0057140c8fb41cbbe0f63ea0cf44a039.ppt

- Количество слайдов: 27

Qingdao Winfull Electronics Co. , Ltd December 2017

Agenda 1. Location 2. General View 3. Basic Information 4. Certificate 5. O-chart 6. Engineering Team Introduction 7. Sample Mold Development Schedule 8. Mass Production Mold Development Schedule 9. Priority Customers 10. Priority Products 11. Mold Manufacturing Equipment 12. Injection Molding 13. Stamping 14. Painting & Printing Suppliers 15. QA 16. Warehouse 1

1. Location High-speed Train Station of Jimo Qingdao Winfull Qingtao Airport • About 12 km to High-speed Train Station, 26 km to Airport • Address: NO. 1 Zhonghe Road Automobile Industrial Park, Jimo, Qingdao 2

2. Genenal View Company Gate GM Office General Office Meeting Room 3

3. Basic Information • Established in March 2015, registered capital with 10 million RMB and total investment with 30 million RMB • With 6000 square meters in Automobile Industrial Park Jimo • Mainly focus on Mold Manufacturing, Injection Molding, Stamping and Assy, and develop the high standard tools and plastic products, • Excellent team with whom from companies of the world top 500 and the listed companies • Priority customers with Omni-ID, Goer. Tek, LS and Sound Solutions • Obtained Qingdao High-tech Enterprise Certificate in 2016 • Signed the cooperation projects of Automobile Management Committee 2017 Winfull 4

4. Certificates – Quality & Environment 5

4. Certificates – TS 16949 6

4. Certificate of High-tech Enterprise 6

4. Signing Ceremony of Key Projects 6

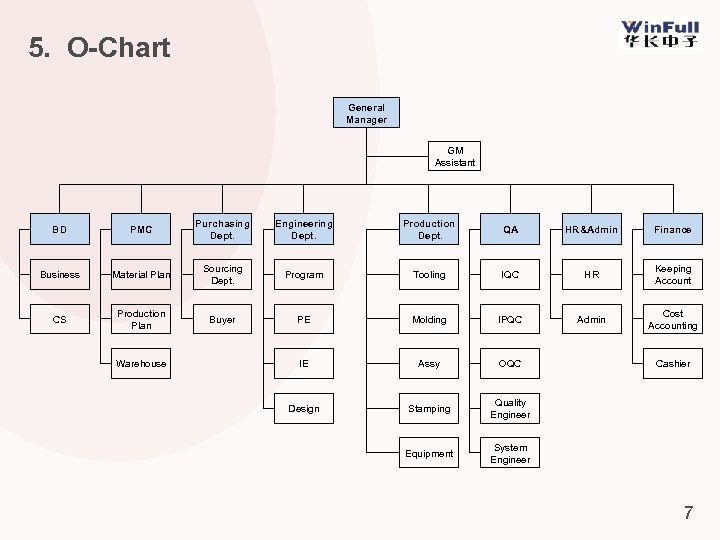

5. O-Chart General Manager BD PMC Warehouse Purchasing Engineering Dept. Business Material Plan Production CS Plan Sourcing Dept. Buyer Program PE IE Design GM Assistant Production Dept. Tooling Molding Assy Stamping Equipment QA IQC IPQC OQC HR&Admin HR Admin Finance Keeping Account Cost Accounting Cashier Quality Engineer System Engineer 7

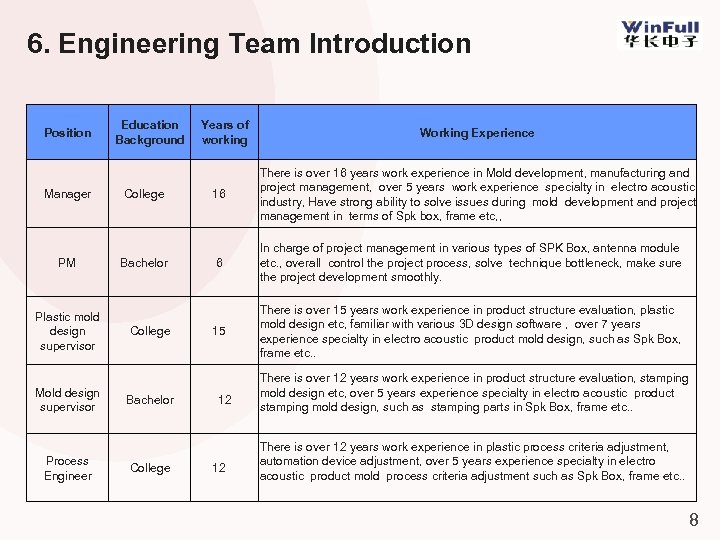

6. Engineering Team Introduction Position Education Background Years of working Working Experience Manager College 16 There is over 16 years work experience in Mold development, manufacturing and project management, over 5 years work experience specialty in electro acoustic industry, Have strong ability to solve issues during mold development and project management in terms of Spk box, frame etc, , PM Bachelor 6 In charge of project management in various types of SPK Box, antenna module etc. , overall control the project process, solve technique bottleneck, make sure the project development smoothly. 15 There is over 15 years work experience in product structure evaluation, plastic mold design etc, familiar with various 3 D design software , over 7 years experience specialty in electro acoustic product mold design, such as Spk Box, frame etc. . Plastic mold design supervisor Mold design supervisor Process Engineer College Bachelor College 12 12 There is over 12 years work experience in product structure evaluation, stamping mold design etc, over 5 years experience specialty in electro acoustic product stamping mold design, such as stamping parts in Spk Box, frame etc. . There is over 12 years work experience in plastic process criteria adjustment, automation device adjustment, over 5 years experience specialty in electro acoustic product mold process criteria adjustment such as Spk Box, frame etc. . 8

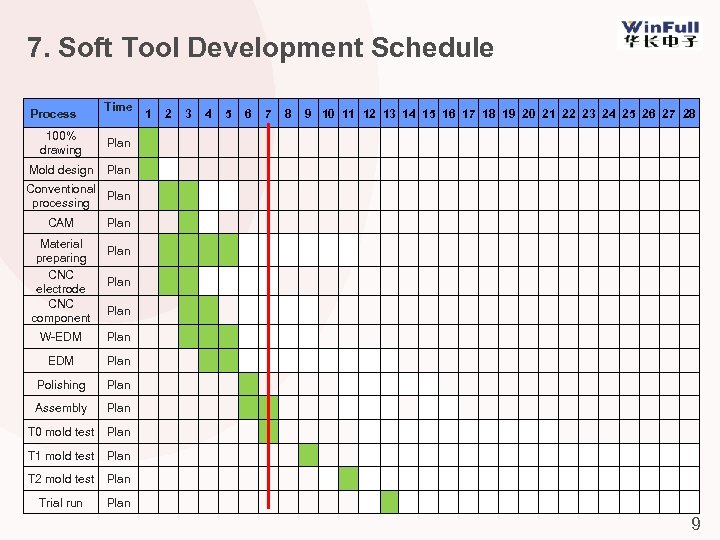

7. Soft Tool Development Schedule Process Time 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 100% drawing Plan Mold design Plan Conventional Plan processing CAM Material preparing CNC electrode CNC component Plan W-EDM Plan Polishing Plan Assembly Plan T 0 mold test Plan T 1 mold test Plan T 2 mold test Plan Trial run Plan 9

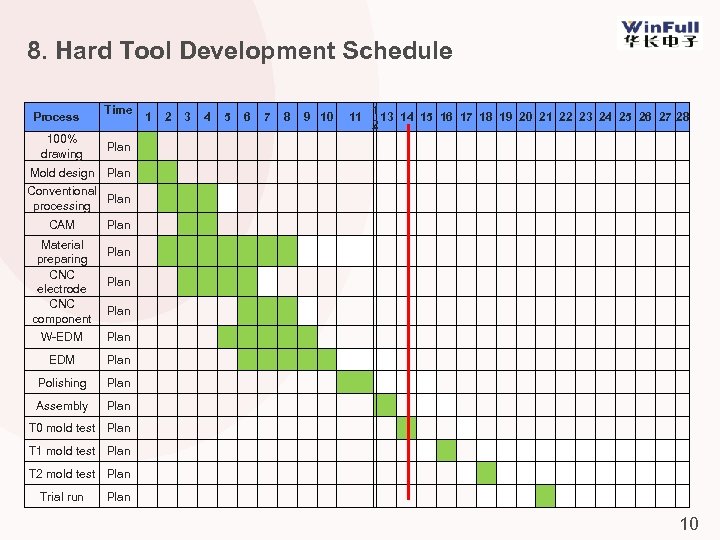

8. Hard Tool Development Schedule Process Time 1 2 3 4 5 6 7 8 9 10 11 1 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 2 100% drawing Plan Mold design Plan Conventional Plan processing Plan W-EDM Plan Polishing Plan Assembly Plan T 0 mold test Plan T 1 mold test Plan T 2 mold test Plan CAM Material preparing CNC electrode CNC component Trial run Plan 10

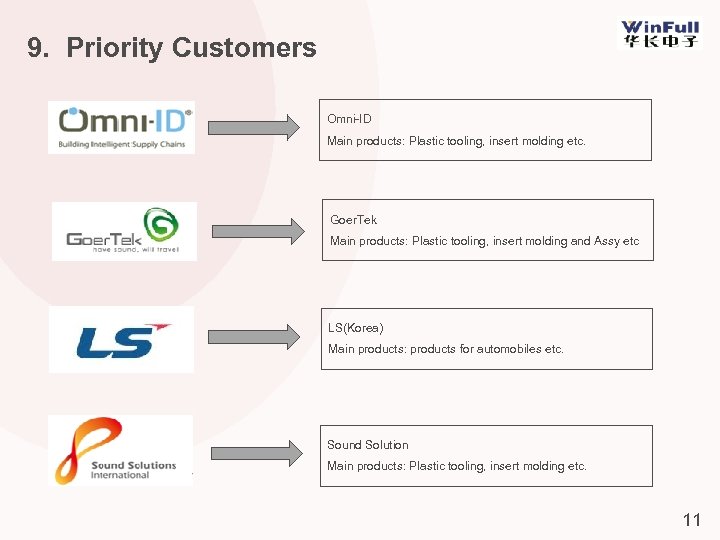

9. Priority Customers Omni-ID Main products: Plastic tooling, insert molding etc. Goer. Tek Main products: Plastic tooling, insert molding and Assy etc LS(Korea) Main products: products for automobiles etc. Sound Solution Main products: Plastic tooling, insert molding etc. 11

10. Priority Products 12

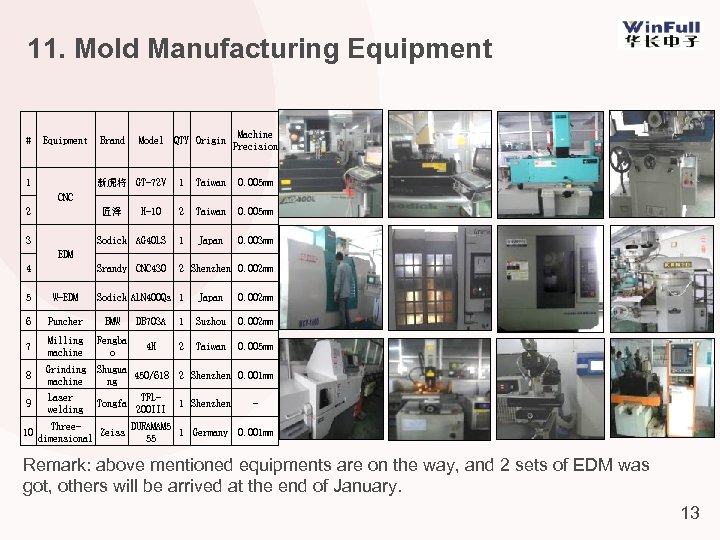

11. Mold Manufacturing Equipment # Equipment 1 Brand Model 新虎将 GT-72 V QTY Origin Machine Precision 1 Taiwan 0. 005 mm 2 Taiwan 0. 005 mm Sodick AG 40 LS 1 Japan 0. 003 mm Srandy CNC 430 2 Shenzhen 0. 002 mm CNC 2 匠泽 3 H-10 EDM 4 5 W-EDM 6 Puncher BMW DB 703 A 7 Milling machine Fengba o 4 H 8 Grinding machine Shugua 450/618 ng 9 Laser welding Tongfa 10 Sodick ALN 400 Qs 1 TFL 200 III Japan 0. 002 mm 1 Suzhou 0. 002 mm 2 Taiwan 0. 005 mm 2 Shenzhen 0. 001 mm 1 Shenzhen - Three. DURAMAM 5 Zeiss 1 Germany 0. 001 mm dimensional 55 Remark: above mentioned equipments are on the way, and 2 sets of EDM was got, others will be arrived at the end of January. 13

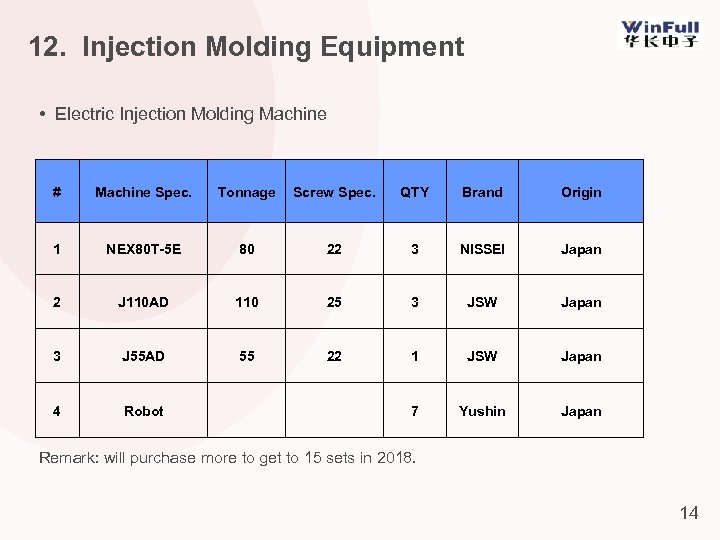

12. Injection Molding Equipment • Electric Injection Molding Machine # Machine Spec. Tonnage Screw Spec. QTY Brand Origin 1 NEX 80 T-5 E 80 22 3 NISSEI Japan 2 J 110 AD 110 25 3 JSW Japan 3 J 55 AD 55 22 1 JSW Japan 4 Robot 7 Yushin Japan Remark: will purchase more to get to 15 sets in 2018. 14

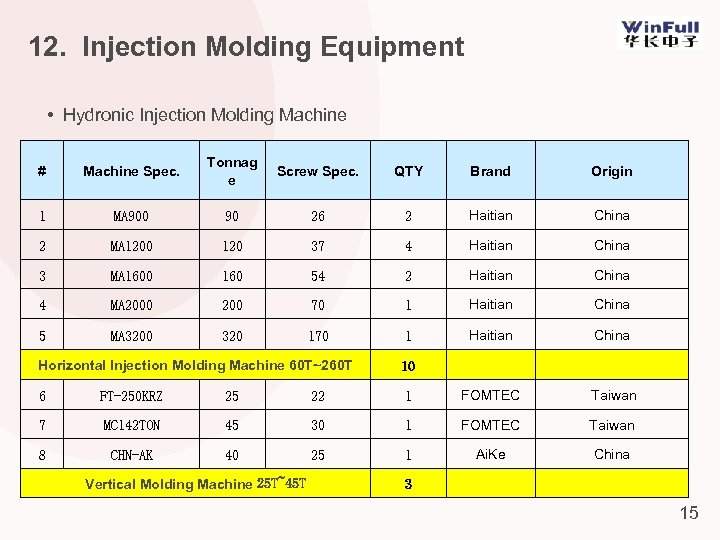

12. Injection Molding Equipment • Hydronic Injection Molding Machine # Machine Spec. Tonnag e Screw Spec. QTY Brand Origin 1 MA 900 90 26 2 Haitian China 2 MA 1200 120 37 4 Haitian China 3 MA 1600 160 54 2 Haitian China 4 MA 2000 200 70 1 Haitian China 5 MA 3200 320 170 1 Haitian China Horizontal Injection Molding Machine 60 T~260 T 10 6 FT-250 KRZ 25 22 1 FOMTEC Taiwan 7 MC 142 TON 45 30 1 FOMTEC Taiwan 8 CHN-AK 40 25 1 Ai. Ke China Vertical Molding Machine 25 T~45 T 3 15

12. Injection Molding Workshop 16

13. Stamping Machine Remark: will purchase stamping machine based on future order plan 17

14. Painting Suppliers Taking Product Area Painting Area Furnace Area USC Painting Area Measuring Area 18

14. Printing/Engraving Suppliers Printing Machine Hign-performance Laser Engraving Machine 19

14. Painting Suppliers – Measuring Equipment ACGN Cleanliness testing instrument Tape machine wear-resisting instrument Colorimete Glossmeter Alcohol rubber and wear tester Temperature Tracker 20

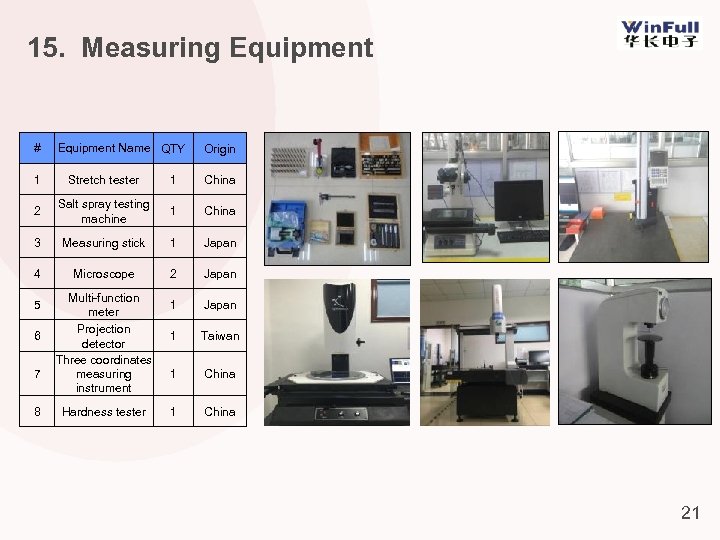

15. Measuring Equipment # Equipment Name QTY Origin 1 Stretch tester 1 China 2 Salt spray testing machine 1 China 3 Measuring stick 1 Japan 4 Microscope 2 Japan 1 Taiwan 1 China 5 6 7 8 Multi-function meter Projection detector Three coordinates measuring instrument Hardness tester 21

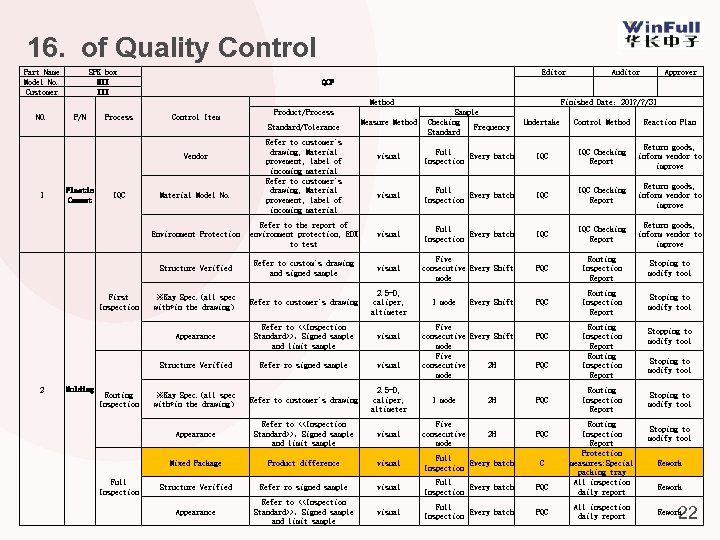

16. of Quality Control Part Name Model No. Customer SPK box HXX XXX Editor Auditor Approver QCP Method NO. P/N Process Control Item Product/Process Standard/Tolerance Vendor 1 Plastic Cement IQC Material Model No. Refer to customer's drawing, Material provement, label of incoming material Finished Date: 2017/7/31 Measure Method Sample Checking Frequency Standard Undertake Control Method Reaction Plan visual Full Every batch Inspection IQC IQC Checking Report Return goods, inform vendor to improve Environment Protection Return goods, inform vendor to improve Refer to custom's drawing and signed sample visual Five consecutive Every Shift mode PQC Routing Inspection Report Stoping to modify tool ※Kay Spec. (all spec with*in the drawing) Refer to customer's drawing 2. 5 -D, caliper, altimeter PQC Routing Inspection Report Stoping to modify tool Refer to <<Inspection Standard>>,Signed sample and limit sample visual Refer ro signed sample visual ※Kay Spec. (all spec with*in the drawing) Refer to customer's drawing 2. 5 -D, caliper, altimeter 1 mode 2 H PQC Refer to <<Inspection Standard>>,Signed sample and limit sample visual Five consecutive mode 2 H PQC Mixed Package Full Inspection IQC Checking Report Appearance Routing Inspection IQC Structure Verified Molding Full Every batch Inspection Appearance 2 visual Structure Verified First Inspection Refer to the report of environment protection, EDX to test Product difference visual Full Every batch Inspection C Structure Verified Refer ro signed sample visual Full Every batch Inspection PQC Appearance Refer to <<Inspection Standard>>,Signed sample and limit sample visual Full Every batch Inspection PQC 1 mode Every Shift Five consecutive Every Shift mode Five consecutive 2 H mode PQC Routing Inspection Report Protection measures: Special packing tray All inspection daily report Stopping to modify tool Stoping to modify tool Rework 22 Rework

17. Warehouse 23

Thank You!

0057140c8fb41cbbe0f63ea0cf44a039.ppt