4c8776982ac3d06aac8ed3cbc7de66c4.ppt

- Количество слайдов: 28

Quantifying and Monetizing Co-benefits: The Case of Pro. Poor Waste-to-Resource Strategies In Developing Countries Paper by Lorenzo Santucci, Ingo Puhl, Abu Hasnat Md. Maqsood, Iftekar Enayetullah and William Kojo Agyemang-Bonsu

PART I NAMA DESIGN PRINCIPLES TO HARNESS SUSTAINABLE DEVELOPMENT CO-BENEFITS

NAMA Design Principle No 1: …a successful NAMA is driven by the value it generates towards domestic policy priorities. • NAMA support/NAMA finance monetizes international willingness to pay (Wt. P) for climate related outcomes. Co-benefits are a decision factor but are not valuated per se’ • Need to identify the existing domestic Wt. P and beneficiary mapping for co-benefits: • • • How much does it cost society to treat a sick person? How much productivity is lost? How much does it cost to clean up dirty water, or bring in clean water from elsewhere? What is the value/willingness to pay for energy from waste? And for raw materials from waste? What is the value of having poor people raising their income & reducing inequality? What is the value of a more competitive economy (that generates more GDP)? Key: identify the key entities/stakeholders that are willing to pay for such outcomes.

NAMA Design Principle No 2: …a successful NAMA has a mechanism to transfer value from those that benefit to those that create the benefit. • Project developers need to benefit from the value they are producing to • • • incentivize investment. What is the simplest way to transform society’s willingness to pay (i. e. , environmental valuation) for those co-benefits into additional revenue for waste management projects? Tipping fees (this can be channeled by the beneficiary entity that receives savings for example) Feed-in-tariffs Tax exemptions / Subsidies Carbon credit payments Pay for performance schemes …in general, result-based finance (RBF) schemes are very well adapted to this Key: identify the NAMA financial architecture and mechanisms to channel that revenue

NAMA Design Principle No 3: …a successful NAMA has tangible, accessible and substantial incentives • A NAMA must provide incentives for actions the CDM could not reach… • CDM carbon credits were ex-post and not bankable: • They take three years to issue, prices are volatile, some red-tape and excessive bureaucracy. • Many banks in developing countries never recognized carbon credits as collateral. • NAMA incentives should include the value of local benefits. • NAMA incentives needs to be “bankable”: easily accessible to qualified project-level implementers • Mitigation impacts at the end of the day still result from on the ground investment decisions by private sector, municipal organizations, etc… Key: identify the ideal set of incentives that will allow for the above

NAMA Design Principle No 4: …a successful NAMA requires inter-agency cooperation • Agencies that are expected to benefit from impacts within their jurisdiction and the NAMA implementing entity, that coordinates the transfer of incentives to the implementers of NAMA’s underlying mitigation actions. • Domestic benefits from NAMA accrue in different sectors which fall under the authority of different agencies (many times different than the NAMA entity). Therefore, the Wt. P for these benefits rests in different agencies. NAMA “beneficiary agencies” and NAMA management entity need to cooperate and jointly design a financial mechanism that provides incentives to those that are expected to implement mitigation actions within the NAMA. • Key: identify the required NAMA institutional & regulatory set-up that facilitates the above

PART II • Example of Ongoing Case Studies: Waste Management

Presentation Outline I. III. IV. V. VI. Waste Generation Worldwide and In Developing Countries Present Situation In Developing Countries What Is Waste to Resource Approach? Economic Opportunities From Climate Change Mitigation Projects Steps to Quantify and Monetize Co-benefits Way Forward

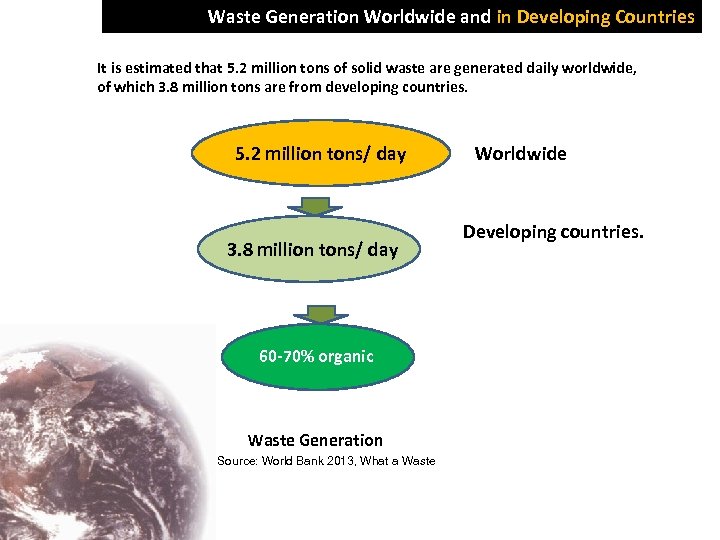

Waste Generation Worldwide and in Developing Countries It is estimated that 5. 2 million tons of solid waste are generated daily worldwide, of which 3. 8 million tons are from developing countries. 5. 2 million tons/ day 3. 8 million tons/ day 60 -70% organic Waste Generation Source: World Bank 2013, What a Waste Worldwide Developing countries.

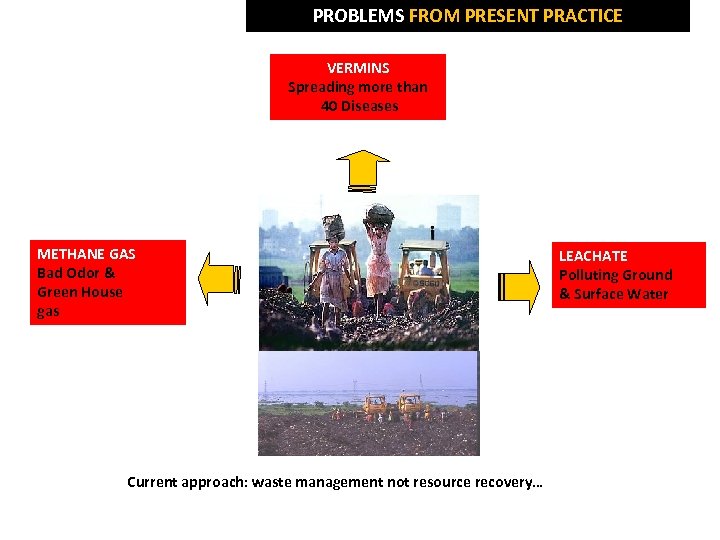

PROBLEMS FROM PRESENT PRACTICE VERMINS Spreading more than 40 Diseases METHANE GAS Bad Odor & Green House gas Current approach: waste management not resource recovery… LEACHATE Polluting Ground & Surface Water

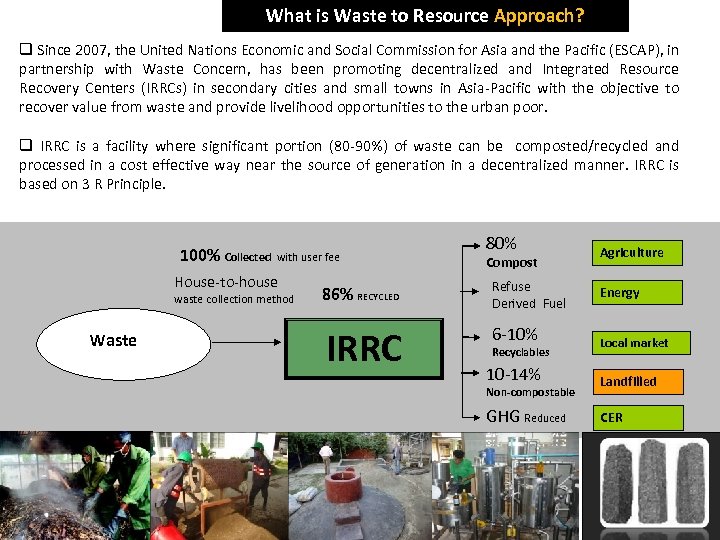

What is Waste to Resource Approach? q Since 2007, the United Nations Economic and Social Commission for Asia and the Pacific (ESCAP), in partnership with Waste Concern, has been promoting decentralized and Integrated Resource Recovery Centers (IRRCs) in secondary cities and small towns in Asia-Pacific with the objective to recover value from waste and provide livelihood opportunities to the urban poor. q IRRC is a facility where significant portion (80 -90%) of waste can be composted/recycled and processed in a cost effective way near the source of generation in a decentralized manner. IRRC is based on 3 R Principle. 100% Collected with user fee House-to-house waste collection method Waste 80% Compost 86% RECYCLED Refuse Derived Fuel IRRC 6 -10% Recyclables Agriculture Energy Local market 10 -14% Landfilled GHG Reduced CER Non-compostable

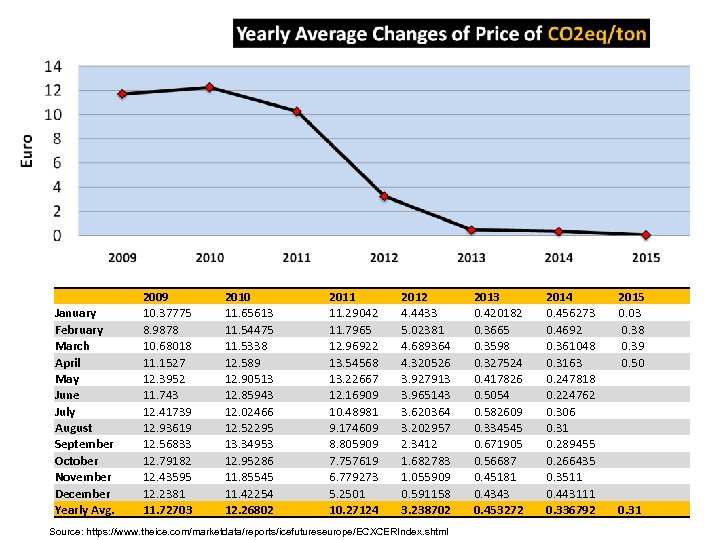

January February March April May June July August September October November December Yearly Avg. 2009 10. 37775 8. 9878 10. 68018 11. 1527 12. 3952 11. 743 12. 41739 12. 93619 12. 56833 12. 79182 12. 43595 12. 2381 11. 72703 2010 11. 65613 11. 54475 11. 5338 12. 589 12. 90513 12. 85943 12. 02466 12. 52295 13. 34953 12. 95286 11. 85545 11. 42254 12. 26802 2011 11. 29042 11. 7965 12. 96922 13. 54568 13. 22667 12. 16909 10. 48981 9. 174609 8. 805909 7. 757619 6. 779273 5. 2501 10. 27124 2012 4. 4433 5. 02381 4. 689364 4. 320526 3. 927913 3. 965143 3. 620364 3. 202957 2. 3412 1. 682783 1. 055909 0. 591158 3. 238702 Source: https: //www. theice. com/marketdata/reports/icefutureseurope/ECXCERIndex. shtml 2013 0. 420182 0. 3665 0. 3598 0. 327524 0. 417826 0. 5054 0. 582609 0. 334545 0. 671905 0. 56687 0. 45181 0. 4343 0. 453272 2014 0. 456273 0. 4692 0. 361048 0. 3163 0. 247818 0. 224762 0. 306 0. 31 0. 289455 0. 266435 0. 3511 0. 443111 0. 336792 2015 0. 03 0. 38 0. 39 0. 50 0. 31

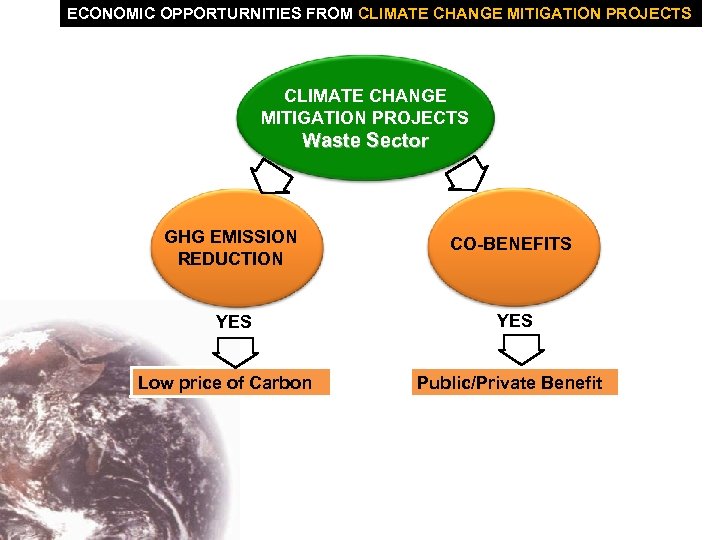

ECONOMIC OPPORTURNITIES FROM CLIMATE CHANGE MITIGATION PROJECTS Waste Sector GHG EMISSION REDUCTION CO-BENEFITS YES Low price of Carbon Public/Private Benefit

What is Co-benefit The term co-benefit is defined as the potential developmental benefits of climate change mitigation actions other than GHG mitigation reduction.

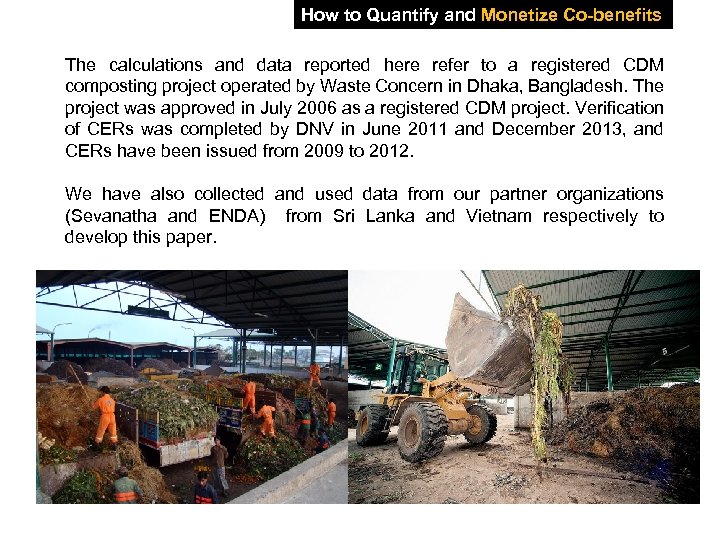

How to Quantify and Monetize Co-benefits The calculations and data reported here refer to a registered CDM composting project operated by Waste Concern in Dhaka, Bangladesh. The project was approved in July 2006 as a registered CDM project. Verification of CERs was completed by DNV in June 2011 and December 2013, and CERs have been issued from 2009 to 2012. We have also collected and used data from our partner organizations (Sevanatha and ENDA) from Sri Lanka and Vietnam respectively to develop this paper.

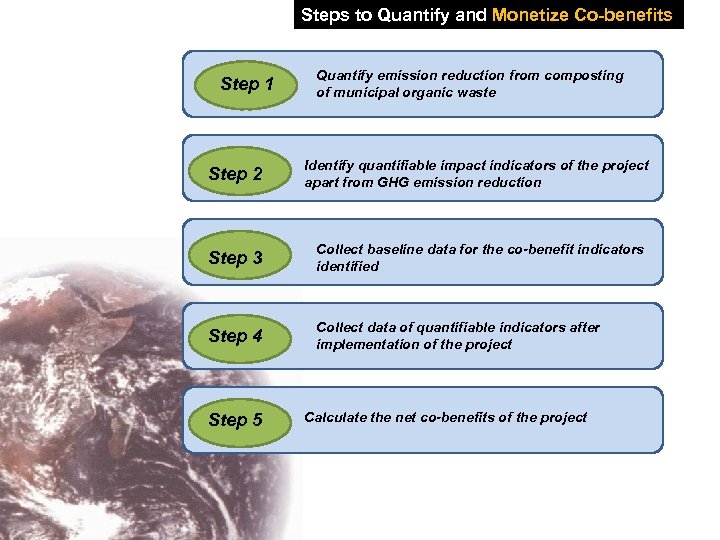

Steps to Quantify and Monetize Co-benefits Step 1 Quantify emission reduction from composting of municipal organic waste Step 2 Identify quantifiable impact indicators of the project apart from GHG emission reduction Step 3 Collect baseline data for the co-benefit indicators identified Step 4 Collect data of quantifiable indicators after implementation of the project Step 5 Calculate the net co-benefits of the project

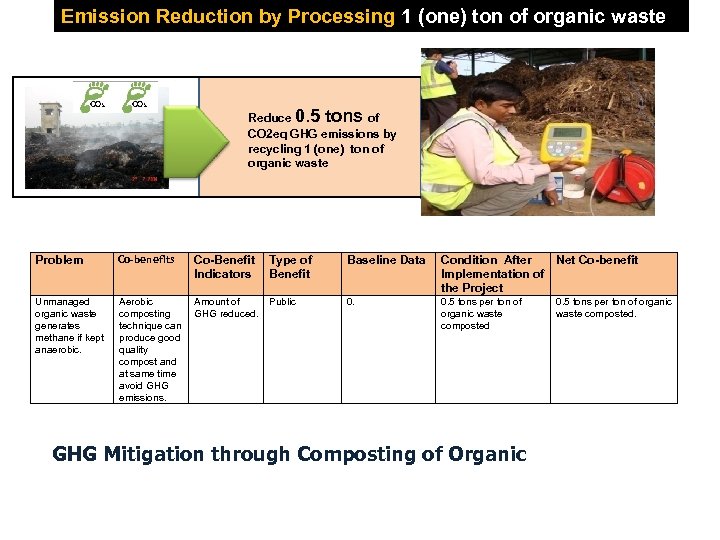

Emission Reduction by Processing 1 (one) ton of organic waste Reduce 0. 5 tons of CO 2 eq GHG emissions by recycling 1 (one) ton of organic waste Problem Co-benefits Unmanaged organic waste generates methane if kept anaerobic. Aerobic Amount of composting GHG reduced. technique can produce good quality compost and at same time avoid GHG emissions. Co-Benefit Type of Indicators Benefit Public Baseline Data Condition After Net Co-benefit Implementation of the Project 0. 5 tons per ton of organic waste composted GHG Mitigation through Composting of Organic 0. 5 tons per ton of organic waste composted.

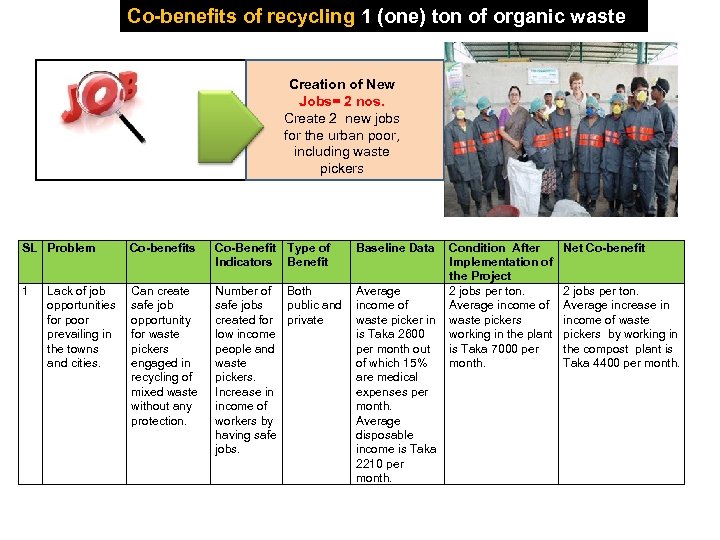

Co-benefits of recycling 1 (one) ton of organic waste Creation of New Jobs= 2 nos. Create 2 new jobs for the urban poor, including waste pickers SL Problem Co-benefits 1 Can create safe job opportunity for waste pickers engaged in recycling of mixed waste without any protection. Lack of job opportunities for poor prevailing in the towns and cities. Co-Benefit Type of Indicators Benefit Baseline Data Condition After Implementation of the Project Number of Both Average 2 jobs per ton. safe jobs public and income of Average income of created for private waste picker in waste pickers low income is Taka 2600 working in the plant people and per month out is Taka 7000 per waste of which 15% month. pickers. are medical Increase in expenses per income of month. workers by Average having safe disposable jobs. income is Taka 2210 per month. Net Co-benefit 2 jobs per ton. Average increase in income of waste pickers by working in the compost plant is Taka 4400 per month.

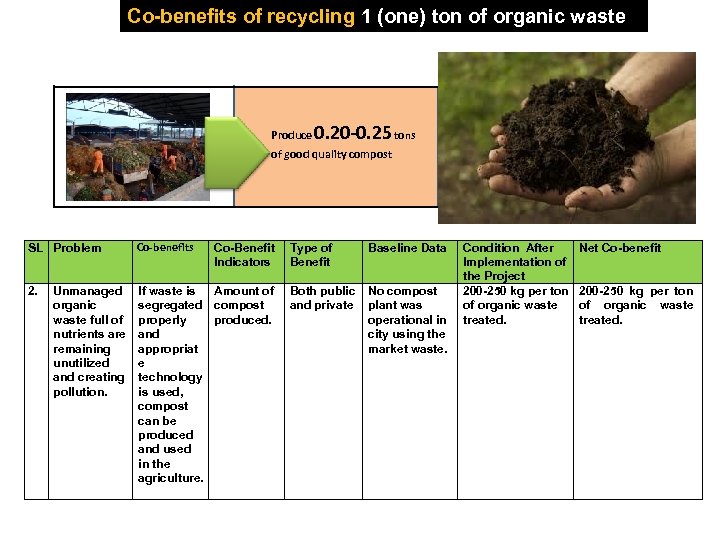

Co-benefits of recycling 1 (one) ton of organic waste 0. 20 -0. 25 tons Produce of good quality compost SL Problem Co-benefits 2. If waste is Amount of segregated compost properly produced. and appropriat e technology is used, compost can be produced and used in the agriculture. Unmanaged organic waste full of nutrients are remaining unutilized and creating pollution. Co-Benefit Type of Indicators Benefit Baseline Data Both public No compost and private plant was operational in city using the market waste. Condition After Implementation of the Project 200 -250 kg per ton of organic waste treated. Net Co-benefit 200 -250 kg per ton of organic waste treated.

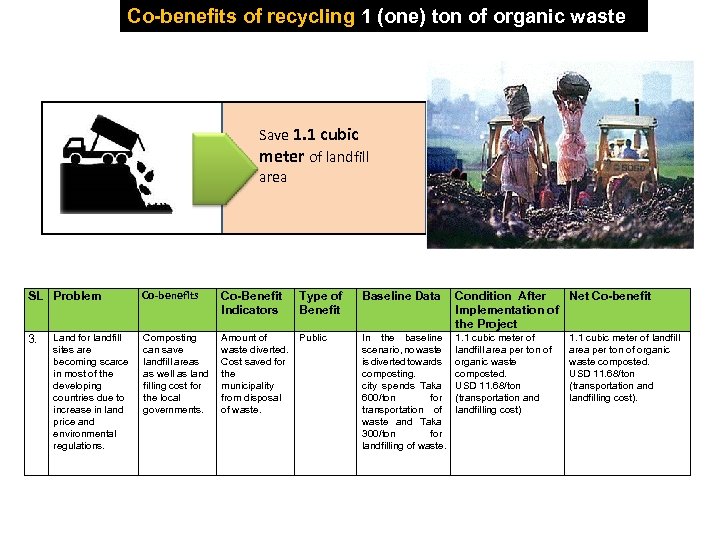

Co-benefits of recycling 1 (one) ton of organic waste Save 1. 1 cubic meter of landfill area SL Problem 3. Land for landfill sites are becoming scarce in most of the developing countries due to increase in land price and environmental regulations. Co-benefits Co-Benefit Indicators Type of Benefit Baseline Data Condition After Net Co-benefit Implementation of the Project Composting can save landfill areas as well as land filling cost for the local governments. Amount of waste diverted. Cost saved for the municipality from disposal of waste. Public In the baseline scenario, no waste is diverted towards composting. city spends Taka 600/ton for transportation of waste and Taka 300/ton for landfilling of waste. 1. 1 cubic meter of landfill area per ton of organic waste composted. USD 11. 68/ton (transportation and landfilling cost).

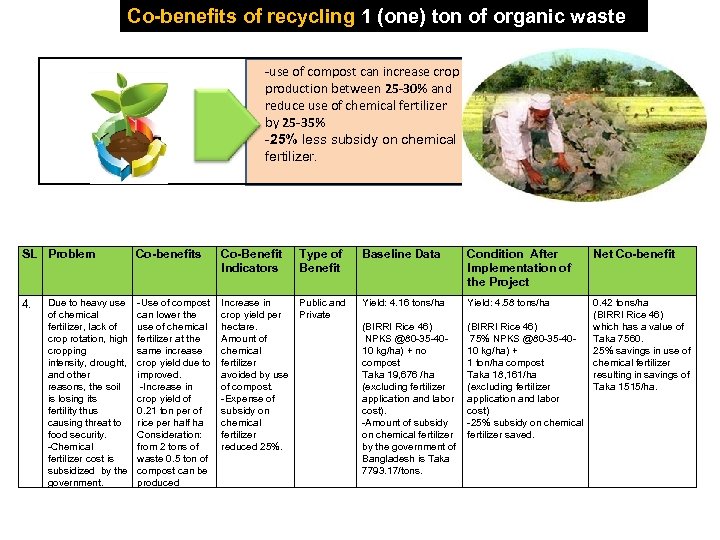

Co-benefits of recycling 1 (one) ton of organic waste -use of compost can increase crop production between 25 -30% and reduce use of chemical fertilizer by 25 -35% -25% less subsidy on chemical fertilizer. SL Problem 4. Due to heavy use of chemical fertilizer, lack of crop rotation, high cropping intensity, drought, and other reasons, the soil is losing its fertility thus causing threat to food security. -Chemical fertilizer cost is subsidized by the government. Co-benefits Co-Benefit Indicators Type of Benefit -Use of compost can lower the use of chemical fertilizer at the same increase crop yield due to improved. -Increase in crop yield of 0. 21 ton per of rice per half ha Consideration: from 2 tons of waste 0. 5 ton of compost can be produced Increase in Public and crop yield per Private hectare. Amount of chemical fertilizer avoided by use of compost. -Expense of subsidy on chemical fertilizer reduced 25%. Baseline Data Condition After Implementation of the Project Net Co-benefit Yield: 4. 16 tons/ha Yield: 4. 58 tons/ha (BIRRI Rice 46) NPKS @80 -35 -4010 kg/ha) + no compost Taka 19, 676 /ha (excluding fertilizer application and labor cost). -Amount of subsidy on chemical fertilizer by the government of Bangladesh is Taka 7793. 17/tons. (BIRRI Rice 46) 75% NPKS @80 -35 -4010 kg/ha) + 1 ton/ha compost Taka 18, 161/ha (excluding fertilizer application and labor cost) -25% subsidy on chemical fertilizer saved. 0. 42 tons/ha (BIRRI Rice 46) which has a value of Taka 7560. 25% savings in use of chemical fertilizer resulting in savings of Taka 1515/ha.

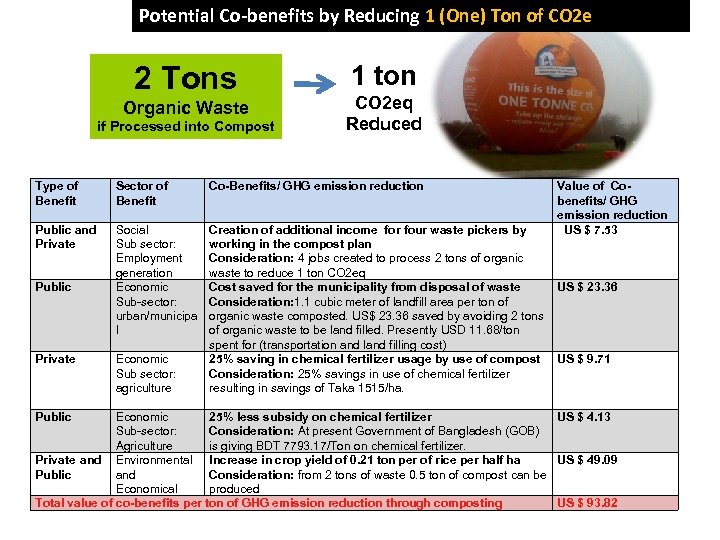

Potential Co-benefits by Reducing 1 (One) Ton of CO 2 e 2 Tons Organic Waste if Processed into Compost 1 ton CO 2 eq Reduced Type of Benefit Sector of Benefit Co-Benefits/ GHG emission reduction Public and Private Social Sub sector: Employment generation Economic Sub-sector: urban/municipa l Creation of additional income for four waste pickers by working in the compost plan Consideration: 4 jobs created to process 2 tons of organic waste to reduce 1 ton CO 2 eq Cost saved for the municipality from disposal of waste US $ 23. 36 Consideration: 1. 1 cubic meter of landfill area per ton of organic waste composted. US$ 23. 36 saved by avoiding 2 tons of organic waste to be land filled. Presently USD 11. 68/ton spent for (transportation and land filling cost) 25% saving in chemical fertilizer usage by use of compost US $ 9. 71 Consideration: 25% savings in use of chemical fertilizer resulting in savings of Taka 1515/ha. Public Private Public Economic Sub sector: agriculture Value of Cobenefits/ GHG emission reduction US $ 7. 53 Economic 25% less subsidy on chemical fertilizer US $ 4. 13 Sub-sector: Consideration: At present Government of Bangladesh (GOB) Agriculture is giving BDT 7793. 17/Ton on chemical fertilizer. Private and Environmental Increase in crop yield of 0. 21 ton per of rice per half ha US $ 49. 09 Public and Consideration: from 2 tons of waste 0. 5 ton of compost can be Economical produced Total value of co-benefits per ton of GHG emission reduction through composting US $ 93. 82

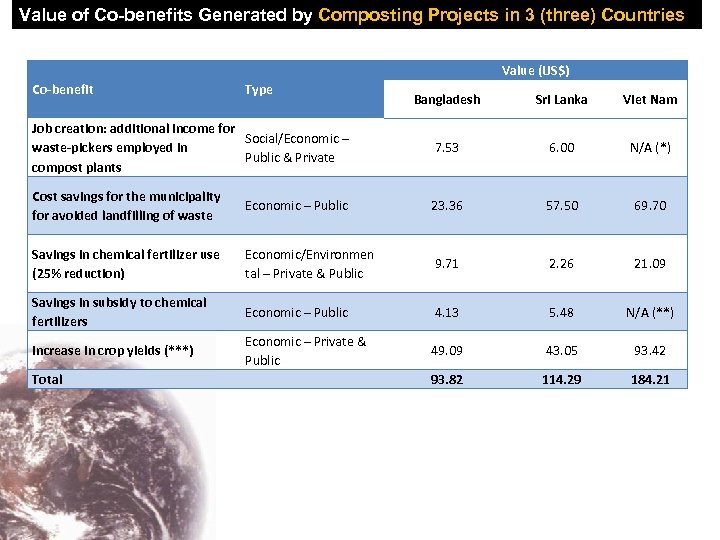

Value of Co-benefits Generated by Composting Projects in 3 (three) Countries Value (US$) Co-benefit Type Bangladesh Sri Lanka Viet Nam Job creation: additional income for Social/Economic – waste-pickers employed in Public & Private compost plants 7. 53 6. 00 N/A (*) Cost savings for the municipality for avoided landfilling of waste Economic – Public 23. 36 57. 50 69. 70 Savings in chemical fertilizer use (25% reduction) Economic/Environmen tal – Private & Public 9. 71 2. 26 21. 09 Savings in subsidy to chemical fertilizers Economic – Public 4. 13 5. 48 N/A (**) Increase in crop yields (***) Economic – Private & Public 49. 09 43. 05 93. 42 93. 82 114. 29 184. 21 Total

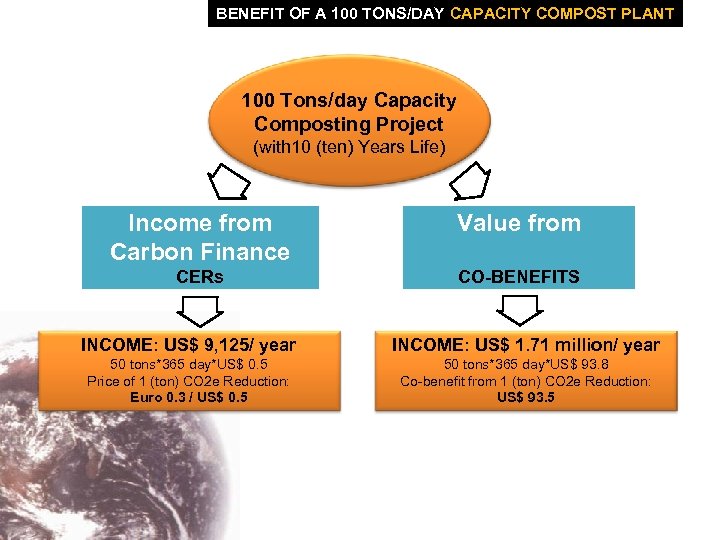

BENEFIT OF A 100 TONS/DAY CAPACITY COMPOST PLANT 100 Tons/day Capacity Composting Project (with 10 (ten) Years Life) Income from Carbon Finance Value from CERs CO-BENEFITS INCOME: US$ 9, 125/ year INCOME: US$ 1. 71 million/ year 50 tons*365 day*US$ 0. 5 50 tons*365 day*US$ 93. 8 Co-benefit from 1 (ton) CO 2 e Reduction: US$ 93. 5 Price of 1 (ton) CO 2 e Reduction: Euro 0. 3 / US$ 0. 5

Mitigation-Adaptation Loop Mitigation Ad ap ta tio n Co-benefits

Way Forward ü Clear cut policy to create conducive environment for investment. ü Inter-ministerial co-ordination essential for easy implementation of projects with priority basis. ü Incentives Required: tipping fees/ free delivery of waste to recycling facility, feed-in tariff, low interest rate/ soft loan, tax holiday, land etc. ü Capacity building training programs: for monitoring of the projects especially MRVs ü Standardization of technology is important by the Govt.

Conclusion Co-benefits are key for NAMA: – Conception and design – identification & selection, and – implementation – This was successfully demonstrated for the waste in Bangladesh: • The NAMA Waste in Bangladesh is now ready to move forward to next phases – Bangladesh case study should be replicated elsewhere: • UN ESCAP is replicating similar projects in Viet Nam and Sri Lanka – The conceptual approach for the valuation and monetization of co-benefits should also be tried out in other sectors and initiatives: • South Pole is developing a NAMA in the cement sector where co-benefits play a key role • Similar applications could be carried out for other NAMA ideas with a high “no regrets” angle i. e. NAMA Forestry, NAMA Agriculture (climate-smart agriculture, sustainable livestock management, etc. ), NAMA RE (Fi. T NAMA, rural electrification NAMA).

THANK YOU

4c8776982ac3d06aac8ed3cbc7de66c4.ppt