2916bcb0233dc1f94464dc22c6da69d4.ppt

- Количество слайдов: 34

Purchasing 101 A Guideline for the Purchasing Department of The Paper Tree/ Davao Unified Corporation

Purchasing 101 A Guideline for the Purchasing Department of The Paper Tree/ Davao Unified Corporation

Definition of Purchasing • Is an organizational function concerned with procurement of the: – Right Kind of Materials – Right Quantities – Right Price – Right Time – Right Place

Definition of Purchasing • Is an organizational function concerned with procurement of the: – Right Kind of Materials – Right Quantities – Right Price – Right Time – Right Place

Objectives of Purchasing • Price: – Contribute to optimum company profits (Find and secure best possible supplies costs) • Reliability: – Provide materials, components and supplies to sales and production operations so as to meet delivery commitments (Develop reliable supply chains). • Quality: – Provide materials that are acceptable in terms of quality to its intended consumers.

Objectives of Purchasing • Price: – Contribute to optimum company profits (Find and secure best possible supplies costs) • Reliability: – Provide materials, components and supplies to sales and production operations so as to meet delivery commitments (Develop reliable supply chains). • Quality: – Provide materials that are acceptable in terms of quality to its intended consumers.

Responsibilities of Purchasing (in relation to its objectives) • Development of dependable sources of supplies • Negotiating and Finalizing prices and other terms and conditions of purchasing.

Responsibilities of Purchasing (in relation to its objectives) • Development of dependable sources of supplies • Negotiating and Finalizing prices and other terms and conditions of purchasing.

To achieve these, the purchaser must: • Study the market and keep oneself updated on conditions of supplies, price trends and deliveries • Maintaining complete record of vendors and their respective offerings. • Periodical review of reliability of vendors and development of new sources of supply.

To achieve these, the purchaser must: • Study the market and keep oneself updated on conditions of supplies, price trends and deliveries • Maintaining complete record of vendors and their respective offerings. • Periodical review of reliability of vendors and development of new sources of supply.

To achieve these, the purchaser must (Cont’d): • Advise management on the effectiveness of purchasing policies and development of new ones as needed. • Developing and maintaining an effective buying service. This is done through the ff actions: – Interviewing sales reps of vendors – Advise consumers of supplies of new materials that can substitute more economically for existing ones.

To achieve these, the purchaser must (Cont’d): • Advise management on the effectiveness of purchasing policies and development of new ones as needed. • Developing and maintaining an effective buying service. This is done through the ff actions: – Interviewing sales reps of vendors – Advise consumers of supplies of new materials that can substitute more economically for existing ones.

To achieve these, the purchaser must (Cont’d): – Advise internal customers regarding delivery schedules, and availability of materials. – Analyzing the most favorable cost, terms and conditions of suppliers and negotiating with them. – Placing orders to vendors who offer the best mix of price, terms and conditions.

To achieve these, the purchaser must (Cont’d): – Advise internal customers regarding delivery schedules, and availability of materials. – Analyzing the most favorable cost, terms and conditions of suppliers and negotiating with them. – Placing orders to vendors who offer the best mix of price, terms and conditions.

Common Purchasing Practices • Buying policies affect the buying practices of the department. • There are different buying practices for the following kinds of items: –Steady Use Items –Big One-Shot items –Middle-Sized Purchases –Small Items

Common Purchasing Practices • Buying policies affect the buying practices of the department. • There are different buying practices for the following kinds of items: –Steady Use Items –Big One-Shot items –Middle-Sized Purchases –Small Items

Steady Use Items • Used continuously for the sales and production operations of the organization. • Must be well-canvassed as this would determine the price-competitiveness of the sales and production departments (at least 3 competent vendors). • Prices are negotiated and stored in the database for future reference and use. • Computer-Generated Purchase Orders (PO) must be issued every time these items are purchased so that all linked departments are informed of purchases, delivery schedules (ETA), and other related information.

Steady Use Items • Used continuously for the sales and production operations of the organization. • Must be well-canvassed as this would determine the price-competitiveness of the sales and production departments (at least 3 competent vendors). • Prices are negotiated and stored in the database for future reference and use. • Computer-Generated Purchase Orders (PO) must be issued every time these items are purchased so that all linked departments are informed of purchases, delivery schedules (ETA), and other related information.

Big One-Shot items • Items include machinery, equipment and the like. • Negotiated among many suppliers. • Usually negotiated and executed by top management.

Big One-Shot items • Items include machinery, equipment and the like. • Negotiated among many suppliers. • Usually negotiated and executed by top management.

Middle-Sized Purchases • Usually comes as new item requisitions from sales and retail departments. • Purchasing dept, invites quotations, selects based on most economical prices and terms, and places orders. • Every time new items are needed, the purchasing department goes through the process. • In case of repeat items, orders are often placed with the vendor who had supplied on a previous occasion.

Middle-Sized Purchases • Usually comes as new item requisitions from sales and retail departments. • Purchasing dept, invites quotations, selects based on most economical prices and terms, and places orders. • Every time new items are needed, the purchasing department goes through the process. • In case of repeat items, orders are often placed with the vendor who had supplied on a previous occasion.

Small Items • These items are of low value – usually not more than P 1, 000. • These items may be expensed out directly by letting the Expense Clerk handle the purchase. • These items are usually bought from local/domestic vendors to save on lead time.

Small Items • These items are of low value – usually not more than P 1, 000. • These items may be expensed out directly by letting the Expense Clerk handle the purchase. • These items are usually bought from local/domestic vendors to save on lead time.

Company Purchasing Policies • Selection of Vendors • Price Negotiations • Discounts • Value Analysis • Gifts • Reciprocity

Company Purchasing Policies • Selection of Vendors • Price Negotiations • Discounts • Value Analysis • Gifts • Reciprocity

Selection of Vendors • To select vendors, the buyer must first have a list of vendors which he/she can find via: – – Salesman’s calls Trade journals Directories (online and paper) Buyer’s guides • Vendors must be the best relative to other vendors of the same products and/or services in terms of: – Price – Quality – Reliability

Selection of Vendors • To select vendors, the buyer must first have a list of vendors which he/she can find via: – – Salesman’s calls Trade journals Directories (online and paper) Buyer’s guides • Vendors must be the best relative to other vendors of the same products and/or services in terms of: – Price – Quality – Reliability

Sidebar: What is Reliability? Reliability is judged by: • Past delivery performance • Production capability • Financial position • Competitiveness of price and delivery record • Cooperation when orders are cancelled due to unavoidable circumstances • Accommodation when rejected materials are returned • Guarantee and repair services (if applicable)

Sidebar: What is Reliability? Reliability is judged by: • Past delivery performance • Production capability • Financial position • Competitiveness of price and delivery record • Cooperation when orders are cancelled due to unavoidable circumstances • Accommodation when rejected materials are returned • Guarantee and repair services (if applicable)

Price Negotiations • • • Always have 2 -3 suppliers for each item. Having several options will give you a better bargaining position than having no options. Keep accurate and up-to-date records of supplier prices. This can be done by recording the items and prices for each item that the seller is offering into our ERP system. Always deal with suppliers who can offer: – Low Prices (we are into wholesaling and the markets that we serve are very – – – price sensitive. When w buy at a price that is very high, our competitive position is adversely affected). Reliable Delivery No stock, No sale. Acceptable Quality. Otherwise, there will be a lot of headaches arising from stock returns by our customers. Worse case, we might lose customers. Adaptability to Time and Cost-Efficient Processes. We are currently maintaining a purchasing website Suppliers are willing to use the website AND who can offer the same price, reliability and quality as those who are not willing should be given very high priority over those who are not willing

Price Negotiations • • • Always have 2 -3 suppliers for each item. Having several options will give you a better bargaining position than having no options. Keep accurate and up-to-date records of supplier prices. This can be done by recording the items and prices for each item that the seller is offering into our ERP system. Always deal with suppliers who can offer: – Low Prices (we are into wholesaling and the markets that we serve are very – – – price sensitive. When w buy at a price that is very high, our competitive position is adversely affected). Reliable Delivery No stock, No sale. Acceptable Quality. Otherwise, there will be a lot of headaches arising from stock returns by our customers. Worse case, we might lose customers. Adaptability to Time and Cost-Efficient Processes. We are currently maintaining a purchasing website Suppliers are willing to use the website AND who can offer the same price, reliability and quality as those who are not willing should be given very high priority over those who are not willing

Discounts • When discounts are available for large volume purchases, compute for the cost of money for the additional quantity that we will be buying. • E. g. . – – Actual Sales for 3 months: 1, 000 @ P 10. 00 factory cost each Price Break Offer: 2, 000 pcs @ 9. 75 each factory cost. Then: P 10/9. 75 = 1. 025641 or 2. 5641%. Since we will be stocking 3 months worth of excess inventory, we compute for the cost of money for 3 months: 10% pa / 12 months = 0. 833% x 3 months = 2. 5%. – Discount = 2. 5% vs Cost of Money = 2. 5641%. – Since the cost of money is greater, we do not buy at the price break quantity (unless we are looking at selling at bigger volume).

Discounts • When discounts are available for large volume purchases, compute for the cost of money for the additional quantity that we will be buying. • E. g. . – – Actual Sales for 3 months: 1, 000 @ P 10. 00 factory cost each Price Break Offer: 2, 000 pcs @ 9. 75 each factory cost. Then: P 10/9. 75 = 1. 025641 or 2. 5641%. Since we will be stocking 3 months worth of excess inventory, we compute for the cost of money for 3 months: 10% pa / 12 months = 0. 833% x 3 months = 2. 5%. – Discount = 2. 5% vs Cost of Money = 2. 5641%. – Since the cost of money is greater, we do not buy at the price break quantity (unless we are looking at selling at bigger volume).

Value Analysis • Value Criteria: – Is it cheaper to buy in bulk (use cost of money analysis) – Will buying the item or price break quantity give us a competitive advantage? • Exclusivity • Salability • Profitability

Value Analysis • Value Criteria: – Is it cheaper to buy in bulk (use cost of money analysis) – Will buying the item or price break quantity give us a competitive advantage? • Exclusivity • Salability • Profitability

Gifts • No gifts other than samples of items that are sold on a regular basis by the company may be accepted by purchasers. • Banned gift items include: – Food – Monetary considerations – Call/Prepaid Cards – Etc.

Gifts • No gifts other than samples of items that are sold on a regular basis by the company may be accepted by purchasers. • Banned gift items include: – Food – Monetary considerations – Call/Prepaid Cards – Etc.

Reciprocity • As much as possible, we buy from suppliers that give us return business (i. e. they also buy items from us or give us certain business (note: not personal) favors.

Reciprocity • As much as possible, we buy from suppliers that give us return business (i. e. they also buy items from us or give us certain business (note: not personal) favors.

Company Purchasing Procedures: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Receipt of purchase requisition (If applicable) selection of supplier/vendor Canvass of prices, terms and conditions Receipt and analysis of quotations Selection of vendor Negotiation and finalization of prices. Issue of Purchase Orders Follow-up to ensure timely deliveries Analysis of Receiving Reports Scrutiny and approval of vendor’s invoice for payment.

Company Purchasing Procedures: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Receipt of purchase requisition (If applicable) selection of supplier/vendor Canvass of prices, terms and conditions Receipt and analysis of quotations Selection of vendor Negotiation and finalization of prices. Issue of Purchase Orders Follow-up to ensure timely deliveries Analysis of Receiving Reports Scrutiny and approval of vendor’s invoice for payment.

Purchasing Procedures 1. Receipt of purchase requisition – – As much as possible, we only entertain requisitions that are directly related to our core business operations (i. e. school and office supplies). We try to discourage unrelated items especially if they are in very small quantities and limited repeat order (because we will end up losing more than gaining). Exception to this rule is when the item is requested by VIP customers or when we have already quoted for the said item.

Purchasing Procedures 1. Receipt of purchase requisition – – As much as possible, we only entertain requisitions that are directly related to our core business operations (i. e. school and office supplies). We try to discourage unrelated items especially if they are in very small quantities and limited repeat order (because we will end up losing more than gaining). Exception to this rule is when the item is requested by VIP customers or when we have already quoted for the said item.

Purchasing Procedures 2. (If applicable) search and selection of supplier/vendor Vendors are selected in the basis of • Price of Products • Reliability of Service and after-sales support • Quality of products and relationships

Purchasing Procedures 2. (If applicable) search and selection of supplier/vendor Vendors are selected in the basis of • Price of Products • Reliability of Service and after-sales support • Quality of products and relationships

Purchasing Procedures 3. Canvass of prices, terms and conditions 4. Receipt and analysis of quotations • Prices are compared based on landed costs (factory + freight costs) • Prices are compared based on equivalent credit terms (bank rate plus a premium of. 5% on the total apply to comparison)

Purchasing Procedures 3. Canvass of prices, terms and conditions 4. Receipt and analysis of quotations • Prices are compared based on landed costs (factory + freight costs) • Prices are compared based on equivalent credit terms (bank rate plus a premium of. 5% on the total apply to comparison)

Purchasing Procedures 5. Selection of vendor 6. Negotiation and finalization of prices. 7. Issue of Purchase Orders – Once a vendor is selected, a PO will have to be issued using the company’s ERP system. – The supplier is asked to inform our company in case there are some discrepancies in terms of price and credit terms, quantity, and other terms listed in the PO.

Purchasing Procedures 5. Selection of vendor 6. Negotiation and finalization of prices. 7. Issue of Purchase Orders – Once a vendor is selected, a PO will have to be issued using the company’s ERP system. – The supplier is asked to inform our company in case there are some discrepancies in terms of price and credit terms, quantity, and other terms listed in the PO.

Side Bar: What Items to Purchase? • Buy the most important items before buying the least important items. • The Pareto Principle states that 20% of items contribute to 80% of sales; corollary is 80% of items contribute only 20% of sales. • Put first things first. Don’t sweat the “small items” unless you have spare time or purchasing resources. • Access Stock Ranking Report of the ERP system to learn more about important items.

Side Bar: What Items to Purchase? • Buy the most important items before buying the least important items. • The Pareto Principle states that 20% of items contribute to 80% of sales; corollary is 80% of items contribute only 20% of sales. • Put first things first. Don’t sweat the “small items” unless you have spare time or purchasing resources. • Access Stock Ranking Report of the ERP system to learn more about important items.

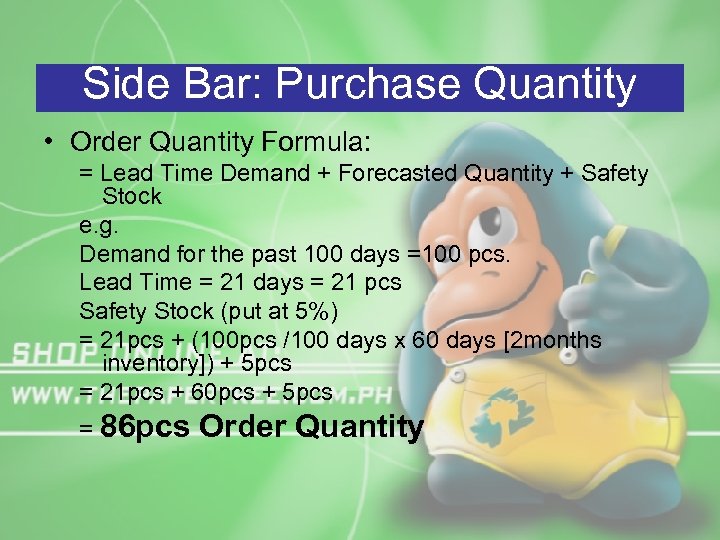

Side Bar: Purchase Quantity • Rule of Thumb: – The longer the total lead time (the time it takes for the supplier and the shipper to serve the items to us), the bigger the order quantity that we should take. – Order quantities should be good for at least 12 months to avoid stock outs.

Side Bar: Purchase Quantity • Rule of Thumb: – The longer the total lead time (the time it takes for the supplier and the shipper to serve the items to us), the bigger the order quantity that we should take. – Order quantities should be good for at least 12 months to avoid stock outs.

Side Bar: Purchase Quantity • Order Quantity Formula: = Lead Time Demand + Forecasted Quantity + Safety Stock e. g. Demand for the past 100 days =100 pcs. Lead Time = 21 days = 21 pcs Safety Stock (put at 5%) = 21 pcs + (100 pcs /100 days x 60 days [2 months inventory]) + 5 pcs = 21 pcs + 60 pcs + 5 pcs = 86 pcs Order Quantity

Side Bar: Purchase Quantity • Order Quantity Formula: = Lead Time Demand + Forecasted Quantity + Safety Stock e. g. Demand for the past 100 days =100 pcs. Lead Time = 21 days = 21 pcs Safety Stock (put at 5%) = 21 pcs + (100 pcs /100 days x 60 days [2 months inventory]) + 5 pcs = 21 pcs + 60 pcs + 5 pcs = 86 pcs Order Quantity

Purchasing Procedures 8. Follow-up to ensure timely deliveries 9. Analysis of Receiving Reports 10. Scrutiny and approval of vendor’s invoice for payment. • • Follow up is done by the purchasing department to ensure that items arrive on time as much as possible. This may be done via phone, fax, cell phone or email Analysis of receiving reports and approval of vendor’s invoice are performed by the Accounts Payables Department. .

Purchasing Procedures 8. Follow-up to ensure timely deliveries 9. Analysis of Receiving Reports 10. Scrutiny and approval of vendor’s invoice for payment. • • Follow up is done by the purchasing department to ensure that items arrive on time as much as possible. This may be done via phone, fax, cell phone or email Analysis of receiving reports and approval of vendor’s invoice are performed by the Accounts Payables Department. .

Purchasing Department Organization Structure

Purchasing Department Organization Structure

Relationship of Purchasing Department with Other Departments • Sales, Retail & Production Departments • Warehouse Department • Accounts Payables Department

Relationship of Purchasing Department with Other Departments • Sales, Retail & Production Departments • Warehouse Department • Accounts Payables Department

Sales, Retail & Production Departments • These departments are the primary internal clients of the purchasing department. • Purchased items should be priced competitively, arrive on time and be in the right quality so that the above departments can perform their functions efficiently effectively.

Sales, Retail & Production Departments • These departments are the primary internal clients of the purchasing department. • Purchased items should be priced competitively, arrive on time and be in the right quality so that the above departments can perform their functions efficiently effectively.

Warehouse Department • The warehouse department is responsible for maintaining records of inventory levels and reporting to the purchasing department in case inventory levels need to be replenished. • Warehouse department is also tasked to fetch, receive and store inventory items.

Warehouse Department • The warehouse department is responsible for maintaining records of inventory levels and reporting to the purchasing department in case inventory levels need to be replenished. • Warehouse department is also tasked to fetch, receive and store inventory items.

Accounts Payables Department • This is the department that scrutinizes vendor invoices for payment. • Payments are disbursed by this department.

Accounts Payables Department • This is the department that scrutinizes vendor invoices for payment. • Payments are disbursed by this department.