410265e28dce5f5a61f741f7fbaab9c3.ppt

- Количество слайдов: 16

REGISTRATION CRITERIA AS AN ACCREDITED PERSON MASTER INSTALLATION ELECTRICIAN (M. I. E) Application to THE CHIEF INSPECTOR for Registration under the OHS Act 85 of 1993 Presented by: Mel Wilmans Hazloc Consultant Moderator for Specialized Elect Installation Codes Member of D. o. L’s IEMIE Committee

REGISTRATION CRITERIA AS AN ACCREDITED PERSON MASTER INSTALLATION ELECTRICIAN (M. I. E) Application to THE CHIEF INSPECTOR for Registration under the OHS Act 85 of 1993 Presented by: Mel Wilmans Hazloc Consultant Moderator for Specialized Elect Installation Codes Member of D. o. L’s IEMIE Committee

INTRODUCTION In order to ensure COMPLIANTE ELECTRICAL INSTALLATIONS, a domino effect starts with the most basic yet DEADLY DOMESTIC installation, thus to minimise the IMPACT/RISK we opted for addressing the level of ‘’qualification’’ this would ensure a new approach and a higher technical skilled candidate. This approach would be more beneficial for future responsibilities as a m. i. e. The QC is done by a non-tech person , i. e. housewife, whereby in the more advance field i. e. industrial the QC is done by another technical person with minimal/limited or some knowledge of the Act & Codes 2

INTRODUCTION In order to ensure COMPLIANTE ELECTRICAL INSTALLATIONS, a domino effect starts with the most basic yet DEADLY DOMESTIC installation, thus to minimise the IMPACT/RISK we opted for addressing the level of ‘’qualification’’ this would ensure a new approach and a higher technical skilled candidate. This approach would be more beneficial for future responsibilities as a m. i. e. The QC is done by a non-tech person , i. e. housewife, whereby in the more advance field i. e. industrial the QC is done by another technical person with minimal/limited or some knowledge of the Act & Codes 2

AIM of the BROUCHER The aim of this (D. o. L’s) brochure is to inform, and provide guidance criteria for candidates interested in applying for accreditation as an ETSP, IE and MIE. The document was developed by appointed IEMIE group members and invited external role-players. 3

AIM of the BROUCHER The aim of this (D. o. L’s) brochure is to inform, and provide guidance criteria for candidates interested in applying for accreditation as an ETSP, IE and MIE. The document was developed by appointed IEMIE group members and invited external role-players. 3

The Philosophy A person must achieve a set qualification considered to be on par with the responsibilities he/she carries Unit standard requirement, measures the application of theory (does the candidate know and can he/she do) One year practical to ensure that the candidate had the opportunity to “touch and feel” techniques and equipment Application of the practical assessment component CLEARLY UNDERSTOOD, and correctly assessed. 4

The Philosophy A person must achieve a set qualification considered to be on par with the responsibilities he/she carries Unit standard requirement, measures the application of theory (does the candidate know and can he/she do) One year practical to ensure that the candidate had the opportunity to “touch and feel” techniques and equipment Application of the practical assessment component CLEARLY UNDERSTOOD, and correctly assessed. 4

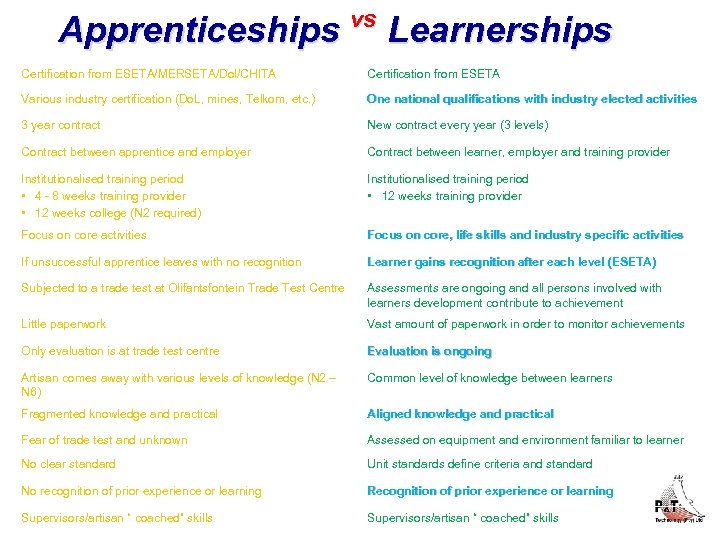

Apprenticeships vs Learnerships Certification from ESETA/MERSETA/Dol/CHITA Certification from ESETA Various industry certification (Do. L, mines, Telkom, etc. ) One national qualifications with industry elected activities 3 year contract New contract every year (3 levels) Contract between apprentice and employer Contract between learner, employer and training provider Institutionalised training period • 4 - 8 weeks training provider • 12 weeks college (N 2 required) Institutionalised training period • 12 weeks training provider Focus on core activities Focus on core, life skills and industry specific activities If unsuccessful apprentice leaves with no recognition Learner gains recognition after each level (ESETA) Subjected to a trade test at Olifantsfontein Trade Test Centre Assessments are ongoing and all persons involved with learners development contribute to achievement Little paperwork Vast amount of paperwork in order to monitor achievements Only evaluation is at trade test centre Evaluation is ongoing Artisan comes away with various levels of knowledge (N 2 – N 6) Common level of knowledge between learners Fragmented knowledge and practical Aligned knowledge and practical Fear of trade test and unknown Assessed on equipment and environment familiar to learner No clear standard Unit standards define criteria and standard No recognition of prior experience or learning Recognition of prior experience or learning Supervisors/artisan “ coached” skills

Apprenticeships vs Learnerships Certification from ESETA/MERSETA/Dol/CHITA Certification from ESETA Various industry certification (Do. L, mines, Telkom, etc. ) One national qualifications with industry elected activities 3 year contract New contract every year (3 levels) Contract between apprentice and employer Contract between learner, employer and training provider Institutionalised training period • 4 - 8 weeks training provider • 12 weeks college (N 2 required) Institutionalised training period • 12 weeks training provider Focus on core activities Focus on core, life skills and industry specific activities If unsuccessful apprentice leaves with no recognition Learner gains recognition after each level (ESETA) Subjected to a trade test at Olifantsfontein Trade Test Centre Assessments are ongoing and all persons involved with learners development contribute to achievement Little paperwork Vast amount of paperwork in order to monitor achievements Only evaluation is at trade test centre Evaluation is ongoing Artisan comes away with various levels of knowledge (N 2 – N 6) Common level of knowledge between learners Fragmented knowledge and practical Aligned knowledge and practical Fear of trade test and unknown Assessed on equipment and environment familiar to learner No clear standard Unit standards define criteria and standard No recognition of prior experience or learning Recognition of prior experience or learning Supervisors/artisan “ coached” skills

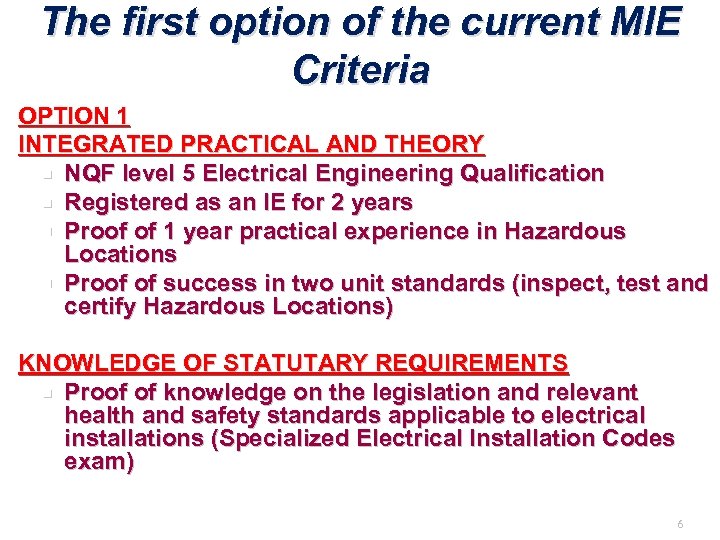

The first option of the current MIE Criteria OPTION 1 INTEGRATED PRACTICAL AND THEORY NQF level 5 Electrical Engineering Qualification Registered as an IE for 2 years Proof of 1 year practical experience in Hazardous Locations Proof of success in two unit standards (inspect, test and certify Hazardous Locations) KNOWLEDGE OF STATUTARY REQUIREMENTS Proof of knowledge on the legislation and relevant health and safety standards applicable to electrical installations (Specialized Electrical Installation Codes exam) 6

The first option of the current MIE Criteria OPTION 1 INTEGRATED PRACTICAL AND THEORY NQF level 5 Electrical Engineering Qualification Registered as an IE for 2 years Proof of 1 year practical experience in Hazardous Locations Proof of success in two unit standards (inspect, test and certify Hazardous Locations) KNOWLEDGE OF STATUTARY REQUIREMENTS Proof of knowledge on the legislation and relevant health and safety standards applicable to electrical installations (Specialized Electrical Installation Codes exam) 6

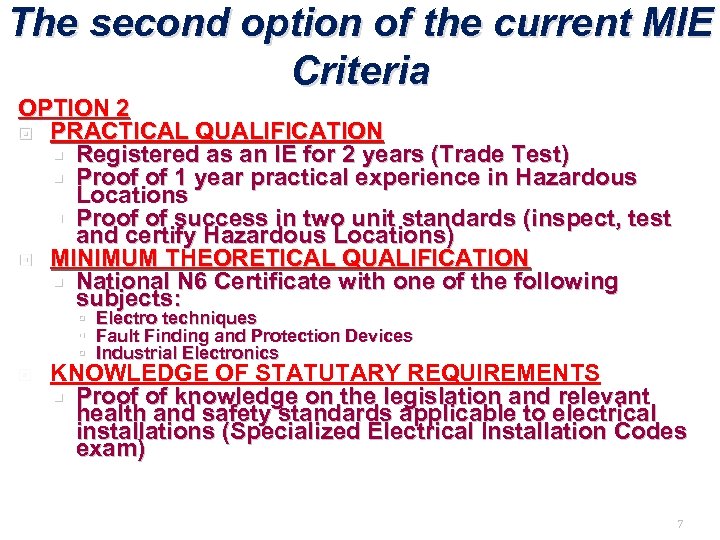

The second option of the current MIE Criteria OPTION 2 PRACTICAL QUALIFICATION Registered as an IE for 2 years (Trade Test) Proof of 1 year practical experience in Hazardous Locations Proof of success in two unit standards (inspect, test and certify Hazardous Locations) MINIMUM THEORETICAL QUALIFICATION National N 6 Certificate with one of the following subjects: Electro techniques Fault Finding and Protection Devices Industrial Electronics KNOWLEDGE OF STATUTARY REQUIREMENTS Proof of knowledge on the legislation and relevant health and safety standards applicable to electrical installations (Specialized Electrical Installation Codes exam) 7

The second option of the current MIE Criteria OPTION 2 PRACTICAL QUALIFICATION Registered as an IE for 2 years (Trade Test) Proof of 1 year practical experience in Hazardous Locations Proof of success in two unit standards (inspect, test and certify Hazardous Locations) MINIMUM THEORETICAL QUALIFICATION National N 6 Certificate with one of the following subjects: Electro techniques Fault Finding and Protection Devices Industrial Electronics KNOWLEDGE OF STATUTARY REQUIREMENTS Proof of knowledge on the legislation and relevant health and safety standards applicable to electrical installations (Specialized Electrical Installation Codes exam) 7

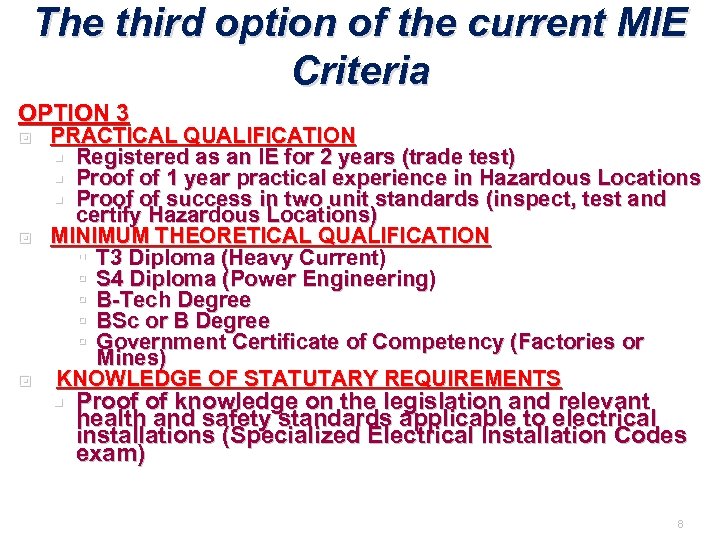

The third option of the current MIE Criteria OPTION 3 PRACTICAL QUALIFICATION Registered as an IE for 2 years (trade test) Proof of 1 year practical experience in Hazardous Locations Proof of success in two unit standards (inspect, test and certify Hazardous Locations) MINIMUM THEORETICAL QUALIFICATION T 3 Diploma (Heavy Current) S 4 Diploma (Power Engineering) B-Tech Degree BSc or B Degree Government Certificate of Competency (Factories or Mines) KNOWLEDGE OF STATUTARY REQUIREMENTS Proof of knowledge on the legislation and relevant health and safety standards applicable to electrical installations (Specialized Electrical Installation Codes exam) 8

The third option of the current MIE Criteria OPTION 3 PRACTICAL QUALIFICATION Registered as an IE for 2 years (trade test) Proof of 1 year practical experience in Hazardous Locations Proof of success in two unit standards (inspect, test and certify Hazardous Locations) MINIMUM THEORETICAL QUALIFICATION T 3 Diploma (Heavy Current) S 4 Diploma (Power Engineering) B-Tech Degree BSc or B Degree Government Certificate of Competency (Factories or Mines) KNOWLEDGE OF STATUTARY REQUIREMENTS Proof of knowledge on the legislation and relevant health and safety standards applicable to electrical installations (Specialized Electrical Installation Codes exam) 8

Advantage of Candidates with high Tertiary Qualifications > Highly qualified pool of candidates > This would in any case be a group of people that strive to achieve more, that just being an artisan > They would be able to express a professional view on all related matters concerning their field of expertise on a higher technical level > They would have theoretical knowledge to write comprehensive technical reports. (make use of reference documentation) > ECSA ranking acceptance for these people, in achieving professional status > There is the three criteria, practical, qualifications, legal knowledge component > The role of the assessor is critical, should the assessment not being done correctly the below average candidates WILL slip through!!! 9

Advantage of Candidates with high Tertiary Qualifications > Highly qualified pool of candidates > This would in any case be a group of people that strive to achieve more, that just being an artisan > They would be able to express a professional view on all related matters concerning their field of expertise on a higher technical level > They would have theoretical knowledge to write comprehensive technical reports. (make use of reference documentation) > ECSA ranking acceptance for these people, in achieving professional status > There is the three criteria, practical, qualifications, legal knowledge component > The role of the assessor is critical, should the assessment not being done correctly the below average candidates WILL slip through!!! 9

Disadvantages of only allowing highly theoretical qualified candidates > The ’POOL’ is getting smaller much quicker that we anticipated > These brilliant people would move into management, since they are prepaired to walk the extra mile and achieve more, than just being an artisan !! > The sharing of knowledge between the experienced people and theoretical have created a gap, Why ? Sharing their practical knowledge to no benefit to themselves. > Paper work is a technical persons worst nightmare > What does a professional status mean to the man in the street !!! Unless it has a financial advantage > The people that were in the process of achieving their MIE status just stopped, why the effort > No more motivation to attempt the M. I. E 10

Disadvantages of only allowing highly theoretical qualified candidates > The ’POOL’ is getting smaller much quicker that we anticipated > These brilliant people would move into management, since they are prepaired to walk the extra mile and achieve more, than just being an artisan !! > The sharing of knowledge between the experienced people and theoretical have created a gap, Why ? Sharing their practical knowledge to no benefit to themselves. > Paper work is a technical persons worst nightmare > What does a professional status mean to the man in the street !!! Unless it has a financial advantage > The people that were in the process of achieving their MIE status just stopped, why the effort > No more motivation to attempt the M. I. E 10

Disadvantage of Appointing Youngsters > They will have theoretical qualifications, but would lack practical ability > No background in this highly specialized environment > Limited coaches / instructors for on job guidance > No or limited practical experience thus limited ability > No access to these specialized plants / installations > Does not understand the legal implications of non-compliances > Do not know what is ‘’Supporting Documentation’’ when conducting an inspection and test or issuing C. o. C’s even how to compile it. > Many youngsters do not have responsibilities, living carefree without considering their future !! 11

Disadvantage of Appointing Youngsters > They will have theoretical qualifications, but would lack practical ability > No background in this highly specialized environment > Limited coaches / instructors for on job guidance > No or limited practical experience thus limited ability > No access to these specialized plants / installations > Does not understand the legal implications of non-compliances > Do not know what is ‘’Supporting Documentation’’ when conducting an inspection and test or issuing C. o. C’s even how to compile it. > Many youngsters do not have responsibilities, living carefree without considering their future !! 11

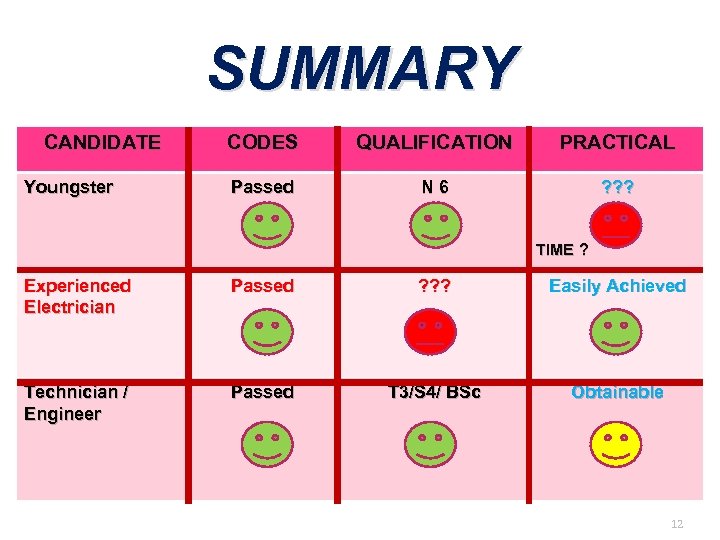

SUMMARY CANDIDATE Youngster CODES QUALIFICATION PRACTICAL Passed N 6 ? ? ? TIME ? Experienced Electrician Passed ? ? ? Easily Achieved Technician / Engineer Passed T 3/S 4/ BSc Obtainable 12

SUMMARY CANDIDATE Youngster CODES QUALIFICATION PRACTICAL Passed N 6 ? ? ? TIME ? Experienced Electrician Passed ? ? ? Easily Achieved Technician / Engineer Passed T 3/S 4/ BSc Obtainable 12

PROPOSAL Re-instate the N 4 in stead of the current N 6 qualification requirement Make available more accredited training facilities available, in all regions Update the Unit standards, and add where shortfalls are identified. A defined career path for all candidates in the electrical fields. Ensure all assessors & training centres apply the same rules, to deliver quality candidates. 13

PROPOSAL Re-instate the N 4 in stead of the current N 6 qualification requirement Make available more accredited training facilities available, in all regions Update the Unit standards, and add where shortfalls are identified. A defined career path for all candidates in the electrical fields. Ensure all assessors & training centres apply the same rules, to deliver quality candidates. 13

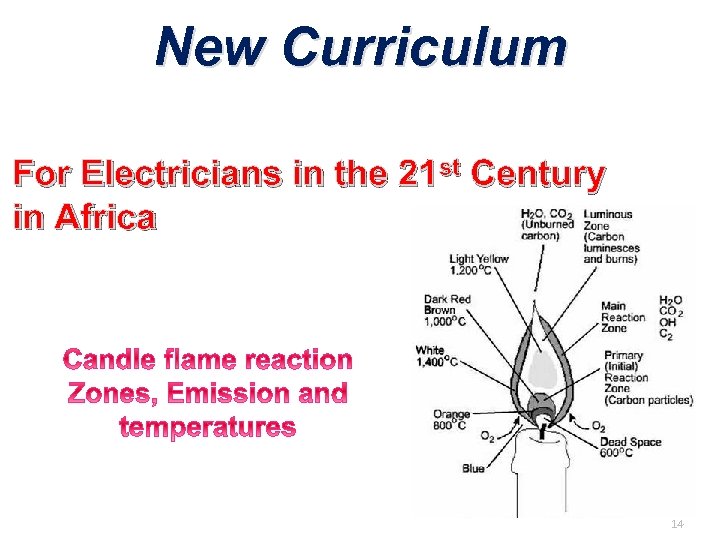

New Curriculum For Electricians in the 21 st Century in Africa 14

New Curriculum For Electricians in the 21 st Century in Africa 14

QUESTIONS THANK YOU

QUESTIONS THANK YOU

CONTACT DETAILS Mel Wilmans National Moderator: SPECIALIZED ELECTRICAL INSTALLATION CODES Tel : (016) 971 4685 Fax: (086) 626 0260 Cell: 082 895 6741 E-mail: melwil@absamail. co. za Pieter Dempsey National Examiner : SPOECIALIZED ELECTRICAL INSTALLATION CODES Tel: (011) 892 0804 Fax : (011) 892 0702 E-mail: kidark@global. co. za Nick Du Plessis P and T Technology (Pty) Ltd Tel: (011) 827 4113/6 Fax : (011) 8274118 http: // www. pandttechnology. co. za E-mail: nick@pandttechnology. co. za 16

CONTACT DETAILS Mel Wilmans National Moderator: SPECIALIZED ELECTRICAL INSTALLATION CODES Tel : (016) 971 4685 Fax: (086) 626 0260 Cell: 082 895 6741 E-mail: melwil@absamail. co. za Pieter Dempsey National Examiner : SPOECIALIZED ELECTRICAL INSTALLATION CODES Tel: (011) 892 0804 Fax : (011) 892 0702 E-mail: kidark@global. co. za Nick Du Plessis P and T Technology (Pty) Ltd Tel: (011) 827 4113/6 Fax : (011) 8274118 http: // www. pandttechnology. co. za E-mail: nick@pandttechnology. co. za 16