c2a1c11c720a700c4953b45680dd8b52.ppt

- Количество слайдов: 34

RAL High Power Targets Group Chris Densham, Otto Caretta, Tristan Davenne, Mike Fitton, Peter Loveridge, Dan Wilcox + Joe O’Dell (PEG) ‘Mission’ • To be a ‘one-stop shop’ (P. Hurh) for target technology • Enable optimum physics performance via sound engineering Chris Densham

RAL High Power Targets Group Chris Densham, Otto Caretta, Tristan Davenne, Mike Fitton, Peter Loveridge, Dan Wilcox + Joe O’Dell (PEG) ‘Mission’ • To be a ‘one-stop shop’ (P. Hurh) for target technology • Enable optimum physics performance via sound engineering Chris Densham

Specific technical expertise • Mechanical & thermal engineering • FLUKA (Monte. Carlo code) • CFX (fluid dynamics code) • ANSYS “classic” (Implicit FEA) • AUTODYN (Explicit FEA) • • • Multi-code integration Specialist joining technology Fluidised powder technology – From conceptual & detailed design through to manufacture, installation & commissioning – energy deposited in target components by the beam – optimisation of useful particle yield – Cooling circuit design – conjugate heat transfer analysis – magnetic, thermal, mechanical analyses – multiphysics simulations – dynamic simulations – Transient & dynamic analysis Chris Densham

Specific technical expertise • Mechanical & thermal engineering • FLUKA (Monte. Carlo code) • CFX (fluid dynamics code) • ANSYS “classic” (Implicit FEA) • AUTODYN (Explicit FEA) • • • Multi-code integration Specialist joining technology Fluidised powder technology – From conceptual & detailed design through to manufacture, installation & commissioning – energy deposited in target components by the beam – optimisation of useful particle yield – Cooling circuit design – conjugate heat transfer analysis – magnetic, thermal, mechanical analyses – multiphysics simulations – dynamic simulations – Transient & dynamic analysis Chris Densham

Multi-code integration for physics & engineering analysis • Analysis procedure for LBNE target/horn

Multi-code integration for physics & engineering analysis • Analysis procedure for LBNE target/horn

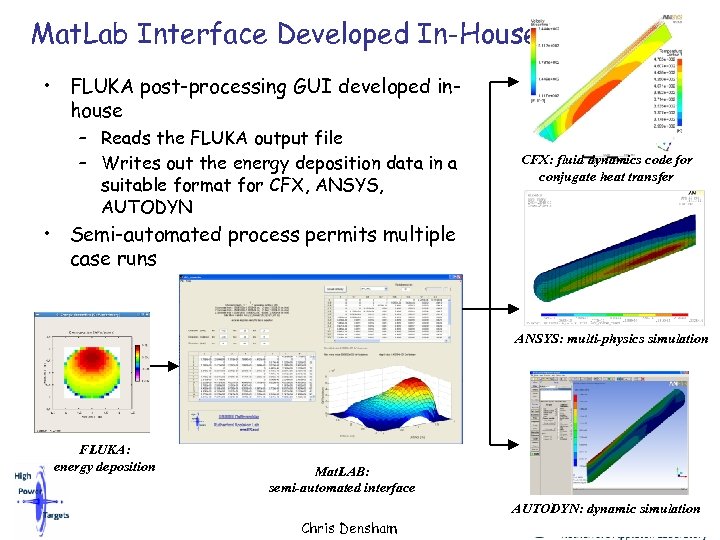

Mat. Lab Interface Developed In-House • FLUKA post-processing GUI developed inhouse – Reads the FLUKA output file – Writes out the energy deposition data in a suitable format for CFX, ANSYS, AUTODYN CFX: fluid dynamics code for conjugate heat transfer • Semi-automated process permits multiple case runs ANSYS: multi-physics simulation FLUKA: energy deposition Mat. LAB: semi-automated interface AUTODYN: dynamic simulation Chris Densham

Mat. Lab Interface Developed In-House • FLUKA post-processing GUI developed inhouse – Reads the FLUKA output file – Writes out the energy deposition data in a suitable format for CFX, ANSYS, AUTODYN CFX: fluid dynamics code for conjugate heat transfer • Semi-automated process permits multiple case runs ANSYS: multi-physics simulation FLUKA: energy deposition Mat. LAB: semi-automated interface AUTODYN: dynamic simulation Chris Densham

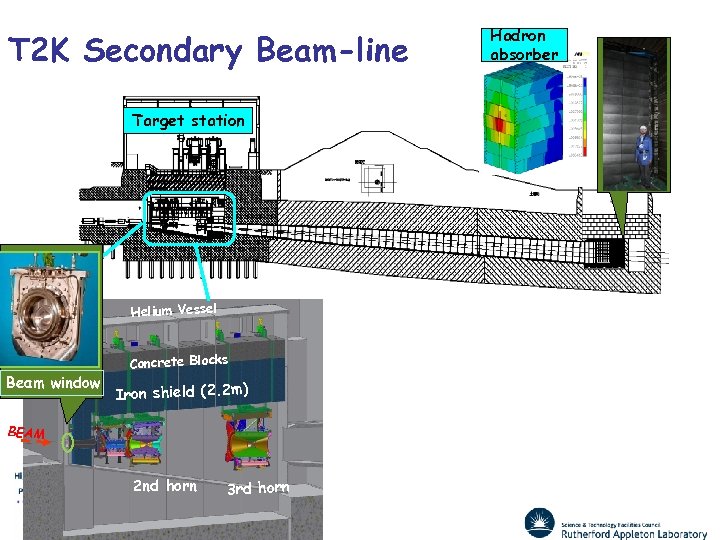

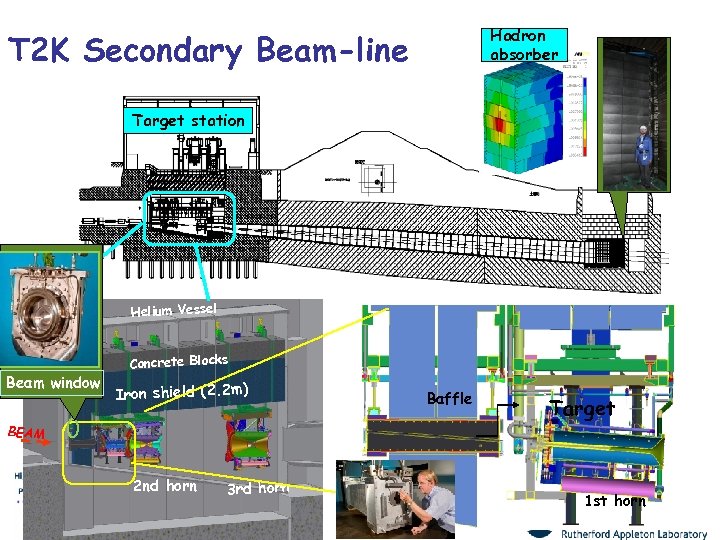

T 2 K Secondary Beam-line Target station Helium Vessel Beam window Concrete Blocks Iron shield (2. 2 m) BEAM 2 nd horn 3 rd horn Hadron absorber

T 2 K Secondary Beam-line Target station Helium Vessel Beam window Concrete Blocks Iron shield (2. 2 m) BEAM 2 nd horn 3 rd horn Hadron absorber

Hadron absorber T 2 K Secondary Beam-line Target station Helium Vessel Beam window Concrete Blocks Iron shield (2. 2 m) Baffle Target BEAM 2 nd horn 3 rd horn 1 st horn

Hadron absorber T 2 K Secondary Beam-line Target station Helium Vessel Beam window Concrete Blocks Iron shield (2. 2 m) Baffle Target BEAM 2 nd horn 3 rd horn 1 st horn

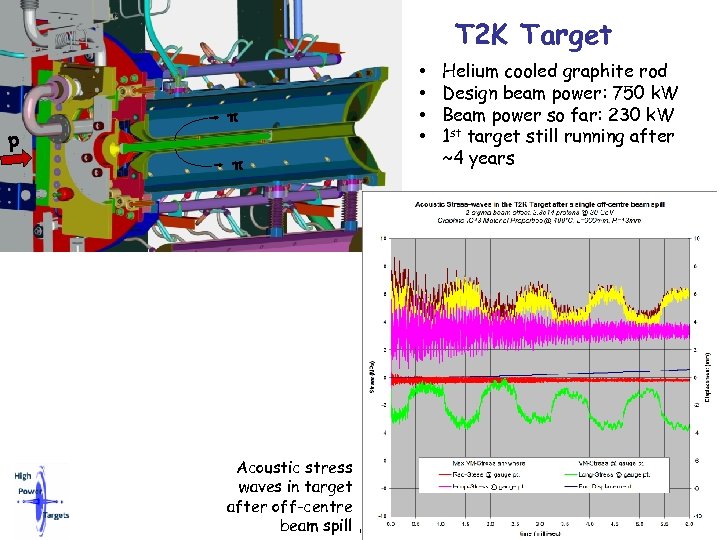

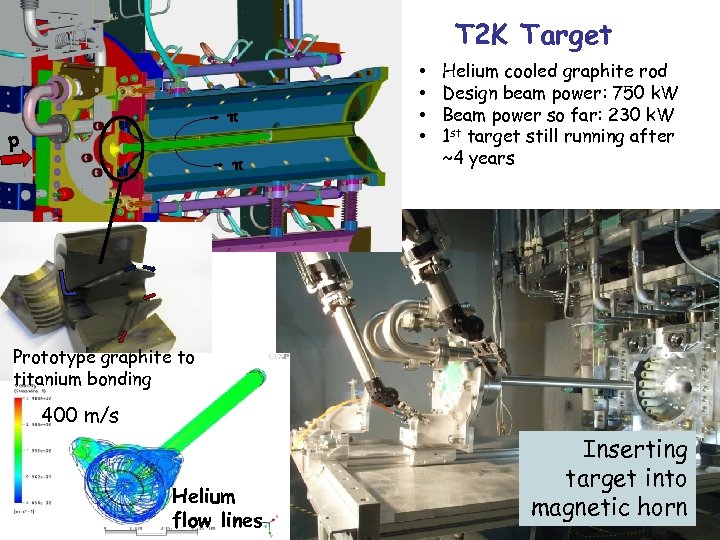

T 2 K Target p π π Acoustic stress waves in target after off-centre beam Densham Chris spill • • Helium cooled graphite rod Design beam power: 750 k. W Beam power so far: 230 k. W 1 st target still running after ~4 years

T 2 K Target p π π Acoustic stress waves in target after off-centre beam Densham Chris spill • • Helium cooled graphite rod Design beam power: 750 k. W Beam power so far: 230 k. W 1 st target still running after ~4 years

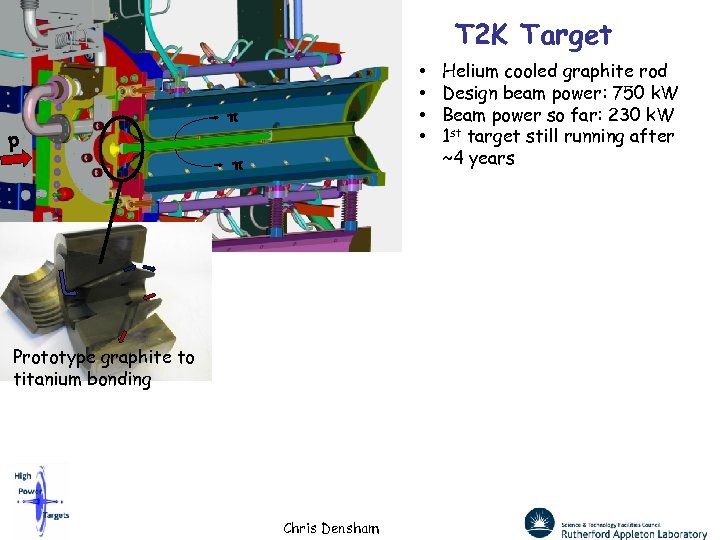

T 2 K Target p • • π π Prototype graphite to titanium bonding Chris Densham Helium cooled graphite rod Design beam power: 750 k. W Beam power so far: 230 k. W 1 st target still running after ~4 years

T 2 K Target p • • π π Prototype graphite to titanium bonding Chris Densham Helium cooled graphite rod Design beam power: 750 k. W Beam power so far: 230 k. W 1 st target still running after ~4 years

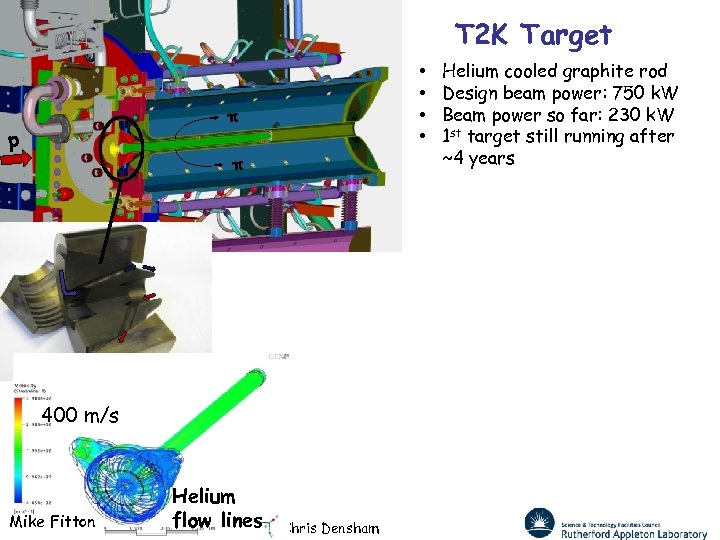

T 2 K Target • • π p π 400 m/s Mike Fitton Helium flow lines Chris Densham Helium cooled graphite rod Design beam power: 750 k. W Beam power so far: 230 k. W 1 st target still running after ~4 years

T 2 K Target • • π p π 400 m/s Mike Fitton Helium flow lines Chris Densham Helium cooled graphite rod Design beam power: 750 k. W Beam power so far: 230 k. W 1 st target still running after ~4 years

T 2 K Target • • π p π Helium cooled graphite rod Design beam power: 750 k. W Beam power so far: 230 k. W 1 st target still running after ~4 years Prototype graphite to titanium bonding 400 m/s Helium flow lines Chris Densham Inserting target into magnetic horn

T 2 K Target • • π p π Helium cooled graphite rod Design beam power: 750 k. W Beam power so far: 230 k. W 1 st target still running after ~4 years Prototype graphite to titanium bonding 400 m/s Helium flow lines Chris Densham Inserting target into magnetic horn

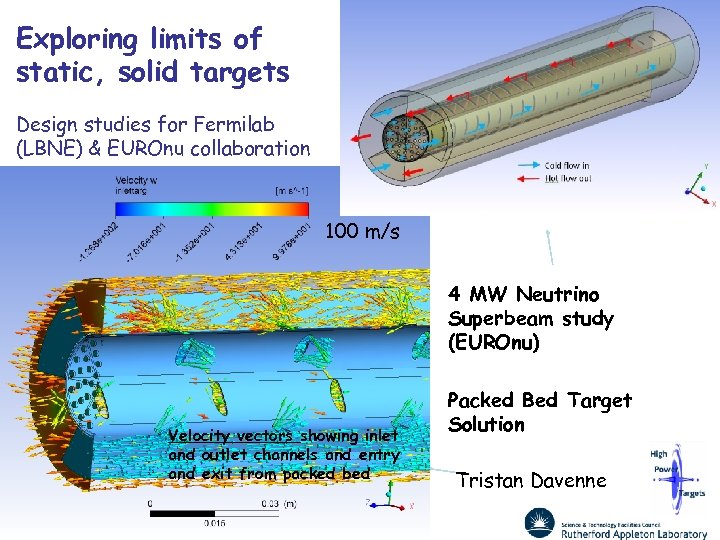

Exploring limits of static, solid targets Design studies for Fermilab (LBNE) & EUROnu collaboration 100 m/s 4 MW Neutrino Superbeam study (EUROnu) Velocity vectors showing inlet and outlet channels and entry and exit from packed bed Packed Bed Target Solution Tristan Davenne

Exploring limits of static, solid targets Design studies for Fermilab (LBNE) & EUROnu collaboration 100 m/s 4 MW Neutrino Superbeam study (EUROnu) Velocity vectors showing inlet and outlet channels and entry and exit from packed bed Packed Bed Target Solution Tristan Davenne

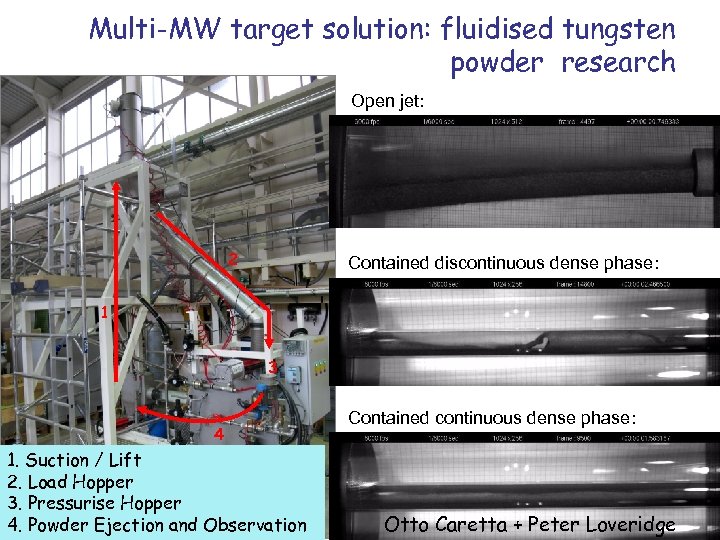

Multi-MW target solution: fluidised tungsten powder research Open jet: 2 Contained discontinuous dense phase: 1 3 4 Contained continuous dense phase: 1. Suction / Lift 2. Load Hopper 3. Pressurise Hopper 4. Powder Ejection and Observation Otto Caretta + Peter Loveridge Chris Densham

Multi-MW target solution: fluidised tungsten powder research Open jet: 2 Contained discontinuous dense phase: 1 3 4 Contained continuous dense phase: 1. Suction / Lift 2. Load Hopper 3. Pressurise Hopper 4. Powder Ejection and Observation Otto Caretta + Peter Loveridge Chris Densham

ISIS Capabilities David Jenkins ISIS Target Design Group Leader 3 rd April 2013

ISIS Capabilities David Jenkins ISIS Target Design Group Leader 3 rd April 2013

Knowledge and expertise in our people • ISIS Target Design Group – Group of 10 mechanical engineers who: – Support the work of the ISIS Target Operations Group – Design and develop new systems and equipment for ISIS target operations.

Knowledge and expertise in our people • ISIS Target Design Group – Group of 10 mechanical engineers who: – Support the work of the ISIS Target Operations Group – Design and develop new systems and equipment for ISIS target operations.

• Target station operation experience

• Target station operation experience

ISIS First Target Station • In operation for 27 years • Current target – 12 tungsten plates clad in tantalum • Typically 180 m. A of 800 Me. V protons • Maximum power density ~1000 MW/m 3 • Peak energy per pulse ~25 MJ/m 3/pulse

ISIS First Target Station • In operation for 27 years • Current target – 12 tungsten plates clad in tantalum • Typically 180 m. A of 800 Me. V protons • Maximum power density ~1000 MW/m 3 • Peak energy per pulse ~25 MJ/m 3/pulse

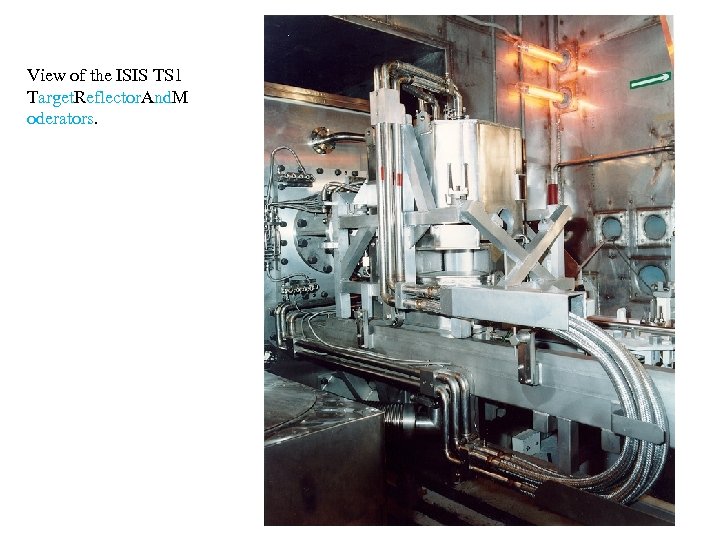

View of the ISIS TS 1 Target. Reflector. And. M oderators.

View of the ISIS TS 1 Target. Reflector. And. M oderators.

ISIS Intermediate Target Station • Muon production target in operation since early 1990 s o 800 Me. V protons interact with 10 mm thick graphite blade o Graphite blade set at 45 o angle to beam o Target cooled by water o Target cassette holds three individual graphite targets

ISIS Intermediate Target Station • Muon production target in operation since early 1990 s o 800 Me. V protons interact with 10 mm thick graphite blade o Graphite blade set at 45 o angle to beam o Target cooled by water o Target cassette holds three individual graphite targets

ISIS Second Target Station • In operation for 4 years • Target - tungsten cylinder clad in tantalum • Typically 45 m. A of 800 Me. V protons • Maximum power density ~1000 MW/m 3 • Peak energy per pulse ~100 MJ/m 3/pulse.

ISIS Second Target Station • In operation for 4 years • Target - tungsten cylinder clad in tantalum • Typically 45 m. A of 800 Me. V protons • Maximum power density ~1000 MW/m 3 • Peak energy per pulse ~100 MJ/m 3/pulse.

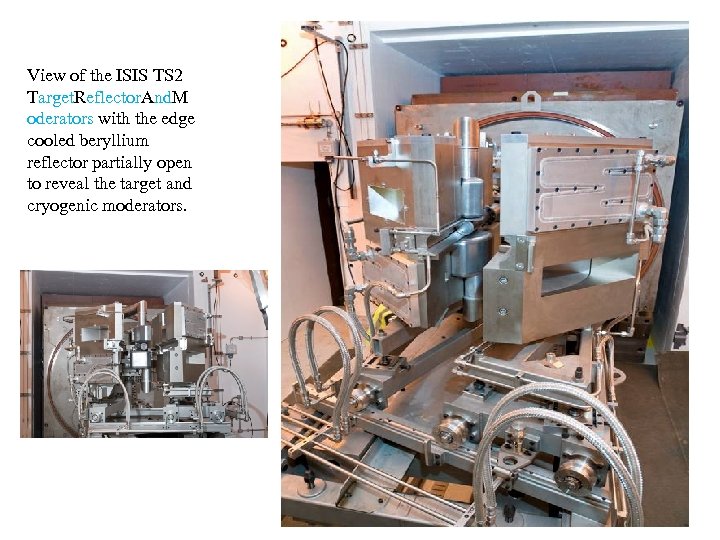

View of the ISIS TS 2 Target. Reflector. And. M oderators with the edge cooled beryllium reflector partially open to reveal the target and cryogenic moderators.

View of the ISIS TS 2 Target. Reflector. And. M oderators with the edge cooled beryllium reflector partially open to reveal the target and cryogenic moderators.

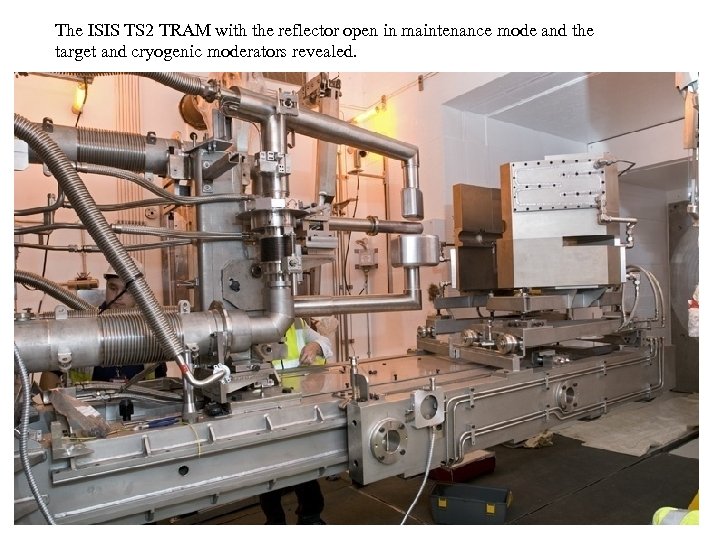

The ISIS TS 2 TRAM with the reflector open in maintenance mode and the target and cryogenic moderators revealed.

The ISIS TS 2 TRAM with the reflector open in maintenance mode and the target and cryogenic moderators revealed.

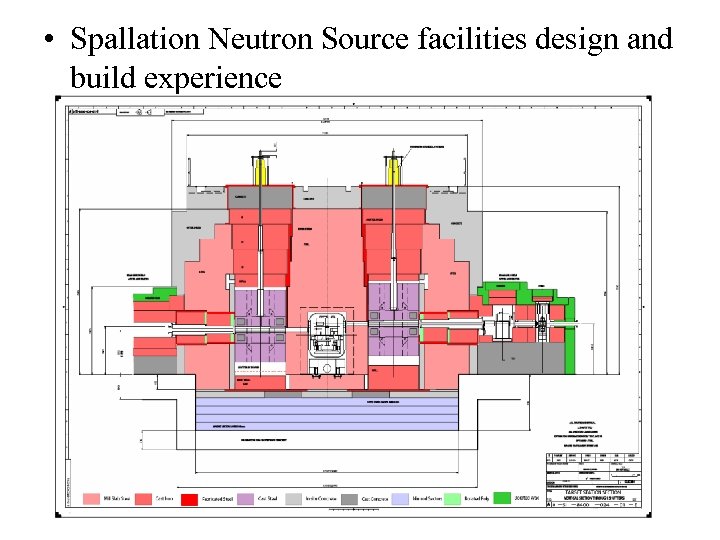

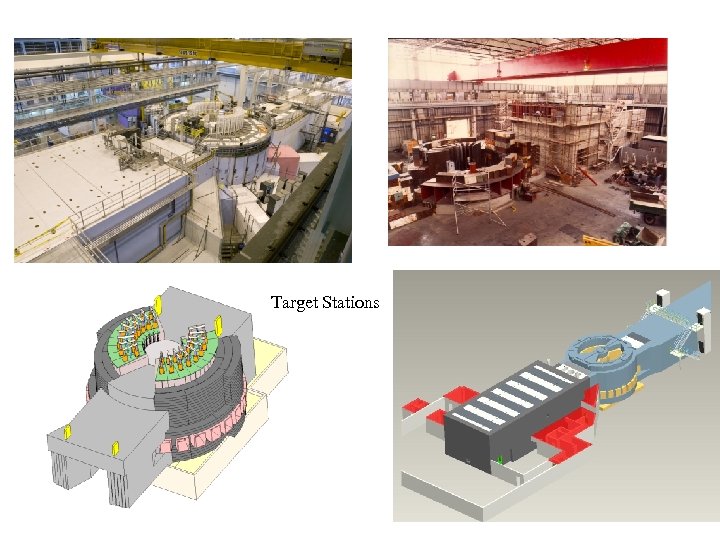

• Spallation Neutron Source facilities design and build experience

• Spallation Neutron Source facilities design and build experience

Target Stations

Target Stations

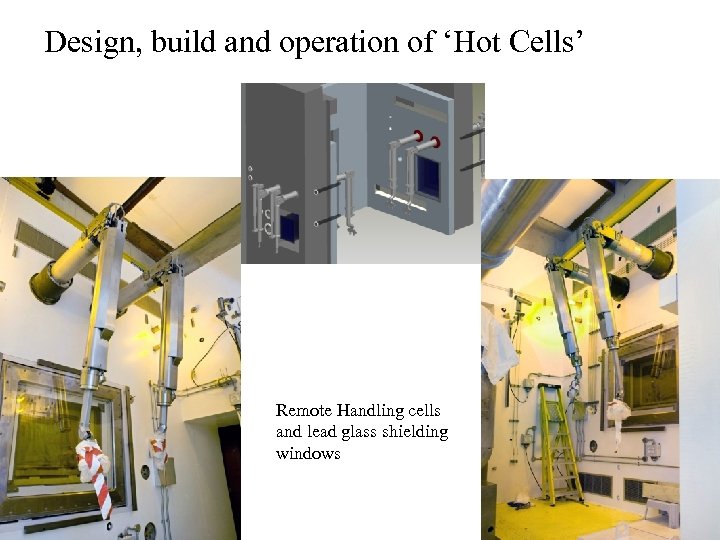

Design, build and operation of ‘Hot Cells’ Remote Handling cells and lead glass shielding windows

Design, build and operation of ‘Hot Cells’ Remote Handling cells and lead glass shielding windows

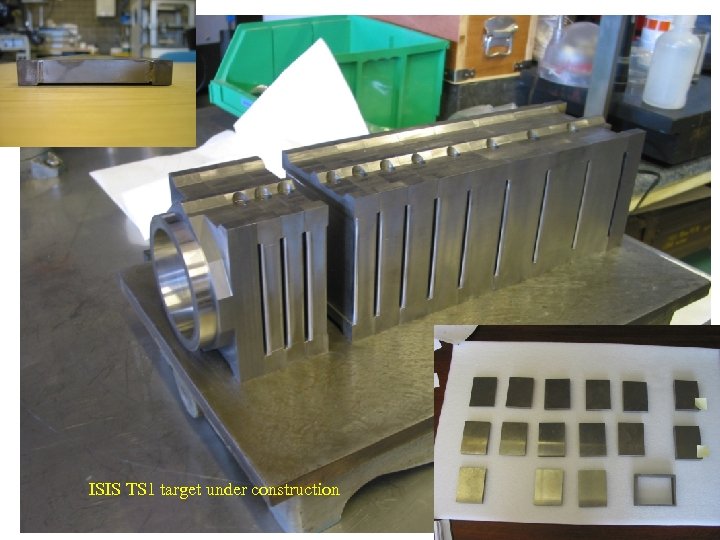

• Target Manufacturing and Assembly – Precision machining – Machining Tungsten and Tantalum • EDM • 5 axis CNC – EB welding of Tantalum cladding and bulk tantalum – Hot Isostatic Pressing of Tantalum cladding – Target assembly

• Target Manufacturing and Assembly – Precision machining – Machining Tungsten and Tantalum • EDM • 5 axis CNC – EB welding of Tantalum cladding and bulk tantalum – Hot Isostatic Pressing of Tantalum cladding – Target assembly

ISIS TS 1 target under construction

ISIS TS 1 target under construction

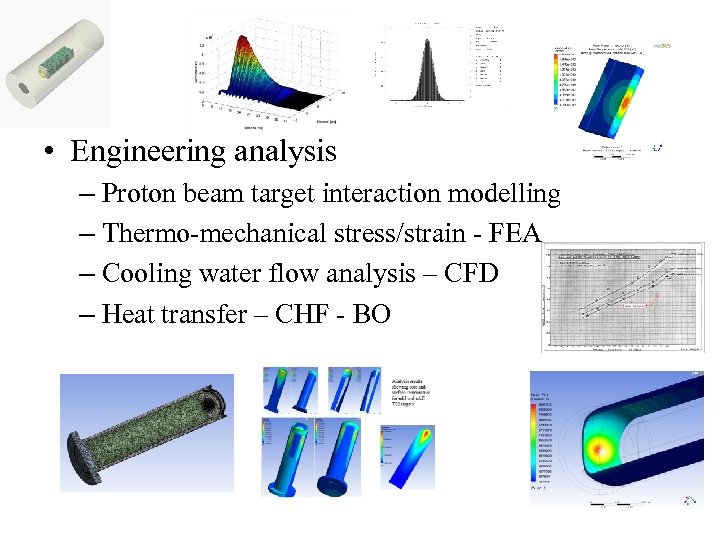

• Engineering analysis – Proton beam target interaction modelling – Thermo-mechanical stress/strain - FEA – Cooling water flow analysis – CFD – Heat transfer – CHF - BO

• Engineering analysis – Proton beam target interaction modelling – Thermo-mechanical stress/strain - FEA – Cooling water flow analysis – CFD – Heat transfer – CHF - BO

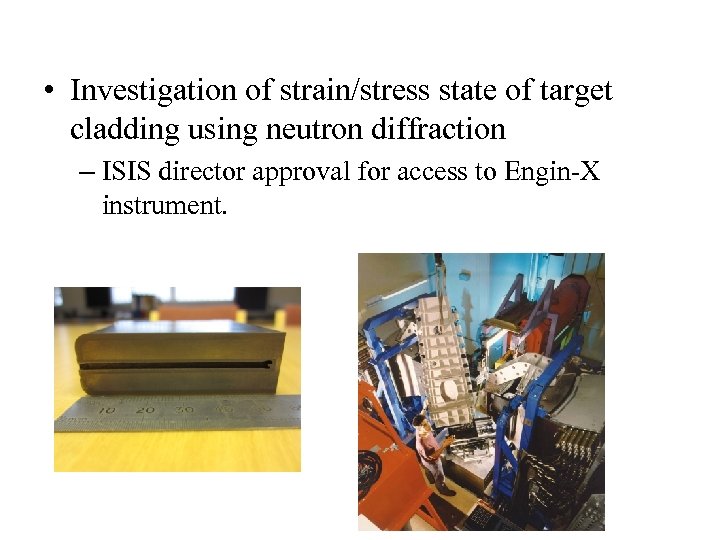

• Investigation of strain/stress state of target cladding using neutron diffraction – ISIS director approval for access to Engin-X instrument.

• Investigation of strain/stress state of target cladding using neutron diffraction – ISIS director approval for access to Engin-X instrument.

ISIS First Target Station upgrade plans • Currently in a definition (feasibility) phase reviewing the options for an upgrade which might include: o An improvement in efficiency o An improvement in reliability o An improvement in specific output o Or a combination of all three. • The existing target station infrastructure will have a strong influence on any upgrade path.

ISIS First Target Station upgrade plans • Currently in a definition (feasibility) phase reviewing the options for an upgrade which might include: o An improvement in efficiency o An improvement in reliability o An improvement in specific output o Or a combination of all three. • The existing target station infrastructure will have a strong influence on any upgrade path.

ISIS Second Target Station upgrade plans • Currently in the middle of the phase II instruments project: o Adding a further 4 instruments to the current suite of 7 o An improvement in flexibility of the beryllium reflector o To accommodate potential future changes to the moderators o Potential changes to the instrument suite. • Again, existing target station infrastructure will have a strong influence on any upgrade path.

ISIS Second Target Station upgrade plans • Currently in the middle of the phase II instruments project: o Adding a further 4 instruments to the current suite of 7 o An improvement in flexibility of the beryllium reflector o To accommodate potential future changes to the moderators o Potential changes to the instrument suite. • Again, existing target station infrastructure will have a strong influence on any upgrade path.