fafb6fccdbfed57ca1fcd16f8abf0673.ppt

- Количество слайдов: 19

Quality Process in Datamatics Corporate Quality

Quality Process in Datamatics Corporate Quality

Agenda Quality Policy Corporate Quality functions Highlights of QMS How we work? 2

Agenda Quality Policy Corporate Quality functions Highlights of QMS How we work? 2

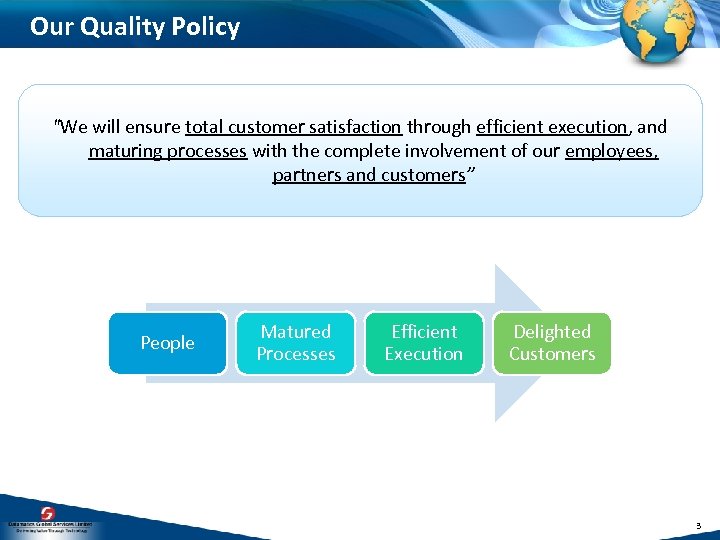

Our Quality Policy "We will ensure total customer satisfaction through efficient execution, and maturing processes with the complete involvement of our employees, partners and customers” People Matured Processes Efficient Execution Delighted Customers 3

Our Quality Policy "We will ensure total customer satisfaction through efficient execution, and maturing processes with the complete involvement of our employees, partners and customers” People Matured Processes Efficient Execution Delighted Customers 3

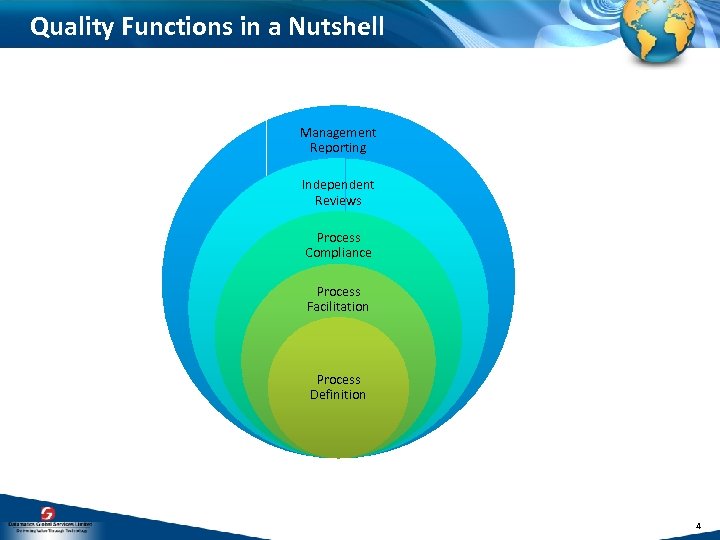

Quality Functions in a Nutshell Management Reporting Independent Reviews Process Compliance Process Facilitation Process Definition 4

Quality Functions in a Nutshell Management Reporting Independent Reviews Process Compliance Process Facilitation Process Definition 4

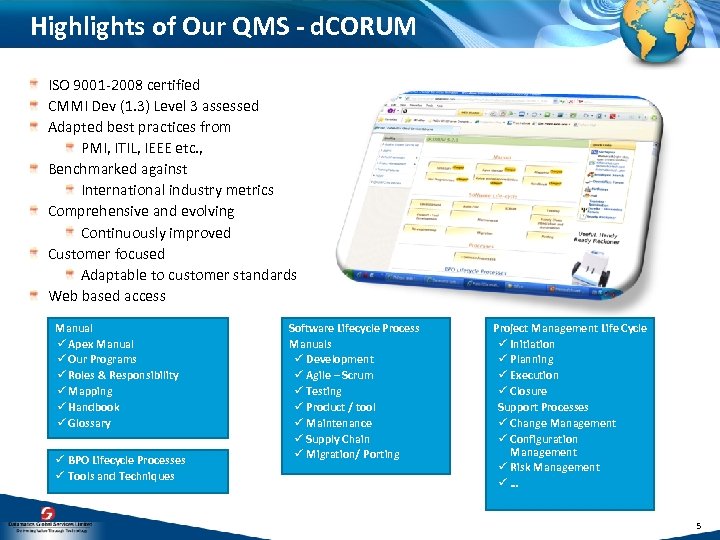

Highlights of Our QMS - d. CORUM ISO 9001 -2008 certified CMMI Dev (1. 3) Level 3 assessed Adapted best practices from PMI, ITIL, IEEE etc. , Benchmarked against International industry metrics Comprehensive and evolving Continuously improved Customer focused Adaptable to customer standards Web based access Manual ü Apex Manual ü Our Programs ü Roles & Responsibility ü Mapping ü Handbook ü Glossary ü BPO Lifecycle Processes ü Tools and Techniques Software Lifecycle Process Manuals ü Development ü Agile – Scrum ü Testing ü Product / tool ü Maintenance ü Supply Chain ü Migration/ Porting Project Management Life Cycle ü Initiation ü Planning ü Execution ü Closure Support Processes ü Change Management ü Configuration Management ü Risk Management ü… 5

Highlights of Our QMS - d. CORUM ISO 9001 -2008 certified CMMI Dev (1. 3) Level 3 assessed Adapted best practices from PMI, ITIL, IEEE etc. , Benchmarked against International industry metrics Comprehensive and evolving Continuously improved Customer focused Adaptable to customer standards Web based access Manual ü Apex Manual ü Our Programs ü Roles & Responsibility ü Mapping ü Handbook ü Glossary ü BPO Lifecycle Processes ü Tools and Techniques Software Lifecycle Process Manuals ü Development ü Agile – Scrum ü Testing ü Product / tool ü Maintenance ü Supply Chain ü Migration/ Porting Project Management Life Cycle ü Initiation ü Planning ü Execution ü Closure Support Processes ü Change Management ü Configuration Management ü Risk Management ü… 5

Information Security Management System (ISO 27001) highlights: Robust Access Control Policy to prevent any unauthorized Data Leakage. Robust Password Policy Clear Desk and Clear Screen Policy. Robust Network Access Control Policy. Email Policy Regular and Effective Information Systems Audits. Compliant to SSAE 16 requirements Compliant to HIPAA requirements 8

Information Security Management System (ISO 27001) highlights: Robust Access Control Policy to prevent any unauthorized Data Leakage. Robust Password Policy Clear Desk and Clear Screen Policy. Robust Network Access Control Policy. Email Policy Regular and Effective Information Systems Audits. Compliant to SSAE 16 requirements Compliant to HIPAA requirements 8

Certifications 9

Certifications 9

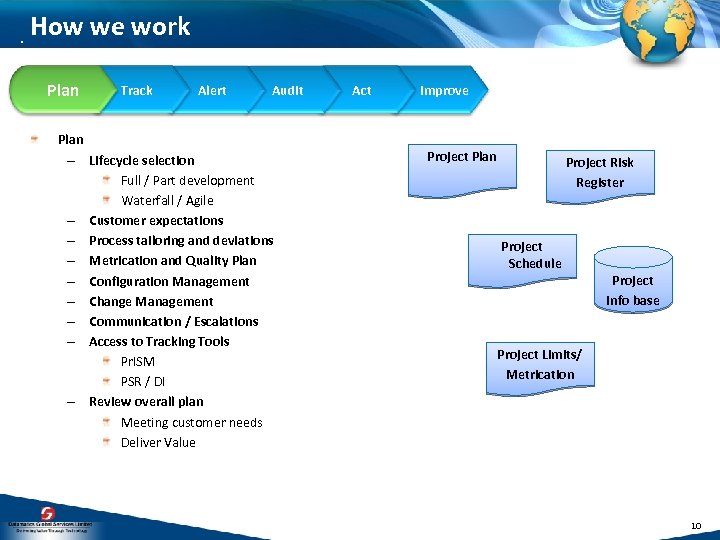

. How Plan we work Track Alert Audit Plan – Lifecycle selection Full / Part development Waterfall / Agile – Customer expectations – Process tailoring and deviations – Metrication and Quality Plan – Configuration Management – Change Management – Communication / Escalations – Access to Tracking Tools Pr. ISM PSR / DI – Review overall plan Meeting customer needs Deliver Value Act Improve Project Plan Project Risk Register Project Schedule Project Info base Project Limits/ Metrication 10

. How Plan we work Track Alert Audit Plan – Lifecycle selection Full / Part development Waterfall / Agile – Customer expectations – Process tailoring and deviations – Metrication and Quality Plan – Configuration Management – Change Management – Communication / Escalations – Access to Tracking Tools Pr. ISM PSR / DI – Review overall plan Meeting customer needs Deliver Value Act Improve Project Plan Project Risk Register Project Schedule Project Info base Project Limits/ Metrication 10

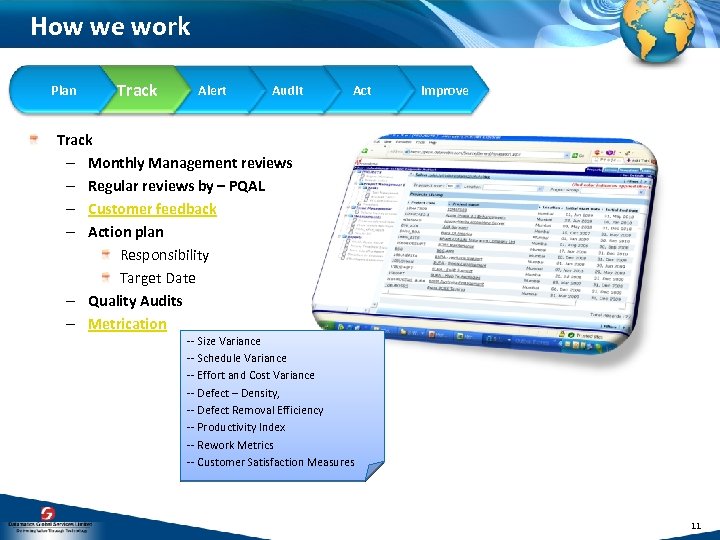

How we work Plan Track Alert Audit Act Improve Track – Monthly Management reviews – Regular reviews by – PQAL – Customer feedback – Action plan Responsibility Target Date – Quality Audits – Metrication -- Size Variance -- Schedule Variance -- Effort and Cost Variance -- Defect – Density, -- Defect Removal Efficiency -- Productivity Index -- Rework Metrics -- Customer Satisfaction Measures 11

How we work Plan Track Alert Audit Act Improve Track – Monthly Management reviews – Regular reviews by – PQAL – Customer feedback – Action plan Responsibility Target Date – Quality Audits – Metrication -- Size Variance -- Schedule Variance -- Effort and Cost Variance -- Defect – Density, -- Defect Removal Efficiency -- Productivity Index -- Rework Metrics -- Customer Satisfaction Measures 11

How we work Plan Track Alert – Customer feedback Causal Analysis Action, Closure – Fortnightly RAG report – Escalations By PQAL / CQ Internal Audits PQAL Audits Third party Audits Audit Act Improve RAG Report Customer feedback Audit Reports 12

How we work Plan Track Alert – Customer feedback Causal Analysis Action, Closure – Fortnightly RAG report – Escalations By PQAL / CQ Internal Audits PQAL Audits Third party Audits Audit Act Improve RAG Report Customer feedback Audit Reports 12

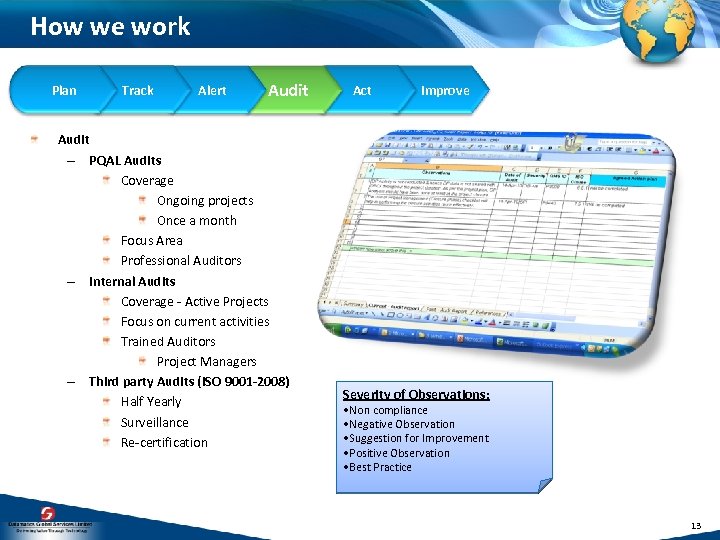

How we work Plan Track Alert Audit – PQAL Audits Coverage Ongoing projects Once a month Focus Area Professional Auditors – Internal Audits Coverage - Active Projects Focus on current activities Trained Auditors Project Managers – Third party Audits (ISO 9001 -2008) Half Yearly Surveillance Re-certification Act Improve Severity of Observations: • Non compliance • Negative Observation • Suggestion for Improvement • Positive Observation • Best Practice 13

How we work Plan Track Alert Audit – PQAL Audits Coverage Ongoing projects Once a month Focus Area Professional Auditors – Internal Audits Coverage - Active Projects Focus on current activities Trained Auditors Project Managers – Third party Audits (ISO 9001 -2008) Half Yearly Surveillance Re-certification Act Improve Severity of Observations: • Non compliance • Negative Observation • Suggestion for Improvement • Positive Observation • Best Practice 13

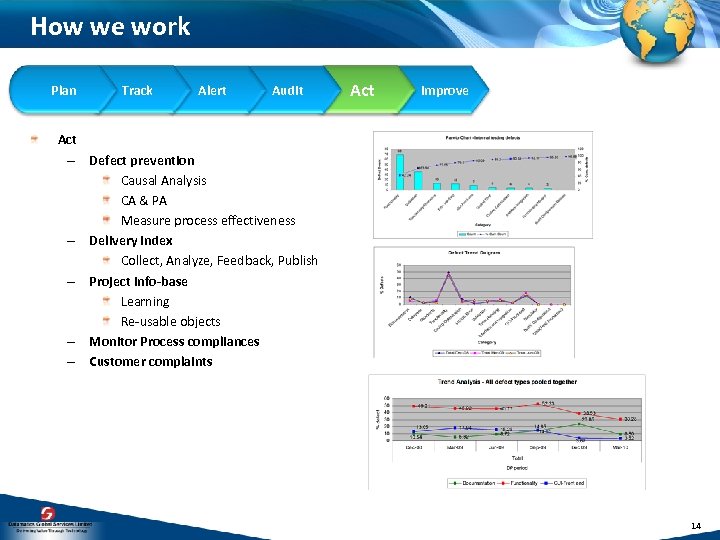

How we work Plan Track Alert Audit Act Improve Act – Defect prevention Causal Analysis CA & PA Measure process effectiveness – Delivery Index Collect, Analyze, Feedback, Publish – Project Info-base Learning Re-usable objects – Monitor Process compliances – Customer complaints 14

How we work Plan Track Alert Audit Act Improve Act – Defect prevention Causal Analysis CA & PA Measure process effectiveness – Delivery Index Collect, Analyze, Feedback, Publish – Project Info-base Learning Re-usable objects – Monitor Process compliances – Customer complaints 14

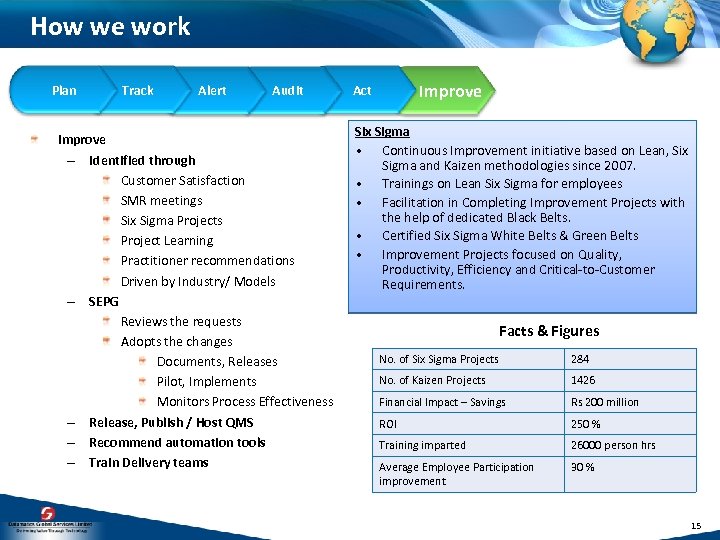

How we work Plan Track Alert Audit Improve – Identified through Customer Satisfaction SMR meetings Six Sigma Projects Project Learning Practitioner recommendations Driven by Industry/ Models – SEPG Reviews the requests Adopts the changes Documents, Releases Pilot, Implements Monitors Process Effectiveness – Release, Publish / Host QMS – Recommend automation tools – Train Delivery teams Improve Act Six Sigma • Continuous Improvement initiative based on Lean, Six Sigma and Kaizen methodologies since 2007. • Trainings on Lean Six Sigma for employees • Facilitation in Completing Improvement Projects with the help of dedicated Black Belts. • Certified Six Sigma White Belts & Green Belts • Improvement Projects focused on Quality, Productivity, Efficiency and Critical-to-Customer Requirements. Facts & Figures No. of Six Sigma Projects 284 No. of Kaizen Projects 1426 Financial Impact – Savings Rs 200 million ROI 250 % Training imparted 26000 person hrs Average Employee Participation improvement 30 % 15

How we work Plan Track Alert Audit Improve – Identified through Customer Satisfaction SMR meetings Six Sigma Projects Project Learning Practitioner recommendations Driven by Industry/ Models – SEPG Reviews the requests Adopts the changes Documents, Releases Pilot, Implements Monitors Process Effectiveness – Release, Publish / Host QMS – Recommend automation tools – Train Delivery teams Improve Act Six Sigma • Continuous Improvement initiative based on Lean, Six Sigma and Kaizen methodologies since 2007. • Trainings on Lean Six Sigma for employees • Facilitation in Completing Improvement Projects with the help of dedicated Black Belts. • Certified Six Sigma White Belts & Green Belts • Improvement Projects focused on Quality, Productivity, Efficiency and Critical-to-Customer Requirements. Facts & Figures No. of Six Sigma Projects 284 No. of Kaizen Projects 1426 Financial Impact – Savings Rs 200 million ROI 250 % Training imparted 26000 person hrs Average Employee Participation improvement 30 % 15

Questions? 16

Questions? 16

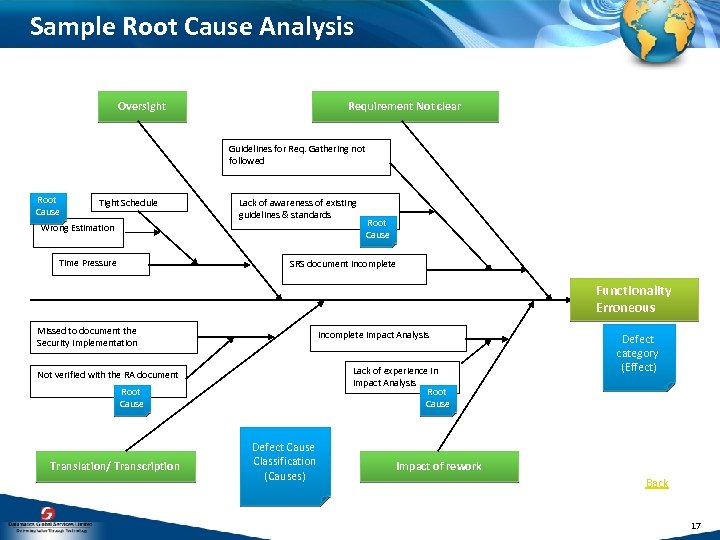

Sample Root Cause Analysis Oversight Requirement Not clear Guidelines for Req. Gathering not followed Root Cause Tight Schedule Lack of awareness of existing guidelines & standards Wrong Estimation Time Pressure Root Cause SRS document incomplete Functionality Erroneous Missed to document the Security Implementation Incomplete Impact Analysis Lack of experience in Impact Analysis Root Cause Not verified with the RA document Root Cause Translation/ Transcription Defect Cause Classification (Causes) Defect category (Effect) Impact of rework Back 17

Sample Root Cause Analysis Oversight Requirement Not clear Guidelines for Req. Gathering not followed Root Cause Tight Schedule Lack of awareness of existing guidelines & standards Wrong Estimation Time Pressure Root Cause SRS document incomplete Functionality Erroneous Missed to document the Security Implementation Incomplete Impact Analysis Lack of experience in Impact Analysis Root Cause Not verified with the RA document Root Cause Translation/ Transcription Defect Cause Classification (Causes) Defect category (Effect) Impact of rework Back 17

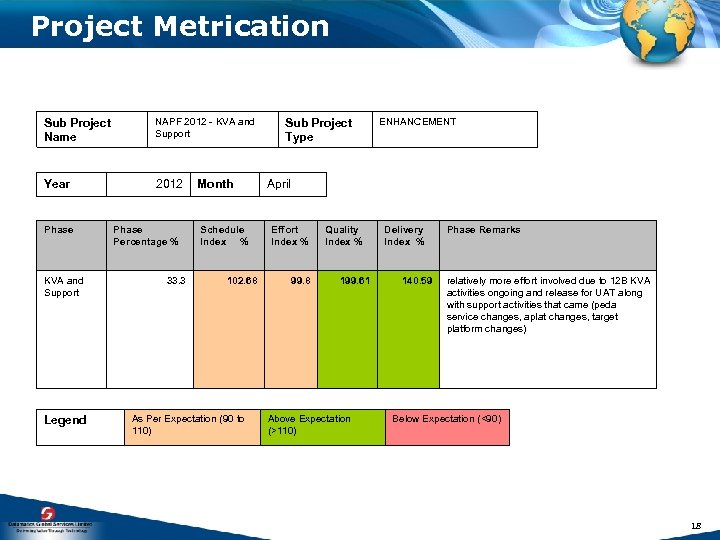

Project Metrication Sub Project Name NAPF 2012 - KVA and Support Year 2012 Phase KVA and Support Legend Phase Percentage % 33. 3 Month Schedule Index % 102. 68 As Per Expectation (90 to 110) Sub Project Type ENHANCEMENT April Effort Index % 99. 8 Quality Index % 199. 61 Above Expectation (>110) Delivery Index % 140. 59 Phase Remarks relatively more effort involved due to 12 B KVA activities ongoing and release for UAT along with support activities that came (peda service changes, aplat changes, target platform changes) Below Expectation (<90) 18

Project Metrication Sub Project Name NAPF 2012 - KVA and Support Year 2012 Phase KVA and Support Legend Phase Percentage % 33. 3 Month Schedule Index % 102. 68 As Per Expectation (90 to 110) Sub Project Type ENHANCEMENT April Effort Index % 99. 8 Quality Index % 199. 61 Above Expectation (>110) Delivery Index % 140. 59 Phase Remarks relatively more effort involved due to 12 B KVA activities ongoing and release for UAT along with support activities that came (peda service changes, aplat changes, target platform changes) Below Expectation (<90) 18

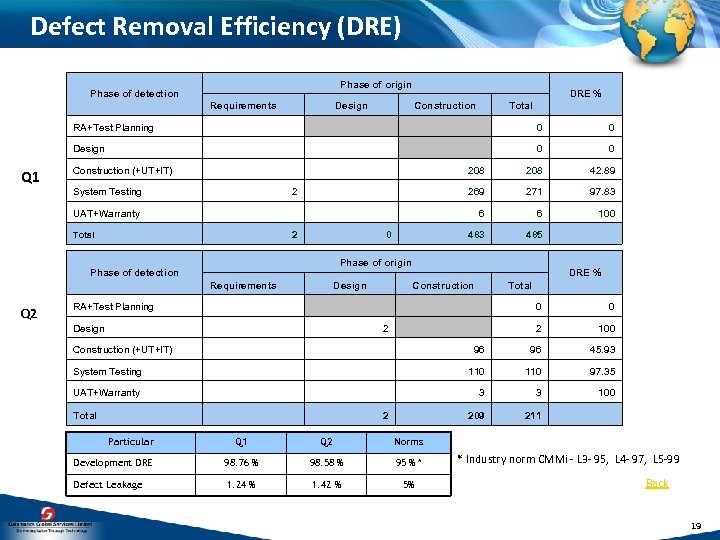

Defect Removal Efficiency (DRE) Phase of origin Phase of detection Requirements Design DRE % Construction Total RA+Test Planning 0 0 Design Q 1 0 0 Construction (+UT+IT) 208 42. 89 269 271 97. 83 6 6 100 483 485 System Testing UAT+Warranty 2 2 Total 0 Phase of origin Phase of detection Requirements Q 2 RA+Test Planning Design Construction (+UT+IT) Design DRE % Construction 0 0 2 100 96 45. 93 110 97. 35 96 3 3 100 209 211 Total 2 Particular Total 2 System Testing UAT+Warranty Q 1 Q 2 Norms Development DRE 98. 76 % 98. 58 % 95 % * Defect Leakage 1. 24 % 1. 42 % 5% * Industry norm CMMi - L 3 - 95, L 4 - 97, L 5 -99 Back 19

Defect Removal Efficiency (DRE) Phase of origin Phase of detection Requirements Design DRE % Construction Total RA+Test Planning 0 0 Design Q 1 0 0 Construction (+UT+IT) 208 42. 89 269 271 97. 83 6 6 100 483 485 System Testing UAT+Warranty 2 2 Total 0 Phase of origin Phase of detection Requirements Q 2 RA+Test Planning Design Construction (+UT+IT) Design DRE % Construction 0 0 2 100 96 45. 93 110 97. 35 96 3 3 100 209 211 Total 2 Particular Total 2 System Testing UAT+Warranty Q 1 Q 2 Norms Development DRE 98. 76 % 98. 58 % 95 % * Defect Leakage 1. 24 % 1. 42 % 5% * Industry norm CMMi - L 3 - 95, L 4 - 97, L 5 -99 Back 19

Customer feedback 20

Customer feedback 20

Customer feedback Datamatics is extremely responsive and accommodating to ad-hoc requests. Very good company and we appreciate all of your help. Datamatics has been a great relationship for us. I would recommend Datamatics. We are very happy with the service we are getting. Datamatics is a great company to work with We continue to be impressed with your work and look forward to working with you into the future. Back 21

Customer feedback Datamatics is extremely responsive and accommodating to ad-hoc requests. Very good company and we appreciate all of your help. Datamatics has been a great relationship for us. I would recommend Datamatics. We are very happy with the service we are getting. Datamatics is a great company to work with We continue to be impressed with your work and look forward to working with you into the future. Back 21