418f3570254961eee8356b018d469343.ppt

- Количество слайдов: 87

Realizing Plants’ Full Potential: Electricity from Biomass By Becky Schanz and Megan Garvey Chicago-Kent College of Law Energy Law Presentation* bjschanz@earthlink. net mgarvey 03@aol. com

Overview of Presentation l l Introduction and Background Technologies that Produce Electricity from Biomass Legal Aspects Conclusion

Biomass: l l Biomass is plant matter or other biological material, such as trees, grasses, or agricultural crops. On average, biomass is made of 75% carbohydrates and 25% lignin. – Lignin forms the woody cell walls of the plants.

Biomass l Wood and Wood products

Biomass l Agricultural Biproducts and Residues

Biomass l Trees, shrubs, grasses and other energy crops l Typically fast growing

Bioenergy: l l Bioenergy or biomass energy is any fuel, electric power, or useful chemical product derived from organic matter. Bioenergy can be derived either directly from the plants or indirectly from plant-derived wastes and residues.

Environmental Factors l l l Generates same amount of heat and carbon dioxide as from natural processes. Renewable energy source Reduces erosion by preserving soil

Environmental Factors l l l Provides a habitat for wildlife species Provides moisture retention and shade, which cools our atmosphere. Most wood used is remnants from the logging industry, such as tree tops and wood chips.

Reliability l l The United States has an estimated 65 -90 billion tons of dry matter. At 2000 energy use levels, this biomass could supply 14 -19 years of energy. The Department of Energy states that all of the biomass available now has an energy content that would produce an estimated 2, 740 Quads. 1 Quad = 1, 000, 000 Btus

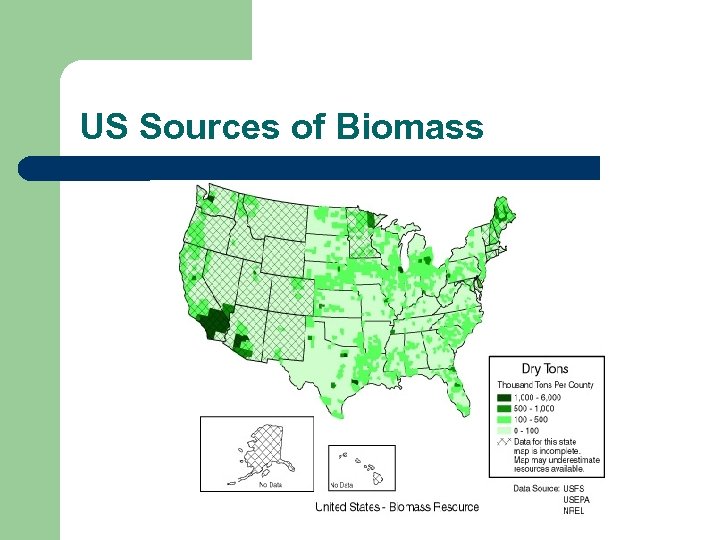

US Sources of Biomass

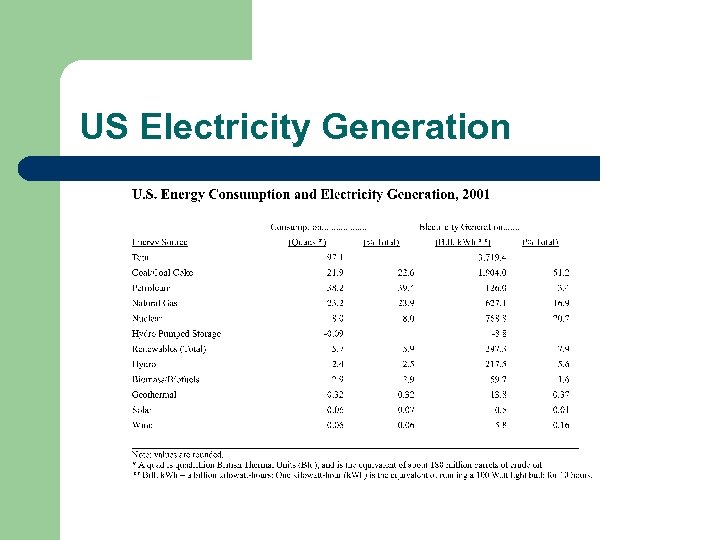

US Electricity Generation

US Biomass Generation l l l The US is the largest biopower generator. It produces 37 billion k. Wh of biomass electricity which requires about 60 million tons of biomass a year. The US has more than 7, 000 MW of installed capacity. We have about $15 billion invested and 66, 000 jobs.

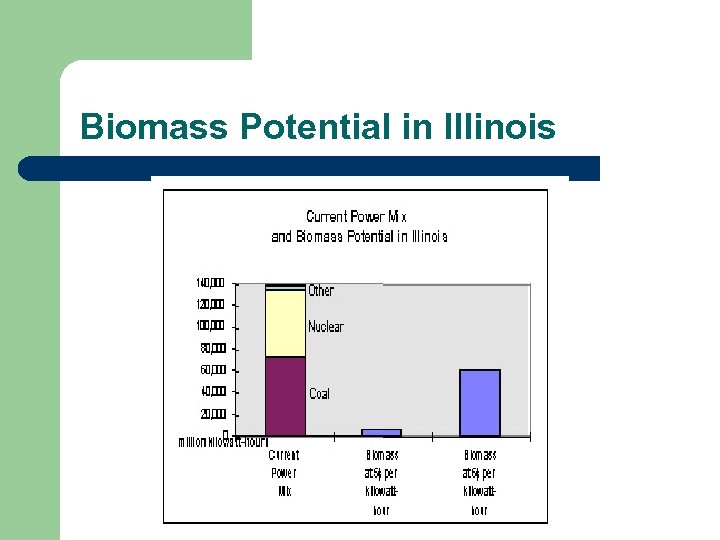

Biomass Potential in Illinois

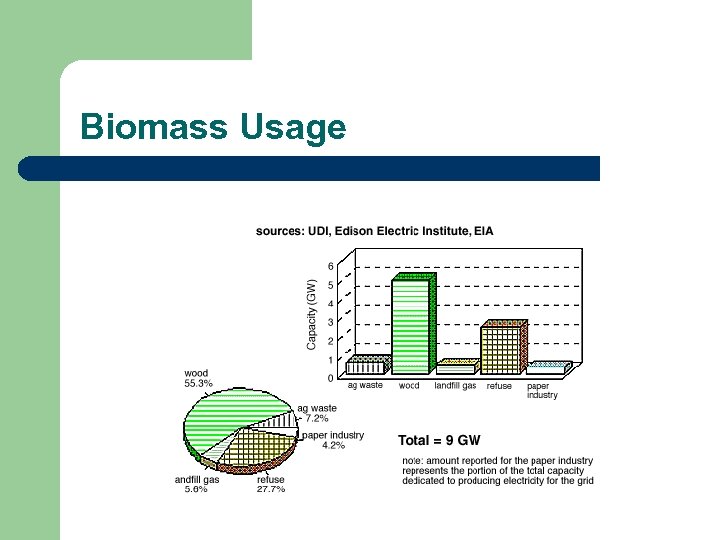

Biomass Usage

Marketing & Incentives l l Green Power Marketing provides choices for consumers to purchase power from renewable or environmentally friendly sources. Customers also pay a premium to support investment in renewable energy technologies.

Marketing & Incentives l The EPA Combined Heat and Power Partnership program is a voluntary partnership between EPA, combined heat and power (CHP) industry, utilities, and state and local governments that create CHP programs.

Biomass Uses for Energy l l Heating – stoves, process heat Cooking – developing world Transportation – ethanol Electric Power Production

Technologies used to Produce Electricity from Biomass l Direct Combustion burning biomass with excess air to produce steam

Technologies (cont. ) l Co-Firing – replaces part of the coal with biomass, as a supplementary energy source.

Technologies (cont. ) l Gasification – heat biomass without oxygen to produce a calorific gas

Technologies (cont. ) l Small Modular Bio. Power – develops small, efficient, clean biopower systems

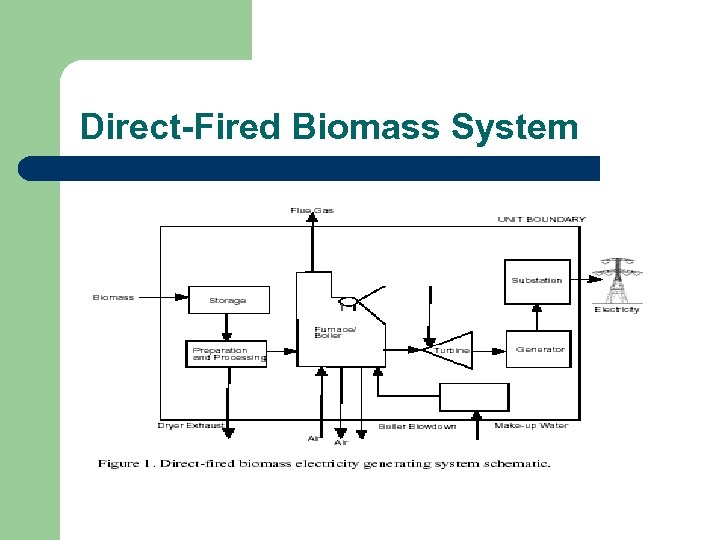

Direct-Fired Combustion l l l Oxidation of air and biomass Produces hot flue gases that produce steam Steam generates electricity in generators

Direct-Fired Biomass System

Small-Modular Systems l l Less than 5 MW Potential to power villages Consist of power generation attached to the transmission and distribution grid, which is close to the end consumer. Potential to supply 2. 5 billion people who are currently without electricity.

Gasification l Two processes: – Pyrolysis – releases volatile compounds of the fuel l – Bigger role here than in coal fired plants Char Conversion – carbon remaining after pyrolysis reacts with steam and/or oxygen (combustion) l Biomass has high reactivity

Types of Gasifiers l Direct Gasifier l Indirect Gasifier

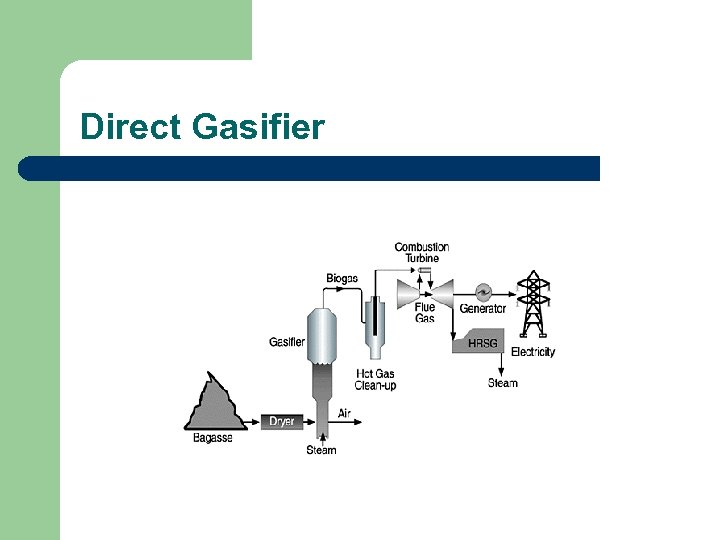

Direct Gasifier

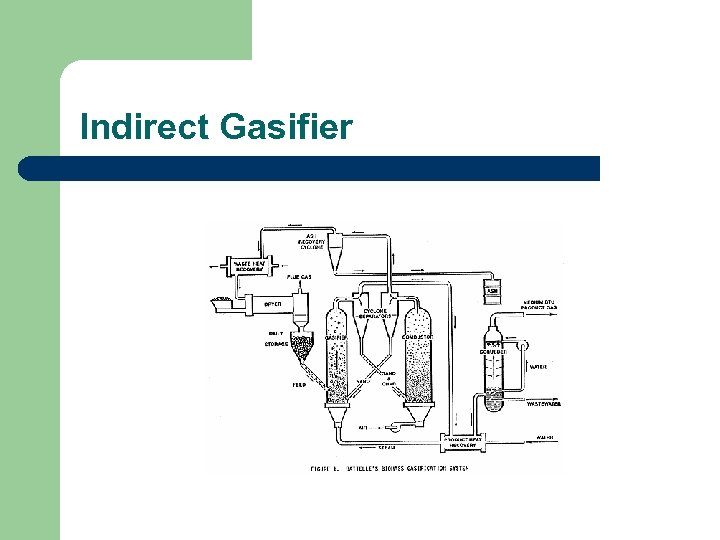

Indirect Gasifier

Gasification Process – Direct Gasifier l l l Plant gets wood chips Biomass is gasified Air is extracted from the gas turbine and fed into the gasifier Gasification steam is extracted. Remaining fuel gases are cooled.

Gasification Process – Direct Gasifier l l l Fuel gas combusts and produces electric power and a high temperature exhaust steam Exhaust steam expands in a steam turbine to produce additional power Steam is extracted and electricity is sent to a substation

Generating Capacity l l The United States has about 7 GW of gridconnected biomass generating capacity. Coal-fired electric units are 297 GW of capacity, which is about 43% of total generating capacity.

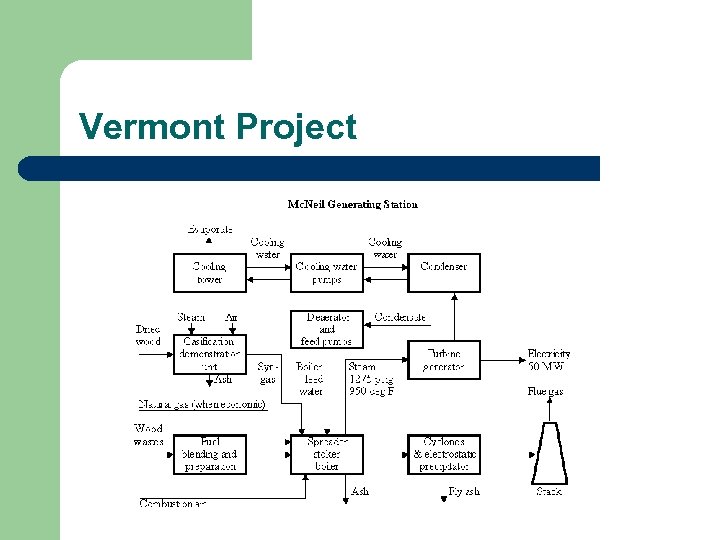

Vermont Project l l Vermont has the first industrial biomass gasification process located in Burlington. The process integrates a high-throughput gasifier with a high-efficiency gas turbine. Circulating hot sand surrounds the biomass particles and the particles break down and produce gas. This project uses an indirect gasifier system.

Vermont Project

Hawaii Project l l Hawaii Biomass Gasifier is part of the DOE’s initiative to demonstrate a gasification system to turn biomass into electricity. Its goal is to provide competitive electric power. The plant uses maple wood chips, California highway clippings, paddy rice straw, fuel from refuse, bark, paper mill sludge, and alfalfa. This project uses a direct gasifier system.

Advantages of Gasification l l Biomass closes the carbon system and therefore reduces emissions. Biomass is low in sulfur – – Biomass contains. 05 to. 20 % of weight is sulfur Coal contains 2 -3% of weight is sulfur

Advantages of Gasification l l l Operates at a lower temperature and wider variety of feedstocks than direct combustion systems. Can produce a Btu gas that is interchangeable with natural gas. Produces nitrogen free gas. Less landfill waste. Future technologies are being developed – Fuel Cell Systems

Disadvantages of Gasification l l l Some biomass plants have closed because of deregulation of the electric utility industry. Hard to compete with cheaper sources, such as coal, oil, and nuclear. Small amounts of tar are released in the gas. The tar can coat parts of the pipe or the equipment. – Catalyst reactor has been developed to decrease the amount of tar to parts-per-million.

Disadvantages of Gasfication l l Still a new technology and the Vermont Plant has not been able to operate continuously yet for a sustained period of days or weeks. Over storage of wood fuel can lead to odor problems and spontaneous combustion.

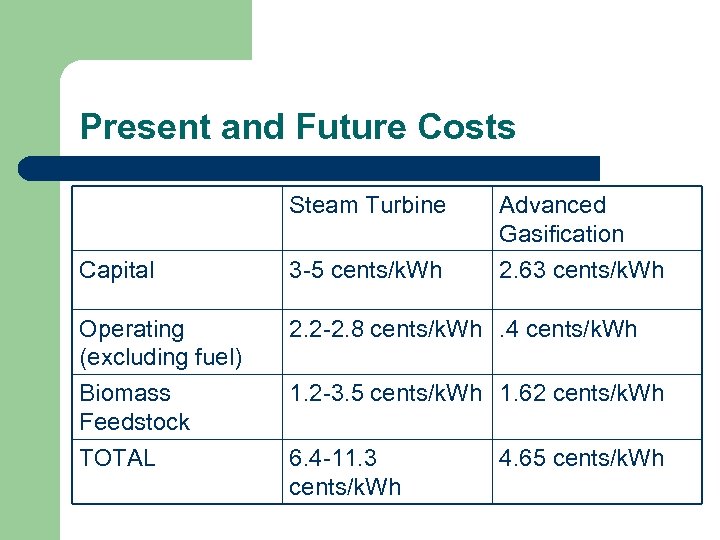

Present and Future Costs Steam Turbine Advanced Gasification Capital 3 -5 cents/k. Wh 2. 63 cents/k. Wh Operating (excluding fuel) 2. 2 -2. 8 cents/k. Wh. 4 cents/k. Wh Biomass Feedstock TOTAL 1. 2 -3. 5 cents/k. Wh 1. 62 cents/k. Wh 6. 4 -11. 3 cents/k. Wh 4. 65 cents/k. Wh

Costs l l Capital costs of building a biomass-fired steam turbine plant is about $2000 -2500 per KW of installed capacity. These costs are expected to decrease in the future.

Future of Gasification l l Gasification has a bright future, once the technology is fine-tuned. If the cost of the process decreases as expected, it will be able to compete economically with current energy sources.

Co-Firing Biomass with Coal and the Legal/Governmental Incentives for Biomass as a Renewable

Co-firing Biomass with Coal to produce Electricity l What is Co-firing? – – The simultaneous combustion of biomass and coal in a preexisting boiler of a traditional coal-fired power plant 2 Methods l Blending (+) Least expensive – (-) Limited amounts; higher possibility of damage – l Separate Feed (+) greater emission reductions; greater amounts of biomass tolerates; less harmful to existing boiler – (-) requires more resources (equipment, $) –

l One form of “blending” is directly adding biomass to the coal-belt.

Advantages of Co-firing: “Something for Everyone” The Existing Power Plant – – – Existing equipment is still utilized Easier to meet environmental regulations and hedge future regulations Cost savings l l – Tax incentives Fuel supply options Good PR

Advantages of Co-firing: “Something for Everyone” Biomass – Encourages development of feedstock infrastructure – Creates a market for residues and energy crops

Advantages of Co-firing: “Something for Everyone” The Environment – – Reduces GHG emissions (CO 2; CH 4) Reduces SO 2 and NOX emissions Reduces burden on landfills Extends the life of coaluse for electricity generation

Advantages of Co-firing: “Something for Everyone” The Economy $$$ l l l Provides an end use for low value/negative value products Maintains existing market for coal Increases domestic economic growth and job creation Increase economic activity in rural/agricultural areas Increase business for equipment suppliers

Disadvantages of Co-firing Technological issues – Existing boilers/systems designed (exclusively) for fossil fuels l l l Negative impact on existing boilers CL-based corrosion Negative impact on boiler capacity

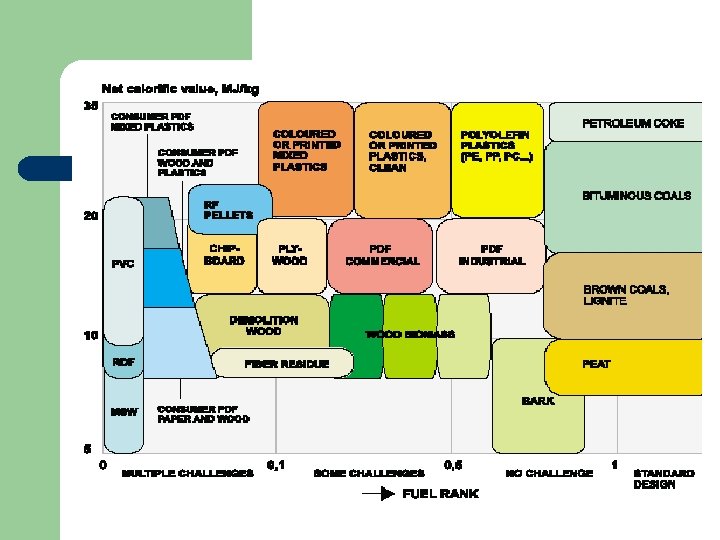

Disadvantages Diverse feedstock – Range of different fuel characteristics l l Woody – Grassy Residues – energy crops Ash content Fuel nitrogen content

Uncertainties due to different biomass properties Differences between biomass and coal – – – Higher moisture content (= low net calorific value) Higher CL content Low heating value Low bulk density Higher content of volatile matter (80%: coal 30%)

Disadvantages l Feeding methods – l Fuel preparation and handling Ash-related issues – – Biomass = source of aerosols Pure-coal ash required for concrete use

Just a couple more…disadvantages l l Engineering to commercial/economical issues? Requires incentives – l Might require additional investments – – l Less incentives for small-scale plants Equipment Biomass material Dependant on the availability and price of lowcost biomass feedstocks

Co-Firing Programs DOE’s Biopower Program Goals: l Promote biomass using the least-cost approach l Broaden the base of utilities employing co-firing l Increase the # and type of cofiring techniques l Provide the underpinning for advanced designs

– Accomplishments l l l Switchgrass; willow = successful bio-material Biomass co-firing = technologically successful Viability demonstrated Pollutant emission reductions verified Economic models/feeding techniques developed

Co-Firing Programs l Regional Biomass Energy Program (RBEP) – – Federally-funded; located in 5 regions of U. S. Goal = to increase the production and use of bioenergy resources l l – Best candidates Full-scale analysis Accomplishments: l Successful biomass co-firing operations from an operational and performance perspective requires… l l Biomass price 20% less than that of coal Reliable and automated procedures

Co-Firing Programs l Co-firing project at Hawaii Commercial Sugar – Result: l Sugar cane (bio-material) + coal = less NOX emissions!

Co-Firing Programs l Co-firing program for urban wood waste – – Northern Indiana Pub. Service Co + Electric Power Research Institute + DOE Urban wood waste + coal (W. bituminous and Powder River Basin)

Current Power Plants Using Co. Firing Method on a Regular Basis l Northern States Power (NSP) – l Tacoma Public Utitlies – l Wood waste + coal Southern Company – l Wood wastes and garbage + coal TVA – l Wood residues + coal Wood residues (grnd pallets/hurricane-damaged trees) + coal NY State Electric and Gas (NYSEG) – Sawdust; furniture factory waste + coal

Furthermore, Numerous Other Power Plants are Exploring the Benefits of Co-Firing l l l Niagara Mohawk Power Co. GPU GENCO Madison Gas & Electric Atlantic Electric American Electric Power l l l Illinois Power Company Plains Electric IES Utilities Northern Indiana Public Service Co. And MANY more!!

Summary Co-Firing biomass capitalizes on the large investment and infrastructure associated with the existing coal-fired power plants while traditional pollutants (SO 2; NOX) and net GHGs (CO 2; CH 4) are decreased!!

Legal Aspects and Governmental Incentives pertaining to Biomass as a renewable form of energy Federal State

Federal 1. Energy Policy Act of 2003 (Energy Bill/S. 2095) – – – Title II: renewable energy incentives Title XIII: energy tax incentives Section 206 2. Biomass R&D Initiative of 2003 3. Bioenery Initiative – Exec. Order 13134

Federal (cont) 4. Ag. Risk Protection Act of 2000 (P. L. 106 -224); Title III. Biomass R&D Act 5. Green Power Purchasing Goal – Exec. Order 13123 6. Renewable Energy Systems and Energy Efficiency Improvement Program 7. CAA amendments

(1) Energy Policy Act of 2003 Energy Bill (S. 2095) l Title II: renewable energy incentives – – New incentives for development and use of renewables Mandates assessments to assist in long-term plans Reauthorizes the Renewable energy Production Incentive Program Grants for turning forest material into biomass energy

Energy Bill (S. 2095) l Title XII: Energy tax incentives – – Previous “Renewable Electricity (and Energy) Production Credit” expired for all new projects on 12/31/2003 Creates a NEW Tax incentive!! Extends placed-in service date for…closed-loop biomass and poultry waste facilities l Adds open-looped biomass, municipal bio-solids, and recycled sludge…as qualifying energy resources l Credit = 1. 8 cents/k. Wh (no inflation adjustment) l Allows for tradable tax credits for tax-exempt entities, co-ops, and municipal utilities l Effective: 10/1/2004 www. energy. senate. gov l

Energy Bill (S. 2095) l Section 206 – – Grants to improve the commercial value of forest biomass for electric energy…and other commercial purposes The government found that: l Risk – l l (wildfire; insect infestation; tree mortality; drought) …requires preventive measures =by-products of biomass BUT no suitable market

Energy Bill (S. 2095) l Section 206 (cont. ) – Therefore, the U. S. should: l Promote economic and entrepreneurial opportunities in using these by-products l Develop and expand markets

(2) Biomass R&D Initiative of 2003 l DOE and USDA – $23 million allocated to 19 different biomass projects

(3) Bioenergy Initiative l Exec. Order 13134: Developing and Promoting Bio-based Products and Bioenergy – Policy = national strategy to stimulate the creation and early adoption of technologies needed to make biobased products and bioenergy cost-competitive l l Expand employment opportunities Create new market Reduce Nation’s dependence on foreign resources Decrease pollution

Bioenergy Initiative l President’s goal = triple U. S. use of bio-based products and bioenergy by 2010 l DOE + federal organizations = national partnership to develop an integrated industry to produce power…from biomass

(4) Agricultural Risk Protection Act of 2000 (P. L. 106 -224) Title III. Biomass R&D Act l l l Recognition that biomass has outstanding potential to benefit the national interest Combined efforts of DOA and DOE Purposes: 1. 2. 3. 4. To understand biomass To develop new and cost-effective technologies that would result in large-scale commercial production To ensure economic and energy security and environmental benefits of bio-products To promote the development and use of agricultural and energy crops for conversion

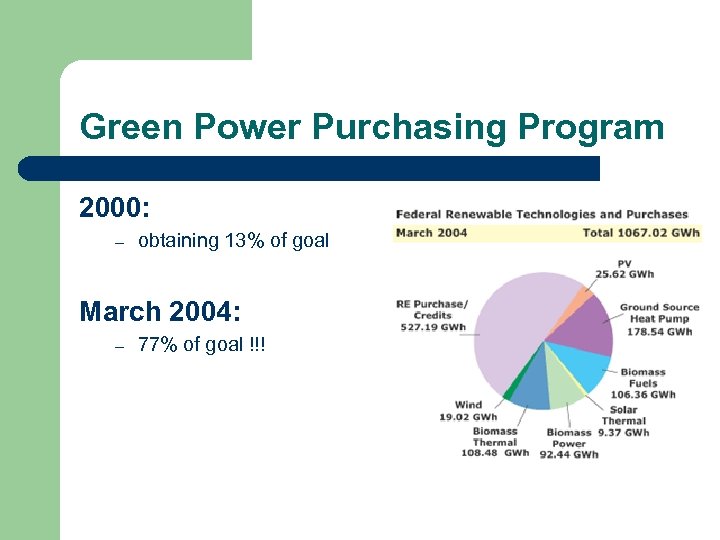

(5) Green Power Purchasing Program l l Applicable sector: federal government Goal = 2. 5% renewables by 2005 Effective: 6/2000 Authority: Exec. Order 13123 – – Requires federal agencies to increase their use of renewable energy Biomass systems installed after 1990 apply as “new” renewable energy resources (emphasis on “new” to reach goal)

Green Power Purchasing Program 2000: – obtaining 13% of goal March 2004: – 77% of goal !!!

(6) Renewable Energy Systems and Energy Efficiency Improvement Program l l Federal grant program through the USDA Commercial/agricultural producers Grants provided for 25% of eligible project costs Producer must demonstrate “financial need”

(7) 1990 Amendments to CAA (7) Lowered baseline limitations for SO 2 emissions – = increase in market-price of air emission allowances – = electricity generators will turn to bio-energy to reduce costs and meet stricter regulations

State Law/Incentives Illinois

State 1. 2. Mainstay Energy Rewards Program IL Clean Energy Community Foundation Grants (ICECF) l 3. Renewable Energy Resources Trust Fund l 4. 5. 220 ILCS 5/16 -111. 1 220 ILCS 687/6 -4 Renewable Energy Resources Program Grants (RERP) Renewables Portfolio Goal l 220 ILCS 5/16 -111. 1

(1) Mainstay Energy Rewards Program l Green Tag Purchase Program = production incentive – – Private company buys the green tags (RECs) which are brought to the market as “Green-e” certified products Participating companies receive regular, recurring payments l – – – Dependant on type of renewable; production of energy; length of K Biomass is eligible Commercial and residential sectors Amount =. 1 -1 cent/k. Wh (for biomass) Certification fee and requirements 200 current participants!

(2) IL Clean Energy Community Foundation (ICECF) Grants l State grant program – – l l Grants, loans, other financial support $250 million endowment from Com. Ed Non-profit; schools, state and local governments serving IL Authority = 20 ILCS 5/16 -111. 1 – IL Resource Development and Energy Security Act l Purposes: “Enhance the state’s energy security by ensuring that…(iv) pilot projects are undertaken to explore the capacity of new, often renewable sources of energy…”

(2) ICECF Grants (cont) l l Effective 2001 How to apply? – l Submit proposal (competitive basis) Between 2001 -2002: – ICECF awarded more than $17 million in grants for renewable energy projects in IL!!

(3) Renewable Energy Resources Trust Fund l l Public benefits fund required in 220 ILCS 687/6 -4 Available for the general public/consumer $50 million for 10 years Collection – – $. 50 cents/month from residential and small commercial electric and gas customers $37. 50/month from large commercial electricity customers

(4) Renewable Energy Resources Program (RERP) Grants l l l State grant program funded by the Renewable Energy Resources Trust Fund Distributed in the form of grants (for large systems) and rebates (for small systems) Involves an annual RFP process

(5) Renewables Portfolio Goal l l Specific standard to IL Applies to Utilities 5% by 2010… 15% by 2020 Effective: 7/2001 Authority: 220 ILCS 5/16 -111. 1 – Contains a “goal” but NO implementation schedule, compliance verification or credit-trading provisions

Biomass Utilization for Electricity Production = SOMETHING FOR EVERYONE!!!

418f3570254961eee8356b018d469343.ppt