9388bfb5aec7a43666447793f7262f07.ppt

- Количество слайдов: 12

REACH Department of Defense Briefing July 16, 2008 1

Agenda • How the automotive industry is addressing REACH • REACH impacts for military equipment • What can be done to protect Do. D capabilities 2

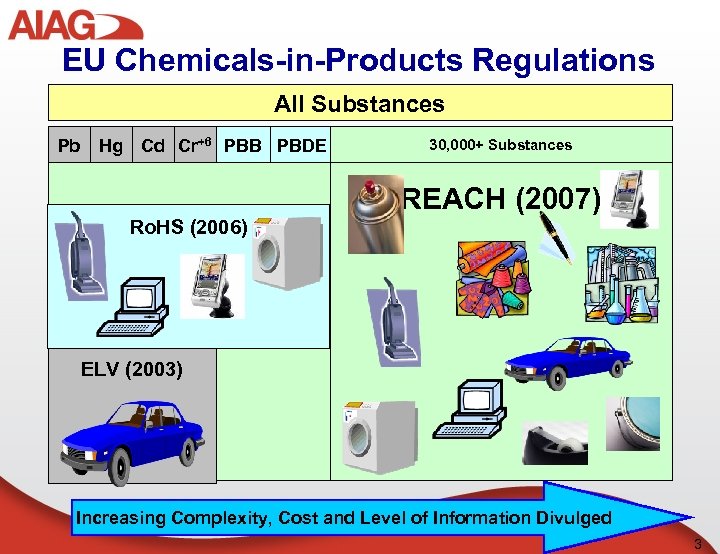

EU Chemicals-in-Products Regulations All Substances Pb Hg Cd Cr+6 PBB PBDE 30, 000+ Substances REACH (2007) Ro. HS (2006) ELV (2003) Increasing Complexity, Cost and Level of Information Divulged 3

International Material Data System (IMDS) – Developed in 2000 in response to EU’s End of Life Vehicles Directive – 130, 000+ users, secure transfer of confidential chemical substance information for vehicular components – Automotive industry may use IMDS to track and manage SVHCs, but will not solve all problems 4

Other tools and processes are being developed • AIAG has established a collaborative relationship with global REACH Task Force and trained 750 suppliers in Detroit -- http: //reach. aiag. org • Supplier risk management methodology (Plan, Assess, Handle, Monitor, Document. . ) being established. Risk factors include – Small market – Small supplier capacity – Complex supply chain – Foreign headquarters deciding REACH strategy – Product contains SVHC 5

REACH Impacts for Do. D • Same risks from automotive as for other industries • Increased costs • Decreased availability of parts and materials • Product delivery delays • Alternatives meet military specs? 6

REACH Impacts for Do. D (cont’d) • OEMs are currently specifying materials and parts for 2012 products, may not be able to remove banned substances (SVHCs) in time • Generally a 3 -5 year lead time needed for design • Testing and qualifying for military specs may take longer in some cases • Preliminary list of SVHCs (16 proposed per ECHA released June 30, 2008) may affect following automotive applications • • • Plasticizers Semiconductor materials Fire retardants Chromium pigments and dyes Metal surface treatments Adhesive additives 7

REACH Impacts for Do. D (cont’d) • Installations are not part of the EU, thus REACH-exempt if vehicles are shipped directly to bases • However, purchases from off-site, within customs area of the EU (plus Norway, Iceland Liechtenstein) are subject to REACH. • This could affect service part availability for vehicle maintenance • Joint venture and foreign military sales may have increased requirements due to importing/manufacturing in the EU • ITAR – what information should not be disclosed to foreign entities? 8

What Can be Done to Protect Do. D Capabilities ? • Work within framework of REACH’s provisions • • • Propose defense exemptions for allied states, especially those with installations Coordinate comment on proposed SVHCs (Aug 15 deadline for current list) Coordinate authorization activities for military applications • Collaborate with industry • Identify suppliers of critical substances which are at risk, using a standardized tool or process. Identify alternative substances and suppliers and communicate with industry on how to replace • Ensure confidentiality for suppliers to protect military secrets • Provide funding for processes, tools, trainings • Provide training/education for Do. D agencies 9

Questions ? AJ Guikema reach@aiag. org http: //reach. aiag. org 10

Supplemental Slide (1) 11

Proposed SVHCs per ECHA • 4, 4'-methylenedianiline 4, 4'diaminodiphenylmethan e • Bis(2 -ethylhexyl) phthalate; di-(2 -ethylhexyl) phthalate; DEHP • Anthracene, pure • Arsenic pentoxide; arsenic oxide • Diarsenic trioxide; arsenic trioxide • Triethyl arsenate • Hexabromocyclodecane (HBCD) • • • Bis(tributyltin)oxide (TBTO) Cobalt dichloride Lead hydrogen arsenate Sodium dichromate, dihydrate 1 -(1, 1 -Dimetyl)-3, 5 dimetyl-2, 4, 6 -trinitrobenzen Dibutyl phthalate; DBP Alkanes, C 10 -C 13, chloro (short-chain chlorinated paraffins) (SCCPs) Benzyl butyl phthalate BBP Cyclododecane 12

9388bfb5aec7a43666447793f7262f07.ppt