484be2fb7659e2ddb58e756f225dceb9.ppt

- Количество слайдов: 22

RADOMES

RADOMES

CONTENTS Radome ? Radar. Principles Physical Fundamentals Properties of EM energy Types of Radomes Case Study on Airborn Radome – Manufacturing – SOF tests & Qualification • Conclusion • • • 2

CONTENTS Radome ? Radar. Principles Physical Fundamentals Properties of EM energy Types of Radomes Case Study on Airborn Radome – Manufacturing – SOF tests & Qualification • Conclusion • • • 2

RADOME • The word radome is a portmanteau of radar and dome. • A radome is a structural, weatherproof enclosure used to protect an antenna. • The material used in building the radome allows a relatively unattenuated electromagnetic signal between the antenna inside the radome and outside equipment. • Radomes are used to protect the surfaces of the antenna from the effects of environmental exposure. 3

RADOME • The word radome is a portmanteau of radar and dome. • A radome is a structural, weatherproof enclosure used to protect an antenna. • The material used in building the radome allows a relatively unattenuated electromagnetic signal between the antenna inside the radome and outside equipment. • Radomes are used to protect the surfaces of the antenna from the effects of environmental exposure. 3

• Radomes can be constructed in several shapes depending upon the particular application using various construction materials (fiberglass, PTFEcoated fabric, etc. ). • When used on UAVs or other aircraft, in addition to such protection, the radome also streamlines the antenna system, thus reducing drag. 4

• Radomes can be constructed in several shapes depending upon the particular application using various construction materials (fiberglass, PTFEcoated fabric, etc. ). • When used on UAVs or other aircraft, in addition to such protection, the radome also streamlines the antenna system, thus reducing drag. 4

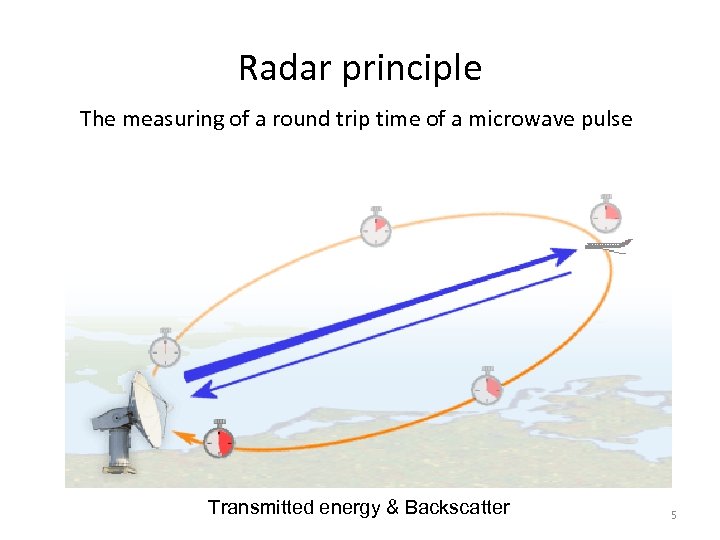

Radar principle The measuring of a round trip time of a microwave pulse Transmitted energy & Backscatter 5

Radar principle The measuring of a round trip time of a microwave pulse Transmitted energy & Backscatter 5

Physical fundamentals • The basic principle of operation of primary radar is simple to understand. • The theory can be quite complex, understanding is essential in order to be able to specify and operate primary radar systems correctly. • The implementation and operation of primary radars systems involve a wide range of disciplines such as building works, heavy mechanical and electrical engineering, high power microwave engineering, and advanced high speed signal and data processing techniques. • Some laws of nature have a greater importance here. • Radar measurement of the distance, the direction and the height of the reflecting object is made possible because of the properties of radiated electromagnetic energy. 6

Physical fundamentals • The basic principle of operation of primary radar is simple to understand. • The theory can be quite complex, understanding is essential in order to be able to specify and operate primary radar systems correctly. • The implementation and operation of primary radars systems involve a wide range of disciplines such as building works, heavy mechanical and electrical engineering, high power microwave engineering, and advanced high speed signal and data processing techniques. • Some laws of nature have a greater importance here. • Radar measurement of the distance, the direction and the height of the reflecting object is made possible because of the properties of radiated electromagnetic energy. 6

Properties of electromagnetic energy • The electromagnetic waves are reflected if they meet an electrically leading surface. If these reflected waves are received again at the place of their origin, then that means an obstacle is in the propagation direction. • Electromagnetic energy travels through air at a constant speed, at approximately the speed of light, 300, 000 km / sec • This constant speed allows the determination of the distance between the reflecting objects (airplanes, ships or cars) and the radar site by measuring the running time of the transmitted pulses. • This energy normally travels through space in a straight line, and will vary only slightly because of atmospheric and weather conditions. By using of special radar antennas this energy can be focused into a desired direction. Thus the direction (in azimuth and elevation) of the reflecting objects can be measured. 7

Properties of electromagnetic energy • The electromagnetic waves are reflected if they meet an electrically leading surface. If these reflected waves are received again at the place of their origin, then that means an obstacle is in the propagation direction. • Electromagnetic energy travels through air at a constant speed, at approximately the speed of light, 300, 000 km / sec • This constant speed allows the determination of the distance between the reflecting objects (airplanes, ships or cars) and the radar site by measuring the running time of the transmitted pulses. • This energy normally travels through space in a straight line, and will vary only slightly because of atmospheric and weather conditions. By using of special radar antennas this energy can be focused into a desired direction. Thus the direction (in azimuth and elevation) of the reflecting objects can be measured. 7

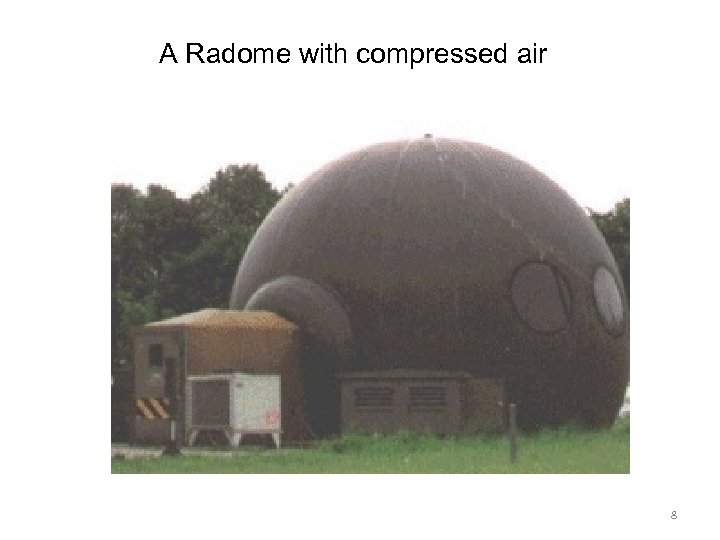

A Radome with compressed air 8

A Radome with compressed air 8

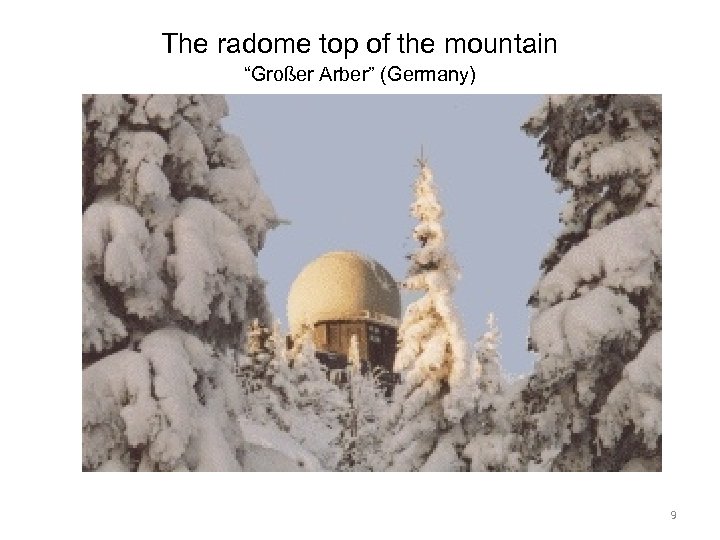

The radome top of the mountain “Großer Arber” (Germany) 9

The radome top of the mountain “Großer Arber” (Germany) 9

Radome made of fibre-glass reinforced polymer resin (for an ATC-radar) 10

Radome made of fibre-glass reinforced polymer resin (for an ATC-radar) 10

TYPES OF RADOMES 1. GROUND BASED RADOMES (STATIC) Wet Lay-up Vacuum Bag 2. AIRBORN RADOMES (FLYING) Autoclave Moulding Resin Transfer Moulding 11

TYPES OF RADOMES 1. GROUND BASED RADOMES (STATIC) Wet Lay-up Vacuum Bag 2. AIRBORN RADOMES (FLYING) Autoclave Moulding Resin Transfer Moulding 11

CASE STUDY AIR BORN RADOME MANUFACTURING USING RTM 12

CASE STUDY AIR BORN RADOME MANUFACTURING USING RTM 12

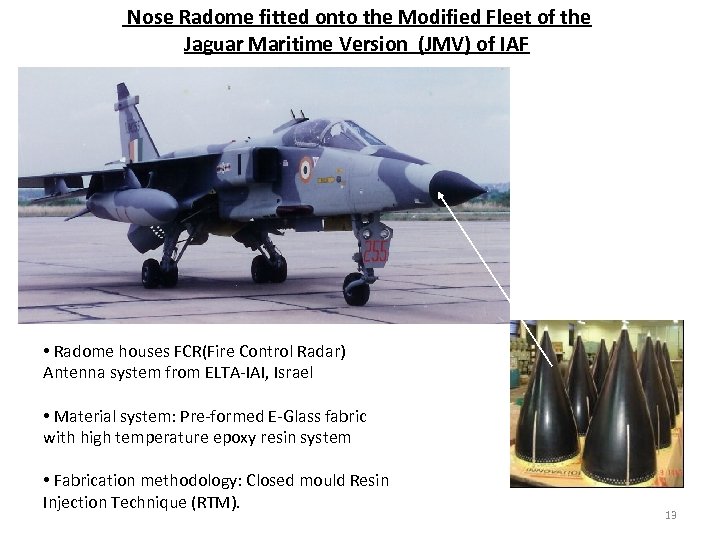

Nose Radome fitted onto the Modified Fleet of the Jaguar Maritime Version (JMV) of IAF • Radome houses FCR(Fire Control Radar) Antenna system from ELTA-IAI, Israel • Material system: Pre-formed E-Glass fabric with high temperature epoxy resin system • Fabrication methodology: Closed mould Resin Injection Technique (RTM). 13

Nose Radome fitted onto the Modified Fleet of the Jaguar Maritime Version (JMV) of IAF • Radome houses FCR(Fire Control Radar) Antenna system from ELTA-IAI, Israel • Material system: Pre-formed E-Glass fabric with high temperature epoxy resin system • Fabrication methodology: Closed mould Resin Injection Technique (RTM). 13

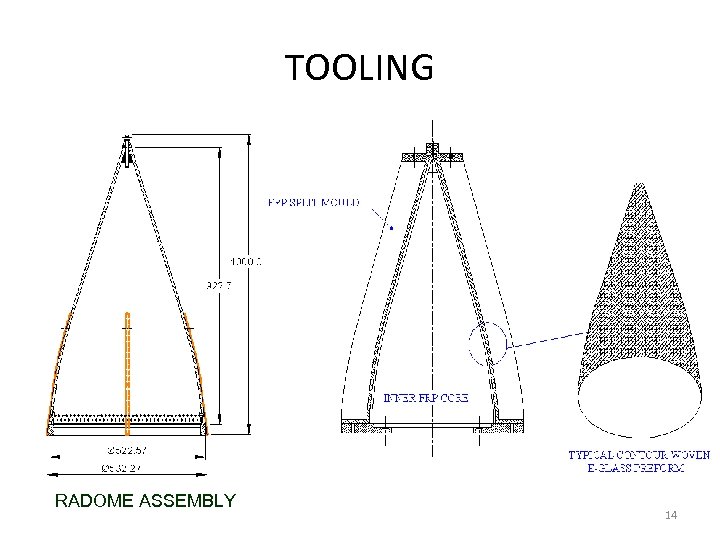

TOOLING RADOME ASSEMBLY 14

TOOLING RADOME ASSEMBLY 14

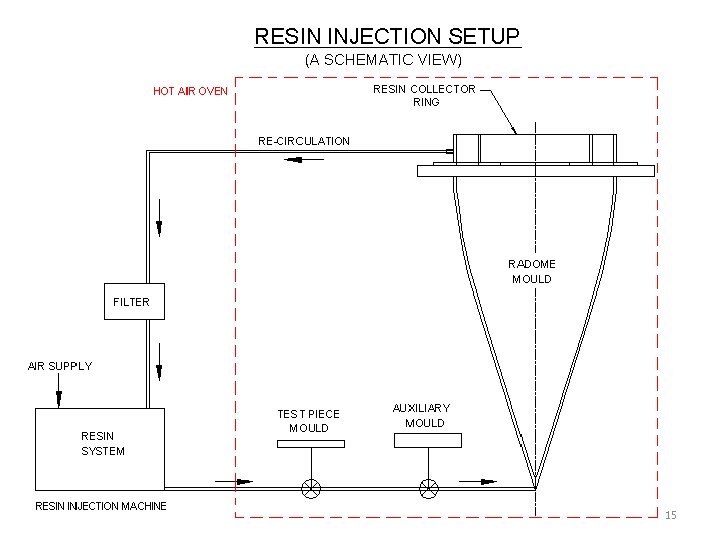

15

15

SOF TESTS 1. STATIC TESTS – HAL 2. VIBRATION TESTS– NAL 3. LIGHTENING TESTS– CABS 4. ELECTROMAGNETIC TESTS – LRDE/ISRO/ELTA 5. FLIGHT TESTS – ASTE 16

SOF TESTS 1. STATIC TESTS – HAL 2. VIBRATION TESTS– NAL 3. LIGHTENING TESTS– CABS 4. ELECTROMAGNETIC TESTS – LRDE/ISRO/ELTA 5. FLIGHT TESTS – ASTE 16

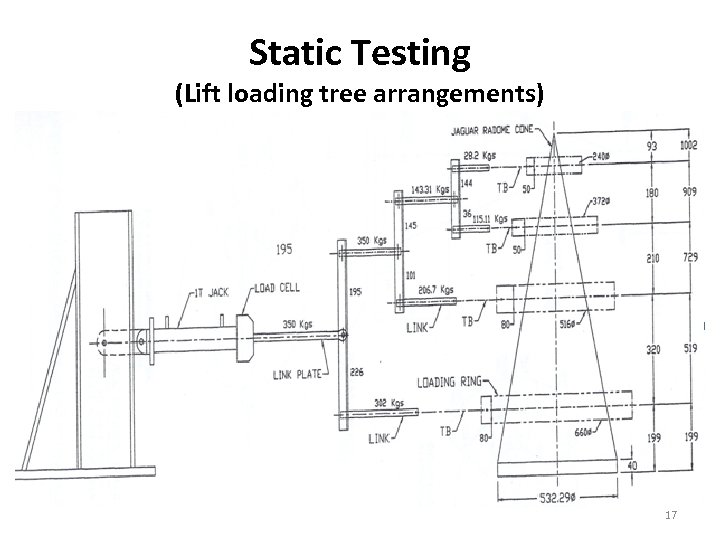

Static Testing (Lift loading tree arrangements) 17

Static Testing (Lift loading tree arrangements) 17

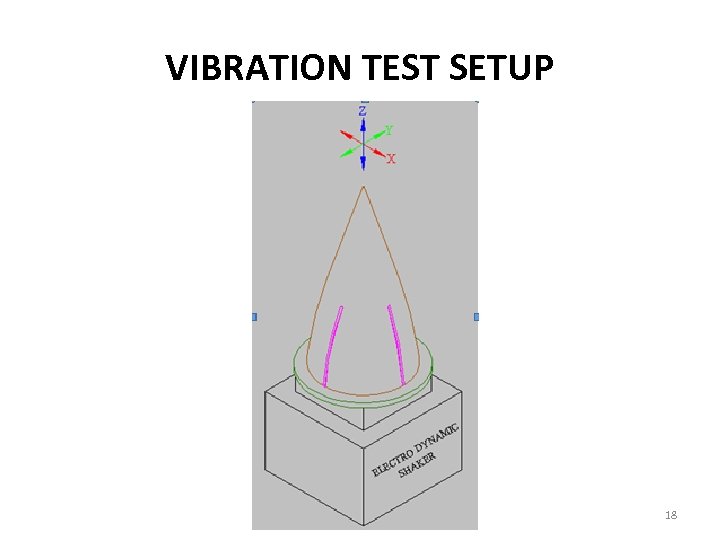

VIBRATION TEST SETUP 18

VIBRATION TEST SETUP 18

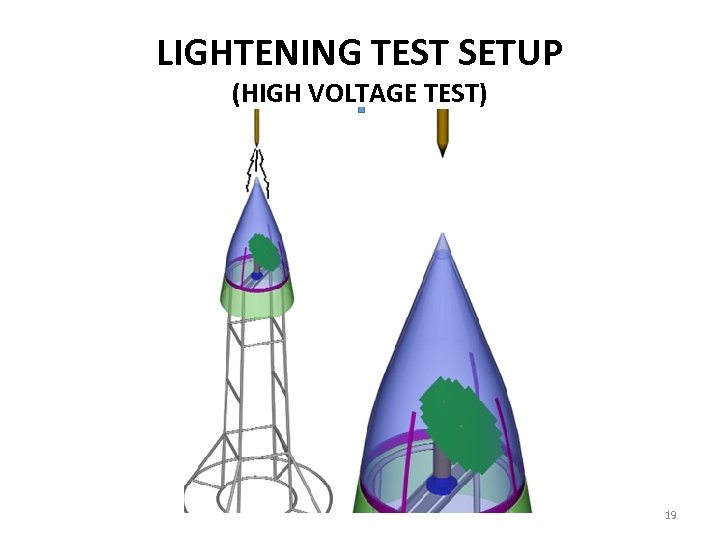

LIGHTENING TEST SETUP (HIGH VOLTAGE TEST) 19

LIGHTENING TEST SETUP (HIGH VOLTAGE TEST) 19

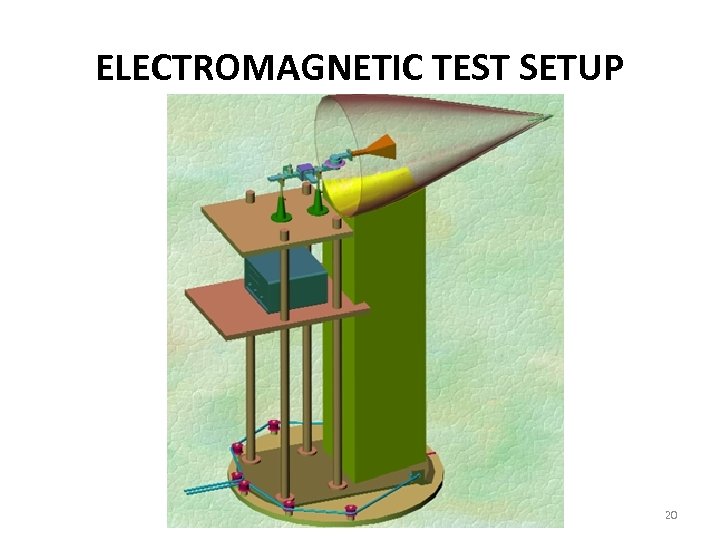

ELECTROMAGNETIC TEST SETUP 20

ELECTROMAGNETIC TEST SETUP 20

CONCLUSION • Vacuum Bagging Moulding technique is best suited for larger surface area panels of Ground Based Radomes • RTM process is best suited for precession Airborn Radomes • Case Study gives the complexity of Multidisciplinary approach to be adopted for development & qualification of Radomes 21

CONCLUSION • Vacuum Bagging Moulding technique is best suited for larger surface area panels of Ground Based Radomes • RTM process is best suited for precession Airborn Radomes • Case Study gives the complexity of Multidisciplinary approach to be adopted for development & qualification of Radomes 21

THANK U 22

THANK U 22