8b584be1974e249dd522a726d0b07361.ppt

- Количество слайдов: 42

QUALITY FUNCTION DEPLOYMENT (QFD) Ömer Yağız Department of Business Administration EMU Originally prepared for the IE 591 seminar series at the IE Department, EMU. Changes made for use in EMBA 5602, Dept. of Bus. Adm. , METU. 2009

QUALITY FUNCTION DEPLOYMENT (QFD) Ömer Yağız Department of Business Administration EMU Originally prepared for the IE 591 seminar series at the IE Department, EMU. Changes made for use in EMBA 5602, Dept. of Bus. Adm. , METU. 2009

Critical Success Factors n n n n n Goods & service design Quality Process & capacity design Location selection Layout design Human resource and job design Supply-chain management Inventory Aggregate planning, scheduling Maintenance 2

Critical Success Factors n n n n n Goods & service design Quality Process & capacity design Location selection Layout design Human resource and job design Supply-chain management Inventory Aggregate planning, scheduling Maintenance 2

Competitive Priorities o Competing on n cost o lean manufacturing/service creation n quality o meet/exceed customer expectations o “fit for intended use” n flexibility o adjust to changes in market conditions o adjust to changes in product mix, production volume and design o flexible manufacturing systems (FMS), mass customization 3

Competitive Priorities o Competing on n cost o lean manufacturing/service creation n quality o meet/exceed customer expectations o “fit for intended use” n flexibility o adjust to changes in market conditions o adjust to changes in product mix, production volume and design o flexible manufacturing systems (FMS), mass customization 3

Competitive Priorities n speed (response) o o design & development production (agile manufacturing) delivery after-sales service n differentiation o uniqueness of product/service o mass customization 4

Competitive Priorities n speed (response) o o design & development production (agile manufacturing) delivery after-sales service n differentiation o uniqueness of product/service o mass customization 4

Common Definitions of Quality o quality means “fitness for use. ” o quality is “meeting or exceeding customer expectations. ” o quality is “the totality of features and characteristics of a product or service that bear on its ability to satisfy needs” (ANSI/ASQ definition) 5

Common Definitions of Quality o quality means “fitness for use. ” o quality is “meeting or exceeding customer expectations. ” o quality is “the totality of features and characteristics of a product or service that bear on its ability to satisfy needs” (ANSI/ASQ definition) 5

The logical thing to do. . . o subscribe to the view that “the customer is the only judge of quality” o listen to the “voice of the customer” o design, develop, produce, and deliver goods/services which will satisfy customer requirements and needs QUALITY FUNCTION DEPLOYMENT 6

The logical thing to do. . . o subscribe to the view that “the customer is the only judge of quality” o listen to the “voice of the customer” o design, develop, produce, and deliver goods/services which will satisfy customer requirements and needs QUALITY FUNCTION DEPLOYMENT 6

Two basic problems o how to determine what really matters to customers in terms of their needs, requirements, and expectations, and o how to translate these needs and requirements into requirements that are meaningful to and can be acted upon by designers and producers of goods and services 7

Two basic problems o how to determine what really matters to customers in terms of their needs, requirements, and expectations, and o how to translate these needs and requirements into requirements that are meaningful to and can be acted upon by designers and producers of goods and services 7

8

8

QFD in Japanese o Hin Shitsu Ki No Ten Kai "A group of courageous people working in harmony pursuing the finest detail to unlock the organization and roll out products that the multitudes in the marketplace will value. " 9

QFD in Japanese o Hin Shitsu Ki No Ten Kai "A group of courageous people working in harmony pursuing the finest detail to unlock the organization and roll out products that the multitudes in the marketplace will value. " 9

QFD – Kalite Fonksiyon Göçerimi Kobe tersanelerinde geliştirilen yöntemin orijinali yani Japoncası : "Hin Shitsu Ki Nou (ya da Ki No) Ten Kai" olarak bilinmektedir(Guinta ve Praizler, 1993, ss. 4 -5; Revelle, 1998, s. 6; Cohen, 1995, s. 17). Bu isim, İngilizce'ye "Quality Function Deployment" olarak tercüme edilmiştir. Japonca'da her sözcük çeşitli anlamlar taşıyabildiğinden, İngilizceye yapılan tercüme aslında tam olarak yöntemin orijinal adının verdiği anlamı karşılayamamaktadır. Zira aşağıdaki tabloda da görüldüğü gibi her bir Japonca terime karşılık birden fazla İngilizce terim karşılık gelmektedir. Yöntemin adı bir de İngilizceden Türkçe'ye tercüme edildiğinde; her sözcüğe daha fazla anlam yüklenmektedir. Yöntemin adından anlaşılması gereken; ürün ya da hizmette müşterilerin bulunmasını istedikleri ve ihtiyaç duydukları niteliklerin, bu nitelikleri yerine getirecek ya da gerçekleştirecek fonksiyonlara dönüştürülüp, bu fonksiyonları gerçekleştirme görevinin örgüt içindeki uygun birimlere aktarılmasıdır. 10

QFD – Kalite Fonksiyon Göçerimi Kobe tersanelerinde geliştirilen yöntemin orijinali yani Japoncası : "Hin Shitsu Ki Nou (ya da Ki No) Ten Kai" olarak bilinmektedir(Guinta ve Praizler, 1993, ss. 4 -5; Revelle, 1998, s. 6; Cohen, 1995, s. 17). Bu isim, İngilizce'ye "Quality Function Deployment" olarak tercüme edilmiştir. Japonca'da her sözcük çeşitli anlamlar taşıyabildiğinden, İngilizceye yapılan tercüme aslında tam olarak yöntemin orijinal adının verdiği anlamı karşılayamamaktadır. Zira aşağıdaki tabloda da görüldüğü gibi her bir Japonca terime karşılık birden fazla İngilizce terim karşılık gelmektedir. Yöntemin adı bir de İngilizceden Türkçe'ye tercüme edildiğinde; her sözcüğe daha fazla anlam yüklenmektedir. Yöntemin adından anlaşılması gereken; ürün ya da hizmette müşterilerin bulunmasını istedikleri ve ihtiyaç duydukları niteliklerin, bu nitelikleri yerine getirecek ya da gerçekleştirecek fonksiyonlara dönüştürülüp, bu fonksiyonları gerçekleştirme görevinin örgüt içindeki uygun birimlere aktarılmasıdır. 10

QFD – Kalite Fonksiyon Göçerimi; ülkemizde tanınmaya başlandığından beri Türkçe'ye çeşitli şekillerde tercüme edilmiştir. Kalite ve Fonksiyon sözcükleri zaten Türkçe'ye yerleşmiş sözcüklerdir ve daha fazla anlam kaybının önlenmesi için değiştirilmelerine gerek yoktur. Ancak "deployment" sözcüğü tercüme edilmelidir. Japonca'da "deployment" yani "ten kai"; İngilizce'deki tanmından daha geniş bir anlam ifade eder: "Faaliyetlerin genişletilmesi"(Kogure ve Akao, 1983, s. 26). Bu sözcüğün yerine getirilebilecek en iyi sözcük "göçerim"dir. Zira KFG'nin yaptığı iş; daha sonraki bölümlerde de anlatıldığı gibi, esas itibarı ile her aşamada en önemli kriterlerin belirlenmesi ve bunları gerçekleştirmek için yapılması gerekenlerin bir sonraki aşamada bulunan; kişilere, parçalara, fonksiyonlara, planlara vb. atanması ya da göçerilmesidir (Göçerim sözcüğünün içerdiği anlam "yetki göçerimi" terimi düşünüldüğünde daha iyi anlaşılacaktır). Yukarıda açıklanan nedenlerden dolayı "Quality Function Deployment"; Türkçe'ye en iyi "Kalite Fonksiyon Göçerimi" olarak çevrilebilmektedir. 11 (http: //www. qfdturkiye. org)

QFD – Kalite Fonksiyon Göçerimi; ülkemizde tanınmaya başlandığından beri Türkçe'ye çeşitli şekillerde tercüme edilmiştir. Kalite ve Fonksiyon sözcükleri zaten Türkçe'ye yerleşmiş sözcüklerdir ve daha fazla anlam kaybının önlenmesi için değiştirilmelerine gerek yoktur. Ancak "deployment" sözcüğü tercüme edilmelidir. Japonca'da "deployment" yani "ten kai"; İngilizce'deki tanmından daha geniş bir anlam ifade eder: "Faaliyetlerin genişletilmesi"(Kogure ve Akao, 1983, s. 26). Bu sözcüğün yerine getirilebilecek en iyi sözcük "göçerim"dir. Zira KFG'nin yaptığı iş; daha sonraki bölümlerde de anlatıldığı gibi, esas itibarı ile her aşamada en önemli kriterlerin belirlenmesi ve bunları gerçekleştirmek için yapılması gerekenlerin bir sonraki aşamada bulunan; kişilere, parçalara, fonksiyonlara, planlara vb. atanması ya da göçerilmesidir (Göçerim sözcüğünün içerdiği anlam "yetki göçerimi" terimi düşünüldüğünde daha iyi anlaşılacaktır). Yukarıda açıklanan nedenlerden dolayı "Quality Function Deployment"; Türkçe'ye en iyi "Kalite Fonksiyon Göçerimi" olarak çevrilebilmektedir. 11 (http: //www. qfdturkiye. org)

What is QFD? q QFD is a comprehensive quality system that systematically links the needs of the customer with various business functions and organizational processes, such as marketing, design, quality, production, manufacturing, sales, etc. , aligning the entire company toward achieving a common goal 12

What is QFD? q QFD is a comprehensive quality system that systematically links the needs of the customer with various business functions and organizational processes, such as marketing, design, quality, production, manufacturing, sales, etc. , aligning the entire company toward achieving a common goal 12

What is QFD? o Quality Function Deployment is n a planning, communication, and documentation technique n a structured process for translating customer values and requirements into specific product or service engineering characteristics, and for specifying the processes and systems to produce that product or service n a disciplined and integrative approach to product design, process 13 engineering, and production

What is QFD? o Quality Function Deployment is n a planning, communication, and documentation technique n a structured process for translating customer values and requirements into specific product or service engineering characteristics, and for specifying the processes and systems to produce that product or service n a disciplined and integrative approach to product design, process 13 engineering, and production

History of QFD o Drs. Shigeru Mizuno and Yoji Akao in the 1960’s. o purpose was to develop a quality assurance method that would design customer satisfaction into a product before it was manufactured. o first application -- Kobe Shipyards of Mitsubishi Heavy Industries, Ltd. in Japan (design of an oil tanker-1972) 14

History of QFD o Drs. Shigeru Mizuno and Yoji Akao in the 1960’s. o purpose was to develop a quality assurance method that would design customer satisfaction into a product before it was manufactured. o first application -- Kobe Shipyards of Mitsubishi Heavy Industries, Ltd. in Japan (design of an oil tanker-1972) 14

History of QFD o Toyota and its suppliers began to use it by adapting to auto industry o Japanese designers used it for n n n n consumer electronics home appliances clothing construction equipment swimming pools retail outlets planning apartment layouts 15

History of QFD o Toyota and its suppliers began to use it by adapting to auto industry o Japanese designers used it for n n n n consumer electronics home appliances clothing construction equipment swimming pools retail outlets planning apartment layouts 15

History of QFD o Ford and Xerox first used it in the USA n Taurus and Mondeo models by Ford n big role in Xerox’s comeback o I have heard that it is being used in Turkey by Brisa, Beksa, Arçelik, and Netaş 16

History of QFD o Ford and Xerox first used it in the USA n Taurus and Mondeo models by Ford n big role in Xerox’s comeback o I have heard that it is being used in Turkey by Brisa, Beksa, Arçelik, and Netaş 16

Voice of the Customer o A fundamental principle of QFD is to determine directly from the customer what they would like a particular product or service to do. There are many different approaches to achieve this goal. They include: n n one-on-one customer interviews focus groups in-context customer visits other more refined techniques 17

Voice of the Customer o A fundamental principle of QFD is to determine directly from the customer what they would like a particular product or service to do. There are many different approaches to achieve this goal. They include: n n one-on-one customer interviews focus groups in-context customer visits other more refined techniques 17

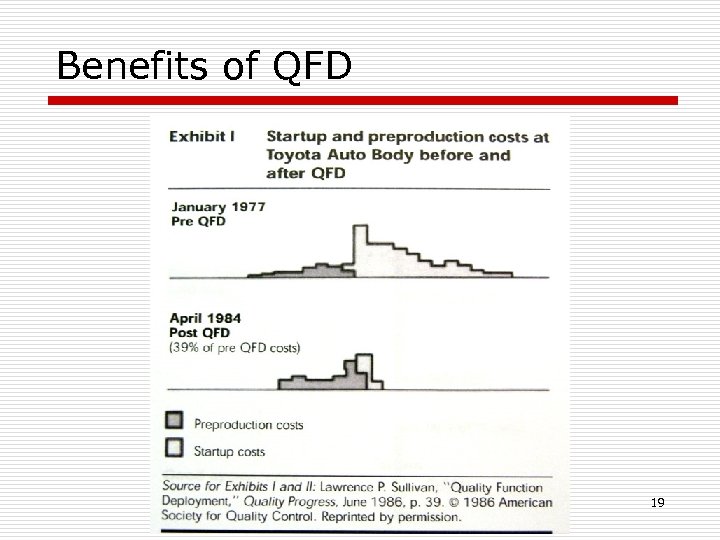

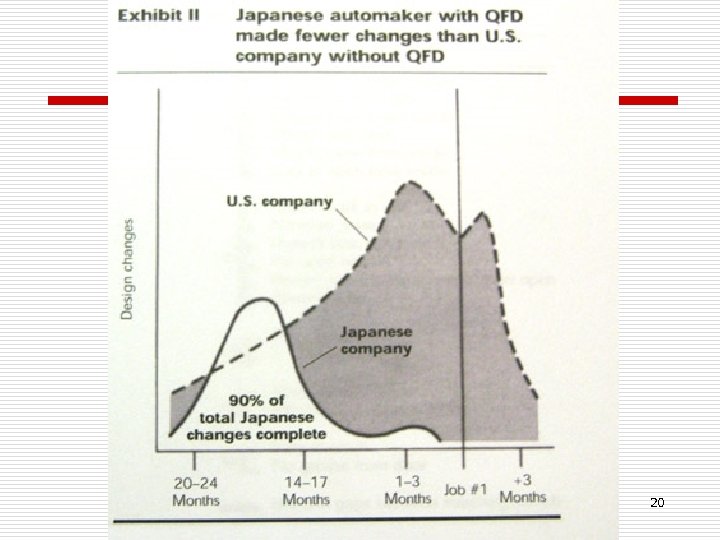

Benefits of QFD o reduced time to market o reduction in design changes o decreased design and manufacturing costs o improved quality o increased customer satisfaction o enhanced (almost forced) cooperation among marketing, design engineering, and production 18

Benefits of QFD o reduced time to market o reduction in design changes o decreased design and manufacturing costs o improved quality o increased customer satisfaction o enhanced (almost forced) cooperation among marketing, design engineering, and production 18

Benefits of QFD 19

Benefits of QFD 19

20

20

QFD Process o The Four Steps of the QFD process: 1. Product Planning (House of Quality) 2. Product Design (Parts Deployment) 3. Process and Production Design (Process Planning) 4. Quality Planning 21

QFD Process o The Four Steps of the QFD process: 1. Product Planning (House of Quality) 2. Product Design (Parts Deployment) 3. Process and Production Design (Process Planning) 4. Quality Planning 21

QFD Process (Stages) 1. Product Planning (House of Quality) Customer requirements translated to technical characteristics 2. Product Design (Parts Deployment) Parts and components determined & their properties and specifications set … 22

QFD Process (Stages) 1. Product Planning (House of Quality) Customer requirements translated to technical characteristics 2. Product Design (Parts Deployment) Parts and components determined & their properties and specifications set … 22

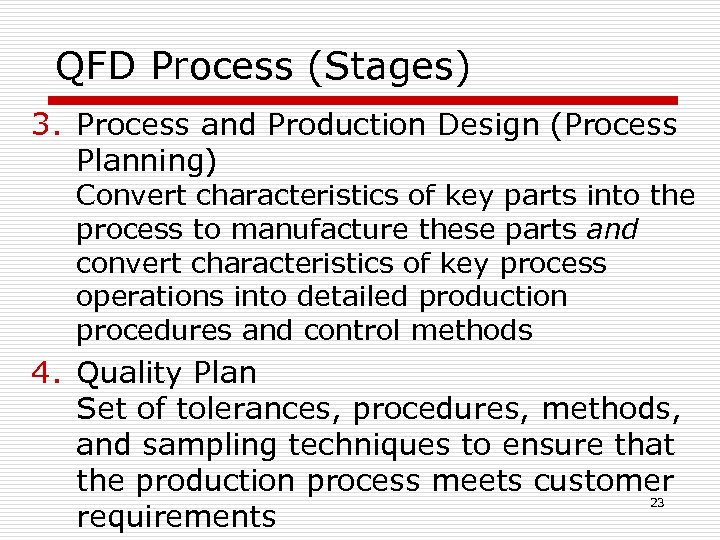

QFD Process (Stages) 3. Process and Production Design (Process Planning) Convert characteristics of key parts into the process to manufacture these parts and convert characteristics of key process operations into detailed production procedures and control methods 4. Quality Plan Set of tolerances, procedures, methods, and sampling techniques to ensure that the production process meets customer requirements 23

QFD Process (Stages) 3. Process and Production Design (Process Planning) Convert characteristics of key parts into the process to manufacture these parts and convert characteristics of key process operations into detailed production procedures and control methods 4. Quality Plan Set of tolerances, procedures, methods, and sampling techniques to ensure that the production process meets customer requirements 23

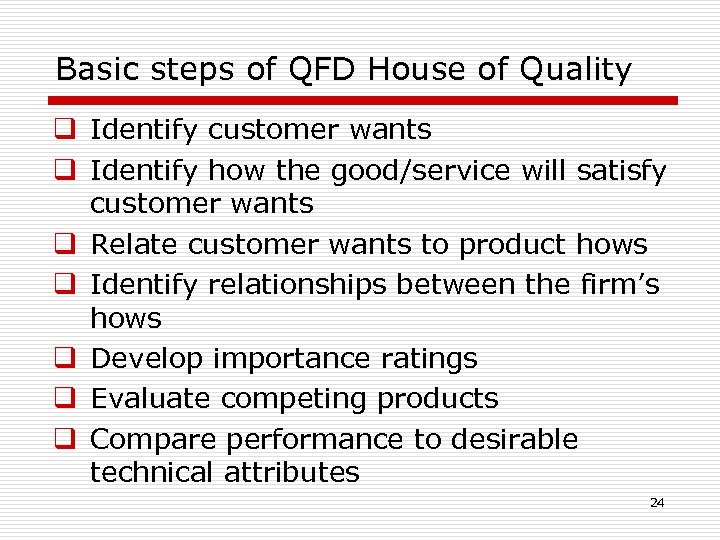

Basic steps of QFD House of Quality q Identify customer wants q Identify how the good/service will satisfy customer wants q Relate customer wants to product hows q Identify relationships between the firm’s hows q Develop importance ratings q Evaluate competing products q Compare performance to desirable technical attributes 24

Basic steps of QFD House of Quality q Identify customer wants q Identify how the good/service will satisfy customer wants q Relate customer wants to product hows q Identify relationships between the firm’s hows q Develop importance ratings q Evaluate competing products q Compare performance to desirable technical attributes 24

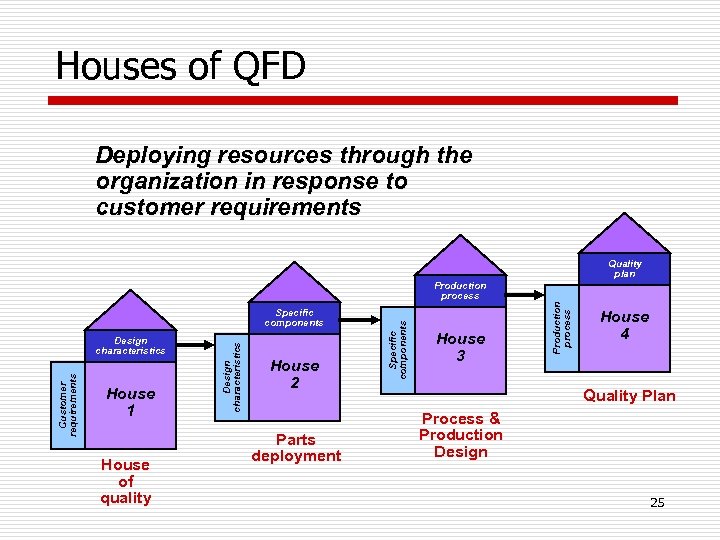

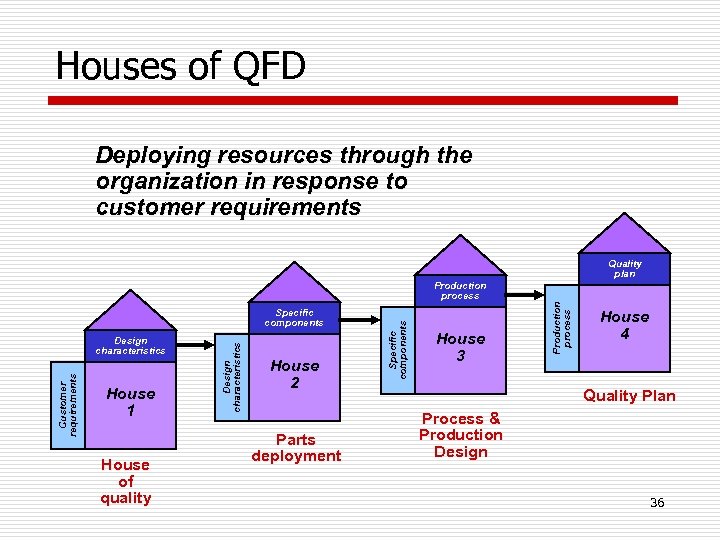

Houses of QFD Deploying resources through the organization in response to customer requirements Quality plan Customer requirements House 1 House of quality House 2 Parts deployment House 3 Production process Design characteristics Specific components Production process House 4 Quality Plan Process & Production Design 25

Houses of QFD Deploying resources through the organization in response to customer requirements Quality plan Customer requirements House 1 House of quality House 2 Parts deployment House 3 Production process Design characteristics Specific components Production process House 4 Quality Plan Process & Production Design 25

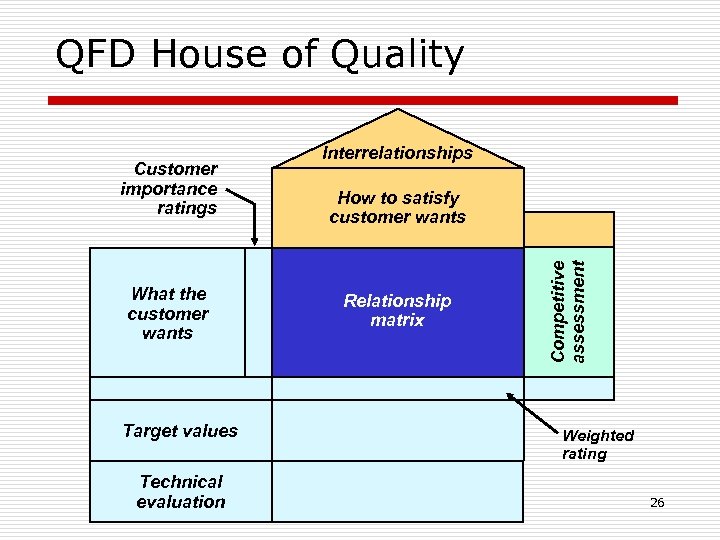

QFD House of Quality What the customer wants Target values Technical evaluation How to satisfy customer wants Relationship matrix Competitive assessment Customer importance ratings Interrelationships Weighted rating 26

QFD House of Quality What the customer wants Target values Technical evaluation How to satisfy customer wants Relationship matrix Competitive assessment Customer importance ratings Interrelationships Weighted rating 26

House of Quality Example o Your team has been charged with designing a new camera for Olympus, Japan o The first action is to construct a House of Quality 27

House of Quality Example o Your team has been charged with designing a new camera for Olympus, Japan o The first action is to construct a House of Quality 27

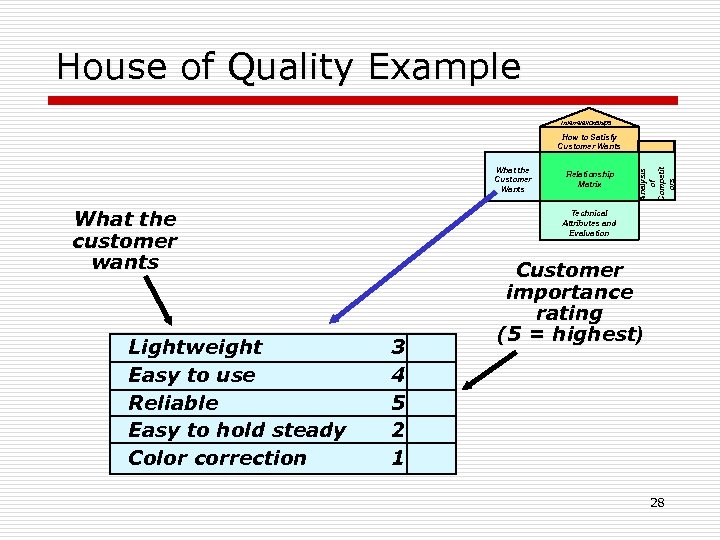

House of Quality Example Interrelationships What the Customer Wants What the customer wants Lightweight Easy to use Reliable Easy to hold steady Color correction Relationship Matrix Analysis of Competit ors How to Satisfy Customer Wants Technical Attributes and Evaluation 3 4 5 2 1 Customer importance rating (5 = highest) 28

House of Quality Example Interrelationships What the Customer Wants What the customer wants Lightweight Easy to use Reliable Easy to hold steady Color correction Relationship Matrix Analysis of Competit ors How to Satisfy Customer Wants Technical Attributes and Evaluation 3 4 5 2 1 Customer importance rating (5 = highest) 28

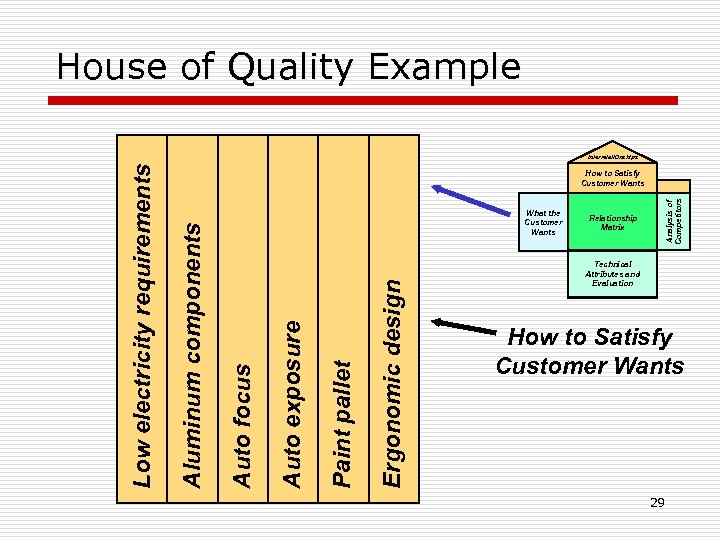

House of Quality Example Ergonomic design Paint pallet Auto exposure Auto focus What the Customer Wants Relationship Matrix Analysis of Competitors How to Satisfy Customer Wants Aluminum components Low electricity requirements Interrelationships Technical Attributes and Evaluation How to Satisfy Customer Wants 29

House of Quality Example Ergonomic design Paint pallet Auto exposure Auto focus What the Customer Wants Relationship Matrix Analysis of Competitors How to Satisfy Customer Wants Aluminum components Low electricity requirements Interrelationships Technical Attributes and Evaluation How to Satisfy Customer Wants 29

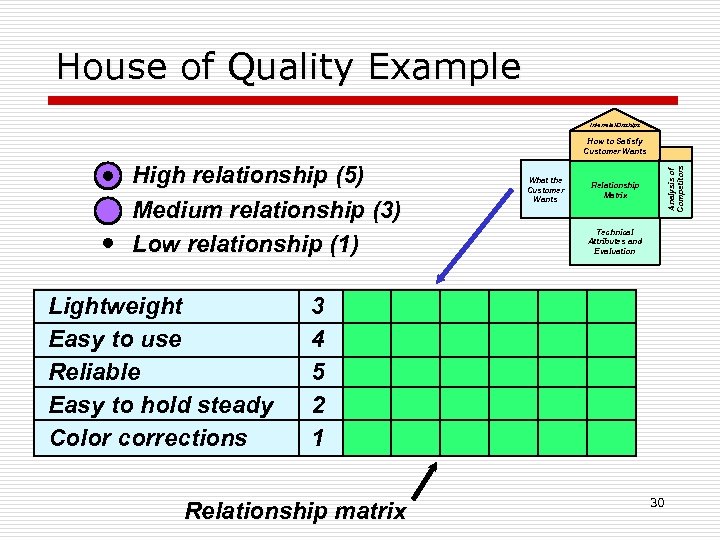

House of Quality Example Interrelationships High relationship (5) Medium relationship (3) Low relationship (1) Lightweight Easy to use Reliable Easy to hold steady Color corrections What the Customer Wants Analysis of Competitors How to Satisfy Customer Wants Relationship Matrix Technical Attributes and Evaluation 3 4 5 2 1 Relationship matrix 30

House of Quality Example Interrelationships High relationship (5) Medium relationship (3) Low relationship (1) Lightweight Easy to use Reliable Easy to hold steady Color corrections What the Customer Wants Analysis of Competitors How to Satisfy Customer Wants Relationship Matrix Technical Attributes and Evaluation 3 4 5 2 1 Relationship matrix 30

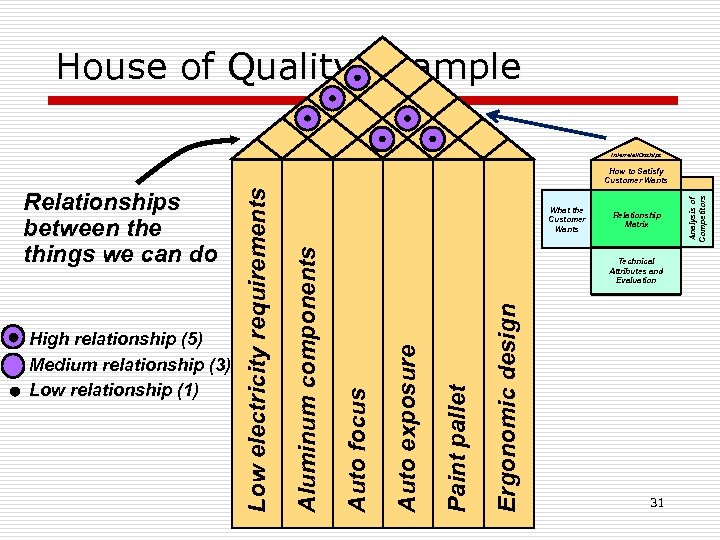

House of Quality Example Interrelationships Ergonomic design Paint pallet Auto exposure 31 Analysis of Competitors Relationship Matrix Technical Attributes and Evaluation Auto focus High relationship (5) Medium relationship (3) Low relationship (1) What the Customer Wants Aluminum components Relationships between the things we can do Low electricity requirements How to Satisfy Customer Wants

House of Quality Example Interrelationships Ergonomic design Paint pallet Auto exposure 31 Analysis of Competitors Relationship Matrix Technical Attributes and Evaluation Auto focus High relationship (5) Medium relationship (3) Low relationship (1) What the Customer Wants Aluminum components Relationships between the things we can do Low electricity requirements How to Satisfy Customer Wants

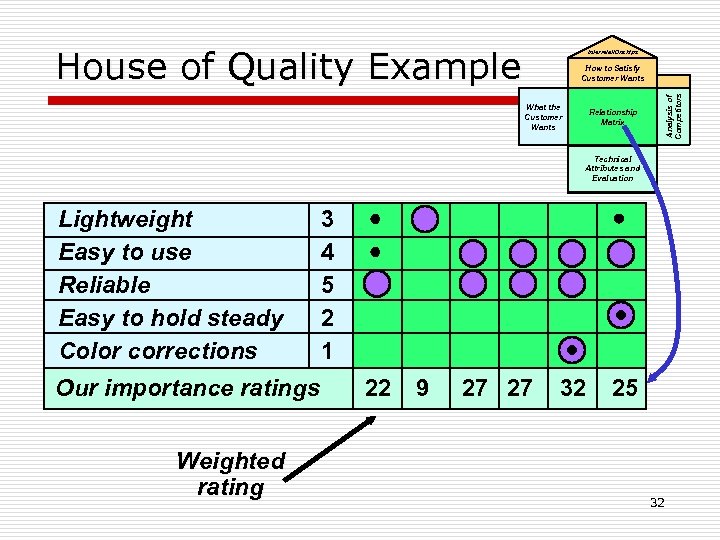

House of Quality Example Interrelationships What the Customer Wants Relationship Matrix Analysis of Competitors How to Satisfy Customer Wants Technical Attributes and Evaluation Lightweight Easy to use Reliable Easy to hold steady Color corrections Our importance ratings Weighted rating 3 4 5 2 1 22 9 27 27 32 25 32

House of Quality Example Interrelationships What the Customer Wants Relationship Matrix Analysis of Competitors How to Satisfy Customer Wants Technical Attributes and Evaluation Lightweight Easy to use Reliable Easy to hold steady Color corrections Our importance ratings Weighted rating 3 4 5 2 1 22 9 27 27 32 25 32

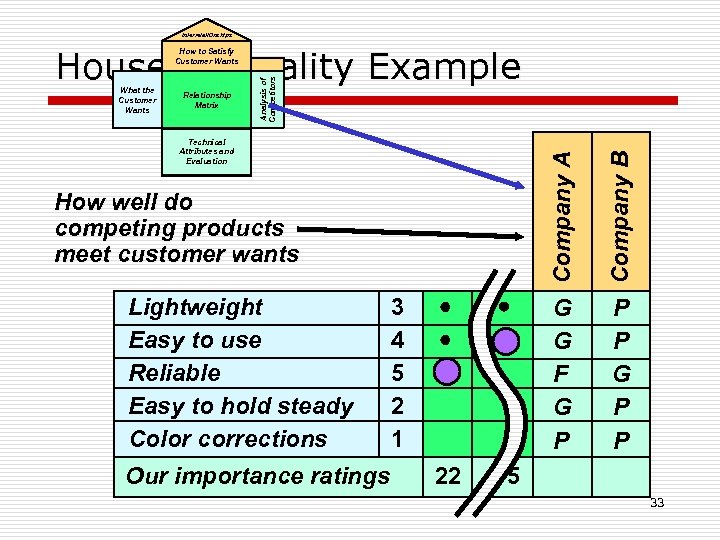

Interrelationships House of Quality Example Relationship Matrix Company A Technical Attributes and Evaluation G G F G P How well do competing products meet customer wants Lightweight Easy to use Reliable Easy to hold steady Color corrections Our importance ratings 3 4 5 2 1 22 Company B What the Customer Wants Analysis of Competitors How to Satisfy Customer Wants P P G P P 5 33

Interrelationships House of Quality Example Relationship Matrix Company A Technical Attributes and Evaluation G G F G P How well do competing products meet customer wants Lightweight Easy to use Reliable Easy to hold steady Color corrections Our importance ratings 3 4 5 2 1 22 Company B What the Customer Wants Analysis of Competitors How to Satisfy Customer Wants P P G P P 5 33

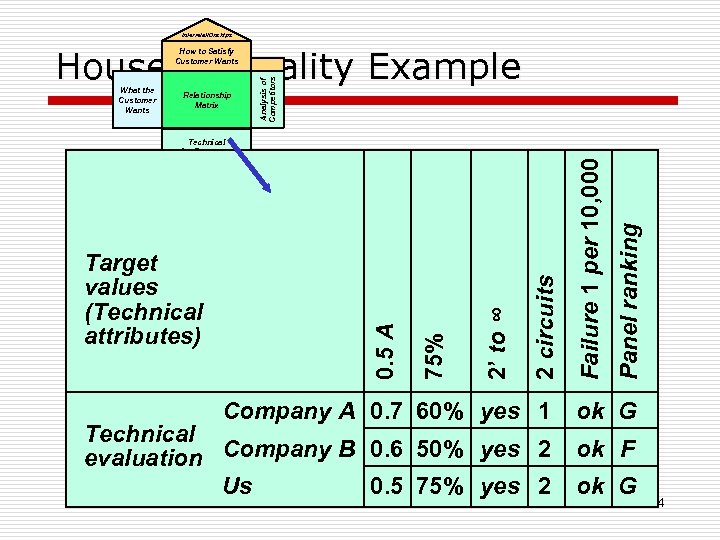

Interrelationships House of Quality Example 2 circuits 2’ to ∞ 75% Target values (Technical attributes) 0. 5 A Technical Attributes and Evaluation Company A 0. 7 60% yes 1 Technical evaluation Company B 0. 6 50% yes 2 Us 0. 5 75% yes 2 Panel ranking Relationship Matrix Failure 1 per 10, 000 What the Customer Wants Analysis of Competitors How to Satisfy Customer Wants ok G ok F ok G 34

Interrelationships House of Quality Example 2 circuits 2’ to ∞ 75% Target values (Technical attributes) 0. 5 A Technical Attributes and Evaluation Company A 0. 7 60% yes 1 Technical evaluation Company B 0. 6 50% yes 2 Us 0. 5 75% yes 2 Panel ranking Relationship Matrix Failure 1 per 10, 000 What the Customer Wants Analysis of Competitors How to Satisfy Customer Wants ok G ok F ok G 34

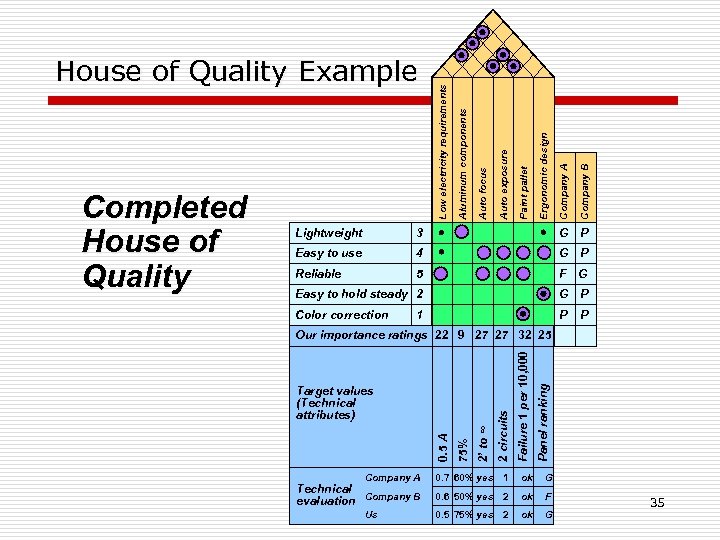

Company B Company A Ergonomic design Paint pallet Auto exposure Auto focus Aluminum components Lightweight 3 G P Easy to use 4 G P Reliable 5 F G Easy to hold steady 2 G P Color correction P 1 P Company A Technical evaluation Company B Us Panel ranking Failure 1 per 10, 000 2’ to ∞ 75% Target values (Technical attributes) 2 circuits Our importance ratings 22 9 27 27 32 25 0. 5 A Completed House of Quality Low electricity requirements House of Quality Example 0. 7 60% yes 1 ok G 0. 6 50% yes 2 ok F 0. 5 75% yes 2 ok G 35

Company B Company A Ergonomic design Paint pallet Auto exposure Auto focus Aluminum components Lightweight 3 G P Easy to use 4 G P Reliable 5 F G Easy to hold steady 2 G P Color correction P 1 P Company A Technical evaluation Company B Us Panel ranking Failure 1 per 10, 000 2’ to ∞ 75% Target values (Technical attributes) 2 circuits Our importance ratings 22 9 27 27 32 25 0. 5 A Completed House of Quality Low electricity requirements House of Quality Example 0. 7 60% yes 1 ok G 0. 6 50% yes 2 ok F 0. 5 75% yes 2 ok G 35

Houses of QFD Deploying resources through the organization in response to customer requirements Quality plan Customer requirements House 1 House of quality House 2 Parts deployment House 3 Production process Design characteristics Specific components Production process House 4 Quality Plan Process & Production Design 36

Houses of QFD Deploying resources through the organization in response to customer requirements Quality plan Customer requirements House 1 House of quality House 2 Parts deployment House 3 Production process Design characteristics Specific components Production process House 4 Quality Plan Process & Production Design 36

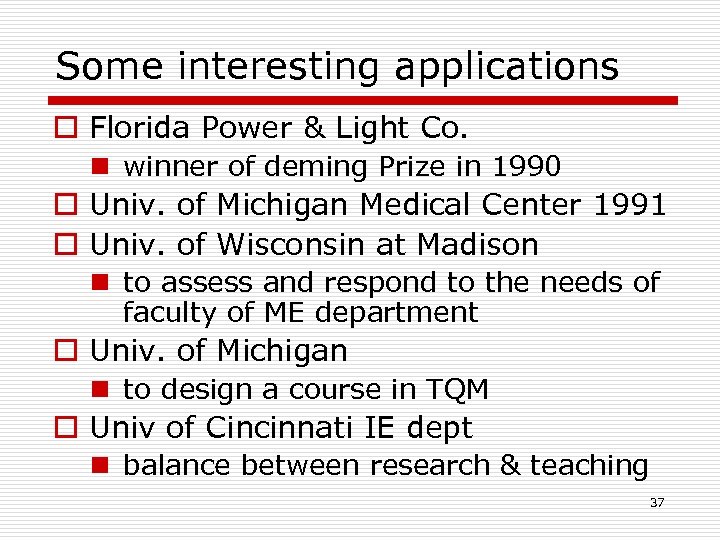

Some interesting applications o Florida Power & Light Co. n winner of deming Prize in 1990 o Univ. of Michigan Medical Center 1991 o Univ. of Wisconsin at Madison n to assess and respond to the needs of faculty of ME department o Univ. of Michigan n to design a course in TQM o Univ of Cincinnati IE dept n balance between research & teaching 37

Some interesting applications o Florida Power & Light Co. n winner of deming Prize in 1990 o Univ. of Michigan Medical Center 1991 o Univ. of Wisconsin at Madison n to assess and respond to the needs of faculty of ME department o Univ. of Michigan n to design a course in TQM o Univ of Cincinnati IE dept n balance between research & teaching 37

Local government services o o o o o public transportation recreational facilities waste disposal library design and operation social services educational & cultural activities city planning and zoning health services sports & athletics environmental programs 38

Local government services o o o o o public transportation recreational facilities waste disposal library design and operation social services educational & cultural activities city planning and zoning health services sports & athletics environmental programs 38

QFD Sources o QFD Institute (http: //www. qfdi. org) o Glenn Mazur (http: //www. mazur. net) o International Council for QFD (ICQFD) (http: //www. icqfd. org) o Akao Prize (http: //qfdi. org/who_is_qfdi/akao_prize. htm) o Isixsigma (http: //www. isixsigma. com) o QFD Türkiye (http: //www. qfdturkiye. org) 39

QFD Sources o QFD Institute (http: //www. qfdi. org) o Glenn Mazur (http: //www. mazur. net) o International Council for QFD (ICQFD) (http: //www. icqfd. org) o Akao Prize (http: //qfdi. org/who_is_qfdi/akao_prize. htm) o Isixsigma (http: //www. isixsigma. com) o QFD Türkiye (http: //www. qfdturkiye. org) 39

QFD Sources o DRM Associates (http: //www. npd-solutions. com) o QFD at Univ. of Sheffield (http: //www. shef. ac. uk ) o QFD 2000 (http: //www. qfd 2000. co. uk) 40

QFD Sources o DRM Associates (http: //www. npd-solutions. com) o QFD at Univ. of Sheffield (http: //www. shef. ac. uk ) o QFD 2000 (http: //www. qfd 2000. co. uk) 40

QFD Software o QFD/CAPTURE by QFD Capture o QFD 2000 (http: //www. ipmmarketing. co. uk/QFD 2000. htm) 41

QFD Software o QFD/CAPTURE by QFD Capture o QFD 2000 (http: //www. ipmmarketing. co. uk/QFD 2000. htm) 41

42

42