13cbd19bd1b8069a76785360f1cd5f8a.ppt

- Количество слайдов: 29

Quality for a Transforming Army Presented to: National Aeronautics and Space Administration Quality Leadership Forum Marc D. Saperstein U. S. Army Tank-automotive and Armaments Command – Armament Research, Development & Engineering Center 25 September 2002

Quality for a Transforming Army Presented to: National Aeronautics and Space Administration Quality Leadership Forum Marc D. Saperstein U. S. Army Tank-automotive and Armaments Command – Armament Research, Development & Engineering Center 25 September 2002

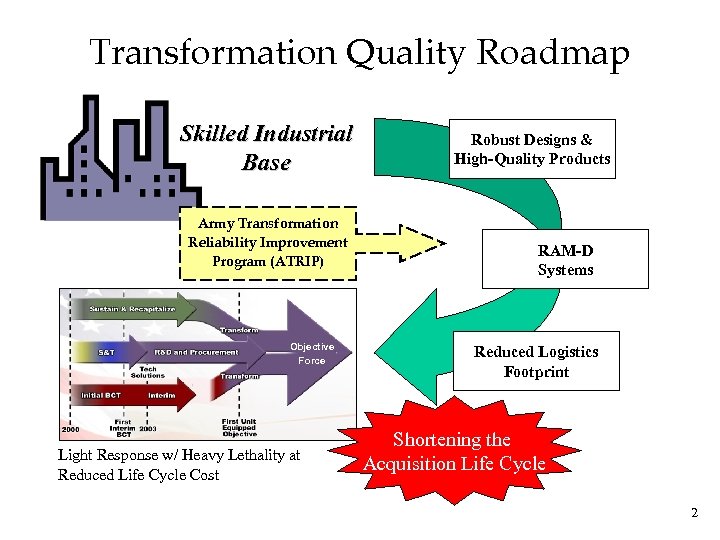

Transformation Quality Roadmap Skilled Industrial Base Army Transformation Reliability Improvement Program (ATRIP) Objective Force Light Response w/ Heavy Lethality at Reduced Life Cycle Cost Robust Designs & High-Quality Products RAM-D Systems Reduced Logistics Footprint Shortening the Acquisition Life Cycle 2

Transformation Quality Roadmap Skilled Industrial Base Army Transformation Reliability Improvement Program (ATRIP) Objective Force Light Response w/ Heavy Lethality at Reduced Life Cycle Cost Robust Designs & High-Quality Products RAM-D Systems Reduced Logistics Footprint Shortening the Acquisition Life Cycle 2

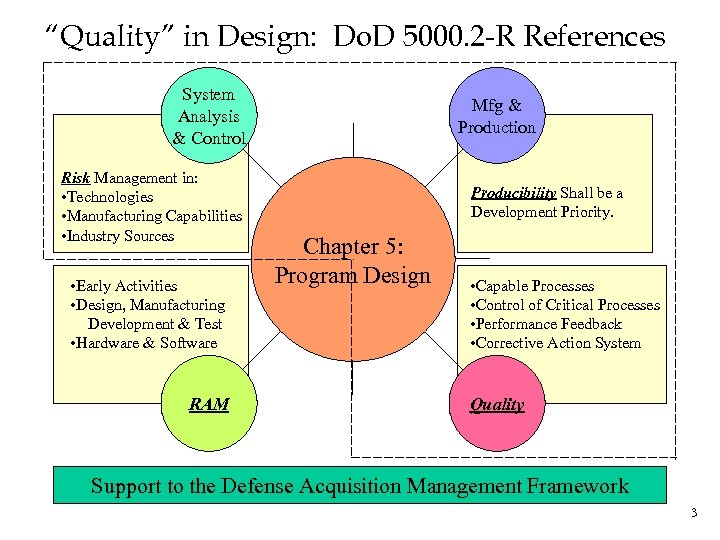

“Quality” in Design: Do. D 5000. 2 -R References System Analysis & Control Risk Management in: • Technologies • Manufacturing Capabilities • Industry Sources • Early Activities • Design, Manufacturing Development & Test • Hardware & Software RAM Mfg & Production Producibility Shall be a Development Priority. Chapter 5: Program Design • Capable Processes • Control of Critical Processes • Performance Feedback • Corrective Action System Quality Support to the Defense Acquisition Management Framework 3

“Quality” in Design: Do. D 5000. 2 -R References System Analysis & Control Risk Management in: • Technologies • Manufacturing Capabilities • Industry Sources • Early Activities • Design, Manufacturing Development & Test • Hardware & Software RAM Mfg & Production Producibility Shall be a Development Priority. Chapter 5: Program Design • Capable Processes • Control of Critical Processes • Performance Feedback • Corrective Action System Quality Support to the Defense Acquisition Management Framework 3

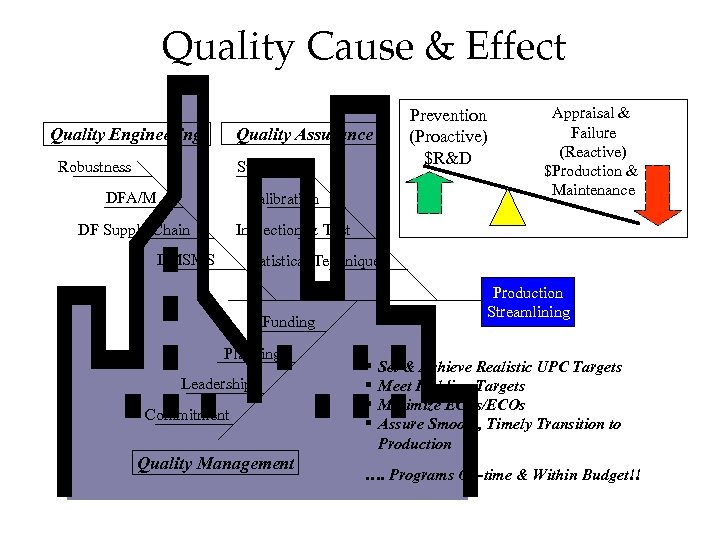

Quality Cause & Effect Quality Engineering Prevention (Proactive) $R&D Quality Assurance Robustness Systems DFA/M Calibration DF Supply Chain Appraisal & Failure (Reactive) $Production & Maintenance Inspection & Test DMSMS Statistical Techniques Production Streamlining Funding Planning Leadership Commitment Quality Management § § Set & Achieve Realistic UPC Targets Meet Fielding Targets Minimize ECPs/ECOs Assure Smooth, Timely Transition to Production …. Programs On-time & Within Budget!!

Quality Cause & Effect Quality Engineering Prevention (Proactive) $R&D Quality Assurance Robustness Systems DFA/M Calibration DF Supply Chain Appraisal & Failure (Reactive) $Production & Maintenance Inspection & Test DMSMS Statistical Techniques Production Streamlining Funding Planning Leadership Commitment Quality Management § § Set & Achieve Realistic UPC Targets Meet Fielding Targets Minimize ECPs/ECOs Assure Smooth, Timely Transition to Production …. Programs On-time & Within Budget!!

GIQLP/JACG Advanced Quality (1996) • • • Membership Emphasized Prevention vs. Detection & Correction Design & Manufacturing Tools & Attributes – Integrated Product/Process Development – – – – – • AMC (IPPD) ID & Control of Key Characteristics Design to Process Capability Design for Assembly/Manufacturing (DFA/M) Robust Design Geometric Dimensioning an Tolerancing (GD&T) Process Variation Reduction (PVR) Control of Variation in the Measurement System Root Cause, Closed Loop Corrective Action Continuous Improvement (Processes and Products) Deployment to Subcontractors – Enabling Practices – Adequate, Up-front Funding – Contract Award/Incentive Fee “If Do. D provides incentives for implementation of the advanced commercial practices, … we believe it can significantly improve quality, reduce costs of its acquisition programs and apply savings to future modernization efforts. ” 5

GIQLP/JACG Advanced Quality (1996) • • • Membership Emphasized Prevention vs. Detection & Correction Design & Manufacturing Tools & Attributes – Integrated Product/Process Development – – – – – • AMC (IPPD) ID & Control of Key Characteristics Design to Process Capability Design for Assembly/Manufacturing (DFA/M) Robust Design Geometric Dimensioning an Tolerancing (GD&T) Process Variation Reduction (PVR) Control of Variation in the Measurement System Root Cause, Closed Loop Corrective Action Continuous Improvement (Processes and Products) Deployment to Subcontractors – Enabling Practices – Adequate, Up-front Funding – Contract Award/Incentive Fee “If Do. D provides incentives for implementation of the advanced commercial practices, … we believe it can significantly improve quality, reduce costs of its acquisition programs and apply savings to future modernization efforts. ” 5

Today’s Acquisition Realities • Do. D Excellence – Performance Contracting – Supplier Empowerment – Use of COTS • • • Systems Contracting Set-Asides and HUBZones Monopolies/Oligopolies Mergers & Acquisitions Shrinking Market Shares – DMSMS 6

Today’s Acquisition Realities • Do. D Excellence – Performance Contracting – Supplier Empowerment – Use of COTS • • • Systems Contracting Set-Asides and HUBZones Monopolies/Oligopolies Mergers & Acquisitions Shrinking Market Shares – DMSMS 6

Army Quality Challenges • Risk-based/Business-based Implementation of Commercial Quality Practices • Sensitivity to “Acquisition Excellence” Principles • The Army needs to be an Educated Customer and Proactive Partner – Proficient in Related Competencies – Provide Detailed RFP/Contract Language Sections C (SOW/SOO), L (ITO) & M (Evaluation) • Basic Quality • Advanced Quality/Quality Engineering • Continuous Improvement Partnerships – Funding Profiles & Contract Incentives Consistent w/ Life Cycle Objectives 7

Army Quality Challenges • Risk-based/Business-based Implementation of Commercial Quality Practices • Sensitivity to “Acquisition Excellence” Principles • The Army needs to be an Educated Customer and Proactive Partner – Proficient in Related Competencies – Provide Detailed RFP/Contract Language Sections C (SOW/SOO), L (ITO) & M (Evaluation) • Basic Quality • Advanced Quality/Quality Engineering • Continuous Improvement Partnerships – Funding Profiles & Contract Incentives Consistent w/ Life Cycle Objectives 7

Status of Army Quality • Subset of Systems Engineering/Industrial Operations at HQ – Resources Limited – Increasing Reliance Upon Sub-Commands • De-Centralization in Several Commodity Areas – Strained (but Improving) Intra-Army Quality Communication – Some Quality Professionals Managed by PEOs/PMs – Functional Integrity/Core Competencies in Jeopardy • Acquisition Community is Reorganizing 8

Status of Army Quality • Subset of Systems Engineering/Industrial Operations at HQ – Resources Limited – Increasing Reliance Upon Sub-Commands • De-Centralization in Several Commodity Areas – Strained (but Improving) Intra-Army Quality Communication – Some Quality Professionals Managed by PEOs/PMs – Functional Integrity/Core Competencies in Jeopardy • Acquisition Community is Reorganizing 8

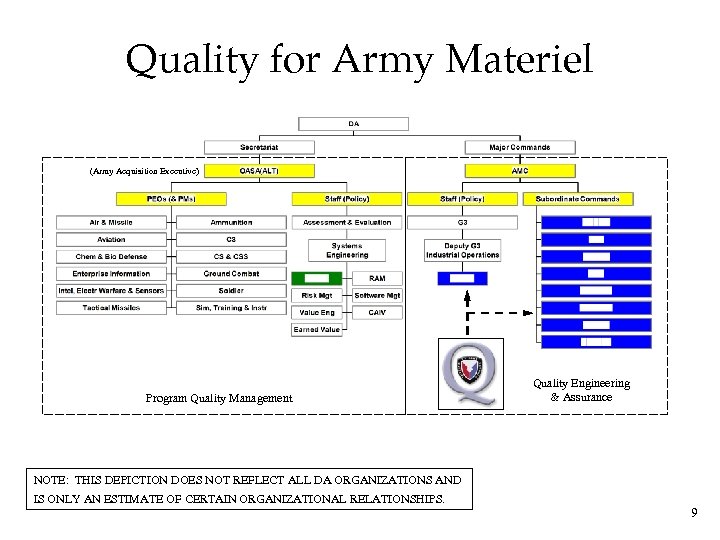

Quality for Army Materiel (Army Acquisition Executive) Program Quality Management Quality Engineering & Assurance NOTE: THIS DEPICTION DOES NOT REFLECT ALL DA ORGANIZATIONS AND IS ONLY AN ESTIMATE OF CERTAIN ORGANIZATIONAL RELATIONSHIPS. 9

Quality for Army Materiel (Army Acquisition Executive) Program Quality Management Quality Engineering & Assurance NOTE: THIS DEPICTION DOES NOT REFLECT ALL DA ORGANIZATIONS AND IS ONLY AN ESTIMATE OF CERTAIN ORGANIZATIONAL RELATIONSHIPS. 9

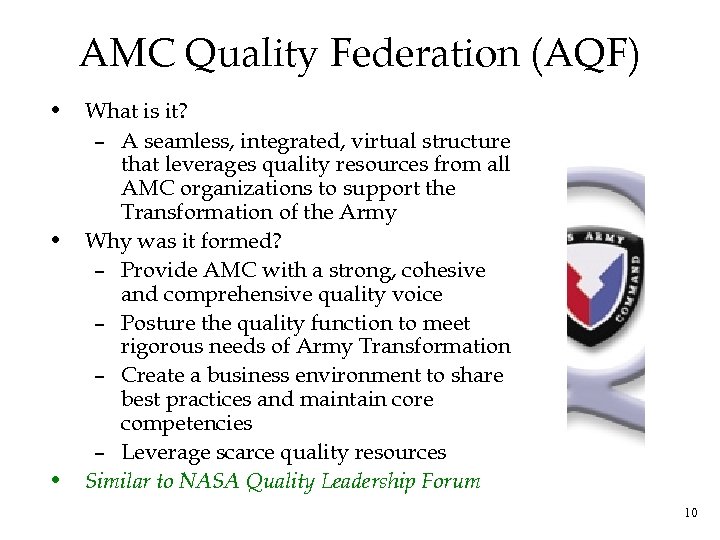

AMC Quality Federation (AQF) • What is it? – A seamless, integrated, virtual structure that leverages quality resources from all AMC organizations to support the Transformation of the Army • Why was it formed? – Provide AMC with a strong, cohesive and comprehensive quality voice – Posture the quality function to meet rigorous needs of Army Transformation – Create a business environment to share best practices and maintain core competencies – Leverage scarce quality resources • Similar to NASA Quality Leadership Forum 10

AMC Quality Federation (AQF) • What is it? – A seamless, integrated, virtual structure that leverages quality resources from all AMC organizations to support the Transformation of the Army • Why was it formed? – Provide AMC with a strong, cohesive and comprehensive quality voice – Posture the quality function to meet rigorous needs of Army Transformation – Create a business environment to share best practices and maintain core competencies – Leverage scarce quality resources • Similar to NASA Quality Leadership Forum 10

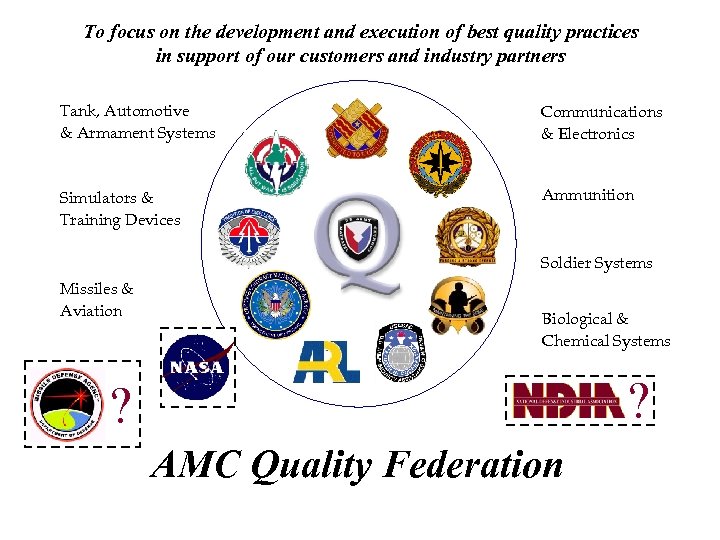

To focus on the development and execution of best quality practices in support of our customers and industry partners Tank, Automotive & Armament Systems Communications & Electronics Simulators & Training Devices Ammunition Soldier Systems Missiles & Aviation Biological & Chemical Systems ? ? AMC Quality Federation

To focus on the development and execution of best quality practices in support of our customers and industry partners Tank, Automotive & Armament Systems Communications & Electronics Simulators & Training Devices Ammunition Soldier Systems Missiles & Aviation Biological & Chemical Systems ? ? AMC Quality Federation

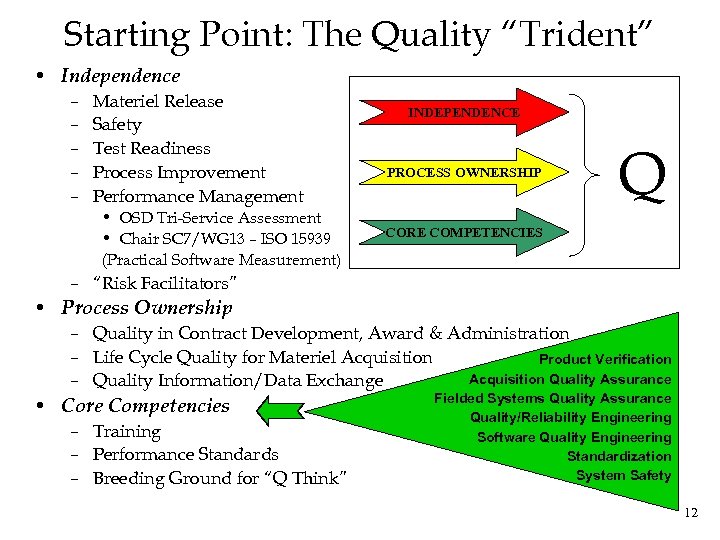

Starting Point: The Quality “Trident” • Independence – – – Materiel Release Safety Test Readiness Process Improvement Performance Management • OSD Tri-Service Assessment • Chair SC 7/WG 13 – ISO 15939 (Practical Software Measurement) INDEPENDENCE PROCESS OWNERSHIP Q CORE COMPETENCIES – “Risk Facilitators” • Process Ownership – Quality in Contract Development, Award & Administration – Life Cycle Quality for Materiel Acquisition Product Verification Acquisition Quality Assurance – Quality Information/Data Exchange • Core Competencies – Training – Performance Standards – Breeding Ground for “Q Think” Fielded Systems Quality Assurance Quality/Reliability Engineering Software Quality Engineering Standardization System Safety 12

Starting Point: The Quality “Trident” • Independence – – – Materiel Release Safety Test Readiness Process Improvement Performance Management • OSD Tri-Service Assessment • Chair SC 7/WG 13 – ISO 15939 (Practical Software Measurement) INDEPENDENCE PROCESS OWNERSHIP Q CORE COMPETENCIES – “Risk Facilitators” • Process Ownership – Quality in Contract Development, Award & Administration – Life Cycle Quality for Materiel Acquisition Product Verification Acquisition Quality Assurance – Quality Information/Data Exchange • Core Competencies – Training – Performance Standards – Breeding Ground for “Q Think” Fielded Systems Quality Assurance Quality/Reliability Engineering Software Quality Engineering Standardization System Safety 12

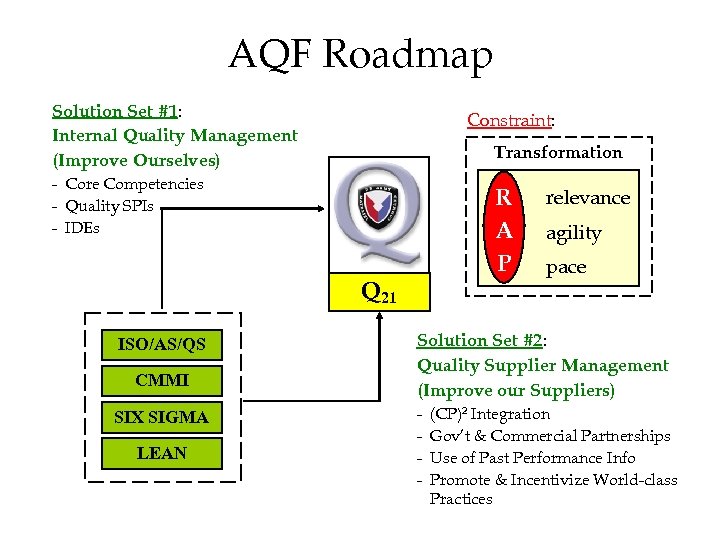

AQF Roadmap Solution Set #1: Internal Quality Management (Improve Ourselves) Constraint: Transformation - Core Competencies - Quality SPIs - IDEs R A P Q 21 ISO/AS/QS CMMI SIX SIGMA LEAN relevance agility pace Solution Set #2: Quality Supplier Management (Improve our Suppliers) - (CP)2 Integration Gov’t & Commercial Partnerships Use of Past Performance Info Promote & Incentivize World-class Practices

AQF Roadmap Solution Set #1: Internal Quality Management (Improve Ourselves) Constraint: Transformation - Core Competencies - Quality SPIs - IDEs R A P Q 21 ISO/AS/QS CMMI SIX SIGMA LEAN relevance agility pace Solution Set #2: Quality Supplier Management (Improve our Suppliers) - (CP)2 Integration Gov’t & Commercial Partnerships Use of Past Performance Info Promote & Incentivize World-class Practices

Corps Quality Corps • Uses the Acquisition Corps Model • Intense Focus on Life Cycle Quality • AQF Competencies include: – – – – Acquisition Quality Assurance Reliability/Quality Engineering Software Quality Assurance Product Verification System Safety Fielded Systems Quality Assurance Standardization ACTEDS Funding Professional Certifications (Pub Law 107 -107) 14

Corps Quality Corps • Uses the Acquisition Corps Model • Intense Focus on Life Cycle Quality • AQF Competencies include: – – – – Acquisition Quality Assurance Reliability/Quality Engineering Software Quality Assurance Product Verification System Safety Fielded Systems Quality Assurance Standardization ACTEDS Funding Professional Certifications (Pub Law 107 -107) 14

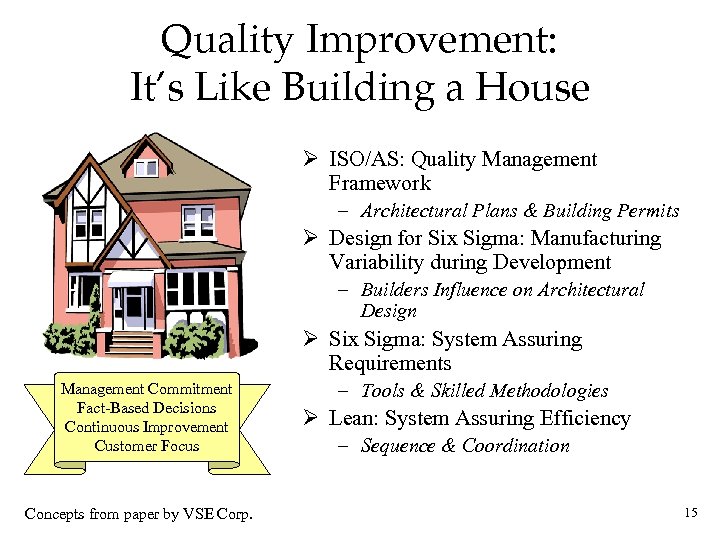

Quality Improvement: It’s Like Building a House Ø ISO/AS: Quality Management Framework – Architectural Plans & Building Permits Ø Design for Six Sigma: Manufacturing Variability during Development – Builders Influence on Architectural Design Ø Six Sigma: System Assuring Requirements Management Commitment Fact-Based Decisions Continuous Improvement Customer Focus Concepts from paper by VSE Corp. – Tools & Skilled Methodologies Ø Lean: System Assuring Efficiency – Sequence & Coordination 15

Quality Improvement: It’s Like Building a House Ø ISO/AS: Quality Management Framework – Architectural Plans & Building Permits Ø Design for Six Sigma: Manufacturing Variability during Development – Builders Influence on Architectural Design Ø Six Sigma: System Assuring Requirements Management Commitment Fact-Based Decisions Continuous Improvement Customer Focus Concepts from paper by VSE Corp. – Tools & Skilled Methodologies Ø Lean: System Assuring Efficiency – Sequence & Coordination 15

CMMi Capability Maturity Model-Integrated • Framework to Aid in Enterprise-wide Process Improvement • Developed by Software Engineering Institute & Sponsored by Do. D • Integrates Discipline-specific Models for Systems Engineering, Software Engineering & Acquisition – Software CMM has been used Extensively in the World-wide Commercial Software Sector for a Decade • Benefits Include: – Higher Quality Processes & Products – Greater Customer Satisfaction • CMMI within AMC: – TACOM Software Elements CMMI/SW-CMM Level 3 (Site Specific) – AMCOM Software Center SW-CMM Level 4 – Investigating Status of Other Sub-Commands • Embraced by the Secretary of the Army 16

CMMi Capability Maturity Model-Integrated • Framework to Aid in Enterprise-wide Process Improvement • Developed by Software Engineering Institute & Sponsored by Do. D • Integrates Discipline-specific Models for Systems Engineering, Software Engineering & Acquisition – Software CMM has been used Extensively in the World-wide Commercial Software Sector for a Decade • Benefits Include: – Higher Quality Processes & Products – Greater Customer Satisfaction • CMMI within AMC: – TACOM Software Elements CMMI/SW-CMM Level 3 (Site Specific) – AMCOM Software Center SW-CMM Level 4 – Investigating Status of Other Sub-Commands • Embraced by the Secretary of the Army 16

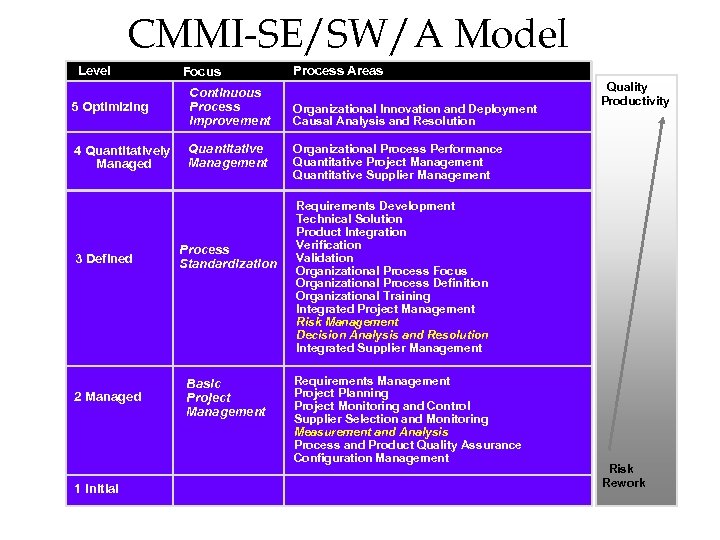

CMMI-SE/SW/A Model Level Focus 5 Optimizing Continuous Process Improvement 4 Quantitatively Managed Quantitative Management 3 Defined Process Standardization 2 Managed Basic Project Management 1 Initial Process Areas Organizational Innovation and Deployment Causal Analysis and Resolution Quality Productivity Organizational Process Performance Quantitative Project Management Quantitative Supplier Management Requirements Development Technical Solution Product Integration Verification Validation Organizational Process Focus Organizational Process Definition Organizational Training Integrated Project Management Risk Management Decision Analysis and Resolution Integrated Supplier Management Requirements Management Project Planning Project Monitoring and Control Supplier Selection and Monitoring Measurement and Analysis Process and Product Quality Assurance Configuration Management Risk Rework

CMMI-SE/SW/A Model Level Focus 5 Optimizing Continuous Process Improvement 4 Quantitatively Managed Quantitative Management 3 Defined Process Standardization 2 Managed Basic Project Management 1 Initial Process Areas Organizational Innovation and Deployment Causal Analysis and Resolution Quality Productivity Organizational Process Performance Quantitative Project Management Quantitative Supplier Management Requirements Development Technical Solution Product Integration Verification Validation Organizational Process Focus Organizational Process Definition Organizational Training Integrated Project Management Risk Management Decision Analysis and Resolution Integrated Supplier Management Requirements Management Project Planning Project Monitoring and Control Supplier Selection and Monitoring Measurement and Analysis Process and Product Quality Assurance Configuration Management Risk Rework

6 s • Six Sigma Started by Motorola & GE in Early 80’s – Structured Approach for Continuous Improvement – Employs Proven Analytical Tools – Focused on Business Bottom Line: Q$SR • • Embraced by Industry as a Process Improvement Tool The Army has begun Six Sigma Implementation – TACOM (Including Depots) Implementing – Other Sub-Commands Gaining Interest • Many Suppliers have Embraced the Methodology – We are Teaming for Success! – Raytheon – General Dynamics – United Defense • Embraced by the Secretary of the Army 18

6 s • Six Sigma Started by Motorola & GE in Early 80’s – Structured Approach for Continuous Improvement – Employs Proven Analytical Tools – Focused on Business Bottom Line: Q$SR • • Embraced by Industry as a Process Improvement Tool The Army has begun Six Sigma Implementation – TACOM (Including Depots) Implementing – Other Sub-Commands Gaining Interest • Many Suppliers have Embraced the Methodology – We are Teaming for Success! – Raytheon – General Dynamics – United Defense • Embraced by the Secretary of the Army 18

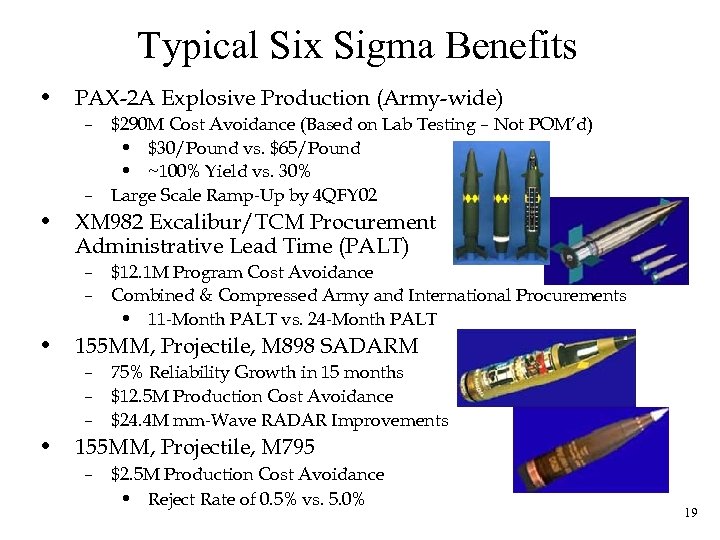

Typical Six Sigma Benefits • PAX-2 A Explosive Production (Army-wide) – $290 M Cost Avoidance (Based on Lab Testing – Not POM’d) • $30/Pound vs. $65/Pound • ~100% Yield vs. 30% – Large Scale Ramp-Up by 4 QFY 02 • XM 982 Excalibur/TCM Procurement Administrative Lead Time (PALT) – $12. 1 M Program Cost Avoidance – Combined & Compressed Army and International Procurements • 11 -Month PALT vs. 24 -Month PALT • 155 MM, Projectile, M 898 SADARM – 75% Reliability Growth in 15 months – $12. 5 M Production Cost Avoidance – $24. 4 M mm-Wave RADAR Improvements • 155 MM, Projectile, M 795 – $2. 5 M Production Cost Avoidance • Reject Rate of 0. 5% vs. 5. 0% 19

Typical Six Sigma Benefits • PAX-2 A Explosive Production (Army-wide) – $290 M Cost Avoidance (Based on Lab Testing – Not POM’d) • $30/Pound vs. $65/Pound • ~100% Yield vs. 30% – Large Scale Ramp-Up by 4 QFY 02 • XM 982 Excalibur/TCM Procurement Administrative Lead Time (PALT) – $12. 1 M Program Cost Avoidance – Combined & Compressed Army and International Procurements • 11 -Month PALT vs. 24 -Month PALT • 155 MM, Projectile, M 898 SADARM – 75% Reliability Growth in 15 months – $12. 5 M Production Cost Avoidance – $24. 4 M mm-Wave RADAR Improvements • 155 MM, Projectile, M 795 – $2. 5 M Production Cost Avoidance • Reject Rate of 0. 5% vs. 5. 0% 19

Process Improvement Strategy • Army Focus on Life Cycle Risk Management and Reduced Production, Operations & Support Costs • Army Secretary Embraces Six Sigma • AMC Commander Embraces Lean • Systems have Similar Tool Kits & Methodology • Process Improvement Strategy: – Integrate Six Sigma (Capability Improvement) & Lean (Waste Reduction) into a Single Process Improvement Program … Army Lean/6 s – Promote Pro-active Improvements using Design for Six Sigma (DFSS) – Deploy throughout AMC and its Supplier Base – Establish HQ Management 20

Process Improvement Strategy • Army Focus on Life Cycle Risk Management and Reduced Production, Operations & Support Costs • Army Secretary Embraces Six Sigma • AMC Commander Embraces Lean • Systems have Similar Tool Kits & Methodology • Process Improvement Strategy: – Integrate Six Sigma (Capability Improvement) & Lean (Waste Reduction) into a Single Process Improvement Program … Army Lean/6 s – Promote Pro-active Improvements using Design for Six Sigma (DFSS) – Deploy throughout AMC and its Supplier Base – Establish HQ Management 20

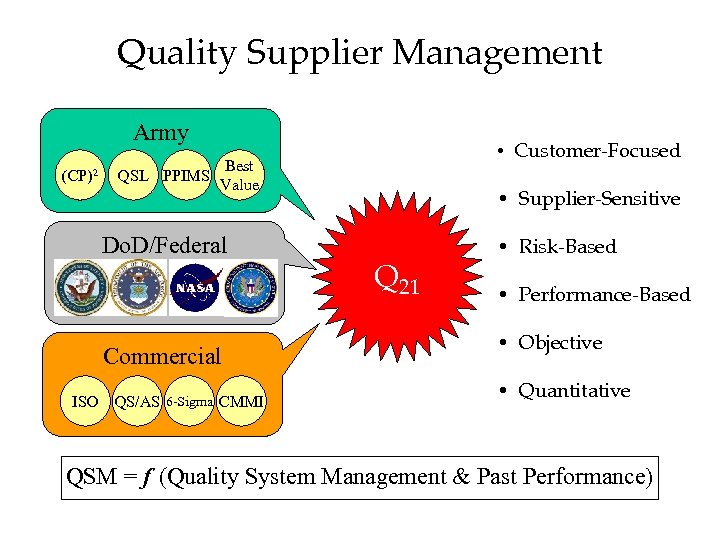

Quality Supplier Management Army (CP)2 Do. D/Federal Commercial ISO • Customer-Focused Best QSL PPIMS Value QS/AS 6 -Sigma CMMI • Supplier-Sensitive Q 21 • Risk-Based • Performance-Based • Objective • Quantitative QSM = f (Quality System Management & Past Performance)

Quality Supplier Management Army (CP)2 Do. D/Federal Commercial ISO • Customer-Focused Best QSL PPIMS Value QS/AS 6 -Sigma CMMI • Supplier-Sensitive Q 21 • Risk-Based • Performance-Based • Objective • Quantitative QSM = f (Quality System Management & Past Performance)

AMC Contractor Performance Certification Program, (CP)2 • • AMC - Supplier Partnership Initiative 2 nd Party Assessment Program ISO 9000: 1994, Supplemented Promotes World Class Quality Practices, Continuous Improvement & Customer Satisfaction • Pockets of Success • Changing Environment Mandates Evolution – Commercial Registration and Assessments – ISO 9000: 2000, QS-9000/TS 16949, AS 9100, TL 9000, etc. – Army Risk-Based Business Model 22

AMC Contractor Performance Certification Program, (CP)2 • • AMC - Supplier Partnership Initiative 2 nd Party Assessment Program ISO 9000: 1994, Supplemented Promotes World Class Quality Practices, Continuous Improvement & Customer Satisfaction • Pockets of Success • Changing Environment Mandates Evolution – Commercial Registration and Assessments – ISO 9000: 2000, QS-9000/TS 16949, AS 9100, TL 9000, etc. – Army Risk-Based Business Model 22

Supplier Quality in Army Past Performance • Army Past Performance Information Management System (PPIMS) Feeds Do. D Past Performance Automated Information System (PPAIS) • PPIMS Overview – Performance Assessment Reports (PARs)/Customer Report Cards • Required Annually & at Close-Out – – System ($5 M) & Non-System ($1 M) Thresholds Growing Database Becoming an Important PPI Tool in Source Selection May become a Useful Partnership Tool 23

Supplier Quality in Army Past Performance • Army Past Performance Information Management System (PPIMS) Feeds Do. D Past Performance Automated Information System (PPAIS) • PPIMS Overview – Performance Assessment Reports (PARs)/Customer Report Cards • Required Annually & at Close-Out – – System ($5 M) & Non-System ($1 M) Thresholds Growing Database Becoming an Important PPI Tool in Source Selection May become a Useful Partnership Tool 23

Supplier Quality in Army Past Performance (Continued) • PPIMS Rating Elements (Systems Only) – Schedule, Cost Control, Management, Other – Technical (Quality of Product) • Product Performance, Systems Engineering, Software Engineering, Logistics Support/ Sustainment, Other • Product Assurance – Quality Objectives (e. g. , producibility, reliability, maintainability, inspectability, testability) – Control of Manufacturing Processes (e. g. , material control, shop floor planning & control, status & control, factory floor design, factory performance) 24

Supplier Quality in Army Past Performance (Continued) • PPIMS Rating Elements (Systems Only) – Schedule, Cost Control, Management, Other – Technical (Quality of Product) • Product Performance, Systems Engineering, Software Engineering, Logistics Support/ Sustainment, Other • Product Assurance – Quality Objectives (e. g. , producibility, reliability, maintainability, inspectability, testability) – Control of Manufacturing Processes (e. g. , material control, shop floor planning & control, status & control, factory floor design, factory performance) 24

Use of Commercial Customer Satisfaction Ratings • Current Army Supplier Management through DCMA RAMP, Partnerships and use of PPI • Customer Satisfaction Ratings often Play a Role in Commercial Buying • J. D. Power provides Customer Ratings for several Sectors (Automotive, Services Consulting, Energy/Communications, Travel, Finance & Home Building) • Army & DCMA to meet with J. D. Power to Identify Opportunities for Partnerships and Resource Leveraging 25

Use of Commercial Customer Satisfaction Ratings • Current Army Supplier Management through DCMA RAMP, Partnerships and use of PPI • Customer Satisfaction Ratings often Play a Role in Commercial Buying • J. D. Power provides Customer Ratings for several Sectors (Automotive, Services Consulting, Energy/Communications, Travel, Finance & Home Building) • Army & DCMA to meet with J. D. Power to Identify Opportunities for Partnerships and Resource Leveraging 25

Army Reliability & Mission Assurance • Army Transformation Reliability Improvement Program (ATRIP) to be Formally Initiated by the Army Acquisition Executive and AMC CG • ATRIP to include: – RMS Leadership Team - Clearinghouse for the Army/Do. D and Knowledge Base for all RMS Innovations for Army/Industry Applications – Assessment Team – Assesses RMS Capabilities and Competencies of Contractors, Government Agencies, etc. , to include Process Assessment of Programs – Deployment Team – Deploys State-of-the-Art Tools to all Programs and Facilitates or Conducts Program Technical Activities – Industry Liaison Team – Works with Industry, Academia and Professional Societies to assure the US Design Culture Changes to an RMS Focus

Army Reliability & Mission Assurance • Army Transformation Reliability Improvement Program (ATRIP) to be Formally Initiated by the Army Acquisition Executive and AMC CG • ATRIP to include: – RMS Leadership Team - Clearinghouse for the Army/Do. D and Knowledge Base for all RMS Innovations for Army/Industry Applications – Assessment Team – Assesses RMS Capabilities and Competencies of Contractors, Government Agencies, etc. , to include Process Assessment of Programs – Deployment Team – Deploys State-of-the-Art Tools to all Programs and Facilitates or Conducts Program Technical Activities – Industry Liaison Team – Works with Industry, Academia and Professional Societies to assure the US Design Culture Changes to an RMS Focus

Army-NASA Partnership for Reliability & Mission Assurance • Joint NASA-Army Relationship Initiated after 2002 CQSDI • Mutual Ultra-Reliability Initiatives Discussed • Areas of focus: – Cultural Change Process for Designing-in Very High Reliability – Probabilistic Design using Physics-based Tools – Probabilistic Risk Assessment Methodologies – Combining Deterministic, Statistical and Probabilistic approaches in RMS Design Growth – Single-Shot Reliability Methods and Applications – Accelerated Aging and Predictive Model development • Need to Re-establish Contact with NASA RMS Activities 27

Army-NASA Partnership for Reliability & Mission Assurance • Joint NASA-Army Relationship Initiated after 2002 CQSDI • Mutual Ultra-Reliability Initiatives Discussed • Areas of focus: – Cultural Change Process for Designing-in Very High Reliability – Probabilistic Design using Physics-based Tools – Probabilistic Risk Assessment Methodologies – Combining Deterministic, Statistical and Probabilistic approaches in RMS Design Growth – Single-Shot Reliability Methods and Applications – Accelerated Aging and Predictive Model development • Need to Re-establish Contact with NASA RMS Activities 27

Other Army-NASA Partnerships/Benchmarking • Supplier Risk Management – Including DCMA • Core Competencies for Tomorrow’s Quality Workforce • Procurement Contract Clauses • Criteria for Receiving Inspection • Soldering Requirements • Army Participation w/ NASA EEE Parts Group • Error Prevention • Supplier Quality Partnerships • NASA participation in Army (CP)2 28

Other Army-NASA Partnerships/Benchmarking • Supplier Risk Management – Including DCMA • Core Competencies for Tomorrow’s Quality Workforce • Procurement Contract Clauses • Criteria for Receiving Inspection • Soldering Requirements • Army Participation w/ NASA EEE Parts Group • Error Prevention • Supplier Quality Partnerships • NASA participation in Army (CP)2 28

Take-a-Ways • Quality Plays an Important Role in the Army’s Transformation • Quality Investments are Needed • Quality must be Promoted … Constantly • Army & Industry Leadership is Critical for Quality Success • Army Partnerships with Gov’t & Industry assures Maximum Quality ROI – NASA – DCMA – MDA? 29

Take-a-Ways • Quality Plays an Important Role in the Army’s Transformation • Quality Investments are Needed • Quality must be Promoted … Constantly • Army & Industry Leadership is Critical for Quality Success • Army Partnerships with Gov’t & Industry assures Maximum Quality ROI – NASA – DCMA – MDA? 29