54b7bcc04b041f12287e103e96ae6650.ppt

- Количество слайдов: 34

Prototype Development of Automated Ring Main Unit System TNB Distribution Presentation Meeting

Prototype Development of Automated Ring Main Unit System TNB Distribution Presentation Meeting

Project Background

Project Background

RMUs Presently Used • What is an RMU? • Who operates it? • Are there safety concerns?

RMUs Presently Used • What is an RMU? • Who operates it? • Are there safety concerns?

RMU Operation • Opening/closing of the load break switch or earthing switch: § Key/lever § Pushed to overcome spring force § Turn 90˚ at ~20 N. m (clockwise or counterclockwise depending on usage) • Who operates it? • Are there safety concerns? • Can it function remotely?

RMU Operation • Opening/closing of the load break switch or earthing switch: § Key/lever § Pushed to overcome spring force § Turn 90˚ at ~20 N. m (clockwise or counterclockwise depending on usage) • Who operates it? • Are there safety concerns? • Can it function remotely?

Project Objectives • To design a motorized retrofit for automatic operation of (F&G*) Ring Main Unit (RMU) as per technical specifications provided by TNB Distribution.

Project Objectives • To design a motorized retrofit for automatic operation of (F&G*) Ring Main Unit (RMU) as per technical specifications provided by TNB Distribution.

Customer Requirements • ? ?

Customer Requirements • ? ?

Deliverables • A prototype RMU Motorization Unit for operation of manually operated F&G* Ring Main Units.

Deliverables • A prototype RMU Motorization Unit for operation of manually operated F&G* Ring Main Units.

Project Impact • The proposed system would be able to switch the RMU breakers in a safe manner via remote control. • Reduce downtime via remote operation and enhance the safety of TNB’s personnel by eliminating the need for manual operation of the RMU.

Project Impact • The proposed system would be able to switch the RMU breakers in a safe manner via remote control. • Reduce downtime via remote operation and enhance the safety of TNB’s personnel by eliminating the need for manual operation of the RMU.

Project Methodology Stages of prototype development: 1. Torque and dimension measurements 2. Study of Actuation Mechanism 3. Grip frame design and material selection 4. Sensors & Alignment 5. Power & Controls 6. Testing & Trials

Project Methodology Stages of prototype development: 1. Torque and dimension measurements 2. Study of Actuation Mechanism 3. Grip frame design and material selection 4. Sensors & Alignment 5. Power & Controls 6. Testing & Trials

RMU Automation Operational Block Diagram Auto/Remote Local/Manual CW CCW Manual push relays & Indicators M 1 Power Supply Unit 28 VDC 10 A Motor Driver M 2 w max current limit CW/CCW control signal M 3 Load switch limit switch Microcontroller SCADA

RMU Automation Operational Block Diagram Auto/Remote Local/Manual CW CCW Manual push relays & Indicators M 1 Power Supply Unit 28 VDC 10 A Motor Driver M 2 w max current limit CW/CCW control signal M 3 Load switch limit switch Microcontroller SCADA

Components List 1. Power supply unit 2. Grip Frame 3. Motor Mounting Rails Assembly 4. Programmable Logic Controller 5. Motor Driver/controller 6. Auto/Manual Cam Selector Switch 7. Push Power Relays 8. Limit/position Sensors 9. Geared DC Motors 10. Miscellaneous

Components List 1. Power supply unit 2. Grip Frame 3. Motor Mounting Rails Assembly 4. Programmable Logic Controller 5. Motor Driver/controller 6. Auto/Manual Cam Selector Switch 7. Push Power Relays 8. Limit/position Sensors 9. Geared DC Motors 10. Miscellaneous

Features 1. Light-weight (require only one person for mounting & installation) 2. Simple gripping and holding mechanism 3. Ready for remote and local operation 4. Completely detachable motor unit for manual operation 5. Continuous Breaker load switch status indicator 6. Motor over-current protection 7. Response time of < 5 seconds 8. Motor interlock operation

Features 1. Light-weight (require only one person for mounting & installation) 2. Simple gripping and holding mechanism 3. Ready for remote and local operation 4. Completely detachable motor unit for manual operation 5. Continuous Breaker load switch status indicator 6. Motor over-current protection 7. Response time of < 5 seconds 8. Motor interlock operation

Estimated Costing* per 2+1 RMU (3 motor set) • Mechanical works (motor mounting and grip frame) – ~ RM 1300 • Geared motors – 3 x RM 700 • Controller – RM 400 • Motor driver – RM 700 • Sensors and electronics components – RM 400 • Power Supply Unit – RM 900 (for prototype only) • TOTAL COST – ~RM 5000 (without PSU) * For large quantities of order

Estimated Costing* per 2+1 RMU (3 motor set) • Mechanical works (motor mounting and grip frame) – ~ RM 1300 • Geared motors – 3 x RM 700 • Controller – RM 400 • Motor driver – RM 700 • Sensors and electronics components – RM 400 • Power Supply Unit – RM 900 (for prototype only) • TOTAL COST – ~RM 5000 (without PSU) * For large quantities of order

Initial survey and testing in ILSAS Load breaker switch sizing Initial motor selection

Initial survey and testing in ILSAS Load breaker switch sizing Initial motor selection

Continuation of motor selection Motor mount and torque testing

Continuation of motor selection Motor mount and torque testing

Testing torque capability DC Motor on mount

Testing torque capability DC Motor on mount

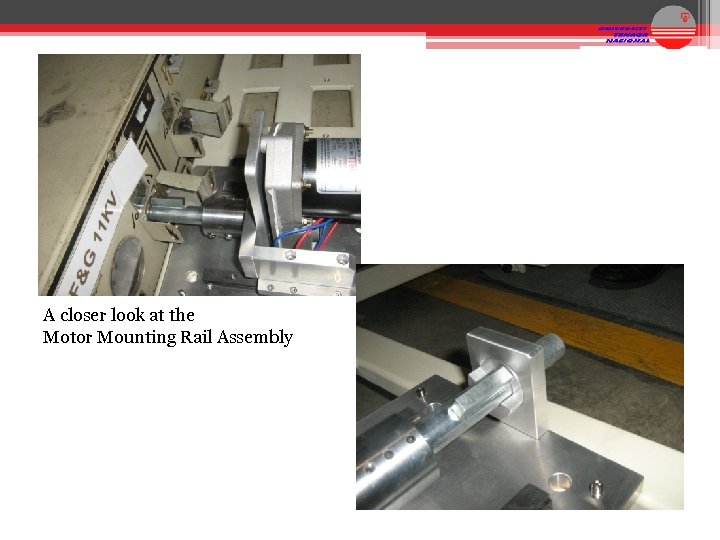

A closer look at the Motor Mounting Rail Assembly

A closer look at the Motor Mounting Rail Assembly

Further testing on actual F&G RMU

Further testing on actual F&G RMU

Procurement of Test Bed RMU

Procurement of Test Bed RMU

Installation of Mount on Grip Frame

Installation of Mount on Grip Frame

Motor mount installed on grip frame on an F&G RMU

Motor mount installed on grip frame on an F&G RMU

Rear view of gripping clamp

Rear view of gripping clamp

F&G ZZTT and ZZT RMUs in UNITEN ZZT F&G RMU ZZTT F&G RMU

F&G ZZTT and ZZT RMUs in UNITEN ZZT F&G RMU ZZTT F&G RMU

Grip Frame

Grip Frame

Detachable Motor Mounting Rail Assembly

Detachable Motor Mounting Rail Assembly

Motor Selection and Testing – ILSAS 30 VDC Circuit Breaker Motor

Motor Selection and Testing – ILSAS 30 VDC Circuit Breaker Motor

Gearbox Failure – Specified Torque 25 N-m

Gearbox Failure – Specified Torque 25 N-m

Switching Key Failure

Switching Key Failure

Testing on RMUs in UNITEN

Testing on RMUs in UNITEN

Motor Mounting Rail Assembly Play Video

Motor Mounting Rail Assembly Play Video

Motor Mounting Rail Assembly Play Video

Motor Mounting Rail Assembly Play Video

Thank you. Questions & Discussions

Thank you. Questions & Discussions

Timeline Month 1 Month 2 Month 3 Month 4 Actuation Mechanism Assy Fabrication and assy Test and Trials Cross Slide Traversing Assy Design and Procurement Fabrication Actuation and Cross slide integration Selection Procurement Integration Test and Trials Selection and Procurement Programming Test and Trials Sensors & Alignment Power & Controls System Networking and Communication PDSB Test and Trials

Timeline Month 1 Month 2 Month 3 Month 4 Actuation Mechanism Assy Fabrication and assy Test and Trials Cross Slide Traversing Assy Design and Procurement Fabrication Actuation and Cross slide integration Selection Procurement Integration Test and Trials Selection and Procurement Programming Test and Trials Sensors & Alignment Power & Controls System Networking and Communication PDSB Test and Trials

Uniten Procurement Procedures Requestor 1. Fill PR Form 2. Prepare Tech. Spec. Evaluation with Endorsement by Dean / HOS Officer-in-Charge approves requirements Finance verifies availability of budget Call for Quotation / Tender Approval of PR Quotation Value: ≤ RM 100 K Float period: 3 - 14 days Min. : 3 companies Tender Value: > RM 100 K Float period: 14 - 21 days Min. : 5 companies Approval / Award Create PO ≤ RM 1 K - Dean ≤ RM 5 K - College Tender Committee ≤ RM 10 K - NC ≤ RM 500 K - TNC(P) Tender Committee ≤RM 5 K : Procurement Manager ≤ RM 100 K : TNC(P) > RM 100 K : NC Approving Authority (PR) : ≤ RM 5 K - Dean ≤ RM 100 K - TNC > RM 100 K - NC Supplier delivers product / provide service

Uniten Procurement Procedures Requestor 1. Fill PR Form 2. Prepare Tech. Spec. Evaluation with Endorsement by Dean / HOS Officer-in-Charge approves requirements Finance verifies availability of budget Call for Quotation / Tender Approval of PR Quotation Value: ≤ RM 100 K Float period: 3 - 14 days Min. : 3 companies Tender Value: > RM 100 K Float period: 14 - 21 days Min. : 5 companies Approval / Award Create PO ≤ RM 1 K - Dean ≤ RM 5 K - College Tender Committee ≤ RM 10 K - NC ≤ RM 500 K - TNC(P) Tender Committee ≤RM 5 K : Procurement Manager ≤ RM 100 K : TNC(P) > RM 100 K : NC Approving Authority (PR) : ≤ RM 5 K - Dean ≤ RM 100 K - TNC > RM 100 K - NC Supplier delivers product / provide service