fa853ba82e1fe9b045c60f1df09394c8.ppt

- Количество слайдов: 30

Project Fish A TOTALLY INTEGRATED SEAFOOD MANAGEMENT SOLUTION Teresa Borrell June 2006

Project Fish A TOTALLY INTEGRATED SEAFOOD MANAGEMENT SOLUTION Teresa Borrell June 2006

Project Fish • Overview of Sanford Limited and existing systems • Design and implementation of our Marel/Wise. Fish/Navision solution • Integration of this system with internal and external systems • Benefits Sanford have achieved from this investment • Changes in the way we work • Questions

Project Fish • Overview of Sanford Limited and existing systems • Design and implementation of our Marel/Wise. Fish/Navision solution • Integration of this system with internal and external systems • Benefits Sanford have achieved from this investment • Changes in the way we work • Questions

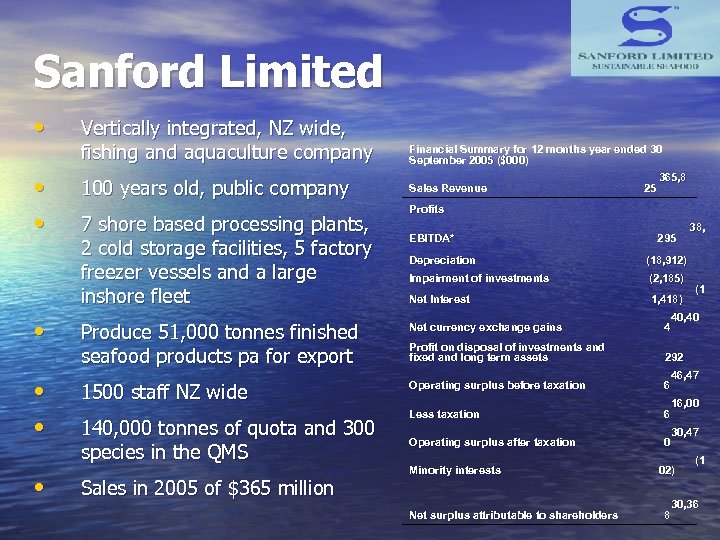

Sanford Limited • • Vertically integrated, NZ wide, fishing and aquaculture company Financial Summary for 12 months year ended 30 September 2005 ($000) 100 years old, public company Sales Revenue 365, 8 25 Profits 7 shore based processing plants, 2 cold storage facilities, 5 factory freezer vessels and a large inshore fleet EBITDA* 38, 295 Depreciation (18, 912) Impairment of investments (2, 185) (1 1, 418) Net Interest Produce 51, 000 tonnes finished seafood products pa for export Net currency exchange gains 40, 40 4 Profit on disposal of investments and fixed and long term assets 292 1500 staff NZ wide Operating surplus before taxation 46, 47 6 Less taxation 16, 00 6 Operating surplus after taxation 30, 47 0 140, 000 tonnes of quota and 300 species in the QMS Sales in 2005 of $365 million Minority interests Net surplus attributable to shareholders (1 02) 30, 36 8

Sanford Limited • • Vertically integrated, NZ wide, fishing and aquaculture company Financial Summary for 12 months year ended 30 September 2005 ($000) 100 years old, public company Sales Revenue 365, 8 25 Profits 7 shore based processing plants, 2 cold storage facilities, 5 factory freezer vessels and a large inshore fleet EBITDA* 38, 295 Depreciation (18, 912) Impairment of investments (2, 185) (1 1, 418) Net Interest Produce 51, 000 tonnes finished seafood products pa for export Net currency exchange gains 40, 40 4 Profit on disposal of investments and fixed and long term assets 292 1500 staff NZ wide Operating surplus before taxation 46, 47 6 Less taxation 16, 00 6 Operating surplus after taxation 30, 47 0 140, 000 tonnes of quota and 300 species in the QMS Sales in 2005 of $365 million Minority interests Net surplus attributable to shareholders (1 02) 30, 36 8

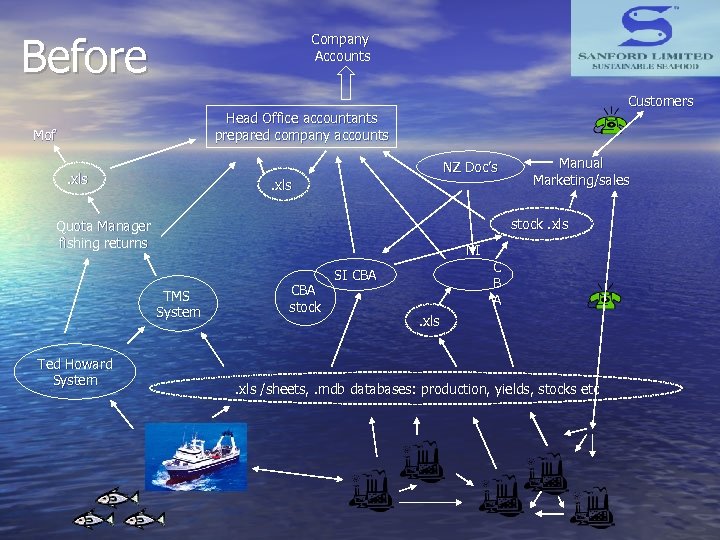

Before Company Accounts Customers Head Office accountants prepared company accounts Mof. xls NZ Doc’s . xls stock. xls Quota Manager fishing returns NI TMS System Ted Howard System Manual Marketing/sales CBA stock SI CBA C B A . xls /sheets, . mdb databases: production, yields, stocks etc

Before Company Accounts Customers Head Office accountants prepared company accounts Mof. xls NZ Doc’s . xls stock. xls Quota Manager fishing returns NI TMS System Ted Howard System Manual Marketing/sales CBA stock SI CBA C B A . xls /sheets, . mdb databases: production, yields, stocks etc

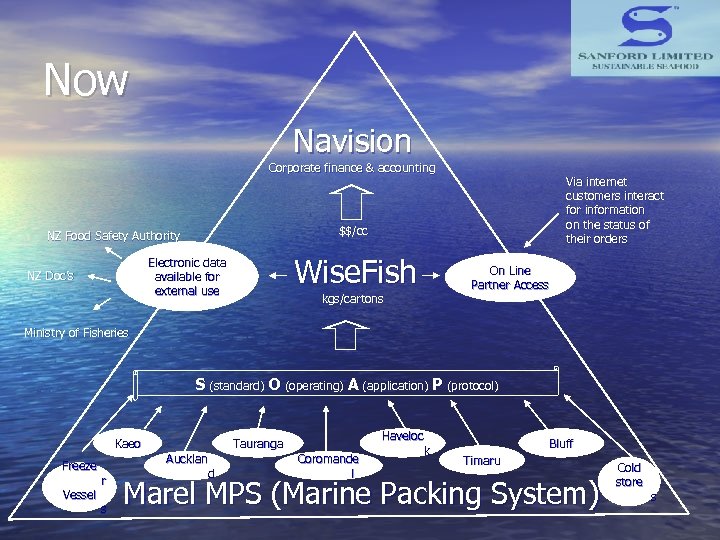

Now Navision Corporate finance & accounting $$/cc NZ Food Safety Authority Wise. Fish Electronic data available for external use NZ Doc’s Via internet customers interact for information on the status of their orders kgs/cartons On Line Partner Access Ministry of Fisheries S (standard) O (operating) A (application) P (protocol) Kaeo Freeze Vessel r s Tauranga Aucklan d Coromande l Haveloc k Bluff Timaru Marel MPS (Marine Packing System) Cold store s

Now Navision Corporate finance & accounting $$/cc NZ Food Safety Authority Wise. Fish Electronic data available for external use NZ Doc’s Via internet customers interact for information on the status of their orders kgs/cartons On Line Partner Access Ministry of Fisheries S (standard) O (operating) A (application) P (protocol) Kaeo Freeze Vessel r s Tauranga Aucklan d Coromande l Haveloc k Bluff Timaru Marel MPS (Marine Packing System) Cold store s

An all-encompassing system • The new system covers our inshore fishing (processed on land), deepwater fishing (processed at sea) and aquaculture farming and processing, New Zealand wide. • The system encompasses: § § § § catching harvesting landing processing storage and inter-branch transfers marketing sales and export of all our product

An all-encompassing system • The new system covers our inshore fishing (processed on land), deepwater fishing (processed at sea) and aquaculture farming and processing, New Zealand wide. • The system encompasses: § § § § catching harvesting landing processing storage and inter-branch transfers marketing sales and export of all our product

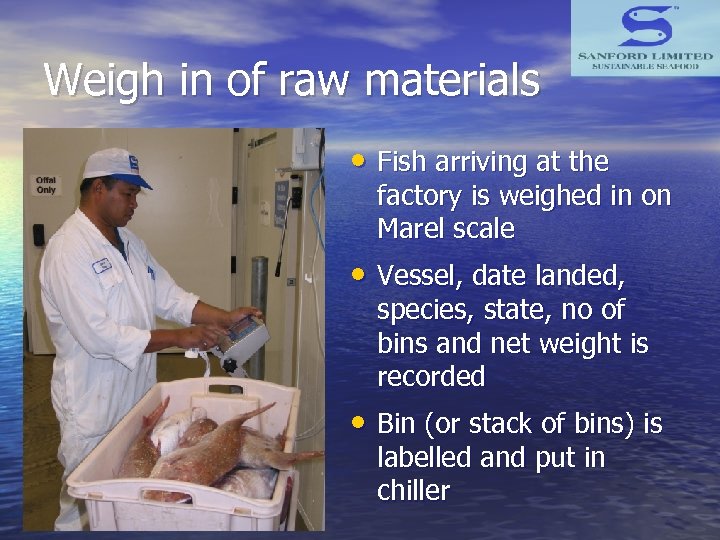

Weigh in of raw materials • Fish arriving at the factory is weighed in on Marel scale • Vessel, date landed, species, state, no of bins and net weight is recorded • Bin (or stack of bins) is labelled and put in chiller

Weigh in of raw materials • Fish arriving at the factory is weighed in on Marel scale • Vessel, date landed, species, state, no of bins and net weight is recorded • Bin (or stack of bins) is labelled and put in chiller

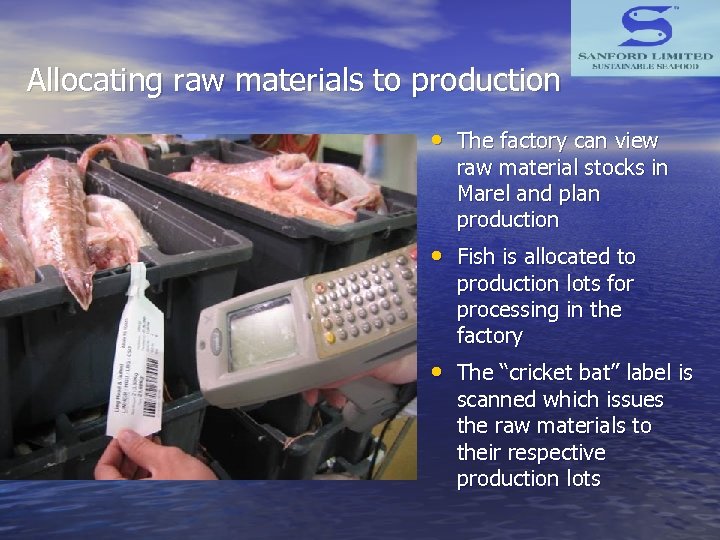

Allocating raw materials to production • The factory can view raw material stocks in Marel and plan production • Fish is allocated to production lots for processing in the factory • The “cricket bat” label is scanned which issues the raw materials to their respective production lots

Allocating raw materials to production • The factory can view raw material stocks in Marel and plan production • Fish is allocated to production lots for processing in the factory • The “cricket bat” label is scanned which issues the raw materials to their respective production lots

Production of finished goods • Fish fillets packed • into cartons are weighed up on Marel weigh label stations Stock code, species, state, grade, date packed, lot number, plant number etc captured

Production of finished goods • Fish fillets packed • into cartons are weighed up on Marel weigh label stations Stock code, species, state, grade, date packed, lot number, plant number etc captured

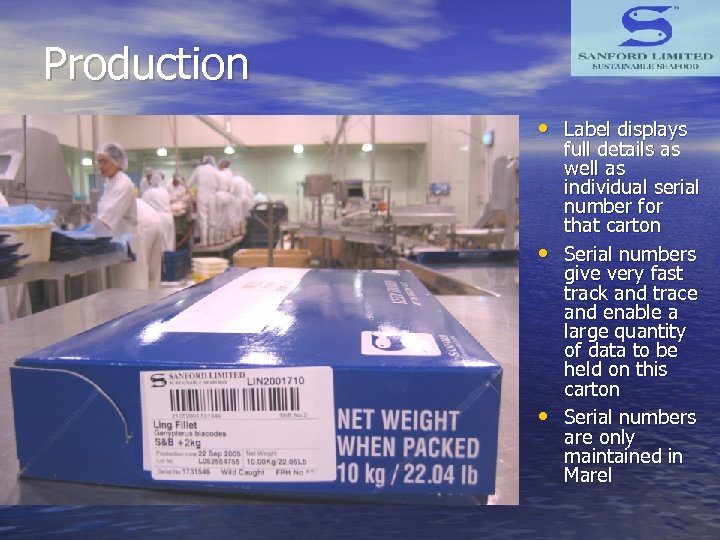

Production • Label displays • • full details as well as individual serial number for that carton Serial numbers give very fast track and trace and enable a large quantity of data to be held on this carton Serial numbers are only maintained in Marel

Production • Label displays • • full details as well as individual serial number for that carton Serial numbers give very fast track and trace and enable a large quantity of data to be held on this carton Serial numbers are only maintained in Marel

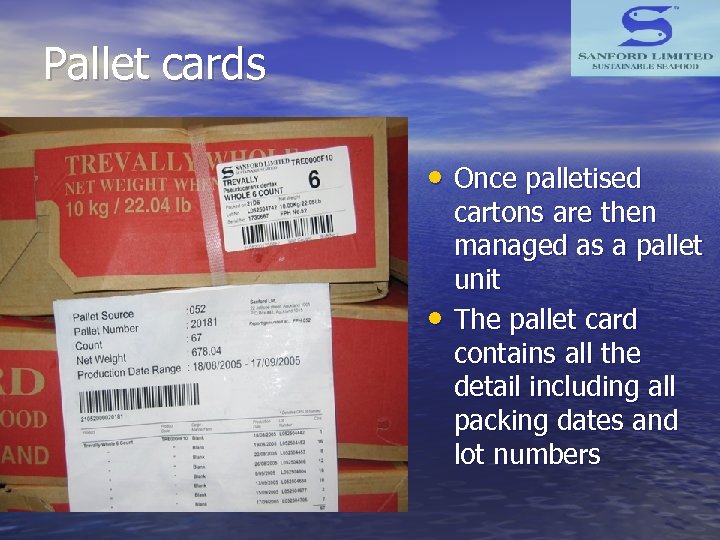

Pallet cards • Once palletised • cartons are then managed as a pallet unit The pallet card contains all the detail including all packing dates and lot numbers

Pallet cards • Once palletised • cartons are then managed as a pallet unit The pallet card contains all the detail including all packing dates and lot numbers

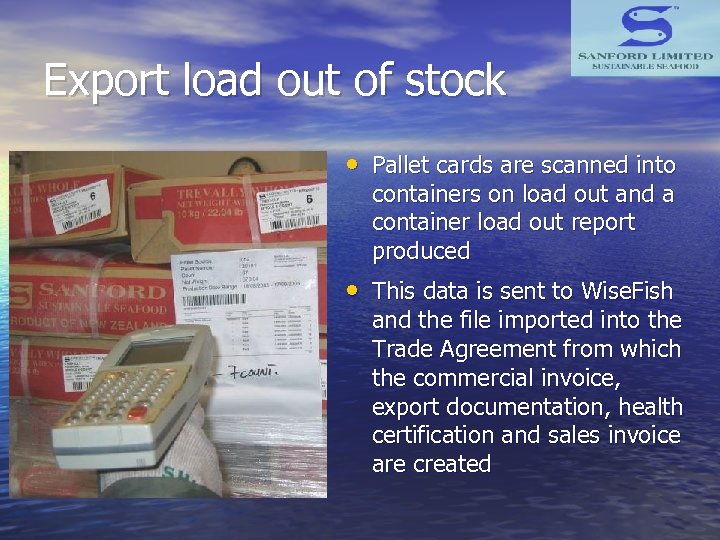

Export load out of stock • Pallet cards are scanned into containers on load out and a container load out report produced • This data is sent to Wise. Fish and the file imported into the Trade Agreement from which the commercial invoice, export documentation, health certification and sales invoice are created

Export load out of stock • Pallet cards are scanned into containers on load out and a container load out report produced • This data is sent to Wise. Fish and the file imported into the Trade Agreement from which the commercial invoice, export documentation, health certification and sales invoice are created

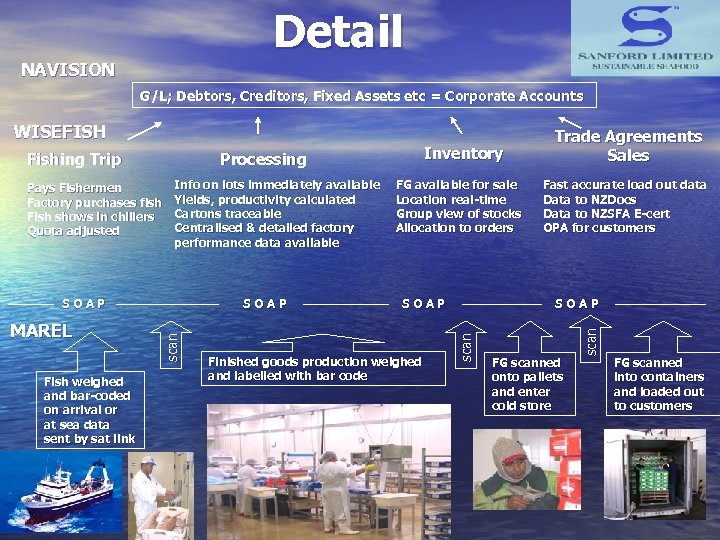

Detail NAVISION G/L; Debtors, Creditors, Fixed Assets etc = Corporate Accounts WISEFISH Info on lots immediately available Yields, productivity calculated Cartons traceable Centralised & detailed factory performance data available MAREL Fish weighed and bar-coded on arrival or at sea data sent by sat link SOAP scan SOAP FG available for sale Location real-time Group view of stocks Allocation to orders SOAP Finished goods production weighed and labelled with bar code Fast accurate load out data Data to NZDocs Data to NZSFA E-cert OPA for customers SOAP FG scanned onto pallets and enter cold store scan Pays Fishermen Factory purchases fish Fish shows in chillers Quota adjusted Inventory Processing scan Fishing Trip Trade Agreements Sales FG scanned into containers and loaded out to customers

Detail NAVISION G/L; Debtors, Creditors, Fixed Assets etc = Corporate Accounts WISEFISH Info on lots immediately available Yields, productivity calculated Cartons traceable Centralised & detailed factory performance data available MAREL Fish weighed and bar-coded on arrival or at sea data sent by sat link SOAP scan SOAP FG available for sale Location real-time Group view of stocks Allocation to orders SOAP Finished goods production weighed and labelled with bar code Fast accurate load out data Data to NZDocs Data to NZSFA E-cert OPA for customers SOAP FG scanned onto pallets and enter cold store scan Pays Fishermen Factory purchases fish Fish shows in chillers Quota adjusted Inventory Processing scan Fishing Trip Trade Agreements Sales FG scanned into containers and loaded out to customers

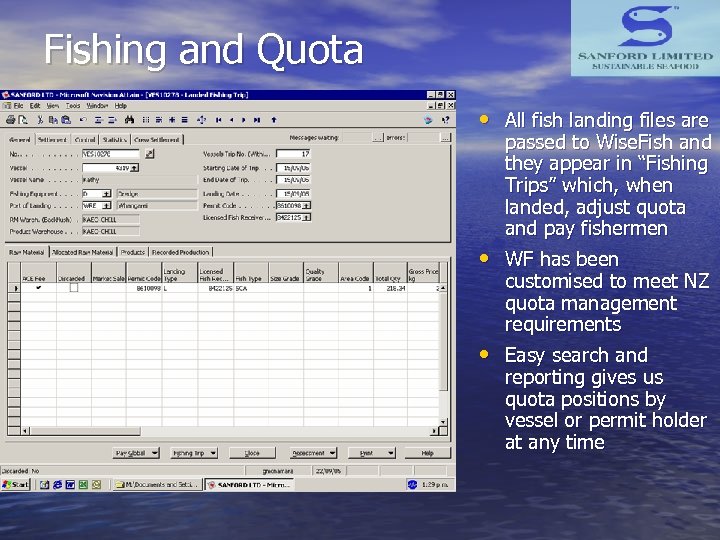

Fishing and Quota • All fish landing files are passed to Wise. Fish and they appear in “Fishing Trips” which, when landed, adjust quota and pay fishermen • WF has been customised to meet NZ quota management requirements • Easy search and reporting gives us quota positions by vessel or permit holder at any time

Fishing and Quota • All fish landing files are passed to Wise. Fish and they appear in “Fishing Trips” which, when landed, adjust quota and pay fishermen • WF has been customised to meet NZ quota management requirements • Easy search and reporting gives us quota positions by vessel or permit holder at any time

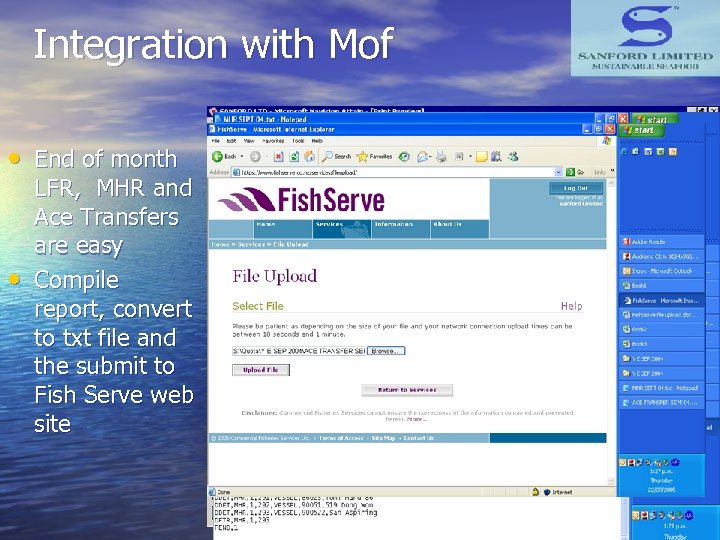

Integration with Mof • End of month • LFR, MHR and Ace Transfers are easy Compile report, convert to txt file and the submit to Fish Serve web site

Integration with Mof • End of month • LFR, MHR and Ace Transfers are easy Compile report, convert to txt file and the submit to Fish Serve web site

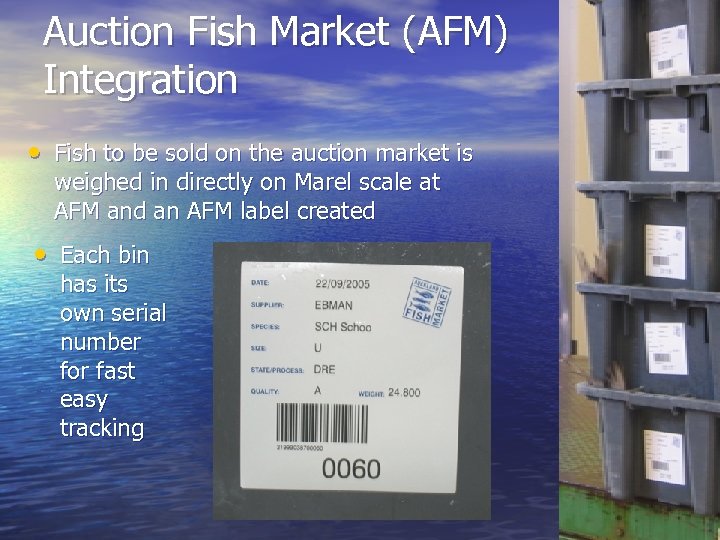

Auction Fish Market (AFM) Integration • Fish to be sold on the auction market is weighed in directly on Marel scale at AFM and an AFM label created • Each bin has its own serial number for fast easy tracking

Auction Fish Market (AFM) Integration • Fish to be sold on the auction market is weighed in directly on Marel scale at AFM and an AFM label created • Each bin has its own serial number for fast easy tracking

Integration with Auckland Fish Market • Marel/Wise. Fish have been • • integrated with the Auxcis Fish Market system. Marel electronically passes Auxcis a file containing bin serial number, vessel, species, weight etc so AFM scanners can access the data in our barcode. When fish is sold Auxcis passes back to Marel the auction price by bin serial number.

Integration with Auckland Fish Market • Marel/Wise. Fish have been • • integrated with the Auxcis Fish Market system. Marel electronically passes Auxcis a file containing bin serial number, vessel, species, weight etc so AFM scanners can access the data in our barcode. When fish is sold Auxcis passes back to Marel the auction price by bin serial number.

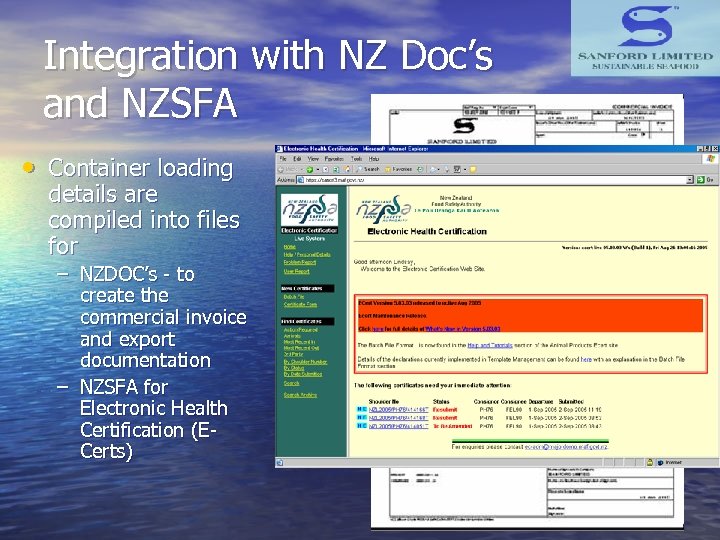

Integration with NZ Doc’s and NZSFA • Container loading details are compiled into files for – NZDOC’s - to create the commercial invoice and export documentation – NZSFA for Electronic Health Certification (ECerts)

Integration with NZ Doc’s and NZSFA • Container loading details are compiled into files for – NZDOC’s - to create the commercial invoice and export documentation – NZSFA for Electronic Health Certification (ECerts)

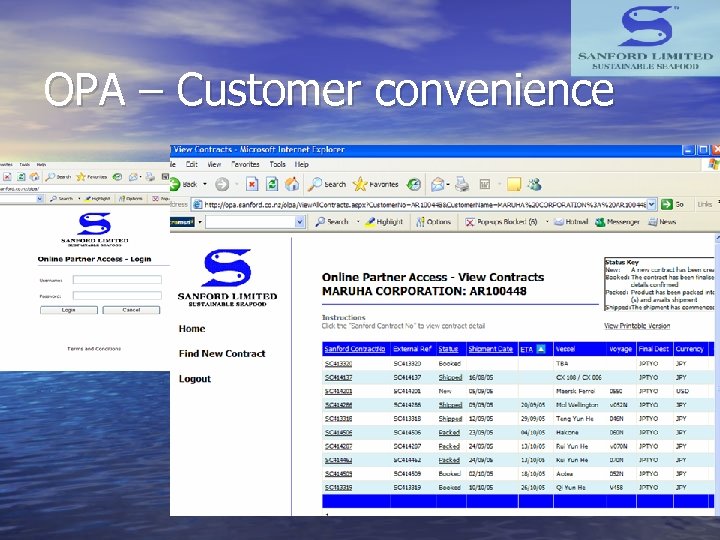

OPA – Customer convenience • On-Line Partner Access enables our • • customers to view their contracts via a secure internet site Search for all contracts and view by contract number, shipment date, ETA, etc Contract status of new, booked, packed and shipped update in real time when the shipment voyage is booked, the container is packed and when it is shipped from NZ

OPA – Customer convenience • On-Line Partner Access enables our • • customers to view their contracts via a secure internet site Search for all contracts and view by contract number, shipment date, ETA, etc Contract status of new, booked, packed and shipped update in real time when the shipment voyage is booked, the container is packed and when it is shipped from NZ

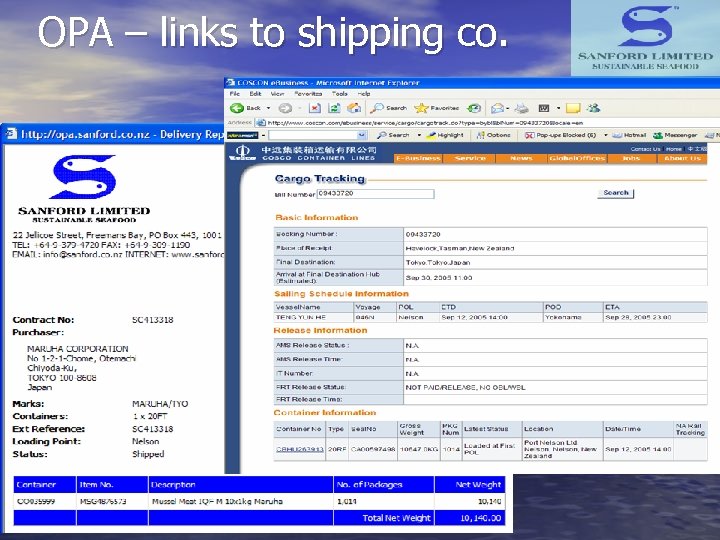

OPA – links to shipping co.

OPA – links to shipping co.

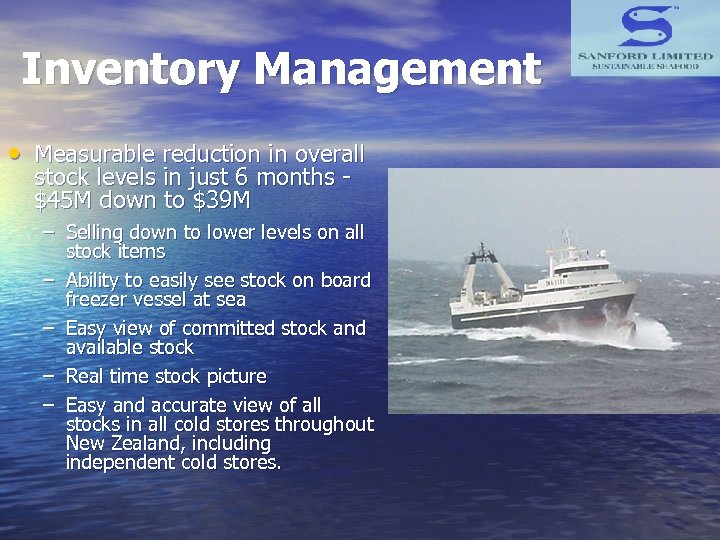

Inventory Management • Measurable reduction in overall stock levels in just 6 months $45 M down to $39 M – Selling down to lower levels on all stock items – Ability to easily see stock on board freezer vessel at sea – Easy view of committed stock and available stock – Real time stock picture – Easy and accurate view of all stocks in all cold stores throughout New Zealand, including independent cold stores.

Inventory Management • Measurable reduction in overall stock levels in just 6 months $45 M down to $39 M – Selling down to lower levels on all stock items – Ability to easily see stock on board freezer vessel at sea – Easy view of committed stock and available stock – Real time stock picture – Easy and accurate view of all stocks in all cold stores throughout New Zealand, including independent cold stores.

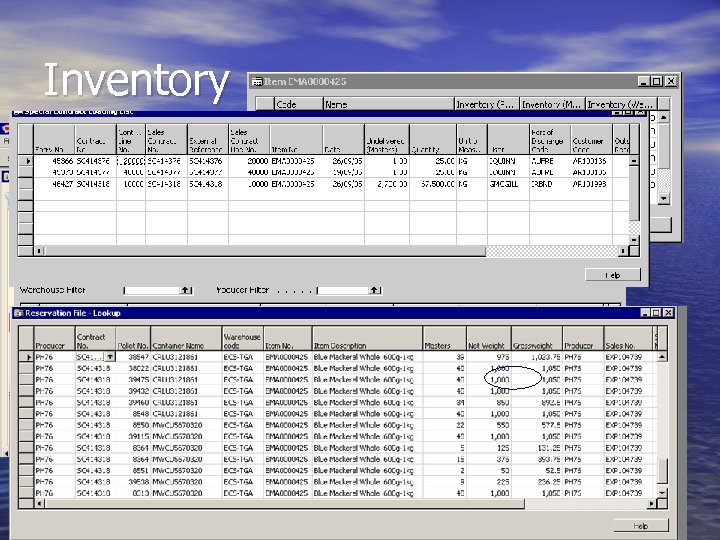

Inventory

Inventory

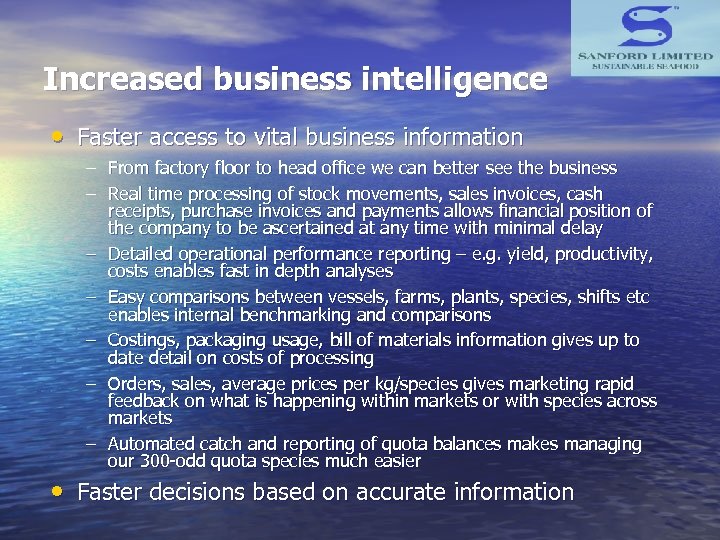

Increased business intelligence • Faster access to vital business information – From factory floor to head office we can better see the business – Real time processing of stock movements, sales invoices, cash receipts, purchase invoices and payments allows financial position of the company to be ascertained at any time with minimal delay – Detailed operational performance reporting – e. g. yield, productivity, costs enables fast in depth analyses – Easy comparisons between vessels, farms, plants, species, shifts etc enables internal benchmarking and comparisons – Costings, packaging usage, bill of materials information gives up to date detail on costs of processing – Orders, sales, average prices per kg/species gives marketing rapid feedback on what is happening within markets or with species across markets – Automated catch and reporting of quota balances makes managing our 300 -odd quota species much easier • Faster decisions based on accurate information

Increased business intelligence • Faster access to vital business information – From factory floor to head office we can better see the business – Real time processing of stock movements, sales invoices, cash receipts, purchase invoices and payments allows financial position of the company to be ascertained at any time with minimal delay – Detailed operational performance reporting – e. g. yield, productivity, costs enables fast in depth analyses – Easy comparisons between vessels, farms, plants, species, shifts etc enables internal benchmarking and comparisons – Costings, packaging usage, bill of materials information gives up to date detail on costs of processing – Orders, sales, average prices per kg/species gives marketing rapid feedback on what is happening within markets or with species across markets – Automated catch and reporting of quota balances makes managing our 300 -odd quota species much easier • Faster decisions based on accurate information

Increased business intelligence • More automation, electronic certification and transmission of authorisations for product movements and exports • Improved tracking of production and sales • Improved coordination of multi-branch export load outs and domestic dispatches • Full product traceability – from the time that the fish is caught, through processing to storage and consignment, and all the way to the buyer

Increased business intelligence • More automation, electronic certification and transmission of authorisations for product movements and exports • Improved tracking of production and sales • Improved coordination of multi-branch export load outs and domestic dispatches • Full product traceability – from the time that the fish is caught, through processing to storage and consignment, and all the way to the buyer

Changes the way we work • The new system is having a far-reaching impact on Sanford staff in two main areas: § Staff accountability § Staff communication

Changes the way we work • The new system is having a far-reaching impact on Sanford staff in two main areas: § Staff accountability § Staff communication

Changes to the way we work Staff accountability • Using the new system has moved more accountability for accurate data collection to production staff as they have to ensure that information is recorded correctly in Marel to enable it to then flow through to Wise. Fish accurately. • In fact, the system, overall, places responsibility on all staff for data accuracy. • Because the system is integrated, data can be used and entered at all levels of the company and if it is not correct it will impact right through the system. • New motto “do to once – do it right”

Changes to the way we work Staff accountability • Using the new system has moved more accountability for accurate data collection to production staff as they have to ensure that information is recorded correctly in Marel to enable it to then flow through to Wise. Fish accurately. • In fact, the system, overall, places responsibility on all staff for data accuracy. • Because the system is integrated, data can be used and entered at all levels of the company and if it is not correct it will impact right through the system. • New motto “do to once – do it right”

Changes to the way we work Staff communication • With the new emphasis on accurate and correct electronic data collection, we have found a positive spin-off being increased and improved inter-branch communication. • It’s is helping break-down branch ‘silo’ mentality. • Staff are beginning to see the company as one integrated whole rather than as a collection of self-contained units.

Changes to the way we work Staff communication • With the new emphasis on accurate and correct electronic data collection, we have found a positive spin-off being increased and improved inter-branch communication. • It’s is helping break-down branch ‘silo’ mentality. • Staff are beginning to see the company as one integrated whole rather than as a collection of self-contained units.

Project Fish - Implementation • 18 month implementation • Identified a core group of “Superusers” – backfilled their jobs to assist with • • • time needed during early phases Wise. Fish Vanilla was customised for NZ quota system Marel and Maritech used SOAP and built interface between MPS and Wise. Fish Built interfaces with NZ Docs, Mo. F, AFM, NZSFA Data available on line for our customers Synchronised all the Marel data bases Fully integrated with vessels at sea and enables accurate discharge and stock immediate available after discharge. • IT team today is 1 database admin and 3 technicians running our network • Well supported by Marel in Iceland now in NZ; by Maritech Iceland by HP.

Project Fish - Implementation • 18 month implementation • Identified a core group of “Superusers” – backfilled their jobs to assist with • • • time needed during early phases Wise. Fish Vanilla was customised for NZ quota system Marel and Maritech used SOAP and built interface between MPS and Wise. Fish Built interfaces with NZ Docs, Mo. F, AFM, NZSFA Data available on line for our customers Synchronised all the Marel data bases Fully integrated with vessels at sea and enables accurate discharge and stock immediate available after discharge. • IT team today is 1 database admin and 3 technicians running our network • Well supported by Marel in Iceland now in NZ; by Maritech Iceland by HP.

Project Fish a success – but not without its challenges • We are seeing strong benefits coming through in our use of the new system, but taking on Project Fish was not without its challenges. – The size and scope of the project, and hence the timeframe, was underestimated. – Although we were confident using the various systems as standalone systems and at single locations we underestimated the work required for the integration of all the systems across our entire group. – The commitment from the super users (one existing Sanford person from each part of our business) was much larger than contemplated and more backfilling of their roles was required.

Project Fish a success – but not without its challenges • We are seeing strong benefits coming through in our use of the new system, but taking on Project Fish was not without its challenges. – The size and scope of the project, and hence the timeframe, was underestimated. – Although we were confident using the various systems as standalone systems and at single locations we underestimated the work required for the integration of all the systems across our entire group. – The commitment from the super users (one existing Sanford person from each part of our business) was much larger than contemplated and more backfilling of their roles was required.

Benefits of Project Fish • Reduced stock levels and improved stock rotation through improved inventory management • Significantly improved and faster access to vital business information. • Improved customer assurance through the extensive use of track & trace functionality. • Increased efficiency and improved business processes through the elimination of data re-keying. • Improved yield management through better operations management. • Improved financial reporting through company wide data integration. • Improved business partner integration through the use of the latest in web technologies.

Benefits of Project Fish • Reduced stock levels and improved stock rotation through improved inventory management • Significantly improved and faster access to vital business information. • Improved customer assurance through the extensive use of track & trace functionality. • Increased efficiency and improved business processes through the elimination of data re-keying. • Improved yield management through better operations management. • Improved financial reporting through company wide data integration. • Improved business partner integration through the use of the latest in web technologies.