qwerty take ----“Type it easy” Case #1: Unilever Antipina Tatiana – International management, GSOM Serikova Tatiana – International management, GSOM Tarasova Yana – International management, GSOM Treskunov Igor – Public administration, GSOM St. Petersburg, 2011

qwerty take ----“Type it easy” Case #1: Unilever Antipina Tatiana – International management, GSOM Serikova Tatiana – International management, GSOM Tarasova Yana – International management, GSOM Treskunov Igor – Public administration, GSOM St. Petersburg, 2011

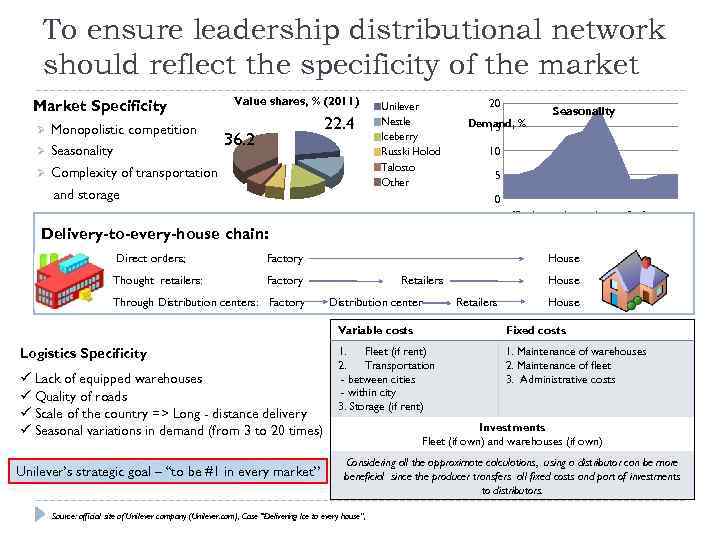

To ensure leadership distributional network should reflect the specificity of the market Market Specificity Ø Monopolistic competition Ø Seasonality Ø Value shares, % (2011) 22. 4 Complexity of transportation 36. 2 and storage Unilever Nestle Iceberry Russki Holod Talosto Other 20 Demand, % 15 Seasonality 10 5 Jan Fe b M rc a h. A p r. M a y Ju n e Ju ly Au g. S ep t. O c t. N o v. D e c 0 Delivery-to-every-house chain: Direct orders; Factory Thought retailers: Factory Through Distribution centers: Factory House Retailers Distribution center House Retailers House Variable costs Logistics Specificity ü Lack of equipped warehouses ü Quality of roads ü Scale of the country => Long - distance delivery ü Seasonal variations in demand (from 3 to 20 times) Unilever’s strategic goal – “to be #1 in every market” Fixed costs 1. Fleet (if rent) 2. Transportation - between cities - within city 3. Storage (if rent) 1. Maintenance of warehouses 2. Maintenance of fleet 3. Administrative costs Investments Fleet (if own) and warehouses (if own) Considering all the approximate calculations, using a distributor can be more beneficial since the producer transfers all fixed costs and part of investments to distributors. Source: official site of Unilever company (Unilever. com), Case “Delivering Ice to every house”,

To ensure leadership distributional network should reflect the specificity of the market Market Specificity Ø Monopolistic competition Ø Seasonality Ø Value shares, % (2011) 22. 4 Complexity of transportation 36. 2 and storage Unilever Nestle Iceberry Russki Holod Talosto Other 20 Demand, % 15 Seasonality 10 5 Jan Fe b M rc a h. A p r. M a y Ju n e Ju ly Au g. S ep t. O c t. N o v. D e c 0 Delivery-to-every-house chain: Direct orders; Factory Thought retailers: Factory Through Distribution centers: Factory House Retailers Distribution center House Retailers House Variable costs Logistics Specificity ü Lack of equipped warehouses ü Quality of roads ü Scale of the country => Long - distance delivery ü Seasonal variations in demand (from 3 to 20 times) Unilever’s strategic goal – “to be #1 in every market” Fixed costs 1. Fleet (if rent) 2. Transportation - between cities - within city 3. Storage (if rent) 1. Maintenance of warehouses 2. Maintenance of fleet 3. Administrative costs Investments Fleet (if own) and warehouses (if own) Considering all the approximate calculations, using a distributor can be more beneficial since the producer transfers all fixed costs and part of investments to distributors. Source: official site of Unilever company (Unilever. com), Case “Delivering Ice to every house”,

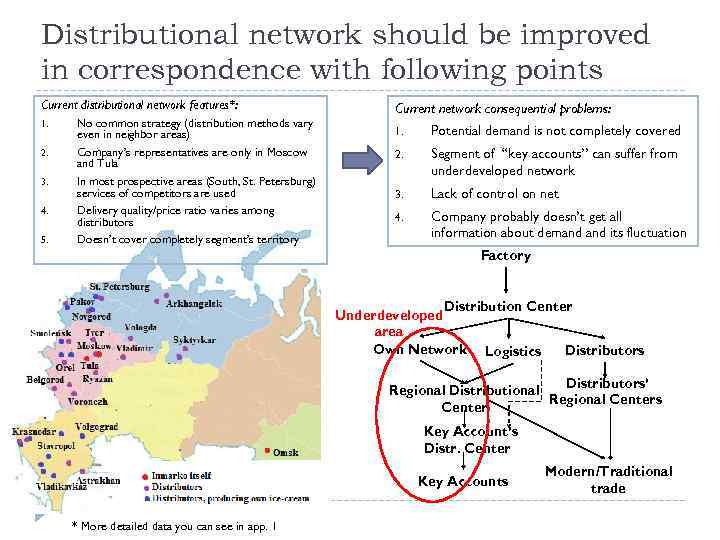

Distributional network should be improved in correspondence with following points Current distributional network features*: 1. 2. 3. 4. 5. No common strategy (distribution methods vary even in neighbor areas) Company’s representatives are only in Moscow and Tula In most prospective areas (South, St. Petersburg) services of competitors are used Delivery quality/price ratio varies among distributors Doesn’t cover completely segment’s territory Current network consequential problems: 1. Potential demand is not completely covered 2. Segment of “key accounts” can suffer from underdeveloped network 3. Lack of control on net 4. Company probably doesn’t get all information about demand its fluctuation Factory Distribution Center Underdeveloped area Own Network Logistics Distributors’ Regional Distributional Regional Centers Center Key Account’s Distr. Center Key Accounts * More detailed data you can see in app. 1 Modern/Traditional trade

Distributional network should be improved in correspondence with following points Current distributional network features*: 1. 2. 3. 4. 5. No common strategy (distribution methods vary even in neighbor areas) Company’s representatives are only in Moscow and Tula In most prospective areas (South, St. Petersburg) services of competitors are used Delivery quality/price ratio varies among distributors Doesn’t cover completely segment’s territory Current network consequential problems: 1. Potential demand is not completely covered 2. Segment of “key accounts” can suffer from underdeveloped network 3. Lack of control on net 4. Company probably doesn’t get all information about demand its fluctuation Factory Distribution Center Underdeveloped area Own Network Logistics Distributors’ Regional Distributional Regional Centers Center Key Account’s Distr. Center Key Accounts * More detailed data you can see in app. 1 Modern/Traditional trade

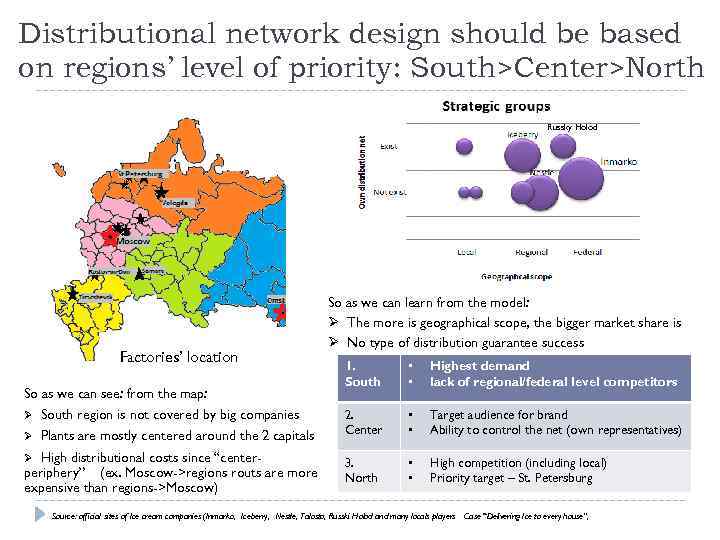

Distributional network design should be based on regions’ level of priority: South>Center>North Russky Holod Factories’ location So as we can see: from the map: Ø South region is not covered by big companies Ø Plants are mostly centered around the 2 capitals High distributional costs since “centerperiphery” (ex. Moscow->regions routs are more expensive than regions->Moscow) Ø So as we can learn from the model: Ø The more is geographical scope, the bigger market share is Ø No type of distribution guarantee success 1. South • • Highest demand lack of regional/federal level competitors 2. Center • • Target audience for brand Ability to control the net (own representatives) 3. North • • High competition (including local) Priority target – St. Petersburg Source: official sites of Ice cream companies (Inmarko, Iceberry, Nestle, Talosto, Russki Holod and many locals players Case “Delivering Ice to every house”,

Distributional network design should be based on regions’ level of priority: South>Center>North Russky Holod Factories’ location So as we can see: from the map: Ø South region is not covered by big companies Ø Plants are mostly centered around the 2 capitals High distributional costs since “centerperiphery” (ex. Moscow->regions routs are more expensive than regions->Moscow) Ø So as we can learn from the model: Ø The more is geographical scope, the bigger market share is Ø No type of distribution guarantee success 1. South • • Highest demand lack of regional/federal level competitors 2. Center • • Target audience for brand Ability to control the net (own representatives) 3. North • • High competition (including local) Priority target – St. Petersburg Source: official sites of Ice cream companies (Inmarko, Iceberry, Nestle, Talosto, Russki Holod and many locals players Case “Delivering Ice to every house”,

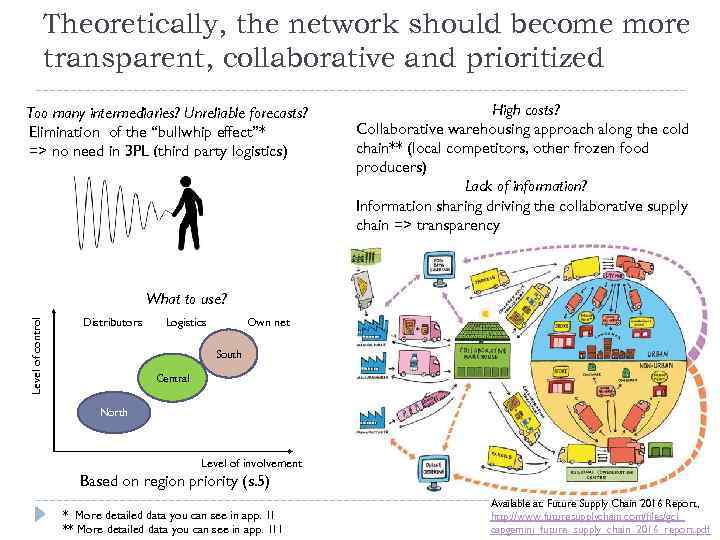

Theoretically, the network should become more transparent, collaborative and prioritized Too many intermediaries? Unreliable forecasts? Elimination of the “bullwhip effect”* => no need in 3 PL (third party logistics) High costs? Collaborative warehousing approach along the cold chain** (local competitors, other frozen food producers) Lack of information? Information sharing driving the collaborative supply chain => transparency Level of control What to use? Distributors Logistics Own net South Central North Level of involvement Based on region priority (s. 5) * More detailed data you can see in app. 1 I ** More detailed data you can see in app. 1 I I Available at: Future Supply Chain 2016 Report, http: //www. futuresupplychain. com/files/gci_ capgemini_future_supply_chain_2016_report. pdf

Theoretically, the network should become more transparent, collaborative and prioritized Too many intermediaries? Unreliable forecasts? Elimination of the “bullwhip effect”* => no need in 3 PL (third party logistics) High costs? Collaborative warehousing approach along the cold chain** (local competitors, other frozen food producers) Lack of information? Information sharing driving the collaborative supply chain => transparency Level of control What to use? Distributors Logistics Own net South Central North Level of involvement Based on region priority (s. 5) * More detailed data you can see in app. 1 I ** More detailed data you can see in app. 1 I I Available at: Future Supply Chain 2016 Report, http: //www. futuresupplychain. com/files/gci_ capgemini_future_supply_chain_2016_report. pdf

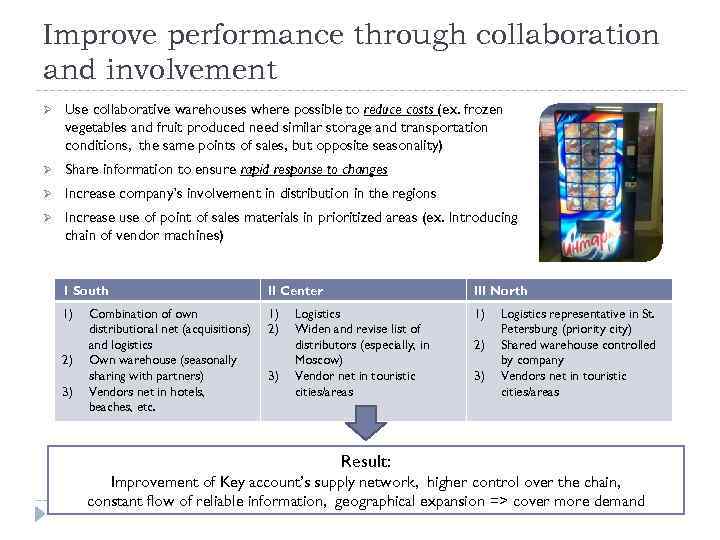

Improve performance through collaboration and involvement Ø Use collaborative warehouses where possible to reduce costs (ex. frozen vegetables and fruit produced need similar storage and transportation conditions, the same points of sales, but opposite seasonality) Ø Share information to ensure rapid response to changes Ø Increase company’s involvement in distribution in the regions Ø Increase use of point of sales materials in prioritized areas (ex. Introducing chain of vendor machines) 1 South II Center III North 1) 1) 2) 3) Combination of own distributional net (acquisitions) and logistics Own warehouse (seasonally sharing with partners) Vendors net in hotels, beaches, etc. 3) Logistics Widen and revise list of distributors (especially, in Moscow) Vendor net in touristic cities/areas 2) 3) Logistics representative in St. Petersburg (priority city) Shared warehouse controlled by company Vendors net in touristic cities/areas Result: Improvement of Key account’s supply network, higher control over the chain, constant flow of reliable information, geographical expansion => cover more demand

Improve performance through collaboration and involvement Ø Use collaborative warehouses where possible to reduce costs (ex. frozen vegetables and fruit produced need similar storage and transportation conditions, the same points of sales, but opposite seasonality) Ø Share information to ensure rapid response to changes Ø Increase company’s involvement in distribution in the regions Ø Increase use of point of sales materials in prioritized areas (ex. Introducing chain of vendor machines) 1 South II Center III North 1) 1) 2) 3) Combination of own distributional net (acquisitions) and logistics Own warehouse (seasonally sharing with partners) Vendors net in hotels, beaches, etc. 3) Logistics Widen and revise list of distributors (especially, in Moscow) Vendor net in touristic cities/areas 2) 3) Logistics representative in St. Petersburg (priority city) Shared warehouse controlled by company Vendors net in touristic cities/areas Result: Improvement of Key account’s supply network, higher control over the chain, constant flow of reliable information, geographical expansion => cover more demand

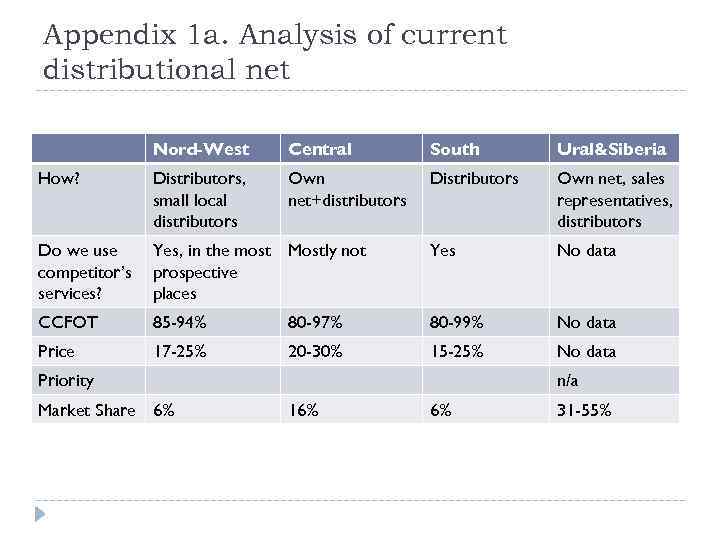

Appendix 1 a. Analysis of current distributional net Nord-West Central South Ural&Siberia How? Distributors, small local distributors Own net+distributors Distributors Own net, sales representatives, distributors Do we use competitor’s services? Yes, in the most Mostly not prospective places Yes No data CCFOT 85 -94% 80 -97% 80 -99% No data Price 17 -25% 20 -30% 15 -25% No data Priority Market Share 6% n/a 16% 6% 31 -55%

Appendix 1 a. Analysis of current distributional net Nord-West Central South Ural&Siberia How? Distributors, small local distributors Own net+distributors Distributors Own net, sales representatives, distributors Do we use competitor’s services? Yes, in the most Mostly not prospective places Yes No data CCFOT 85 -94% 80 -97% 80 -99% No data Price 17 -25% 20 -30% 15 -25% No data Priority Market Share 6% n/a 16% 6% 31 -55%

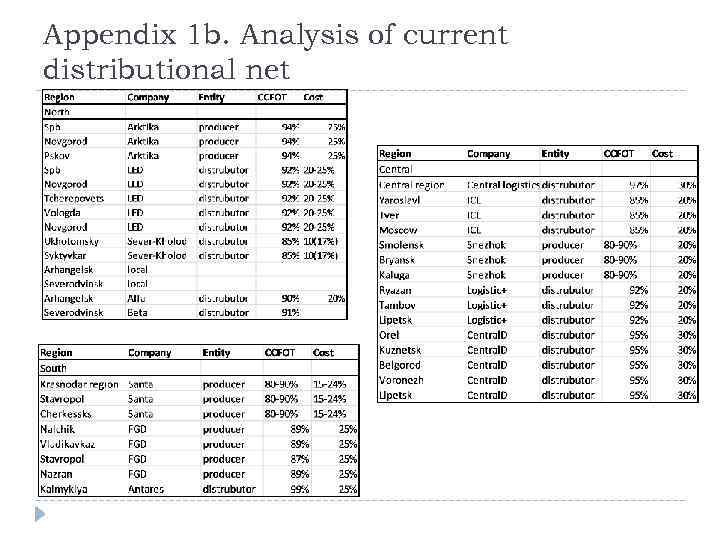

Appendix 1 b. Analysis of current distributional net

Appendix 1 b. Analysis of current distributional net

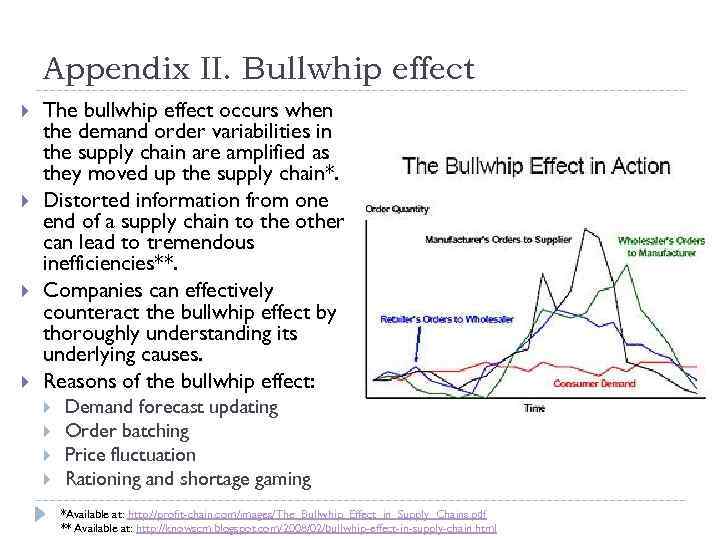

Appendix II. Bullwhip effect The bullwhip effect occurs when the demand order variabilities in the supply chain are amplified as they moved up the supply chain*. Distorted information from one end of a supply chain to the other can lead to tremendous inefficiencies**. Companies can effectively counteract the bullwhip effect by thoroughly understanding its underlying causes. Reasons of the bullwhip effect: Demand forecast updating Order batching Price fluctuation Rationing and shortage gaming *Available at: http: //profit-chain. com/images/The_Bullwhip_Effect_in_Supply_Chains. pdf ** Available at: http: //knowscm. blogspot. com/2008/02/bullwhip-effect-in-supply-chain. html

Appendix II. Bullwhip effect The bullwhip effect occurs when the demand order variabilities in the supply chain are amplified as they moved up the supply chain*. Distorted information from one end of a supply chain to the other can lead to tremendous inefficiencies**. Companies can effectively counteract the bullwhip effect by thoroughly understanding its underlying causes. Reasons of the bullwhip effect: Demand forecast updating Order batching Price fluctuation Rationing and shortage gaming *Available at: http: //profit-chain. com/images/The_Bullwhip_Effect_in_Supply_Chains. pdf ** Available at: http: //knowscm. blogspot. com/2008/02/bullwhip-effect-in-supply-chain. html

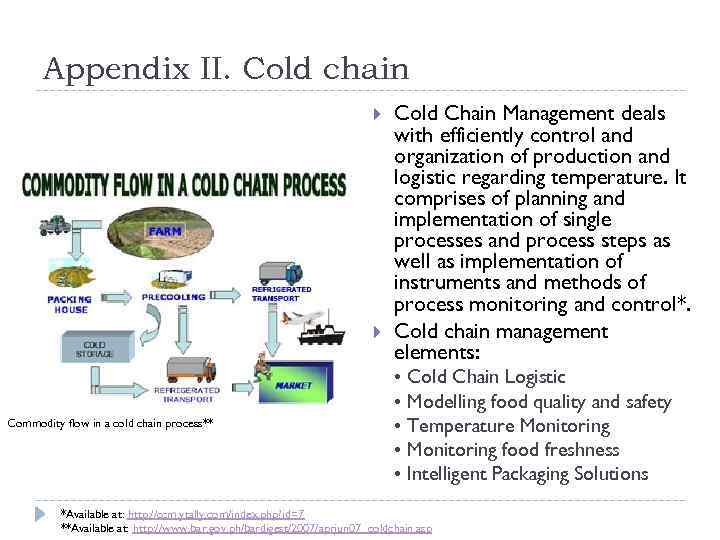

Appendix II. Cold chain Commodity flow in a cold chain process** Cold Chain Management deals with efficiently control and organization of production and logistic regarding temperature. It comprises of planning and implementation of single processes and process steps as well as implementation of instruments and methods of process monitoring and control*. Cold chain management elements: • Cold Chain Logistic • Modelling food quality and safety • Temperature Monitoring • Monitoring food freshness • Intelligent Packaging Solutions *Available at: http: //ccm. ytally. com/index. php? id=7 **Available at: http: //www. bar. gov. ph/bardigest/2007/aprjun 07_coldchain. asp

Appendix II. Cold chain Commodity flow in a cold chain process** Cold Chain Management deals with efficiently control and organization of production and logistic regarding temperature. It comprises of planning and implementation of single processes and process steps as well as implementation of instruments and methods of process monitoring and control*. Cold chain management elements: • Cold Chain Logistic • Modelling food quality and safety • Temperature Monitoring • Monitoring food freshness • Intelligent Packaging Solutions *Available at: http: //ccm. ytally. com/index. php? id=7 **Available at: http: //www. bar. gov. ph/bardigest/2007/aprjun 07_coldchain. asp