valve_02' Index 57 - Upper average intensity limit reached for image Time index 24

Tests at the Halden Reactor cont. Index 42 - Upper average intensity limit reached for segment 'Valve_02' Temperature Index 54 - Upper relative fraction limit reached for segment 'Valve_02' Index 57 - Upper average intensity limit reached for image Time index 24

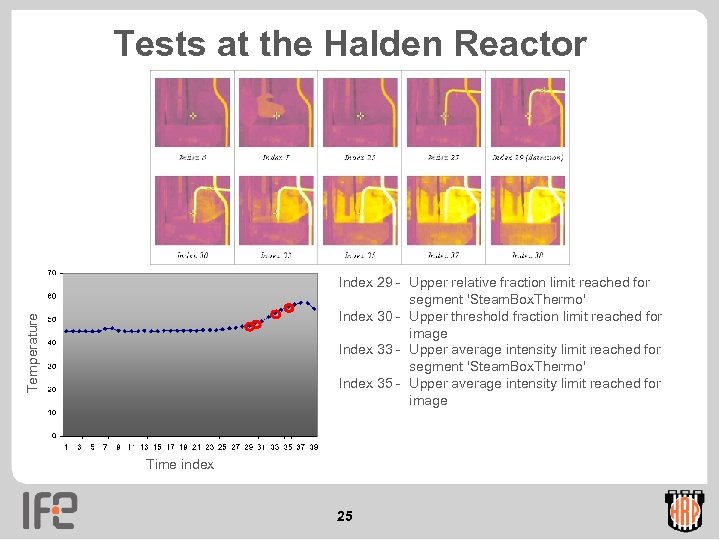

Tests at the Halden Reactor Temperature Index 29 - Upper relative fraction limit reached for segment 'Steam. Box. Thermo' Index 30 - Upper threshold fraction limit reached for image Index 33 - Upper average intensity limit reached for segment 'Steam. Box. Thermo' Index 35 - Upper average intensity limit reached for image Time index 25

Tests at the Halden Reactor Temperature Index 29 - Upper relative fraction limit reached for segment 'Steam. Box. Thermo' Index 30 - Upper threshold fraction limit reached for image Index 33 - Upper average intensity limit reached for segment 'Steam. Box. Thermo' Index 35 - Upper average intensity limit reached for image Time index 25

Cable Monitoring • LIRA (LIne Resonance Analysis) as a Cable Analyzer • Local degradation detection and localization • • Thermal degradation Mechanical damage Gamma irradiation damage Global degradation assessment and residual life estimation • • • Thermal degradation Gamma irradiation degradation Harsh environment Paolo Fantoni 26

Cable Monitoring • LIRA (LIne Resonance Analysis) as a Cable Analyzer • Local degradation detection and localization • • Thermal degradation Mechanical damage Gamma irradiation damage Global degradation assessment and residual life estimation • • • Thermal degradation Gamma irradiation degradation Harsh environment Paolo Fantoni 26

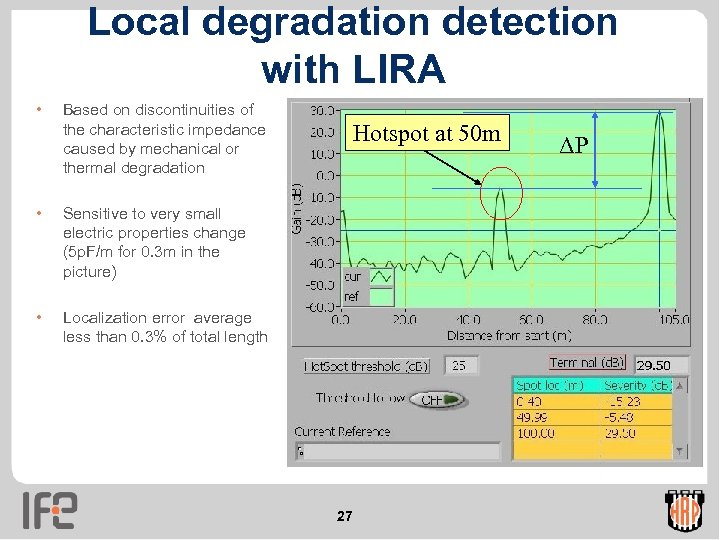

Local degradation detection with LIRA • Based on discontinuities of the characteristic impedance caused by mechanical or thermal degradation • Sensitive to very small electric properties change (5 p. F/m for 0. 3 m in the picture) • Hotspot at 50 m Localization error average less than 0. 3% of total length 27 ΔP

Local degradation detection with LIRA • Based on discontinuities of the characteristic impedance caused by mechanical or thermal degradation • Sensitive to very small electric properties change (5 p. F/m for 0. 3 m in the picture) • Hotspot at 50 m Localization error average less than 0. 3% of total length 27 ΔP

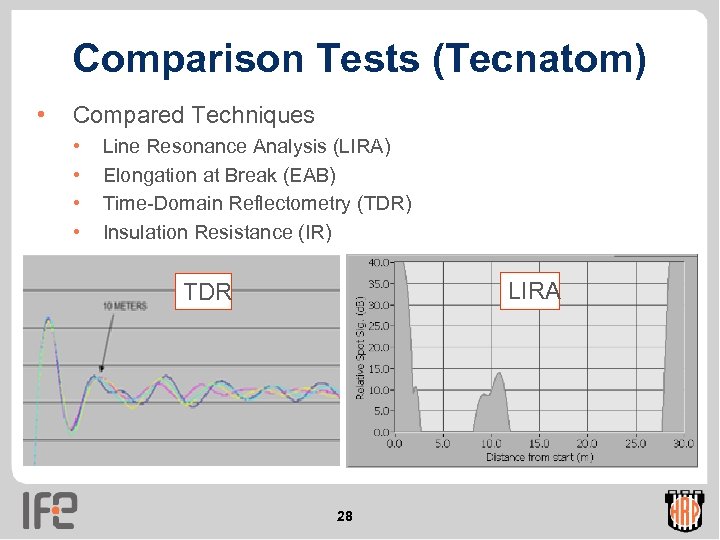

Comparison Tests (Tecnatom) • Compared Techniques • • Line Resonance Analysis (LIRA) Elongation at Break (EAB) Time-Domain Reflectometry (TDR) Insulation Resistance (IR) LIRA TDR 28

Comparison Tests (Tecnatom) • Compared Techniques • • Line Resonance Analysis (LIRA) Elongation at Break (EAB) Time-Domain Reflectometry (TDR) Insulation Resistance (IR) LIRA TDR 28

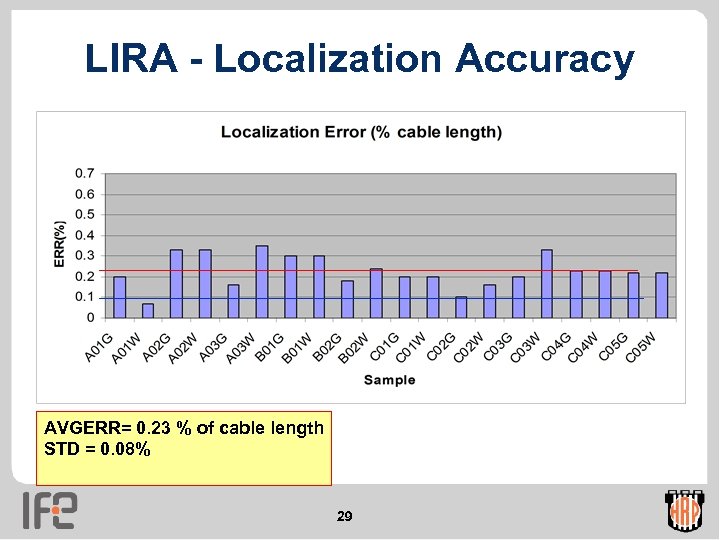

LIRA - Localization Accuracy AVGERR= 0. 23 % of cable length STD = 0. 08% 29

LIRA - Localization Accuracy AVGERR= 0. 23 % of cable length STD = 0. 08% 29

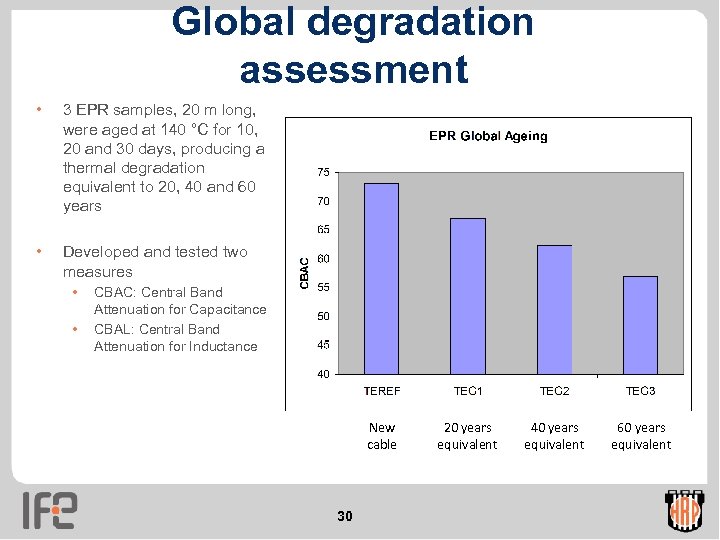

Global degradation assessment • 3 EPR samples, 20 m long, were aged at 140 °C for 10, 20 and 30 days, producing a thermal degradation equivalent to 20, 40 and 60 years • Developed and tested two measures • • CBAC: Central Band Attenuation for Capacitance CBAL: Central Band Attenuation for Inductance New cable 30 20 years equivalent 40 years equivalent 60 years equivalent

Global degradation assessment • 3 EPR samples, 20 m long, were aged at 140 °C for 10, 20 and 30 days, producing a thermal degradation equivalent to 20, 40 and 60 years • Developed and tested two measures • • CBAC: Central Band Attenuation for Capacitance CBAL: Central Band Attenuation for Inductance New cable 30 20 years equivalent 40 years equivalent 60 years equivalent

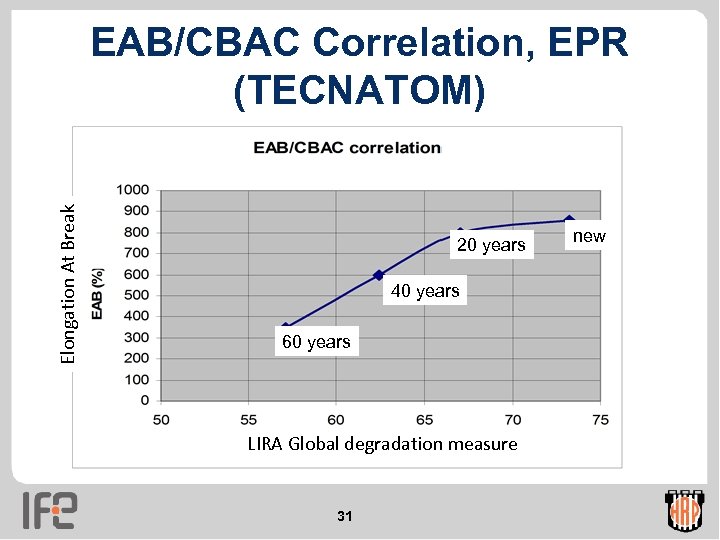

Elongation At Break EAB/CBAC Correlation, EPR (TECNATOM) 20 years 40 years 60 years LIRA Global degradation measure CBAC 31 new

Elongation At Break EAB/CBAC Correlation, EPR (TECNATOM) 20 years 40 years 60 years LIRA Global degradation measure CBAC 31 new

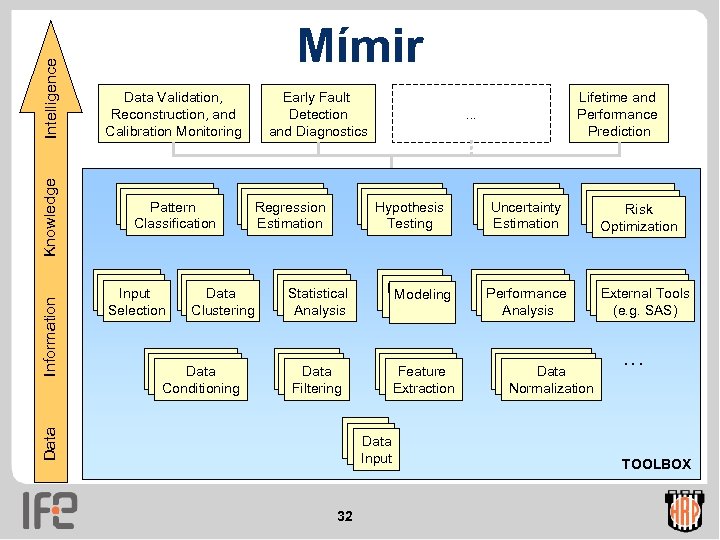

Intelligence Knowledge Information Data Mímir Data Validation, Reconstruction, and Calibration Monitoring Pattern Classification Input Selection Early Fault Detection and Diagnostics Regression Estimation Data Clustering Data Conditioning . . . Hypothesis Testing Statistical Analysis Modeling Data Filtering Feature Extraction Data Input 32 Lifetime and Performance Prediction Uncertainty Estimation Performance Analysis Risk Optimization Optimisation Optimization External Tools (e. g. SAS) Data Normalization . . . TOOLBOX

Intelligence Knowledge Information Data Mímir Data Validation, Reconstruction, and Calibration Monitoring Pattern Classification Input Selection Early Fault Detection and Diagnostics Regression Estimation Data Clustering Data Conditioning . . . Hypothesis Testing Statistical Analysis Modeling Data Filtering Feature Extraction Data Input 32 Lifetime and Performance Prediction Uncertainty Estimation Performance Analysis Risk Optimization Optimisation Optimization External Tools (e. g. SAS) Data Normalization . . . TOOLBOX

Why Mímir Virtual Grouping Signal PEANO aladdin. Sensing Empirical Ensemble-Based Virtual Sensing using regression models Signal grouping for detection and diagnosis through Monitoring A system early fault. Validation applications through the use of Performs for Signal large scale and On-line Calibrationthe dynamic to estimate quantities not directly measured with physical Random auto-associative Ensemble based on. Feature Selection empirical measurement signals recognition of observable changes inmodels instruments 33

Why Mímir Virtual Grouping Signal PEANO aladdin. Sensing Empirical Ensemble-Based Virtual Sensing using regression models Signal grouping for detection and diagnosis through Monitoring A system early fault. Validation applications through the use of Performs for Signal large scale and On-line Calibrationthe dynamic to estimate quantities not directly measured with physical Random auto-associative Ensemble based on. Feature Selection empirical measurement signals recognition of observable changes inmodels instruments 33

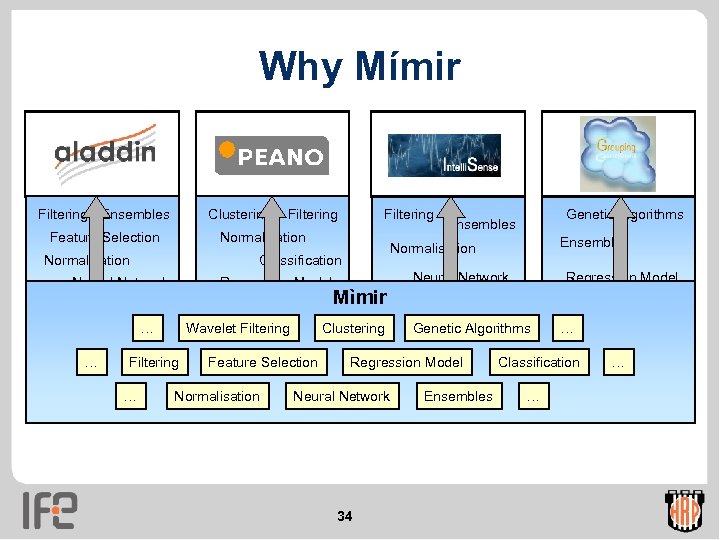

Why Mímir Filtering Ensembles Clustering Feature Selection Regression Model … Wavelet Filtering Normalisation Ensembles Neural Network Regression Model Mìmir Clustering Feature Selection Genetic Algorithms Ensembles Normalisation Classification Neural Network … Filtering Normalisation … Filtering Genetic Algorithms Regression Model Neural Network 34 Ensembles … Classification … …

Why Mímir Filtering Ensembles Clustering Feature Selection Regression Model … Wavelet Filtering Normalisation Ensembles Neural Network Regression Model Mìmir Clustering Feature Selection Genetic Algorithms Ensembles Normalisation Classification Neural Network … Filtering Normalisation … Filtering Genetic Algorithms Regression Model Neural Network 34 Ensembles … Classification … …

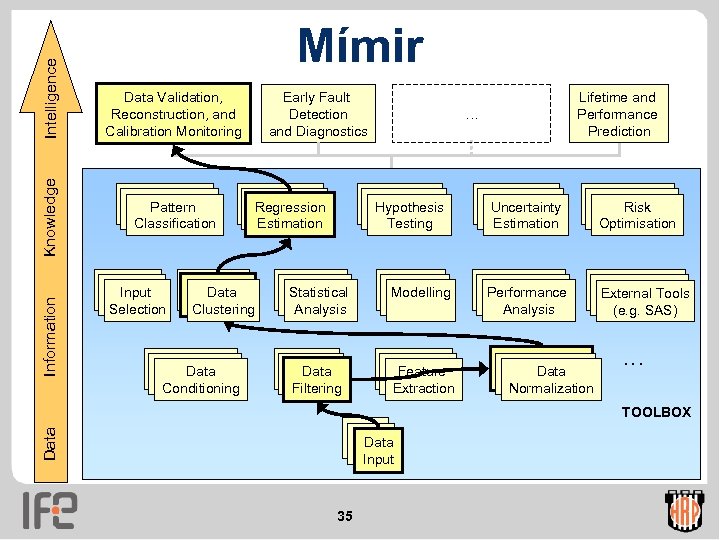

Intelligence Knowledge Information Mímir Data Validation, Reconstruction, and Calibration Monitoring Pattern Classification Input Selection Early Fault Detection and Diagnostics Regression Estimation Data Clustering Data Conditioning Lifetime and Performance Prediction … Hypothesis Testing Statistical Analysis Modelling Data Filtering Feature Extraction Uncertainty Estimation Risk Optimisation Performance Analysis External Tools (e. g. SAS) Data Normalization . . . Data TOOLBOX Data Input 35

Intelligence Knowledge Information Mímir Data Validation, Reconstruction, and Calibration Monitoring Pattern Classification Input Selection Early Fault Detection and Diagnostics Regression Estimation Data Clustering Data Conditioning Lifetime and Performance Prediction … Hypothesis Testing Statistical Analysis Modelling Data Filtering Feature Extraction Uncertainty Estimation Risk Optimisation Performance Analysis External Tools (e. g. SAS) Data Normalization . . . Data TOOLBOX Data Input 35

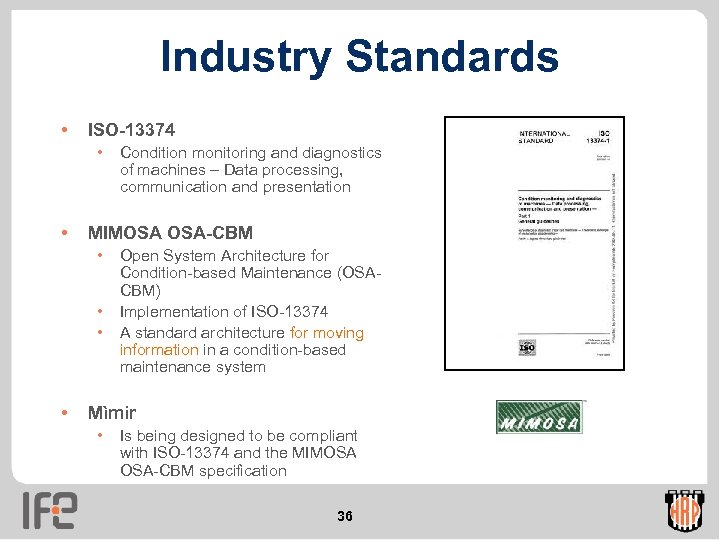

Industry Standards • ISO-13374 • • MIMOSA OSA-CBM • • Condition monitoring and diagnostics of machines – Data processing, communication and presentation Open System Architecture for Condition-based Maintenance (OSACBM) Implementation of ISO-13374 A standard architecture for moving information in a condition-based maintenance system Mìmir • Is being designed to be compliant with ISO-13374 and the MIMOSA OSA-CBM specification 36

Industry Standards • ISO-13374 • • MIMOSA OSA-CBM • • Condition monitoring and diagnostics of machines – Data processing, communication and presentation Open System Architecture for Condition-based Maintenance (OSACBM) Implementation of ISO-13374 A standard architecture for moving information in a condition-based maintenance system Mìmir • Is being designed to be compliant with ISO-13374 and the MIMOSA OSA-CBM specification 36

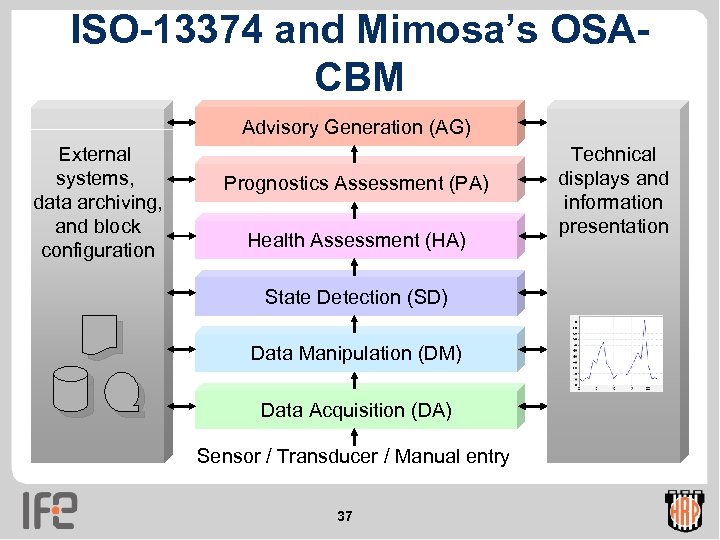

ISO-13374 and Mimosa’s OSACBM Advisory Generation (AG) External systems, data archiving, and block configuration Prognostics Assessment (PA) Health Assessment (HA) State Detection (SD) Data Manipulation (DM) Data Acquisition (DA) Sensor / Transducer / Manual entry 37 Technical displays and information presentation

ISO-13374 and Mimosa’s OSACBM Advisory Generation (AG) External systems, data archiving, and block configuration Prognostics Assessment (PA) Health Assessment (HA) State Detection (SD) Data Manipulation (DM) Data Acquisition (DA) Sensor / Transducer / Manual entry 37 Technical displays and information presentation

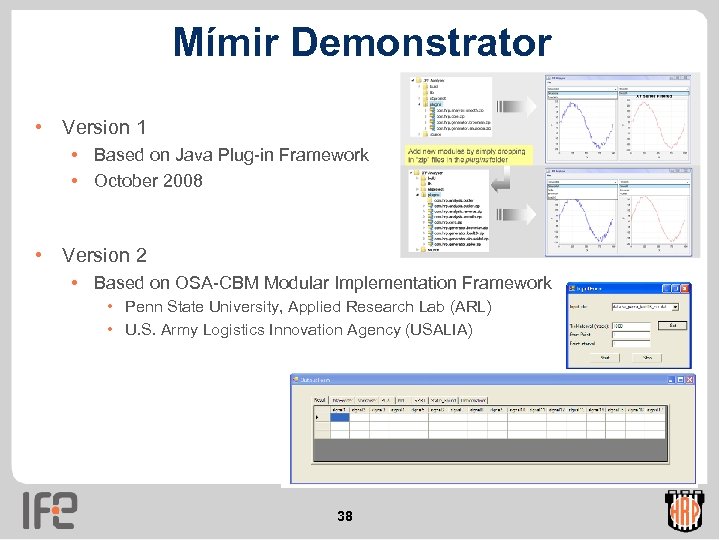

Mímir Demonstrator • Version 1 • Based on Java Plug-in Framework • October 2008 • Version 2 • Based on OSA-CBM Modular Implementation Framework • Penn State University, Applied Research Lab (ARL) • U. S. Army Logistics Innovation Agency (USALIA) 38

Mímir Demonstrator • Version 1 • Based on Java Plug-in Framework • October 2008 • Version 2 • Based on OSA-CBM Modular Implementation Framework • Penn State University, Applied Research Lab (ARL) • U. S. Army Logistics Innovation Agency (USALIA) 38

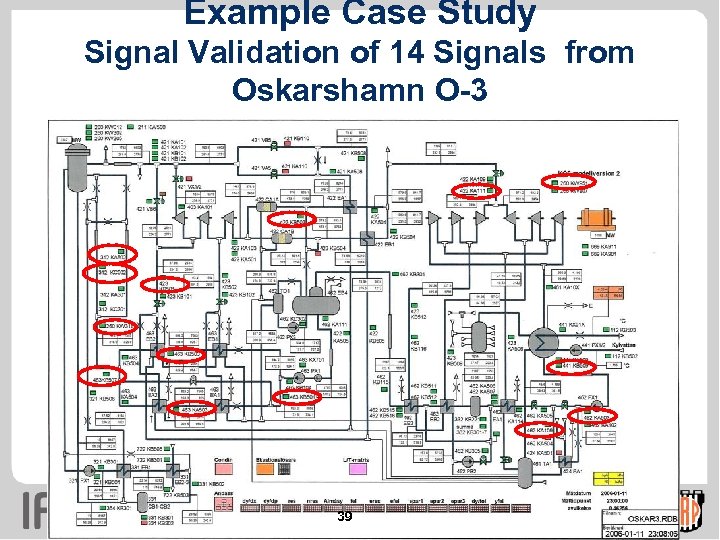

Example Case Study Signal Validation of 14 Signals from Oskarshamn O-3 39

Example Case Study Signal Validation of 14 Signals from Oskarshamn O-3 39

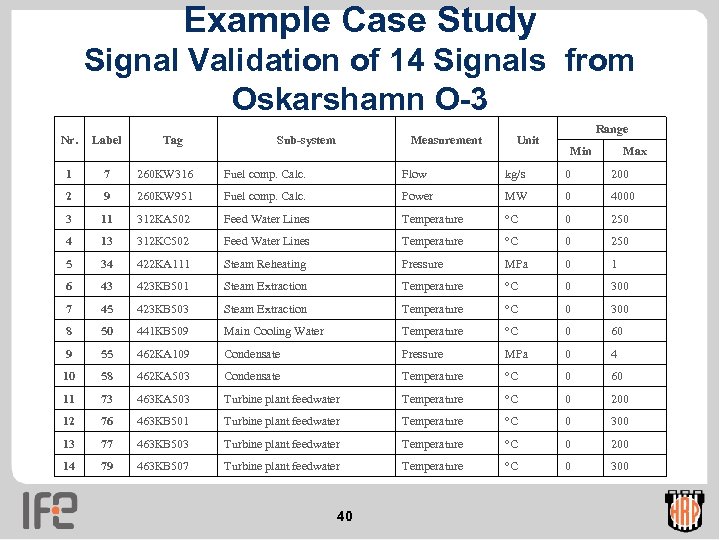

Example Case Study Signal Validation of 14 Signals from Oskarshamn O-3 Tag Sub-system Measurement Label 1 7 260 KW 316 Fuel comp. Calc. Flow kg/s 0 200 2 9 260 KW 951 Fuel comp. Calc. Power MW 0 4000 3 11 312 KA 502 Feed Water Lines Temperature °C 0 250 4 13 312 KC 502 Feed Water Lines Temperature °C 0 250 5 34 422 KA 111 Steam Reheating Pressure MPa 0 1 6 43 423 KB 501 Steam Extraction Temperature °C 0 300 7 45 423 KB 503 Steam Extraction Temperature °C 0 300 8 50 441 KB 509 Main Cooling Water Temperature °C 0 60 9 55 462 KA 109 Condensate Pressure MPa 0 4 10 58 462 KA 503 Condensate Temperature °C 0 60 11 73 463 KA 503 Turbine plant feedwater Temperature °C 0 200 12 76 463 KB 501 Turbine plant feedwater Temperature °C 0 300 13 77 463 KB 503 Turbine plant feedwater Temperature °C 0 200 14 79 463 KB 507 Turbine plant feedwater Temperature °C 0 300 40 Unit Range Nr. Min Max

Example Case Study Signal Validation of 14 Signals from Oskarshamn O-3 Tag Sub-system Measurement Label 1 7 260 KW 316 Fuel comp. Calc. Flow kg/s 0 200 2 9 260 KW 951 Fuel comp. Calc. Power MW 0 4000 3 11 312 KA 502 Feed Water Lines Temperature °C 0 250 4 13 312 KC 502 Feed Water Lines Temperature °C 0 250 5 34 422 KA 111 Steam Reheating Pressure MPa 0 1 6 43 423 KB 501 Steam Extraction Temperature °C 0 300 7 45 423 KB 503 Steam Extraction Temperature °C 0 300 8 50 441 KB 509 Main Cooling Water Temperature °C 0 60 9 55 462 KA 109 Condensate Pressure MPa 0 4 10 58 462 KA 503 Condensate Temperature °C 0 60 11 73 463 KA 503 Turbine plant feedwater Temperature °C 0 200 12 76 463 KB 501 Turbine plant feedwater Temperature °C 0 300 13 77 463 KB 503 Turbine plant feedwater Temperature °C 0 200 14 79 463 KB 507 Turbine plant feedwater Temperature °C 0 300 40 Unit Range Nr. Min Max

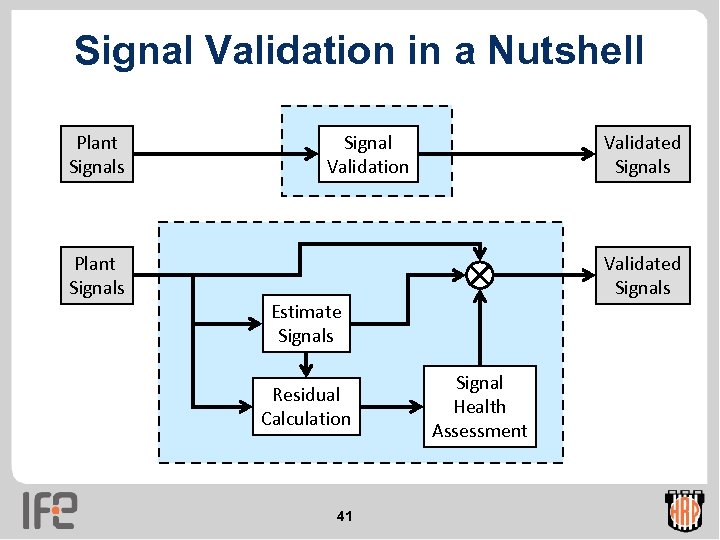

Signal Validation in a Nutshell Plant Signals Signal Validation Validated Signals Plant Signals Validated Signals Estimate Signals Residual Calculation 41 Signal Health Assessment

Signal Validation in a Nutshell Plant Signals Signal Validation Validated Signals Plant Signals Validated Signals Estimate Signals Residual Calculation 41 Signal Health Assessment

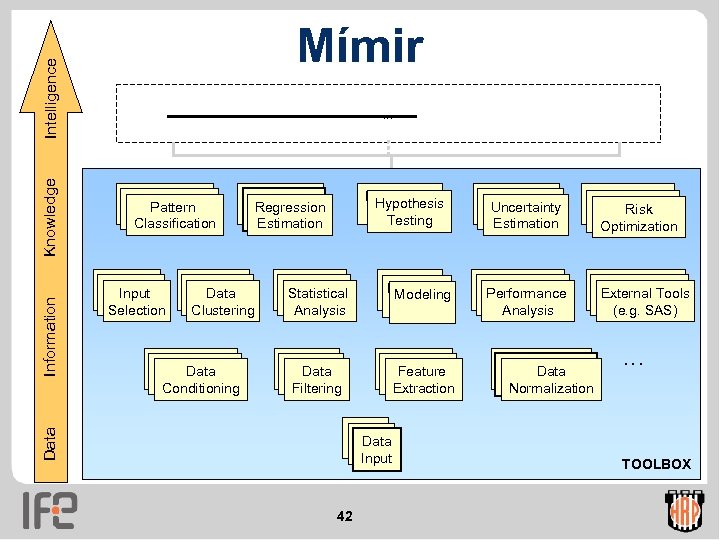

Data Information Knowledge Intelligence Mímir. . . Pattern Classification Input Selection Regression PCA Regression Estimation Data Clustering Data Conditioning Hypothesis SPRT Testing Statistical Analysis Modeling Data Filtering Feature Extraction Data Input 42 Uncertainty Estimation Performance Analysis Risk Optimization Optimisation Optimization External Tools (e. g. SAS) Data STD Data Normalization . . . TOOLBOX

Data Information Knowledge Intelligence Mímir. . . Pattern Classification Input Selection Regression PCA Regression Estimation Data Clustering Data Conditioning Hypothesis SPRT Testing Statistical Analysis Modeling Data Filtering Feature Extraction Data Input 42 Uncertainty Estimation Performance Analysis Risk Optimization Optimisation Optimization External Tools (e. g. SAS) Data STD Data Normalization . . . TOOLBOX

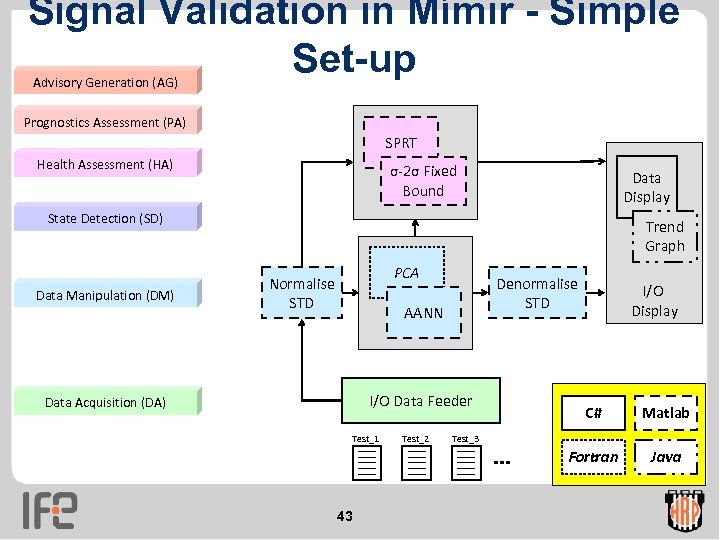

Signal Validation in Mímir - Simple Set-up Advisory Generation (AG) Prognostics Assessment (PA) SPRT Health Assessment (HA) σ-2σ Fixed Bound Data Display State Detection (SD) Data Manipulation (DM) Trend Graph PCA Normalise STD Denormalise STD AANN I/O Data Feeder Data Acquisition (DA) I/O Display 43 Test_2 Matlab Fortran Test_1 C# Java Test_3

Signal Validation in Mímir - Simple Set-up Advisory Generation (AG) Prognostics Assessment (PA) SPRT Health Assessment (HA) σ-2σ Fixed Bound Data Display State Detection (SD) Data Manipulation (DM) Trend Graph PCA Normalise STD Denormalise STD AANN I/O Data Feeder Data Acquisition (DA) I/O Display 43 Test_2 Matlab Fortran Test_1 C# Java Test_3

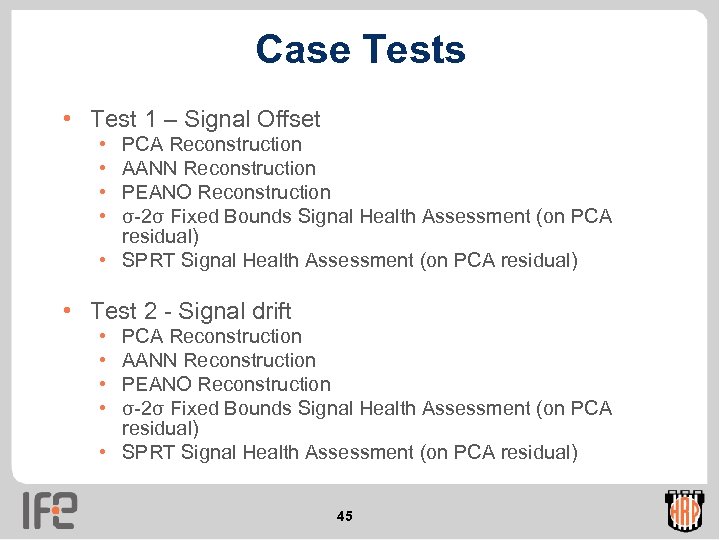

Case Tests • Test 1 – Signal Offset • • PCA Reconstruction AANN Reconstruction PEANO Reconstruction σ-2σ Fixed Bounds Signal Health Assessment (on PCA residual) • SPRT Signal Health Assessment (on PCA residual) • Test 2 - Signal drift • • PCA Reconstruction AANN Reconstruction PEANO Reconstruction σ-2σ Fixed Bounds Signal Health Assessment (on PCA residual) • SPRT Signal Health Assessment (on PCA residual) 45

Case Tests • Test 1 – Signal Offset • • PCA Reconstruction AANN Reconstruction PEANO Reconstruction σ-2σ Fixed Bounds Signal Health Assessment (on PCA residual) • SPRT Signal Health Assessment (on PCA residual) • Test 2 - Signal drift • • PCA Reconstruction AANN Reconstruction PEANO Reconstruction σ-2σ Fixed Bounds Signal Health Assessment (on PCA residual) • SPRT Signal Health Assessment (on PCA residual) 45

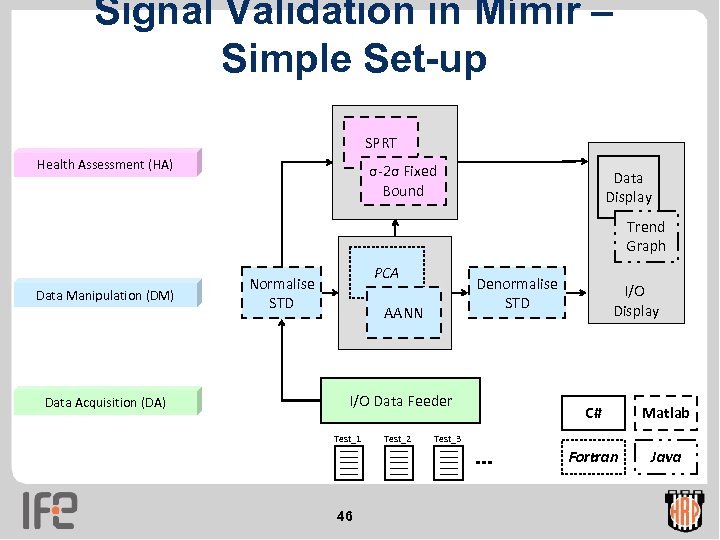

Signal Validation in Mímir – Simple Set-up SPRT Health Assessment (HA) σ-2σ Fixed Bound Data Display Trend Graph Data Manipulation (DM) Data Acquisition (DA) PCA Normalise STD Denormalise STD AANN I/O Data Feeder I/O Display 46 Test_2 Matlab Fortran Test_1 C# Java Test_3

Signal Validation in Mímir – Simple Set-up SPRT Health Assessment (HA) σ-2σ Fixed Bound Data Display Trend Graph Data Manipulation (DM) Data Acquisition (DA) PCA Normalise STD Denormalise STD AANN I/O Data Feeder I/O Display 46 Test_2 Matlab Fortran Test_1 C# Java Test_3

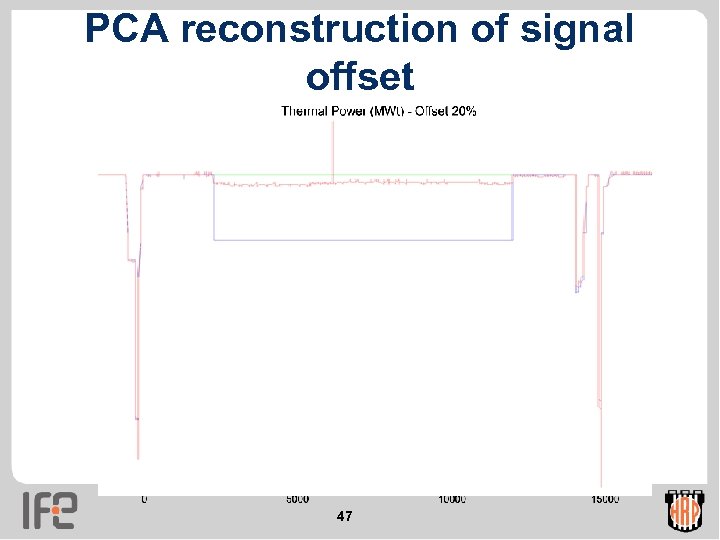

PCA reconstruction of signal offset 47

PCA reconstruction of signal offset 47

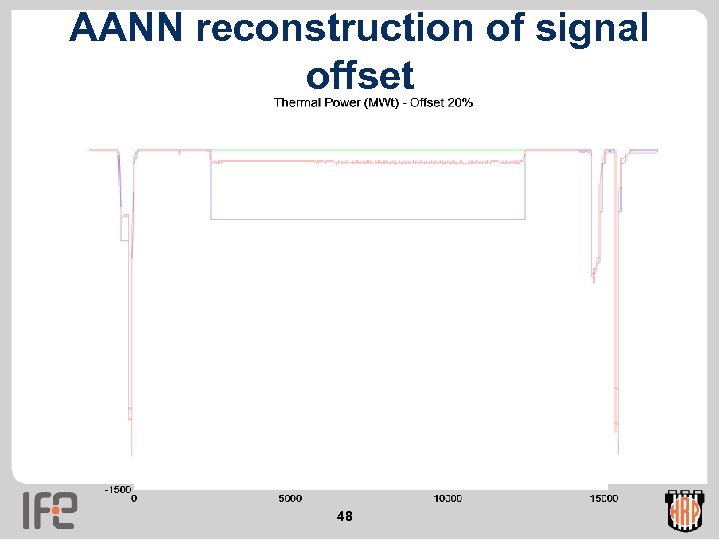

AANN reconstruction of signal offset 48

AANN reconstruction of signal offset 48

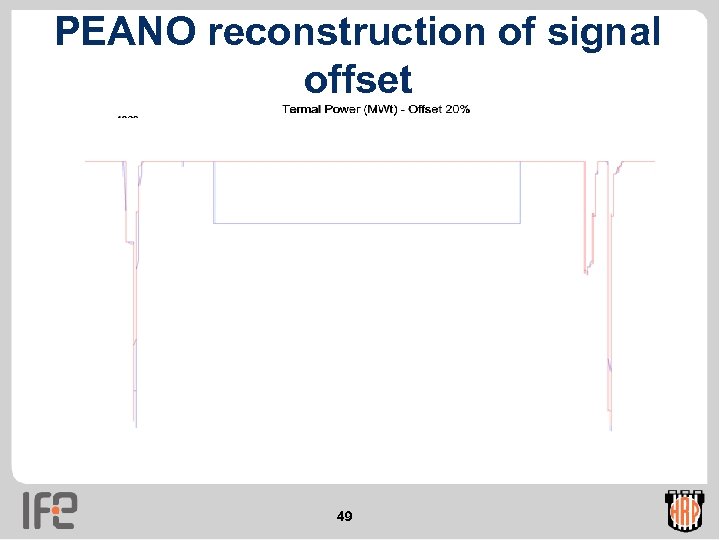

PEANO reconstruction of signal offset 49

PEANO reconstruction of signal offset 49

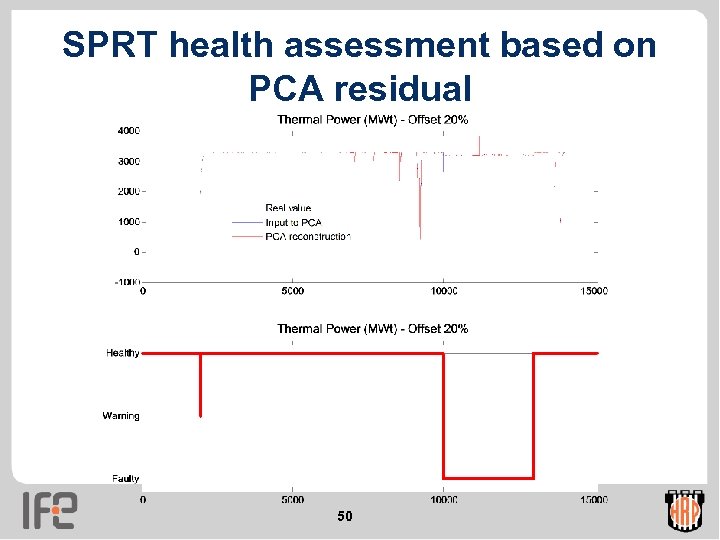

SPRT health assessment based on PCA residual 50

SPRT health assessment based on PCA residual 50

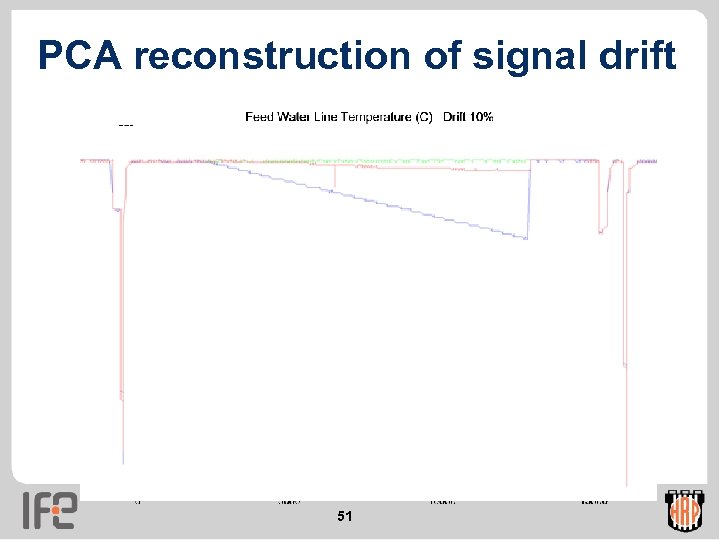

PCA reconstruction of signal drift 51

PCA reconstruction of signal drift 51

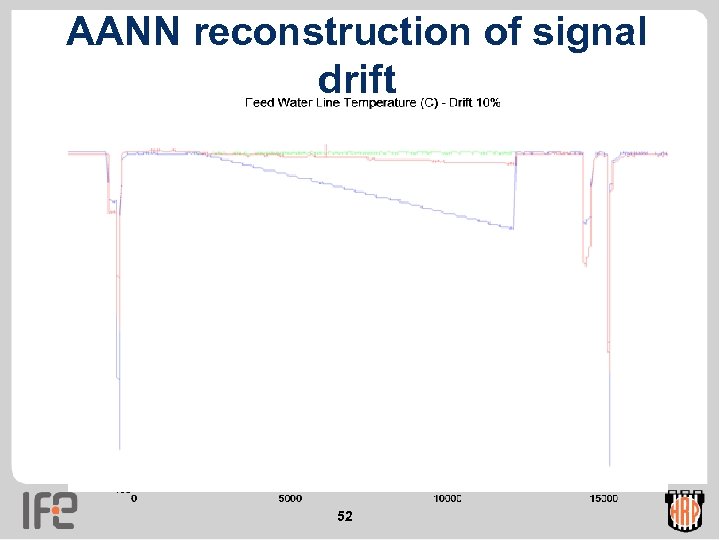

AANN reconstruction of signal drift 52

AANN reconstruction of signal drift 52

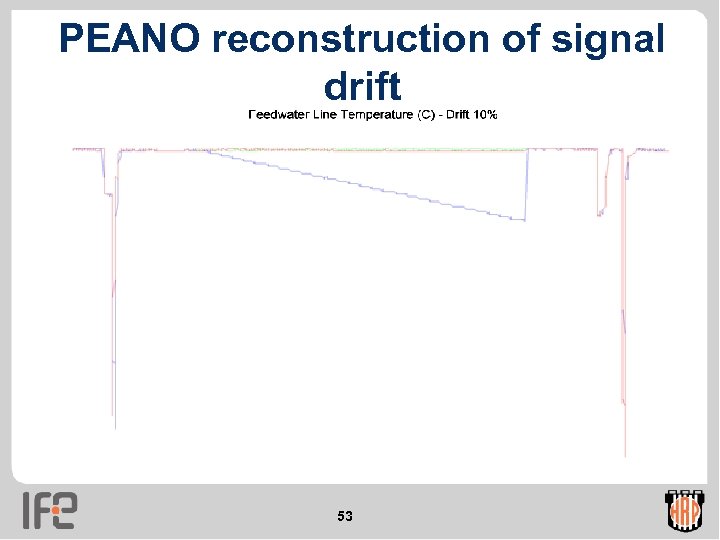

PEANO reconstruction of signal drift 53

PEANO reconstruction of signal drift 53

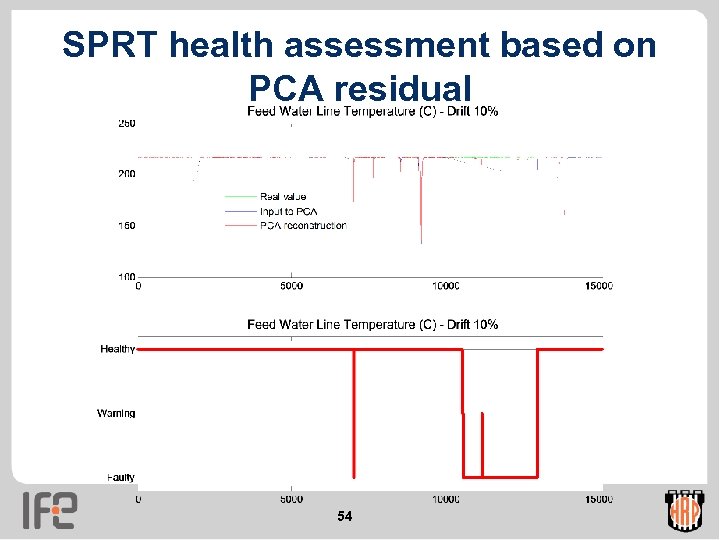

SPRT health assessment based on PCA residual 54

SPRT health assessment based on PCA residual 54

A Prognostics case study from Oskarshamn O 1 Use of d. P measures over heat exchanger filters 55

A Prognostics case study from Oskarshamn O 1 Use of d. P measures over heat exchanger filters 55

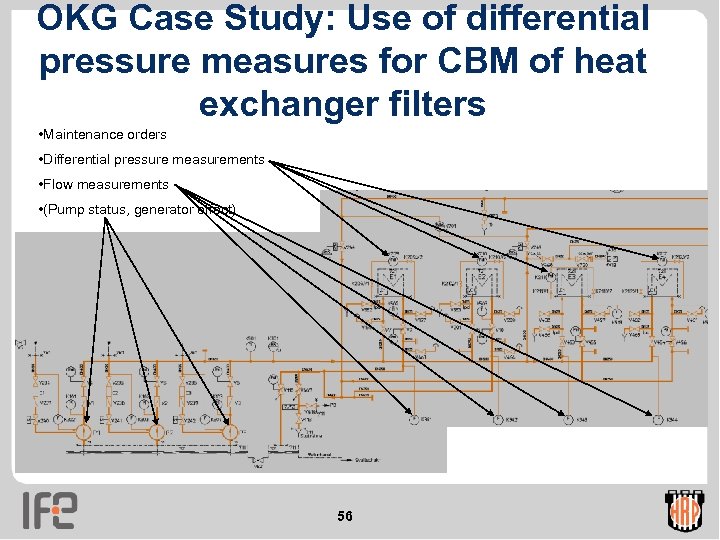

OKG Case Study: Use of differential pressure measures for CBM of heat exchanger filters • Maintenance orders • Differential pressure measurements • Flow measurements • (Pump status, generator effect) 56

OKG Case Study: Use of differential pressure measures for CBM of heat exchanger filters • Maintenance orders • Differential pressure measurements • Flow measurements • (Pump status, generator effect) 56

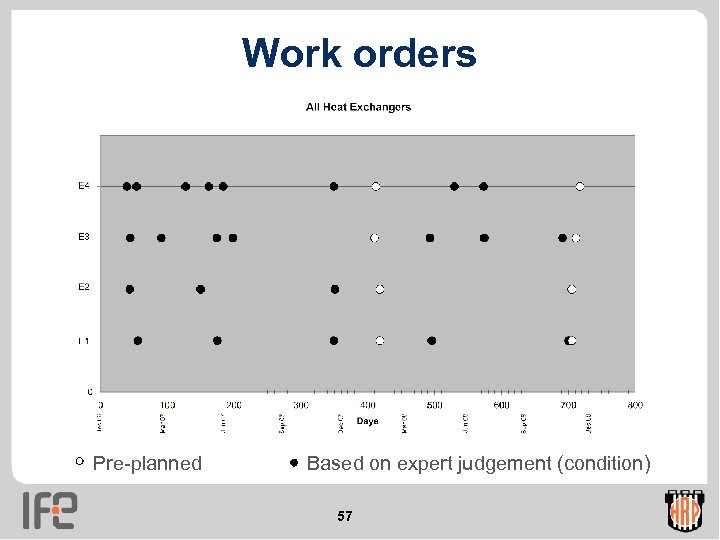

Work orders Pre-planned Based on expert judgement (condition) 57

Work orders Pre-planned Based on expert judgement (condition) 57

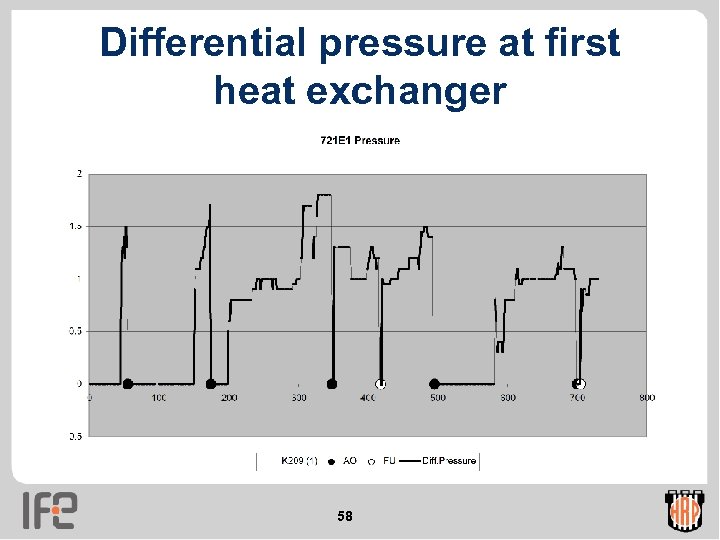

Differential pressure at first heat exchanger 58

Differential pressure at first heat exchanger 58

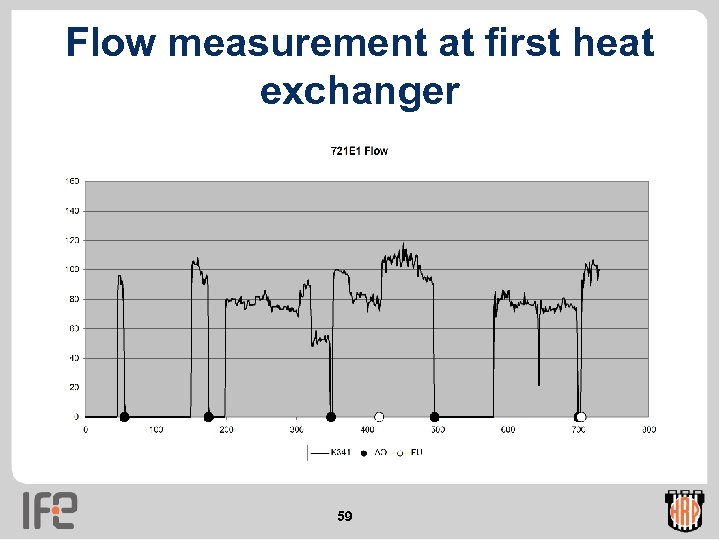

Flow measurement at first heat exchanger 59

Flow measurement at first heat exchanger 59

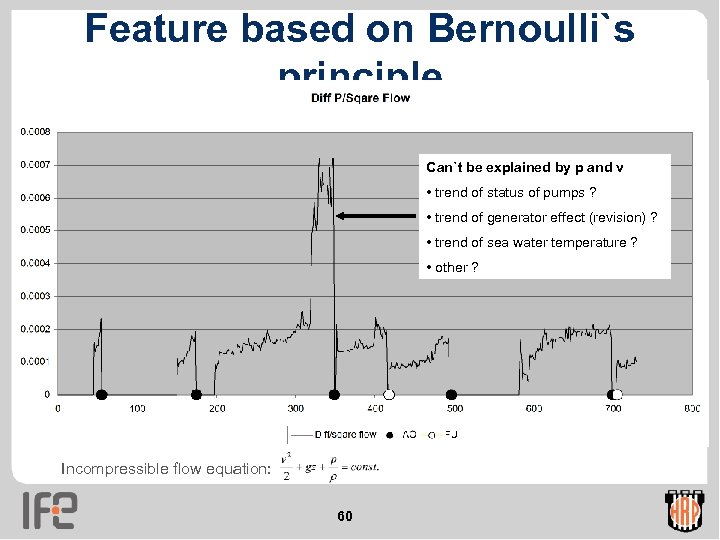

Feature based on Bernoulli`s principle Can`t be explained by p and v • trend of status of pumps ? • trend of generator effect (revision) ? • trend of sea water temperature ? • other ? Incompressible flow equation: 60

Feature based on Bernoulli`s principle Can`t be explained by p and v • trend of status of pumps ? • trend of generator effect (revision) ? • trend of sea water temperature ? • other ? Incompressible flow equation: 60

Recommendations to the IAEA 61

Recommendations to the IAEA 61

Recommendations to the IAEA (1) • Standards • Identification and analysis of existing standards for condition-monitoring, diagnostics and prognostics • ISO-13374 • MIMOSA OSA-CBM • … • Can these be applied as-is to the nuclear industry or does the nuclear industry need new specific standards? 62

Recommendations to the IAEA (1) • Standards • Identification and analysis of existing standards for condition-monitoring, diagnostics and prognostics • ISO-13374 • MIMOSA OSA-CBM • … • Can these be applied as-is to the nuclear industry or does the nuclear industry need new specific standards? 62

Recommendations to the IAEA (2) • “Aging” of digital systems • Digital I&C and SW systems have comparatively very short life spans due to rapid technological advances • Systems need to have technology modernisation and replacement as a fundamental design requirement in order to age gracefully • Possible approaches could include: • Identification of several levels of abstraction in the system design and architecture so that lower levels close to the implementation can be more easily modernised swapping obsolete components with modern ones without affecting the overall system • Investigate automatic code generation from platformindependent specifications 63

Recommendations to the IAEA (2) • “Aging” of digital systems • Digital I&C and SW systems have comparatively very short life spans due to rapid technological advances • Systems need to have technology modernisation and replacement as a fundamental design requirement in order to age gracefully • Possible approaches could include: • Identification of several levels of abstraction in the system design and architecture so that lower levels close to the implementation can be more easily modernised swapping obsolete components with modern ones without affecting the overall system • Investigate automatic code generation from platformindependent specifications 63

Recommendations to the IAEA (3) • Uncertainty Management • Highly automated I&C and SW systems will rely on real time data and additional information originating from other systems (e. g. condition monitoring and diagnostic systems) • Most sources of information will have associated a certain degree of uncertainty that will have to be appropriately assessed and taken into account in further information processing • Mechanisms for defining and treating uncertain information will be necessary 64

Recommendations to the IAEA (3) • Uncertainty Management • Highly automated I&C and SW systems will rely on real time data and additional information originating from other systems (e. g. condition monitoring and diagnostic systems) • Most sources of information will have associated a certain degree of uncertainty that will have to be appropriately assessed and taken into account in further information processing • Mechanisms for defining and treating uncertain information will be necessary 64

Recommendations to the IAEA (4) • Advances in Human System Interfaces • New I&C and SW systems deployed in new settings will require new HSI solutions • New work practices, higher automation, modular plant designs • Context-aware, multi-abstraction, multi-user HSIs • Emerging technologies could enable new work practices • Augmented Reality and hand-held technologies enable portable access to technology and advanced guidance • New interaction and collaboration technologies for distributed decision-making • User interfaces dynamically integrating data from multiple sources • Integrated Operations 65

Recommendations to the IAEA (4) • Advances in Human System Interfaces • New I&C and SW systems deployed in new settings will require new HSI solutions • New work practices, higher automation, modular plant designs • Context-aware, multi-abstraction, multi-user HSIs • Emerging technologies could enable new work practices • Augmented Reality and hand-held technologies enable portable access to technology and advanced guidance • New interaction and collaboration technologies for distributed decision-making • User interfaces dynamically integrating data from multiple sources • Integrated Operations 65

Recommendations to the IAEA (5) • Interrelation between Technological, Human and Organisational Factors • Factors related to structure, including established roles and responsibilities (within a specific role), established task description procedures, established training procedures (often activityoriented), and established supervision and management strategies • Factors related to culture, including the manners of using artefacts to produce cultural contents, Artefacts can be of tangible nature, ones such as manuals, computers, etc. , or of intangible nature, such as language, ethical values, senses of realism, etc. • Factors related to process, that are directly the result of using cultural contents to produce cultural expressions – the manifestation of the contents. Examples here are established or “accepted” ways of communication, experienced patterns of conflicts, and experienced ways of handling changes Atoosa P-J Thunem 66

Recommendations to the IAEA (5) • Interrelation between Technological, Human and Organisational Factors • Factors related to structure, including established roles and responsibilities (within a specific role), established task description procedures, established training procedures (often activityoriented), and established supervision and management strategies • Factors related to culture, including the manners of using artefacts to produce cultural contents, Artefacts can be of tangible nature, ones such as manuals, computers, etc. , or of intangible nature, such as language, ethical values, senses of realism, etc. • Factors related to process, that are directly the result of using cultural contents to produce cultural expressions – the manifestation of the contents. Examples here are established or “accepted” ways of communication, experienced patterns of conflicts, and experienced ways of handling changes Atoosa P-J Thunem 66

Invitation 6 th HOLMUG meeting (Halden On-Line Monitoring User Group) Loviisa, Finland, October 8 th- 9 th, 2009

Invitation 6 th HOLMUG meeting (Halden On-Line Monitoring User Group) Loviisa, Finland, October 8 th- 9 th, 2009

• Objectives • Information dissemination and User Feedback on on-line monitoring: • • Methods Available systems Regulatory aspects Feedback from utilities, research institutes, universities, and vendors • Previous Meetings • 2003 in Halden, • 2004 at the EHPG in Sandefjord • 2004 IAEA technical meeting on ”Increasing instrument calibration interval through on-line monitoring technologies”, in Halden • 2006 at Oskarshamn (OKG), Sweden • 2007 at Olkiluoto (TVO), Finland • 2008 at Ringhals (Vattenfall), Sweden 68

• Objectives • Information dissemination and User Feedback on on-line monitoring: • • Methods Available systems Regulatory aspects Feedback from utilities, research institutes, universities, and vendors • Previous Meetings • 2003 in Halden, • 2004 at the EHPG in Sandefjord • 2004 IAEA technical meeting on ”Increasing instrument calibration interval through on-line monitoring technologies”, in Halden • 2006 at Oskarshamn (OKG), Sweden • 2007 at Olkiluoto (TVO), Finland • 2008 at Ringhals (Vattenfall), Sweden 68

Topics • Calibration monitoring and signal validation • Tools (e. g. PEANO) and methods • Experiences • Equipment condition monitoring • Tools (e. g. aladdin, TEMPO, LIRA) and methods • Experiences • Core Surveillance • Tools (e. g. SCORPIO, VNEM) and methods • Experiences • Regulatory aspects • Requirements and experiences You are welcome and encouraged to contribute! 69

Topics • Calibration monitoring and signal validation • Tools (e. g. PEANO) and methods • Experiences • Equipment condition monitoring • Tools (e. g. aladdin, TEMPO, LIRA) and methods • Experiences • Core Surveillance • Tools (e. g. SCORPIO, VNEM) and methods • Experiences • Regulatory aspects • Requirements and experiences You are welcome and encouraged to contribute! 69

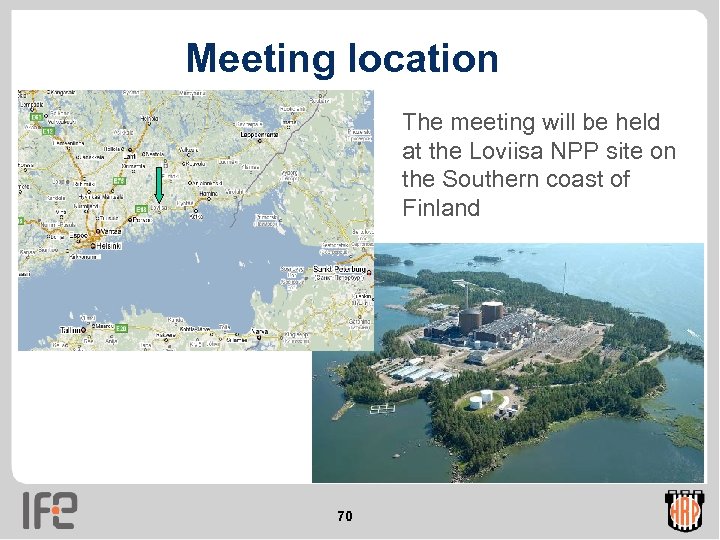

Meeting location The meeting will be held at the Loviisa NPP site on the Southern coast of Finland 70

Meeting location The meeting will be held at the Loviisa NPP site on the Southern coast of Finland 70

Meeting information • Expression of interest: June 30 th, 2009 • Contribution deadline: September 18 th, 2009 • Registration deadline: September 23 rd, 2009 • Accommodation: • Visits: Sannäs Manor www. sannaskartano. fi Loviisa plant site-tour Finnish Sauna http: //www. ife. no/events/holmug 2009 71

Meeting information • Expression of interest: June 30 th, 2009 • Contribution deadline: September 18 th, 2009 • Registration deadline: September 23 rd, 2009 • Accommodation: • Visits: Sannäs Manor www. sannaskartano. fi Loviisa plant site-tour Finnish Sauna http: //www. ife. no/events/holmug 2009 71

72

72