5016b1a2fd87a0e82a6d6ee8dbcaf0cc.ppt

- Количество слайдов: 36

Relex Reliability Software “the intuitive solution!” Relex Software Corporation 1 1

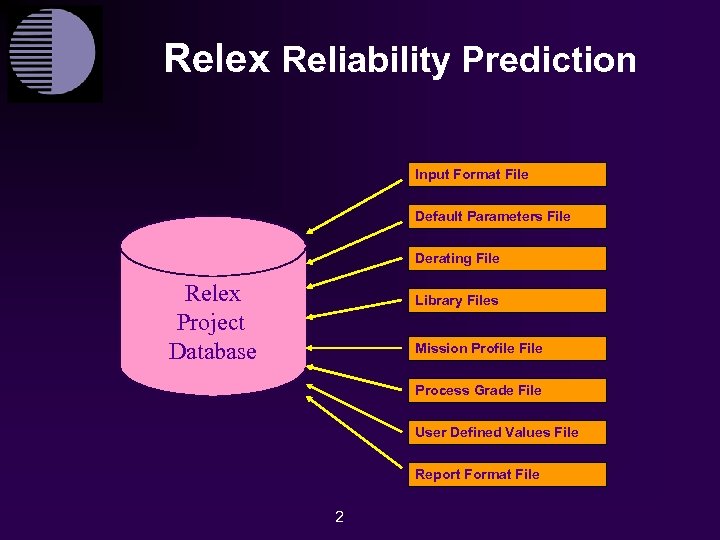

Relex Reliability Prediction Input Format File Default Parameters File Derating File Relex Project Database Library Files Mission Profile File Process Grade File User Defined Values File Report Format File 2

Primary File Type = Relex Project File (Primary Database) 3

Project File Contents · · · System Tree or Hierarchy Information Reliability Prediction Data FMEA Data Maintainability Data Reliability Block Diagram(s) Fault Tree(s) and Event Tree(s) 4

Three Major Windows · · · System Tree Window Parts Table Window FMEA Tree Window 5

System Tree Window · System Tree · · · System Hierarchy System/Assembly Properties RBD Table Fault Tree Table Event Tree Table 6

Parts Table Window · · · · Assembly Properties Parts List Prediction Data FMEA Data Maintainability Data Reliability Block Diagram Fault Tree Event Tree 7

FMEA Tree Window · Displays FMEA data for Assembly/Part · Manage FMEA items, modes, causes 8

Relex Reliability Prediction Entering Parts & Part Data. . . 9

Entering Part Data · System Tree window · Parts Table · General Data Sheet · Prediction Data Sheet 10

System Tree · Edit part data, as needed · Fields that appear based on Parts Table Input Format file 11

Parts Table · Enter parts list for the selected assembly · Simplified area for data entry · Fields & order of fields customizable · Synchronized with General Data and Prediction Data Sheets 12

General Data Tab · Enter “general information” for a selected part · Fields available are the same for all part types 13

Prediction Data Tab · Enter parameters which are specific to the selected part · Fields that are displayed are based on part type of selected part · Data requested is only that data required by the models 14

Relex Reliability Prediction “Value-Added” Files 15

Input Format Files · A file that allows you to customize data entry · Determine fields on Parts Table and System Tree 16

Defaults Files What? A file containing default parameters based on part type Why? Supply Relex with all data necessary to calculate (Calculate a quick estimate before specific data available) 17

Defaults Files Additional Notes: · · Relex built-in defaults available (Parts Count Analysis) Custom user defined default files can be created 18

Defaults Files Use in conjunction with Project files: 1. Create a Defaults file, as needed. 2. Activate the Defaults file. 3. Enter parts without part data. 4. Calculate the reliability prediction estimate. 19

Derating Files What? A table of maximum/minimum stress values allowed for each part type Why? Provides an easy way to review data 20

Derating Files Additional Notes: · · · Relex built-in derating available Custom user defined derating files can be created Several Derating files are supplied (each based on a standard) 21

Derating Files Use in conjunction with Project files: 1. Create a Derating file, as needed. 2. Activate the Derating file. 3. Enter parts/part data & calculate the prediction. 4. Determine if any parts are operating at an overstressed condition. 22

Derating Files How to determine if a part is “overstressed: ” 1. Part Record has special color on Parts Table (selected on Display tab in Tools>Options) 2. Pi Factors window indicates overstressed and why 3. Part is included on overstressed parts report 23

Derating Files What do I do if part is “overstressed? ” 1. Determine which stress value(s) are “out of range. ” 2. Consider changing the operating conditions for the part. 24

Parts Library Files What? A database or table that contains standard parts and their parameters Why? Simplifies part and part data entry 25

Parts Library Files Additional Notes: · Relex Libraries are available · Custom User Libraries can be created 26

Parts Library Files Use in conjunction with Project files: 1. Create a Library file, as needed. 2. Activate the Library file. 3. Enter a part number (press <TAB>). 4. Relex pulls the associated data from the Library file into the Project file. 27

Mission Profile Files What? A file containing conditions of a changing mission Why? 1. Supply mission time for Reliability 2. Supply data for Mission Calculations 28

Mission Profile Files Additional Notes: User enters the following parameters: · Total Mission Time (hours) · Mission phase data (Environment, Temperature, Percentage) 29

Mission Profile Files Use in conjunction with Project files: (Reliability Prediction association*) 1. Customize a Mission Profile. 2. Activate the Mission Profile. · Calculate the reliability prediction, including Mission Calculations. * Can also used in association with FMEA 30

Process Grade Files Used in conjunction PRISM only: (RAC PRISM Reliability Prediction ) · Evaluation of maturity of processes within production, etc. · Define company process grade factors 31

User-Defined Values Files What? A file that allows users to establish custom environments, quality levels, categories & subcategories Why? Account for additional environments, quality levels, categories & subcategories 32

User-Defined Values Files Use in conjunction with Project files: 1. Create a User Defined Values file, as needed. 2. Activate the User Defined Values file. 3. Enter assemblies and parts. 4. Select user defined entries from choice lists. 33

Correlation File · A list matching in-house part numbers & library part numbers · Examples: In-House PN ACME 1 ACME 2 Library PN 74 LS 00 2 N 2222 34

Correlation File Use in conjunction with Project files: 1. Create a Correlation file. 2. Activate the Correlation file. 3. Enter a part number (press <TAB>). 4. Relex pulls the data for the “associated” Library part into the Project file. 35

Report File Used in conjunction with Project files: 1. Create a Report file. 2. Activate a standard report for each project file. 3. Report formats can be used by any project and selected before printing 36

5016b1a2fd87a0e82a6d6ee8dbcaf0cc.ppt