254c57102056d2aea2855937de0c05f6.ppt

- Количество слайдов: 14

Refractory Solutions for Cement Manufacturing

Refractory Solutions for Cement Manufacturing

Vesuvius Linings - Industrial Processes Company Overview VESUVIUS is a worldwide leader in the development, manufacture and marketing of high performance speciality ceramics, refractory products and control systems for demanding industrial applications. Through continuous improvement and monitoring of our business, Vesuvius strives to develop high quality products that offer tangible productivity benefits to our customers There are: Ø Ø Ø 80 manufacturing locations; 130 Sales and service locations; 14 Research and Development facilities; worldwide, with offices or representation in most industrialised countries. To enable us to focus on the needs of our customers, the company’s Linings business is divided by user application. Non-steel, glass and foundry industries are served by the Industrial Processes Division VESUVIUS Industrial Process Division supplies a wide range of industries and applications including: Ø Ø Ø Ø www. vesuvius. com Aluminium Cement & Lime Minerals Processing Hydrocarbon Processing Power Generation Incineration Ceramics

Vesuvius Linings - Industrial Processes Company Overview VESUVIUS is a worldwide leader in the development, manufacture and marketing of high performance speciality ceramics, refractory products and control systems for demanding industrial applications. Through continuous improvement and monitoring of our business, Vesuvius strives to develop high quality products that offer tangible productivity benefits to our customers There are: Ø Ø Ø 80 manufacturing locations; 130 Sales and service locations; 14 Research and Development facilities; worldwide, with offices or representation in most industrialised countries. To enable us to focus on the needs of our customers, the company’s Linings business is divided by user application. Non-steel, glass and foundry industries are served by the Industrial Processes Division VESUVIUS Industrial Process Division supplies a wide range of industries and applications including: Ø Ø Ø Ø www. vesuvius. com Aluminium Cement & Lime Minerals Processing Hydrocarbon Processing Power Generation Incineration Ceramics

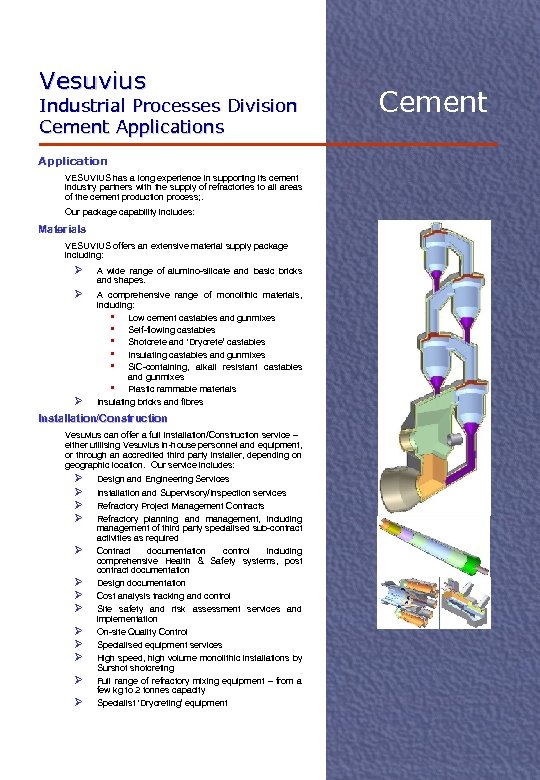

Vesuvius Industrial Processes Division Cement Applications Application VESUVIUS has a long experience in supporting its cement industry partners with the supply of refractories to all areas of the cement production process; . Our package capability includes: Materials VESUVIUS offers an extensive material supply package including: Ø A wide range of alumino-silicate and basic bricks and shapes. Ø A comprehensive range of monolithic materials, including: • Low cement castables and gunmixes • Self-flowing castables • Shotcrete and ‘Drycrete’ castables • Insulating castables and gunmixes • Si. C-containing, alkali resistant castables and gunmixes • Plastic rammable materials Insulating bricks and fibres Ø Installation/Construction Vesuvius can offer a full Installation/Construction service – either utilising Vesuvius in-house personnel and equipment, or through an accredited third party installer, depending on geographic location. Our service includes: Ø Ø Ø Ø Design and Engineering Services Installation and Supervisory/Inspection services Refractory Project Management Contracts Refractory planning and management, including management of third party specialised sub-contract activities as required Contract documentation control including comprehensive Health & Safety systems, post contract documentation Design documentation Cost analysis tracking and control Site safety and risk assessment services and implementation On-site Quality Control Specialised equipment services High speed, high volume monolithic installations by Surshotcreting Full range of refractory mixing equipment – from a few kg to 2 tonnes capacity Specialist ‘Drycreting’ equipment Cement

Vesuvius Industrial Processes Division Cement Applications Application VESUVIUS has a long experience in supporting its cement industry partners with the supply of refractories to all areas of the cement production process; . Our package capability includes: Materials VESUVIUS offers an extensive material supply package including: Ø A wide range of alumino-silicate and basic bricks and shapes. Ø A comprehensive range of monolithic materials, including: • Low cement castables and gunmixes • Self-flowing castables • Shotcrete and ‘Drycrete’ castables • Insulating castables and gunmixes • Si. C-containing, alkali resistant castables and gunmixes • Plastic rammable materials Insulating bricks and fibres Ø Installation/Construction Vesuvius can offer a full Installation/Construction service – either utilising Vesuvius in-house personnel and equipment, or through an accredited third party installer, depending on geographic location. Our service includes: Ø Ø Ø Ø Design and Engineering Services Installation and Supervisory/Inspection services Refractory Project Management Contracts Refractory planning and management, including management of third party specialised sub-contract activities as required Contract documentation control including comprehensive Health & Safety systems, post contract documentation Design documentation Cost analysis tracking and control Site safety and risk assessment services and implementation On-site Quality Control Specialised equipment services High speed, high volume monolithic installations by Surshotcreting Full range of refractory mixing equipment – from a few kg to 2 tonnes capacity Specialist ‘Drycreting’ equipment Cement

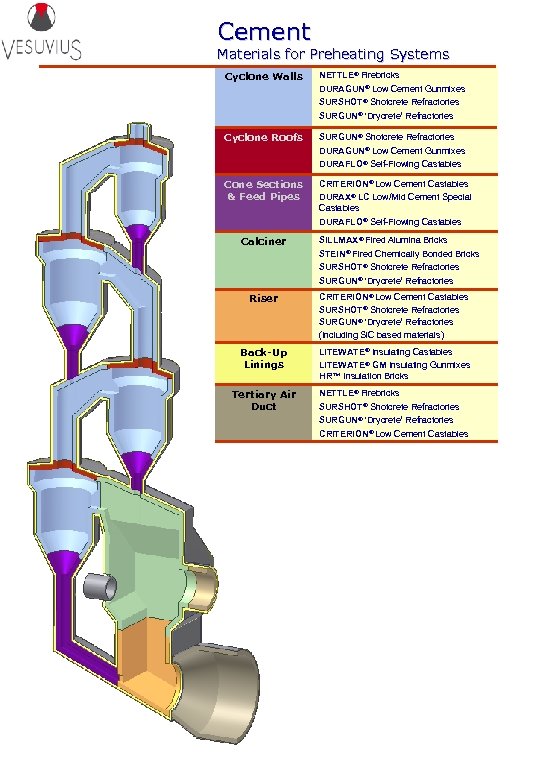

Cement Materials for Preheating Systems Cyclone Walls NETTLE® Firebricks DURAGUN® Low Cement Gunmixes SURSHOT® Shotcrete Refractories SURGUN® ‘Drycrete’ Refractories Cyclone Roofs SURGUN® Shotcrete Refractories DURAGUN® Low Cement Gunmixes DURAFLO® Self-Flowing Castables Cone Sections & Feed Pipes CRITERION® Low Cement Castables DURAX® LC Low/Mid Cement Special Castables DURAFLO® Self-Flowing Castables Calciner SILLMAX® Fired Alumina Bricks STEIN® Fired Chemically Bonded Bricks SURSHOT® Shotcrete Refractories SURGUN® ‘Drycrete’ Refractories Riser Back-Up Linings Tertiary Air Duct CRITERION® Low Cement Castables SURSHOT® Shotcrete Refractories SURGUN® ‘Drycrete’ Refractories (Including Si. C based materials) LITEWATE® Insulating Castables LITEWATE® GM Insulating Gunmixes HR™ Insulation Bricks NETTLE® Firebricks SURSHOT® Shotcrete Refractories SURGUN® ‘Drycrete’ Refractories CRITERION® Low Cement Castables

Cement Materials for Preheating Systems Cyclone Walls NETTLE® Firebricks DURAGUN® Low Cement Gunmixes SURSHOT® Shotcrete Refractories SURGUN® ‘Drycrete’ Refractories Cyclone Roofs SURGUN® Shotcrete Refractories DURAGUN® Low Cement Gunmixes DURAFLO® Self-Flowing Castables Cone Sections & Feed Pipes CRITERION® Low Cement Castables DURAX® LC Low/Mid Cement Special Castables DURAFLO® Self-Flowing Castables Calciner SILLMAX® Fired Alumina Bricks STEIN® Fired Chemically Bonded Bricks SURSHOT® Shotcrete Refractories SURGUN® ‘Drycrete’ Refractories Riser Back-Up Linings Tertiary Air Duct CRITERION® Low Cement Castables SURSHOT® Shotcrete Refractories SURGUN® ‘Drycrete’ Refractories (Including Si. C based materials) LITEWATE® Insulating Castables LITEWATE® GM Insulating Gunmixes HR™ Insulation Bricks NETTLE® Firebricks SURSHOT® Shotcrete Refractories SURGUN® ‘Drycrete’ Refractories CRITERION® Low Cement Castables

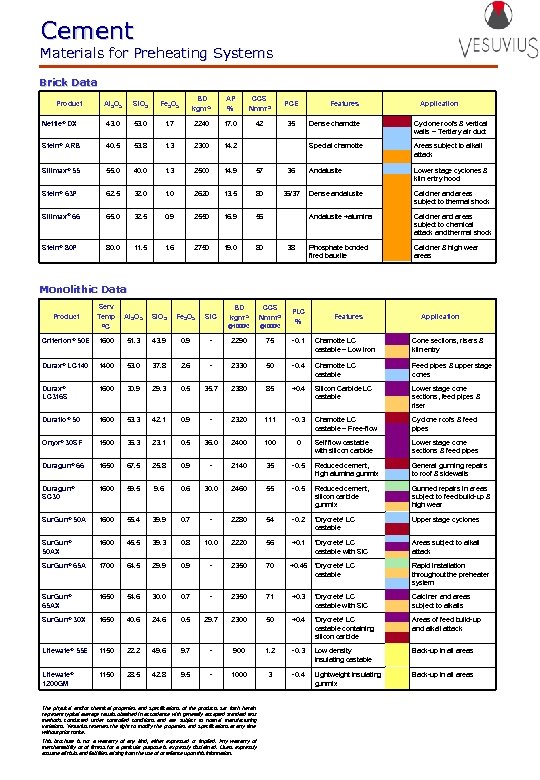

Cement Materials for Preheating Systems Brick Data Al 2 O 3 Si. O 2 Fe 2 O 3 BD kgm-3 AP % CCS Nmm-2 PCE Nettle® DX 43. 0 53. 0 1. 7 2240 17. 0 42 35 Stein® ARB 40. 5 53. 8 1. 3 2300 14. 2 Sillmax® 55 55. 0 40. 0 1. 3 2500 14. 9 57 36 Stein® 63 P 62. 5 32. 0 1. 0 2620 13. 5 80 36/37 Sillmax® 66 65. 0 32. 5 0. 9 2550 16. 9 56 Stein® 80 P 80. 0 11. 5 1. 6 2750 19. 0 80 Product Features Application Dense chamotte Special chamotte Areas subject to alkali attack Andalusite Lower stage cyclones & kiln entry hood Dense andalusite Calciner and areas subject to thermal shock Andalusite +alumina Calciner and areas subject to chemical attack and thermal shock Phosphate bonded fired bauxite 38 Cyclone roofs & vertical walls – Tertiary air duct Calciner & high wear areas Monolithic Data Serv Temp °C Al 2 O 3 Criterion® 50 E 1600 51. 3 43. 9 0. 9 Durax® LC 1400 53. 0 37. 8 Durax® LC 316 S 1600 30. 9 Duraflo® 50 1600 Onyx® 30 SF BD kgm-3 CCS Nmm-2 @1000°C - 2290 75 -0. 1 Chamotte LC castable – Low iron Cone sections, risers & kiln entry 2. 6 - 2330 50 -0. 4 Chamotte LC castable Feed pipes & upper stage cones 29. 3 0. 5 35. 7 2380 85 +0. 4 Silicon Carbide LC castable Lower stage cone sections, feed pipes & riser 53. 3 42. 1 0. 9 - 2320 111 -0. 3 Chamotte LC castable – Free-flow Cyclone roofs & feed pipes 1500 36. 3 23. 1 0. 5 36. 0 2400 100 0 Self flow castable with silicon carbide Lower stage cone sections & feed pipes Duragun® 66 1650 67. 5 25. 8 0. 9 - 2140 35 -0. 5 Reduced cement, high alumina gunmix General gunning repairs to roof & sidewalls Duragun® SC 30 1600 59. 5 9. 6 0. 6 30. 0 2460 55 -0. 5 Reduced cement, silicon carbide gunmix Gunned repairs in areas subject to feed build-up & high wear Sur. Gun® 50 A 1600 55. 4 39. 9 0. 7 - 2280 54 -0. 2 ‘Drycrete’ LC castable Upper stage cyclones Sur. Gun® 50 AX 1600 45. 5 39. 3 0. 8 10. 0 2220 56 +0. 1 ‘Drycrete’ LC castable with Si. C Areas subject to alkali attack Sur. Gun® 65 A 1700 64. 5 29. 9 0. 9 - 2350 70 +0. 45 ‘Drycrete’ LC castable Rapid installation throughout the preheater system Sur. Gun® 65 AX 1650 54. 6 30. 0 0. 7 - 2350 71 +0. 3 ‘Drycrete’ LC castable with Si. C Calciner and areas subject to alkalis Sur. Gun® 30 X 1650 40. 6 24. 6 0. 5 29. 7 2300 50 +0. 4 ‘Drycrete’ LC castable containing silicon carbide Areas of feed build-up and alkali attack Litewate® 55 E 1150 22. 2 49. 6 9. 7 - 900 1. 2 -0. 3 Low density insulating castable Back-up in all areas Litewate® 1200 GM 1150 28. 5 42. 8 9. 5 - 1000 3 -0. 4 Lightweight insulating gunmix Back-up in all areas Product Si. O 2 Fe 2 O 3 Si. C The physical and/or chemical properties and specifications of the products set forth herein represent typical average results obtained in accordance with generally accepted standard test methods conducted under controlled conditions and are subject to normal manufacturing variations. Vesuvius reserves the right to modify the properties and specifications at any time without prior notice. This brochure is not a warranty of any kind, either expressed or implied. Any warranty of merchantability or of fitness for a particular purpose is expressly disclaimed. Users expressly assume all risks and liabilities arising from the use of or reliance upon this information. PLC % Features Application

Cement Materials for Preheating Systems Brick Data Al 2 O 3 Si. O 2 Fe 2 O 3 BD kgm-3 AP % CCS Nmm-2 PCE Nettle® DX 43. 0 53. 0 1. 7 2240 17. 0 42 35 Stein® ARB 40. 5 53. 8 1. 3 2300 14. 2 Sillmax® 55 55. 0 40. 0 1. 3 2500 14. 9 57 36 Stein® 63 P 62. 5 32. 0 1. 0 2620 13. 5 80 36/37 Sillmax® 66 65. 0 32. 5 0. 9 2550 16. 9 56 Stein® 80 P 80. 0 11. 5 1. 6 2750 19. 0 80 Product Features Application Dense chamotte Special chamotte Areas subject to alkali attack Andalusite Lower stage cyclones & kiln entry hood Dense andalusite Calciner and areas subject to thermal shock Andalusite +alumina Calciner and areas subject to chemical attack and thermal shock Phosphate bonded fired bauxite 38 Cyclone roofs & vertical walls – Tertiary air duct Calciner & high wear areas Monolithic Data Serv Temp °C Al 2 O 3 Criterion® 50 E 1600 51. 3 43. 9 0. 9 Durax® LC 1400 53. 0 37. 8 Durax® LC 316 S 1600 30. 9 Duraflo® 50 1600 Onyx® 30 SF BD kgm-3 CCS Nmm-2 @1000°C - 2290 75 -0. 1 Chamotte LC castable – Low iron Cone sections, risers & kiln entry 2. 6 - 2330 50 -0. 4 Chamotte LC castable Feed pipes & upper stage cones 29. 3 0. 5 35. 7 2380 85 +0. 4 Silicon Carbide LC castable Lower stage cone sections, feed pipes & riser 53. 3 42. 1 0. 9 - 2320 111 -0. 3 Chamotte LC castable – Free-flow Cyclone roofs & feed pipes 1500 36. 3 23. 1 0. 5 36. 0 2400 100 0 Self flow castable with silicon carbide Lower stage cone sections & feed pipes Duragun® 66 1650 67. 5 25. 8 0. 9 - 2140 35 -0. 5 Reduced cement, high alumina gunmix General gunning repairs to roof & sidewalls Duragun® SC 30 1600 59. 5 9. 6 0. 6 30. 0 2460 55 -0. 5 Reduced cement, silicon carbide gunmix Gunned repairs in areas subject to feed build-up & high wear Sur. Gun® 50 A 1600 55. 4 39. 9 0. 7 - 2280 54 -0. 2 ‘Drycrete’ LC castable Upper stage cyclones Sur. Gun® 50 AX 1600 45. 5 39. 3 0. 8 10. 0 2220 56 +0. 1 ‘Drycrete’ LC castable with Si. C Areas subject to alkali attack Sur. Gun® 65 A 1700 64. 5 29. 9 0. 9 - 2350 70 +0. 45 ‘Drycrete’ LC castable Rapid installation throughout the preheater system Sur. Gun® 65 AX 1650 54. 6 30. 0 0. 7 - 2350 71 +0. 3 ‘Drycrete’ LC castable with Si. C Calciner and areas subject to alkalis Sur. Gun® 30 X 1650 40. 6 24. 6 0. 5 29. 7 2300 50 +0. 4 ‘Drycrete’ LC castable containing silicon carbide Areas of feed build-up and alkali attack Litewate® 55 E 1150 22. 2 49. 6 9. 7 - 900 1. 2 -0. 3 Low density insulating castable Back-up in all areas Litewate® 1200 GM 1150 28. 5 42. 8 9. 5 - 1000 3 -0. 4 Lightweight insulating gunmix Back-up in all areas Product Si. O 2 Fe 2 O 3 Si. C The physical and/or chemical properties and specifications of the products set forth herein represent typical average results obtained in accordance with generally accepted standard test methods conducted under controlled conditions and are subject to normal manufacturing variations. Vesuvius reserves the right to modify the properties and specifications at any time without prior notice. This brochure is not a warranty of any kind, either expressed or implied. Any warranty of merchantability or of fitness for a particular purpose is expressly disclaimed. Users expressly assume all risks and liabilities arising from the use of or reliance upon this information. PLC % Features Application

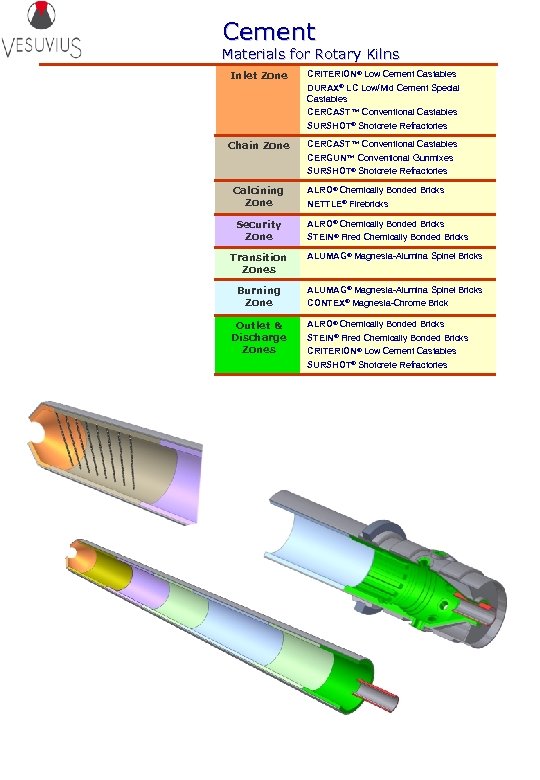

Cement Materials for Rotary Kilns Inlet Zone CRITERION® Low Cement Castables DURAX® LC Low/Mid Cement Special Castables CERCAST™ Conventional Castables SURSHOT® Shotcrete Refractories Chain Zone CERCAST™ Conventional Castables CERGUN™ Conventional Gunmixes SURSHOT® Shotcrete Refractories Calcining Zone ALRO® Chemically Bonded Bricks Security Zone ALRO® Chemically Bonded Bricks NETTLE® Firebricks STEIN® Fired Chemically Bonded Bricks Transition Zones ALUMAG® Magnesia-Alumina Spinel Bricks Burning Zone ALUMAG® Magnesia-Alumina Spinel Bricks Outlet & Discharge Zones CONTEX® Magnesia-Chrome Brick ALRO® Chemically Bonded Bricks STEIN® Fired Chemically Bonded Bricks CRITERION® Low Cement Castables SURSHOT® Shotcrete Refractories

Cement Materials for Rotary Kilns Inlet Zone CRITERION® Low Cement Castables DURAX® LC Low/Mid Cement Special Castables CERCAST™ Conventional Castables SURSHOT® Shotcrete Refractories Chain Zone CERCAST™ Conventional Castables CERGUN™ Conventional Gunmixes SURSHOT® Shotcrete Refractories Calcining Zone ALRO® Chemically Bonded Bricks Security Zone ALRO® Chemically Bonded Bricks NETTLE® Firebricks STEIN® Fired Chemically Bonded Bricks Transition Zones ALUMAG® Magnesia-Alumina Spinel Bricks Burning Zone ALUMAG® Magnesia-Alumina Spinel Bricks Outlet & Discharge Zones CONTEX® Magnesia-Chrome Brick ALRO® Chemically Bonded Bricks STEIN® Fired Chemically Bonded Bricks CRITERION® Low Cement Castables SURSHOT® Shotcrete Refractories

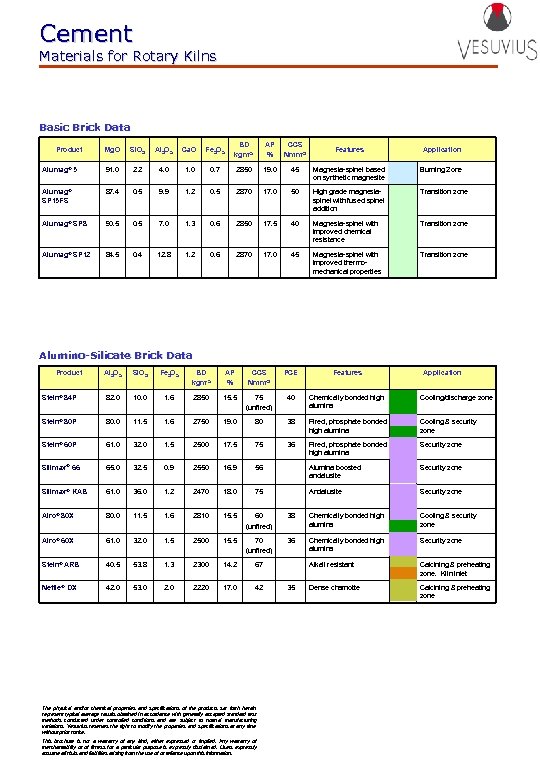

Cement Materials for Rotary Kilns Basic Brick Data Mg. O Si. O 2 Al 2 O 3 Ca. O Fe 2 O 3 BD kgm-3 AP % CCS Nmm-2 Alumag® 5 91. 0 2. 2 4. 0 1. 0 0. 7 2850 19. 0 Alumag® SP 15 FS 87. 4 0. 5 9. 9 1. 2 0. 5 2870 Alumag® SP 8 90. 5 7. 0 1. 3 0. 6 Alumag® SP 12 84. 5 0. 4 12. 8 1. 2 0. 6 Product Features Application 45 Magnesia-spinel based on synthetic magnesite Burning Zone 17. 0 50 High grade magnesiaspinel with fused spinel addition Transition zone 2850 17. 5 40 Magnesia-spinel with improved chemical resistance Transition zone 2870 17. 0 45 Magnesia-spinel with improved thermomechanical properties Transition zone Application Alumino-Silicate Brick Data Product Al 2 O 3 Si. O 2 Fe 2 O 3 BD kgm-3 AP % CCS Nmm-2 PCE Features Stein® 84 P 82. 0 10. 0 1. 6 2850 15. 5 75 (unfired) 40 Chemically bonded high alumina Cooling/discharge zone Stein® 80 P 80. 0 11. 5 1. 6 2750 19. 0 80 38 Fired, phosphate bonded high alumina Cooling & security zone Stein® 60 P 61. 0 32. 0 1. 5 2500 17. 5 75 36 Fired, phosphate bonded high alumina Security zone Sillmax® 66 65. 0 32. 5 0. 9 2550 16. 9 56 Alumina boosted andalusite Security zone Sillmax® KAB 61. 0 36. 0 1. 2 2470 18. 0 75 Andalusite Security zone Alro® 80 X 80. 0 11. 5 1. 6 2810 15. 5 60 (unfired) 38 Chemically bonded high alumina Cooling & security zone Alro® 60 X 61. 0 32. 0 1. 5 2500 15. 5 70 (unfired) 36 Chemically bonded high alumina Security zone Stein® ARB 40. 5 53. 8 1. 3 2300 14. 2 67 Alkali resistant Calcining & preheating zone. Kiln inlet Nettle® DX 42. 0 53. 0 2220 17. 0 42 Dense chamotte Calcining & preheating zone The physical and/or chemical properties and specifications of the products set forth herein represent typical average results obtained in accordance with generally accepted standard test methods conducted under controlled conditions and are subject to normal manufacturing variations. Vesuvius reserves the right to modify the properties and specifications at any time without prior notice. This brochure is not a warranty of any kind, either expressed or implied. Any warranty of merchantability or of fitness for a particular purpose is expressly disclaimed. Users expressly assume all risks and liabilities arising from the use of or reliance upon this information. 35

Cement Materials for Rotary Kilns Basic Brick Data Mg. O Si. O 2 Al 2 O 3 Ca. O Fe 2 O 3 BD kgm-3 AP % CCS Nmm-2 Alumag® 5 91. 0 2. 2 4. 0 1. 0 0. 7 2850 19. 0 Alumag® SP 15 FS 87. 4 0. 5 9. 9 1. 2 0. 5 2870 Alumag® SP 8 90. 5 7. 0 1. 3 0. 6 Alumag® SP 12 84. 5 0. 4 12. 8 1. 2 0. 6 Product Features Application 45 Magnesia-spinel based on synthetic magnesite Burning Zone 17. 0 50 High grade magnesiaspinel with fused spinel addition Transition zone 2850 17. 5 40 Magnesia-spinel with improved chemical resistance Transition zone 2870 17. 0 45 Magnesia-spinel with improved thermomechanical properties Transition zone Application Alumino-Silicate Brick Data Product Al 2 O 3 Si. O 2 Fe 2 O 3 BD kgm-3 AP % CCS Nmm-2 PCE Features Stein® 84 P 82. 0 10. 0 1. 6 2850 15. 5 75 (unfired) 40 Chemically bonded high alumina Cooling/discharge zone Stein® 80 P 80. 0 11. 5 1. 6 2750 19. 0 80 38 Fired, phosphate bonded high alumina Cooling & security zone Stein® 60 P 61. 0 32. 0 1. 5 2500 17. 5 75 36 Fired, phosphate bonded high alumina Security zone Sillmax® 66 65. 0 32. 5 0. 9 2550 16. 9 56 Alumina boosted andalusite Security zone Sillmax® KAB 61. 0 36. 0 1. 2 2470 18. 0 75 Andalusite Security zone Alro® 80 X 80. 0 11. 5 1. 6 2810 15. 5 60 (unfired) 38 Chemically bonded high alumina Cooling & security zone Alro® 60 X 61. 0 32. 0 1. 5 2500 15. 5 70 (unfired) 36 Chemically bonded high alumina Security zone Stein® ARB 40. 5 53. 8 1. 3 2300 14. 2 67 Alkali resistant Calcining & preheating zone. Kiln inlet Nettle® DX 42. 0 53. 0 2220 17. 0 42 Dense chamotte Calcining & preheating zone The physical and/or chemical properties and specifications of the products set forth herein represent typical average results obtained in accordance with generally accepted standard test methods conducted under controlled conditions and are subject to normal manufacturing variations. Vesuvius reserves the right to modify the properties and specifications at any time without prior notice. This brochure is not a warranty of any kind, either expressed or implied. Any warranty of merchantability or of fitness for a particular purpose is expressly disclaimed. Users expressly assume all risks and liabilities arising from the use of or reliance upon this information. 35

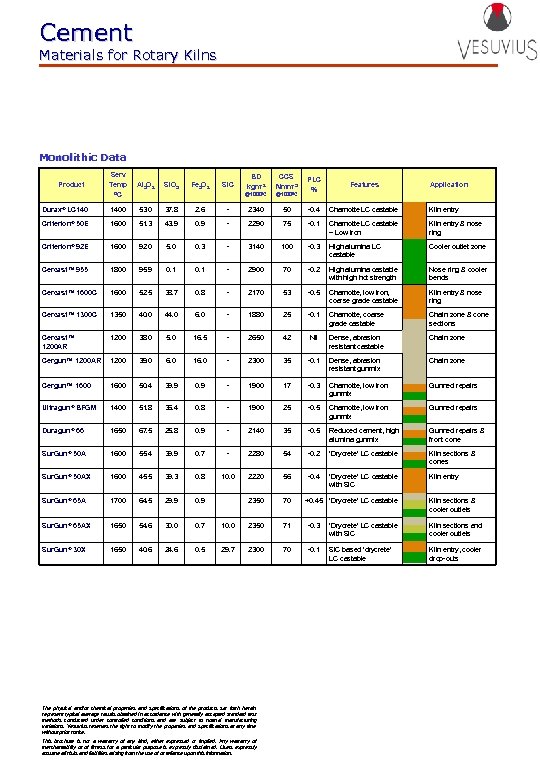

Cement Materials for Rotary Kilns Monolithic Data Serv Temp °C Al 2 O 3 Durax® LC 1400 53. 0 37. 8 2. 6 Criterion® 50 E 1600 51. 3 43. 9 Criterion® 92 E 1600 92. 0 Cercast™ 955 1800 Cercast™ 1600 C BD kgm-3 CCS Nmm-2 @1000°C - 2340 0. 9 - 5. 0 0. 3 95. 9 0. 1 1600 52. 5 Cercast™ 1300 C 1350 Cercast™ 1200 AR PLC % Features 50 -0. 4 Chamotte LC castable Kiln entry 2290 75 -0. 1 Chamotte LC castable – Low iron Kiln entry & nose ring - 3140 100 -0. 3 High alumina LC castable Cooler outlet zone 0. 1 - 2900 70 -0. 2 High alumina castable with high hot strength Nose ring & cooler bends 38. 7 0. 8 - 2170 53 -0. 5 Chamotte, low iron, coarse grade castable Kiln entry & nose ring 40. 0 44. 0 6. 0 - 1880 25 -0. 1 Chamotte, coarse grade castable Chain zone & cone sections 1200 38. 0 5. 0 16. 5 - 2650 42 Nil Dense, abrasion resistant castable Chain zone Cergun™ 1200 AR 1200 39. 0 6. 0 16. 0 - 2300 35 -0. 1 Dense, abrasion resistant gunmix Chain zone Cergun™ 1600 50. 4 39. 9 0. 9 - 1900 17 -0. 3 Chamotte, low iron gunmix Gunned repairs Ultragun® BFGM 1400 51. 8 36. 4 0. 8 - 1900 25 -0. 5 Chamotte, low iron gunmix Gunned repairs Duragun® 66 1650 67. 5 25. 8 0. 9 - 2140 35 -0. 5 Reduced cement, high alumina gunmix Gunned repairs & front cone Sur. Gun® 50 A 1600 55. 4 39. 9 0. 7 - 2280 54 -0. 2 ‘Drycrete’ LC castable Kiln sections & cones Sur. Gun® 50 AX 1600 45. 5 39. 3 0. 8 10. 0 2220 56 -0. 4 ‘Drycrete’ LC castable with Si. C Kiln entry Sur. Gun® 65 A 1700 64. 5 29. 9 0. 9 2350 70 Sur. Gun® 65 AX 1650 54. 6 30. 0 0. 7 10. 0 2350 71 -0. 3 ‘Drycrete’ LC castable with Si. C Kiln sections and cooler outlets Sur. Gun® 30 X 1650 40. 6 24. 6 0. 5 29. 7 2300 70 -0. 1 Si. C based ‘drycrete’ LC castable Kiln entry, cooler drop-outs Product Si. O 2 Fe 2 O 3 Si. C The physical and/or chemical properties and specifications of the products set forth herein represent typical average results obtained in accordance with generally accepted standard test methods conducted under controlled conditions and are subject to normal manufacturing variations. Vesuvius reserves the right to modify the properties and specifications at any time without prior notice. This brochure is not a warranty of any kind, either expressed or implied. Any warranty of merchantability or of fitness for a particular purpose is expressly disclaimed. Users expressly assume all risks and liabilities arising from the use of or reliance upon this information. +0. 45 ‘Drycrete’ LC castable Application Kiln sections & cooler outlets

Cement Materials for Rotary Kilns Monolithic Data Serv Temp °C Al 2 O 3 Durax® LC 1400 53. 0 37. 8 2. 6 Criterion® 50 E 1600 51. 3 43. 9 Criterion® 92 E 1600 92. 0 Cercast™ 955 1800 Cercast™ 1600 C BD kgm-3 CCS Nmm-2 @1000°C - 2340 0. 9 - 5. 0 0. 3 95. 9 0. 1 1600 52. 5 Cercast™ 1300 C 1350 Cercast™ 1200 AR PLC % Features 50 -0. 4 Chamotte LC castable Kiln entry 2290 75 -0. 1 Chamotte LC castable – Low iron Kiln entry & nose ring - 3140 100 -0. 3 High alumina LC castable Cooler outlet zone 0. 1 - 2900 70 -0. 2 High alumina castable with high hot strength Nose ring & cooler bends 38. 7 0. 8 - 2170 53 -0. 5 Chamotte, low iron, coarse grade castable Kiln entry & nose ring 40. 0 44. 0 6. 0 - 1880 25 -0. 1 Chamotte, coarse grade castable Chain zone & cone sections 1200 38. 0 5. 0 16. 5 - 2650 42 Nil Dense, abrasion resistant castable Chain zone Cergun™ 1200 AR 1200 39. 0 6. 0 16. 0 - 2300 35 -0. 1 Dense, abrasion resistant gunmix Chain zone Cergun™ 1600 50. 4 39. 9 0. 9 - 1900 17 -0. 3 Chamotte, low iron gunmix Gunned repairs Ultragun® BFGM 1400 51. 8 36. 4 0. 8 - 1900 25 -0. 5 Chamotte, low iron gunmix Gunned repairs Duragun® 66 1650 67. 5 25. 8 0. 9 - 2140 35 -0. 5 Reduced cement, high alumina gunmix Gunned repairs & front cone Sur. Gun® 50 A 1600 55. 4 39. 9 0. 7 - 2280 54 -0. 2 ‘Drycrete’ LC castable Kiln sections & cones Sur. Gun® 50 AX 1600 45. 5 39. 3 0. 8 10. 0 2220 56 -0. 4 ‘Drycrete’ LC castable with Si. C Kiln entry Sur. Gun® 65 A 1700 64. 5 29. 9 0. 9 2350 70 Sur. Gun® 65 AX 1650 54. 6 30. 0 0. 7 10. 0 2350 71 -0. 3 ‘Drycrete’ LC castable with Si. C Kiln sections and cooler outlets Sur. Gun® 30 X 1650 40. 6 24. 6 0. 5 29. 7 2300 70 -0. 1 Si. C based ‘drycrete’ LC castable Kiln entry, cooler drop-outs Product Si. O 2 Fe 2 O 3 Si. C The physical and/or chemical properties and specifications of the products set forth herein represent typical average results obtained in accordance with generally accepted standard test methods conducted under controlled conditions and are subject to normal manufacturing variations. Vesuvius reserves the right to modify the properties and specifications at any time without prior notice. This brochure is not a warranty of any kind, either expressed or implied. Any warranty of merchantability or of fitness for a particular purpose is expressly disclaimed. Users expressly assume all risks and liabilities arising from the use of or reliance upon this information. +0. 45 ‘Drycrete’ LC castable Application Kiln sections & cooler outlets

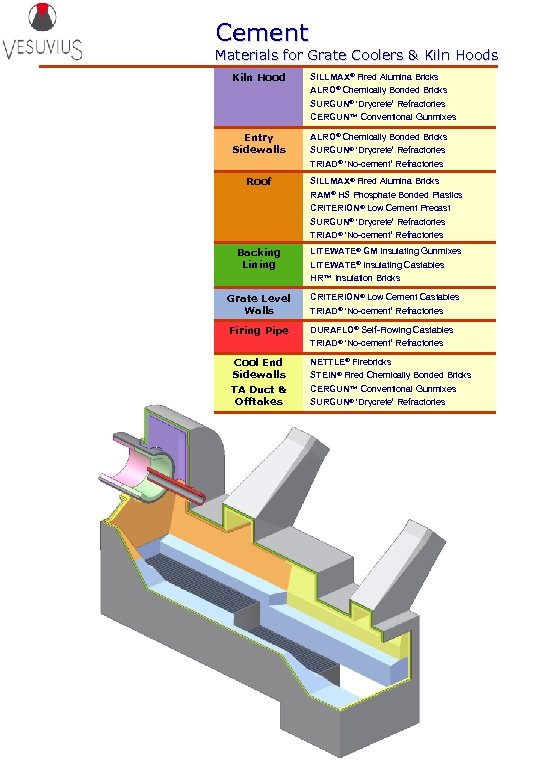

Cement Materials for Grate Coolers & Kiln Hoods Kiln Hood SILLMAX® Fired Alumina Bricks ALRO® Chemically Bonded Bricks SURGUN® ‘Drycrete’ Refractories CERGUN™ Conventional Gunmixes Entry Sidewalls Roof ALRO® Chemically Bonded Bricks SURGUN® ‘Drycrete’ Refractories TRIAD® ‘No-cement’ Refractories SILLMAX® Fired Alumina Bricks RAM® HS Phosphate Bonded Plastics CRITERION® Low Cement Precast SURGUN® ‘Drycrete’ Refractories TRIAD® ‘No-cement’ Refractories Backing Lining LITEWATE® GM Insulating Gunmixes Grate Level Walls CRITERION® Low Cement Castables Firing Pipe DURAFLO® Self-Flowing Castables LITEWATE® Insulating Castables HR™ Insulation Bricks TRIAD® ‘No-cement’ Refractories Cool End Sidewalls TA Duct & Offtakes NETTLE® Firebricks STEIN® Fired Chemically Bonded Bricks CERGUN™ Conventional Gunmixes SURGUN® ‘Drycrete’ Refractories

Cement Materials for Grate Coolers & Kiln Hoods Kiln Hood SILLMAX® Fired Alumina Bricks ALRO® Chemically Bonded Bricks SURGUN® ‘Drycrete’ Refractories CERGUN™ Conventional Gunmixes Entry Sidewalls Roof ALRO® Chemically Bonded Bricks SURGUN® ‘Drycrete’ Refractories TRIAD® ‘No-cement’ Refractories SILLMAX® Fired Alumina Bricks RAM® HS Phosphate Bonded Plastics CRITERION® Low Cement Precast SURGUN® ‘Drycrete’ Refractories TRIAD® ‘No-cement’ Refractories Backing Lining LITEWATE® GM Insulating Gunmixes Grate Level Walls CRITERION® Low Cement Castables Firing Pipe DURAFLO® Self-Flowing Castables LITEWATE® Insulating Castables HR™ Insulation Bricks TRIAD® ‘No-cement’ Refractories Cool End Sidewalls TA Duct & Offtakes NETTLE® Firebricks STEIN® Fired Chemically Bonded Bricks CERGUN™ Conventional Gunmixes SURGUN® ‘Drycrete’ Refractories

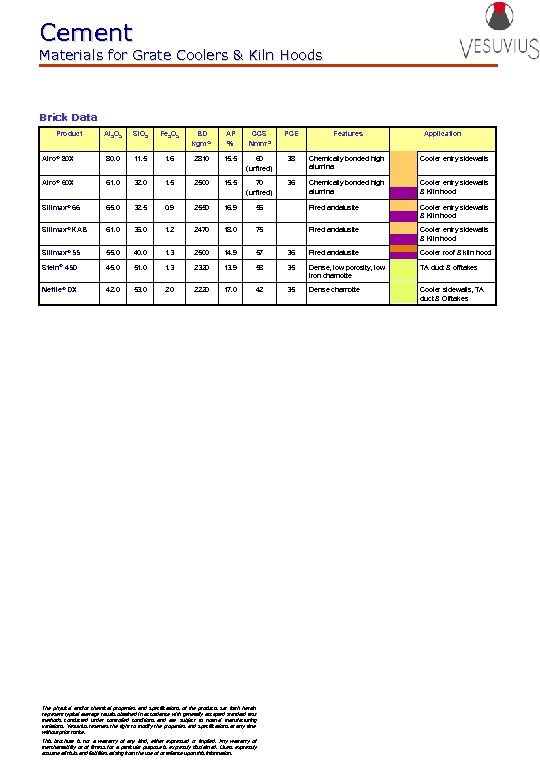

Cement Materials for Grate Coolers & Kiln Hoods Brick Data Product Al 2 O 3 Si. O 2 Fe 2 O 3 BD kgm-3 AP % CCS Nmm-2 PCE Features Alro® 80 X 80. 0 11. 5 1. 6 2810 15. 5 60 (unfired) 38 Chemically bonded high alumina Cooler entry sidewalls Alro® 60 X 61. 0 32. 0 1. 5 2500 15. 5 70 (unfired) 36 Chemically bonded high alumina Cooler entry sidewalls & Kiln hood Sillmax® 66 65. 0 32. 5 0. 9 2550 16. 9 56 Fired andalusite Cooler entry sidewalls & Kiln hood Sillmax® KAB 61. 0 36. 0 1. 2 2470 18. 0 75 Fired andalusite Cooler entry sidewalls & Kiln hood Sillmax® 55 55. 0 40. 0 1. 3 2500 14. 9 57 36 Fired andalusite Cooler roof & kiln hood Stein® 45 D 45. 0 51. 0 1. 3 2320 13. 9 58 35 Dense, low porosity, low iron chamotte TA duct & offtakes Nettle® DX 42. 0 53. 0 2220 17. 0 42 35 Dense chamotte Cooler sidewalls, TA duct & Offtakes The physical and/or chemical properties and specifications of the products set forth herein represent typical average results obtained in accordance with generally accepted standard test methods conducted under controlled conditions and are subject to normal manufacturing variations. Vesuvius reserves the right to modify the properties and specifications at any time without prior notice. This brochure is not a warranty of any kind, either expressed or implied. Any warranty of merchantability or of fitness for a particular purpose is expressly disclaimed. Users expressly assume all risks and liabilities arising from the use of or reliance upon this information. Application

Cement Materials for Grate Coolers & Kiln Hoods Brick Data Product Al 2 O 3 Si. O 2 Fe 2 O 3 BD kgm-3 AP % CCS Nmm-2 PCE Features Alro® 80 X 80. 0 11. 5 1. 6 2810 15. 5 60 (unfired) 38 Chemically bonded high alumina Cooler entry sidewalls Alro® 60 X 61. 0 32. 0 1. 5 2500 15. 5 70 (unfired) 36 Chemically bonded high alumina Cooler entry sidewalls & Kiln hood Sillmax® 66 65. 0 32. 5 0. 9 2550 16. 9 56 Fired andalusite Cooler entry sidewalls & Kiln hood Sillmax® KAB 61. 0 36. 0 1. 2 2470 18. 0 75 Fired andalusite Cooler entry sidewalls & Kiln hood Sillmax® 55 55. 0 40. 0 1. 3 2500 14. 9 57 36 Fired andalusite Cooler roof & kiln hood Stein® 45 D 45. 0 51. 0 1. 3 2320 13. 9 58 35 Dense, low porosity, low iron chamotte TA duct & offtakes Nettle® DX 42. 0 53. 0 2220 17. 0 42 35 Dense chamotte Cooler sidewalls, TA duct & Offtakes The physical and/or chemical properties and specifications of the products set forth herein represent typical average results obtained in accordance with generally accepted standard test methods conducted under controlled conditions and are subject to normal manufacturing variations. Vesuvius reserves the right to modify the properties and specifications at any time without prior notice. This brochure is not a warranty of any kind, either expressed or implied. Any warranty of merchantability or of fitness for a particular purpose is expressly disclaimed. Users expressly assume all risks and liabilities arising from the use of or reliance upon this information. Application

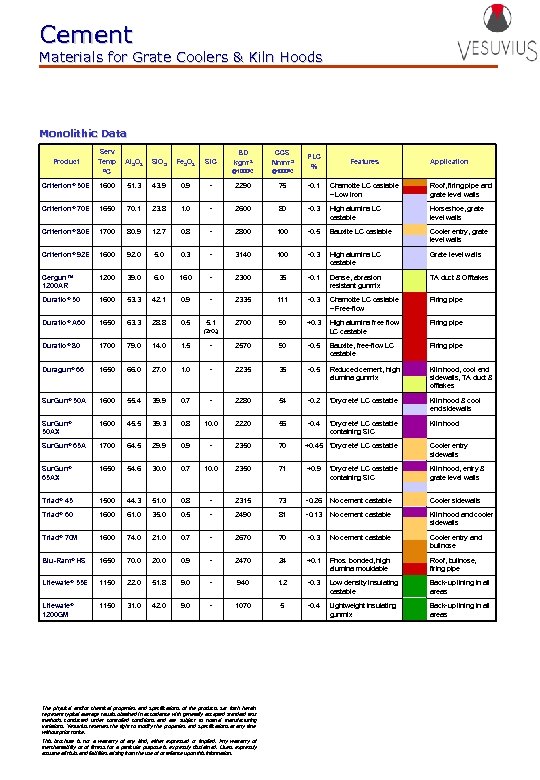

Cement Materials for Grate Coolers & Kiln Hoods Monolithic Data Serv Temp °C Al 2 O 3 Criterion® 50 E 1600 51. 3 43. 9 0. 9 Criterion® 70 E 1650 70. 1 23. 8 Criterion® 80 E 1700 80. 9 Criterion® 92 E 1600 Cergun™ 1200 AR BD kgm-3 CCS Nmm-2 @1000°C - 2290 75 -0. 1 Chamotte LC castable – Low iron Roof, firing pipe and grate level walls 1. 0 - 2600 80 -0. 3 High alumina LC castable Horseshoe, grate level walls 12. 7 0. 8 - 2800 100 -0. 5 Bauxite LC castable Cooler entry, grate level walls 92. 0 5. 0 0. 3 - 3140 100 -0. 3 High alumina LC castable Grate level walls 1200 39. 0 6. 0 16. 0 - 2300 35 -0. 1 Dense, abrasion resistant gunmix TA duct & Offtakes Duraflo® 50 1600 53. 3 42. 1 0. 9 - 2335 111 -0. 3 Chamotte LC castable – Free-flow Firing pipe Duraflo® A 60 1650 63. 3 28. 8 0. 5 5. 1 2700 90 +0. 3 High alumina free flow LC castable Firing pipe Product Si. O 2 Fe 2 O 3 Si. C PLC % (Zr. O 2) Features Application Duraflo® 80 1700 79. 0 14. 0 1. 5 - 2570 90 -0. 5 Bauxite, free-flow LC castable Firing pipe Duragun® 66 1650 66. 0 27. 0 1. 0 - 2235 35 -0. 5 Reduced cement, high alumina gunmix Kiln hood, cool end sidewalls, TA duct & offtakes Sur. Gun® 50 A 1600 55. 4 39. 9 0. 7 - 2280 54 -0. 2 ‘Drycrete’ LC castable Kiln hood & cool end sidewalls Sur. Gun® 50 AX 1600 45. 5 39. 3 0. 8 10. 0 2220 56 -0. 4 ‘Drycrete’ LC castable containing Si. C Kiln hood Sur. Gun® 65 A 1700 64. 5 29. 9 0. 9 - 2350 70 +0. 45 ‘Drycrete’ LC castable Cooler entry sidewalls Sur. Gun® 65 AX 1650 54. 6 30. 0 0. 7 10. 0 2350 71 +0. 9 ‘Drycrete’ LC castable containing Si. C Kiln hood, entry & grate level walls Triad® 45 1500 44. 3 51. 0 0. 8 - 2315 73 -0. 26 No cement castable Cooler sidewalls Triad® 1600 61. 0 35. 0 0. 5 - 2490 81 -0. 13 No cement castable Kiln hood and cooler sidewalls Triad® 70 M 1600 74. 0 21. 0 0. 7 - 2670 70 -0. 3 No cement castable Cooler entry and bullnose Blu-Ram® HS 1650 70. 0 20. 0 0. 9 - 2470 24 +0. 1 Phos. bonded, high alumina mouldable Roof, bullnose, firing pipe Litewate® 55 E 1150 22. 0 51. 8 9. 0 - 940 1. 2 -0. 3 Low density insulating castable Back-up lining in all areas Litewate® 1200 GM 1150 31. 0 42. 0 9. 0 - 1070 5 -0. 4 Lightweight insulating gunmix Back-up lining in all areas 60 The physical and/or chemical properties and specifications of the products set forth herein represent typical average results obtained in accordance with generally accepted standard test methods conducted under controlled conditions and are subject to normal manufacturing variations. Vesuvius reserves the right to modify the properties and specifications at any time without prior notice. This brochure is not a warranty of any kind, either expressed or implied. Any warranty of merchantability or of fitness for a particular purpose is expressly disclaimed. Users expressly assume all risks and liabilities arising from the use of or reliance upon this information.

Cement Materials for Grate Coolers & Kiln Hoods Monolithic Data Serv Temp °C Al 2 O 3 Criterion® 50 E 1600 51. 3 43. 9 0. 9 Criterion® 70 E 1650 70. 1 23. 8 Criterion® 80 E 1700 80. 9 Criterion® 92 E 1600 Cergun™ 1200 AR BD kgm-3 CCS Nmm-2 @1000°C - 2290 75 -0. 1 Chamotte LC castable – Low iron Roof, firing pipe and grate level walls 1. 0 - 2600 80 -0. 3 High alumina LC castable Horseshoe, grate level walls 12. 7 0. 8 - 2800 100 -0. 5 Bauxite LC castable Cooler entry, grate level walls 92. 0 5. 0 0. 3 - 3140 100 -0. 3 High alumina LC castable Grate level walls 1200 39. 0 6. 0 16. 0 - 2300 35 -0. 1 Dense, abrasion resistant gunmix TA duct & Offtakes Duraflo® 50 1600 53. 3 42. 1 0. 9 - 2335 111 -0. 3 Chamotte LC castable – Free-flow Firing pipe Duraflo® A 60 1650 63. 3 28. 8 0. 5 5. 1 2700 90 +0. 3 High alumina free flow LC castable Firing pipe Product Si. O 2 Fe 2 O 3 Si. C PLC % (Zr. O 2) Features Application Duraflo® 80 1700 79. 0 14. 0 1. 5 - 2570 90 -0. 5 Bauxite, free-flow LC castable Firing pipe Duragun® 66 1650 66. 0 27. 0 1. 0 - 2235 35 -0. 5 Reduced cement, high alumina gunmix Kiln hood, cool end sidewalls, TA duct & offtakes Sur. Gun® 50 A 1600 55. 4 39. 9 0. 7 - 2280 54 -0. 2 ‘Drycrete’ LC castable Kiln hood & cool end sidewalls Sur. Gun® 50 AX 1600 45. 5 39. 3 0. 8 10. 0 2220 56 -0. 4 ‘Drycrete’ LC castable containing Si. C Kiln hood Sur. Gun® 65 A 1700 64. 5 29. 9 0. 9 - 2350 70 +0. 45 ‘Drycrete’ LC castable Cooler entry sidewalls Sur. Gun® 65 AX 1650 54. 6 30. 0 0. 7 10. 0 2350 71 +0. 9 ‘Drycrete’ LC castable containing Si. C Kiln hood, entry & grate level walls Triad® 45 1500 44. 3 51. 0 0. 8 - 2315 73 -0. 26 No cement castable Cooler sidewalls Triad® 1600 61. 0 35. 0 0. 5 - 2490 81 -0. 13 No cement castable Kiln hood and cooler sidewalls Triad® 70 M 1600 74. 0 21. 0 0. 7 - 2670 70 -0. 3 No cement castable Cooler entry and bullnose Blu-Ram® HS 1650 70. 0 20. 0 0. 9 - 2470 24 +0. 1 Phos. bonded, high alumina mouldable Roof, bullnose, firing pipe Litewate® 55 E 1150 22. 0 51. 8 9. 0 - 940 1. 2 -0. 3 Low density insulating castable Back-up lining in all areas Litewate® 1200 GM 1150 31. 0 42. 0 9. 0 - 1070 5 -0. 4 Lightweight insulating gunmix Back-up lining in all areas 60 The physical and/or chemical properties and specifications of the products set forth herein represent typical average results obtained in accordance with generally accepted standard test methods conducted under controlled conditions and are subject to normal manufacturing variations. Vesuvius reserves the right to modify the properties and specifications at any time without prior notice. This brochure is not a warranty of any kind, either expressed or implied. Any warranty of merchantability or of fitness for a particular purpose is expressly disclaimed. Users expressly assume all risks and liabilities arising from the use of or reliance upon this information.

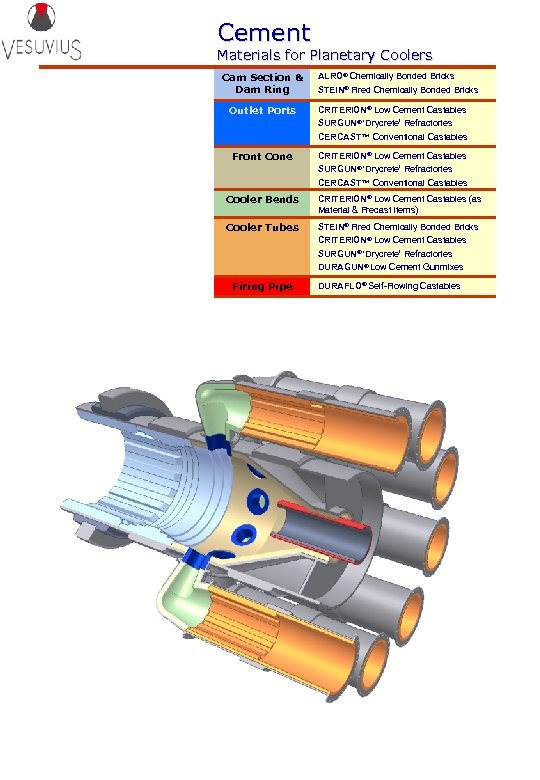

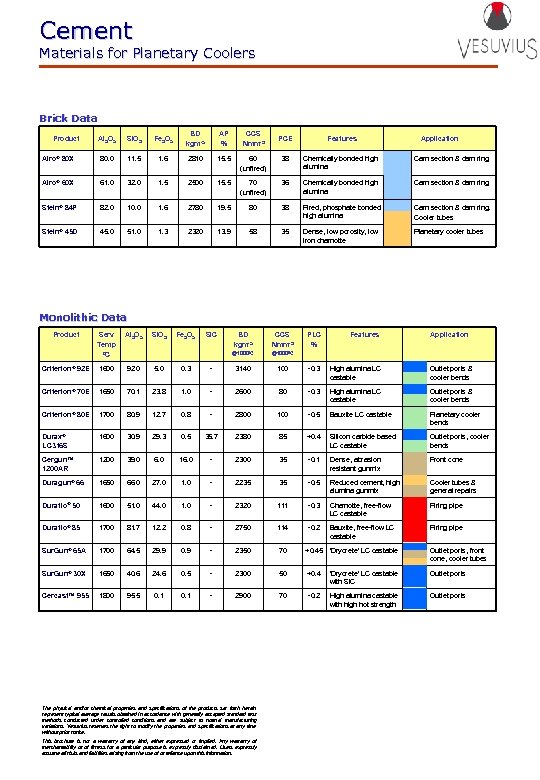

Cement Materials for Planetary Coolers Cam Section & Dam Ring Outlet Ports ALRO® Chemically Bonded Bricks STEIN® Fired Chemically Bonded Bricks CRITERION® Low Cement Castables SURGUN® ‘Drycrete’ Refractories CERCAST™ Conventional Castables Front Cone CRITERION® Low Cement Castables SURGUN® ‘Drycrete’ Refractories CERCAST™ Conventional Castables Cooler Bends CRITERION® Low Cement Castables (as Material & Precast Items) Cooler Tubes STEIN® Fired Chemically Bonded Bricks CRITERION® Low Cement Castables SURGUN® ‘Drycrete’ Refractories DURAGUN® Low Cement Gunmixes Firing Pipe DURAFLO® Self-Flowing Castables

Cement Materials for Planetary Coolers Cam Section & Dam Ring Outlet Ports ALRO® Chemically Bonded Bricks STEIN® Fired Chemically Bonded Bricks CRITERION® Low Cement Castables SURGUN® ‘Drycrete’ Refractories CERCAST™ Conventional Castables Front Cone CRITERION® Low Cement Castables SURGUN® ‘Drycrete’ Refractories CERCAST™ Conventional Castables Cooler Bends CRITERION® Low Cement Castables (as Material & Precast Items) Cooler Tubes STEIN® Fired Chemically Bonded Bricks CRITERION® Low Cement Castables SURGUN® ‘Drycrete’ Refractories DURAGUN® Low Cement Gunmixes Firing Pipe DURAFLO® Self-Flowing Castables

Cement Materials for Planetary Coolers Brick Data Al 2 O 3 Si. O 2 Fe 2 O 3 BD kgm-3 AP % CCS Nmm-2 Alro® 80 X 80. 0 11. 5 1. 6 2810 15. 5 Alro® 60 X 61. 0 32. 0 1. 5 2500 Stein® 84 P 82. 0 10. 0 1. 6 Stein® 45 D 45. 0 51. 0 1. 3 Serv Temp °C Al 2 O 3 Si. O 2 Criterion® 92 E 1600 92. 0 5. 0 0. 3 Criterion® 70 E 1650 70. 1 23. 8 Criterion® 80 E 1700 80. 9 Durax® LC 316 S 1600 Cergun™ 1200 AR Product PCE Features Application 60 (unfired) 38 Chemically bonded high alumina Cam section & dam ring 15. 5 70 (unfired) 36 Chemically bonded high alumina Cam section & dam ring 2780 19. 5 80 38 Fired, phosphate bonded high alumina Cam section & dam ring. Cooler tubes 2320 13. 9 58 35 Dense, low porosity, low iron chamotte Planetary cooler tubes Monolithic Data Product Fe 2 O 3 Si. C BD kgm-3 CCS Nmm-2 PLC % Features @1000°C - 3140 1. 0 - 12. 7 0. 8 30. 9 29. 3 1200 39. 0 Duragun® 66 1650 Duraflo® 50 100 -0. 3 High alumina LC castable Outlet ports & cooler bends 2600 80 -0. 3 High alumina LC castable Outlet ports & cooler bends - 2800 100 -0. 5 Bauxite LC castable Planetary cooler bends 0. 5 35. 7 2380 85 +0. 4 Silicon carbide based LC castable Outlet ports, cooler bends 6. 0 16. 0 - 2300 35 -0. 1 Dense, abrasion resistant gunmix Front cone 66. 0 27. 0 1. 0 - 2235 35 -0. 5 Reduced cement, high alumina gunmix Cooler tubes & general repairs 1600 51. 0 44. 0 1. 0 - 2320 111 -0. 3 Chamotte, free-flow LC castable Firing pipe Duraflo® 85 1700 81. 7 12. 2 0. 8 - 2750 114 -0. 2 Bauxite, free-flow LC castable Firing pipe Sur. Gun® 65 A 1700 64. 5 29. 9 0. 9 - 2350 70 +0. 45 ‘Drycrete’ LC castable Outlet ports, front cone, cooler tubes Sur. Gun® 30 X 1650 40. 6 24. 6 0. 5 - 2300 50 +0. 4 ‘Drycrete’ LC castable with Si. C Outlet ports Cercast™ 955 1800 95. 5 0. 1 - 2900 70 -0. 2 High alumina castable with high hot strength Outlet ports The physical and/or chemical properties and specifications of the products set forth herein represent typical average results obtained in accordance with generally accepted standard test methods conducted under controlled conditions and are subject to normal manufacturing variations. Vesuvius reserves the right to modify the properties and specifications at any time without prior notice. This brochure is not a warranty of any kind, either expressed or implied. Any warranty of merchantability or of fitness for a particular purpose is expressly disclaimed. Users expressly assume all risks and liabilities arising from the use of or reliance upon this information. Application

Cement Materials for Planetary Coolers Brick Data Al 2 O 3 Si. O 2 Fe 2 O 3 BD kgm-3 AP % CCS Nmm-2 Alro® 80 X 80. 0 11. 5 1. 6 2810 15. 5 Alro® 60 X 61. 0 32. 0 1. 5 2500 Stein® 84 P 82. 0 10. 0 1. 6 Stein® 45 D 45. 0 51. 0 1. 3 Serv Temp °C Al 2 O 3 Si. O 2 Criterion® 92 E 1600 92. 0 5. 0 0. 3 Criterion® 70 E 1650 70. 1 23. 8 Criterion® 80 E 1700 80. 9 Durax® LC 316 S 1600 Cergun™ 1200 AR Product PCE Features Application 60 (unfired) 38 Chemically bonded high alumina Cam section & dam ring 15. 5 70 (unfired) 36 Chemically bonded high alumina Cam section & dam ring 2780 19. 5 80 38 Fired, phosphate bonded high alumina Cam section & dam ring. Cooler tubes 2320 13. 9 58 35 Dense, low porosity, low iron chamotte Planetary cooler tubes Monolithic Data Product Fe 2 O 3 Si. C BD kgm-3 CCS Nmm-2 PLC % Features @1000°C - 3140 1. 0 - 12. 7 0. 8 30. 9 29. 3 1200 39. 0 Duragun® 66 1650 Duraflo® 50 100 -0. 3 High alumina LC castable Outlet ports & cooler bends 2600 80 -0. 3 High alumina LC castable Outlet ports & cooler bends - 2800 100 -0. 5 Bauxite LC castable Planetary cooler bends 0. 5 35. 7 2380 85 +0. 4 Silicon carbide based LC castable Outlet ports, cooler bends 6. 0 16. 0 - 2300 35 -0. 1 Dense, abrasion resistant gunmix Front cone 66. 0 27. 0 1. 0 - 2235 35 -0. 5 Reduced cement, high alumina gunmix Cooler tubes & general repairs 1600 51. 0 44. 0 1. 0 - 2320 111 -0. 3 Chamotte, free-flow LC castable Firing pipe Duraflo® 85 1700 81. 7 12. 2 0. 8 - 2750 114 -0. 2 Bauxite, free-flow LC castable Firing pipe Sur. Gun® 65 A 1700 64. 5 29. 9 0. 9 - 2350 70 +0. 45 ‘Drycrete’ LC castable Outlet ports, front cone, cooler tubes Sur. Gun® 30 X 1650 40. 6 24. 6 0. 5 - 2300 50 +0. 4 ‘Drycrete’ LC castable with Si. C Outlet ports Cercast™ 955 1800 95. 5 0. 1 - 2900 70 -0. 2 High alumina castable with high hot strength Outlet ports The physical and/or chemical properties and specifications of the products set forth herein represent typical average results obtained in accordance with generally accepted standard test methods conducted under controlled conditions and are subject to normal manufacturing variations. Vesuvius reserves the right to modify the properties and specifications at any time without prior notice. This brochure is not a warranty of any kind, either expressed or implied. Any warranty of merchantability or of fitness for a particular purpose is expressly disclaimed. Users expressly assume all risks and liabilities arising from the use of or reliance upon this information. Application

Vesuvius Industrial Processes Division Sales Offices United Kingdom Germany Vesuvius UK Limited 2, Midland Way, Central Park Barlborough Links S 43 4 XA, UK Tel: +44 (0)1246 571700 Fax: +44 (0)1246 571701 Vesuvius VGT-DYKO Gmb. H Grossalmeroder Strasse 18 37247 Grossalmerode-Rommerode Germany Tel: +49 5604 934 000 Fax: +49 5604 934 225 France Poland Vesuvius France SA 68, Rue Paul Deudon 59750 Feignies France Tel: +33 327 691010 Fax: + 33 327 681411 Vesuvius Skawina Materialy Ogniotrwale Sp. Z o. o. ul. Tyniecka 12 32 -050 Skawina Poland Tel: +48 12 277 5100 Fax: +48 12 277 5110 Belgium Vesuvius Group S. A. /N. V. Rue de Douvrain 17 7011 Ghlin Belgium Tel: +32 65 400810 Fax: +32 65 311474 Italy Vesuvius Italia S. p. A. Corte Lambruschini P. zza Borgo Pila, 40 Torre "A" - 10° PIANO 16129 Genova Italy Tel: +39 010 5602100 Fax: +39 010 5602299 www. vesuvius. com Vesuvius Group S. A. Mechelsesteenweg 455/1 B-1950 Kraainem Belgium Tel: +32 2 766 0130 Fax: +32 2 767 1351

Vesuvius Industrial Processes Division Sales Offices United Kingdom Germany Vesuvius UK Limited 2, Midland Way, Central Park Barlborough Links S 43 4 XA, UK Tel: +44 (0)1246 571700 Fax: +44 (0)1246 571701 Vesuvius VGT-DYKO Gmb. H Grossalmeroder Strasse 18 37247 Grossalmerode-Rommerode Germany Tel: +49 5604 934 000 Fax: +49 5604 934 225 France Poland Vesuvius France SA 68, Rue Paul Deudon 59750 Feignies France Tel: +33 327 691010 Fax: + 33 327 681411 Vesuvius Skawina Materialy Ogniotrwale Sp. Z o. o. ul. Tyniecka 12 32 -050 Skawina Poland Tel: +48 12 277 5100 Fax: +48 12 277 5110 Belgium Vesuvius Group S. A. /N. V. Rue de Douvrain 17 7011 Ghlin Belgium Tel: +32 65 400810 Fax: +32 65 311474 Italy Vesuvius Italia S. p. A. Corte Lambruschini P. zza Borgo Pila, 40 Torre "A" - 10° PIANO 16129 Genova Italy Tel: +39 010 5602100 Fax: +39 010 5602299 www. vesuvius. com Vesuvius Group S. A. Mechelsesteenweg 455/1 B-1950 Kraainem Belgium Tel: +32 2 766 0130 Fax: +32 2 767 1351