0e42b98c35faa5d9599a8e21c4568ac3.ppt

- Количество слайдов: 22

PT. Kubota Indonesia Safety & Health Of Work Environment By. Danang Rismawan ST.

Agenda Of Presentation: 4 Record Of Accident In 2001 ~ 2004 & Counter Measure At PT. Kubota Indonesia. 4 System & implementation Of. In. Safety & Health Of Work Environment At PT. Kubota Indonesia Start 2003. 4 Sample Action Of Safety & Health Of Work Environment Implementation At PT. Kubota Indonesia. 4 Safety & Health Of Work Environment Auditor Team At PT. Kubota Indonesia

PT. Kubota Indonesia Record Of Accident In 2001 ~ 2004 & Counter Measure At PT. Kubota Indonesia

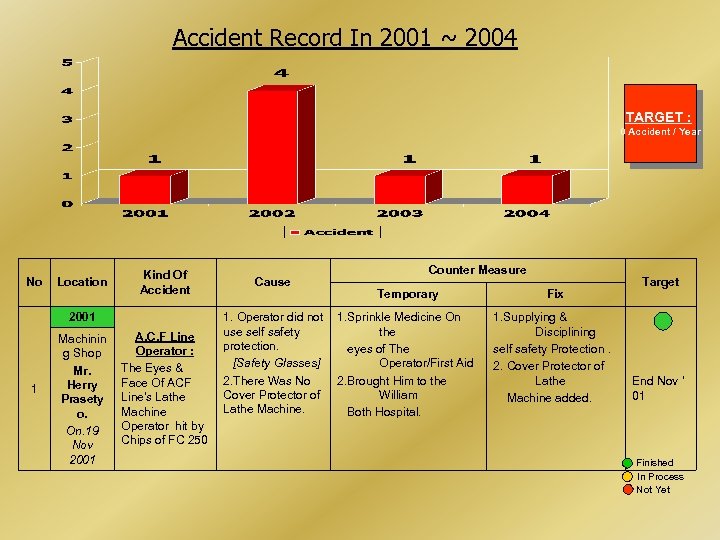

Accident Record In 2001 ~ 2004 TARGET : 0 Accident / Year No Location Kind Of Accident 2001 1 Machinin g Shop Mr. Herry Prasety o. On. 19 Nov 2001 A. C. F Line Operator : The Eyes & Face Of ACF Line's Lathe Machine Operator hit by Chips of FC 250 Cause 1. Operator did not use self safety protection. [Safety Glasses] 2. There Was No Cover Protector of Lathe Machine. Counter Measure Temporary Fix 1. Sprinkle Medicine On the eyes of The Operator/First Aid 2. Brought Him to the William Both Hospital. 1. Supplying & Disciplining self safety Protection. 2. Cover Protector of Lathe Machine added. Target End Nov ‘ 01 Finished In Process Not Yet

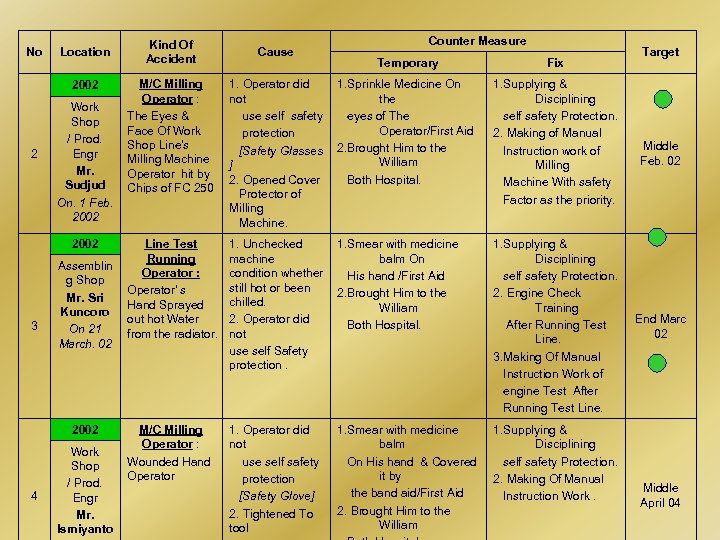

No Location 2002 2 Work Shop / Prod. Engr Mr. Sudjud On. 1 Feb. 2002 3 Assemblin g Shop Mr. Sri Kuncoro On 21 March. 02 2002 4 Work Shop / Prod. Engr Mr. Ismiyanto Kind Of Accident Cause Counter Measure Temporary Fix M/C Milling Operator : The Eyes & Face Of Work Shop Line's Milling Machine Operator hit by Chips of FC 250 1. Operator did not use self safety protection [Safety Glasses ] 2. Opened Cover Protector of Milling Machine. 1. Sprinkle Medicine On the eyes of The Operator/First Aid 2. Brought Him to the William Both Hospital. 1. Supplying & Disciplining self safety Protection. 2. Making of Manual Instruction work of Milling Machine With safety Factor as the priority. Line Test Running Operator : Operator' s Hand Sprayed out hot Water from the radiator. 1. Unchecked machine condition whether still hot or been chilled. 2. Operator did not use self Safety protection. 1. Smear with medicine balm On His hand /First Aid 2. Brought Him to the William Both Hospital. 1. Supplying & Disciplining self safety Protection. 2. Engine Check Training After Running Test Line. 3. Making Of Manual Instruction Work of engine Test After Running Test Line. M/C Milling Operator : Wounded Hand Operator 1. Operator did not use self safety protection [Safety Glove] 2. Tightened To tool 1. Smear with medicine balm On His hand & Covered it by the band aid/First Aid 2. Brought Him to the William 1. Supplying & Disciplining self safety Protection. 2. Making Of Manual Instruction Work. Target Middle Feb. 02 End Marc 02 Middle April 04

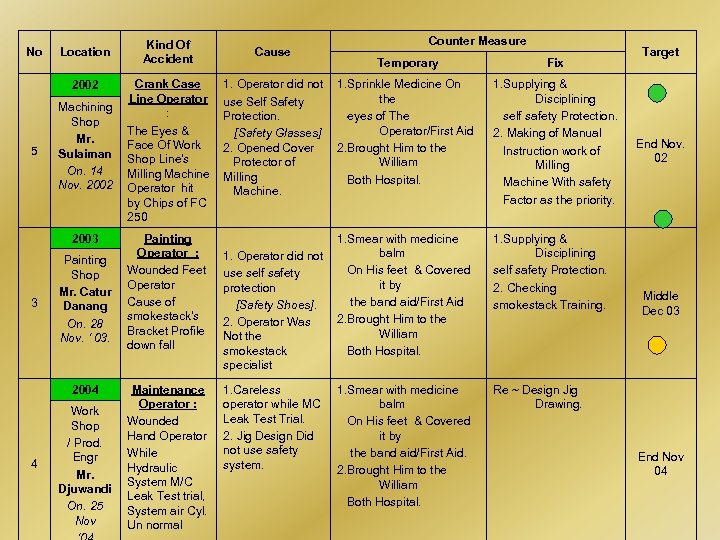

No Location 2002 5 Machining Shop Mr. Sulaiman On. 14 Nov. 2002 2003 3 Painting Shop Mr. Catur Danang On. 28 Nov. ‘ 03. 2004 4 Work Shop / Prod. Engr Mr. Djuwandi On. 25 Nov Kind Of Accident Crank Case Line Operator : The Eyes & Face Of Work Shop Line's Milling Machine Operator hit by Chips of FC 250 Painting Operator : Wounded Feet Operator Cause of smokestack’s Bracket Profile down fall Maintenance Operator : Wounded Hand Operator While Hydraulic System M/C Leak Test trial, System air Cyl. Un normal Cause 1. Operator did not use Self Safety Protection. [Safety Glasses] 2. Opened Cover Protector of Milling Machine. 1. Operator did not use self safety protection [Safety Shoes]. 2. Operator Was Not the smokestack specialist 1. Careless operator while MC Leak Test Trial. 2. Jig Design Did not use safety system. Counter Measure Temporary Fix 1. Sprinkle Medicine On the eyes of The Operator/First Aid 2. Brought Him to the William Both Hospital. 1. Supplying & Disciplining self safety Protection. 2. Making of Manual Instruction work of Milling Machine With safety Factor as the priority. 1. Smear with medicine balm On His feet & Covered it by the band aid/First Aid 2. Brought Him to the William Both Hospital. 1. Supplying & Disciplining self safety Protection. 2. Checking smokestack Training. 1. Smear with medicine balm On His feet & Covered it by the band aid/First Aid. 2. Brought Him to the William Both Hospital. Target Re ~ Design Jig Drawing. End Nov. 02 Middle Dec 03 End Nov 04

PT. Kubota Indonesia System & implementation Of Safety & Health Of Work Environment In PT. Kubota Indonesia Start In 2003.

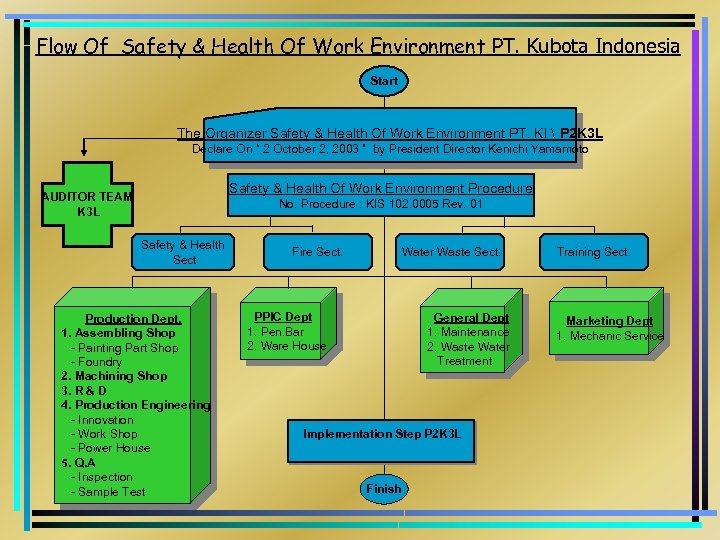

Flow Of Safety & Health Of Work Environment PT. Kubota Indonesia Start The Organizer Safety & Health Of Work Environment PT. KI P 2 K 3 L Declare On “ 2 October 2, 2003 ” by President Director Kenichi Yamamoto Safety & Health Of Work Environment Procedure AUDITOR TEAM K 3 L No. Procedure : KIS 102. 0005 Rev. 01 Safety & Health Sect Production Dept. 1. Assembling Shop - Painting Part Shop - Foundry 2. Machining Shop 3. R & D 4. Production Engineering - Innovation - Work Shop - Power House 5. Q. A - Inspection - Sample Test Fire Sect. Water Waste Sect. PPIC Dept 1. Pen. Bar 2. Ware House General Dept 1. Maintenance 2. Waste Water Treatment Implementation Step P 2 K 3 L Finish Training Sect. Marketing Dept 1. Mechanic Service

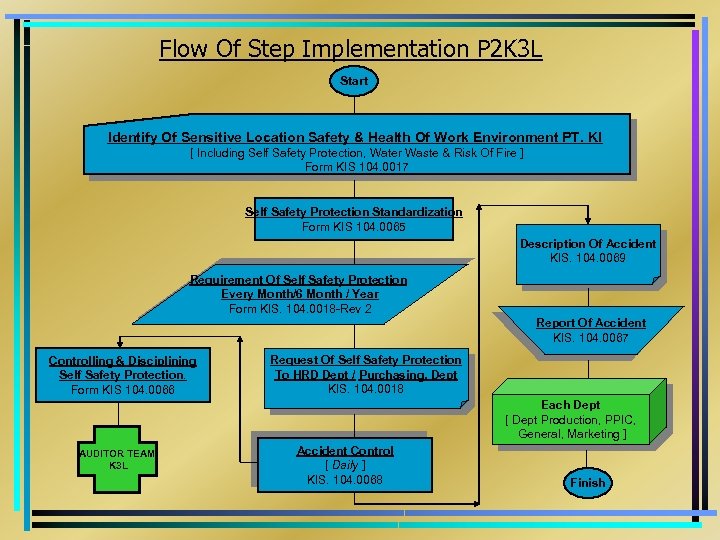

Flow Of Step Implementation P 2 K 3 L Start Identify Of Sensitive Location Safety & Health Of Work Environment PT. KI [ Including Self Safety Protection, Water Waste & Risk Of Fire ] Form KIS 104. 0017 Self Safety Protection Standardization Form KIS 104. 0065 Description Of Accident KIS. 104. 0069 Requirement Of Self Safety Protection Every Month/6 Month / Year Form KIS. 104. 0018 -Rev 2 Report Of Accident KIS. 104. 0067 Controlling & Disciplining Self Safety Protection. Form KIS 104. 0066 Request Of Self Safety Protection To HRD Dept / Purchasing. Dept KIS. 104. 0018 Each Dept [ Dept Production, PPIC, General, Marketing ] AUDITOR TEAM K 3 L Accident Control [ Daily ] KIS. 104. 0068 Finish

PT. Kubota Indonesia Sample Action Of Safety & Health Of Work Environment Implementation At PT. Kubota Indonesia.

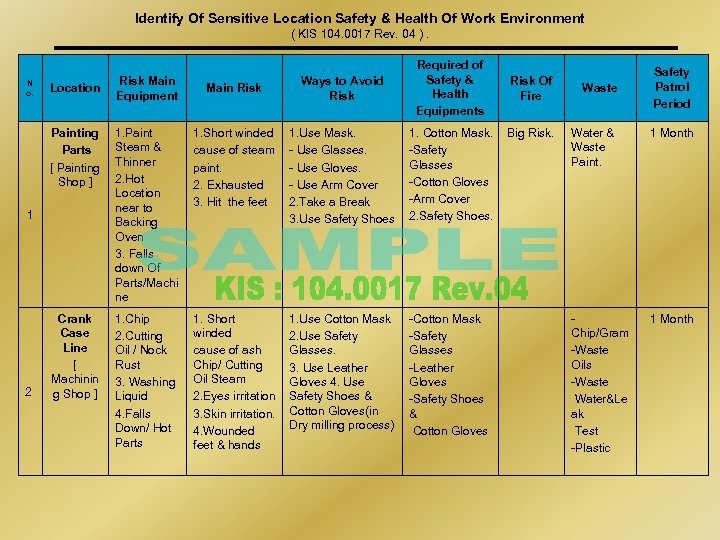

Identify Of Sensitive Location Safety & Health Of Work Environment ( KIS 104. 0017 Rev. 04 ). N o. Location Risk Main Equipment Main Risk Ways to Avoid Risk Required of Safety & Health Equipments Painting Parts [ Painting Shop ] 1. Paint Steam & Thinner 2. Hot Location near to Backing Oven 3. Falls down Of Parts/Machi ne 1. Short winded cause of steam paint. 2. Exhausted 3. Hit the feet 1. Use Mask. - Use Glasses. - Use Gloves. - Use Arm Cover 2. Take a Break 3. Use Safety Shoes 1. Cotton Mask. -Safety Glasses -Cotton Gloves -Arm Cover 2. Safety Shoes. Crank Case Line [ Machinin g Shop ] 1. Chip 2. Cutting Oil / Nock Rust 3. Washing Liquid 4. Falls Down/ Hot Parts 1. Short winded cause of ash Chip/ Cutting Oil Steam 2. Eyes irritation 3. Skin irritation. 4. Wounded feet & hands 1. Use Cotton Mask 2. Use Safety Glasses. 3. Use Leather Gloves 4. Use Safety Shoes & Cotton Gloves(in Dry milling process) -Cotton Mask -Safety Glasses -Leather Gloves -Safety Shoes & Cotton Gloves 1 2 Risk Of Fire Big Risk. Waste Safety Patrol Period Water & Waste Paint. 1 Month Chip/Gram -Waste Oils -Waste Water&Le ak Test -Plastic 1 Month

![KIS : 104. 0018 Rev 02 [ PROTECTOR SAFETY CHECK SHEET ] DEPARTEMENT NUMBER KIS : 104. 0018 Rev 02 [ PROTECTOR SAFETY CHECK SHEET ] DEPARTEMENT NUMBER](https://present5.com/presentation/0e42b98c35faa5d9599a8e21c4568ac3/image-12.jpg)

KIS : 104. 0018 Rev 02 [ PROTECTOR SAFETY CHECK SHEET ] DEPARTEMENT NUMBER OF EMPLOYEE DIVISION MONTH SECTION YEAR NO NAME SELF SAFETY PROTECTOR [ A. P. D ] Eye Protector 1 a. Ash White Glasses Protector b. Welding Glasses Protector / Face Mask Hand Protector 2 a. Cotton Gloves b. Synthetic C. Rubber Glove Hearing Protector 3 a. Ear Plug b. Ear Mulf Respiratory Protector 4 a. Cotton Mask b. Masker With Filter Body Protector a. Protector Shoes b. Booth 5 C. Chest Protector D. Arm Protector E. Safety Helmet F. Face Protector REQUIREME NT AVAILABL E CONDITION BROKEN ADDITIONAL SHORTAGE REMARKS

STANDARDIZATION OF SELF SAFETY PROTECTOR IN PAITING PART SHOP LINE : PAINTING Safety Hat Ear Plug Safety Glasses Mask ID Card Cover Arm Protector Uniform T-Shirt Cotton Glove Chest Cover Protection Jeans Safety Shoes KIS : 104. 0065

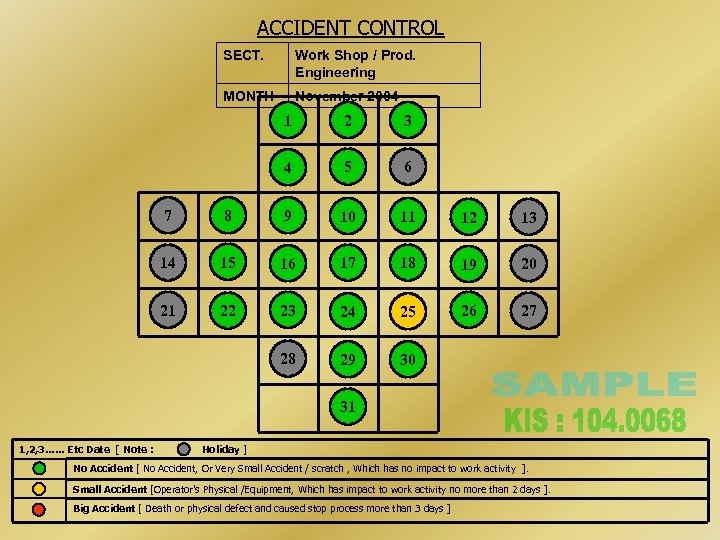

ACCIDENT CONTROL SECT. Work Shop / Prod. Engineering MONTH November 2004 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 1, 2, 3…… Etc Date [ Note : Holiday ] No Accident [ No Accident, Or Very Small Accident / scratch , Which has no impact to work activity ]. Small Accident [Operator’s Physical /Equipment, Which has impact to work activity no more than 2 days ]. Big Accident [ Death or physical defect and caused stop process more than 3 days ]

Safety & Health Of Work Environment Auditor Team At PT. Kubota Indonesia

AUDITOR TRAINING OF SAFETY & HEALTH / K 3 L By : President Director PT. Kubota Indonesia Mr. Koji Tani Meaning : “ Work accident is same thing happens cause stop process “. How to Avoid work Accident : 1. Use Standardization Self Safety Protector / APD. 2. Use Manual Instruction. Stop process is the effect of : 1. Worker Accident. 2. Broken Equipment of machine.

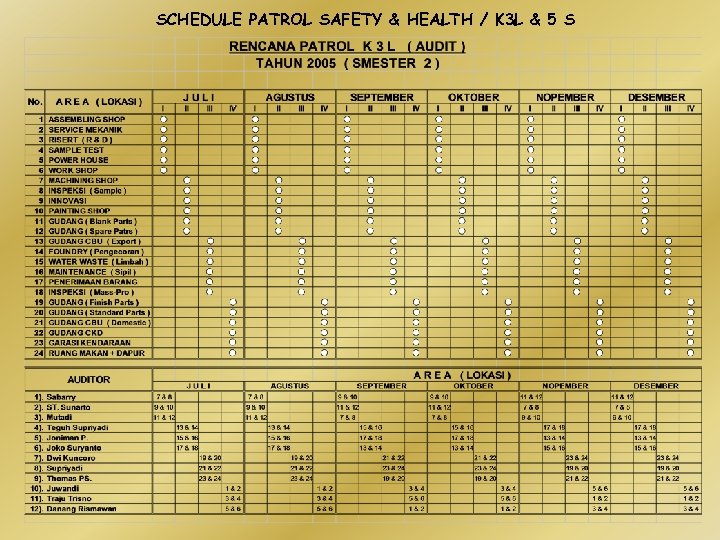

SCHEDULE PATROL SAFETY & HEALTH / K 3 L & 5 S

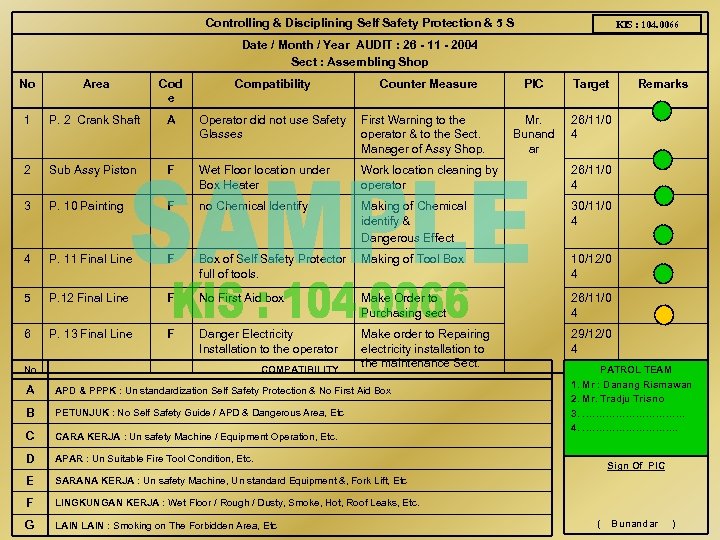

Controlling & Disciplining Self Safety Protection & 5 S KIS : 104. 0066 Date / Month / Year AUDIT : 26 - 11 - 2004 Sect : Assembling Shop No Area Cod e Compatibility 1 P. 2 Crank Shaft A Operator did not use Safety Glasses First Warning to the operator & to the Sect. Manager of Assy Shop. 2 Sub Assy Piston F Wet Floor location under Box Heater Work location cleaning by operator 26/11/0 4 3 P. 10 Painting F no Chemical Identify Making of Chemical identify & Dangerous Effect 30/11/0 4 4 P. 11 Final Line F Box of Self Safety Protector full of tools. Making of Tool Box 10/12/0 4 5 P. 12 Final Line F No First Aid box Make Order to Purchasing sect 26/11/0 4 6 P. 13 Final Line F Danger Electricity Installation to the operator Make order to Repairing electricity installation to the maintenance Sect. 29/12/0 4 No COMPATIBILITY Counter Measure A APD & PPPK : Un standardization Self Safety Protection & No First Aid Box B PETUNJUK : No Self Safety Guide / APD & Dangerous Area, Etc C CARA KERJA : Un safety Machine / Equipment Operation, Etc. D LAIN : Smoking on The Forbidden Area, Etc 26/11/0 4 PATROL TEAM 1. Mr : Danang Rismawan 2. Mr. Tradju Trisno 3. ……………. 4. ……………. . LINGKUNGAN KERJA : Wet Floor / Rough / Dusty, Smoke, Hot, Roof Leaks, Etc. G Mr. Bunand ar Remarks SARANA KERJA : Un safety Machine, Un standard Equipment &, Fork Lift, Etc F Target APAR : Un Suitable Fire Tool Condition, Etc. E PIC Sign Of PIC ( Bunandar )

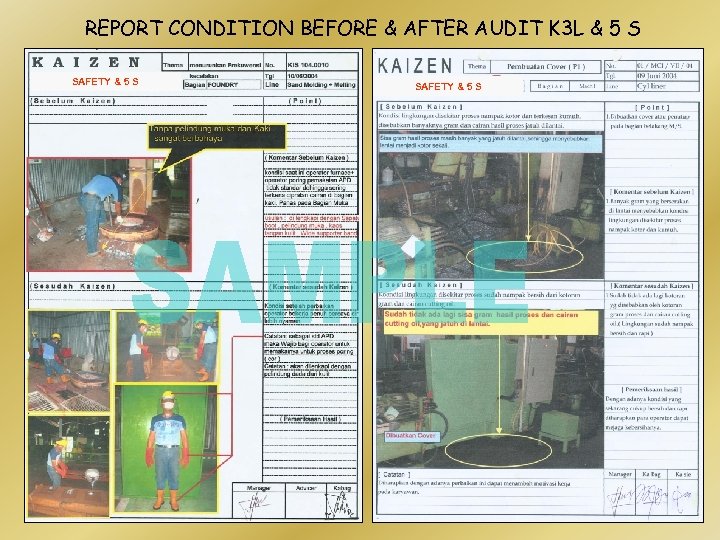

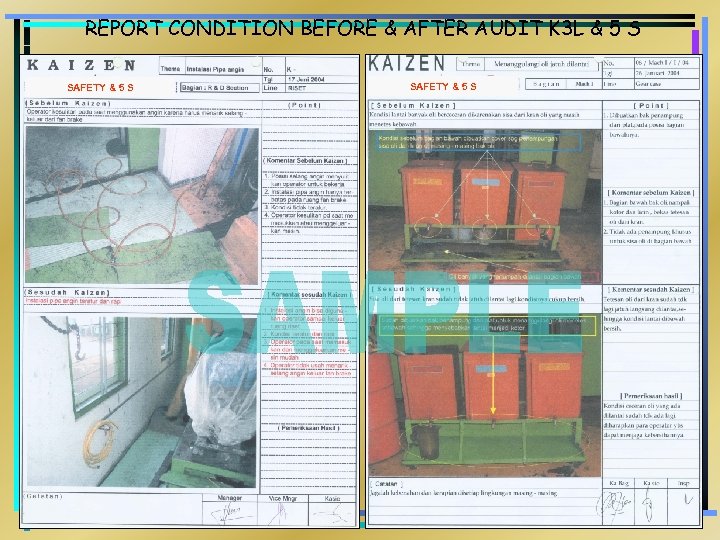

REPORT CONDITION BEFORE & AFTER AUDIT K 3 L & 5 S SAFETY & 5 S

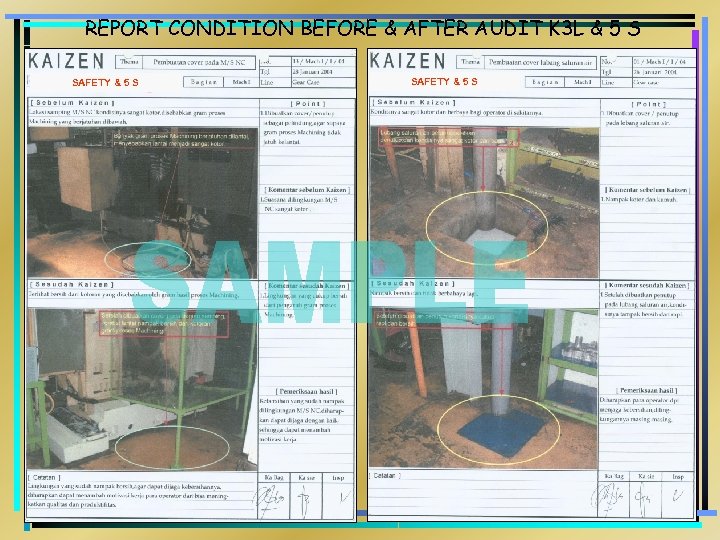

REPORT CONDITION BEFORE & AFTER AUDIT K 3 L & 5 S SAFETY & 5 S

REPORT CONDITION BEFORE & AFTER AUDIT K 3 L & 5 S SAFETY & 5 S

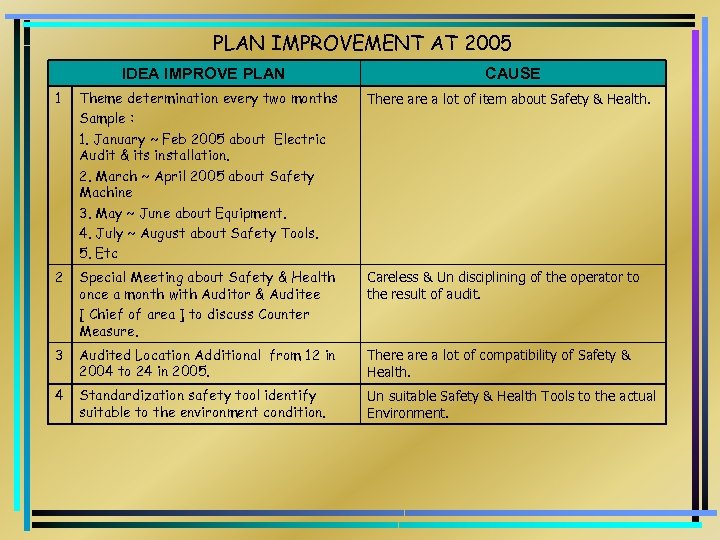

PLAN IMPROVEMENT AT 2005 IDEA IMPROVE PLAN CAUSE 1 Theme determination every two months Sample : 1. January ~ Feb 2005 about Electric Audit & its installation. 2. March ~ April 2005 about Safety Machine 3. May ~ June about Equipment. 4. July ~ August about Safety Tools. 5. Etc There a lot of item about Safety & Health. 2 Special Meeting about Safety & Health once a month with Auditor & Auditee [ Chief of area ] to discuss Counter Measure. Careless & Un disciplining of the operator to the result of audit. 3 Audited Location Additional from 12 in 2004 to 24 in 2005. There a lot of compatibility of Safety & Health. 4 Standardization safety tool identify suitable to the environment condition. Un suitable Safety & Health Tools to the actual Environment.

0e42b98c35faa5d9599a8e21c4568ac3.ppt