6aa681d3e12dd583de31b594b379a199.ppt

- Количество слайдов: 24

QUALITY FUNCTION DEPLOYMENT PRESENTED BY GROUP 1

CONTENTS • • Evolution of quality and QFD Definition Benefits Process House of Quality Using house of Quality Application

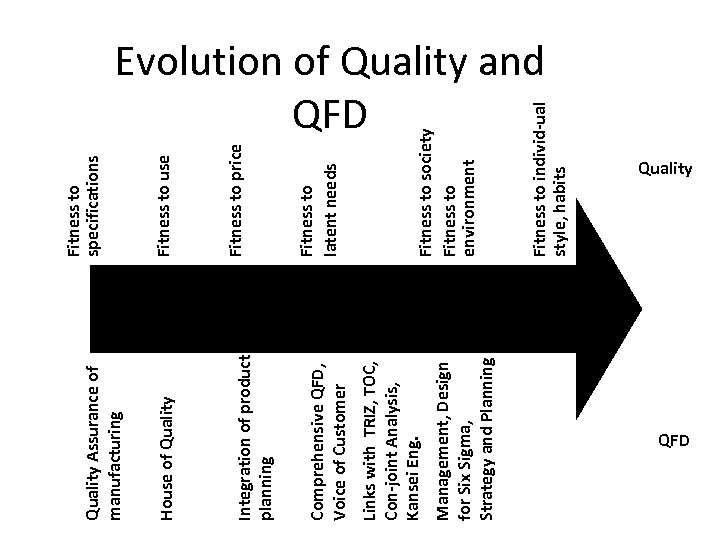

Management, Design for Six Sigma, Strategy and Planning Links with TRIZ, TOC, Con-joint Analysis, Kansei Eng. Comprehensive QFD, Voice of Customer Integration of product planning House of Quality Assurance of manufacturing Fitness to individ-ual 2005 style, habits 2000 1990 Fitness to society Fitness to 1995 environment 1985 1975 Fitness to latent needs 1980 1965 Fitness to price 1970 Fitness to use 1960 Fitness to specifications Evolution of Quality and QFD Quality QFD

QUALITY FUNCTION DEPLOYMENT QFD process defined by the “Voice of the customer” while the traditional approach the specification is defined by the “Voice of the engineer”

Benefits of QFD • Shorter development cycles • Trade-offs are made in design, strategically, rather than in the market, tactically. • Lower costs, increased productivity • Documentation orientation • Team involvement and commitment at the design stage

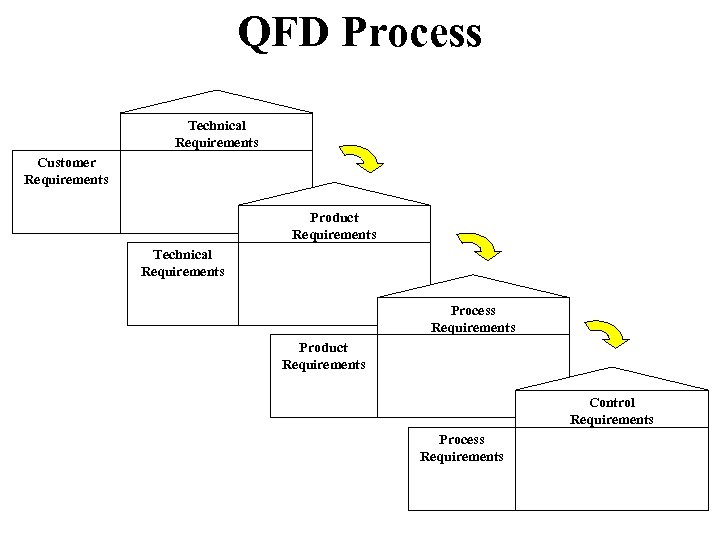

QFD Process Technical Requirements Customer Requirements Product Requirements Technical Requirements Process Requirements Product Requirements Control Requirements Process Requirements

When is QFD Appropriate? § Poor communications and expectations get lost in the complexity of product development. § Lack of structure or logic to the allocation of product development resources. § Lack of efficient and / or effective product / process development teamwork. § Extended development time caused by excessive redesign, problem solving, or fire fighting.

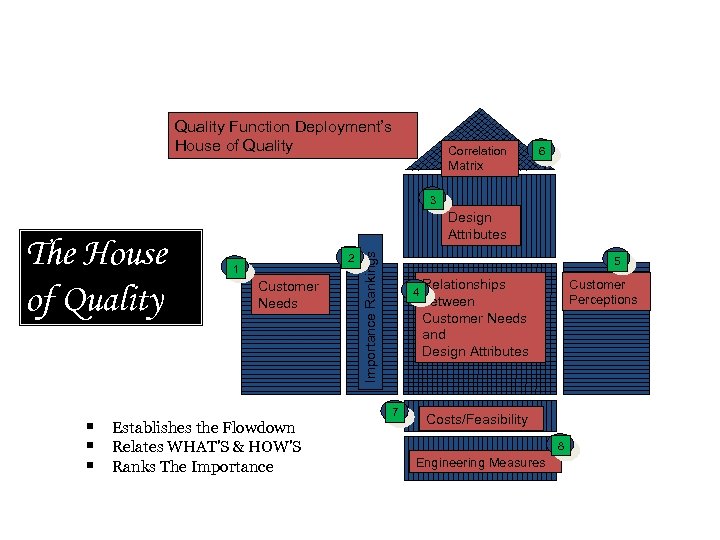

Quality Function Deployment’s House of Quality Correlation 6 Matrix 3 § § § 2 1 Customer Needs Establishes the Flowdown Relates WHAT'S & HOW'S Ranks The Importance Rankings The House of Quality Design Attributes 5 4 7 Relationships between Customer Needs and Design Attributes Customer Perceptions Costs/Feasibility 8 Engineering Measures

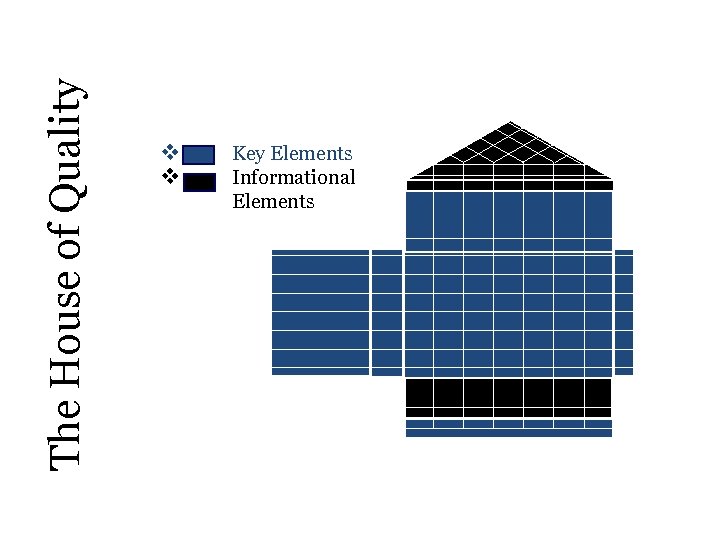

The House of Quality v v Key Elements Informational Elements

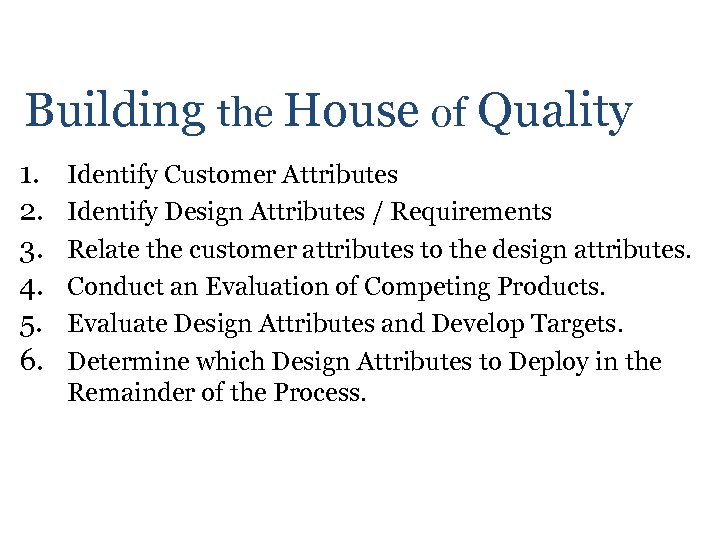

Building the House of Quality 1. 2. 3. 4. 5. 6. Identify Customer Attributes Identify Design Attributes / Requirements Relate the customer attributes to the design attributes. Conduct an Evaluation of Competing Products. Evaluate Design Attributes and Develop Targets. Determine which Design Attributes to Deploy in the Remainder of the Process.

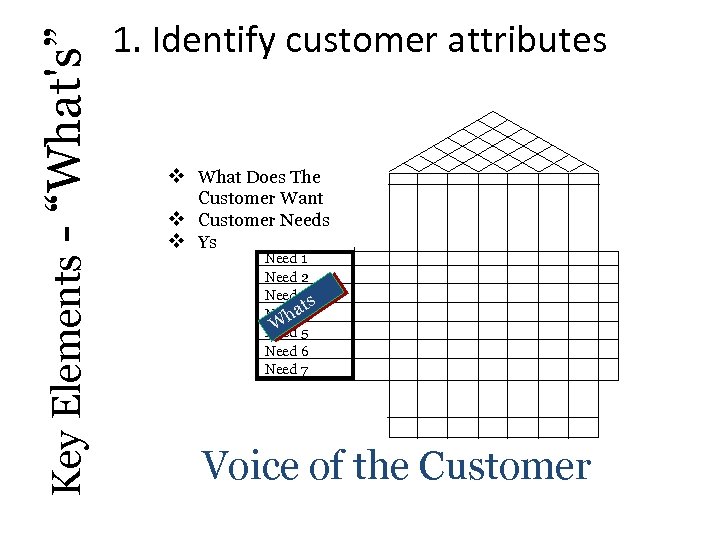

Key Elements - “What's” 1. Identify customer attributes v What Does The Customer Want v Customer Needs v Ys Need 1 Need 2 Need 3 ts Needa 4 h W 5 Need 6 Need 7 Voice of the Customer

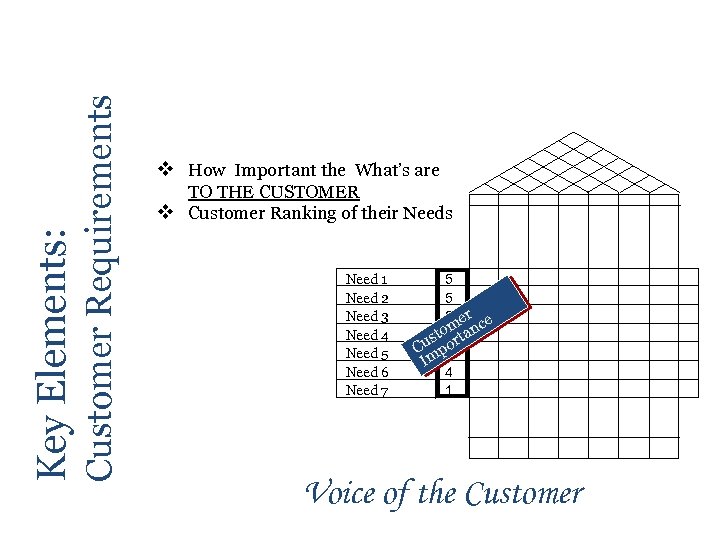

Customer Requirements Key Elements: v How Important the What’s are TO THE CUSTOMER v Customer Ranking of their Needs Need 1 Need 2 Need 3 Need 4 Need 5 Need 6 Need 7 5 5 3 er e m c 4 n stoorta Cu p 2 Im 4 1 Voice of the Customer

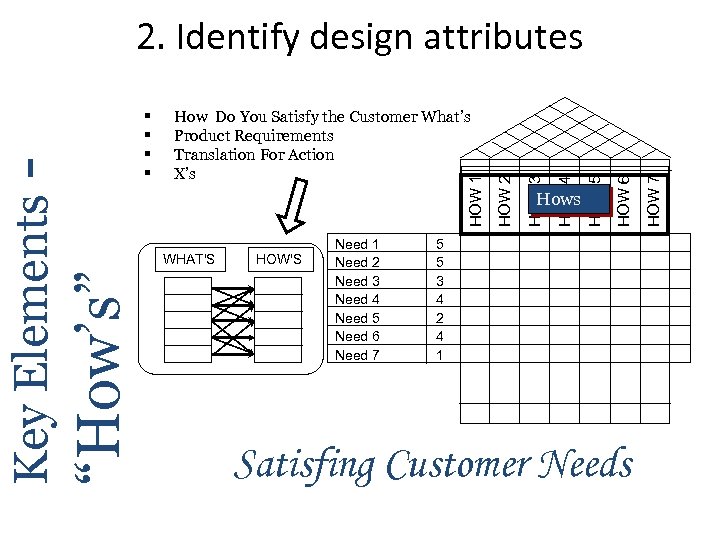

HOW'S Need 1 Need 2 Need 3 Need 4 Need 5 Need 6 Need 7 5 5 3 4 2 4 1 Satisfing Customer Needs HOW 7 HOW 6 Hows HOW 5 HOW 4 HOW 3 HOW 1 How Do You Satisfy the Customer What’s Product Requirements Translation For Action X’s WHAT'S “How’s” Key Elements - § § HOW 2 2. Identify design attributes

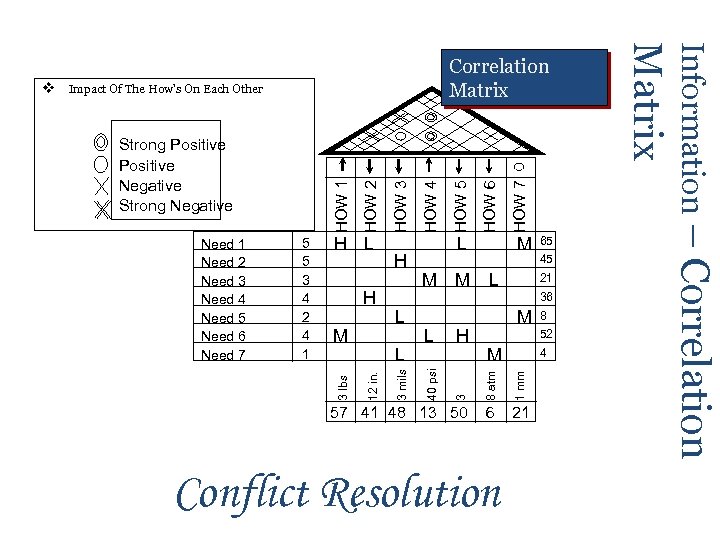

M H L L M M L M 8 52 M 8 atm 1 mm 4 6 21 12 in. 45 36 57 41 48 13 50 3 lbs 65 21 3 H HOW 7 HOW 6 HOW 5 HOW 4 L 40 psi H HOW 3 HOW 2 H L 3 mils 5 5 3 4 2 4 1 Conflict Resolution Correlation Need 1 Need 2 Need 3 Need 4 Need 5 Need 6 Need 7 HOW 1 Strong Positive Negative Strong Negative Information – v Impact Of The How’s On Each Other Matrix Correlation Matrix

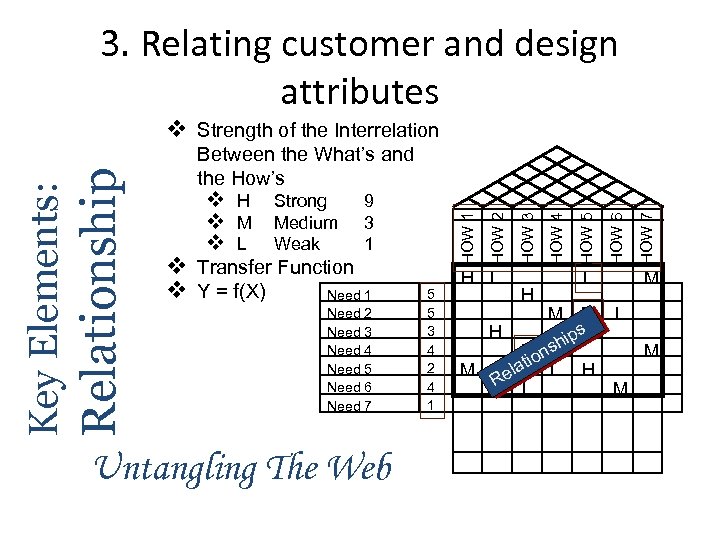

3. Relating customer and design attributes Need 2 Need 3 Need 4 Need 5 Need 6 Need 7 Untangling The Web 5 5 3 4 2 4 1 H L HOW 7 HOW 6 HOW 5 v Transfer Function v Y = f(X) Need 1 HOW 4 9 3 1 HOW 3 v H Strong v M Medium v L Weak HOW 2 Between the What’s and the How’s HOW 1 Relationship Key Elements: v Strength of the Interrelation M M M L s H hip L ons M ti L H la M Re L M

This step includes identifying importance ratings for each customer attribute AND evaluating existing products / services for each of the attributes 4. Add Market Evaluation & Key Selling Points

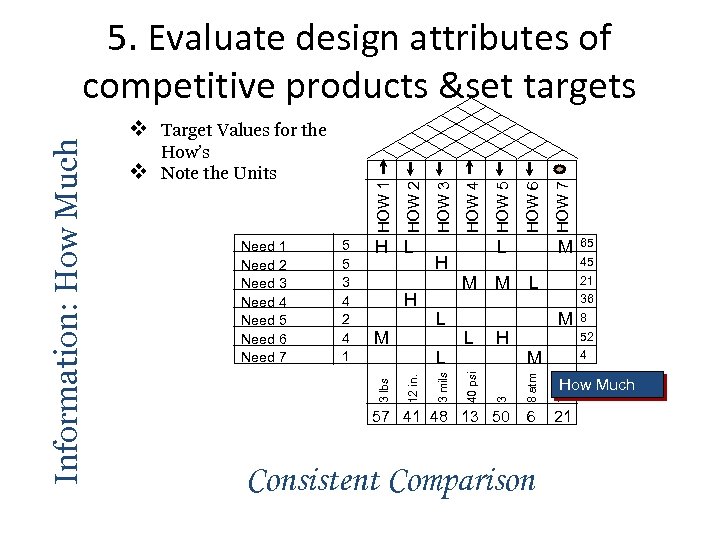

H L H M L L M M L 45 36 M 8 52 M 8 atm 1 mm 4 57 41 48 13 50 6 21 12 in. 65 21 3 H HOW 7 HOW 6 HOW 5 HOW 4 HOW 3 H L 40 psi 5 5 3 4 2 4 1 3 mils Need 1 Need 2 Need 3 Need 4 Need 5 Need 6 Need 7 HOW 1 v How’s Note the Units HOW 2 v Target Values for the 3 lbs Information: How Much 5. Evaluate design attributes of competitive products &set targets Consistent Comparison How Much

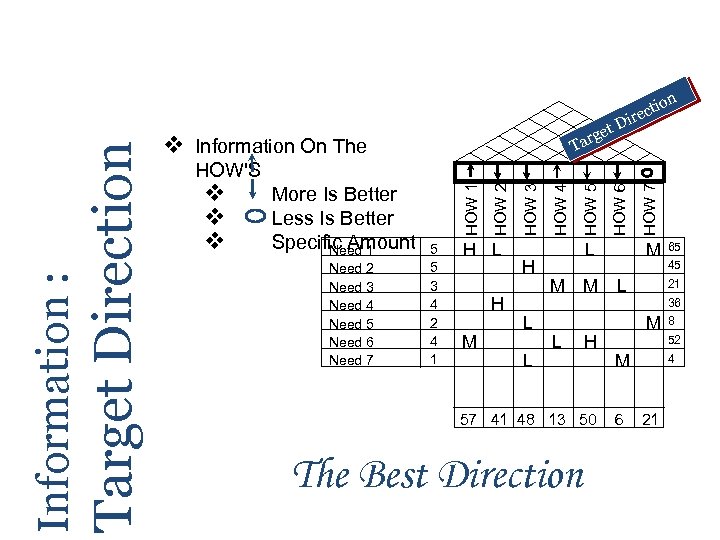

et arg T v Information On The D Need 2 Need 3 Need 4 Need 5 Need 6 Need 7 5 5 3 4 2 4 1 H L H M H L L L M M L H 57 41 48 13 50 The Best Direction HOW 7 HOW 6 HOW 5 HOW 4 More Is Better Less Is Better Specific Amount Need 1 HOW 3 v v v HOW 2 HOW'S HOW 1 Target Direction Information : ion ct ire M L 65 45 21 36 M 8 52 M 6 4 21

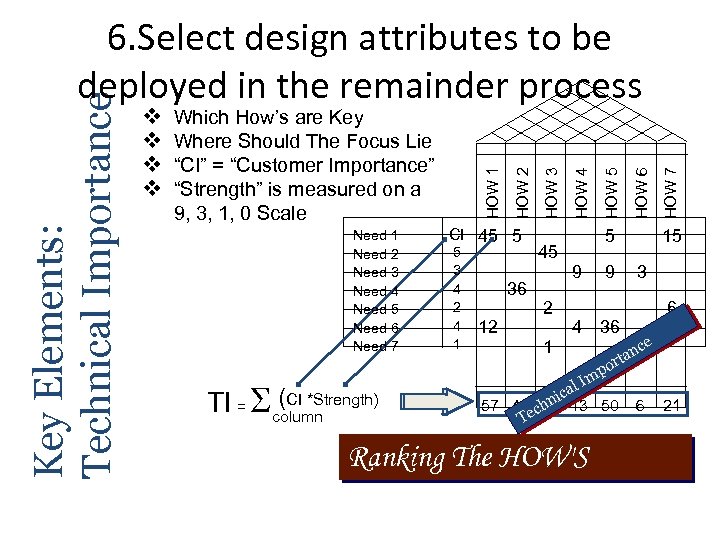

Need 1 Need 2 Need 3 Need 4 Need 5 Need 6 Need 7 (CI *Strength) TI = Scolumn CI 45 5 5 3 4 2 4 1 36 12 45 2 1 5 9 9 15 3 6 4 36 c Me tan r o p l Im a nic 13 50 57 41 ech 48 T Ranking The HOW'S HOW 7 HOW 6 HOW 5 HOW 4 HOW 3 Which How’s are Key Where Should The Focus Lie “CI” = “Customer Importance” “Strength” is measured on a 9, 3, 1, 0 Scale HOW 2 v v HOW 1 Key Elements: Technical Importance 6. Select design attributes to be deployed in the remainder process 6 21

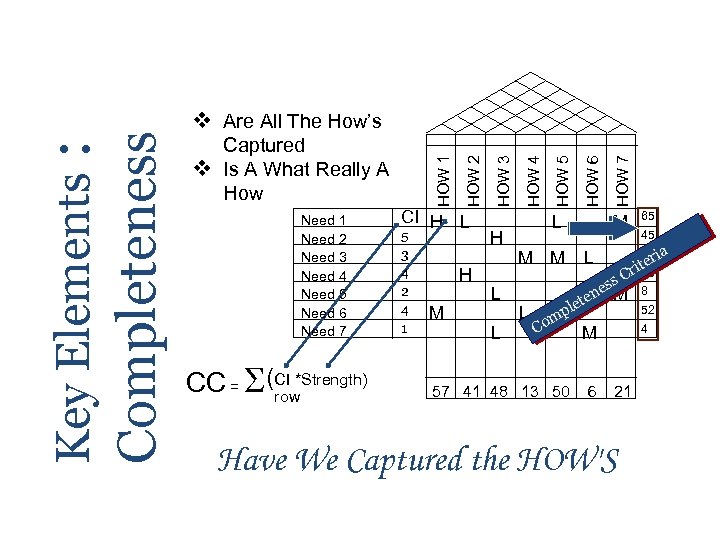

Need 1 Need 2 Need 3 Need 4 Need 5 Need 6 Need 7 CI CC = S (row*Strength) CI H L 5 3 4 2 4 1 H M H L L L 57 41 48 13 50 45 21 ia ter ri 36 L s. C es. M n ete Hl mp o C 65 M M M L HOW 7 HOW 6 HOW 5 HOW 4 HOW 3 HOW 2 Captured v Is A What Really A How HOW 1 Completeness : Key Elements v Are All The How’s 52 4 M 6 8 21 Have We Captured the HOW'S

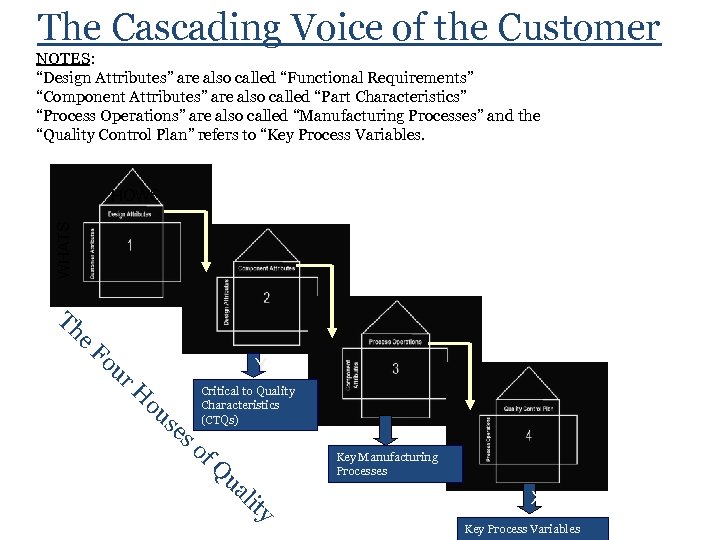

Using the House of Quality The voice of the customer MUST be carried THROUGHOUT the production process. Three other “houses of quality” are used to do this and, together with the first, these carry the customer’s voice from its initial expression, through design attributes, on to component attributes, to process operations, and eventually to a quality control and improvement plans. In Japan, all four are used. The tendency in the West is to use only the first one or two.

The Cascading Voice of the Customer NOTES: “Design Attributes” are also called “Functional Requirements” “Component Attributes” are also called “Part Characteristics” “Process Operations” are also called “Manufacturing Processes” and the “Quality Control Plan” refers to “Key Process Variables. WHATS HOWS Th e Fo ur H Y ou se so Critical to Quality Characteristics (CTQs) f. Q ua lit y Key Manufacturing Processes X Key Process Variables

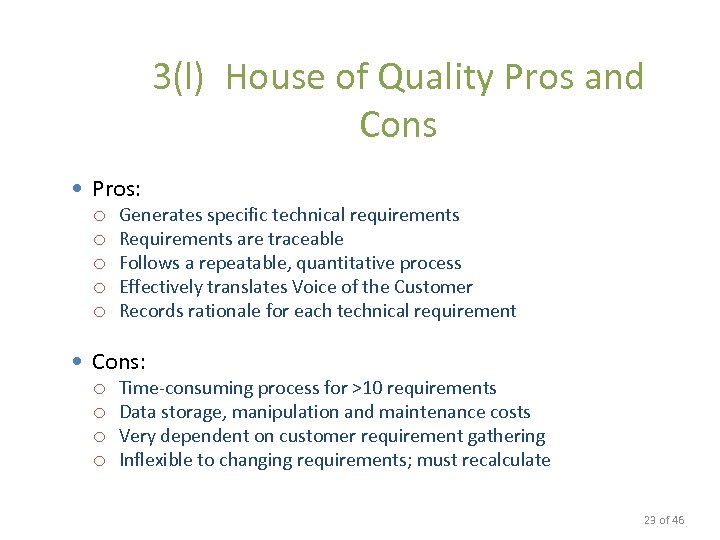

3(l) House of Quality Pros and Cons Pros: Generates specific technical requirements Requirements are traceable Follows a repeatable, quantitative process Effectively translates Voice of the Customer Records rationale for each technical requirement Cons: Time-consuming process for >10 requirements Data storage, manipulation and maintenance costs Very dependent on customer requirement gathering Inflexible to changing requirements; must recalculate 23 of 46

Thank you

6aa681d3e12dd583de31b594b379a199.ppt