575dc3491732de2122e84fc0fda09053.ppt

- Количество слайдов: 36

Recent and Future Developments in Facilities Engineering By Kenneth E. Arnold Paragon Engineering Services July 13, 2004 Paragon Engineering Services, Inc.

• • • History Job of a Production Facility Facilities Engineering Today Emerging Process Technology Project Management Technology

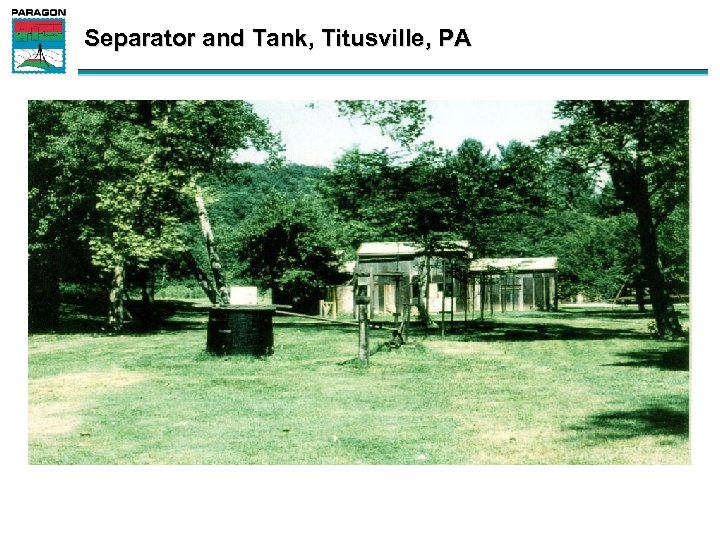

Separator and Tank, Titusville, PA

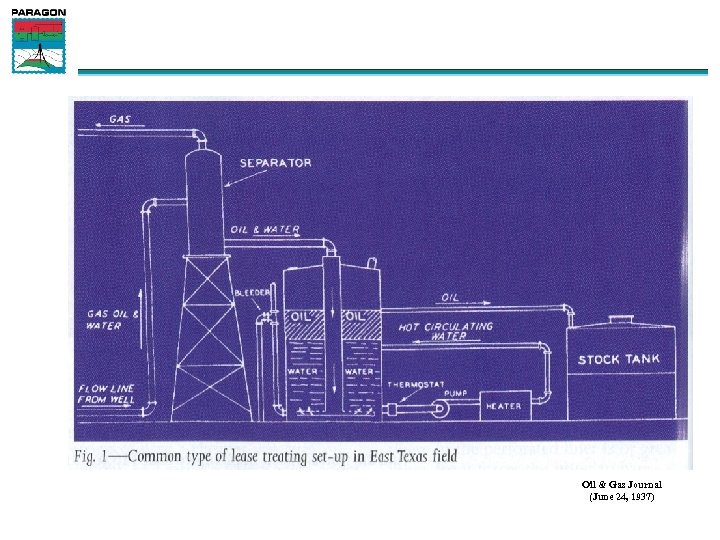

Oil & Gas Journal (June 24, 1937)

First Test of Horizontal Two Phase Separator, 1940

Offshore Field, 1940 s

Offshore Platform, 1950 s

Facilities Engineers • After World War II demand for: – – High pressure gas production – Produced water treating – • Offshore facilities Heavy Oil Steam Floods Led to: – More complex facilities – “Mechanical, ” “Facilities” and “Construction” Engineering Departments introduced

Facilities Engineering (1950 s to 2000) • Money is made by discovering and exploiting reserves – Reservoir engineering and management are critical – Surface facilities are a necessary evil • This means: – Facilities engineering as recognized specialty didn’t even begin until 1960 s – Recent emphasis on “core competence” led to elimination of facilities training and R&D efforts • Increased reliance on Engineering Companies to develop and implement design

Facilities Engineering Today • But… good corporate citizenship puts emphasis on: – Safety – Environment • Design – Larger, more complex projects • Ten years ago – Hundreds of $1 MM to $25 MM projects • Now several $500 MM – $2 B projects – Facilities cost is becoming a large part of total field development cost • A $4. 2 B North Sea Field Development Drilling $1. 0 B 23 % Topsides - $2. 0 B 47% Hull - $0. 8 B 20% $0. 4 B 10% Commissioning & Operations Support -

Facilities Engineering Today • Construction – Project cycle times significantly impact project profitability – Construction options limited – Construction execution plan critical to meeting profitability

Emerging Process Technology • Improved Separator Internals – Use of CFD – Centrifugal Devices • Oil and water treating – De-oiling Hydrocyclones – De-watering Hydrocyclones • Multiphase Technology – Meters – Pumps • Absorption and Contact Towers – Improved Packing – Co-current Flow in Pipes

Emerging Process Technology (Continued) • Subsea and Downhole Systems – Direct Water Injection/Disposal – Direct Gas Injection – Reduce Backpressure • Stranded Gas and Alternatives to Flaring for Associated Gas (Especially Offshore) – – – CNG Transportation Gas to Methanol Gas to Middle Distillates Gas to Hydrates Gas to Power

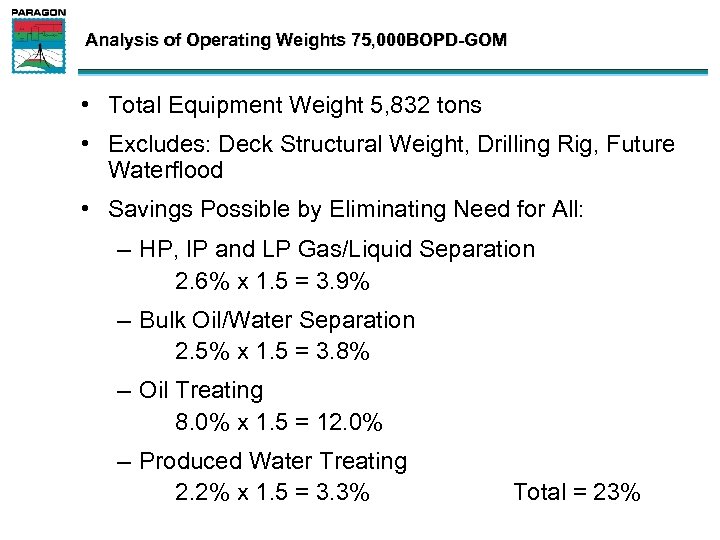

Analysis of Operating Weights 75, 000 BOPD-GOM • Total Equipment Weight 5, 832 tons • Excludes: Deck Structural Weight, Drilling Rig, Future Waterflood • Savings Possible by Eliminating Need for All: – HP, IP and LP Gas/Liquid Separation 2. 6% x 1. 5 = 3. 9% – Bulk Oil/Water Separation 2. 5% x 1. 5 = 3. 8% – Oil Treating 8. 0% x 1. 5 = 12. 0% – Produced Water Treating 2. 2% x 1. 5 = 3. 3% Total = 23%

Choosing the Proper Technology – Innovative Process Technology • Each has applications and limitations depending on project specifics • It takes a knowledgeable engineer to apply this known technology correctly • New technology will help us reduce costs • There is no “magic bullet” process concept that will results in a significant decrease in facilities costs • But…. The way in which we manage a project has a potentially large impact on cost

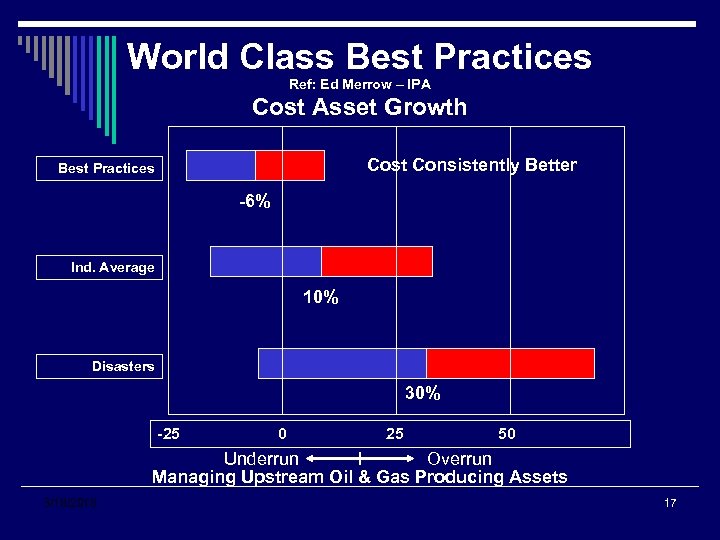

World Class Best Practices Ref: Ed Merrow – IPA Cost Asset Growth Cost Consistently Better Best Practices -6% Ind. Average 10% Disasters 30% -25 0 25 50 Underrun Overrun Managing Upstream Oil & Gas Producing Assets 3/18/2018 17

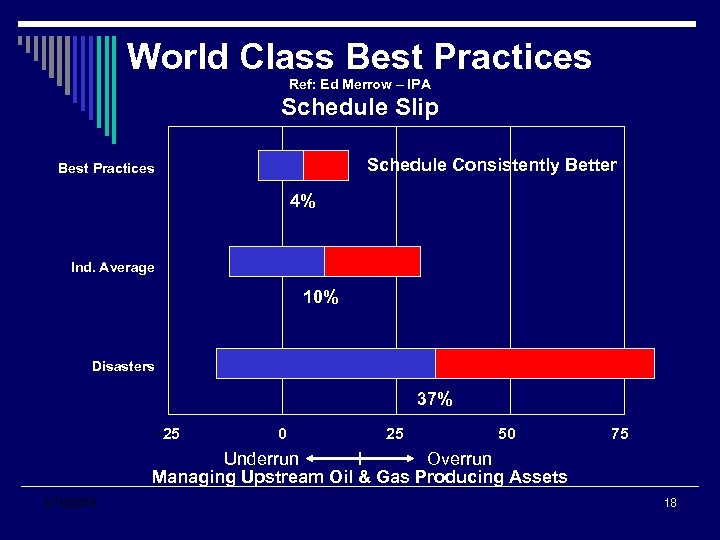

World Class Best Practices Ref: Ed Merrow – IPA Schedule Slip Schedule Consistently Better Best Practices 4% Ind. Average 10% Disasters 37% -25 0 25 50 75 Underrun Overrun Managing Upstream Oil & Gas Producing Assets 3/18/2018 18

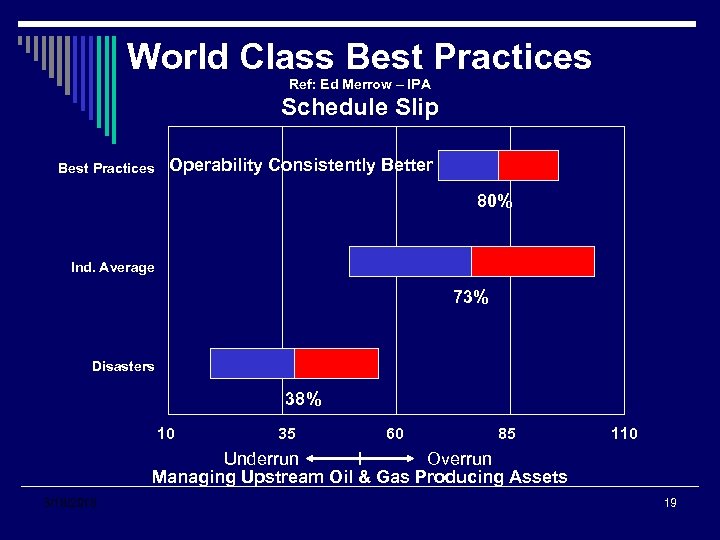

World Class Best Practices Ref: Ed Merrow – IPA Schedule Slip Best Practices Operability Consistently Better 80% Ind. Average 73% Disasters 38% 10 35 60 85 110 Underrun Overrun Managing Upstream Oil & Gas Producing Assets 3/18/2018 19

Project Management Technology A Project Requires: • Basic Concept and Plan of Execution • Efficient Design – Appropriate Choice of Equipment – Simplicity • Procurement Plan – – – What to Buy Where to Buy it From Management of Interfaces Quality Control Expediting

Project Management Technology (Continued) • Construction Plan • • Contractor vs. Owner Supply Managing Owner Supply Site Management Between Contractors Management of Interfaces Safety Management Quality Control Expediting • Startup and Commissioning Plan • • • Mechanical Completion Instrument Check-out Initial Fall of Chemicals, etc. Purge Closeout

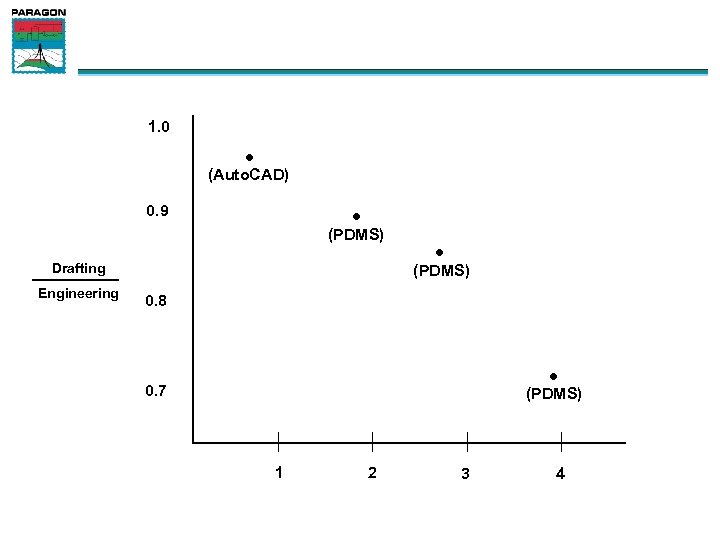

Developing Project Management Technology • 1980 s Engineering – Emphasis on Developing Training Materials and Automating Selection and Sizing of Equipment – Facilities Bookware Series (tutorials and sizing programs) – “Typical Facility Concept” (logic diagrams and standard P&ID modules) • 1980 s Design – Auto. CAD – 2 D • 1990’s Engineering – Emphasis on Cost Estimating and Material Control – Automatic Time Entry and Billing – Estimating Tools and Databases – EMAC Procurement and Tracking Systems • 1990 s Design – PDMS

1. 0 • (Auto. CAD) • 0. 9 (PDMS) Drafting Engineering • (PDMS) 0. 8 • 0. 7 (PDMS) 1 2 3 4

Project Management Emphasis Today • Integration of Work Processes – ISO Certification • Codify work processes • Assure consistency • Audit – Full implementation of PDMS as design tool for all disciplines – Link in Engineering Work Processes (VPE) – Link in Smart P&ID (VPID) – Link in procurement and material control (VPRM) • More efficient design • Use design models for more effective human factors, operability and maintainability reviews

Project Management-The Future • Utilize work processes, standards, “typicals” to automate and reduce engineering manhours/ton. • Link multiple locations: design, fabrication, operations, maintenance. Take advantage of knowledge where it is. • Use database to help schedule maintenance, reduce operating costs and manage change. • Create a real time life cycle database.

Conclusions • We’ve come along way • There are exciting new technologies becoming available • We have to use them wisely • New process technologies will surely help reduce costs and increase capabilities • Large impacts are possible by applying developing project management technologies

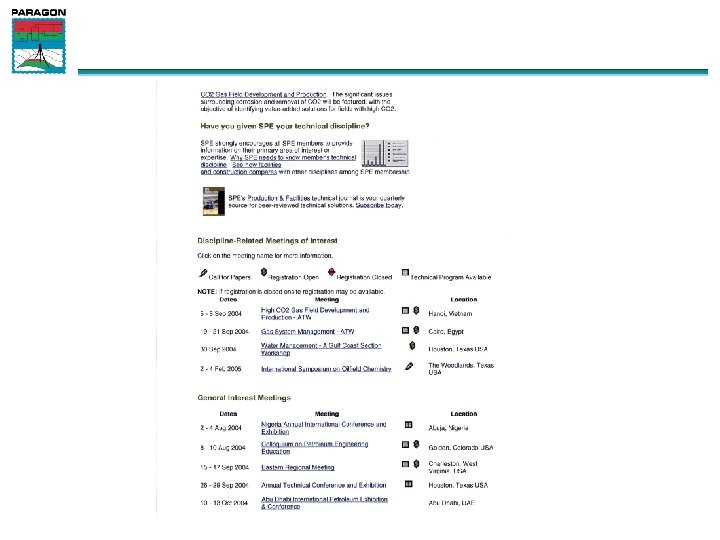

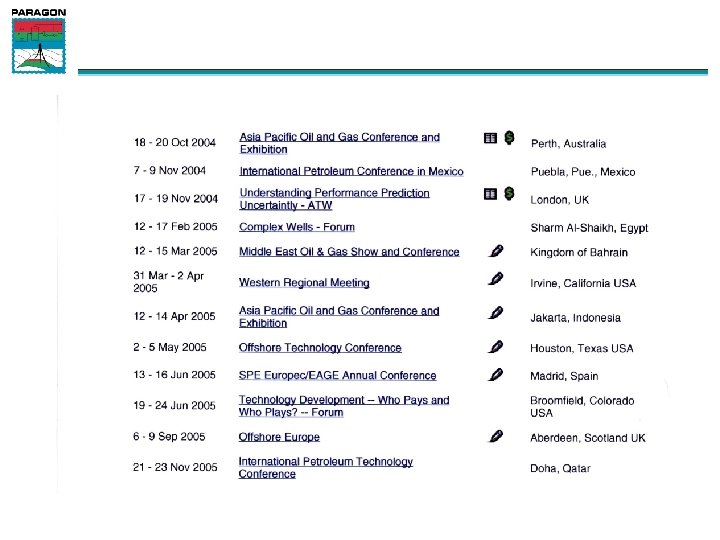

How Does SPE Help Keep Facilities Technology Current • Publications • Conferences and Symposia • Forum Series • Applied Technology Workshops • Technical Interest Groups

Types of Meetings • Annual Technical Conference and Exhibition (ATCE) – F & C Programming Committee • Regional Meetings & Symposia – Region plans and manages under SPE Meetings Policy. Held periodically • Applied Technology Workshop (ATW) – Limited attendance focused on latest applications of a specific technology. One or two days with no formal papers. • Forum Series – Brings together experts on specific topics to focus on future aspects. Usually one week with no formal papers • Section Meeting – Held on periodic basis for benefit of section members. Often scheduled for lunch or dinner. • Joint Meeting – Offshore Technology Conference

Future Programming • Facilities and Construction Committee • Local Chapter Facility Study Group • Facilities and Construction Volunteer Database

Future Programming • Join SPE – www. SPE. org • Choose facilities and construction technical discipline • Work with local section to develop F & C programming • Work with Local Section to encourage more F & C membership – operators, vendors, consultants and contractors • Volunteer to help with SPEI programming – Email me your interests Karnold@paraengr. com • List your interests (Level 2 of TIL) and your expertise (Level 3 of TIL)

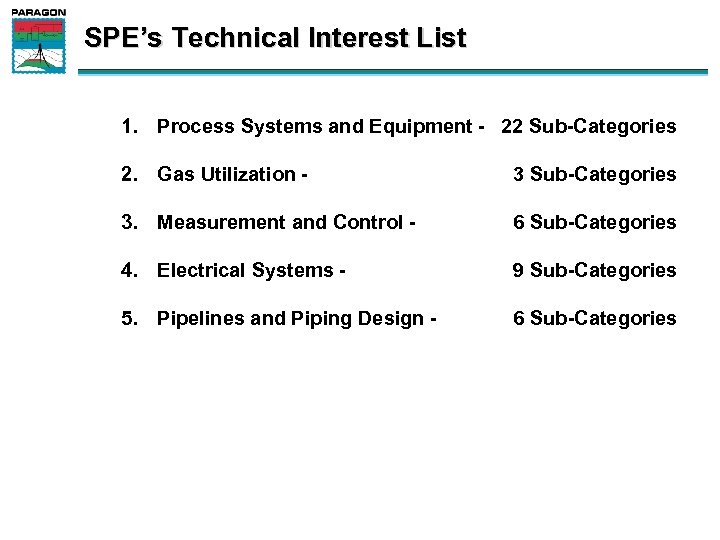

SPE’s Technical Interest List 1. Process Systems and Equipment - 22 Sub-Categories 2. Gas Utilization - 3 Sub-Categories 3. Measurement and Control - 6 Sub-Categories 4. Electrical Systems - 9 Sub-Categories 5. Pipelines and Piping Design - 6 Sub-Categories

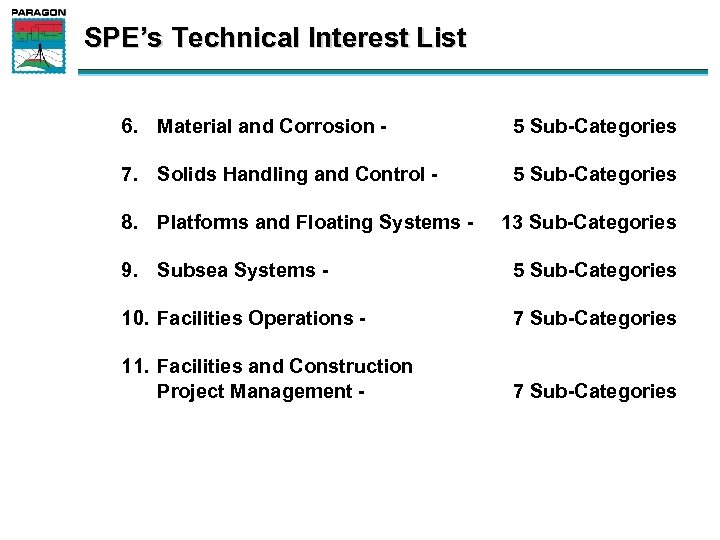

SPE’s Technical Interest List 6. Material and Corrosion - 5 Sub-Categories 7. Solids Handling and Control - 5 Sub-Categories 8. Platforms and Floating Systems - 13 Sub-Categories 9. Subsea Systems - 5 Sub-Categories 10. Facilities Operations - 7 Sub-Categories 11. Facilities and Construction Project Management - 7 Sub-Categories

Conclusions • The Facilities and Construction specialty is important • This is a field that is growing in importance and complexity • SPE has programming in place to help F & C engineers • SPE wants to expand this programming

575dc3491732de2122e84fc0fda09053.ppt