94664ef98ecf7bc3f8c2115d33217f75.ppt

- Количество слайдов: 15

Project # 04039 Team Members: Maham Suleman, EE Anne Johnson, ME Joe Farnsworth, EE Josh Brown, ME Jerry Money, EE Sanh Ha, ME Jeffrey Miller, EE Faculty Advisors: Dr. Sahin, EE Dr. Kochersberger, ME Faulty Coordinator: Prof. George Slack

Project Sponsor TRANSCAT ØLocated in Rochester, NY – Industry leader in calibration services Instrumentation ØTranscat Contact – Howard Zion – Philip Mistretta – Rainer Stellrecht – Robert Maddamma

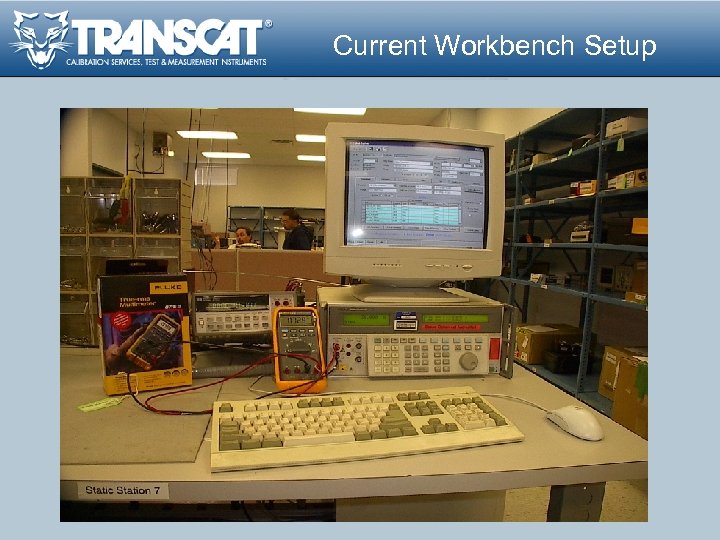

Current Workbench Setup

Project Background Problem Description ØHigh volume unit ØUndergoes preliminary testing process – Semi-automated through Cal. Trak® – Technician still required

Project Mission Statement Investigate viable methodologies and approaches to automate the“as received data” calibration process for the Fluke 80 Series multimeters. Project Description Ø Build a working prototype to – – Automate the reading process Toggle the push buttons Switch between test leads Rotate the VOM rotary switch

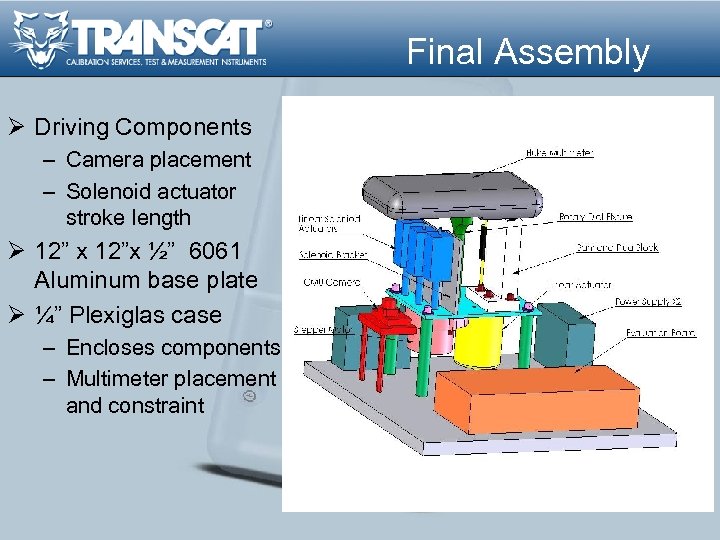

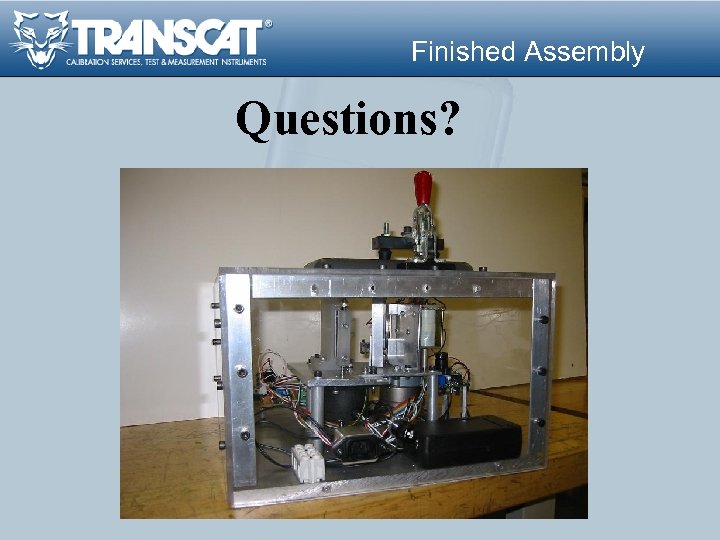

Final Assembly Ø Driving Components – Camera placement – Solenoid actuator stroke length Ø 12” x 12”x ½” 6061 Aluminum base plate Ø ¼” Plexiglas case – Encloses components – Multimeter placement and constraint

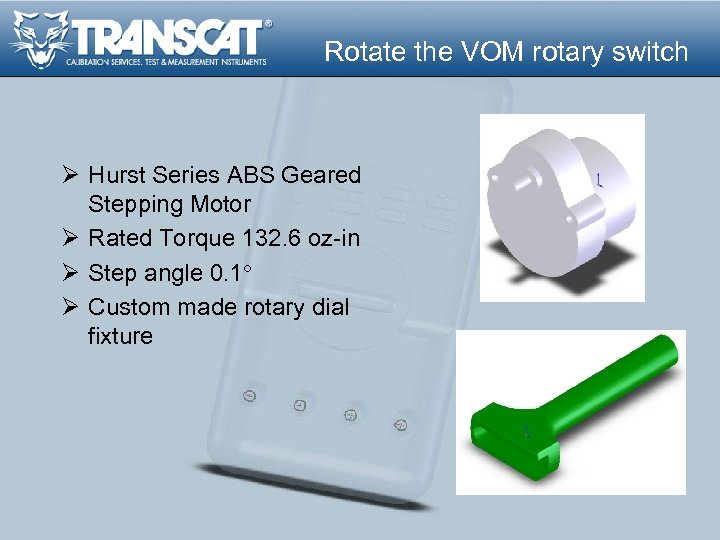

Rotate the VOM rotary switch Ø Hurst Series ABS Geared Stepping Motor Ø Rated Torque 132. 6 oz-in Ø Step angle 0. 1 Ø Custom made rotary dial fixture

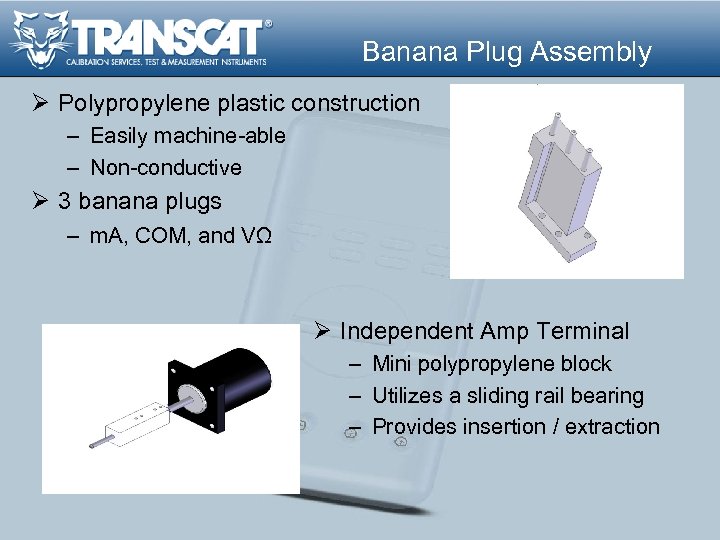

Banana Plug Assembly Ø Polypropylene plastic construction – Easily machine-able – Non-conductive Ø 3 banana plugs – m. A, COM, and VΩ Ø Independent Amp Terminal – Mini polypropylene block – Utilizes a sliding rail bearing – Provides insertion / extraction

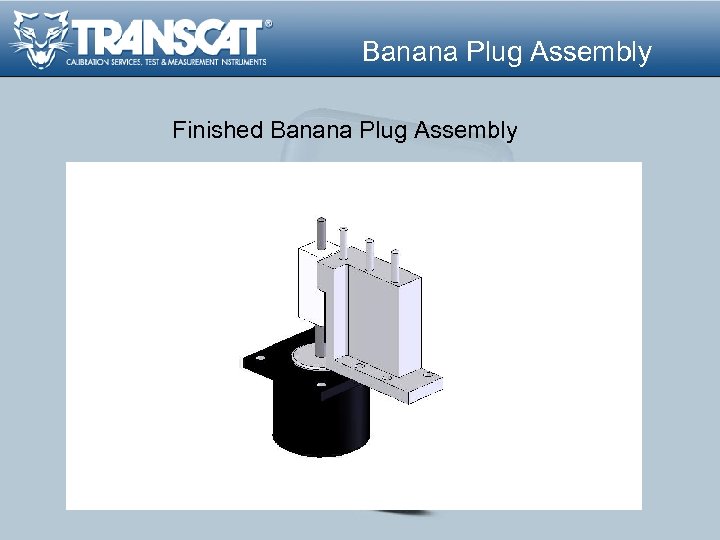

Banana Plug Assembly Finished Banana Plug Assembly

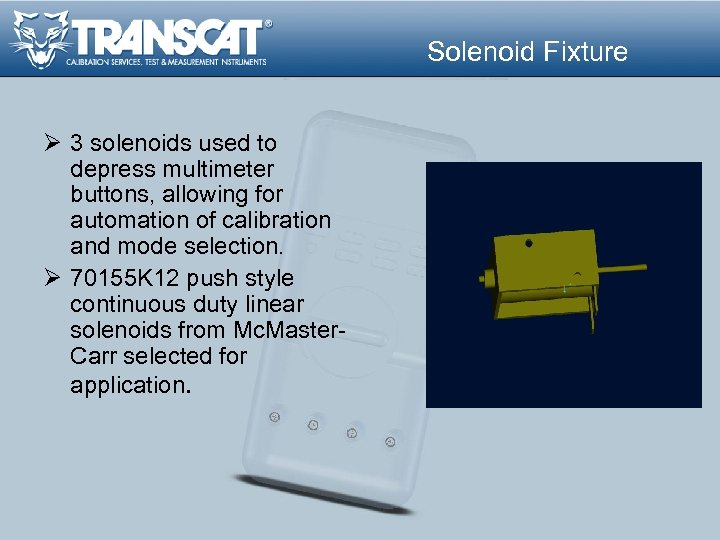

Solenoid Fixture Ø 3 solenoids used to depress multimeter buttons, allowing for automation of calibration and mode selection. Ø 70155 K 12 push style continuous duty linear solenoids from Mc. Master. Carr selected for application.

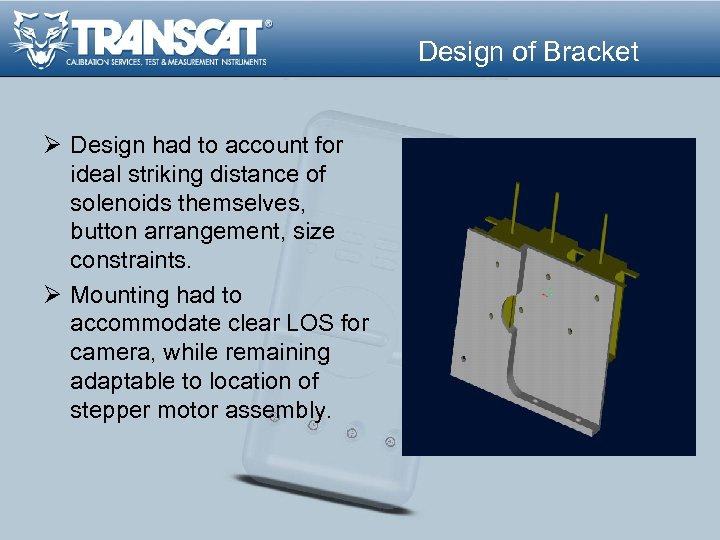

Design of Bracket Ø Design had to account for ideal striking distance of solenoids themselves, button arrangement, size constraints. Ø Mounting had to accommodate clear LOS for camera, while remaining adaptable to location of stepper motor assembly.

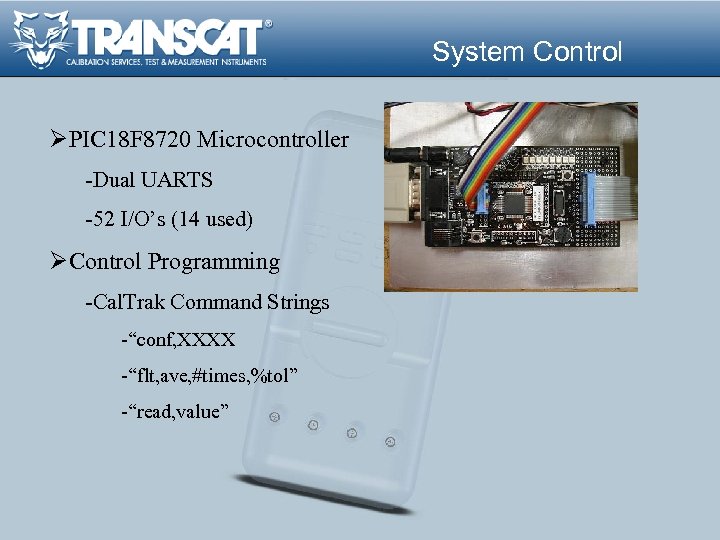

System Control ØPIC 18 F 8720 Microcontroller -Dual UARTS -52 I/O’s (14 used) ØControl Programming -Cal. Trak Command Strings -“conf, XXXX -“flt, ave, #times, %tol” -“read, value”

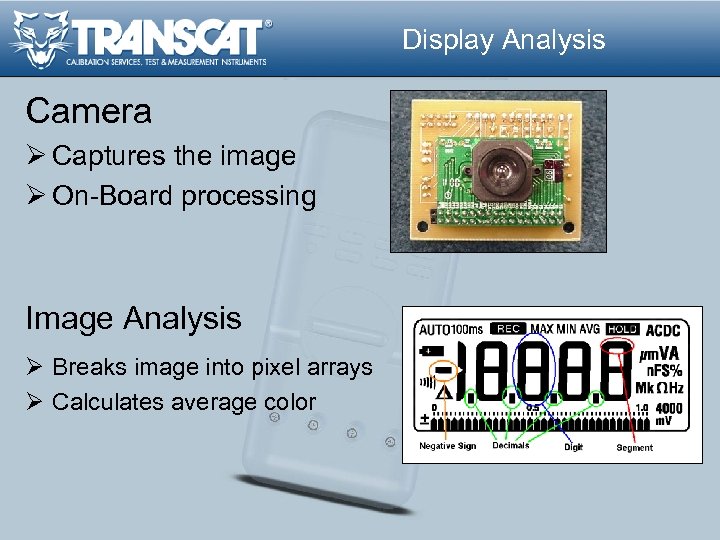

Display Analysis Camera Ø Captures the image Ø On-Board processing Image Analysis Ø Breaks image into pixel arrays Ø Calculates average color

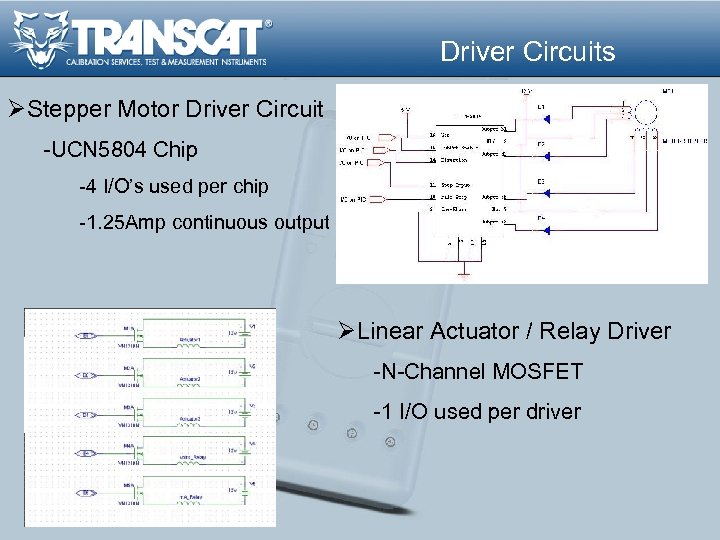

Driver Circuits ØStepper Motor Driver Circuit -UCN 5804 Chip -4 I/O’s used per chip -1. 25 Amp continuous output ØLinear Actuator / Relay Driver -N-Channel MOSFET -1 I/O used per driver

Finished Assembly Questions?

94664ef98ecf7bc3f8c2115d33217f75.ppt