b0da0938b30206edcda1fe2c6761b15c.ppt

- Количество слайдов: 78

Quality Improvement Principles, Methods and Tools Marlene “Marni” Mason MCPP Healthcare Consulting

Quality Improvement Principles, Methods and Tools Marlene “Marni” Mason MCPP Healthcare Consulting

Marni Mason BSN, MBA n Thirty+ years in healthcare as clinician, manager and consultant n n n Primary & specialty care clinic nurse and nursing director – 15 years Consultant in healthcare performance measurement and improvement – 18 years Public health performance management – since 2000 Surveyor for NCQA (10 years) and Senior Examiner for state Baldrige Quality Award (late 1990 s) Consultant for PHAB Standards Development (20082009) 2

Marni Mason BSN, MBA n Thirty+ years in healthcare as clinician, manager and consultant n n n Primary & specialty care clinic nurse and nursing director – 15 years Consultant in healthcare performance measurement and improvement – 18 years Public health performance management – since 2000 Surveyor for NCQA (10 years) and Senior Examiner for state Baldrige Quality Award (late 1990 s) Consultant for PHAB Standards Development (20082009) 2

Learning Objectives In today’s learning session, the participants will develop a better understanding of: n. Principles of Quality Improvement n. Selected Quality Improvement Methods n. Selected Quality Planning Tools n. Learn about Rapid Cycle Improvement (RCI) And n. Start development of QI team AIM statement 3

Learning Objectives In today’s learning session, the participants will develop a better understanding of: n. Principles of Quality Improvement n. Selected Quality Improvement Methods n. Selected Quality Planning Tools n. Learn about Rapid Cycle Improvement (RCI) And n. Start development of QI team AIM statement 3

Collaborative with a Capital “C” Systems are perfectly designed to produce the results they achieve 4

Collaborative with a Capital “C” Systems are perfectly designed to produce the results they achieve 4

IHI’s* Breakthrough Series n n n Also known as the Collaborative Method It is an improvement method that relies on spread and adaptation of existing knowledge to multiple settings to accomplish a common aim Methodology to accomplish organizational system change *Institute for Healthcare Improvement www. ihi. org 5

IHI’s* Breakthrough Series n n n Also known as the Collaborative Method It is an improvement method that relies on spread and adaptation of existing knowledge to multiple settings to accomplish a common aim Methodology to accomplish organizational system change *Institute for Healthcare Improvement www. ihi. org 5

The Advantage of a Learning Collaborative for Improvement n n Learning collaborative: a group of multidisciplinary teams from multiple organizations which come together over the course of a year in structured meetings and phone contacts to accomplish specific learning objectives. National experience demonstrates significant boost in pace and level of achievement of outcomes by sharing lessons learned. 6

The Advantage of a Learning Collaborative for Improvement n n Learning collaborative: a group of multidisciplinary teams from multiple organizations which come together over the course of a year in structured meetings and phone contacts to accomplish specific learning objectives. National experience demonstrates significant boost in pace and level of achievement of outcomes by sharing lessons learned. 6

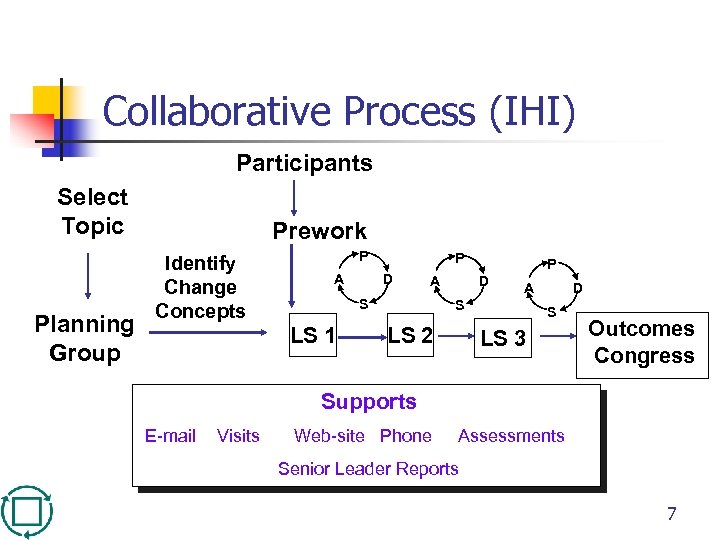

Collaborative Process (IHI) Participants Select Topic Planning Group Prework Identify Change Concepts P A P D A S LS 1 P D A S LS 2 D S LS 3 Outcomes Congress Supports E-mail Visits Web-site Phone Assessments Senior Leader Reports 7

Collaborative Process (IHI) Participants Select Topic Planning Group Prework Identify Change Concepts P A P D A S LS 1 P D A S LS 2 D S LS 3 Outcomes Congress Supports E-mail Visits Web-site Phone Assessments Senior Leader Reports 7

Characteristics of a Collaborative n n n n Team approach Performance measures Teams from multiple organizations One for all, all for one Promotes a culture of change Standardizes practice Sustainable change 8

Characteristics of a Collaborative n n n n Team approach Performance measures Teams from multiple organizations One for all, all for one Promotes a culture of change Standardizes practice Sustainable change 8

MLC-3 Collaborative Targets n In Illinois, participation in the MLC-3 Learning Collaborative is focused on improvement in two target areas for MLC-3: n n Community Health Improvement Plans Chronic Disease Prevention-Obesity/Physical Activity (reduce preventable risk factors that predispose to chronic disease) 9

MLC-3 Collaborative Targets n In Illinois, participation in the MLC-3 Learning Collaborative is focused on improvement in two target areas for MLC-3: n n Community Health Improvement Plans Chronic Disease Prevention-Obesity/Physical Activity (reduce preventable risk factors that predispose to chronic disease) 9

MLC-3 Collaborative Approach n All sites receive training in: n n n Quality Improvement Methods & Tools Data Analysis Tools Rapid Cycle Improvement Method Site-based teams develop implementation plan for improvement Series of web-based phone sessions with coaching from consultant 10

MLC-3 Collaborative Approach n All sites receive training in: n n n Quality Improvement Methods & Tools Data Analysis Tools Rapid Cycle Improvement Method Site-based teams develop implementation plan for improvement Series of web-based phone sessions with coaching from consultant 10

Principles of Quality Improvement “Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction and skillful execution; it represents the wise choice of many alternatives. ” William Foster (many variations attributed to others) 11

Principles of Quality Improvement “Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction and skillful execution; it represents the wise choice of many alternatives. ” William Foster (many variations attributed to others) 11

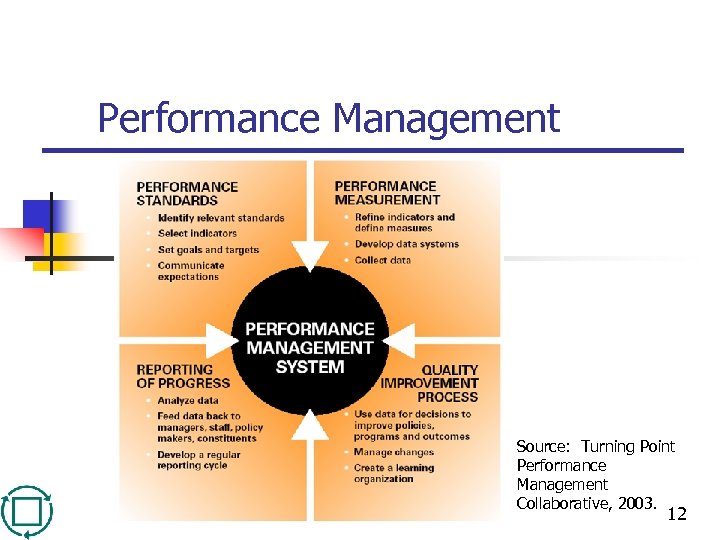

Performance Management Source: Turning Point Performance Management Collaborative, 2003. 12

Performance Management Source: Turning Point Performance Management Collaborative, 2003. 12

The Quality Environment n Do you have an organization-wide commitment to assessing and continuously improving quality over time? n n n Are your system decisions based on data? Do you know if your agency is achieving its goals? Do you use data to decide on improvement initiatives and to know if the improvements are successful? 13

The Quality Environment n Do you have an organization-wide commitment to assessing and continuously improving quality over time? n n n Are your system decisions based on data? Do you know if your agency is achieving its goals? Do you use data to decide on improvement initiatives and to know if the improvements are successful? 13

Change vs. Improvement n W. Edwards Deming stated “Of all changes I’ve observed, about 5% were improvements, the rest, at best, were illusions of progress. ” n We must become masters of improvement n We must learn how to improve rapidly n We must learn to discern the difference between improvement and illusions of progress 14

Change vs. Improvement n W. Edwards Deming stated “Of all changes I’ve observed, about 5% were improvements, the rest, at best, were illusions of progress. ” n We must become masters of improvement n We must learn how to improve rapidly n We must learn to discern the difference between improvement and illusions of progress 14

Principles of Quality Management 1. 2. 3. 4. 5. 6. 7. Know your stakeholders and what they need Focus on processes Use data for making decisions Understand variation in processes Use teamwork to improve work Make quality improvement continuous Demonstrate leadership commitment 15

Principles of Quality Management 1. 2. 3. 4. 5. 6. 7. Know your stakeholders and what they need Focus on processes Use data for making decisions Understand variation in processes Use teamwork to improve work Make quality improvement continuous Demonstrate leadership commitment 15

1. Know Your Stakeholders n n Identify stakeholders and their needs Set goals based on stakeholder needs Monitor performance and satisfaction to target performance improvement opportunities Improve or redesign how work is done 16

1. Know Your Stakeholders n n Identify stakeholders and their needs Set goals based on stakeholder needs Monitor performance and satisfaction to target performance improvement opportunities Improve or redesign how work is done 16

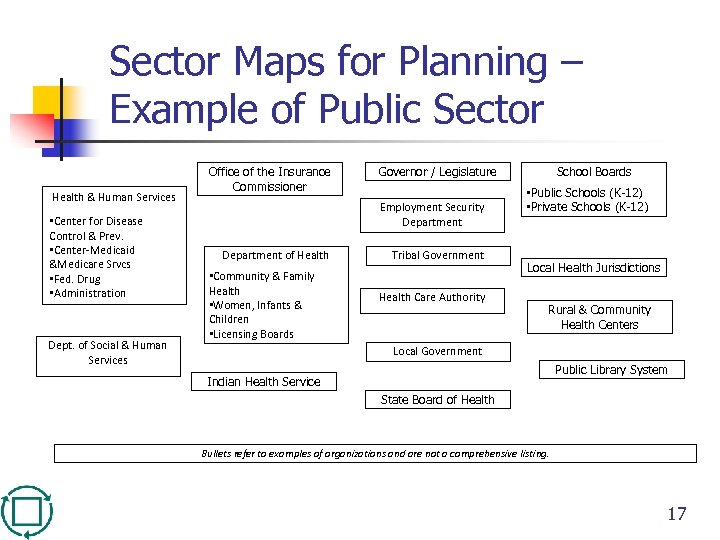

Sector Maps for Planning – Example of Public Sector Health & Human Services • Center for Disease Control & Prev. • Center-Medicaid &Medicare Srvcs • Fed. Drug • Administration Dept. of Social & Human Services Office of the Insurance Commissioner Governor / Legislature Employment Security Department of Health • Community & Family Health • Women, Infants & Children • Licensing Boards Tribal Government Health Care Authority School Boards • Public Schools (K-12) • Private Schools (K-12) Local Health Jurisdictions Rural & Community Health Centers Local Government Public Library System Indian Health Service State Board of Health Bullets refer to examples of organizations and are not a comprehensive listing. 17

Sector Maps for Planning – Example of Public Sector Health & Human Services • Center for Disease Control & Prev. • Center-Medicaid &Medicare Srvcs • Fed. Drug • Administration Dept. of Social & Human Services Office of the Insurance Commissioner Governor / Legislature Employment Security Department of Health • Community & Family Health • Women, Infants & Children • Licensing Boards Tribal Government Health Care Authority School Boards • Public Schools (K-12) • Private Schools (K-12) Local Health Jurisdictions Rural & Community Health Centers Local Government Public Library System Indian Health Service State Board of Health Bullets refer to examples of organizations and are not a comprehensive listing. 17

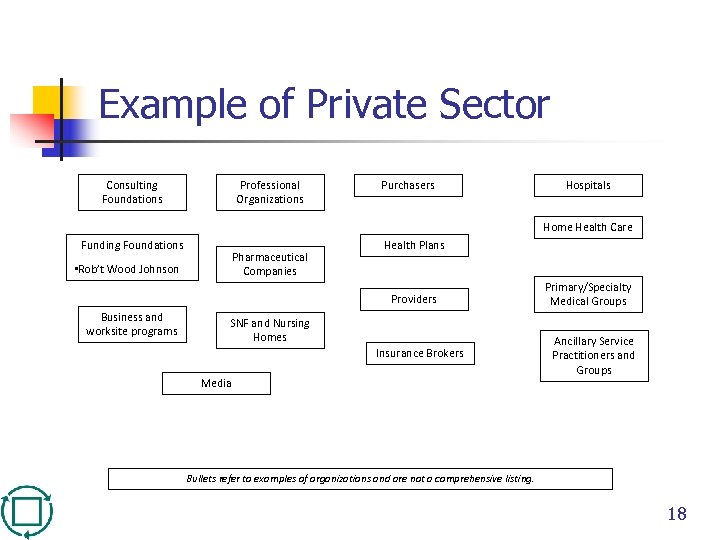

Example of Private Sector Consulting Foundations Professional Organizations Purchasers Hospitals Home Health Care Funding Foundations Pharmaceutical Companies • Rob’t Wood Johnson Health Plans Providers Business and worksite programs SNF and Nursing Homes Insurance Brokers Media Primary/Specialty Medical Groups Ancillary Service Practitioners and Groups Bullets refer to examples of organizations and are not a comprehensive listing. 18

Example of Private Sector Consulting Foundations Professional Organizations Purchasers Hospitals Home Health Care Funding Foundations Pharmaceutical Companies • Rob’t Wood Johnson Health Plans Providers Business and worksite programs SNF and Nursing Homes Insurance Brokers Media Primary/Specialty Medical Groups Ancillary Service Practitioners and Groups Bullets refer to examples of organizations and are not a comprehensive listing. 18

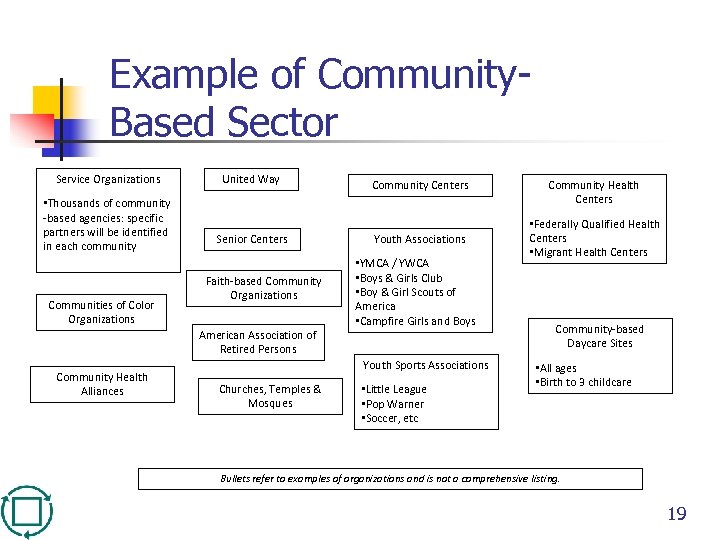

Example of Community. Based Sector Service Organizations • Thousands of community -based agencies: specific partners will be identified in each community Communities of Color Organizations United Way Senior Centers Faith-based Community Organizations American Association of Retired Persons Community Health Alliances Community Centers Youth Associations • YMCA / YWCA • Boys & Girls Club • Boy & Girl Scouts of America • Campfire Girls and Boys Youth Sports Associations Churches, Temples & Mosques • Little League • Pop Warner • Soccer, etc Community Health Centers • Federally Qualified Health Centers • Migrant Health Centers Community-based Daycare Sites • All ages • Birth to 3 childcare Bullets refer to examples of organizations and is not a comprehensive listing. 19

Example of Community. Based Sector Service Organizations • Thousands of community -based agencies: specific partners will be identified in each community Communities of Color Organizations United Way Senior Centers Faith-based Community Organizations American Association of Retired Persons Community Health Alliances Community Centers Youth Associations • YMCA / YWCA • Boys & Girls Club • Boy & Girl Scouts of America • Campfire Girls and Boys Youth Sports Associations Churches, Temples & Mosques • Little League • Pop Warner • Soccer, etc Community Health Centers • Federally Qualified Health Centers • Migrant Health Centers Community-based Daycare Sites • All ages • Birth to 3 childcare Bullets refer to examples of organizations and is not a comprehensive listing. 19

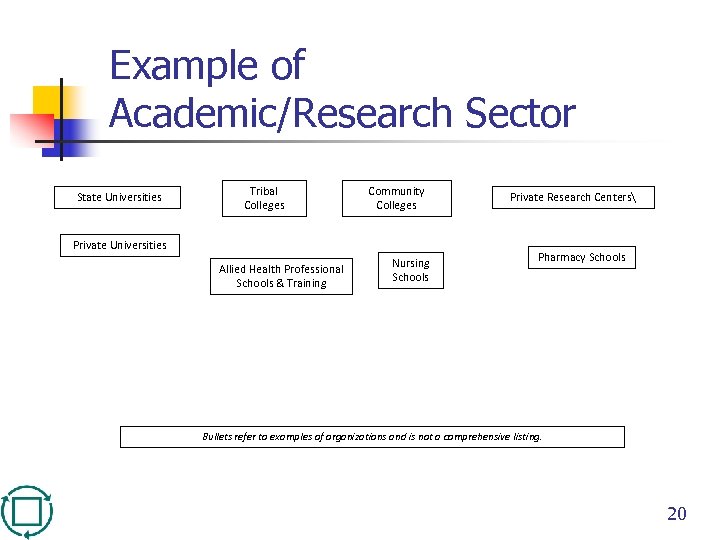

Example of Academic/Research Sector State Universities Tribal Colleges Community Colleges Private Universities Allied Health Professional Schools & Training Nursing Schools Private Research Centers Pharmacy Schools Bullets refer to examples of organizations and is not a comprehensive listing. 20

Example of Academic/Research Sector State Universities Tribal Colleges Community Colleges Private Universities Allied Health Professional Schools & Training Nursing Schools Private Research Centers Pharmacy Schools Bullets refer to examples of organizations and is not a comprehensive listing. 20

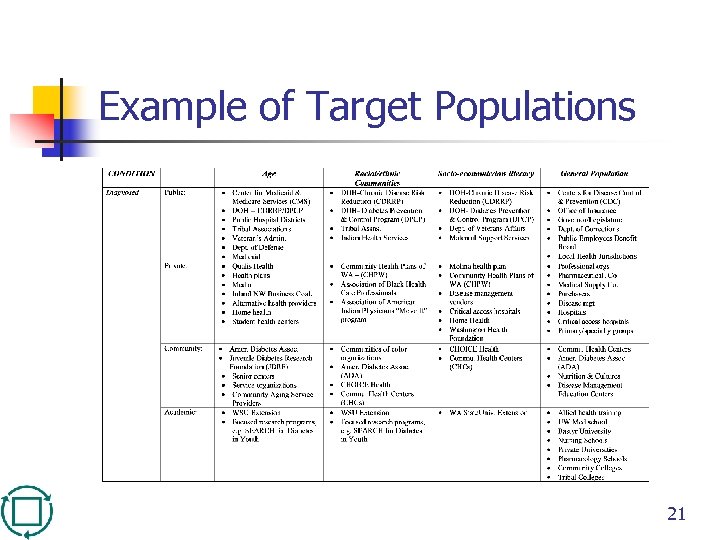

Example of Target Populations 21

Example of Target Populations 21

2. Focus on Processes n n n 85% of poor quality is a result of poor work processes, not of staff doing a bad job Processes often “go wrong” at the point of the “handoff” Attend to improving the overall process, not just one part—some of the most complex processes are the result of creating a “work around” 22

2. Focus on Processes n n n 85% of poor quality is a result of poor work processes, not of staff doing a bad job Processes often “go wrong” at the point of the “handoff” Attend to improving the overall process, not just one part—some of the most complex processes are the result of creating a “work around” 22

Focus on Processes n Advice from NCQA, JCAHO and others— measure processes that are n n High-risk High-volume Problem-prone And Can be tracked and reported as summary or aggregate statistics 23

Focus on Processes n Advice from NCQA, JCAHO and others— measure processes that are n n High-risk High-volume Problem-prone And Can be tracked and reported as summary or aggregate statistics 23

![Develop Process Flow Charts n High level flow charts [6 -12 steps] initially n Develop Process Flow Charts n High level flow charts [6 -12 steps] initially n](https://present5.com/presentation/b0da0938b30206edcda1fe2c6761b15c/image-24.jpg) Develop Process Flow Charts n High level flow charts [6 -12 steps] initially n n Identify customer-supplier relationships More detailed flow charts as project unfolds [client flow, information flow, materials flow, decision making flow] Use for process redesign Use for adapting or adopting best practices 24

Develop Process Flow Charts n High level flow charts [6 -12 steps] initially n n Identify customer-supplier relationships More detailed flow charts as project unfolds [client flow, information flow, materials flow, decision making flow] Use for process redesign Use for adapting or adopting best practices 24

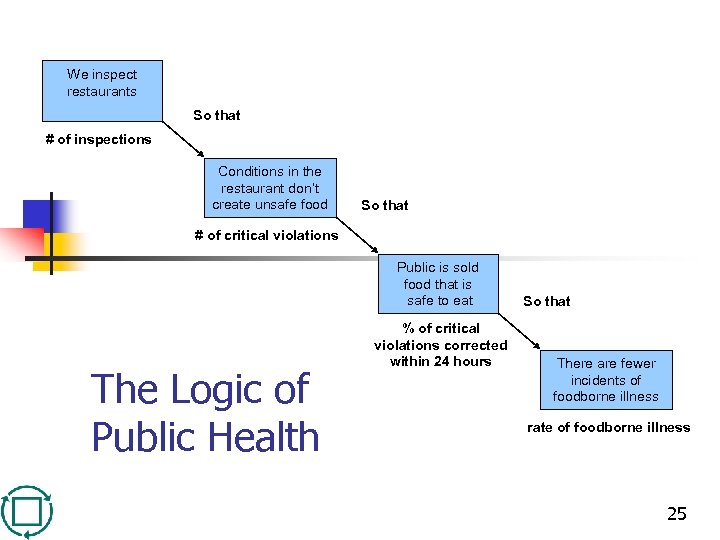

We inspect restaurants So that # of inspections Conditions in the restaurant don’t create unsafe food So that # of critical violations Public is sold food that is safe to eat The Logic of Public Health % of critical violations corrected within 24 hours So that There are fewer incidents of foodborne illness rate of foodborne illness 25

We inspect restaurants So that # of inspections Conditions in the restaurant don’t create unsafe food So that # of critical violations Public is sold food that is safe to eat The Logic of Public Health % of critical violations corrected within 24 hours So that There are fewer incidents of foodborne illness rate of foodborne illness 25

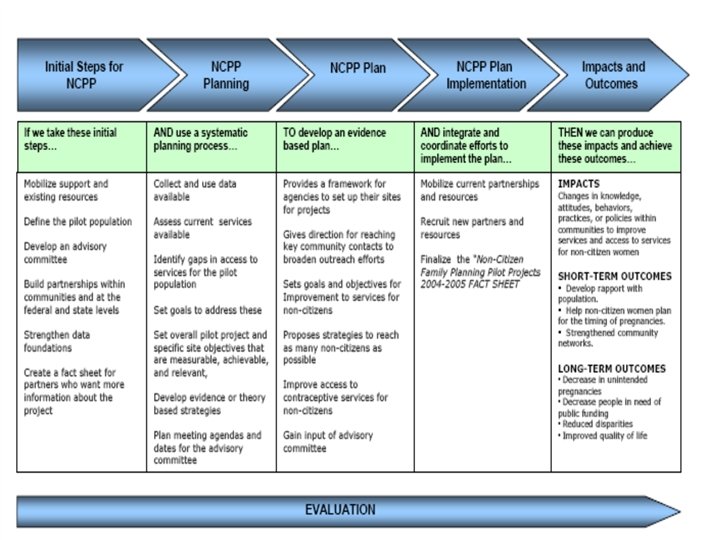

Logic Models (Many Shapes/Sizes) n n n Connect what we do every day to why we do it Show logical links between activities and goals Link our process objectives to our outcome objectives As long as the format is legible, logical, and it works for you, it’s probably fine Boxes and arrows are not required New computer software is not required 26

Logic Models (Many Shapes/Sizes) n n n Connect what we do every day to why we do it Show logical links between activities and goals Link our process objectives to our outcome objectives As long as the format is legible, logical, and it works for you, it’s probably fine Boxes and arrows are not required New computer software is not required 26

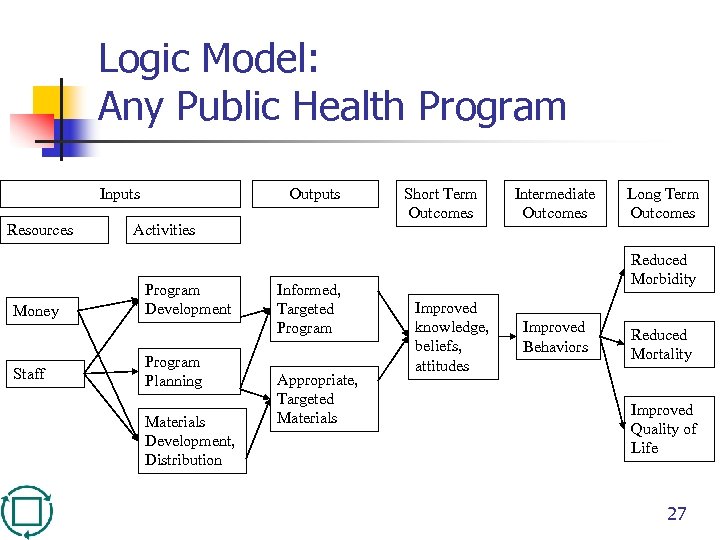

Logic Model: Any Public Health Program Inputs Resources Money Staff Outputs Activities Program Development Program Planning Materials Development, Distribution Informed, Targeted Program Appropriate, Targeted Materials Short Term Outcomes Intermediate Outcomes Long Term Outcomes Reduced Morbidity Improved knowledge, beliefs, attitudes Improved Behaviors Reduced Mortality Improved Quality of Life 27

Logic Model: Any Public Health Program Inputs Resources Money Staff Outputs Activities Program Development Program Planning Materials Development, Distribution Informed, Targeted Program Appropriate, Targeted Materials Short Term Outcomes Intermediate Outcomes Long Term Outcomes Reduced Morbidity Improved knowledge, beliefs, attitudes Improved Behaviors Reduced Mortality Improved Quality of Life 27

28

28

3. Use Data to Make Decisions n n Use performance assessment data to target improvement Use data analysis tools to develop information Analyze data to identify root cause Use data to monitor performance outcomes 29

3. Use Data to Make Decisions n n Use performance assessment data to target improvement Use data analysis tools to develop information Analyze data to identify root cause Use data to monitor performance outcomes 29

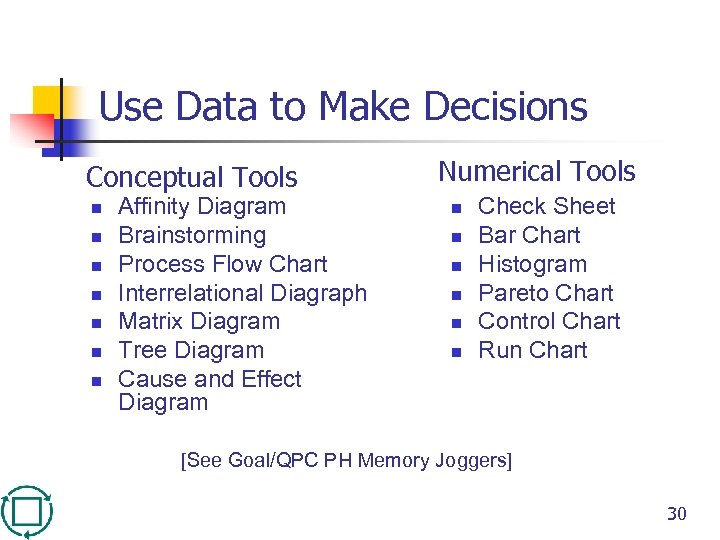

Use Data to Make Decisions Conceptual Tools n n n n Affinity Diagram Brainstorming Process Flow Chart Interrelational Diagraph Matrix Diagram Tree Diagram Cause and Effect Diagram Numerical Tools n n n Check Sheet Bar Chart Histogram Pareto Chart Control Chart Run Chart [See Goal/QPC PH Memory Joggers] 30

Use Data to Make Decisions Conceptual Tools n n n n Affinity Diagram Brainstorming Process Flow Chart Interrelational Diagraph Matrix Diagram Tree Diagram Cause and Effect Diagram Numerical Tools n n n Check Sheet Bar Chart Histogram Pareto Chart Control Chart Run Chart [See Goal/QPC PH Memory Joggers] 30

Use Data to Make Decisions n Brainstorming for root causes—theory generation relies on divergent thinking, no idea is a bad one… n What can go wrong in the process we are studying? n n n Problems in hand-offs between steps Problems in execution within steps Look at machines, materials, methods, measurements, and people 31

Use Data to Make Decisions n Brainstorming for root causes—theory generation relies on divergent thinking, no idea is a bad one… n What can go wrong in the process we are studying? n n n Problems in hand-offs between steps Problems in execution within steps Look at machines, materials, methods, measurements, and people 31

Cause-effect or Fishbone Diagram Exercise: Constructing a Fishbone Diagram n Organizes and displays theories n Encourages divergent thinking n Demonstrates the complexity of the problem n Encourages scientific analysis (rule-out) Turn to page 23 in the PH Memory Jogger. 32

Cause-effect or Fishbone Diagram Exercise: Constructing a Fishbone Diagram n Organizes and displays theories n Encourages divergent thinking n Demonstrates the complexity of the problem n Encourages scientific analysis (rule-out) Turn to page 23 in the PH Memory Jogger. 32

4. Understand Variation n Sources of variation include: machines, materials, methods, measurements, people, environment Common cause variation occurs if the process is stable—variation in data points will be random and obey a mathematical law—it is said to be in statistical control, with a large number of small sources of variation Reacting to random variation in a process that is stable/in statistical control, it is called tampering and leads to further complexity, increasing variation and mistakes 33

4. Understand Variation n Sources of variation include: machines, materials, methods, measurements, people, environment Common cause variation occurs if the process is stable—variation in data points will be random and obey a mathematical law—it is said to be in statistical control, with a large number of small sources of variation Reacting to random variation in a process that is stable/in statistical control, it is called tampering and leads to further complexity, increasing variation and mistakes 33

Understand Variation n Special cause variation arises because of specific circumstances which are not part of the process all the time and may or may not ever recur—if the recurrence is periodic, clues to the root cause may emerge Variation can be shown in control charts with mean and standard deviation Control charts are pictures of trend data with an extra feature—the range of variation built into the system 34

Understand Variation n Special cause variation arises because of specific circumstances which are not part of the process all the time and may or may not ever recur—if the recurrence is periodic, clues to the root cause may emerge Variation can be shown in control charts with mean and standard deviation Control charts are pictures of trend data with an extra feature—the range of variation built into the system 34

Understand Variation n n A sentinel event is a special cause variation requiring root cause analysis Examine specific incident(s) of special cause variation and make changes to a single element only after very careful analysis Need to investigate special cause variation before making any conclusions about performance level Failure to distinguish between common and special cause variation can be hazardous to organizational performance! 35

Understand Variation n n A sentinel event is a special cause variation requiring root cause analysis Examine specific incident(s) of special cause variation and make changes to a single element only after very careful analysis Need to investigate special cause variation before making any conclusions about performance level Failure to distinguish between common and special cause variation can be hazardous to organizational performance! 35

Variation Exercise n Joiner Associates – Hunter Conference exercise n Attributed to Brian Joiner’s 9 year-old son 36

Variation Exercise n Joiner Associates – Hunter Conference exercise n Attributed to Brian Joiner’s 9 year-old son 36

5. Use Teamwork n n n QI efforts need buy-in from all stakeholders Creative ideas are needed Division of labor is needed Process often crosses functions Solution generally affects many 37

5. Use Teamwork n n n QI efforts need buy-in from all stakeholders Creative ideas are needed Division of labor is needed Process often crosses functions Solution generally affects many 37

Use Teamwork n n Teams should develop a clear charge and support resources Teams should adopt working agreements (cell phone etiquette to decision procedures) Teams should assign roles of facilitators and recorders Team process has predictable stages that are useful to keep in mind: n Forming, Storming, Norming, Performing 38

Use Teamwork n n Teams should develop a clear charge and support resources Teams should adopt working agreements (cell phone etiquette to decision procedures) Teams should assign roles of facilitators and recorders Team process has predictable stages that are useful to keep in mind: n Forming, Storming, Norming, Performing 38

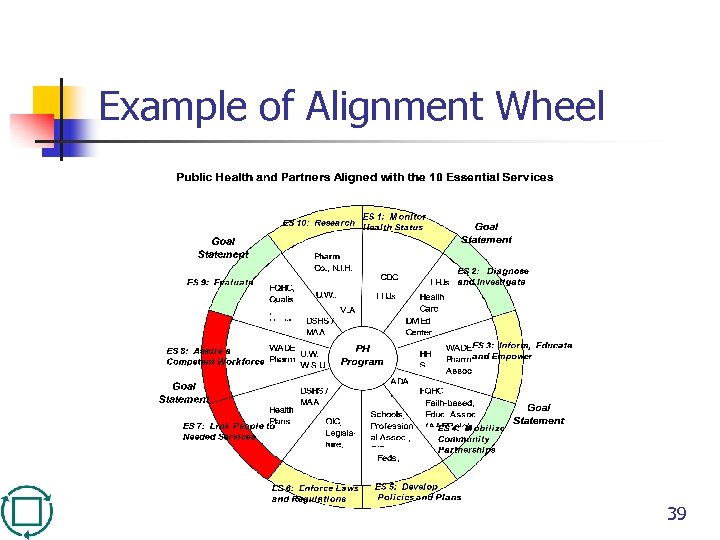

Example of Alignment Wheel 39

Example of Alignment Wheel 39

6. Make QI Continuous n QI is a system-wide approach to assessing and continuously improving quality of the processes and services over time n n n See inter-relationships, not parts Understand the flow of work, not the one-time snapshot Detail the work processes Determine cause and effect relationships Identify points of highest leverage Improve and innovate, not just change for change’s sake 40

6. Make QI Continuous n QI is a system-wide approach to assessing and continuously improving quality of the processes and services over time n n n See inter-relationships, not parts Understand the flow of work, not the one-time snapshot Detail the work processes Determine cause and effect relationships Identify points of highest leverage Improve and innovate, not just change for change’s sake 40

PDCA/PDSA Cycle definition n n The Plan Do Check/Study Act Cycle is a trial-and -learning method to discover what is an effective and efficient way to design or change a process The “check” part of the cycle may require some clarification; after all, we are used to planning, doing/acting. It compels the team to learn from the data collected, its effects on other parts of the system, and under different conditions, such as different communities 41

PDCA/PDSA Cycle definition n n The Plan Do Check/Study Act Cycle is a trial-and -learning method to discover what is an effective and efficient way to design or change a process The “check” part of the cycle may require some clarification; after all, we are used to planning, doing/acting. It compels the team to learn from the data collected, its effects on other parts of the system, and under different conditions, such as different communities 41

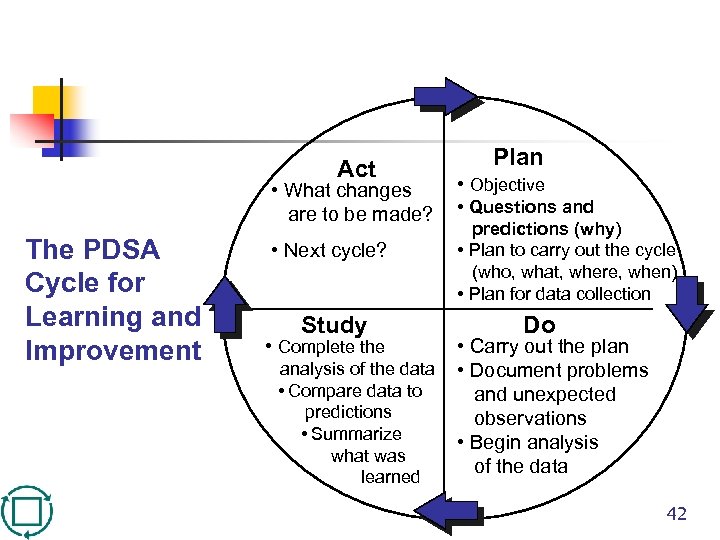

Act • What changes are to be made? The PDSA Cycle for Learning and Improvement • Next cycle? Study • Complete the analysis of the data • Compare data to predictions • Summarize what was learned Plan • Objective • Questions and predictions (why) • Plan to carry out the cycle (who, what, where, when) • Plan for data collection Do • Carry out the plan • Document problems and unexpected observations • Begin analysis of the data 42

Act • What changes are to be made? The PDSA Cycle for Learning and Improvement • Next cycle? Study • Complete the analysis of the data • Compare data to predictions • Summarize what was learned Plan • Objective • Questions and predictions (why) • Plan to carry out the cycle (who, what, where, when) • Plan for data collection Do • Carry out the plan • Document problems and unexpected observations • Begin analysis of the data 42

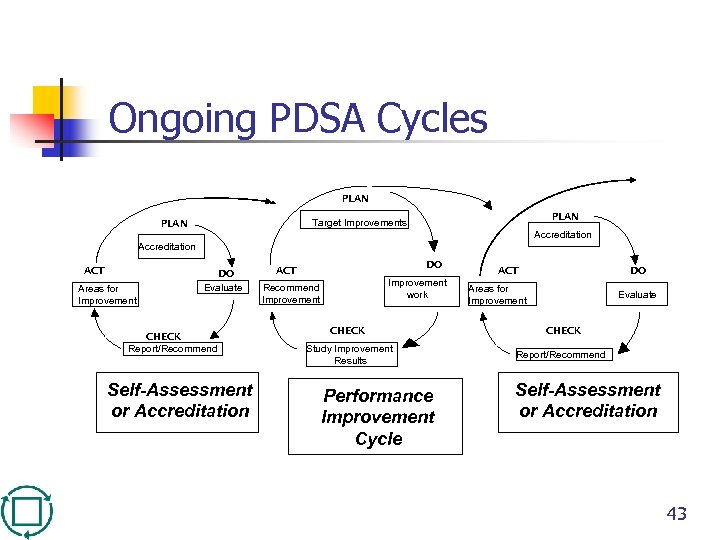

Ongoing PDSA Cycles PLAN Target Improvements PLAN Accreditation ACT Areas for Improvement DO Evaluate CHECK Report/Recommend Self-Assessment or Accreditation DO ACT Improvement work Recommend Improvement ACT DO Areas for Improvement Evaluate CHECK Study Improvement Results Report/Recommend Performance Improvement Cycle Self-Assessment or Accreditation 43

Ongoing PDSA Cycles PLAN Target Improvements PLAN Accreditation ACT Areas for Improvement DO Evaluate CHECK Report/Recommend Self-Assessment or Accreditation DO ACT Improvement work Recommend Improvement ACT DO Areas for Improvement Evaluate CHECK Study Improvement Results Report/Recommend Performance Improvement Cycle Self-Assessment or Accreditation 43

Make QI Continuous n n Use assessment to identify areas for improvement Charge QI team and provide support n n n Provide QI training Use tools to understand root causes Use data for baseline and analysis Design process improvement to address root causes Train…train… staff on the newly designed process improvement 44

Make QI Continuous n n Use assessment to identify areas for improvement Charge QI team and provide support n n n Provide QI training Use tools to understand root causes Use data for baseline and analysis Design process improvement to address root causes Train…train… staff on the newly designed process improvement 44

Adopt or Adapt Model Practices n n Use data to identify need for improvement Identify exemplary practices in: n n n n other local departments, Michigan state programs and other states, CDC and other national organizations, www. naccho. org/topics/modelpractices other industries Describe your process (Logic Model) Study the exemplary practice process Adopt or adapt as appropriate 45

Adopt or Adapt Model Practices n n Use data to identify need for improvement Identify exemplary practices in: n n n n other local departments, Michigan state programs and other states, CDC and other national organizations, www. naccho. org/topics/modelpractices other industries Describe your process (Logic Model) Study the exemplary practice process Adopt or adapt as appropriate 45

7. Demonstrate Leadership Commitment n n n Build a QI culture Connect the organization’s strategic plan to performance improvement Know and use quality principles Encourage all staff to use quality improvement in daily work Reward improvements Assure adequate QI infrastructure for quality assessment and improvement activities 46

7. Demonstrate Leadership Commitment n n n Build a QI culture Connect the organization’s strategic plan to performance improvement Know and use quality principles Encourage all staff to use quality improvement in daily work Reward improvements Assure adequate QI infrastructure for quality assessment and improvement activities 46

What questions do you have? 47

What questions do you have? 47

Rapid Cycle Improvement (RCI) and PDSA Cycles 48

Rapid Cycle Improvement (RCI) and PDSA Cycles 48

Why do we need a systematic model for improvement? “All improvements require change but not all change will result in improvement. A primary aim of the science of improvement is to increase the chance that a change will actually result in sustained improvement from the viewpoint of those affected by the change. ” --The Improvement Guide, 1996 49

Why do we need a systematic model for improvement? “All improvements require change but not all change will result in improvement. A primary aim of the science of improvement is to increase the chance that a change will actually result in sustained improvement from the viewpoint of those affected by the change. ” --The Improvement Guide, 1996 49

Rapid Cycle Improvement The idea behind rapid cycle improvement is to first try a change idea on a small scale to see how it works, and then modify it and try it again until it works very well for staff and customers. Then, and only then, does a change become a permanent improvement. 50

Rapid Cycle Improvement The idea behind rapid cycle improvement is to first try a change idea on a small scale to see how it works, and then modify it and try it again until it works very well for staff and customers. Then, and only then, does a change become a permanent improvement. 50

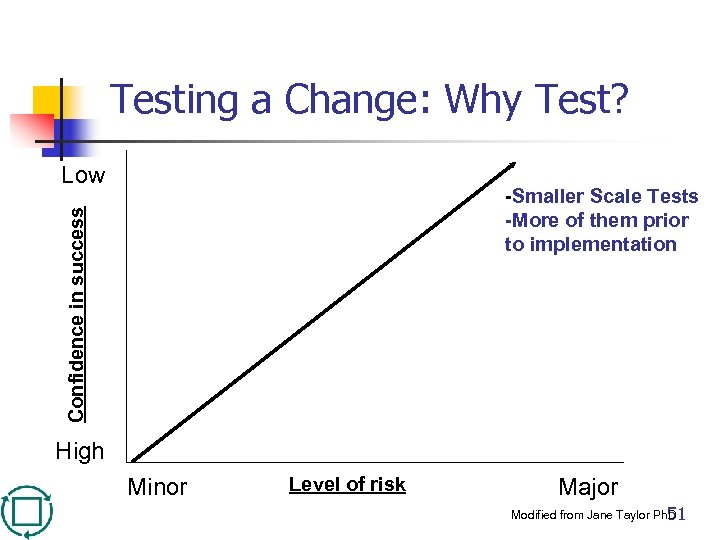

Testing a Change: Why Test? Low Confidence in success -Smaller Scale Tests -More of them prior to implementation High Minor Level of risk Major Modified from Jane Taylor Ph. D 51

Testing a Change: Why Test? Low Confidence in success -Smaller Scale Tests -More of them prior to implementation High Minor Level of risk Major Modified from Jane Taylor Ph. D 51

Testing a Change: Why Test? n n n Minimize risks of potential failure and of potential adverse or unanticipated side effects Predict how much improvement can be expected from the change Learn how to adapt the change to conditions in the local environment Evaluate costs and side-effects of the change Minimize resistance to implementation 52

Testing a Change: Why Test? n n n Minimize risks of potential failure and of potential adverse or unanticipated side effects Predict how much improvement can be expected from the change Learn how to adapt the change to conditions in the local environment Evaluate costs and side-effects of the change Minimize resistance to implementation 52

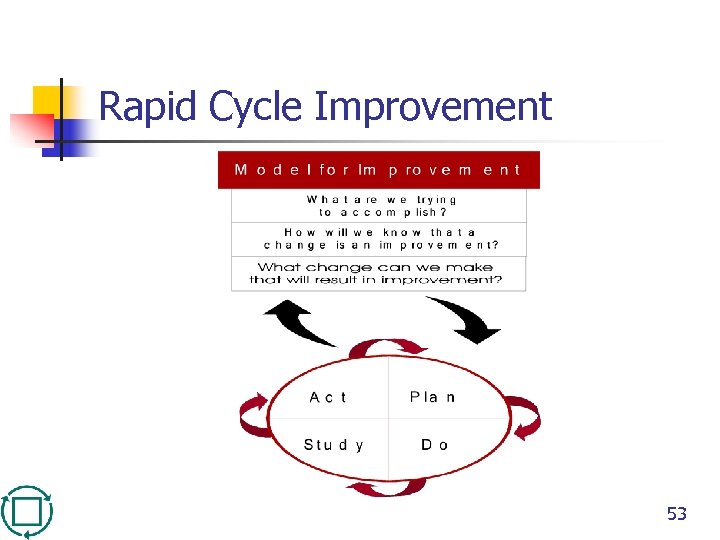

Rapid Cycle Improvement 53

Rapid Cycle Improvement 53

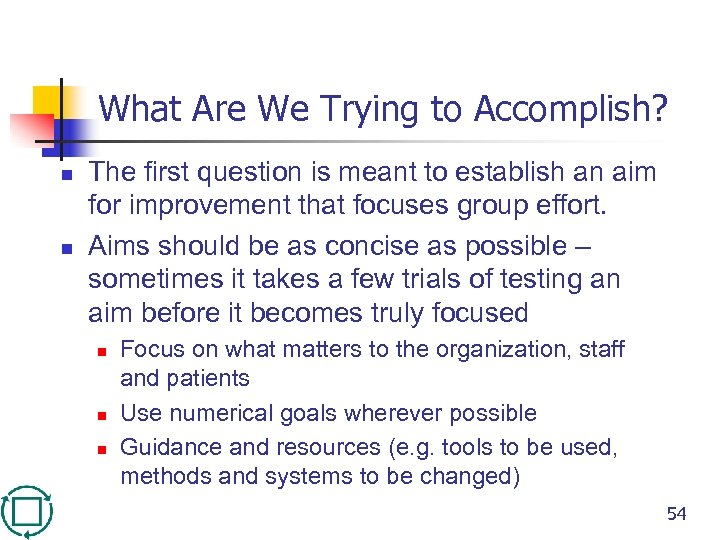

What Are We Trying to Accomplish? n n The first question is meant to establish an aim for improvement that focuses group effort. Aims should be as concise as possible – sometimes it takes a few trials of testing an aim before it becomes truly focused n n n Focus on what matters to the organization, staff and patients Use numerical goals wherever possible Guidance and resources (e. g. tools to be used, methods and systems to be changed) 54

What Are We Trying to Accomplish? n n The first question is meant to establish an aim for improvement that focuses group effort. Aims should be as concise as possible – sometimes it takes a few trials of testing an aim before it becomes truly focused n n n Focus on what matters to the organization, staff and patients Use numerical goals wherever possible Guidance and resources (e. g. tools to be used, methods and systems to be changed) 54

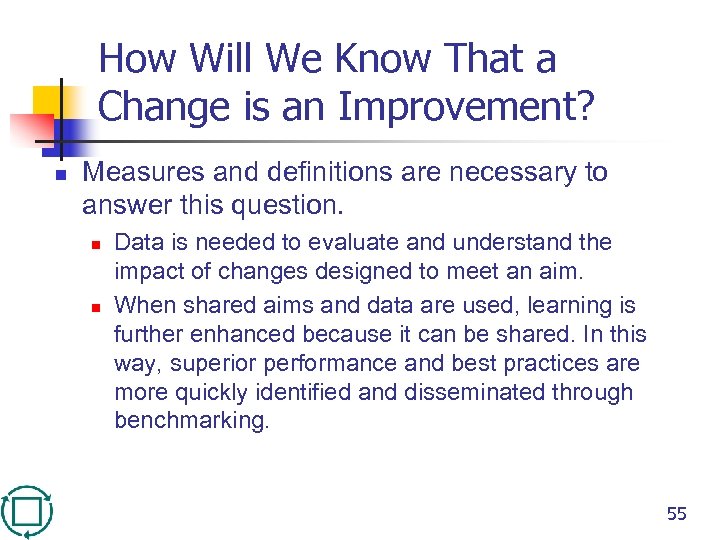

How Will We Know That a Change is an Improvement? n Measures and definitions are necessary to answer this question. n n Data is needed to evaluate and understand the impact of changes designed to meet an aim. When shared aims and data are used, learning is further enhanced because it can be shared. In this way, superior performance and best practices are more quickly identified and disseminated through benchmarking. 55

How Will We Know That a Change is an Improvement? n Measures and definitions are necessary to answer this question. n n Data is needed to evaluate and understand the impact of changes designed to meet an aim. When shared aims and data are used, learning is further enhanced because it can be shared. In this way, superior performance and best practices are more quickly identified and disseminated through benchmarking. 55

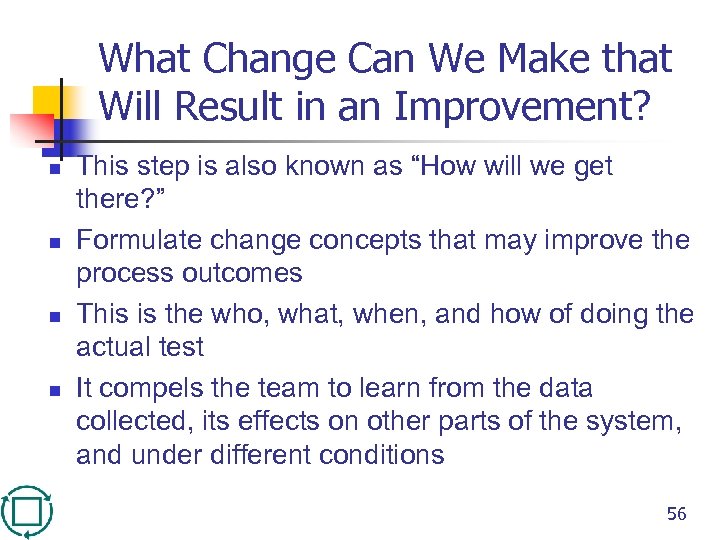

What Change Can We Make that Will Result in an Improvement? n n This step is also known as “How will we get there? ” Formulate change concepts that may improve the process outcomes This is the who, what, when, and how of doing the actual test It compels the team to learn from the data collected, its effects on other parts of the system, and under different conditions 56

What Change Can We Make that Will Result in an Improvement? n n This step is also known as “How will we get there? ” Formulate change concepts that may improve the process outcomes This is the who, what, when, and how of doing the actual test It compels the team to learn from the data collected, its effects on other parts of the system, and under different conditions 56

Consolidation of Relevant Knowledge and Experience n n Develop a set of change concepts Definition of Change Concepts - Ideas for interventions and actions for improvement with a greater likelihood of working based on n evidence, quantitatively documented experience, and/or internal data. 57

Consolidation of Relevant Knowledge and Experience n n Develop a set of change concepts Definition of Change Concepts - Ideas for interventions and actions for improvement with a greater likelihood of working based on n evidence, quantitatively documented experience, and/or internal data. 57

Some Sources for Improvement Interventions and Actions n n n Published literature in scientific journals Documented (with data) experience from other public health agencies Internal qualitative analysis of work processes n n Internal quantitative analysis of work processes n n Use qualitative analysis tools (e. g. fishbone diagrams, root cause concepts) to identify barriers e. g. Pareto analysis National experts (e. g. IHI, NACCHO, PHF, ASQ, Goal/QPC, MLC states and many others) 58

Some Sources for Improvement Interventions and Actions n n n Published literature in scientific journals Documented (with data) experience from other public health agencies Internal qualitative analysis of work processes n n Internal quantitative analysis of work processes n n Use qualitative analysis tools (e. g. fishbone diagrams, root cause concepts) to identify barriers e. g. Pareto analysis National experts (e. g. IHI, NACCHO, PHF, ASQ, Goal/QPC, MLC states and many others) 58

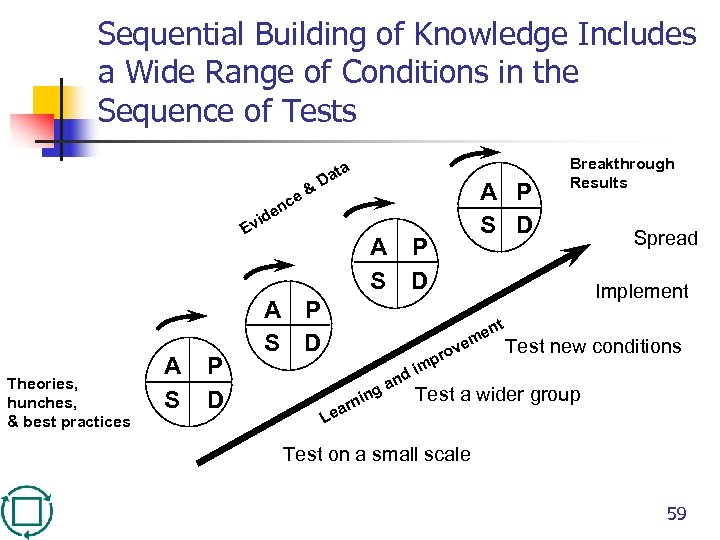

Sequential Building of Knowledge Includes a Wide Range of Conditions in the Sequence of Tests e id Ev Theories, hunches, & best practices A S P D e nc & ta Da A P S D ng Le i arn im Spread Implement e d an Breakthrough Results v pro t en m Test new conditions Test a wider group Test on a small scale 59

Sequential Building of Knowledge Includes a Wide Range of Conditions in the Sequence of Tests e id Ev Theories, hunches, & best practices A S P D e nc & ta Da A P S D ng Le i arn im Spread Implement e d an Breakthrough Results v pro t en m Test new conditions Test a wider group Test on a small scale 59

Sequential Testing…. when do you move to implementation? n After each PDSA… n n n Implement as is Abandon it Increase in scope n e. g. more clients, more programs Modify it and test again Test under different conditions 60

Sequential Testing…. when do you move to implementation? n After each PDSA… n n n Implement as is Abandon it Increase in scope n e. g. more clients, more programs Modify it and test again Test under different conditions 60

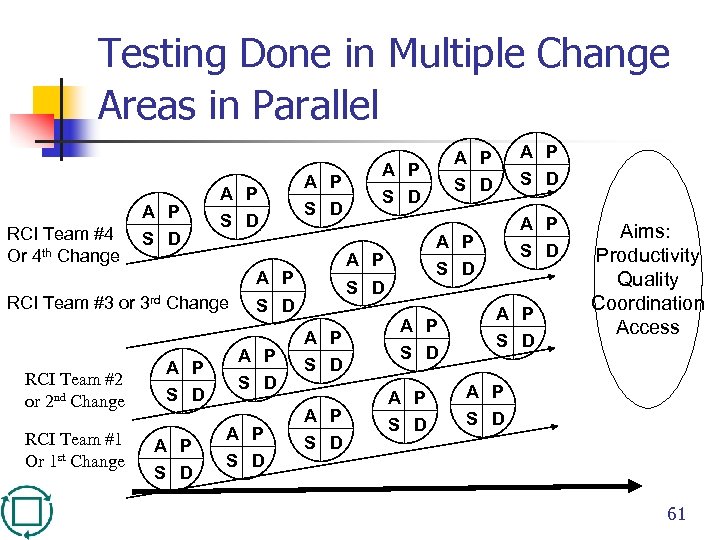

Testing Done in Multiple Change Areas in Parallel A P RCI Team #4 Or 4 th Change S D A P S D RCI Team #3 or RCI Team #2 or 2 nd Change RCI Team #1 Or 1 st Change 3 rd Change A P S D S D A P S D A P S D A P A P A P S D Aims: Productivity Quality Coordination Access S D 61

Testing Done in Multiple Change Areas in Parallel A P RCI Team #4 Or 4 th Change S D A P S D RCI Team #3 or RCI Team #2 or 2 nd Change RCI Team #1 Or 1 st Change 3 rd Change A P S D S D A P S D A P S D A P A P A P S D Aims: Productivity Quality Coordination Access S D 61

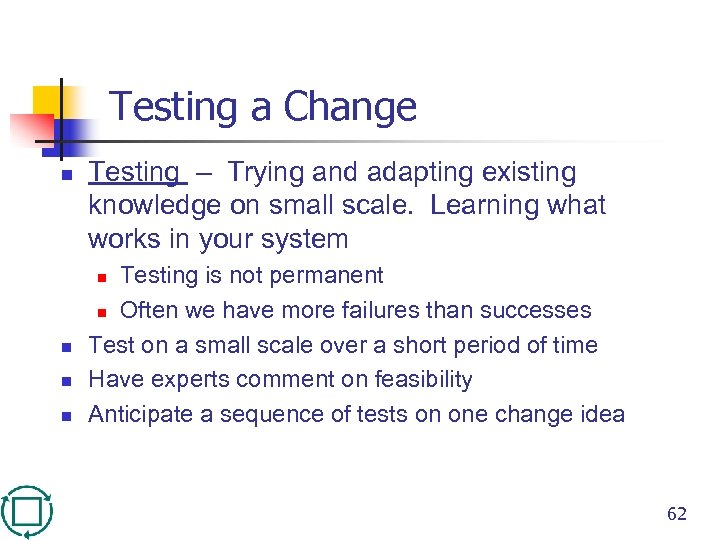

Testing a Change n Testing – Trying and adapting existing knowledge on small scale. Learning what works in your system Testing is not permanent n Often we have more failures than successes Test on a small scale over a short period of time Have experts comment on feasibility Anticipate a sequence of tests on one change idea n n 62

Testing a Change n Testing – Trying and adapting existing knowledge on small scale. Learning what works in your system Testing is not permanent n Often we have more failures than successes Test on a small scale over a short period of time Have experts comment on feasibility Anticipate a sequence of tests on one change idea n n 62

Testing a Change: Tips n n Move from ideas to action quickly Decrease the scope of the test n n Test of oneness n One stakeholder, one program, one day As you are designing the test, ask ‘What design would enable us to do this test now, tomorrow or next week 63

Testing a Change: Tips n n Move from ideas to action quickly Decrease the scope of the test n n Test of oneness n One stakeholder, one program, one day As you are designing the test, ask ‘What design would enable us to do this test now, tomorrow or next week 63

Implementing a Change n Implementation – Making this change a part of the day-to-day operation of the system n n Implement a change ONLY if it will lead to improvement Involves more people and conditions: you will run into more resistance and factors which require “design tweaks” 64

Implementing a Change n Implementation – Making this change a part of the day-to-day operation of the system n n Implement a change ONLY if it will lead to improvement Involves more people and conditions: you will run into more resistance and factors which require “design tweaks” 64

What Can We Do Now… … by Next Week, …by Tuesday, …by Tomorrow …that we can learn from without harming clients or burdening staff? Modified from Jane Taylor Ph. D 65

What Can We Do Now… … by Next Week, …by Tuesday, …by Tomorrow …that we can learn from without harming clients or burdening staff? Modified from Jane Taylor Ph. D 65

Rapid Cycle Improvement–Example 66

Rapid Cycle Improvement–Example 66

What are We Trying to Accomplish? n Increase accurate and complete reporting of CD to 80% or more of all reports by 10/07, and more than 95% by 2/08 with clear definition of complete reports. We do this in order to provide valid data for planning and program improvement 67

What are We Trying to Accomplish? n Increase accurate and complete reporting of CD to 80% or more of all reports by 10/07, and more than 95% by 2/08 with clear definition of complete reports. We do this in order to provide valid data for planning and program improvement 67

How Will We Know When We Get There? : Measurements n n n Increase (trended) in percent of accurately completed CD reports Decrease in staff time to input incomplete information Trend in overall measures in right direction (direction of goodness indicated by arrow) n n Other CD reporting measures Other process measures 68

How Will We Know When We Get There? : Measurements n n n Increase (trended) in percent of accurately completed CD reports Decrease in staff time to input incomplete information Trend in overall measures in right direction (direction of goodness indicated by arrow) n n Other CD reporting measures Other process measures 68

What Changes Can We Make? n Data analysis of reasons for incomplete reports. n n n Identify reasons with definitions Assure that database can capture each reason Initiate data collection process Train staff and providers in definition and reporting process Address lack of knowledge of providers Create plan to identify high volume providers and target for extra training 69

What Changes Can We Make? n Data analysis of reasons for incomplete reports. n n n Identify reasons with definitions Assure that database can capture each reason Initiate data collection process Train staff and providers in definition and reporting process Address lack of knowledge of providers Create plan to identify high volume providers and target for extra training 69

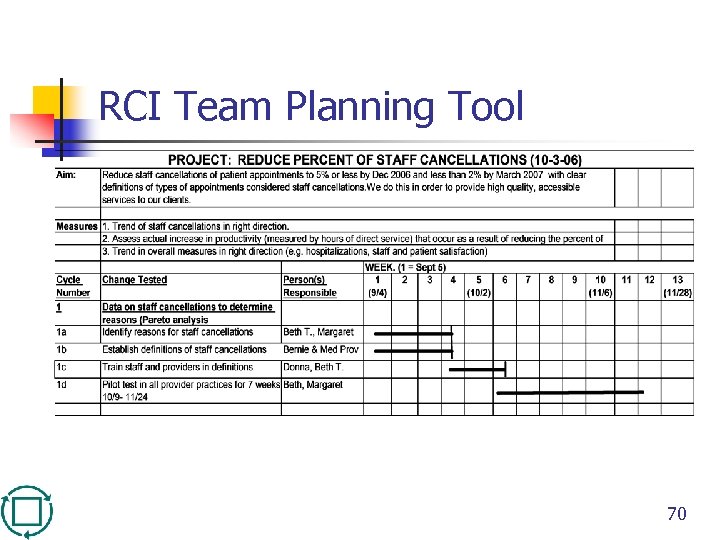

RCI Team Planning Tool 70

RCI Team Planning Tool 70

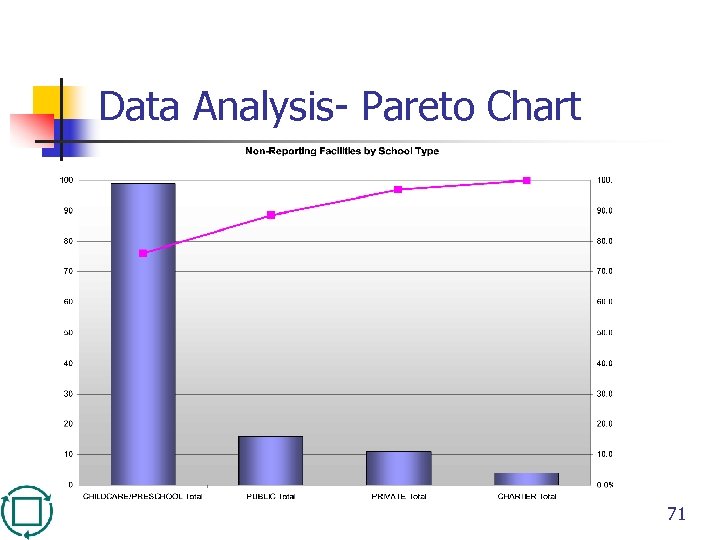

Data Analysis- Pareto Chart 71

Data Analysis- Pareto Chart 71

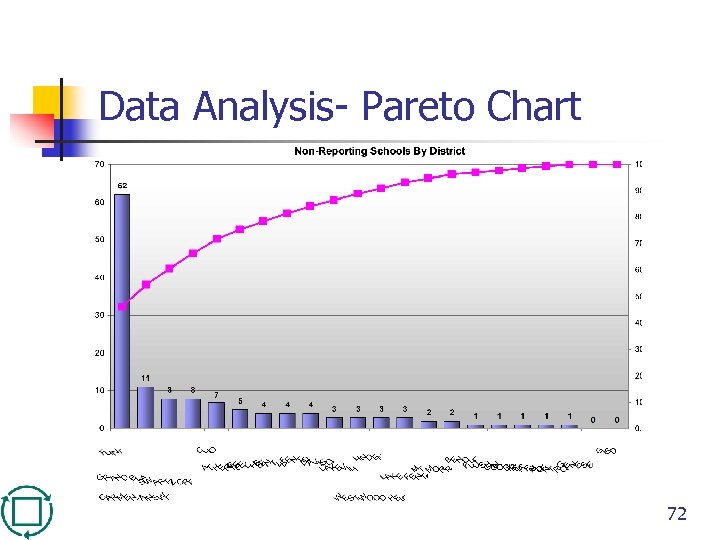

Data Analysis- Pareto Chart 72

Data Analysis- Pareto Chart 72

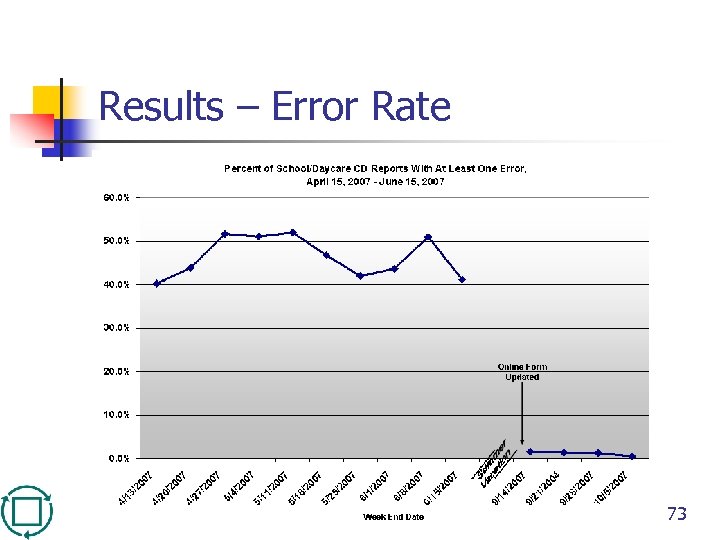

Results – Error Rate 73

Results – Error Rate 73

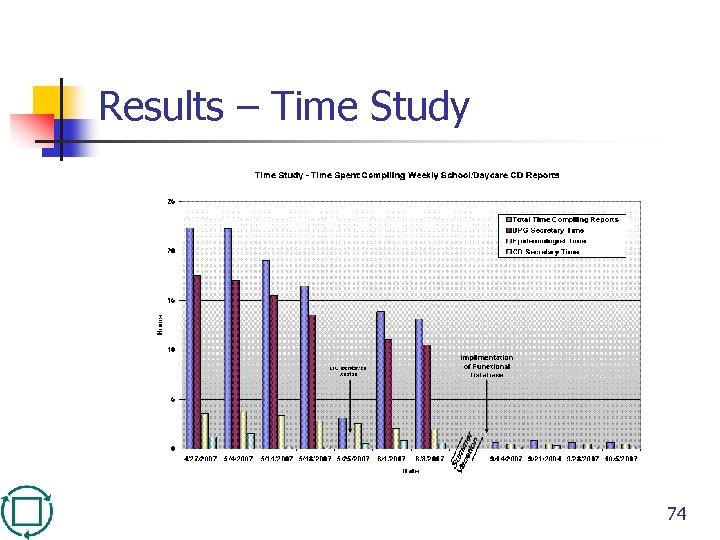

Results – Time Study 74

Results – Time Study 74

Steps to Set Up a Rapid Cycle Improvement n n n Establish a multi-disciplinary RCI team Identify a positive opinion leader Align leadership and administrative support Consolidation of relevant knowledge and experience (national) for multiple changes Development of an overall aim statement (using the three questions at a high level) Decide where to start and develop a strategy for a series of rapid cycles. 75

Steps to Set Up a Rapid Cycle Improvement n n n Establish a multi-disciplinary RCI team Identify a positive opinion leader Align leadership and administrative support Consolidation of relevant knowledge and experience (national) for multiple changes Development of an overall aim statement (using the three questions at a high level) Decide where to start and develop a strategy for a series of rapid cycles. 75

Guidance on Following the Steps n n It is important not to try to write the perfect AIM statement and develop the most thorough rapid cycle strategy at the start. It is more important to start small, rapid tests of change through PDSA cycles as soon as possible. The AIM statement and strategy evolve continually as you learn from testing. The major objective is to build organizational learning from small tests of change. 76

Guidance on Following the Steps n n It is important not to try to write the perfect AIM statement and develop the most thorough rapid cycle strategy at the start. It is more important to start small, rapid tests of change through PDSA cycles as soon as possible. The AIM statement and strategy evolve continually as you learn from testing. The major objective is to build organizational learning from small tests of change. 76

Key Lessons from RCI n n n The rapid improvement work must be seen as The Work and not a separate project Implementation and holding the gains requires integration into daily work and meetings Start work with those interested in change Communicate what is happening persistently Provide support to providers and staff who take on this new work 77

Key Lessons from RCI n n n The rapid improvement work must be seen as The Work and not a separate project Implementation and holding the gains requires integration into daily work and meetings Start work with those interested in change Communicate what is happening persistently Provide support to providers and staff who take on this new work 77

What questions do you have? 78

What questions do you have? 78