1cd489f7307004a4eeae84ecd33b8d20.ppt

- Количество слайдов: 49

Quality and Productivity Improvement Outline for Evening Syllabus – Joint Responsibilities Overview: Six Sigma and the Organization By Robin Seavers University of Wisconsin Milwaukee

Brainstorming Generate a list of examples of good quality in a cell phone/service provider OR Generate a list of examples of poor quality in a cell phone/service provider W 2

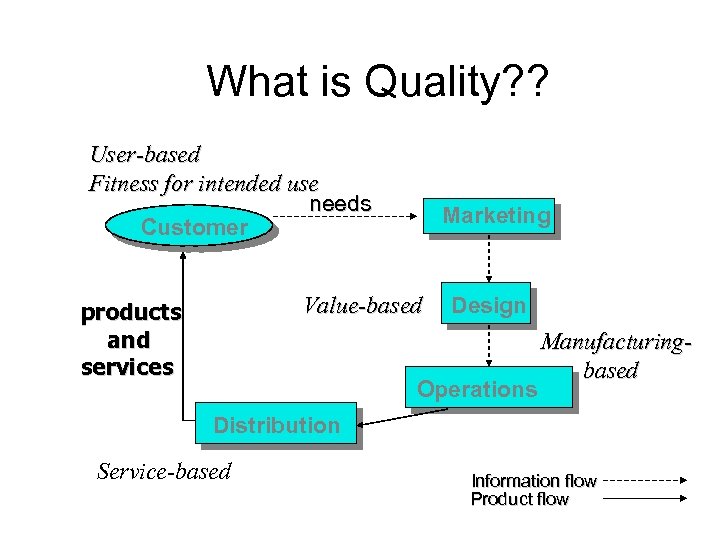

What is Quality? ? User-based Fitness for intended use needs Customer Marketing Value-based products and services Design Operations Manufacturingbased Distribution Service-based Information flow Product flow

Quality in …… Processes Products Services Systems 4

Part 1 Six Sigma and The Organization 5

History: Quality Approaches (1 of 2) • Industrial Revolution: rise of inspection and separate quality departments • Early 20 th Century: statistical methods at Bell System • Quality control during World War II • Post-war Japan: evolution of quality management 6

History: Quality Approaches (2 of 2) • Statistical Process Control • ISO 9000 • Benchmarking • Balanced Scorecard • Malcolm Baldrige National Quality Award • Six Sigma • Lean 7

Quality Standard: ISO 9000: 2008 • Quality system standards adopted by International Organization for Standardization in 1987; revised in 1994, 2000 and 2008 • ISO series describes standards for a QMS addressing the processes surrounding the design, development and delivery of a product or service. W 8

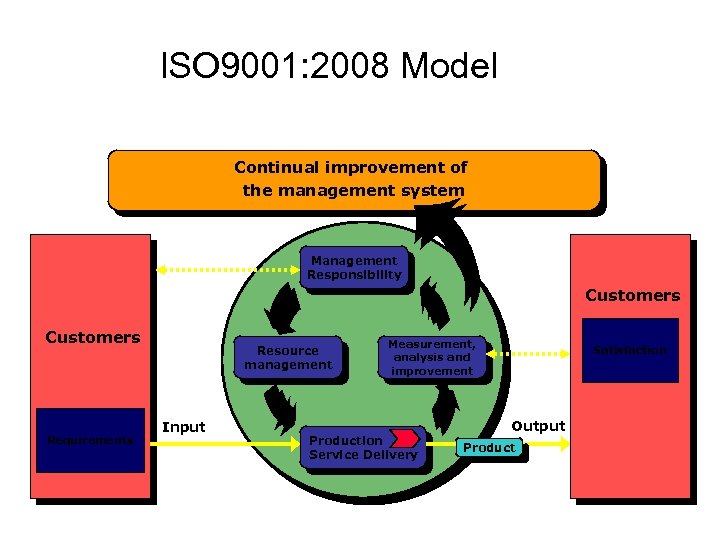

ISO 9001: 2008 Model Continual improvement of the management system Management Responsibility Customers Requirements Resource management Input Measurement, analysis and improvement Production Service Delivery Satisfaction Output Product

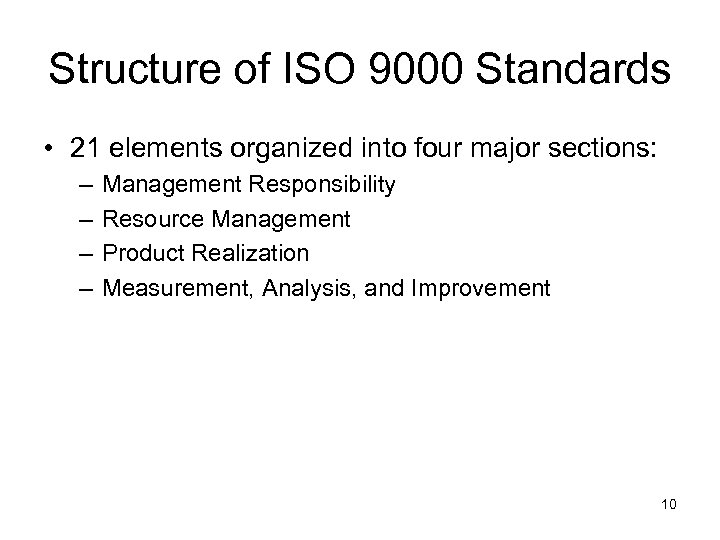

Structure of ISO 9000 Standards • 21 elements organized into four major sections: – – Management Responsibility Resource Management Product Realization Measurement, Analysis, and Improvement 10

Malcolm Baldrige National Quality Award • Help improve quality in U. S. companies • Recognize achievements of excellent firms and provide examples to others • Establish criteria for evaluating quality efforts • Provide guidance for other American companies Malcolm Baldrige, former U. S. Secretary of Commerce 11

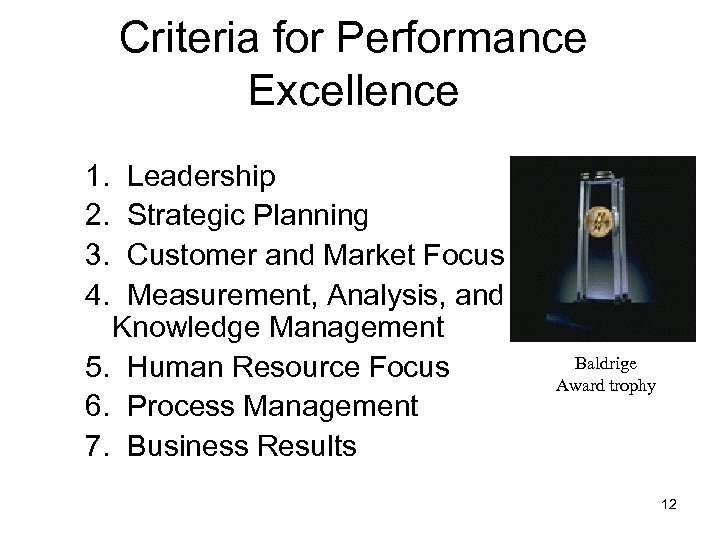

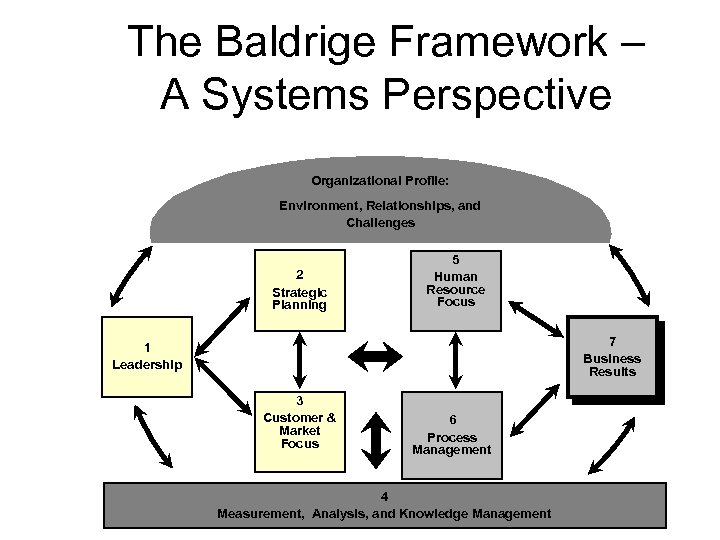

Criteria for Performance Excellence 1. 2. 3. 4. Leadership Strategic Planning Customer and Market Focus Measurement, Analysis, and Knowledge Management 5. Human Resource Focus 6. Process Management 7. Business Results Baldrige Award trophy 12

The Baldrige Framework – A Systems Perspective Organizational Profile: Environment, Relationships, and Challenges 2 Strategic Planning 5 Human Resource Focus 7 Business Results 1 Leadership 3 Customer & Market Focus 6 Process Management 4 Measurement, Analysis, and Knowledge Management

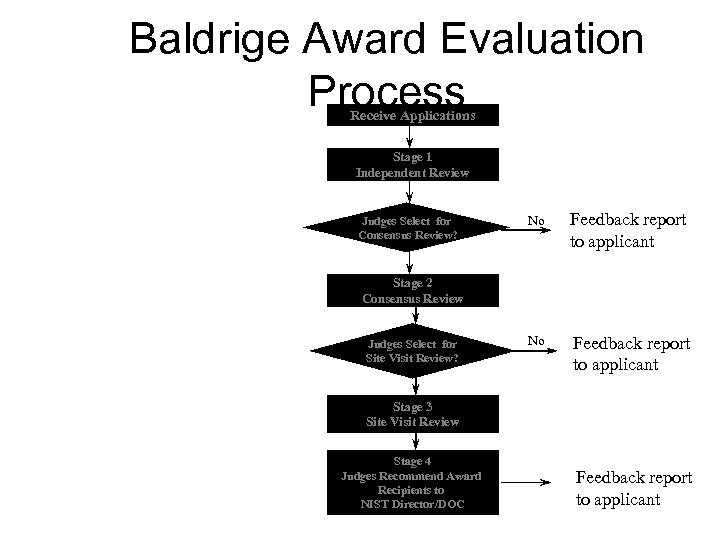

Baldrige Award Evaluation Process Receive Applications Stage 1 Independent Review Judges Select for Consensus Review? No Feedback report to applicant Stage 2 Consensus Review Judges Select for Site Visit Review? Stage 3 Site Visit Review Stage 4 Judges Recommend Award Recipients to NIST Director/DOC Feedback report to applicant

What is Six Sigma? Six Sigma can be described as a business improvement approach that seeks to find and eliminate causes of defects and errors in manufacturing and service processes by focusing on outputs that are critical to customers and a clear financial return for the organization. Six Sigma was pioneered by Motorola in the mid -1980 s and popularized by the success of General Electric. W

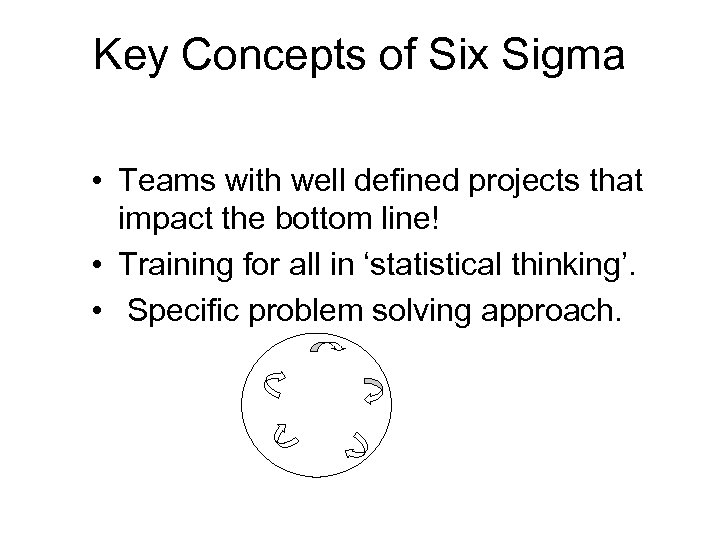

Key Concepts of Six Sigma • Teams with well defined projects that impact the bottom line! • Training for all in ‘statistical thinking’. • Specific problem solving approach. Define Control Measure DMAIC Analyze Improve

Six Sigma Works for Everyone • Plant managers – reduce waste, improve product consistency, solve equipment problems, create capacity • Human resource managers – reduce cycle time for hiring processes • Sales managers – improve forecast reliability, pricing strategies, pricing variation • Anyone – better understand customer needs and tailor service offerings to meet them

Quality Pioneers • • Walter Shewhart W. Edwards Deming Joseph Juran Philip Crosby Armand Feigenbaum Kaoru Ishikawa Genichi Taguchi

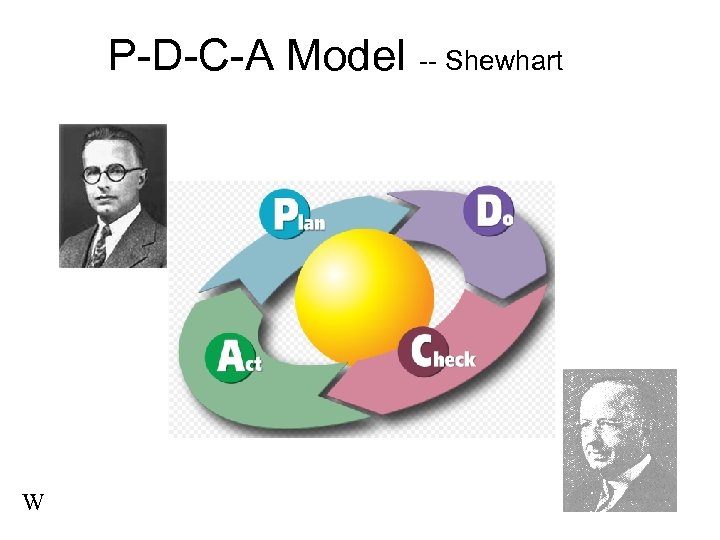

P-D-C-A Model -- Shewhart W

Plan (1 of 2) 1. 2. 3. 4. Define/describe the process Describe the players Define customer expectations Determine what historical data are available on process performance

Plan (2 of 2) 6. Describe the perceived problems associated with the process 7. Identify the primary causes of the problems and their impacts on process performance. 8. Develop potential changes or solutions to the process 9. Select the most promising solution(s).

Do 1. Conduct a pilot study or experiment to test the impact of the potential solution(s). 2. Identify measures to understand how any changes or solutions are successful in addressing the perceived problems.

Check 1. Examine the results of the pilot study or experiment. 2. Determine whether process performance has improved. 3. Identify further experimentation that may be necessary.

Act 1. Select the best change or solution. 2. Develop an implementation plan: what, who when. 3. Standardize the solution. 4. Establish a process to monitor and control process performance.

Deming’s System of Profound Knowledge 1. Appreciation for a system 2. Understand variation 3. Theory of Knowledge 4. Psychology of workers and managers

1. Systems -- Deming • Most organizational processes are crossfunctional • Parts of a system must work together • Every system must have a purpose • Management must optimize the whole system

2. Variation -- Deming • Many sources of uncontrollable variation exist in any process • Excessive variation results in product failures, unhappy customers and unnecessary costs • Statistical methods can be used to identify and quantify variation to help understand it and lead to improvements (find assignable causes)

3. Theory of Knowledge -- Deming • Knowledge is not possible without theory • Experience alone does not establish a theory, it only describes • Theory shows a cause-and-effect relationship and can be used for prediction; allows for a “test” • MEANING: management should base decisions on facts, not instincts

4. Psychology • People are motivated intrinsically and extrinsically; intrinsic motivation is the most powerful • Fear is demotivating • Managers should develop pride and joy in work 29

Deming’s 14 Points www. deming. org 30

Joseph Juran Pareto – 80/20 Quality Control Handbook (1951) Managerial Breakthrough (1964) Juran Trilogy®

Juran’s Quality Trilogy • Quality planning • Quality control • Quality improvement www. juran. com 32

Phillip B. Crosby Quality is free. . . “Quality is free. It’s not a gift, but it is free. What costs money are the unquality things -- all the actions that involve not doing jobs right the first time. ”

Philip B. Crosby Absolutes of Quality Management: • Quality means conformance to requirements • Problems must be identified by the individuals or departments that cause them • It is always cheaper to do the job right the first time • Cost of quality is the only useful measurement • Zero defects is the only performance www. philipcrosby. com standard 34

Don and Armand Feigenbaum Total Quality Control Total Quality Management (1983) Total Quality Costs (1956) Quality is an organization-wide process Quality is what the customer says it is

A. V. Feigenbaum • Three Steps to Quality – Quality Leadership, with a strong focus on planning – Modern Quality Technology, involving the entire work force – Organizational Commitment, supported by continuous training and motivation

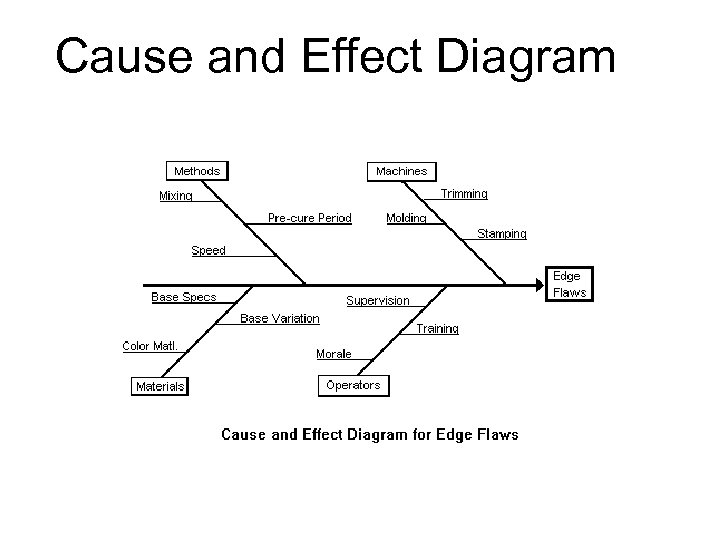

Kaoru Ishikawa • Quality goes beyond the product – customer service • Cause and Effect Diagram – view all possible causes of a result

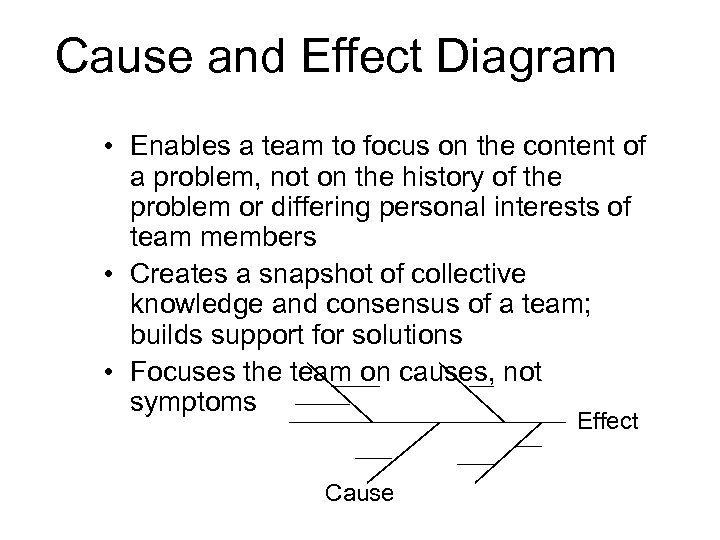

Cause and Effect Diagram • Enables a team to focus on the content of a problem, not on the history of the problem or differing personal interests of team members • Creates a snapshot of collective knowledge and consensus of a team; builds support for solutions • Focuses the team on causes, not symptoms Effect Cause

Cause and Effect Diagram

Kaoru Ishikawa Contributions • Instrumental in developing Japanese quality strategy • Influenced participative approaches involving all workers • Advocated the use of simple visual tools and statistical techniques

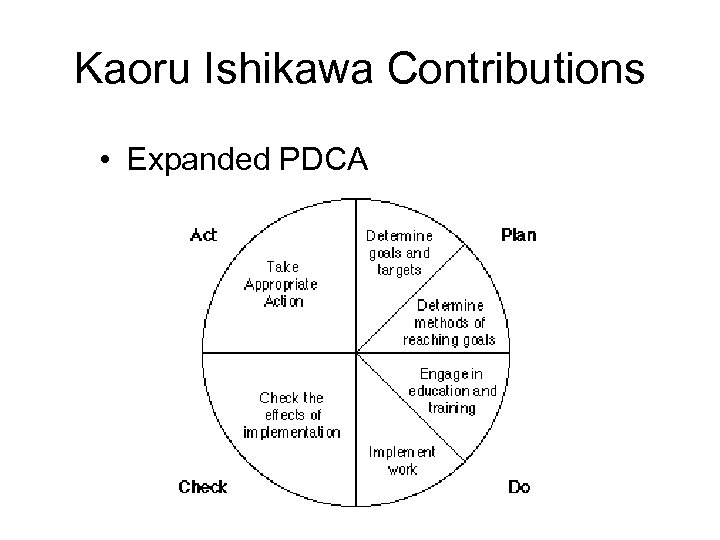

Kaoru Ishikawa Contributions • Expanded PDCA

Genichi Taguchi • From Japan to America in 1980 • Departures from the target value for a characteristic represents a loss to society

Six Sigma and Business Results Considerable evidence exists that Six Sigma initiatives positively impact bottom-line results from companies such as GE, Allied Signal, 3 M, Xerox, Raytheon, Citibank, and many others.

Processes • A process is a series of steps designed to produce products and/or services. – Inputs to the process 44

Significance of Six Sigma for YOU • Collect data on a process • Use the data to analyze and interpret what is happening • Continually improve the process to satisfy the customer

Affinity Diagram • A participative, team approach • Encourages creative solutions • Breaks down communication barriers • Encourages nontraditional connections between ideas/issues

Class Exercise: Affinity Diagram What are some ideas to make Monday and Wednesday’s more tolerable between the hours of 5: 30 PM – 9: 15 PM? 1. Divide into small groups of 8 – 10 around posters. 2. Individually, take 2 min to write all of your own ideas on a post-it note. 3. Assign a person to collect all ideas (go around the group collecting one idea each time). Place on flipchart. 4. Sort ideas into related groups. 5. For each group, create a summary or header.

Next Lecture • Organizational Drivers for SS • Design for SS • More about Processes

Discussion • Tonight – Discussion Exercise #1 will be done in discussion – Ask questions related to Homework #1 • Homework #1 is due next Wednesday by the START of discussion

1cd489f7307004a4eeae84ecd33b8d20.ppt