436c0d21ed64d812312292b38880536b.ppt

- Количество слайдов: 47

PUNJAB BEVEL GEARS

INTRODUCTION Sahibabad Sitarganj Sahibabad

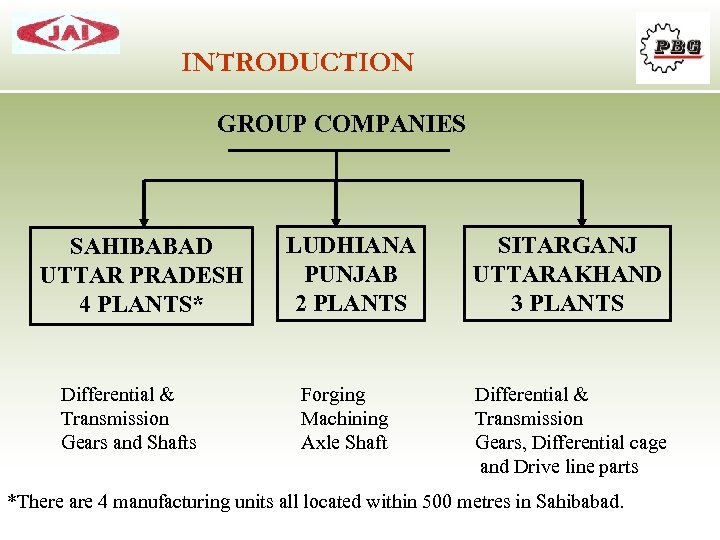

INTRODUCTION GROUP COMPANIES SAHIBABAD UTTAR PRADESH 4 PLANTS* Differential & Transmission Gears and Shafts LUDHIANA PUNJAB 2 PLANTS Forging Machining Axle Shaft SITARGANJ UTTARAKHAND 3 PLANTS Differential & Transmission Gears, Differential cage and Drive line parts *There are 4 manufacturing units all located within 500 metres in Sahibabad.

INTRODUCTION • Started operations in 1979 • Manufactures more than 2000 different type of gears • Leading manufacturer, supplier and exporter of automotive and tractor parts • Caters to industries like commercial vehicles, agricultural tractors, passenger cars, three wheelers & construction equipments

INTRODUCTION Our competitiveness lies in the fact that we are: • Cost Competitive, • Quality Conscious, • Having track record of on time delivery • Having capability to develop new products in a comparatively shorter period

INTRODUCTION • Financially sound having credit rating of ‘care BBB-’ (Triple B Minus) For long term bank facilities for 2014 • Having assurances from financial institutions for support in the on going and future expansions • Having very sound HR policies with almost nil employee turnover • The average of employees is 40 years • Having 100% captive power back up at all plants • An ISO/TS 16949: 2009 Certified Company

PRODUCT RANGE ØCrown Wheel & Pinion (Face Mill, Face Mill Completing and Face Hob in both Dry and Wet cutting) ØST. Bevel Gear & Pinions (Gleason Coniflex System) ØTransmission Gears(Spur, Helical) ØDifferential Cages ØAxle Shafts ØForgings/Machined Forgings ØDrive Line Parts

PRODUCT RANGE Crown Wheel & Pinion (Face Mill and Face Hob Wet Cutting process) Crown Teeth Cutting Pinion Teeth Cutting Crown & Pinion Testing

PRODUCT RANGE St. Bevel Gears & Pinions (Gleason Coniflex System) Teeth Cutting Gear & Pinion Testing Teeth Cutting

PRODUCT RANGE Transmission Gears and Shafts (Spur, Helical) CNC Blanking CNC Hobbing Spline Hobbing Stack Hobbing

PRODUCT RANGE Transmission Gears and Shafts (Products)

PRODUCT RANGE Differential Cages CNC Machining CMM

PRODUCT RANGE Axle Shafts

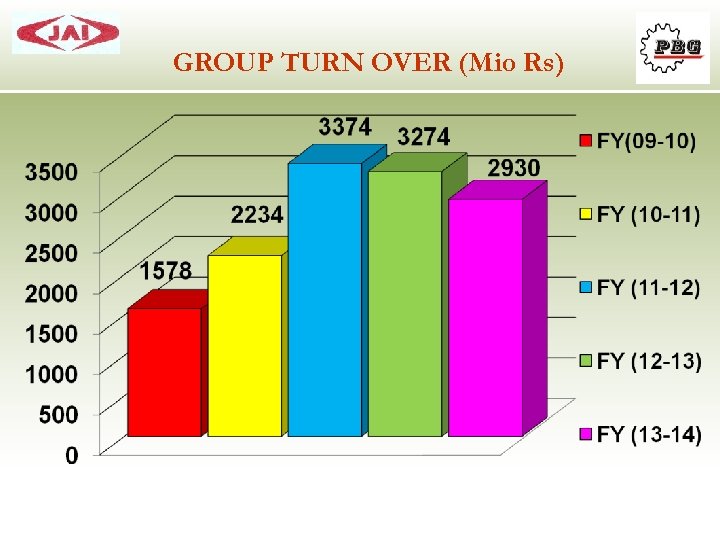

GROUP TURN OVER (Mio Rs)

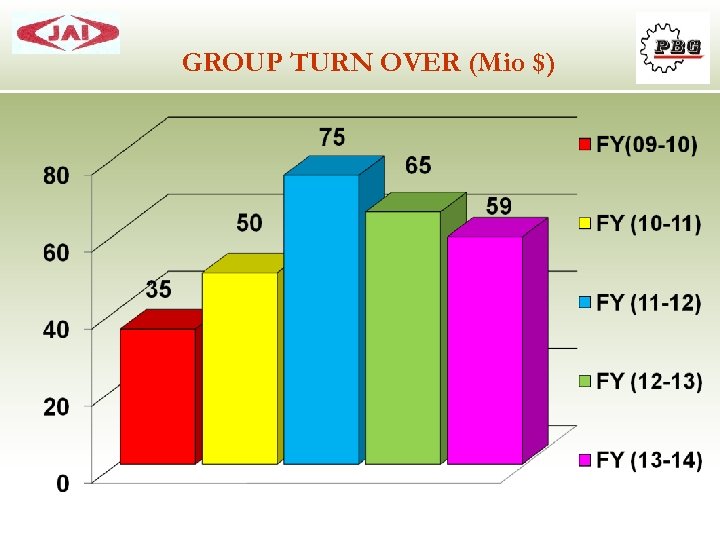

GROUP TURN OVER (Mio $)

SEGMENT WISE SALES FY 13 -14

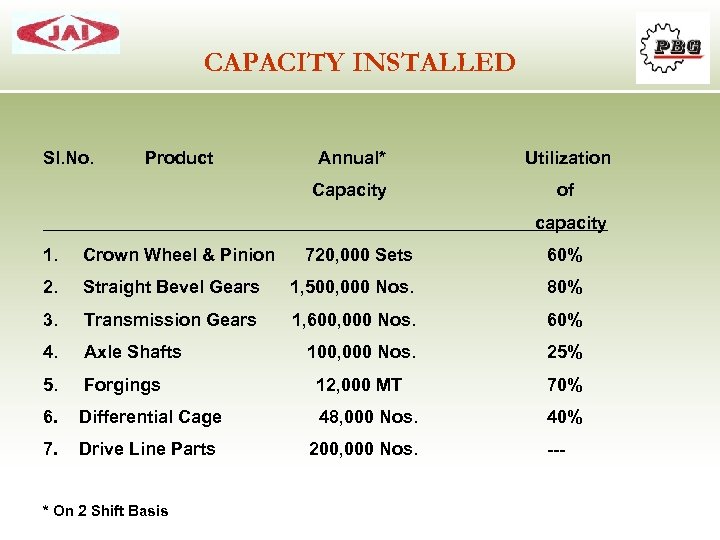

CAPACITY INSTALLED Sl. No. Product Annual* Utilization Capacity of capacity 1. Crown Wheel & Pinion 720, 000 Sets 60% 2. Straight Bevel Gears 1, 500, 000 Nos. 80% 3. Transmission Gears 1, 600, 000 Nos. 60% 4. Axle Shafts 100, 000 Nos. 25% 5. Forgings 12, 000 MT 70% 6. Differential Cage 48, 000 Nos. 40% 7. Drive Line Parts 200, 000 Nos. * On 2 Shift Basis ---

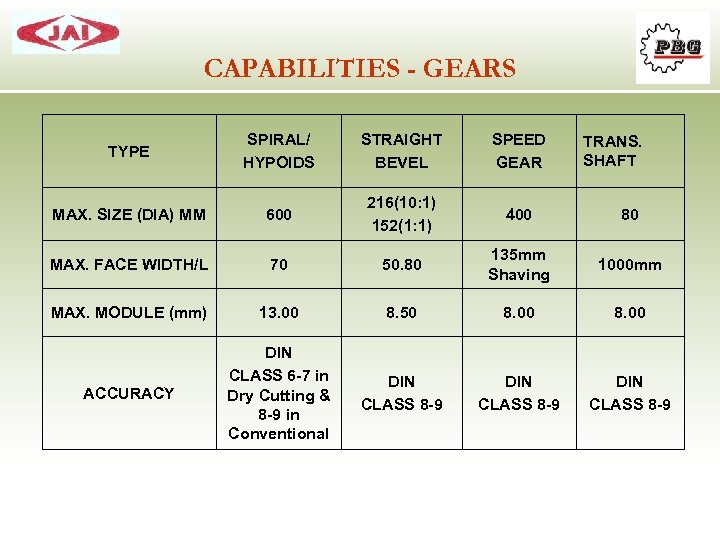

CAPABILITIES - GEARS TYPE SPIRAL/ HYPOIDS STRAIGHT BEVEL SPEED GEAR MAX. SIZE (DIA) MM 600 216(10: 1) 152(1: 1) 400 80 MAX. FACE WIDTH/L 70 50. 80 135 mm Shaving 1000 mm MAX. MODULE (mm) 13. 00 8. 50 8. 00 ACCURACY DIN CLASS 6 -7 in Dry Cutting & 8 -9 in Conventional DIN CLASS 8 -9 TRANS. SHAFT

CAPABILITIES - FORGINGS • Weight 0. 5 Kg to 50 Kgs • Round Forging Min. Dia 80 mm Max. Dia 500 mm • Shaft Forgings Length 1200 mm Flange Dia 325 mm

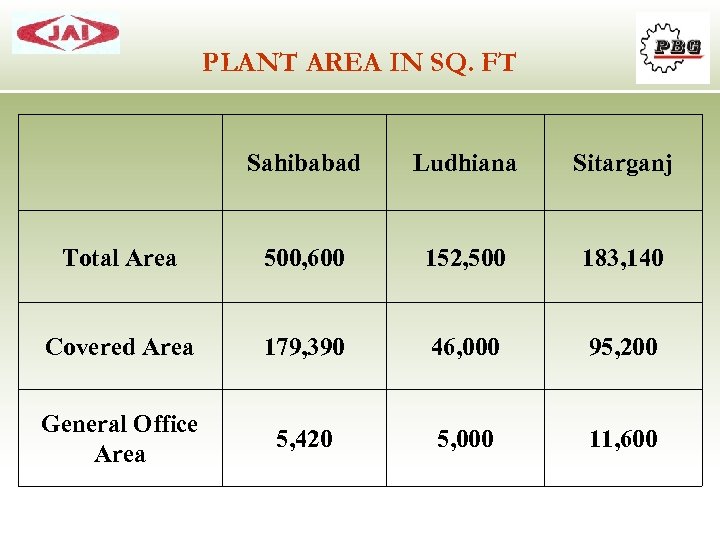

PLANT AREA IN SQ. FT Sahibabad Ludhiana Sitarganj Total Area 500, 600 152, 500 183, 140 Covered Area 179, 390 46, 000 95, 200 General Office Area 5, 420 5, 000 11, 600

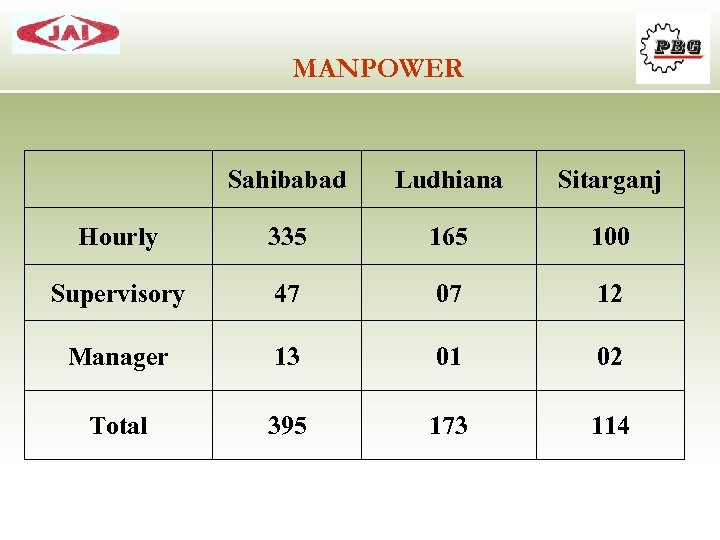

MANPOWER Sahibabad Ludhiana Sitarganj Hourly 335 165 100 Supervisory 47 07 12 Manager 13 01 02 Total 395 173 114

CERTIFICATION / AWARD QUALITY SYSTEMS: • • • Plants at Sahibabad and Sitarganj are ISO/TS 16949: 2009 certified Forging plant at Ludhiana is ISO 9001: 2008 certified Differential gear plant is ISO 9001, ISO 14000 & ISO 18000 certified EXPORT PROMOTION: • Recognized star export house • Awarded silver shield for export performance during 2005 -06, 2007 -08, 2008 -09, 2009 -10, 2010 -11 & 2011 -2012 by Engineering Export Promotion Council, India

CERTIFICATION / AWARD CUSTOMER AWARDS: • Best supplier award for new product development by TAFE in 2010 • Best supplier award for consistent delivery performance through pull system-KANBAN by TAFE in 2013 • Supplier recognition award by American Axle in 2010 • Direct on line supplier award by TAFE & International Tractors Limited

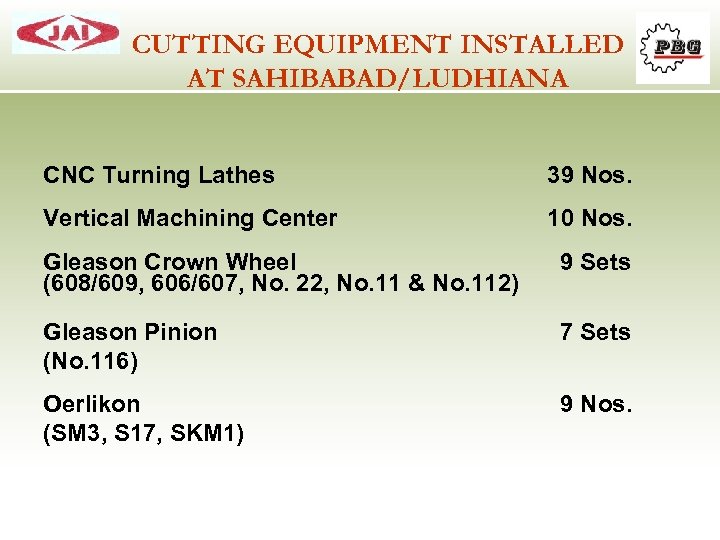

CUTTING EQUIPMENT INSTALLED AT SAHIBABAD/LUDHIANA CNC Turning Lathes 39 Nos. Vertical Machining Center 10 Nos. Gleason Crown Wheel (608/609, 606/607, No. 22, No. 11 & No. 112) 9 Sets Gleason Pinion (No. 116) 7 Sets Oerlikon (SM 3, S 17, SKM 1) 9 Nos.

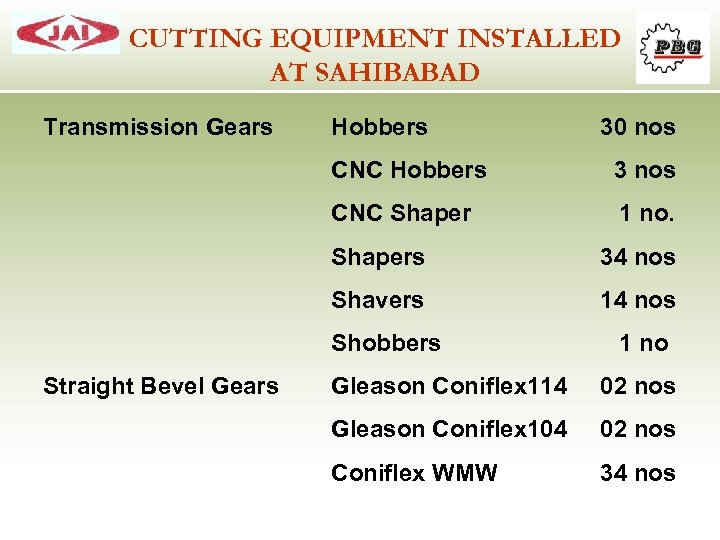

CUTTING EQUIPMENT INSTALLED AT SAHIBABAD Transmission Gears Hobbers 30 nos CNC Hobbers 3 nos CNC Shaper 1 no. Shapers 34 nos Shavers 14 nos Shobbers Straight Bevel Gears 1 no Gleason Coniflex 114 02 nos Gleason Coniflex 104 02 nos Coniflex WMW 34 nos

HEAT TREATMENT FACILITIES Sealed Quench Furnace Continuous Gas Carburising Furnace

HEAT TREATMENT FACILITIES • Sealed Quench Furnaces • Continuous Gas Carburizing Furnace • Rotary Hearth Furnaces • Induction Hardening / Softening • Quench Presses – Gleason • Tempering Furnaces • Manganese Phosphating Facilities • Shot Peening Equipment • Shot Blasting Equipments • Straightening Presses

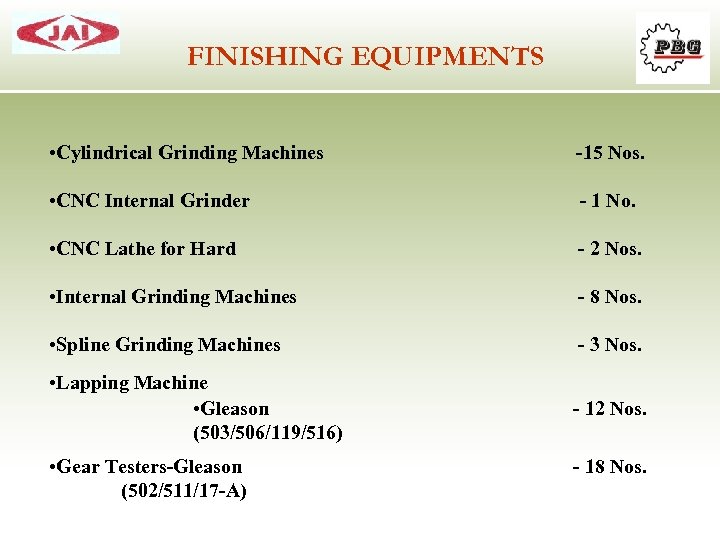

FINISHING EQUIPMENTS • Cylindrical Grinding Machines -15 Nos. • CNC Internal Grinder - 1 No. • CNC Lathe for Hard - 2 Nos. • Internal Grinding Machines - 8 Nos. • Spline Grinding Machines - 3 Nos. • Lapping Machine • Gleason (503/506/119/516) - 12 Nos. • Gear Testers-Gleason (502/511/17 -A) - 18 Nos.

METALLURGICAL LAB FACILITIES • Full range of Hardness Testers • ( Rockwell, Brinell, Micro Vickers) • Hardenability (Jominy) Apparatus • Microscope with camera and image analyzer • Magnetic Particle Inspection • Macro Etching • Muffle Furnaces • Manganese Phosphating Solution Analyzer

METROLOGY LAB FACILITIES • CMM with Gear Analyzer • Lead and Profile Testers • Surface Roughness Tester • Contouro Graph • Profile Projectors • Gear Roll Testers • Digital Temperature Calibrator • d. B Meter

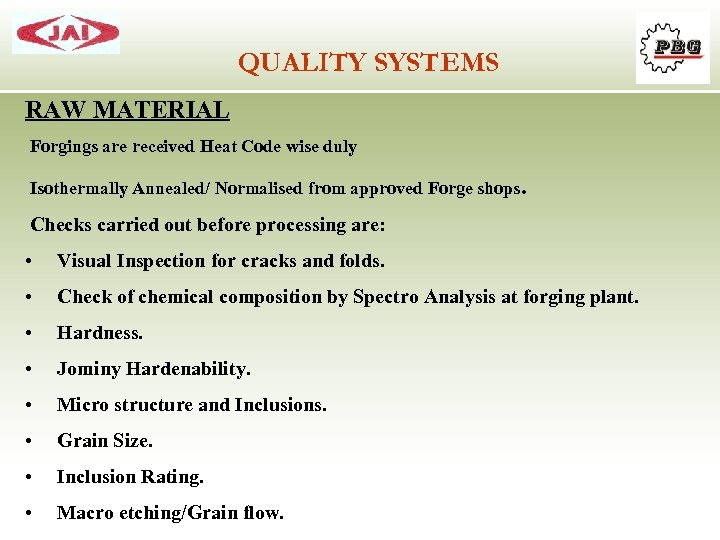

QUALITY SYSTEMS RAW MATERIAL Forgings are received Heat Code wise duly Isothermally Annealed/ Normalised from approved Forge shops. Checks carried out before processing are: • Visual Inspection for cracks and folds. • Check of chemical composition by Spectro Analysis at forging plant. • Hardness. • Jominy Hardenability. • Micro structure and Inclusions. • Grain Size. • Inclusion Rating. • Macro etching/Grain flow.

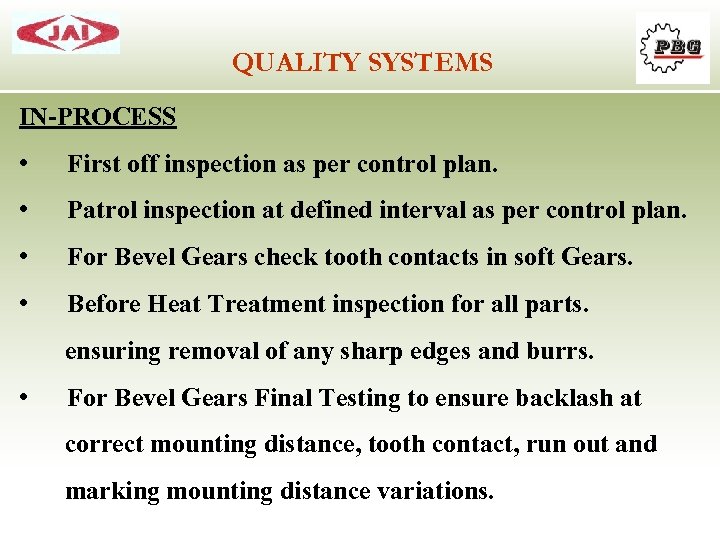

QUALITY SYSTEMS IN-PROCESS • First off inspection as per control plan. • Patrol inspection at defined interval as per control plan. • For Bevel Gears check tooth contacts in soft Gears. • Before Heat Treatment inspection for all parts. ensuring removal of any sharp edges and burrs. • For Bevel Gears Final Testing to ensure backlash at correct mounting distance, tooth contact, run out and marking mounting distance variations.

QUALITY SYSTEMS HEAT TREATMENT Batches are subjected to checks on: • Effective Case Depth • Core and Surface Hardness • Microstructure- Case & Core • Flatness & ovality of bore for Crown Wheels • Straightness for Shaft items • Magnetic particle inspection

TRACEABILITY • RAW MATERIAL TRACEABILITY - Unique TR No. Identifying steel mill, grade & forge shop punched on parts wherever possible • HEAT TREATMENT TRACEABILITY - Unique charge No. identifying furnace, month & process parameters punched on parts wherever possible • CWP SET TRACEABILITY - Unique set no. etched on both the members • LOGO MARKING - Customer / PBG logo punched / Laser marked / Bar Code as per customer requirements

INVESTMENT COMMITTED • Additional Continuous Gas Carburizing Furnace • Additional Sealed Quench Furnaces • Shaving Cutter Sharpening- Gleason • Additional CNC Hobbers • Additional CNC Shapers • CNC Shavers • Additional CNC Internal Grinder • CNC External Grinders • Additional Vertical Machining Center

CUSTOMER PROFILE–DOMESTIC OEMs AUTOMOTIVE • Tata Motors • Mahindra & Mahindra • American Axle & Manufacturing • Scooters India

CUSTOMER PROFILE–DOMESTIC OEMs AGRICULTURE • Tractors and Farm Equipment • International Tractors • John Deere Equipment • Dana India • Indo Farm Equipment • Sicma India

CUSTOMER PROFILE–EXPORT OEMs • Meritor, Brazil • Dana, USA • Hema Endustri A. S. , Turkey • Mega Motors Company, Iran • Iran Tractor Mfg Company, Iran

CUSTOMER PROFILE-EXPORTS We also Export our products to Importers, Gear Makers & After Markets in: USA , U. K. , France, S. Africa, Indonesia, Malaysia, Thailand, Singapore, Myanmar, Syria, Egypt, Turkey, Bangladesh, Sri Lanka, Iran, Dubai, Italy, Argentina, Australia, Hungary, Germany, Brazil.

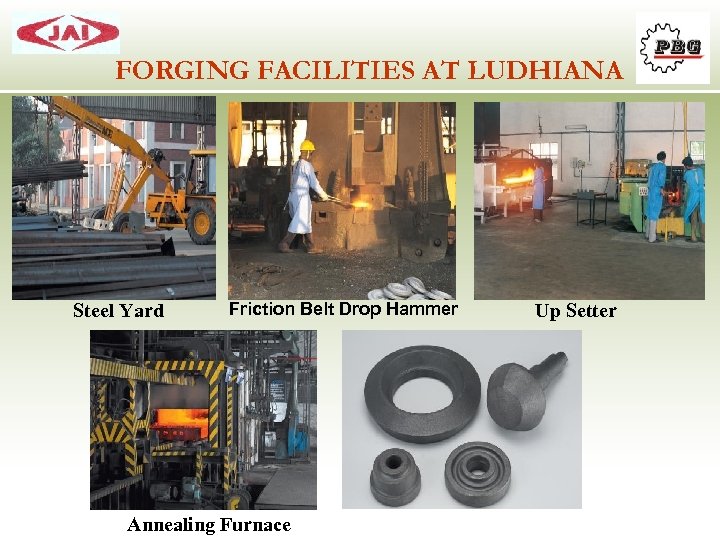

FORGING FACILITIES AT LUDHIANA Steel Yard Friction Belt Drop Hammer Annealing Furnace Up Setter

FORGING FACILITIES AT LUDHIANA • Friction Belt Drop Hammer (1. 00, 1. 50, 2. 00, 2. 50, 3. 00, 6. 00, 8. 00 M. T. and a 25 T Counter Blow hammer) • Up Setter - 3 Inches & 7 Inches • Furnaces for Isothermal annealing & normalizing • Fully equipped die making facilities • Material testing facilities includes Spectro Meter & Universal Testing Machine along with Izol Impact & Charpy Testing Machines • 100% back up with Captive Power • An ISO 9001: 2008 certified

FACILITIES AT SITARGANJ Latest Generation Gleason Phoenix CNC Dry/Wet Cutting System

FACILITIES AT SITARGANJ Pinion Teeth Cutting Line Sealed Quench Furnace Forging Press Crown Teeth Cutting Line Phosphating Plant Forging Press Lapping & Testing Line Metallurgical Lab Annealing Furnace

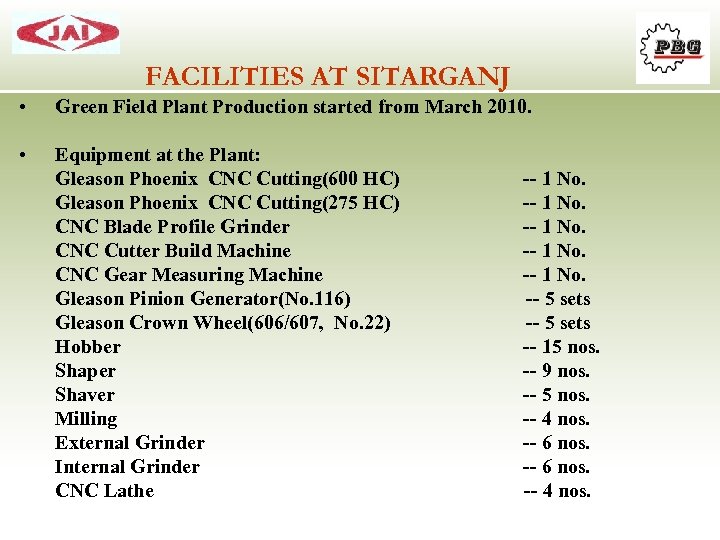

FACILITIES AT SITARGANJ • Green Field Plant Production started from March 2010. • Equipment at the Plant: Gleason Phoenix CNC Cutting(600 HC) -- 1 No. Gleason Phoenix CNC Cutting(275 HC) -- 1 No. CNC Blade Profile Grinder -- 1 No. CNC Cutter Build Machine -- 1 No. CNC Gear Measuring Machine -- 1 No. Gleason Pinion Generator(No. 116) -- 5 sets Gleason Crown Wheel(606/607, No. 22) -- 5 sets Hobber -- 15 nos. Shaper -- 9 nos. Shaver -- 5 nos. Milling -- 4 nos. External Grinder -- 6 nos. Internal Grinder -- 6 nos. CNC Lathe -- 4 nos.

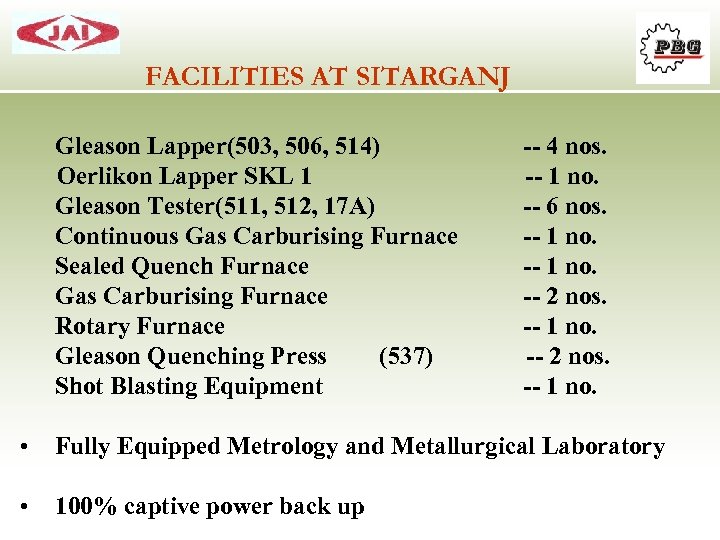

FACILITIES AT SITARGANJ Gleason Lapper(503, 506, 514) -- 4 nos. Oerlikon Lapper SKL 1 -- 1 no. Gleason Tester(511, 512, 17 A) -- 6 nos. Continuous Gas Carburising Furnace -- 1 no. Sealed Quench Furnace -- 1 no. Gas Carburising Furnace -- 2 nos. Rotary Furnace -- 1 no. Gleason Quenching Press (537) -- 2 nos. Shot Blasting Equipment -- 1 no. • Fully Equipped Metrology and Metallurgical Laboratory • 100% captive power back up

PLANT ADDRESS PUNJAB BEVEL GEARS LIMITED Unit-I &Address for communications: B-44/1 & 52/2, Site-IV, Industrial Area, Sahibabad-201010, Ghaziabad (U. P) INDIA Tel. : +91 -120 -4505100 -129, Fax: +91 -120 -4505104/4505105 Email: mktg@pbgl. in URL: www. pbgl. in Unit-II : B-174, Phase –I, Eldeco Sidcul Industrial Park, Sitarganj -261453, Udhamsingh Nagar , (Uttarakhand), INDIA Email: sitarganj@pbgl. in Unit-III: V&PO: Bhama Kalan, Kohara-Machiwara Road, Ludhiana- 141115(Punjab), INDIA E-mail: ldh@pbgl. in

436c0d21ed64d812312292b38880536b.ppt