f963610716b286dd5a5d9781efd5d9a9.ppt

- Количество слайдов: 9

QFD in the Third Millennium Glenn Mazur QFD Institute University of Michigan Japan Business Consultants

QFD in the Third Millennium Glenn Mazur QFD Institute University of Michigan Japan Business Consultants

Notice These materials are for the exclusive use of participants. Further they are protected by United States and International copyright law. No further reproduction is permitted without the express written permission of the copyright holder. QFD in the Third Millenium Copyright © 2001 by Glenn Mazur All rights reserved. Please contact the author for permission at +1 (734) 995 -0847, fax +1 (775) 307 -4637 email: glenn@mazur. net www. mazur. net

Notice These materials are for the exclusive use of participants. Further they are protected by United States and International copyright law. No further reproduction is permitted without the express written permission of the copyright holder. QFD in the Third Millenium Copyright © 2001 by Glenn Mazur All rights reserved. Please contact the author for permission at +1 (734) 995 -0847, fax +1 (775) 307 -4637 email: glenn@mazur. net www. mazur. net

Presenter Glenn H. Mazur – Service and consumer product specialist – Background in Japanese Quality methods – The “voice of QFD” in North America – 1998 recipient of Akao Prize – Senior Grandmaster QFD Black Belt – QFD Institute, ICQFD, Univ Michigan, Japan Business Consult.

Presenter Glenn H. Mazur – Service and consumer product specialist – Background in Japanese Quality methods – The “voice of QFD” in North America – 1998 recipient of Akao Prize – Senior Grandmaster QFD Black Belt – QFD Institute, ICQFD, Univ Michigan, Japan Business Consult.

We don’t have any quality problems! 1. We have a clear strategy for product and market growth. 2. We know exactly what our customers want. 3. Our customers never change their minds. 4. Our products fulfill their basic needs. 5. Our products delight and attract new customers. 6. We never lose customers to the competition. 7. Our products work exactly as designed. 8. We never force our customers to accept tradeoffs. 9. Our products make it to market on time, on budget, without sacrificing quality or functionality. 10. Our plants and service operations are defect free.

We don’t have any quality problems! 1. We have a clear strategy for product and market growth. 2. We know exactly what our customers want. 3. Our customers never change their minds. 4. Our products fulfill their basic needs. 5. Our products delight and attract new customers. 6. We never lose customers to the competition. 7. Our products work exactly as designed. 8. We never force our customers to accept tradeoffs. 9. Our products make it to market on time, on budget, without sacrificing quality or functionality. 10. Our plants and service operations are defect free.

A New Product Development Process Should… 1. Help our organisations achieve their goals. 2. Highlight what is most important to the customer. 3. Give us a complete understanding of both spoken and unspoken needs. 4. Create products that are clearly best in class. 5. Translate customer needs into product specifications. 6. Resolve technical problems, not force customers to choose between unacceptable alternatives. 7. Help us meet cost and timing targets. 8. Maximize operating efficiency and quality.

A New Product Development Process Should… 1. Help our organisations achieve their goals. 2. Highlight what is most important to the customer. 3. Give us a complete understanding of both spoken and unspoken needs. 4. Create products that are clearly best in class. 5. Translate customer needs into product specifications. 6. Resolve technical problems, not force customers to choose between unacceptable alternatives. 7. Help us meet cost and timing targets. 8. Maximize operating efficiency and quality.

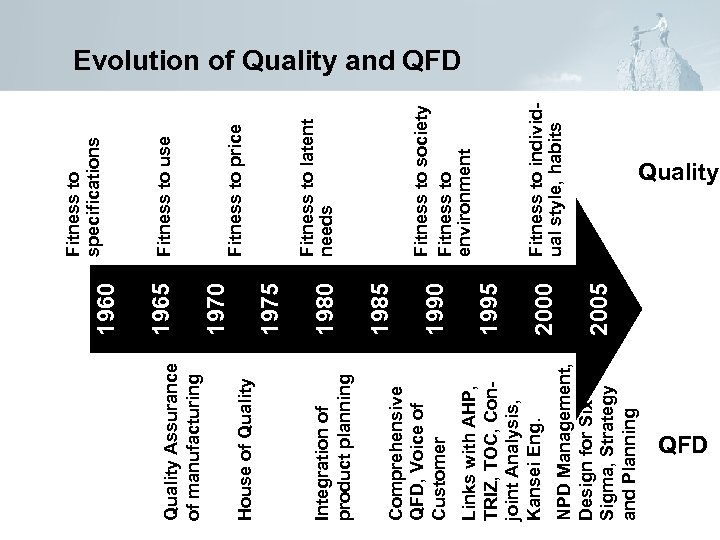

NPD Management, Design for Six Sigma, Strategy and Planning Links with AHP, TRIZ, TOC, Conjoint Analysis, Kansei Eng. Comprehensive QFD, Voice of Customer Integration of product planning House of Quality Assurance of manufacturing 2005 2000 1995 1990 1985 1980 1975 1970 1965 1960 Fitness to individual style, habits Fitness to society Fitness to environment Fitness to latent needs Fitness to price Fitness to use Fitness to specifications Evolution of Quality and QFD Quality QFD

NPD Management, Design for Six Sigma, Strategy and Planning Links with AHP, TRIZ, TOC, Conjoint Analysis, Kansei Eng. Comprehensive QFD, Voice of Customer Integration of product planning House of Quality Assurance of manufacturing 2005 2000 1995 1990 1985 1980 1975 1970 1965 1960 Fitness to individual style, habits Fitness to society Fitness to environment Fitness to latent needs Fitness to price Fitness to use Fitness to specifications Evolution of Quality and QFD Quality QFD

Trends • Competition on price will force companies to continuously seek lower wage countries. • Profitability will come from increased differentiation as customers demand value. • Change from caveat emptor to ‘caveat vendor. ’ • Technology advances and globalisation will increase latent (unspoken) needs. • Greater societal demands for environmental friendliness and economic parity. • Customers will “buy” integrated package of hardware, software, and service, regardless of who sells what.

Trends • Competition on price will force companies to continuously seek lower wage countries. • Profitability will come from increased differentiation as customers demand value. • Change from caveat emptor to ‘caveat vendor. ’ • Technology advances and globalisation will increase latent (unspoken) needs. • Greater societal demands for environmental friendliness and economic parity. • Customers will “buy” integrated package of hardware, software, and service, regardless of who sells what.

Keys to success • Rapid response to changing markets, technologies, economics. • Become market driven in design and agile in manufacturing. • Pursue a global strategy for prosperity, education, freedom of choice. • Promote flexibility, systems thinking, and long term gains, not rigidity, local thinking, and short term gains.

Keys to success • Rapid response to changing markets, technologies, economics. • Become market driven in design and agile in manufacturing. • Pursue a global strategy for prosperity, education, freedom of choice. • Promote flexibility, systems thinking, and long term gains, not rigidity, local thinking, and short term gains.

QFD Resources • Training – Iran 30/6 to 5/7 i 7625928@cic. aku. ac. ir – Saudi 14 -18/7 osamaatabani@hotmail. com – UAE 21 -25/7 cspme@destination. com. lb • Conferences – Europe 45 th EOQ Congress Istanbul www. eoq 2001. org – Global 22 -24/10 Tokyo www. windvale. com/isqfd 2001/ – US 4 -8/11 Baltimore www. qfdi. org • Websites – www. mazur. net – www. qfdi. org

QFD Resources • Training – Iran 30/6 to 5/7 i 7625928@cic. aku. ac. ir – Saudi 14 -18/7 osamaatabani@hotmail. com – UAE 21 -25/7 cspme@destination. com. lb • Conferences – Europe 45 th EOQ Congress Istanbul www. eoq 2001. org – Global 22 -24/10 Tokyo www. windvale. com/isqfd 2001/ – US 4 -8/11 Baltimore www. qfdi. org • Websites – www. mazur. net – www. qfdi. org