5e0f772e3f32ab1e125332685d0ccb1d.ppt

- Количество слайдов: 65

Rapid Assemblers: From Analog to Digital Additive Manufacturing Hod Lipson, Jonathan Hiller Mechanical & Aerospace Engineering Computing & Information Science Cornell University Computational Synthesis Lab

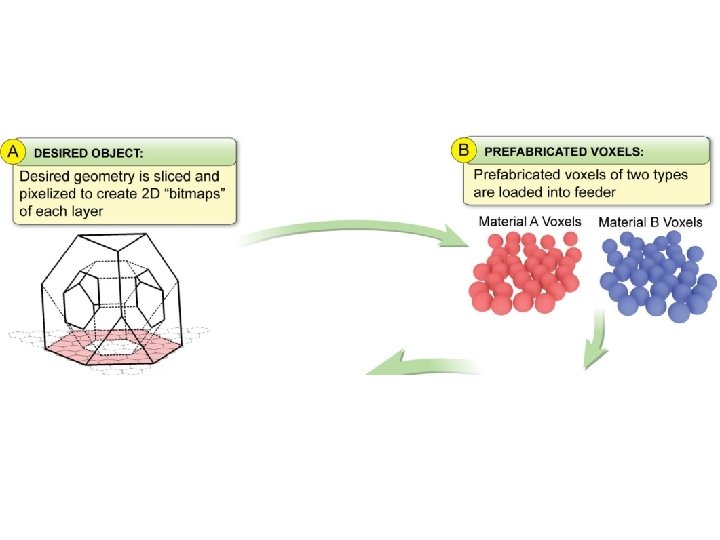

Conclusions • Digital Materials – Comprise lattice of physical voxels – High precision, work with incompatible materials – Tunable properties • Rapid Assemblers – Assembles millions of prefabricated components into a integrated active structure – Parallel (laser printer) – Serial (inkjet printer)

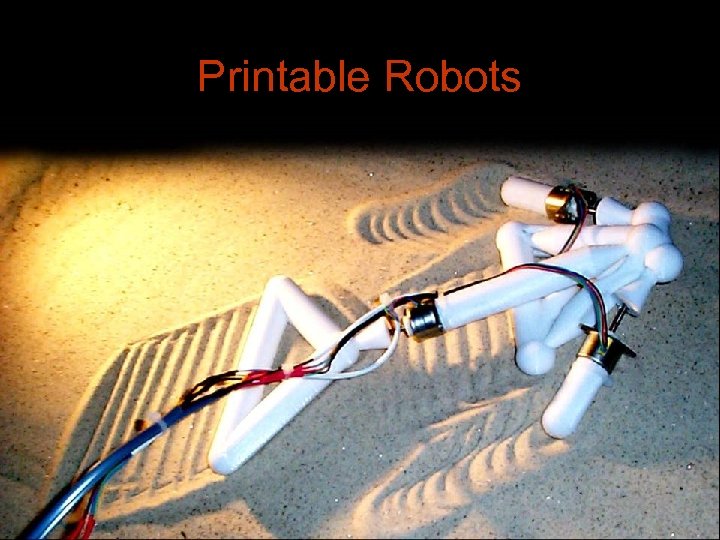

Printable Robots

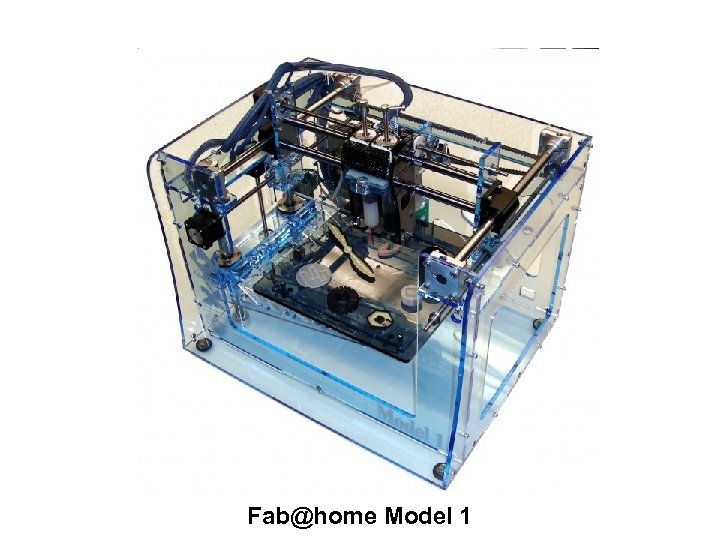

Fab@home Model 1

Fab@home Model 2

With Max Lobovsky

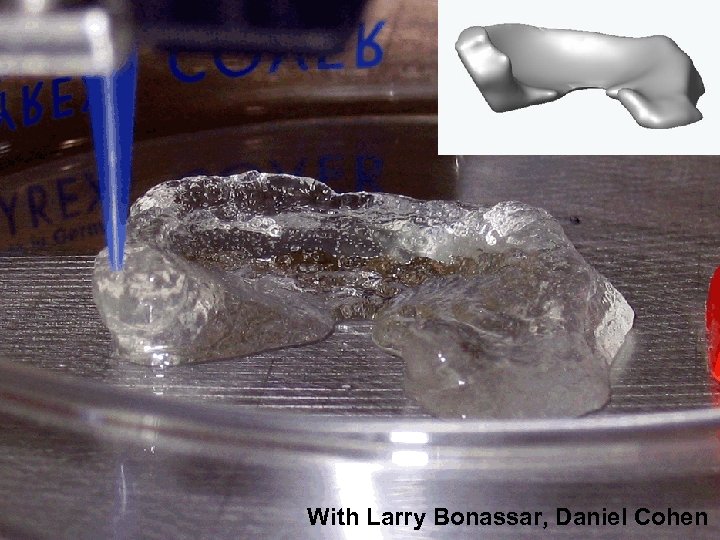

With Larry Bonassar, Daniel Cohen

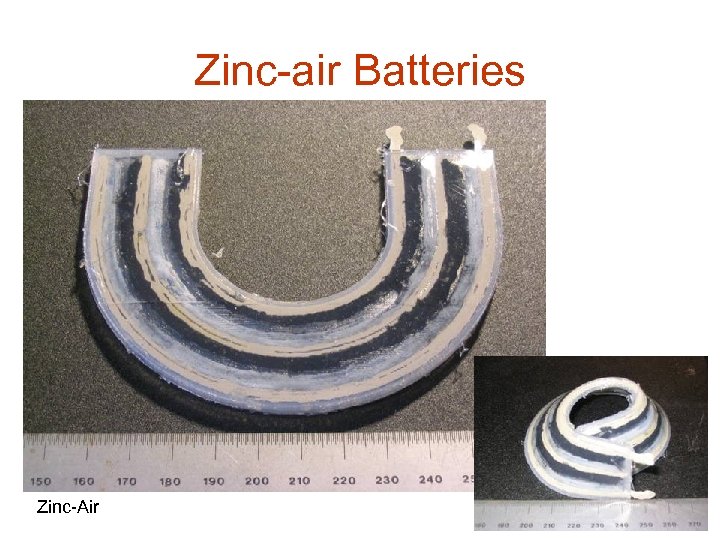

Zinc-air Batteries Zinc-Air

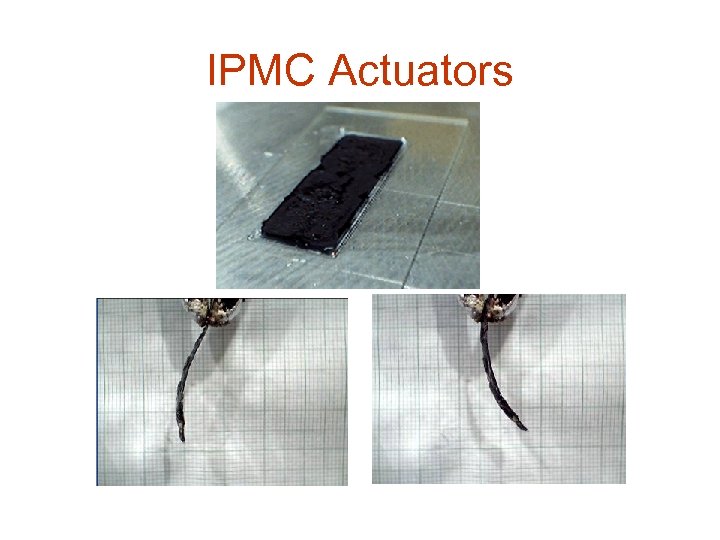

IPMC Actuators

With Evan Malone

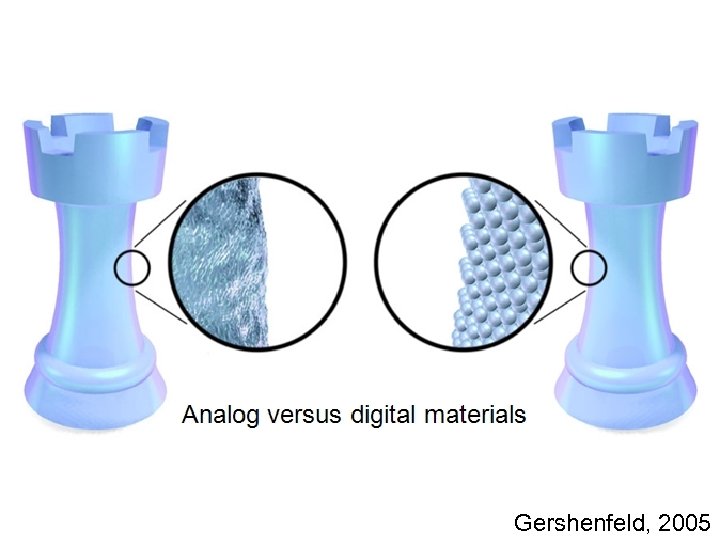

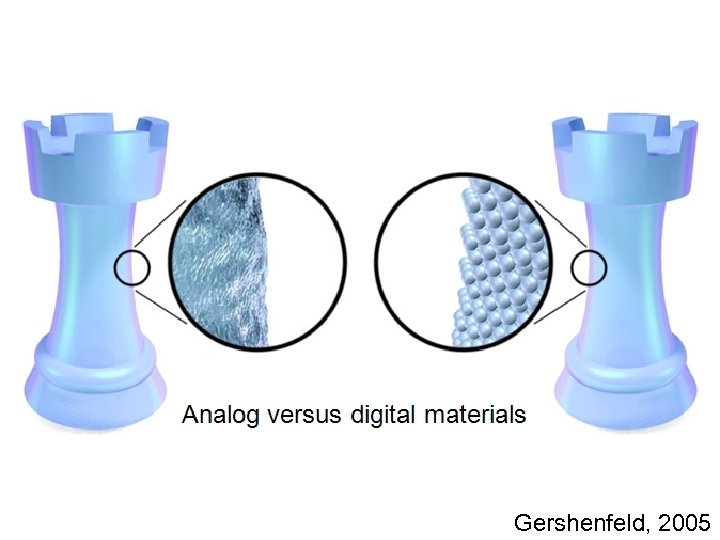

Gershenfeld, 2005

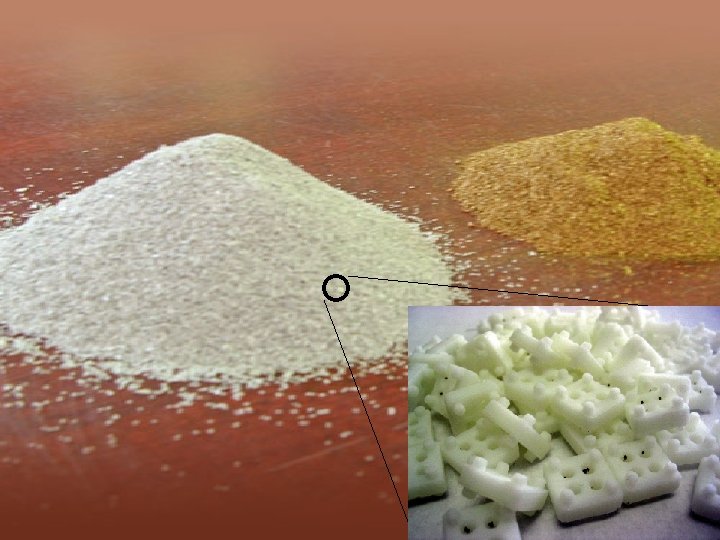

Digital Materials

700 1, 000 4, 500, 000 187, 000 363, 000 80, 000 10, 000 25, 000

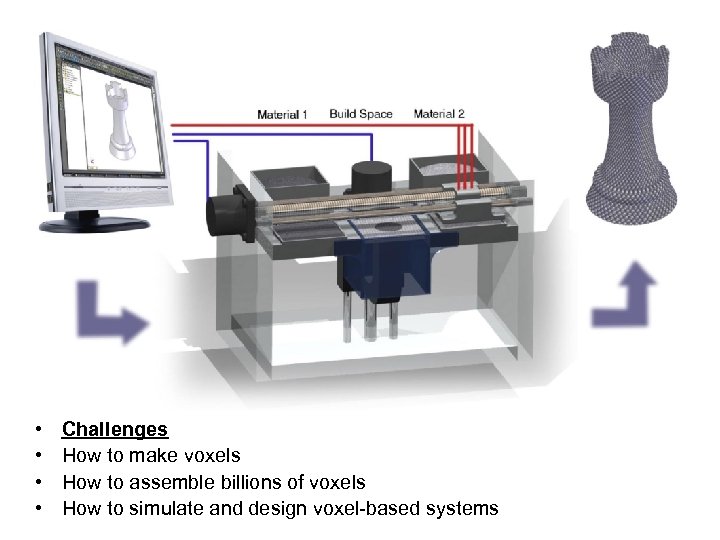

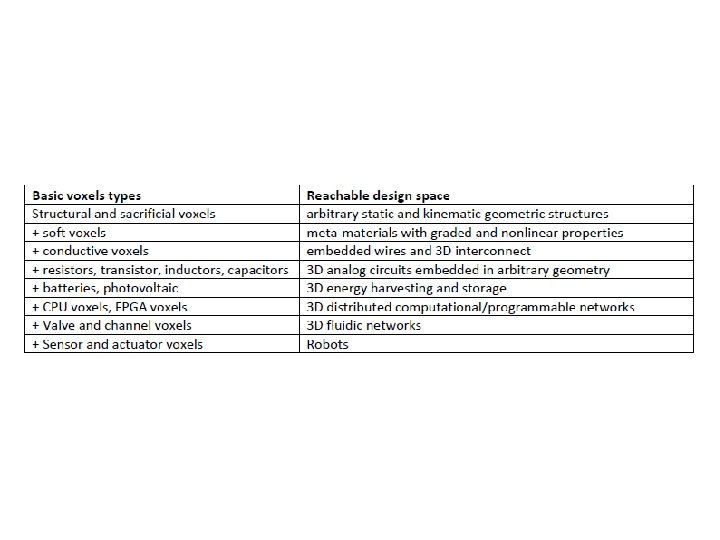

• • Challenges How to make voxels How to assemble billions of voxels How to simulate and design voxel-based systems

Key Challenges • How to fabricate voxels • How to assemble billions of voxels • How to simulate and design in voxel space

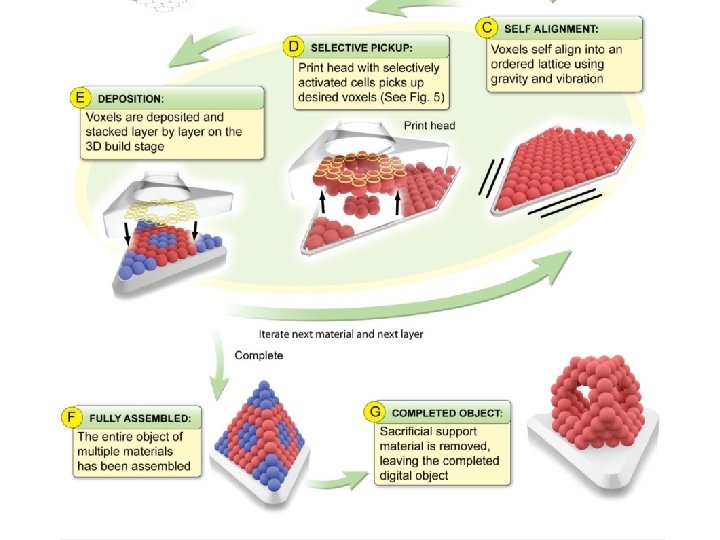

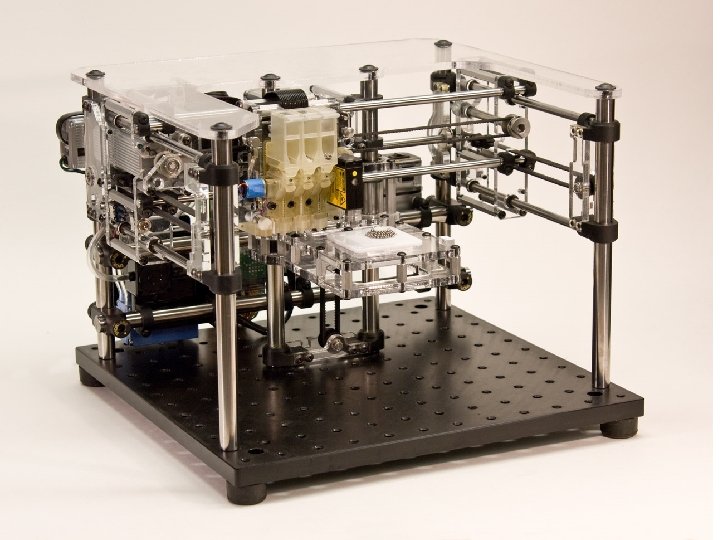

Printing Digital Materials Parallel Assembly

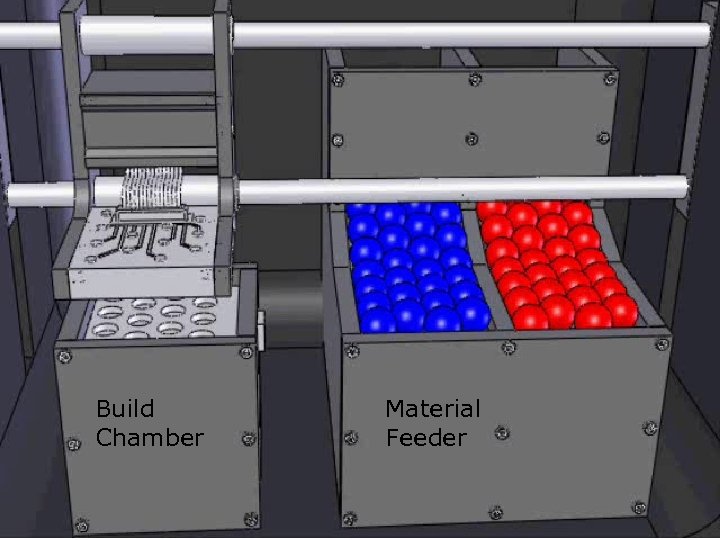

Build Chamber Material Feeder

Fabricator

With Jonathan Hiller

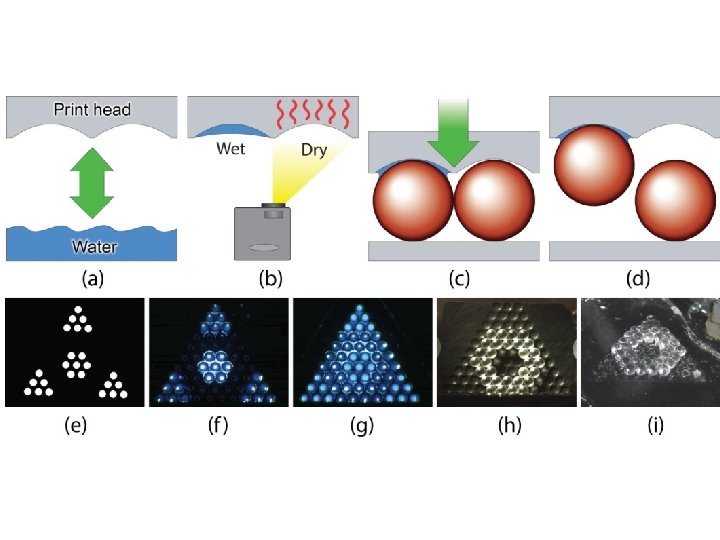

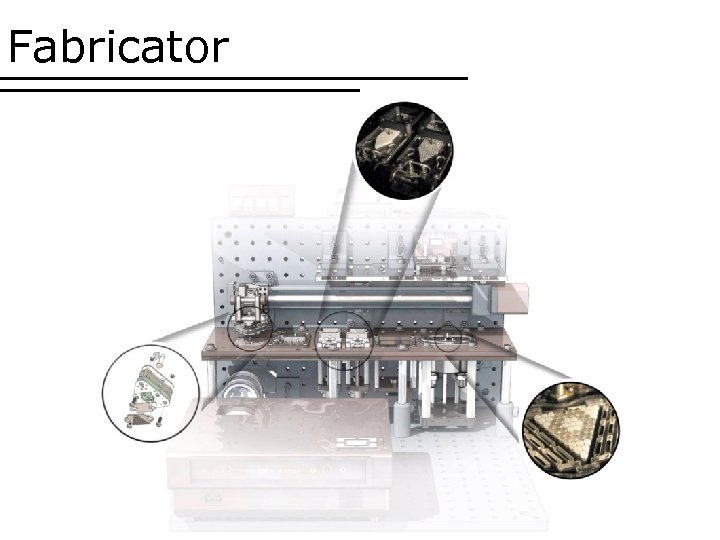

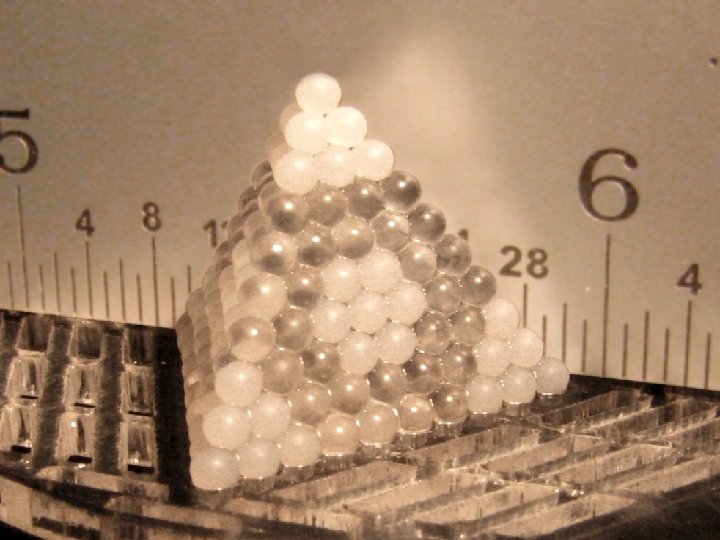

Spheres

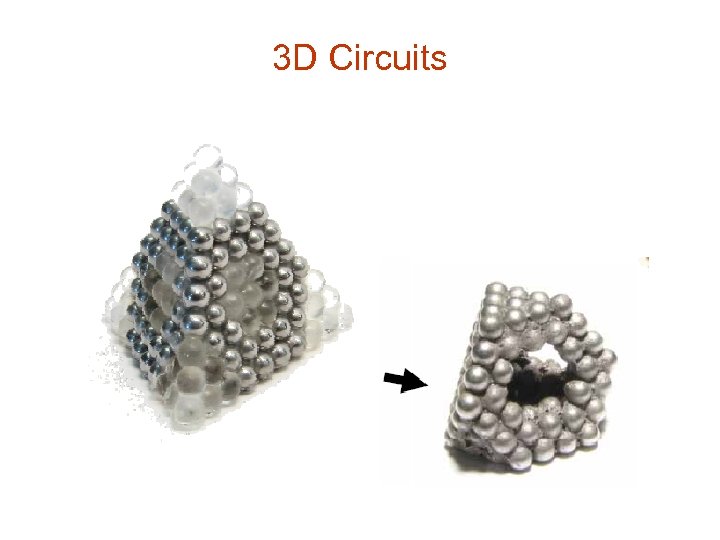

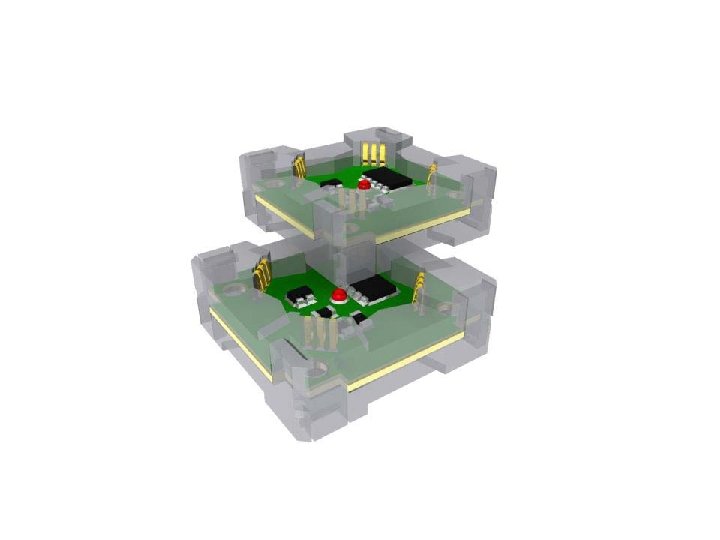

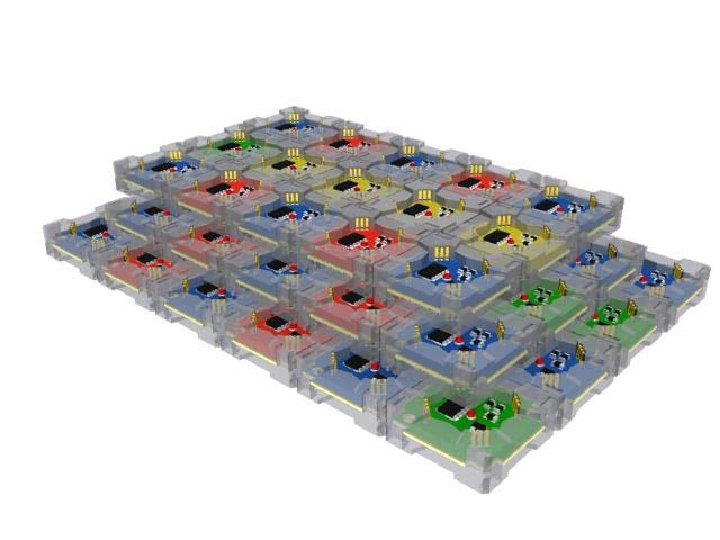

3 D Circuits

3 D Circuits

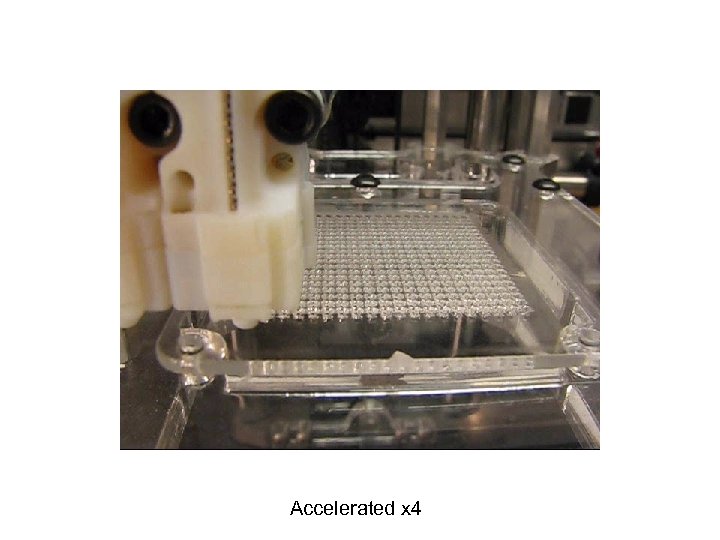

Printing Digital Materials Rapid Serial Assembly

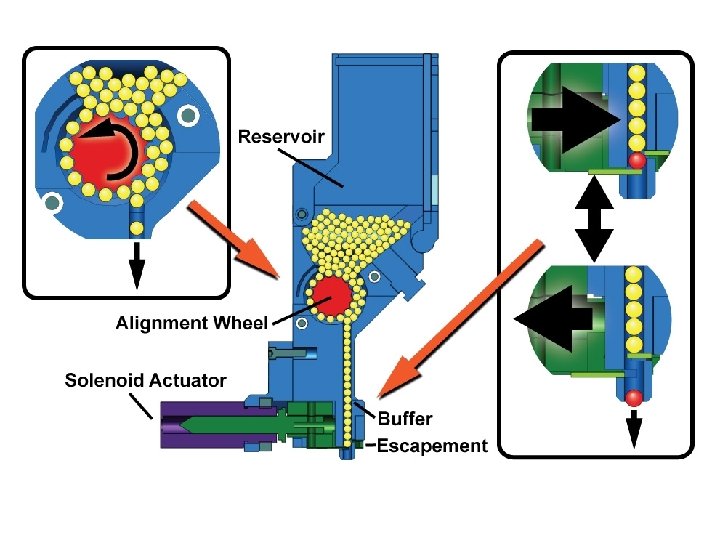

Vox. Jet

Accelerated x 4

Voxels Tunable Material Properties

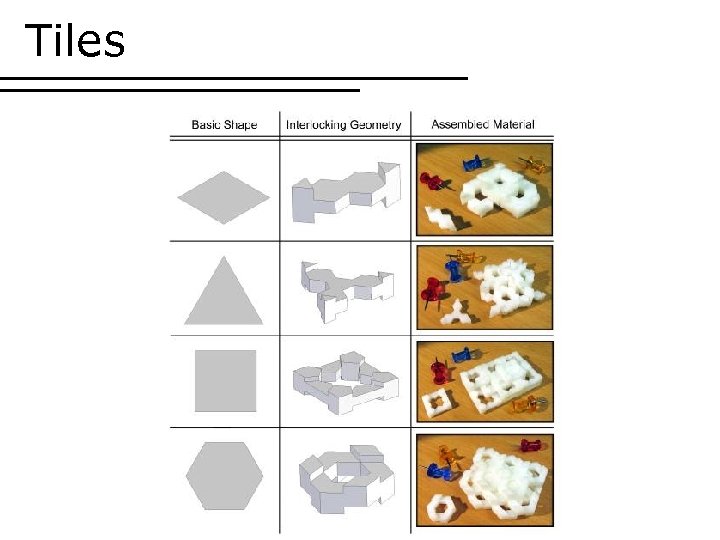

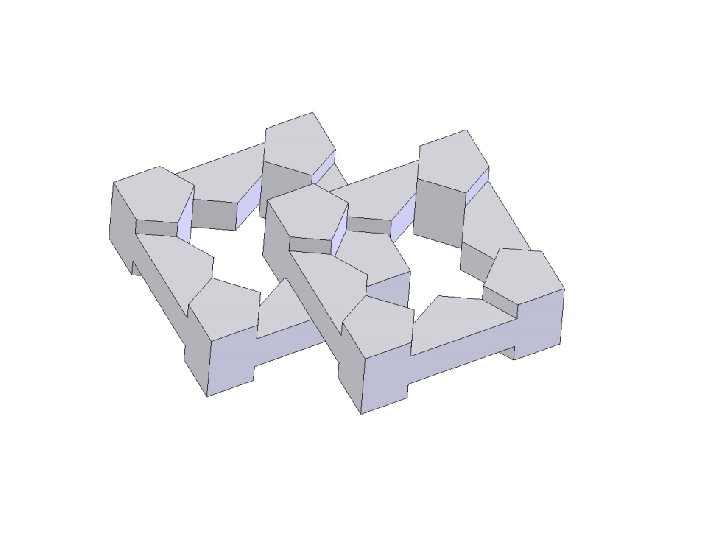

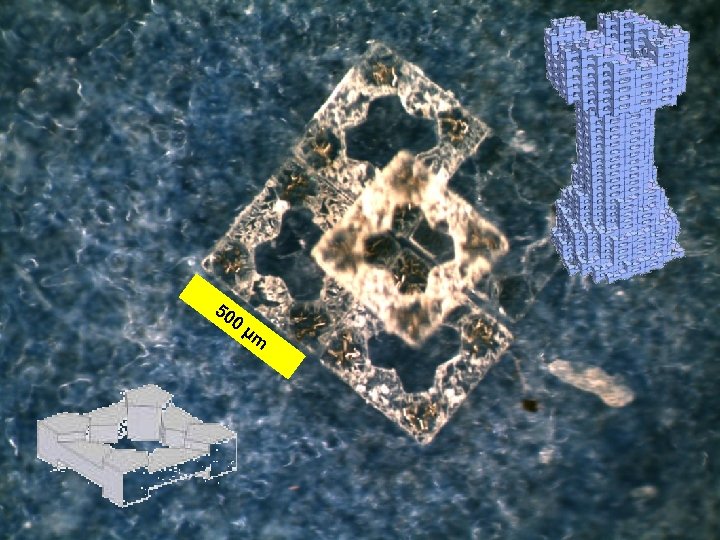

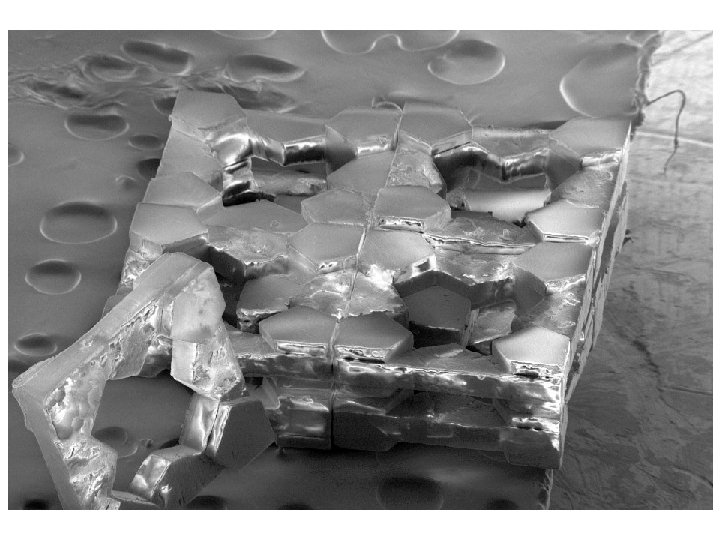

Tiles

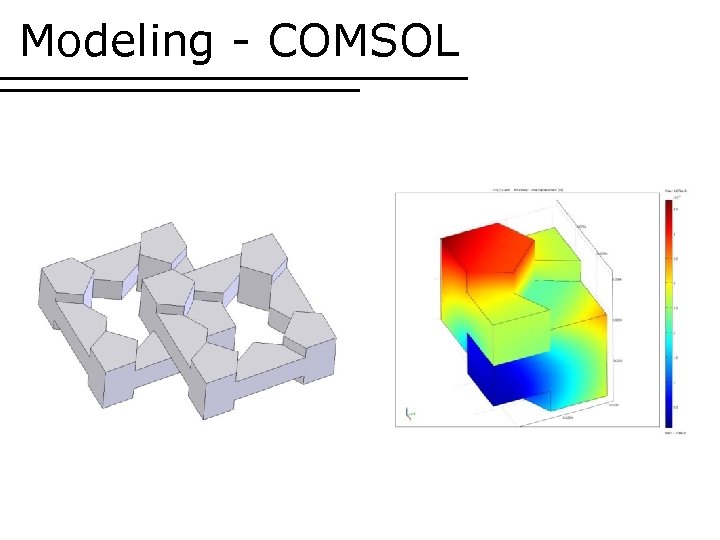

Modeling - COMSOL

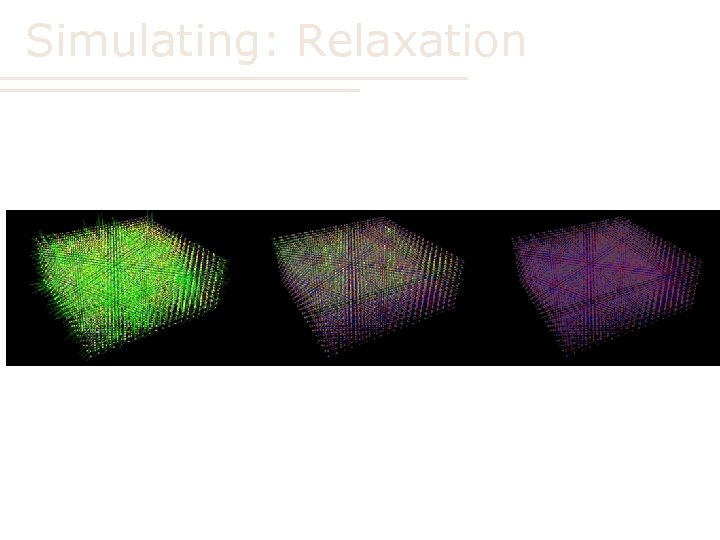

Simulating: Relaxation

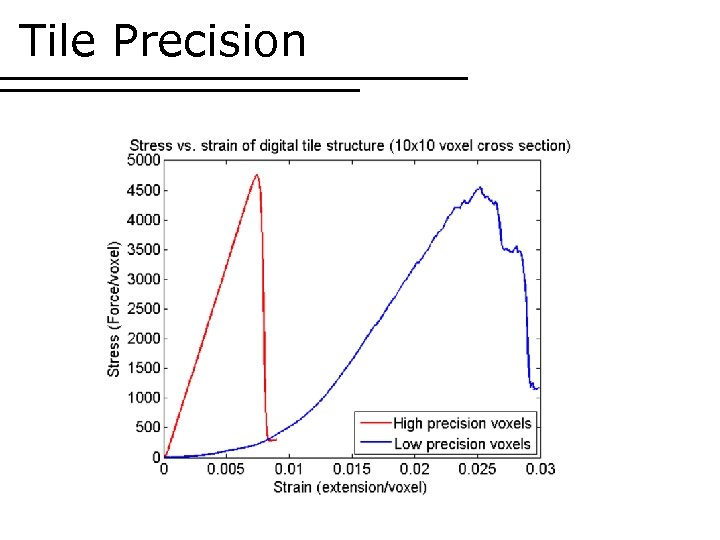

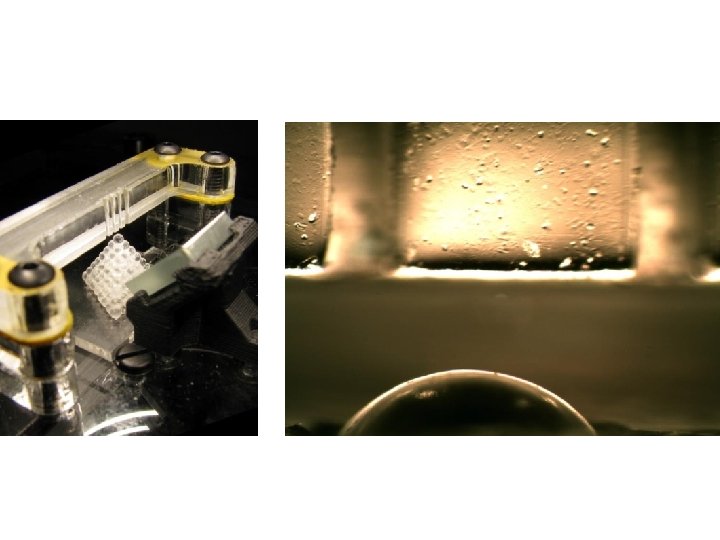

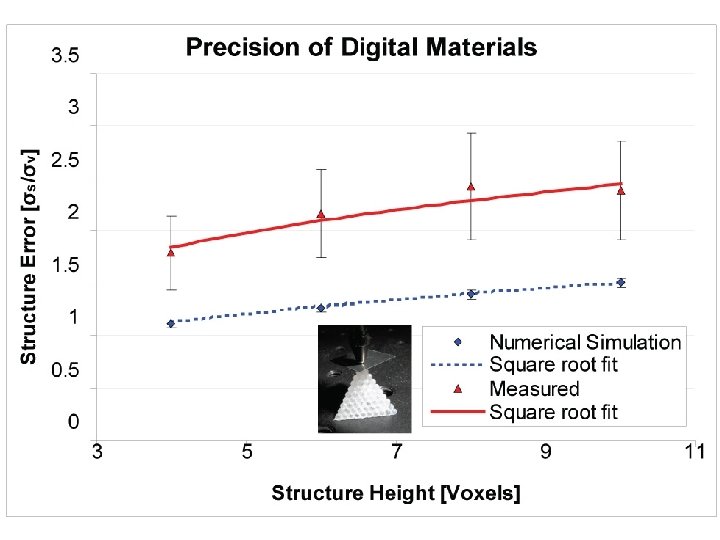

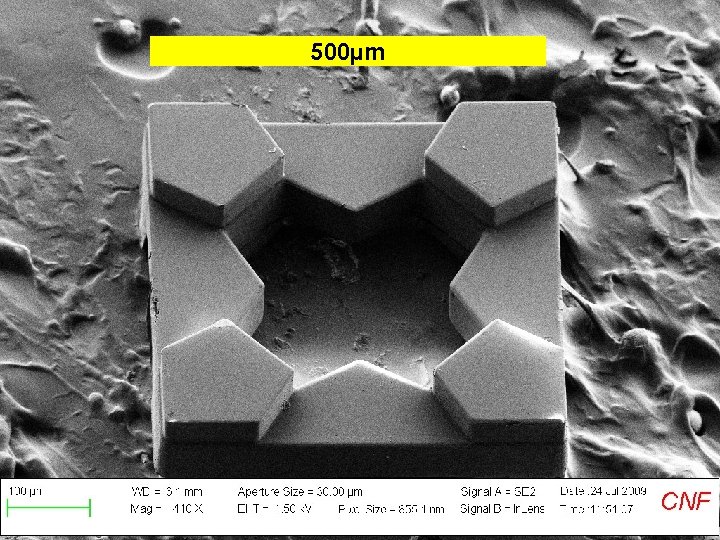

Tile Precision

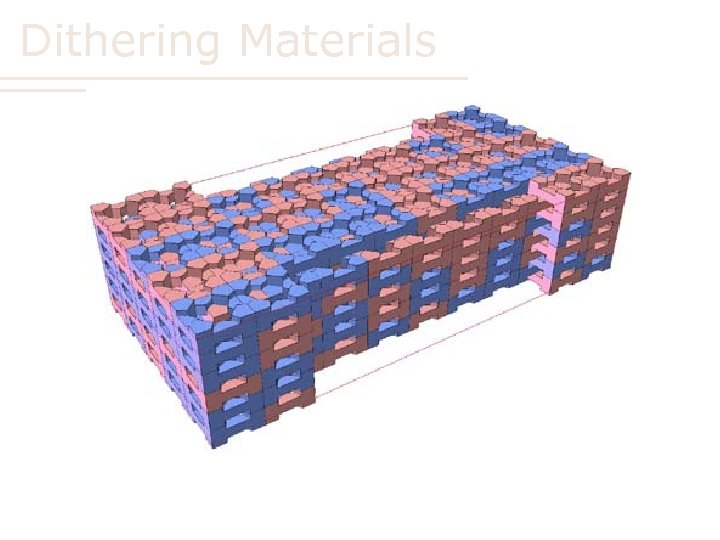

Dithering Materials

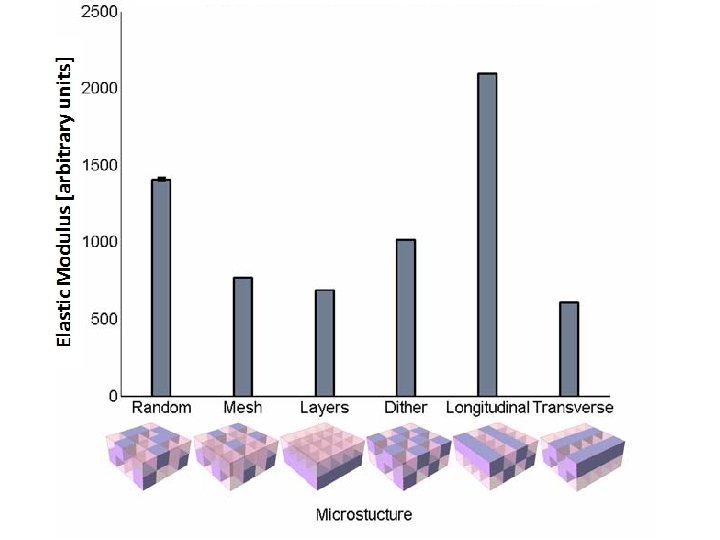

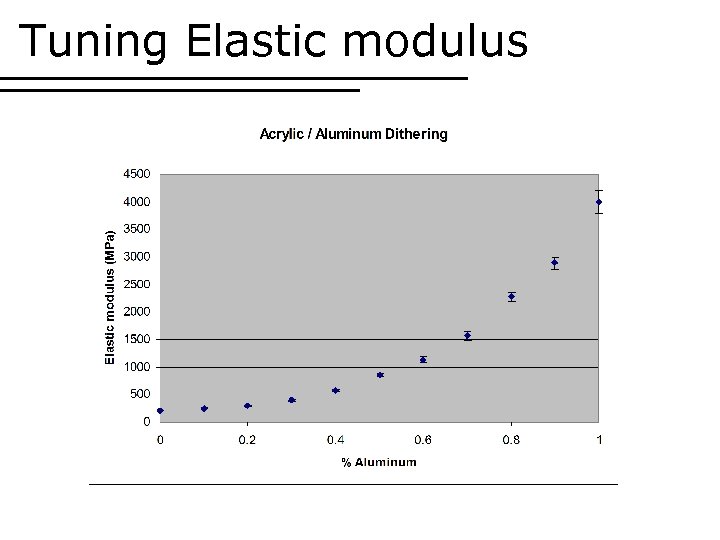

Tuning Elastic modulus

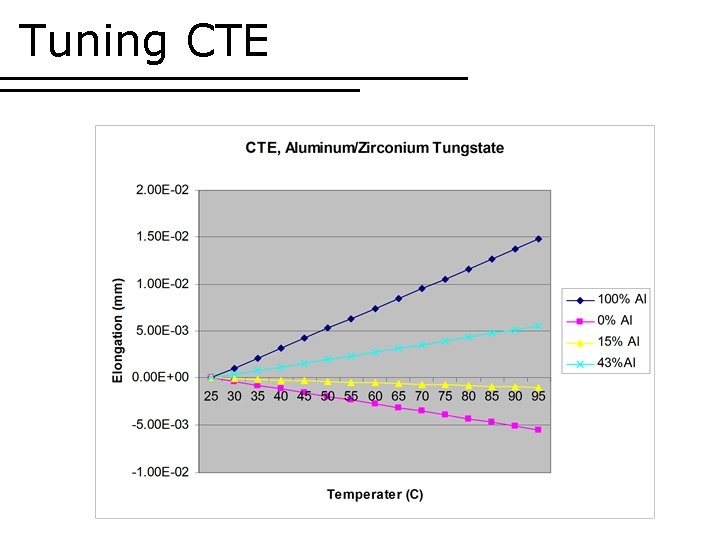

Tuning CTE

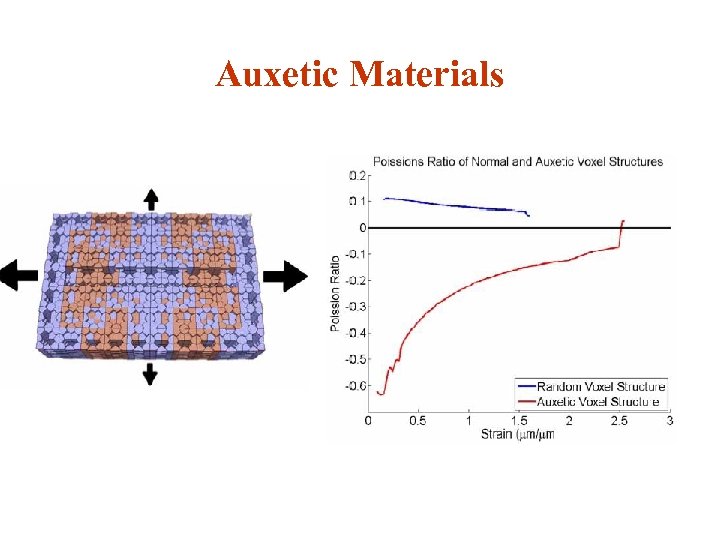

Auxetic Materials

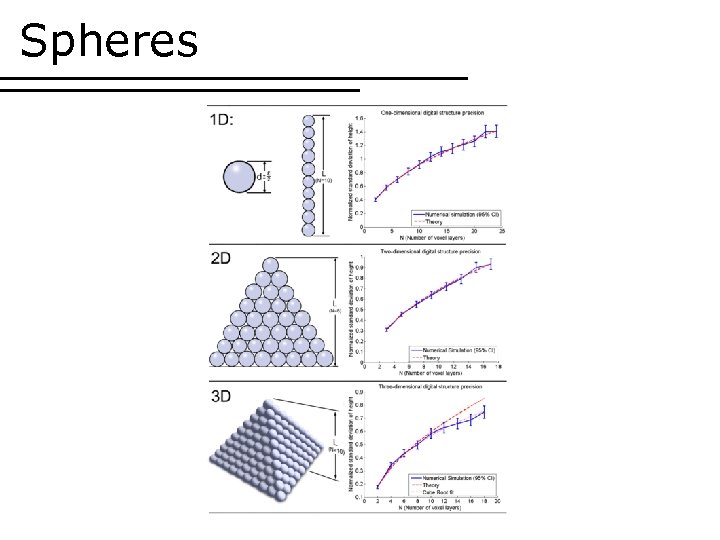

Spheres

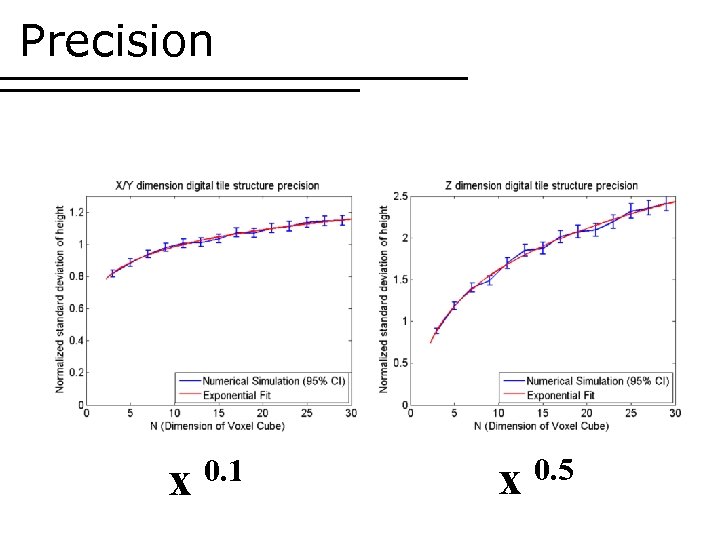

Precision x 0. 1 x 0. 5

Smart Voxels Future Directions

50 0 µm

500µm

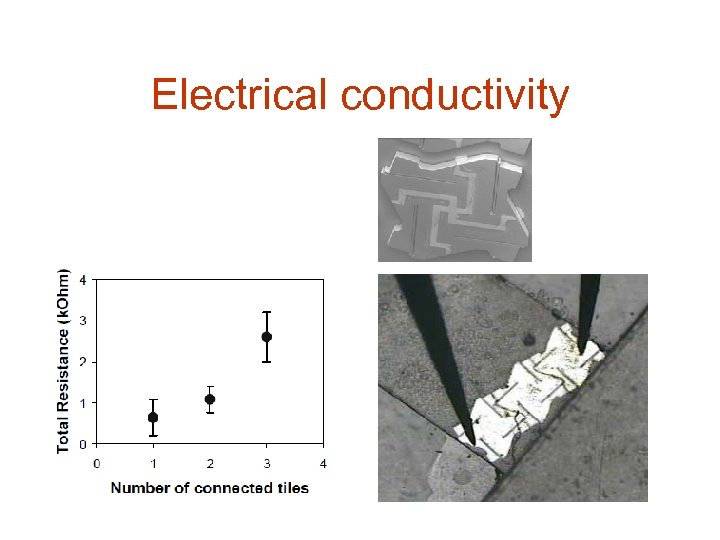

Electrical conductivity

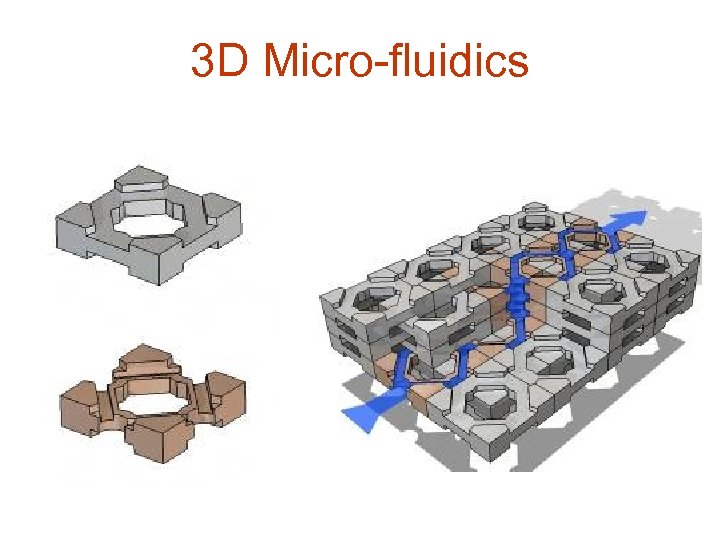

3 D Micro-fluidics

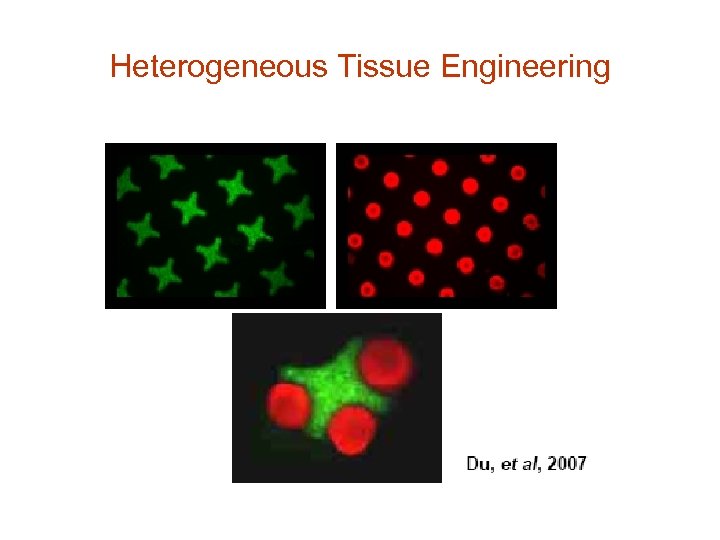

Heterogeneous Tissue Engineering

Gershenfeld, 2005

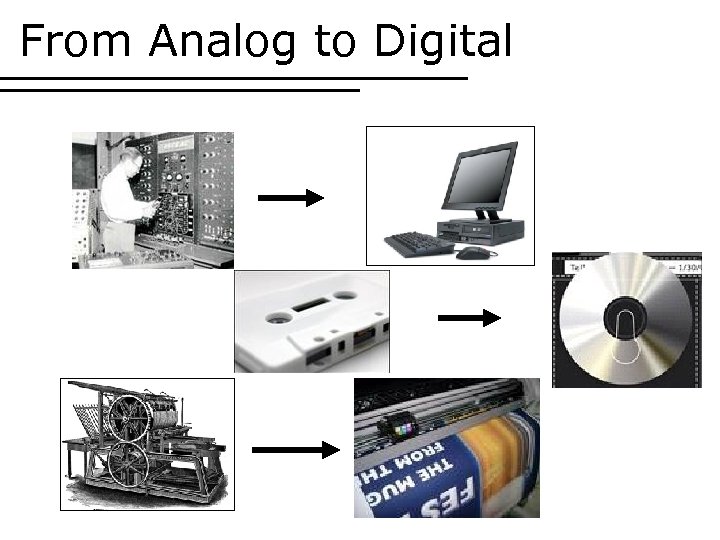

From Analog to Digital

Conclusions • Digital Materials – Comprise lattice of physical voxels – High precision, work with incompatible materials – Tunable properties • Rapid Assemblers – Assembles millions of prefabricated components into a integrated active structure – Parallel (laser printer) – Serial (inkjet printer) • New functionality – Desktop manufacturing of complex, 3 D integrated active devices, without special tooling

Jeff I. Lipton Jonathan Hiller Daniel L. Cohen Evan Malone

5e0f772e3f32ab1e125332685d0ccb1d.ppt