a750b51f42fcdeb1c55e4e002a78abd3.ppt

- Количество слайдов: 36

RE-ENGINEERING OPERATIONS FOR NUTRIENT REMOVAL IN SECONDARY WWTPS MT DEQ PARTNERING WITH LOCAL COMMUNITIES TO AVOID OR MINIMIZE CAPITAL IMPROVEMENT PROJECTS TO HELP MEET NUTRIENT REDUCTION OBJECTIVES

RE-ENGINEERING OPERATIONS FOR NUTRIENT REMOVAL IN SECONDARY WWTPS MT DEQ PARTNERING WITH LOCAL COMMUNITIES TO AVOID OR MINIMIZE CAPITAL IMPROVEMENT PROJECTS TO HELP MEET NUTRIENT REDUCTION OBJECTIVES

Key Concepts 1. Brief primer on MT’s Numeric Nutrient Standards 2. State agency directly helping communities meet new nutrient effluent limits (directed technical assistance) 3. Biological Nutrient Removal is not new 4. Completely shifting the focus from engineering/construction to operations 5. The value of educating operators Effluent quality Non-tangible benefits

Key Concepts 1. Brief primer on MT’s Numeric Nutrient Standards 2. State agency directly helping communities meet new nutrient effluent limits (directed technical assistance) 3. Biological Nutrient Removal is not new 4. Completely shifting the focus from engineering/construction to operations 5. The value of educating operators Effluent quality Non-tangible benefits

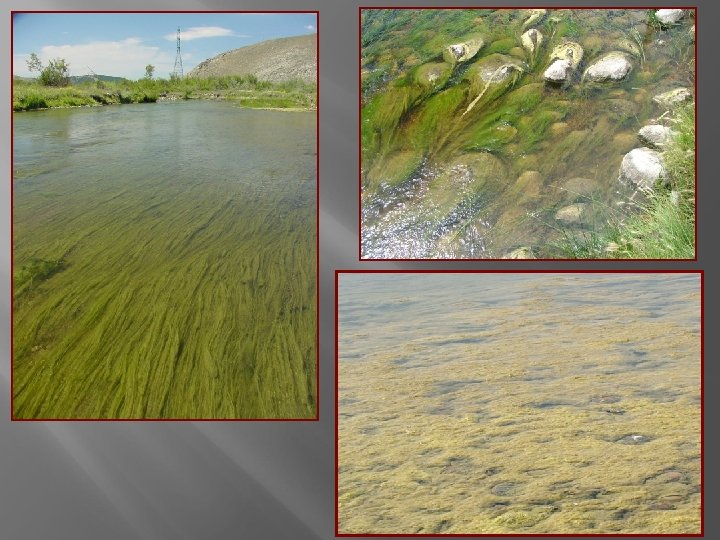

Why Nutrients?

Why Nutrients?

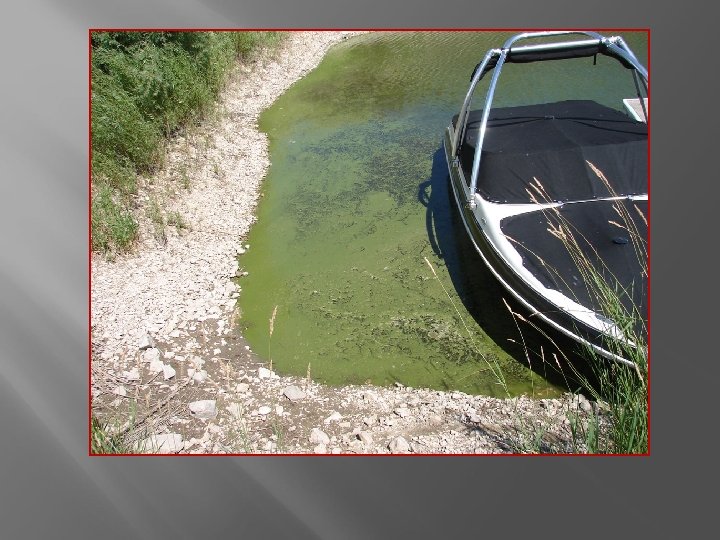

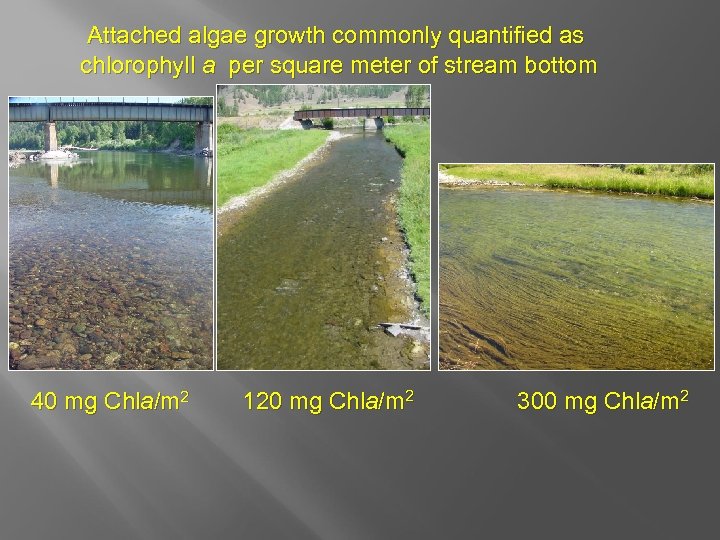

Attached algae growth commonly quantified as chlorophyll a per square meter of stream bottom 40 mg Chla/m 2 120 mg Chla/m 2 300 mg Chla/m 2

Attached algae growth commonly quantified as chlorophyll a per square meter of stream bottom 40 mg Chla/m 2 120 mg Chla/m 2 300 mg Chla/m 2

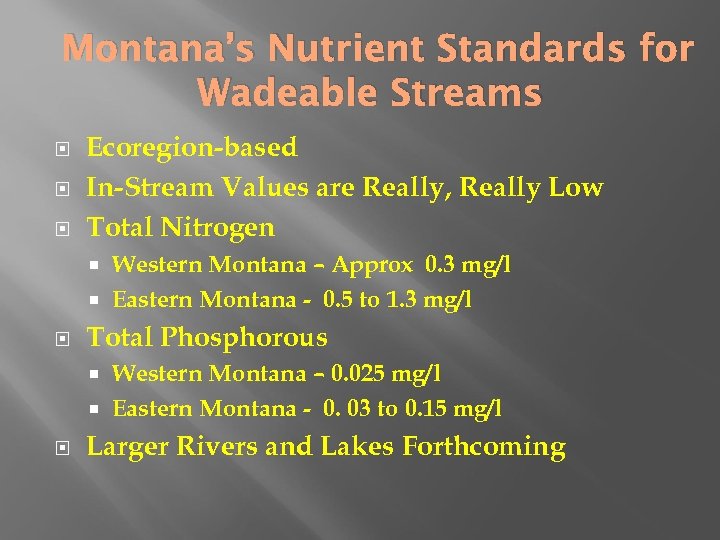

Montana’s Nutrient Standards for Wadeable Streams Ecoregion-based In-Stream Values are Really, Really Low Total Nitrogen Western Montana – Approx 0. 3 mg/l Eastern Montana - 0. 5 to 1. 3 mg/l Total Phosphorous Western Montana – 0. 025 mg/l Eastern Montana - 0. 03 to 0. 15 mg/l Larger Rivers and Lakes Forthcoming

Montana’s Nutrient Standards for Wadeable Streams Ecoregion-based In-Stream Values are Really, Really Low Total Nitrogen Western Montana – Approx 0. 3 mg/l Eastern Montana - 0. 5 to 1. 3 mg/l Total Phosphorous Western Montana – 0. 025 mg/l Eastern Montana - 0. 03 to 0. 15 mg/l Larger Rivers and Lakes Forthcoming

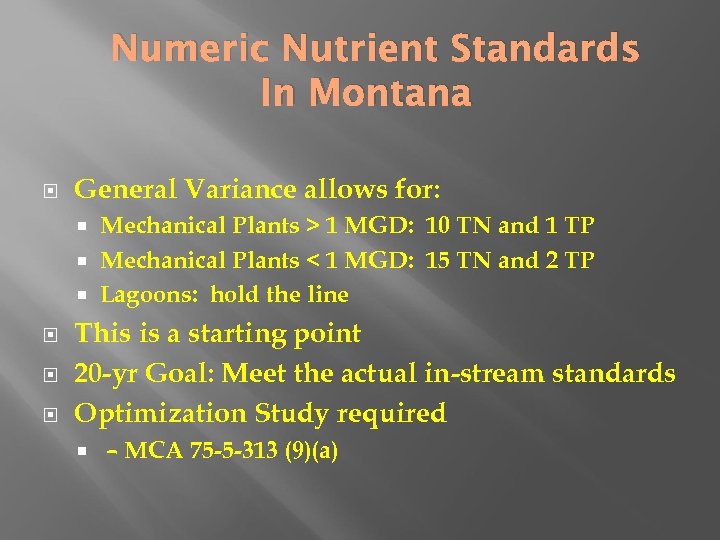

Numeric Nutrient Standards In Montana General Variance allows for: Mechanical Plants > 1 MGD: 10 TN and 1 TP Mechanical Plants < 1 MGD: 15 TN and 2 TP Lagoons: hold the line This is a starting point 20 -yr Goal: Meet the actual in-stream standards Optimization Study required – MCA 75 -5 -313 (9)(a)

Numeric Nutrient Standards In Montana General Variance allows for: Mechanical Plants > 1 MGD: 10 TN and 1 TP Mechanical Plants < 1 MGD: 15 TN and 2 TP Lagoons: hold the line This is a starting point 20 -yr Goal: Meet the actual in-stream standards Optimization Study required – MCA 75 -5 -313 (9)(a)

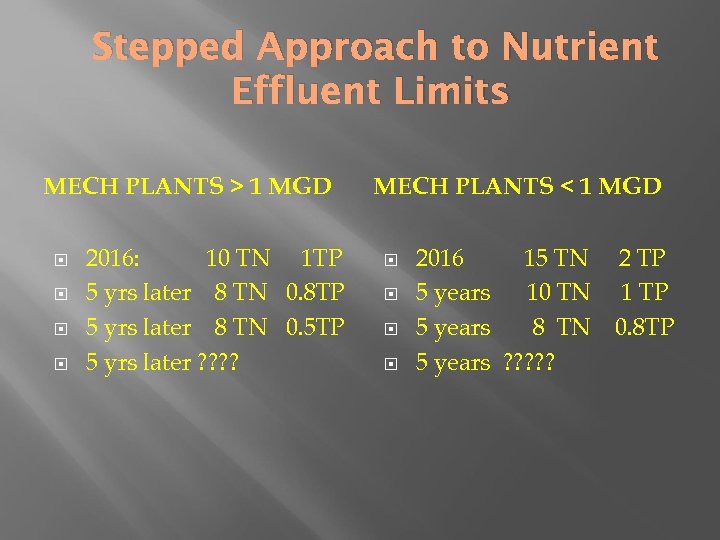

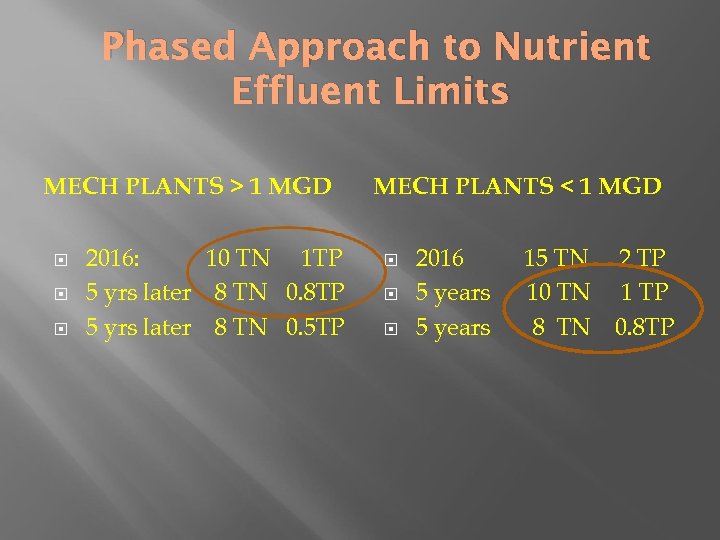

Stepped Approach to Nutrient Effluent Limits MECH PLANTS > 1 MGD 2016: 10 TN 1 TP 5 yrs later 8 TN 0. 8 TP 5 yrs later 8 TN 0. 5 TP 5 yrs later ? ? MECH PLANTS < 1 MGD 2016 15 TN 5 years 10 TN 5 years 8 TN 5 years ? ? ? 2 TP 1 TP 0. 8 TP

Stepped Approach to Nutrient Effluent Limits MECH PLANTS > 1 MGD 2016: 10 TN 1 TP 5 yrs later 8 TN 0. 8 TP 5 yrs later 8 TN 0. 5 TP 5 yrs later ? ? MECH PLANTS < 1 MGD 2016 15 TN 5 years 10 TN 5 years 8 TN 5 years ? ? ? 2 TP 1 TP 0. 8 TP

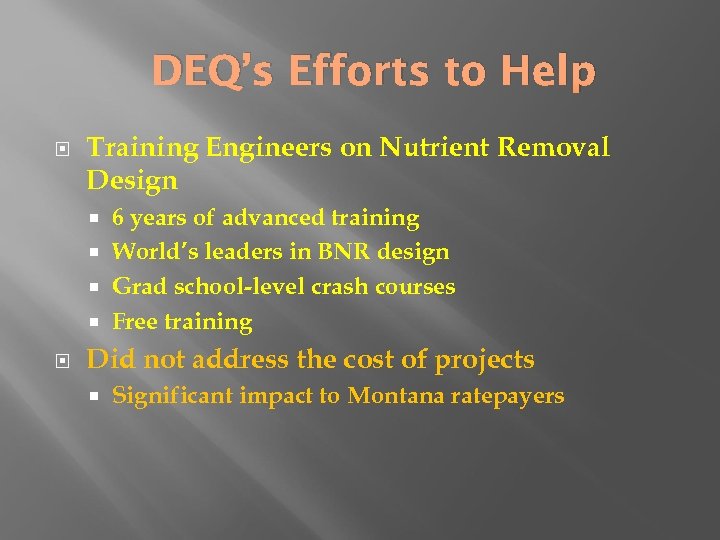

DEQ’s Efforts to Help Training Engineers on Nutrient Removal Design 6 years of advanced training World’s leaders in BNR design Grad school-level crash courses Free training Did not address the cost of projects Significant impact to Montana ratepayers

DEQ’s Efforts to Help Training Engineers on Nutrient Removal Design 6 years of advanced training World’s leaders in BNR design Grad school-level crash courses Free training Did not address the cost of projects Significant impact to Montana ratepayers

So, we needed to try something else. Can we reduce nutrients without building/ upgrading treatment plants? What if we focused on operations? Do we have the expertise in-house? Is anyone else trying this?

So, we needed to try something else. Can we reduce nutrients without building/ upgrading treatment plants? What if we focused on operations? Do we have the expertise in-house? Is anyone else trying this?

More Specifically, …. Using existing infrastructure, can we re-engineer our operations to make the facility do things it was not originally designed to do? OR Can we get better performance from our existing infrastructure, including BNR plants, by operating the facilities differently? Completely shifting the focus from engineering to operations

More Specifically, …. Using existing infrastructure, can we re-engineer our operations to make the facility do things it was not originally designed to do? OR Can we get better performance from our existing infrastructure, including BNR plants, by operating the facilities differently? Completely shifting the focus from engineering to operations

A RECOGNITION OF THE IMPORTANCE OF OPERATORS Operators are on the front line of environmental protection efforts. They are the implementers of water pollution control regulations. The success or failure of a designed system falls on the shoulders of the operator. The un-sung heroes of our profession.

A RECOGNITION OF THE IMPORTANCE OF OPERATORS Operators are on the front line of environmental protection efforts. They are the implementers of water pollution control regulations. The success or failure of a designed system falls on the shoulders of the operator. The un-sung heroes of our profession.

The Problem with Operators • UNDER-APPRECIATED • UNDER-UTILIZED • UNDER-TRAINED

The Problem with Operators • UNDER-APPRECIATED • UNDER-UTILIZED • UNDER-TRAINED

Under-Training: A Fundamental Problem? Design Engineer trains the operator how to run the plant initially – O&M Manual Operator will pick a couple of parameters MLSS, DO, wasting rate, etc. Same approach passed on through the years Operator lacks necessary detailed knowledge of what is really going on within the plant Plant cannot be manipulated without this knowledge We need more and better training

Under-Training: A Fundamental Problem? Design Engineer trains the operator how to run the plant initially – O&M Manual Operator will pick a couple of parameters MLSS, DO, wasting rate, etc. Same approach passed on through the years Operator lacks necessary detailed knowledge of what is really going on within the plant Plant cannot be manipulated without this knowledge We need more and better training

Specific, Advanced Operator Training Classroom Training Very targeted education Biochemistry of BNR Operator collaboration on case studies An Expert operator training operators – key On-site training 3 – 7 facilities per year 3 visits to each facility over 3 months Regular Email follow up It’s Free to the communities

Specific, Advanced Operator Training Classroom Training Very targeted education Biochemistry of BNR Operator collaboration on case studies An Expert operator training operators – key On-site training 3 – 7 facilities per year 3 visits to each facility over 3 months Regular Email follow up It’s Free to the communities

Ultimate Goal of the Training Give the operators knowledge and confidence Get the operators to understand identify the specific areas within their facility to create the conditions necessary to achieve nitrification, denitrification and/or phosphorous release and uptake Get operators to understand how to manipulate the various unit processes to create the desired conditions within the constraints of their existing infrastructure

Ultimate Goal of the Training Give the operators knowledge and confidence Get the operators to understand identify the specific areas within their facility to create the conditions necessary to achieve nitrification, denitrification and/or phosphorous release and uptake Get operators to understand how to manipulate the various unit processes to create the desired conditions within the constraints of their existing infrastructure

The Trainer The trainer’s qualifications and intent are critical to the success of this approach. No substitute for operational experience Operators relate to other operators Typically a microbiologist or biochemist Engineer? ? A motivational person – May live in a van down by the river There aren’t many qualified trainers left

The Trainer The trainer’s qualifications and intent are critical to the success of this approach. No substitute for operational experience Operators relate to other operators Typically a microbiologist or biochemist Engineer? ? A motivational person – May live in a van down by the river There aren’t many qualified trainers left

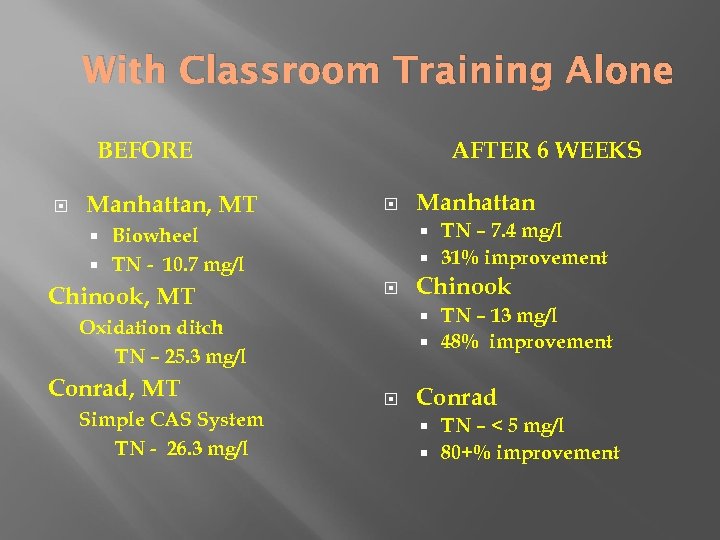

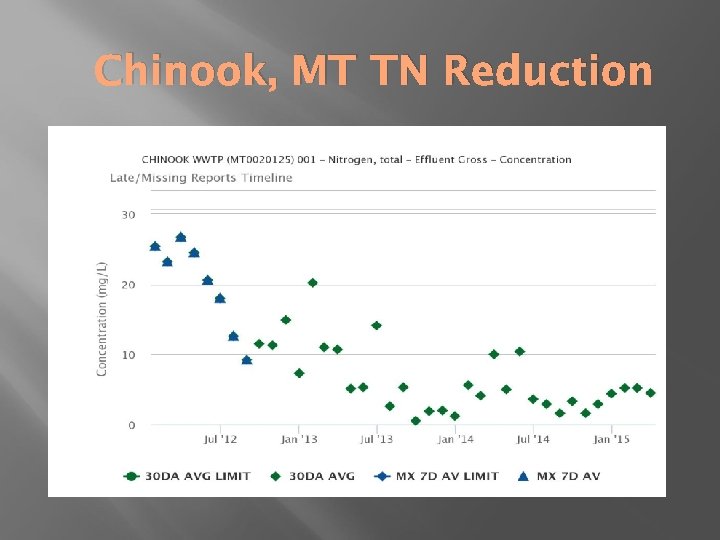

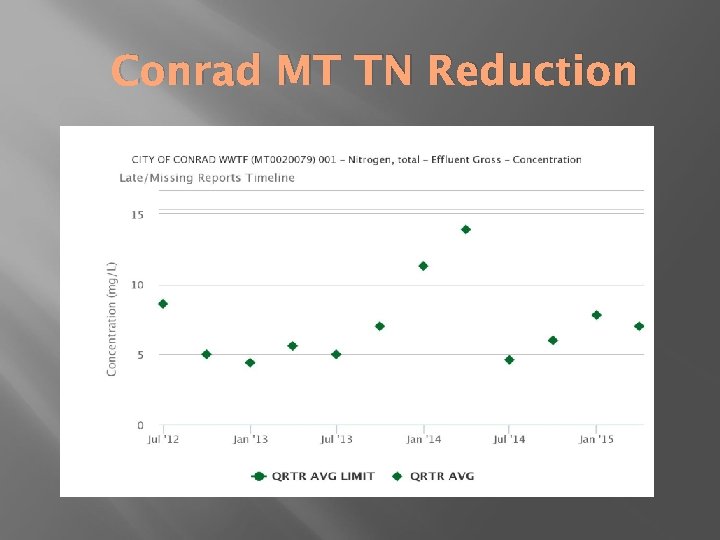

With Classroom Training Alone BEFORE Manhattan, MT AFTER 6 WEEKS TN – 7. 4 mg/l 31% improvement Biowheel TN - 10. 7 mg/l Chinook, MT Simple CAS System TN - 26. 3 mg/l Chinook TN – 13 mg/l 48% improvement Oxidation ditch TN – 25. 3 mg/l Conrad, MT Manhattan Conrad TN – < 5 mg/l 80+% improvement

With Classroom Training Alone BEFORE Manhattan, MT AFTER 6 WEEKS TN – 7. 4 mg/l 31% improvement Biowheel TN - 10. 7 mg/l Chinook, MT Simple CAS System TN - 26. 3 mg/l Chinook TN – 13 mg/l 48% improvement Oxidation ditch TN – 25. 3 mg/l Conrad, MT Manhattan Conrad TN – < 5 mg/l 80+% improvement

The Facility What is important to success? Existing Infrastructure – what do you have? Loading - industrial sources? Capacity – growth? Public works/City council buy-in Regulator cooperation/understanding State/ Federal Operations staff attitude – most important

The Facility What is important to success? Existing Infrastructure – what do you have? Loading - industrial sources? Capacity – growth? Public works/City council buy-in Regulator cooperation/understanding State/ Federal Operations staff attitude – most important

What Happens After the Trainer Leaves? ? Operators have a much better understanding of wastewater treatment Operators are typically more engaged in the performance of the facility. Collect meaningful data Understand why the data is important Understand how to use data to improve performance Operators are empowered

What Happens After the Trainer Leaves? ? Operators have a much better understanding of wastewater treatment Operators are typically more engaged in the performance of the facility. Collect meaningful data Understand why the data is important Understand how to use data to improve performance Operators are empowered

Chinook, MT TN Reduction

Chinook, MT TN Reduction

Conrad MT TN Reduction

Conrad MT TN Reduction

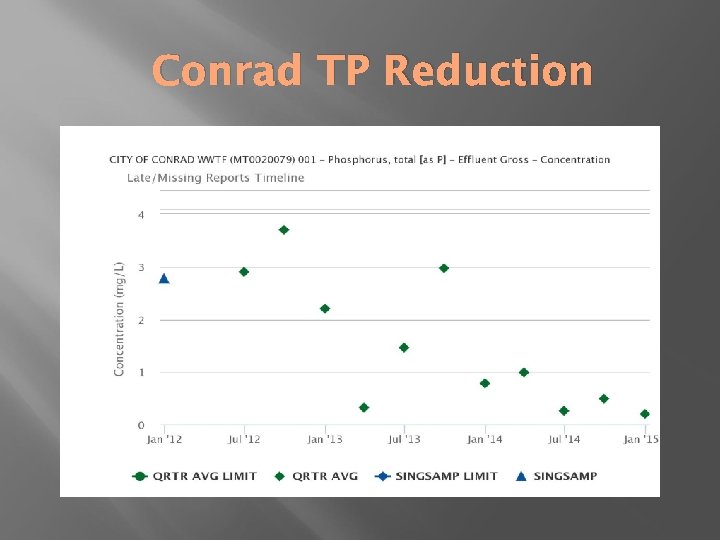

Conrad TP Reduction

Conrad TP Reduction

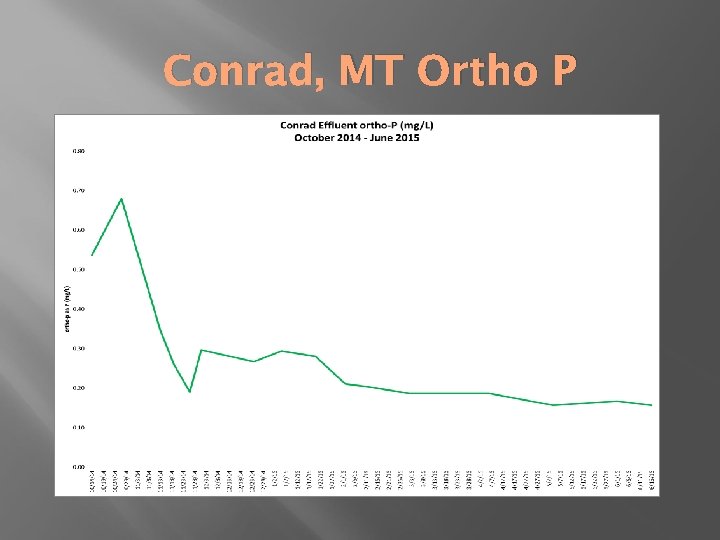

Conrad, MT Ortho P

Conrad, MT Ortho P

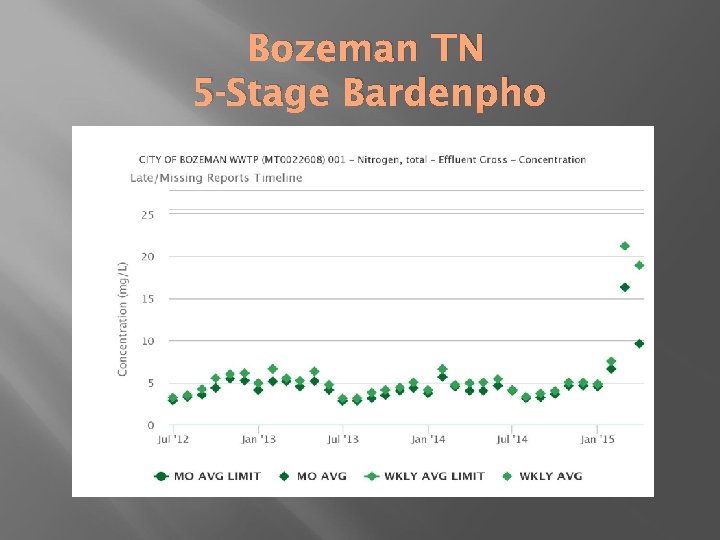

Bozeman TN 5 -Stage Bardenpho

Bozeman TN 5 -Stage Bardenpho

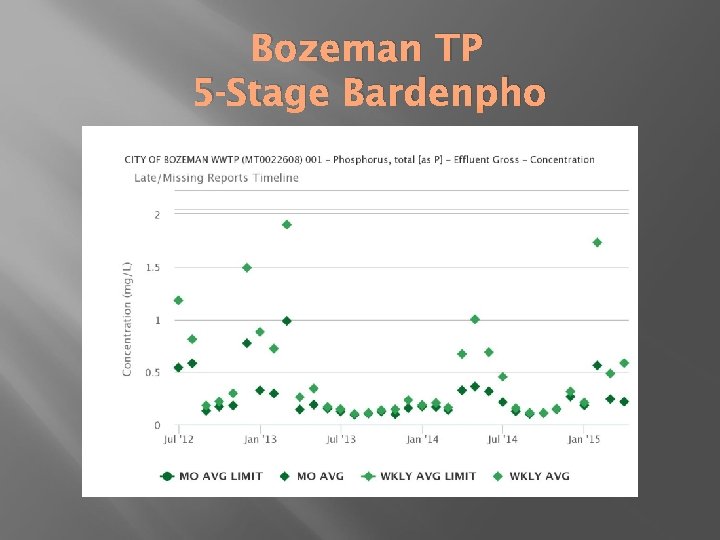

Bozeman TP 5 -Stage Bardenpho

Bozeman TP 5 -Stage Bardenpho

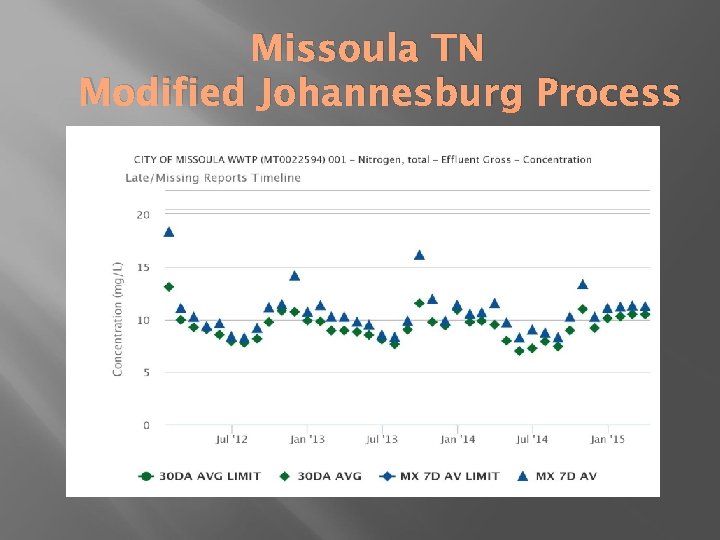

Missoula TN Modified Johannesburg Process

Missoula TN Modified Johannesburg Process

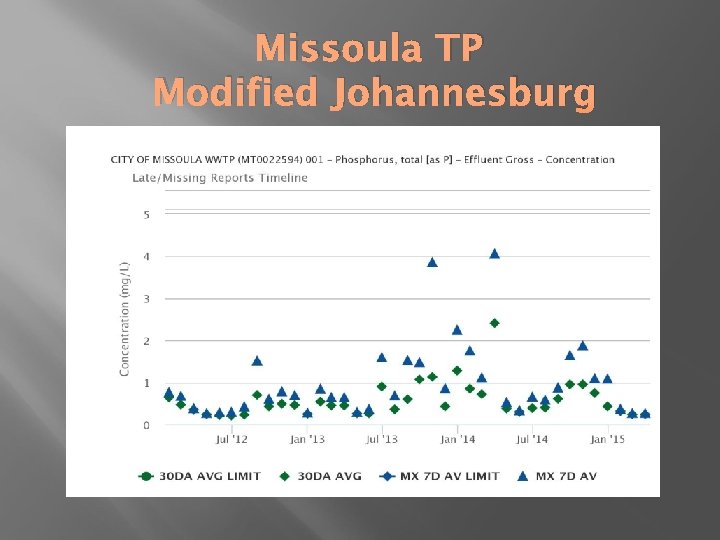

Missoula TP Modified Johannesburg

Missoula TP Modified Johannesburg

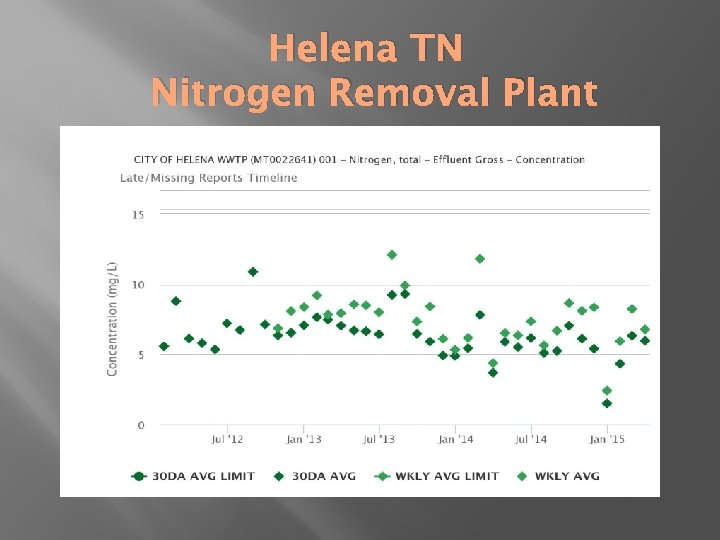

Helena TN Nitrogen Removal Plant

Helena TN Nitrogen Removal Plant

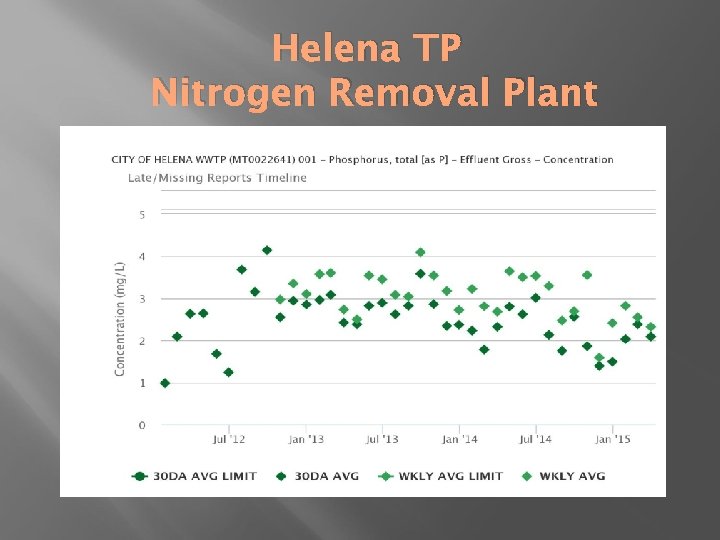

Helena TP Nitrogen Removal Plant

Helena TP Nitrogen Removal Plant

Phased Approach to Nutrient Effluent Limits MECH PLANTS > 1 MGD 2016: 10 TN 1 TP 5 yrs later 8 TN 0. 8 TP 5 yrs later 8 TN 0. 5 TP MECH PLANTS < 1 MGD 2016 5 years 15 TN 10 TN 8 TN 2 TP 1 TP 0. 8 TP

Phased Approach to Nutrient Effluent Limits MECH PLANTS > 1 MGD 2016: 10 TN 1 TP 5 yrs later 8 TN 0. 8 TP 5 yrs later 8 TN 0. 5 TP MECH PLANTS < 1 MGD 2016 5 years 15 TN 10 TN 8 TN 2 TP 1 TP 0. 8 TP

MT DEQ’s Future Efforts Lagoon-based Nutrient and Ammonia reduction research project Potential Pilot Study Lagoon Optimization Contract Continue with Mech Plant Optimization

MT DEQ’s Future Efforts Lagoon-based Nutrient and Ammonia reduction research project Potential Pilot Study Lagoon Optimization Contract Continue with Mech Plant Optimization

Summary Major retrofits or upgrades for nutrient removal can be avoided or minimized in many cases through well thought-out operational strategies – enormous cost savings with relatively immediate results The trainer/consultant is critical to success Choose him or her carefully We’re shifting the focus from engineers to operators – choose them wisely. The ultimate example of sustainability?

Summary Major retrofits or upgrades for nutrient removal can be avoided or minimized in many cases through well thought-out operational strategies – enormous cost savings with relatively immediate results The trainer/consultant is critical to success Choose him or her carefully We’re shifting the focus from engineers to operators – choose them wisely. The ultimate example of sustainability?

Operators Are Important

Operators Are Important

CONTACT INFORMATION Paul La. Vigne Water Pollution Control SRF Montana DEQ plavigne@mt. gov (406) 444 -5321 Grant Weaver The Water Planet Company g. weaver@cleanwaterops. com www. cleanwaterops. com (860) 444 -0866

CONTACT INFORMATION Paul La. Vigne Water Pollution Control SRF Montana DEQ plavigne@mt. gov (406) 444 -5321 Grant Weaver The Water Planet Company g. weaver@cleanwaterops. com www. cleanwaterops. com (860) 444 -0866