005d5730ff0d139189316237a33e11ff.ppt

- Количество слайдов: 26

Releasing Hidden Capital To Maximise Profitability How to be Creative, Innovative, Fast & Flexible Dr. John Blakemore Principal Innovation Blakemore Consulting Int. , masc@blakemore. com. au, www. blakemore. com. au, 0414970758 National President Manufacturing Society of Australia Advisor to Previous Australian Government on Innovation and Research and Development

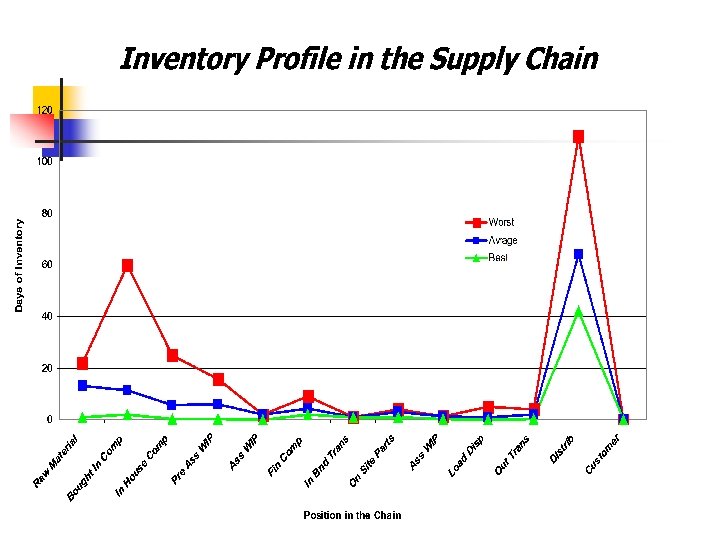

Sources of Hidden Capital And Costs 1. Inventory (RM, WIP, FG ) 2. Consignment Stock 3. Old Inventory 4. Excess labour 5. Waste in all forms 6. Product made greater than EPR 7. Debtors > Creditors 8. Interest rates overdraft > borrowings 9. Repairs and rework and errors 10. Defective product and process. 11. Not optimizing cycle time and lead time etc…

Lessons from The Best Companies in the World 1. John Blakemore recently visited some of the best companies in the world including, Honda, Toyota, Canon, Mazda, Kawai, Panasonic as part of an investigation to add to our understanding of Creative Lean Flow. 2. These lessons can be applied to all Enterprises for both information flow and product flow. 3. To the list of TQM, and Lean we now need to add Kyosei, and the German Meister system. 4. Demand=Production=Supply

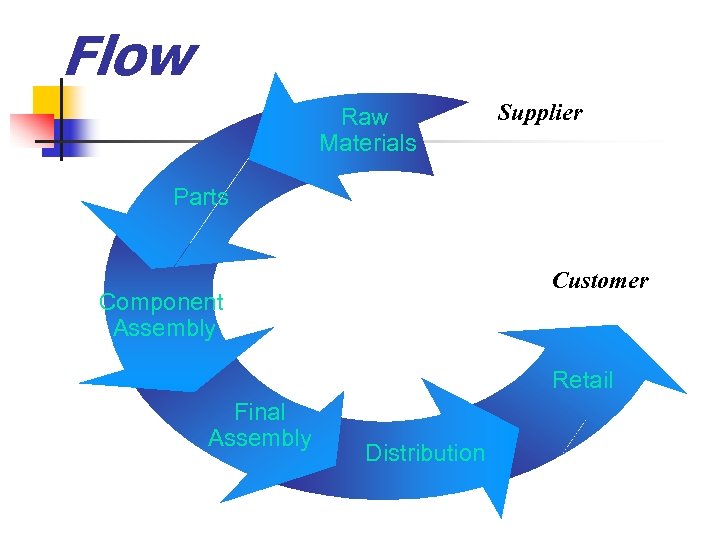

Flow Raw Materials Supplier Parts Customer Component Assembly Retail Final Assembly Distribution

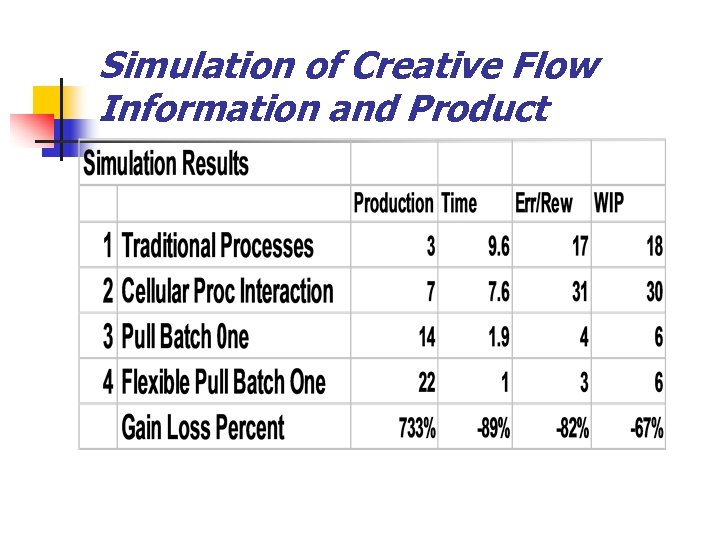

Simulation of Creative Flow Information and Product

Strategy What we need to Know 1. Your Business 2. Industry Trends 3. Organisational Effectiveness 4. Market Opportunities 5. Competitive Position 6. The Environment 7. Global Trends Strategic Advantage for Winning (SAW) Match Vision With Capability and put in Control Systems Strategic Plan Action Plans

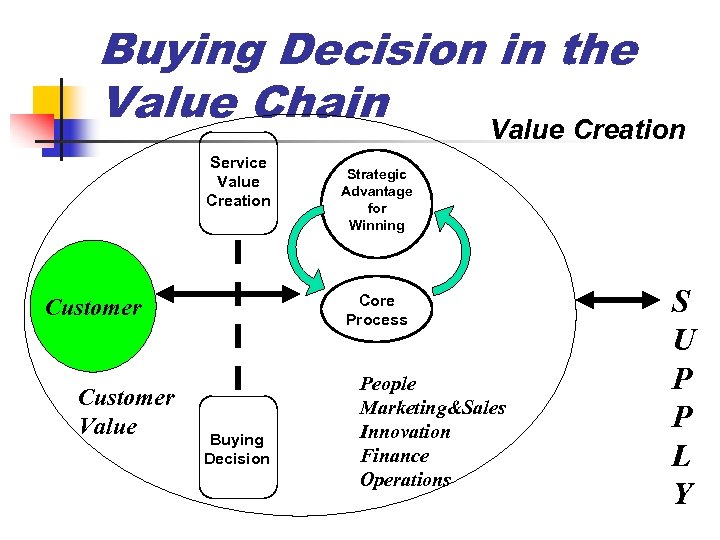

Buying Decision in the Value Chain Value Creation Service Value Creation Core Process Customer Value Strategic Advantage for Winning Buying Decision People Marketing&Sales Innovation Finance Operations S U P P L Y

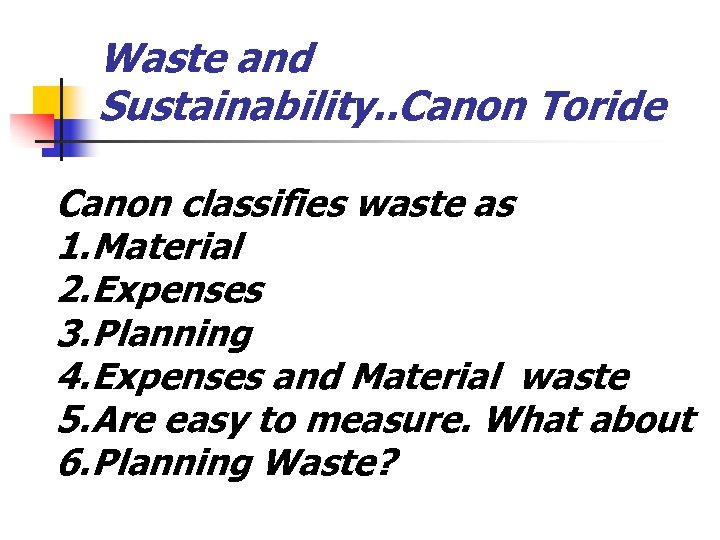

Waste and Sustainability. . Canon Toride Canon classifies waste as 1. Material 2. Expenses 3. Planning 4. Expenses and Material waste 5. Are easy to measure. What about 6. Planning Waste?

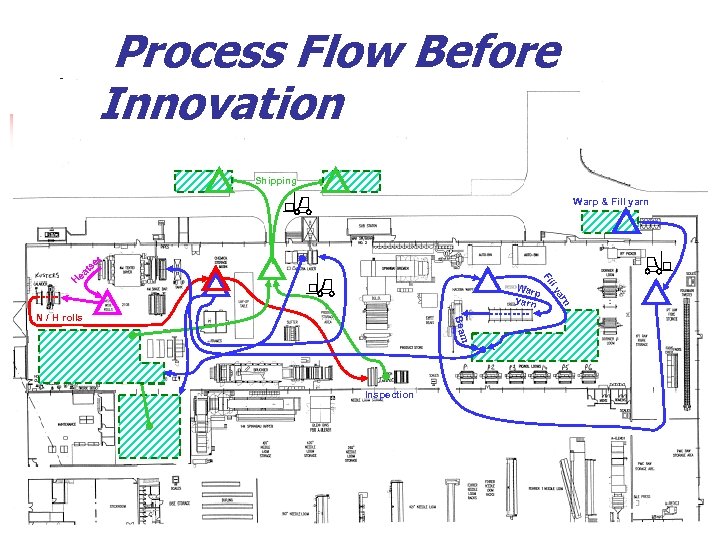

Process Flow Before Innovation Shipping Warp & Fill yarn t se rn Inspection ya m Bea N / H rolls ll Warp yarn Fi at He

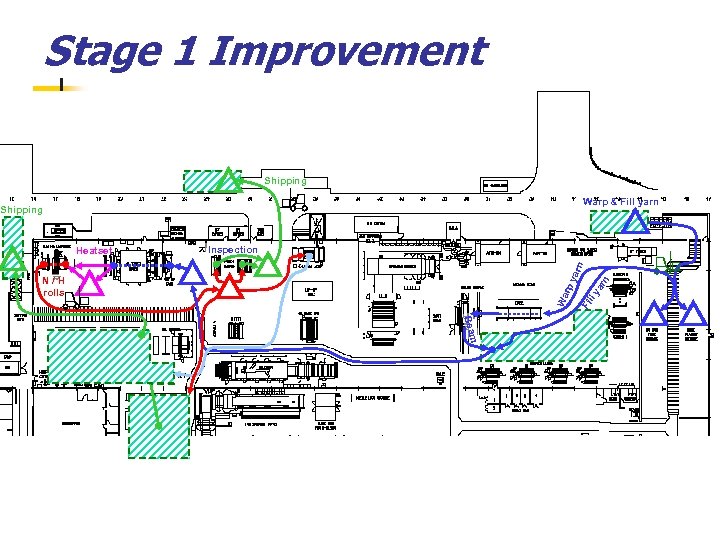

Stage 1 Improvement Shipping Warp & Fill yarn Shipping Inspection ya rn Fi Wa rp N/H rolls ll yar n Heatset m Bea

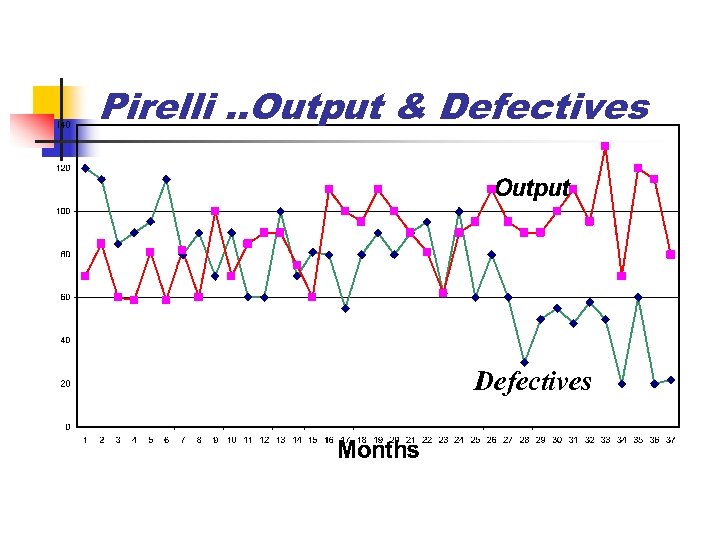

Pirelli. . Output & Defectives

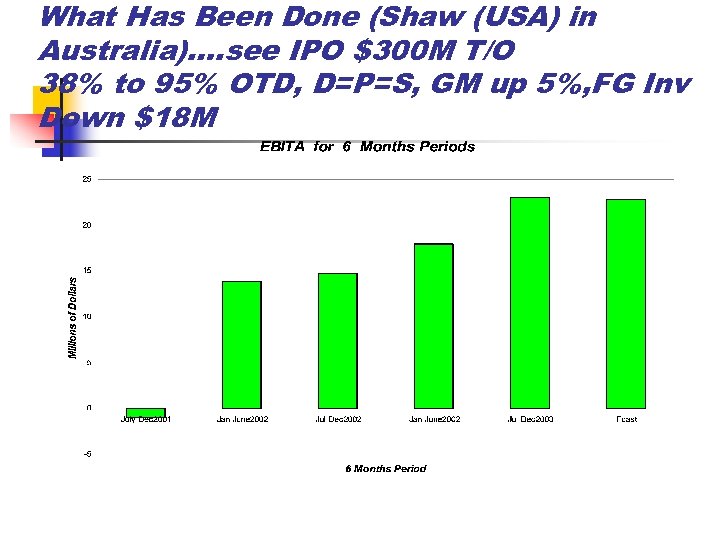

What Has Been Done (Shaw (USA) in Australia)…. see IPO $300 M T/O 38% to 95% OTD, D=P=S, GM up 5%, FG Inv Down $18 M

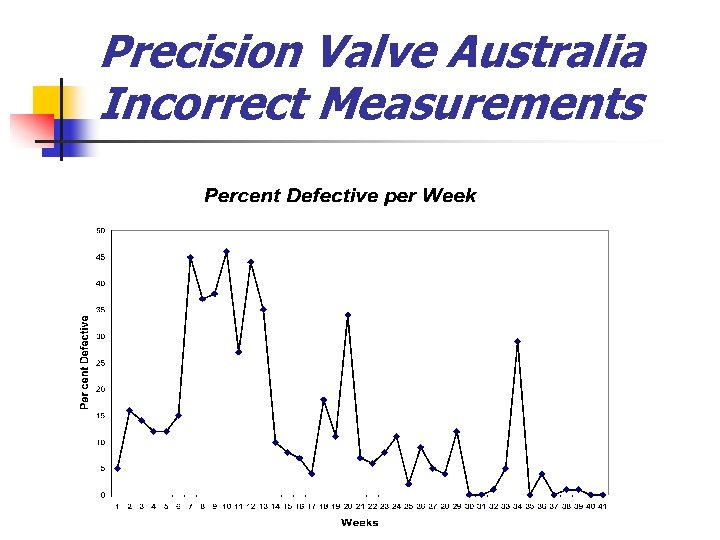

Precision Valve Australia Incorrect Measurements

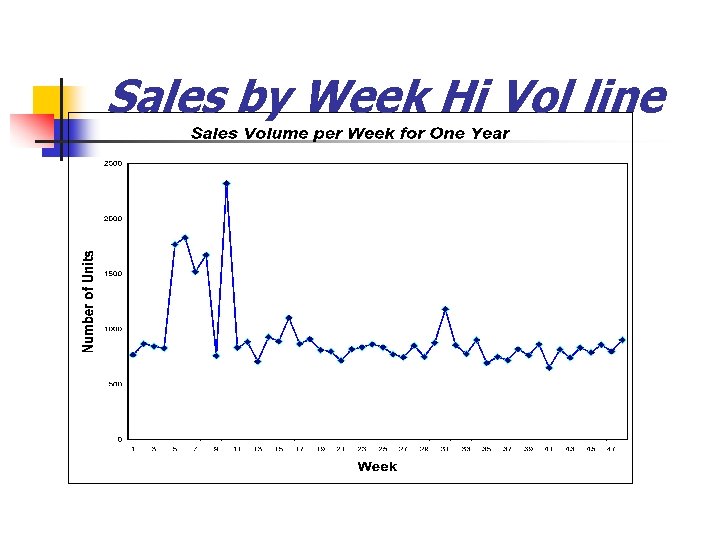

Sales by Week Hi Vol line

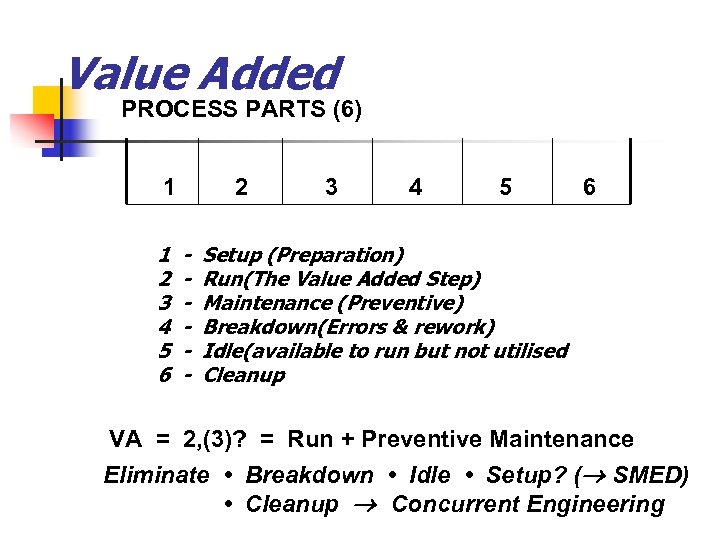

Value Added PROCESS PARTS (6) 1 1 2 3 4 5 6 2 - 3 4 5 6 Setup (Preparation) Run(The Value Added Step) Maintenance (Preventive) Breakdown(Errors & rework) Idle(available to run but not utilised Cleanup VA = 2, (3)? = Run + Preventive Maintenance Eliminate • Breakdown • Idle • Setup? ( SMED) • Cleanup Concurrent Engineering

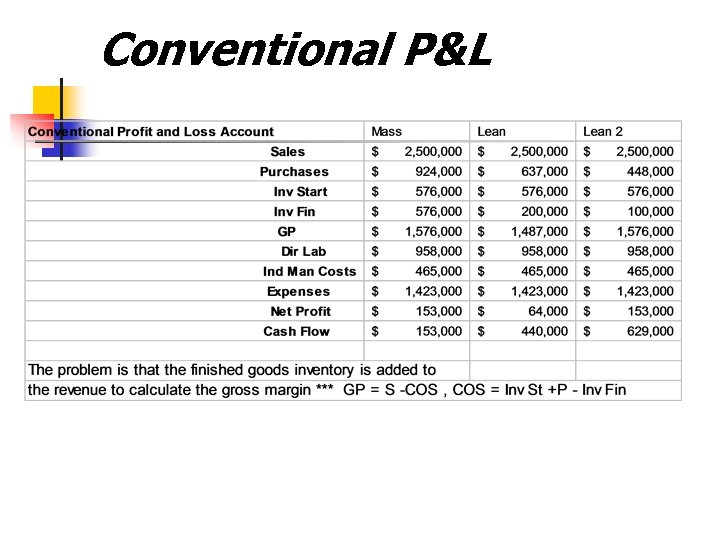

Conventional P&L

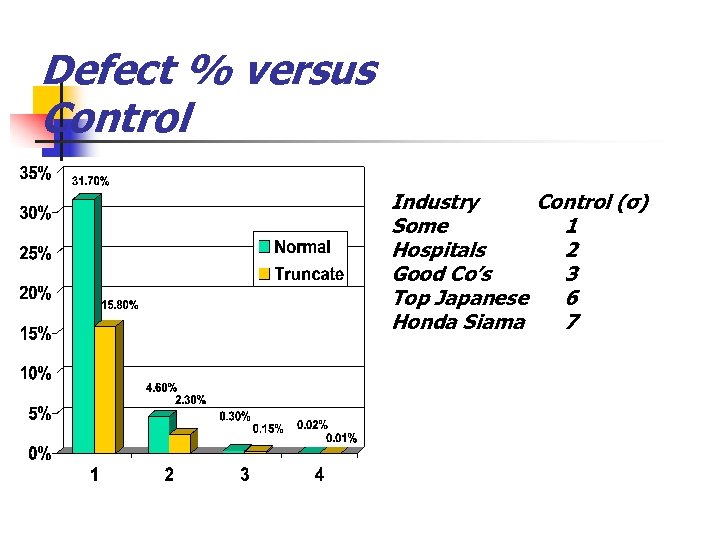

Defect % versus Control Industry Control (σ) Some 1 Hospitals 2 Good Co’s 3 Top Japanese 6 Honda Siama 7

25 Lean, Green, Rules 1. People (1, 2, 3) 2. Integration (4 to 9) 3. Planning(10 to 16) 4. Operations(17 to 25)

Cochlear and Toyota 1. Cochlear is Australia’s most innovative company. (Ibis 2005) 2. Blakemore Consulting consults to Dr Chris Roberts and has redesigned all major manufacturing systems using Lean 3. USA hospitals were losing money fitting Cochlear Implants until they studied the Toyota system in Japan…now profitable. (ref Chris Roberts 2005) 4. GM was the world’s biggest carmaker but Toyota could have bought all of GM with last years profit alone (Ref The Australian 2005)…since then GM, Ford and Chrysler are virtually bankrupt

Concepts • Cooperative Team Based Culture • Continuous learning and improvement • Kaizen and Kyosei • Continuous Flow, Max Value Added • Optimize the Whole • Pull by Customer on Demand • Lead Time Reduction (Velocity) • Quality Cost Delivery • Recognize 6 parts of a process • Measure and improve the VA step • Do Not Change the plan but reduce plan time

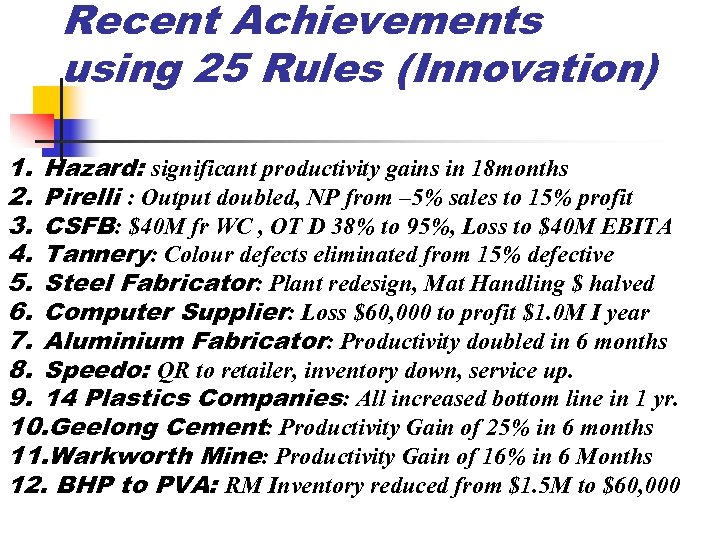

Recent Achievements using 25 Rules (Innovation) 1. Hazard: significant productivity gains in 18 months 2. Pirelli : Output doubled, NP from – 5% sales to 15% profit 3. CSFB: $40 M fr WC , OT D 38% to 95%, Loss to $40 M EBITA 4. Tannery: Colour defects eliminated from 15% defective 5. Steel Fabricator: Plant redesign, Mat Handling $ halved 6. Computer Supplier: Loss $60, 000 to profit $1. 0 M I year 7. Aluminium Fabricator: Productivity doubled in 6 months 8. Speedo: QR to retailer, inventory down, service up. 9. 14 Plastics Companies: All increased bottom line in 1 yr. 10. Geelong Cement: Productivity Gain of 25% in 6 months 11. Warkworth Mine: Productivity Gain of 16% in 6 Months 12. BHP to PVA: RM Inventory reduced from $1. 5 M to $60, 000

The End

Acknowledgements • • • Blakemore Consulting is very conscious of the importance of the confidentiality we afford to our clients. All results and comments presented here have been supported by the relevant executives and in particular we would like to thank the following clients: Dr. Ezzelino Leonardi Tech Director Pirelli Cables Dr Chris Roberts CEO Cochlear Mr. Michael Gerakios MD Albany International Mr. Norris Little President Shaw USA Dr. Bob Blake, Mr Barry Connell, MD Precision Valve Australia Mr. Brendan Dalton Ausindustry Canberra Mr. Gary Lingford GM Geelong Cement Mr. Nick Stump MD Comalco Australia Mr. Don Mathews President SCAHA Mr. Chuck Smith CEO Moore Business Systems Mr Richard Hammond CEO Adelaide Brighton Mr Bob Mc. Callum, CEO Panasonic Australia

005d5730ff0d139189316237a33e11ff.ppt