be7f5f0684eb31ec11dad0418451279a.ppt

- Количество слайдов: 21

Providing a Custom Abutment System with Must-Have Solutions for the Global Dental Implant Industry

DISCLAIMER This presentation may contain forward-looking information that involves risks, uncertainties and other factors which could cause actual events, results, performance, prospects and opportunities to differ materially from those expressed or implied by such forward-looking information. Forward-looking information may include, but is not limited to, the Company's objectives, goals or future plans. Factors that could cause actual results to differ materially from such forward-looking information include, but are not limited to, those risks set out in the Company's public documents filed on SEDAR. Although the Company believes that the assumptions and factors used in preparing the forward-looking information in this presentation are reasonable, undue reliance should not be placed on such information, which only applies as of todays date, and no assurance can be given that such events will occur in the disclosed time frames or at all. The Company disclaims any intention or obligation to update or revise any forward-looking information, whether as a result of new information, future events or otherwise, other than as required by law. All product names referenced herein are trademarks of their respective companies.

COMPANY HISTORY Innovative & Practical Solutions for the Dental Industry • Completed acquisition of Preferred Dental Implant Corp. – Developer of the Evolutionary Accessory Series (EAS) for dental implants • Founded by European trained dental technician with 50 years experience in the field • Experienced many of the most difficult dental implant restorations; saw many problems plaguing the field • His Vision: Develop a universal platform for dental abutments which makes easy corrections to misaligned implants and allow easy care over

ACCOMPLISHMENTS • FDA Registered • Multiple Platforms: Multiple manufactured components cover Zimmer, Straumann, 3 I and Astra Dentsply implant platforms. • Precious/Non-Precious: Current components satisfy precious dental alloy market. Non-precious alloy identified and will allow penetration into alternate markets • One System, Multiple Methods: More design freedom for professionals to meet patient needs – from traditional manual techniques like casting and soldering to cutting edge digital techniques. Established Product Design. A Vision Of Dentistry’s Future.

MANAGEMENT TEAM Erik Siegmund - CEO, President Son of Founder - Instrumental in development of the EAS System George Gale, Ph. D – Director Wealth of private and public company management experience Camille Pinette – CFO Over 32 years of experience in the financial industry John Schillinger, BA - Officer Practicing accountant - Strong financial background & experience as a Manager Lionel Gosselin, Director Strong sales and Business Development skills from years of private business. A Tightly Knit Team Carrying Forward Founder’s Vision

ADVISORY BOARD Dr. Igor J Pesun DMD, MSc, FACP, FRCD(C) Division Head, Prosthodontics Restorative Dentistry, University of Manitoba Highly regarded public educator and published lecturer Dr. Rodrigo França, DDS, MSc, Ph. D Division Head, Dental Materials, University of Manitoba Internationally recognized researcher on dental materials and biocompatibility Dr. George Bambara, MS, DMD Implant dentistry expert, national and international lecturer and educator Dr. Errol Wright, DDS Experienced dentist, consultant on dental affairs to major insurance corporation An Experienced Team of Academics, Educators and Practitioners

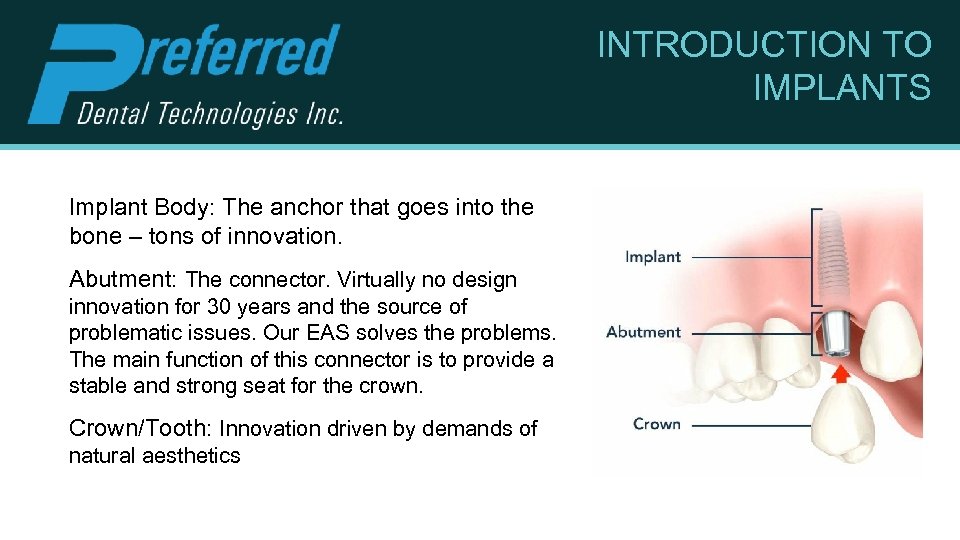

INTRODUCTION TO IMPLANTS Implant Body: The anchor that goes into the bone – tons of innovation. Abutment: The connector. Virtually no design innovation for 30 years and the source of problematic issues. Our EAS solves the problems. The main function of this connector is to provide a stable and strong seat for the crown. Crown/Tooth: Innovation driven by demands of natural aesthetics

COMPONENTS Transmucosal Collar: Reverse left-hand threaded, implant-specific base allows use on multiple manufacturer types Fixation Screw: Right-hand thread screws into implant placed in jawbone. Prevents loosening while remaining easy to retrieve for maintenance Domed Mounting Base: Reverse threads onto Transmucosal collar, effectively capping the fixation screw, eliminating loosening. Plastic Casting Cylinder: Unlimited 360 degree placement with Mounting Base dome. Easy to modify. Allows full control in case design. Our multi-component abutment

UNSOLVED PROBLEMS Angulation/Parallelism: Neighboring abutments must be parallel. Has to line up so the teeth are not too far forward, back or sideways. Has to be perfect to be pain-free. Fixation Screw Loosening: Loosening of screws leads to failure. How many times have you heard someone say “I have a loose tooth”. Easy Retrievability/Cement-Free Restoration: Cement as an alternative to screws leads to long term gum and bone disease. More failure. Like welding shut your hood of a brand new car. Stagnation: Very little research and development has

PROBLEMS SOLVED The EAS solves all the aforementioned deficiencies. No special tools or skillset is required to effectively use the EAS. Lack of design vision has led to long term problems, health issues and dissatisfaction with current dental abutments.

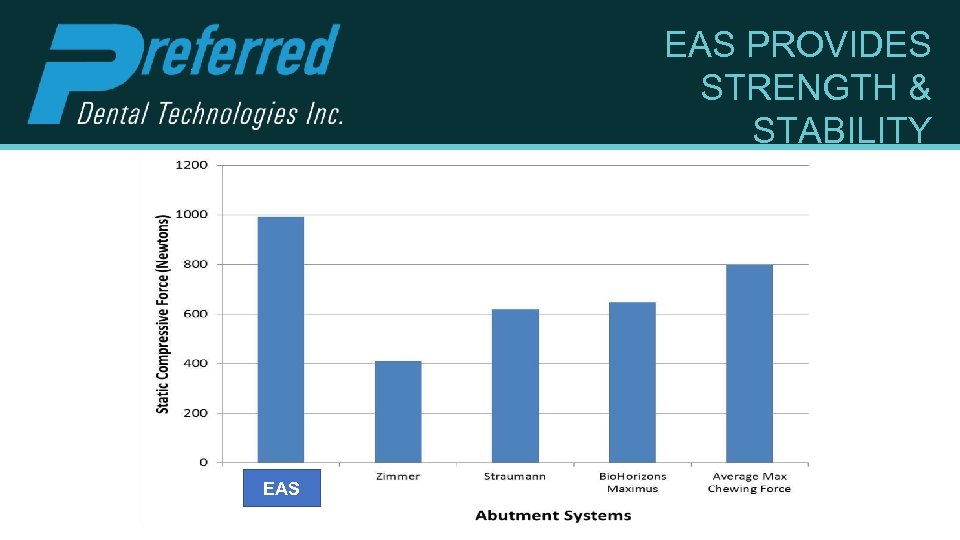

EAS PROVIDES STRENGTH & STABILITY EAS

EASE OF USE 1 -2 -3 -4 1: Secure Transmucosal Collar to implant body with Fixation Screw 2: Reverse thread Domed Mounting Base onto Collar 3: Place Casting Cylinder into position for perfect fit, first time, every time 4: Cast or solder final abutment Ease of use allows small labs to compete with the largest well equipped labs. Maintaining case in house increases lab profits. Relationships with patients are maintained through provided superior work and life-time

SMALL LABS, BIG IMPACT • 1 -5 Person Labs Represent 77% of all labs in the U. S • ~80% offer implants • ~45% offer digital restorations • ~70% outsource work to other labs or manufacturers • Serve an average of 14 dentist-clients • CAD/CAM titanium abutment average fee: $270 Source: LMT Communications, Inc. The Answers Issue: A Look Inside Different Sized Labs February 18, 2016 The Small Lab Majority Can Compete Using the EAS

DIGITAL DENTISTRY ADVANCEMENTS • Digital oral scans are replacing x-rays and impressions allowing efficient transfer of case files to labs. • Increasing numbers of labs utilize digital files to design cases. • Digital files are then sent for CAD/CAM machining to produce final abutments. • The universal nature of the EAS platform is being adapted to work with both current and developing digital manufacturing processes, meeting a rapidly growing market segment.

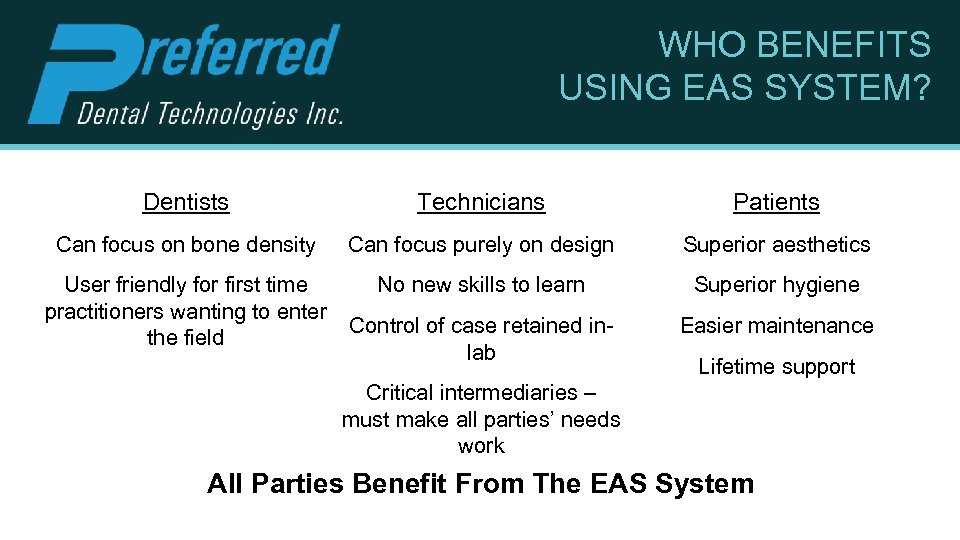

WHO BENEFITS USING EAS SYSTEM? Dentists Technicians Patients Can focus on bone density Can focus purely on design Superior aesthetics User friendly for first time No new skills to learn practitioners wanting to enter Control of case retained inthe field lab Superior hygiene Easier maintenance Lifetime support Critical intermediaries – must make all parties’ needs work All Parties Benefit From The EAS System

INVENTORY CONTROL Virtually 1, 000’s of different abutments from over 200 manufacturers Replaced by 11 EAS Units Simplifying Ever-Growing Complexity For Dental Professionals

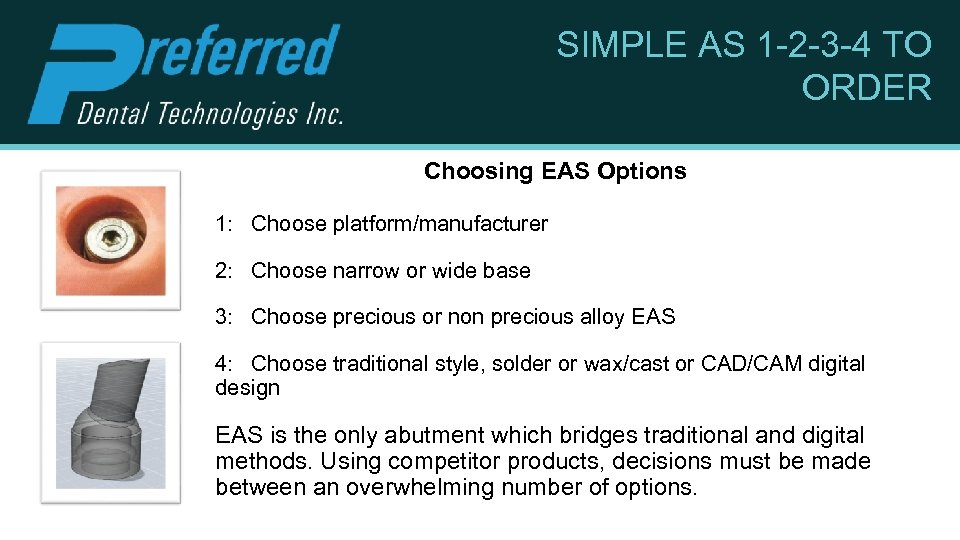

SIMPLE AS 1 -2 -3 -4 TO ORDER Choosing EAS Options 1: Choose platform/manufacturer 2: Choose narrow or wide base 3: Choose precious or non precious alloy EAS 4: Choose traditional style, solder or wax/cast or CAD/CAM digital design EAS is the only abutment which bridges traditional and digital methods. Using competitor products, decisions must be made between an overwhelming number of options.

TARGET MARKET/DEMOGRAPHICS • • Nearly 200, 000 dentists in Continental US Almost 20, 000 Dental Labs in the US alone Immediate launch in the US Non-precious components under development will open foreign markets such as Brazil. • Brazilian market has highest number of dentists per capita. 15% of dentists world wide • 3 rd largest dental market after US and China.

CAPITAL EFFICIENT BUSINESS MODEL • Outsourced contract manufacturing: NO large capital costs • Outsourced fulfillment and shipping: NO excess labor costs • Commission based sales team: NO huge payroll burden • High margins on product: 40% EBITDA forecast • Profitability can be reached with a small fraction of the market • Easily scalable model: Higher volume of orders to manufacturer will get us better discounts further improving on our healthy margins

FUTURE OUTLOOK Growth Opportunities Include: • International Markets: Non-precious metal alternatives directed to rapidly growing markets. • Acquisition/Establishing of Dental Labs: Leveraging dental labs as promotional and education centers in strategic regions • Additional Product Design: A single Universal EAS, as well as advancement into denture market, commonly referred to as hybrids or fixed removable. There is also a segment using ball attachments and floating mounts known as Zest Locator system. All developments maintain the EAS core competencies, solving difficult angles, fixing loose screws and easily retrievable. • JV’s: Each partner will be vetted with minimum annual sales volumes

www. prefdent. com LISTED CSE: PDTI

be7f5f0684eb31ec11dad0418451279a.ppt