34e99e958d6759a8eb24055d4abdde02.ppt

- Количество слайдов: 30

Quality and Operations Management MS&E 269 Malcolm Baldrige National Quality Award

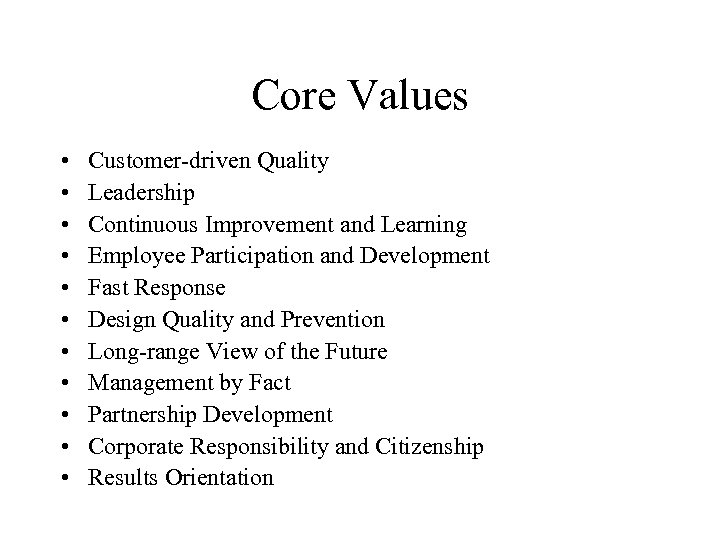

Core Values • • • Customer-driven Quality Leadership Continuous Improvement and Learning Employee Participation and Development Fast Response Design Quality and Prevention Long-range View of the Future Management by Fact Partnership Development Corporate Responsibility and Citizenship Results Orientation

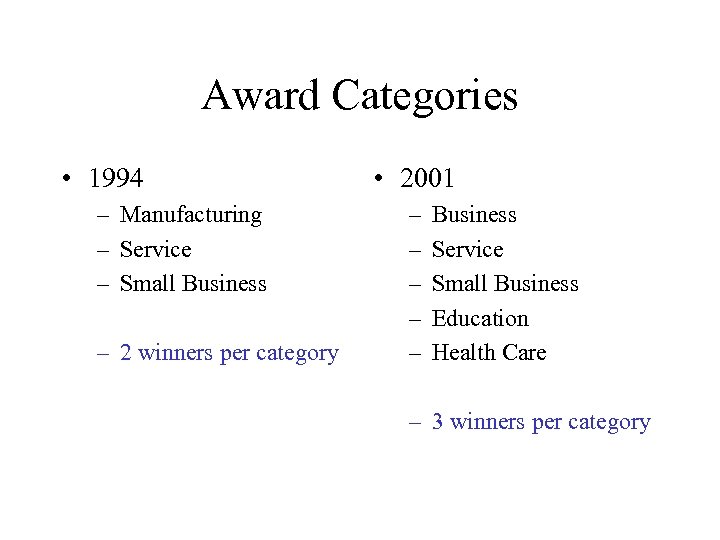

Award Categories • 1994 – Manufacturing – Service – Small Business – 2 winners per category • 2001 – – – Business Service Small Business Education Health Care – 3 winners per category

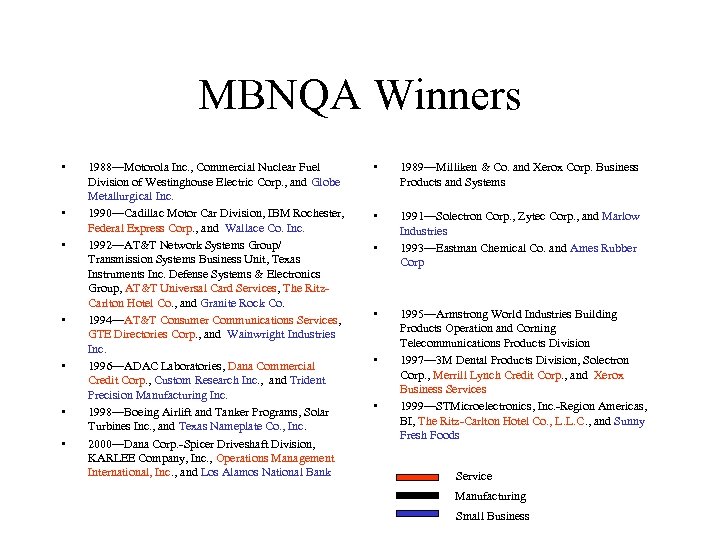

MBNQA Winners • • 1988—Motorola Inc. , Commercial Nuclear Fuel Division of Westinghouse Electric Corp. , and Globe Metallurgical Inc. 1990—Cadillac Motor Car Division, IBM Rochester, Federal Express Corp. , and Wallace Co. Inc. 1992—AT&T Network Systems Group/ Transmission Systems Business Unit, Texas Instruments Inc. Defense Systems & Electronics Group, AT&T Universal Card Services, The Ritz. Carlton Hotel Co. , and Granite Rock Co. 1994—AT&T Consumer Communications Services, GTE Directories Corp. , and Wainwright Industries Inc. 1996—ADAC Laboratories, Dana Commercial Credit Corp. , Custom Research Inc. , and Trident Precision Manufacturing Inc. 1998—Boeing Airlift and Tanker Programs, Solar Turbines Inc. , and Texas Nameplate Co. , Inc. 2000—Dana Corp. -Spicer Driveshaft Division, KARLEE Company, Inc. , Operations Management International, Inc. , and Los Alamos National Bank • 1989—Milliken & Co. and Xerox Corp. Business Products and Systems • 1991—Solectron Corp. , Zytec Corp. , and Marlow Industries 1993—Eastman Chemical Co. and Ames Rubber Corp • • 1995—Armstrong World Industries Building Products Operation and Corning Telecommunications Products Division 1997— 3 M Dental Products Division, Solectron Corp. , Merrill Lynch Credit Corp. , and Xerox Business Services 1999—STMicroelectronics, Inc. -Region Americas, BI, The Ritz-Carlton Hotel Co. , L. L. C. , and Sunny Fresh Foods Service Manufacturing Small Business

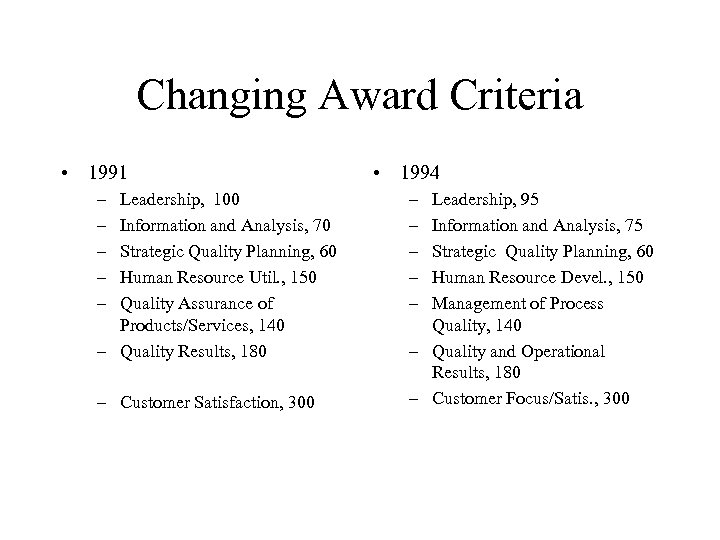

Changing Award Criteria • 1991 – – – Leadership, 100 Information and Analysis, 70 Strategic Quality Planning, 60 Human Resource Util. , 150 Quality Assurance of Products/Services, 140 – Quality Results, 180 – Customer Satisfaction, 300 • 1994 – – – Leadership, 95 Information and Analysis, 75 Strategic Quality Planning, 60 Human Resource Devel. , 150 Management of Process Quality, 140 – Quality and Operational Results, 180 – Customer Focus/Satis. , 300

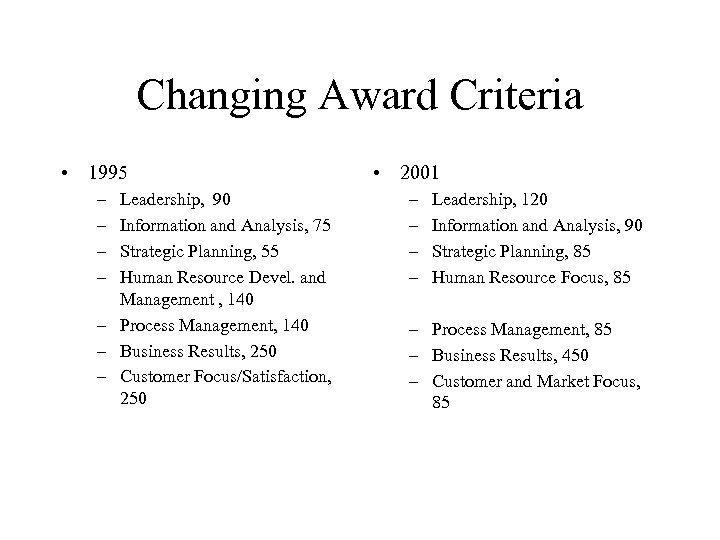

Changing Award Criteria • 1995 – – Leadership, 90 Information and Analysis, 75 Strategic Planning, 55 Human Resource Devel. and Management , 140 – Process Management, 140 – Business Results, 250 – Customer Focus/Satisfaction, 250 • 2001 – – Leadership, 120 Information and Analysis, 90 Strategic Planning, 85 Human Resource Focus, 85 – Process Management, 85 – Business Results, 450 – Customer and Market Focus, 85

Criteria Characteristics • • Results oriented Non-prescriptive Assessment Diagnostic

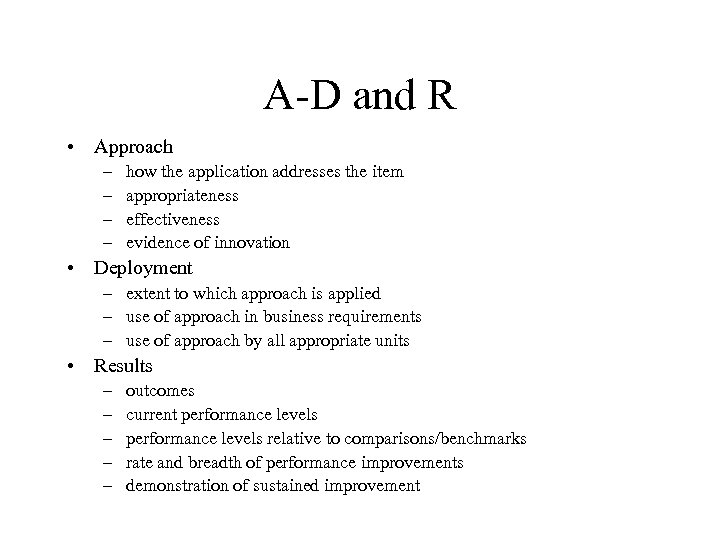

A-D and R • Approach – – how the application addresses the item appropriateness effectiveness evidence of innovation • Deployment – extent to which approach is applied – use of approach in business requirements – use of approach by all appropriate units • Results – – – outcomes current performance levels relative to comparisons/benchmarks rate and breadth of performance improvements demonstration of sustained improvement

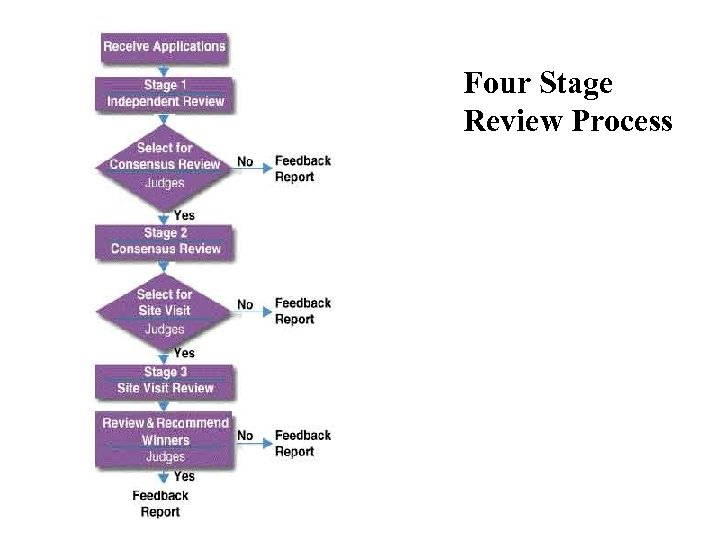

Four Stage Review Process

Leadership • 1. 1 Senior Executive Leadership • 1. 2 Management for Quality • 1. 3 Public Responsibility and Corporate Citizenship

Leadership • • • Values and Expectations Empowerment and Innovation Performance Reviews Findings and Improvement Regulatory, Legal, Ethical Responsibilities Support of Key Communities

Information and Analysis • 2. 1 Scope and Management of Quality and Performance Data and Information • 2. 2 Competitive Comparisons and Benchmarking • 2. 3 Analysis and Use of Company-level Data

Information and Analysis • • Selection and Integration of Measures / Indicators Comparative Data and Information Reliability Currency w. r. t. Changing Needs Senior Executive Reviews and Planning Functional-level Decisions Daily Operational Support

Strategic Quality Planning • 3. 1 Strategy Quality and Company Performance Planning Process • 3. 2 Quality and Performance Plans

Strategic Quality Planning • • • Strategy Development Strategy Objectives and Timelines Actions Plans and Measures Human Resource Plans Performance Projections

Human Resource Development and Management • 4. 1 Human Resource Planning and Management • 4. 2 Employee Involvement • 4. 3 Employee Education and Training • 4. 4 Employee Performance and Recognition • 4. 5 Employee Well-being and Satisfaction

Human Resource Development and Management • • Short and Long Term Key Needs Employee Education, Training and Development Delivery and Reinforcement Safe Work Environment Support and Motivation Satisfaction Determination Improvement Priorities

Management of Process Quality • 5. 1 Design and Introduction of Quality Products and Services • 5. 2 Process Management: Product and Service Production and Delivery Processes • 5. 3 Process Management: Business and Support Service Processes • 5. 4 Supplier Quality • 5. 5 Quality Assessment

Management of Process Quality • • • Design Processes Production and Delivery Processes Key Supplier Products and Services Key Support Processes Requirements and Measures Evaluation and Improvement

Quality and Operational Results • • 6. 1 Product and Service Quality Results 6. 2 Company Operational Results 6. 3 Business and Support Service Results 6. 4 Supplier Quality Results

Quality and Operational Results • Customer Evaluations • Operational, Financial and Market Performance • Strategy-driven Results

Customer Focus and Satisfaction • 7. 1 Customer Expectations: Current and Future • 7. 2 Customer Relationship Management • 7. 3 Commitment to Customers • 7. 4 Customer Satisfaction Determination • 7. 5 Customer Satisfaction Results • 7. 6 Customer Satisfaction Comparison

Customer Focus and Satisfaction • • Customer Groups and Market Segments Listening and Learning Strategies Important Product and Service Features Business Needs and Directions Currency Accessibility and Complaint Management Building Relationships Competitive Performance

Leadership • Symbolism – is it talk or walk – what is the visible role for management • Systems • Results – hard to measure • Issues – is there to much going on at one time – increase weight of category

Information and Analysis • Key purposes – Use of Info Sys to achieve quality goals – Reporting/feedback to support quality – Competitive Analysis/Benchmarks • Approach and deployment orientation • Key is the choice of indicators to track and relationship to critical business drivers • Applicant can improve scores simply through wordsmanship, clarity of submission • During site visit easier to observe actuals than statements on application

Strategic Quality Planning • Category design intent: aggressive, concrete goals, • short term / long term • horizontal and vertical integration • • Expect to see documented fundamentals Demonstrated understanding of industry On-site review best at determining validity of submission Shortcoming: deployment to suppliers Long-term planning not concrete wrt to rollout and method Components are satisfactory, burden on Great Northern Need more emphasis on long-term success and results

Human Resource Development • Does the documentation match / support the results – too much on deployment, not enough on results – “ 50 ways to please a …” • • • What about near-term programs? Timeline on result goals not clear Overly focused on individuals vs. teams Results and categories are ambiguous Warm fuzzies or real processes? – Wish upon a star – Needs and feelings survey • How can tangible evidence be demonstrated?

Management of Process Quality • • • Rationale: is process preventive or reactive Design of service/product offerings Monitoring matrix Pushed down to each department Use of analysis tools -- business process mapping Processes in place – BLERA – QSEG – BLI • Use of mainstream process management methods • Recommendations, timelines, champions identified – weak on follow-up

Quality and Operational Analysis • System represents linking performance results to quality progress • Repetition in indicators • Overall completeness lacking – weakness on benchmarking • Can metrics be compared across industries?

Customer Focus and Satisfaction • • Relative balance in 1994 between AD & R Looking for commitment, proactive behaviors Are results comprehensive wrt all numbers and metrics? Who determines what the correct response level is vs. customer expectations and comparisons to industry • Focus is based on own customers, hence how do you apply and compare benchmark data with different populations

34e99e958d6759a8eb24055d4abdde02.ppt