c166641800ea50fa2f116739ce4123d9.ppt

- Количество слайдов: 28

Progress Towards Mass-Production Layering Presented by Neil Alexander Don Bittner, Kurt Boehm, Amy Bozek, Dan Frey, Dan Goodin, Jim Kulchar, Ron Petzoldt, Robert Stemke and Emanuil Valmianski San Diego HAPL meeting August 8 -9, 2006

Summary of progress on Layering • Mass Production Layering Experiment (MPLX) Cryostat being assembled at GA – It is being outfitted for layering • Uses cryogenic fluidized bed • Can be outfitted for alternate methods including bounce-pan, rolling, micro-wave heating et al • Fluidized Bed loop tests at room temperature – Capsules rotate fast enough • Will produce the high average thermal symmetry • Should produce uniform fuel layers IFTP 2006 -071

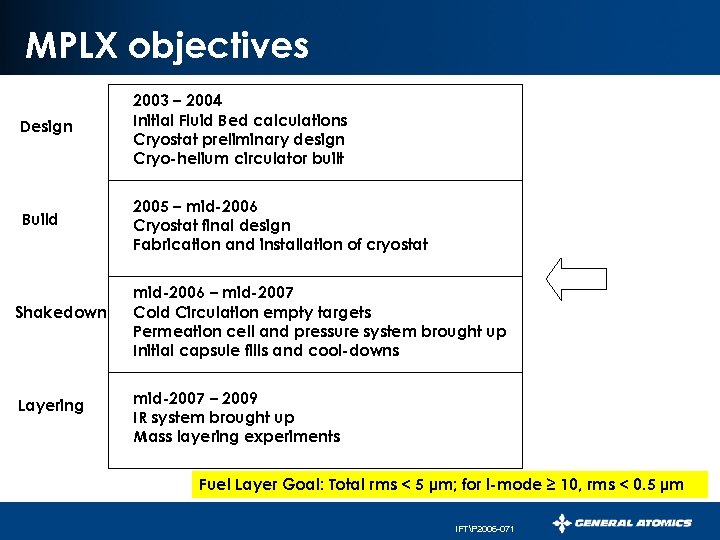

MPLX objectives Design 2003 – 2004 Initial Fluid Bed calculations Cryostat preliminary design Cryo-helium circulator built Build 2005 – mid-2006 Cryostat final design Fabrication and installation of cryostat Shakedown Layering mid-2006 – mid-2007 Cold Circulation empty targets Permeation cell and pressure system brought up Initial capsule fills and cool-downs mid-2007 – 2009 IR system brought up Mass layering experiments Fuel Layer Goal: Total rms < 5 µm; for l-mode ≥ 10, rms < 0. 5 µm IFTP 2006 -071

MPLX has been installed near the target injector front end Dome Lift MPLX Layering Dome Thermal Shield MPLX Layering Dome Vacuum Vessel MPLX Cooling Plant Dome Target Injector Target Crossing Sensor “Target Chamber Center” IFTP 2006 -071

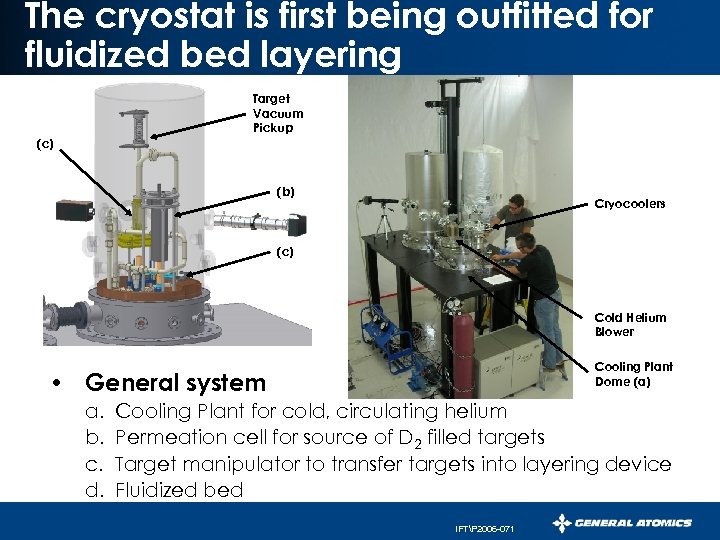

The cryostat is first being outfitted for fluidized bed layering Target Vacuum Pickup (c) (b) Cryocoolers (c) Cold Helium Blower Cooling Plant Dome (a) • General system a. b. c. d. Cooling Plant for cold, circulating helium Permeation cell for source of D 2 filled targets Target manipulator to transfer targets into layering device Fluidized bed IFTP 2006 -071

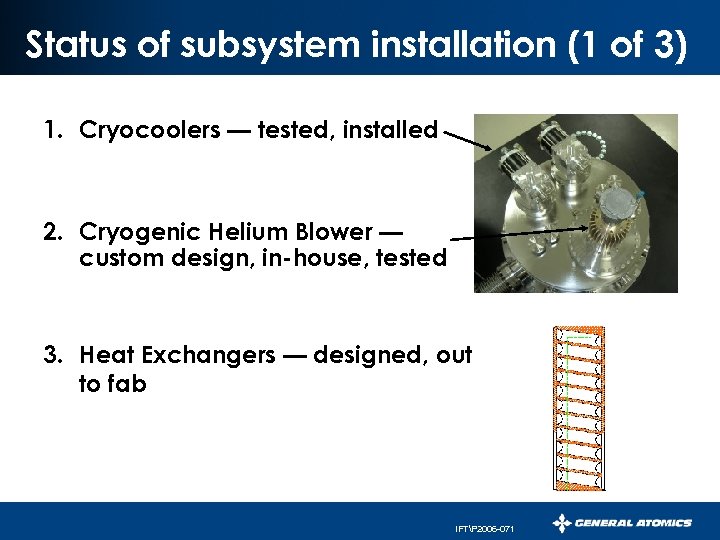

Status of subsystem installation (1 of 3) 1. Cryocoolers — tested, installed 2. Cryogenic Helium Blower — custom design, in-house, tested 3. Heat Exchangers — designed, out to fab IFTP 2006 -071

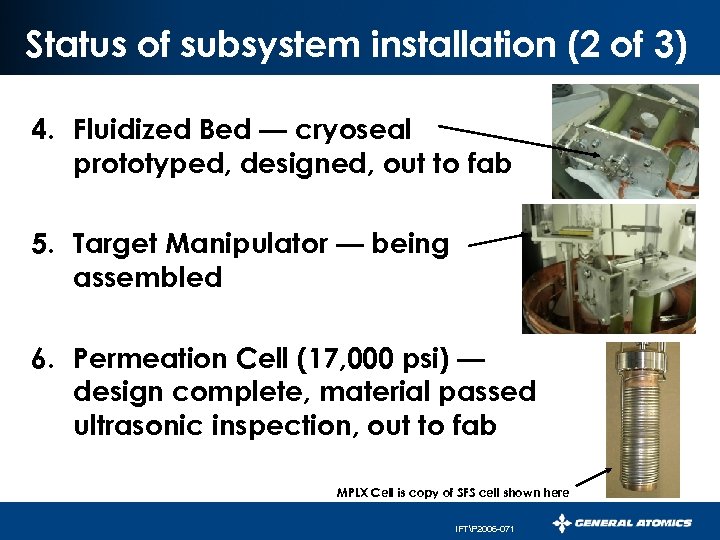

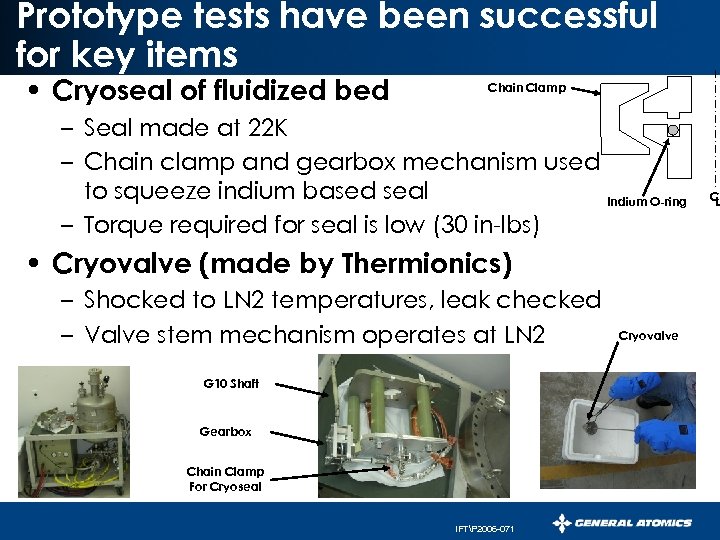

Status of subsystem installation (2 of 3) 4. Fluidized Bed — cryoseal prototyped, designed, out to fab 5. Target Manipulator — being assembled 6. Permeation Cell (17, 000 psi) — design complete, material passed ultrasonic inspection, out to fab MPLX Cell is copy of SFS cell shown here IFTP 2006 -071

Status of subsystem installation (3 of 3) 7. Target Pickup — Prototyped, in design 8. Cryovalves — prototype tested, inhouse 9. Characterization cameras and lenses — lenses in-house 10. Lower Cost IR System — designed around blackbody source IFTP 2006 -071

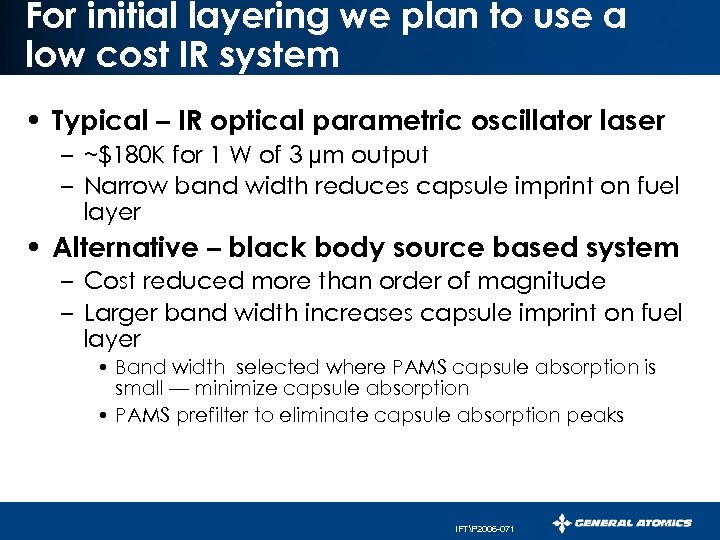

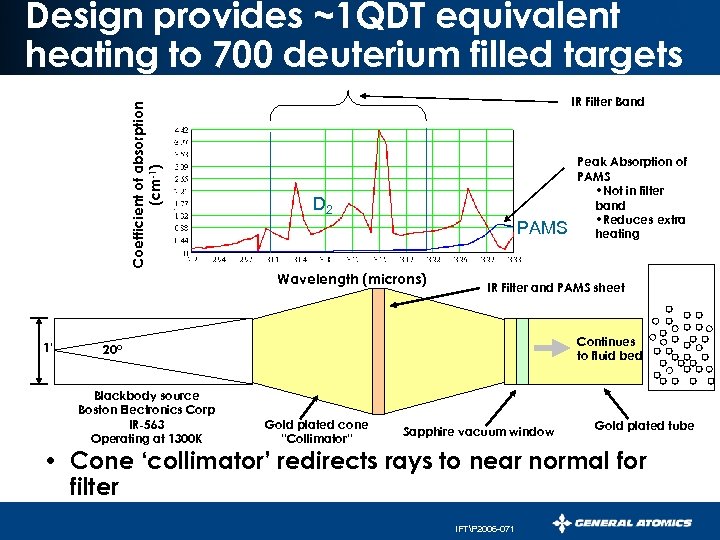

For initial layering we plan to use a low cost IR system • Typical – IR optical parametric oscillator laser – ~$180 K for 1 W of 3 µm output – Narrow band width reduces capsule imprint on fuel layer • Alternative – black body source based system – Cost reduced more than order of magnitude – Larger band width increases capsule imprint on fuel layer • Band width selected where PAMS capsule absorption is small — minimize capsule absorption • PAMS prefilter to eliminate capsule absorption peaks IFTP 2006 -071

Coefficient of absorption (cm-1) Design provides ~1 QDT equivalent heating to 700 deuterium filled targets IR Filter Band D 2 PAMS Wavelength (microns) 1” IR Filter and PAMS sheet Continues to fluid bed 20° Blackbody source Boston Electronics Corp IR-563 Operating at 1300 K Peak Absorption of PAMS • Not in filter band • Reduces extra heating Gold plated cone “Collimator” Sapphire vacuum window Gold plated tube • Cone ‘collimator’ redirects rays to near normal for filter IFTP 2006 -071

Prototype tests have been successful for key items • Cryoseal of fluidized bed Chain Clamp – Seal made at 22 K – Chain clamp and gearbox mechanism used to squeeze indium based seal Indium O-ring – Torque required for seal is low (30 in-lbs) • Cryovalve (made by Thermionics) – Shocked to LN 2 temperatures, leak checked – Valve stem mechanism operates at LN 2 G 10 Shaft Gearbox Chain Clamp For Cryoseal IFTP 2006 -071 Cryovalve C L

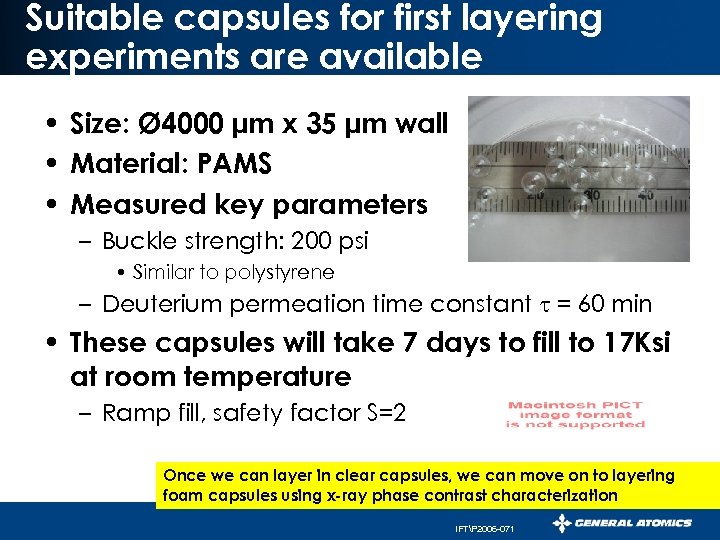

Suitable capsules for first layering experiments are available • Size: Ø 4000 µm x 35 µm wall • Material: PAMS • Measured key parameters – Buckle strength: 200 psi • Similar to polystyrene – Deuterium permeation time constant = 60 min • These capsules will take 7 days to fill to 17 Ksi at room temperature – Ramp fill, safety factor S=2 Once we can layer in clear capsules, we can move on to layering foam capsules using x-ray phase contrast characterization IFTP 2006 -071

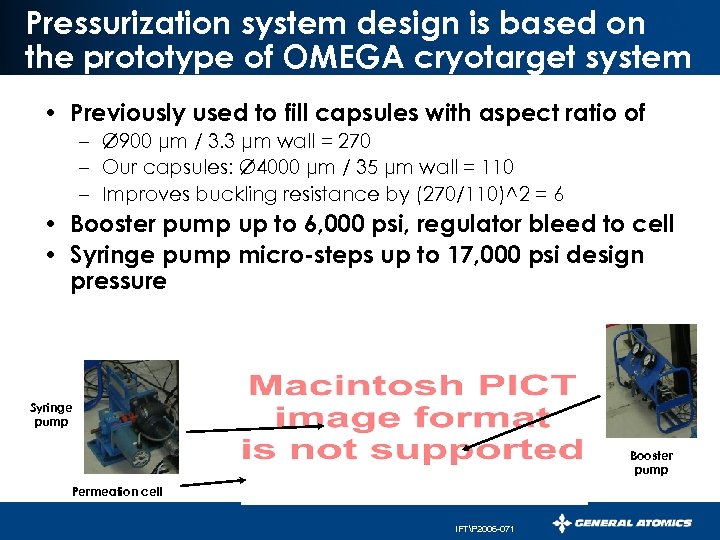

Pressurization system design is based on the prototype of OMEGA cryotarget system • Previously used to fill capsules with aspect ratio of – Ø 900 µm / 3. 3 µm wall = 270 – Our capsules: Ø 4000 µm / 35 µm wall = 110 – Improves buckling resistance by (270/110)^2 = 6 • Booster pump up to 6, 000 psi, regulator bleed to cell • Syringe pump micro-steps up to 17, 000 psi design pressure Syringe pump Booster pump Permeation cell IFTP 2006 -071

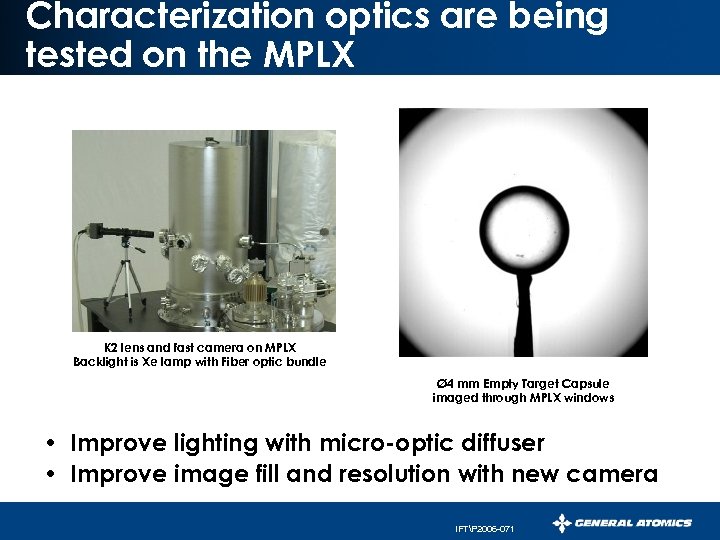

Characterization optics are being tested on the MPLX K 2 lens and fast camera on MPLX Backlight is Xe lamp with Fiber optic bundle Ø 4 mm Empty Target Capsule imaged through MPLX windows • Improve lighting with micro-optic diffuser • Improve image fill and resolution with new camera IFTP 2006 -071

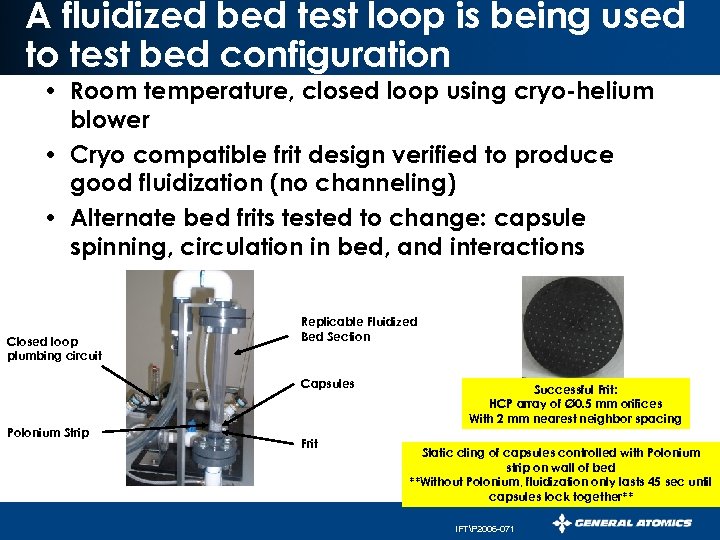

A fluidized bed test loop is being used to test bed configuration • Room temperature, closed loop using cryo-helium blower • Cryo compatible frit design verified to produce good fluidization (no channeling) • Alternate bed frits tested to change: capsule spinning, circulation in bed, and interactions Closed loop plumbing circuit Replicable Fluidized Bed Section Capsules Polonium Strip Frit Successful Frit: HCP array of Ø 0. 5 mm orifices With 2 mm nearest neighbor spacing Static cling of capsules controlled with Polonium strip on wall of bed **Without Polonium, fluidization only lasts 45 sec until capsules lock together** IFTP 2006 -071

Capsules move rapidly through the bed Slow Speed Video (x 17) Normal Speed Video HCP frit • Note capsules not filled IFTP 2006 -071

Whirling bed* enhances capsule spin and circulation within the bed Slow Speed Video (x 17) Whirling bed frit HCP frit Whirling bed frit • Whirling bed uses a wedge on the orifice plate *Rios, G. M. , Baxerras, J. L. and Gilbert, H. , in Fluidization, Eds. Grace, J. R. and Madsen, J. M. , 529, Plenum Press, New York (1980) IFTP 2006 -071

Offset mass capsules also have significant spin rates Slow Speed Video (x 17) Symmetric Capsule Offset Mass Capsule • 2 mg offset mass injected into capsule – Similar to a starting condensed capsule IFTP 2006 -071 Injected Whiteout

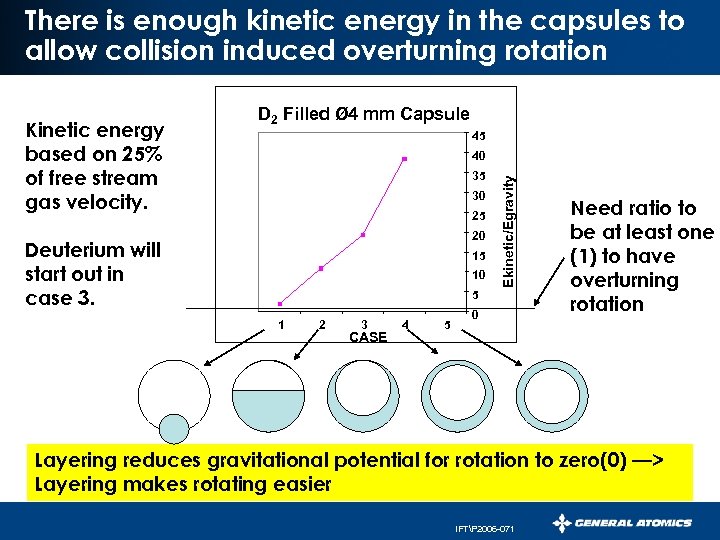

There is enough kinetic energy in the capsules to allow collision induced overturning rotation 45 40 35 30 25 20 Deuterium will start out in case 3. 15 10 Ekinetic/Egravity Kinetic energy based on 25% of free stream gas velocity. D 2 Filled Ø 4 mm Capsule 5 1 2 3 CASE 4 5 0 Need ratio to be at least one (1) to have overturning rotation Layering reduces gravitational potential for rotation to zero(0) —> Layering makes rotating easier IFTP 2006 -071

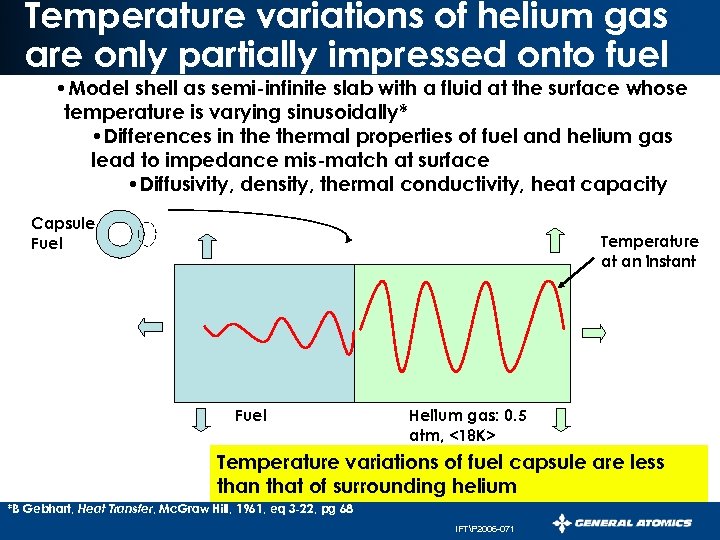

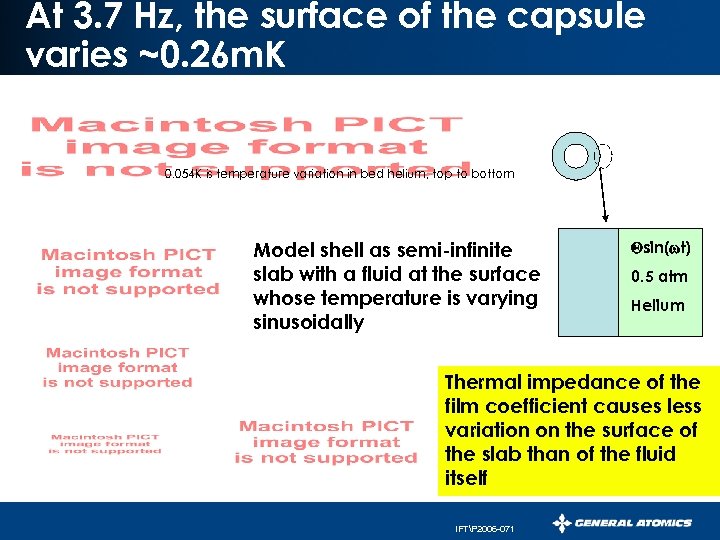

Temperature variations of helium gas are only partially impressed onto fuel • Model shell as semi-infinite slab with a fluid at the surface whose temperature is varying sinusoidally* • Differences in thermal properties of fuel and helium gas lead to impedance mis-match at surface • Diffusivity, density, thermal conductivity, heat capacity Capsule Fuel Temperature at an instant Fuel Helium gas: 0. 5 atm, <18 K> Temperature variations of fuel capsule are less than that of surrounding helium *B Gebhart, Heat Transfer, Mc. Graw Hill, 1961, eq 3 -22, pg 68 IFTP 2006 -071

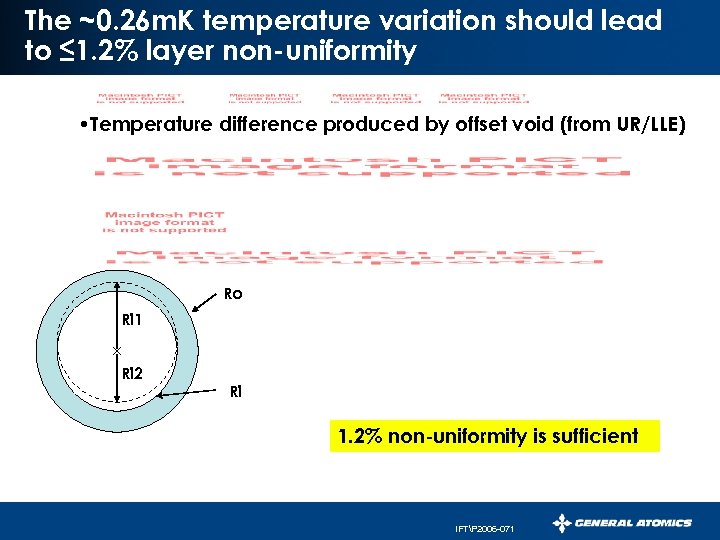

Experiment spin rates indicate fuel layer will be uniform • Previous modeling of bed circulation led to – 3. 7 Hz circulation in 54 m. K bed top to bottom, with bed expansion of 2 – Thermal impedance mis-match implies fuel surface variation will be 0. 26 m. K – 1 -D layering analysis predicts that 0. 26 m. K top to bottom on fuel layer will produce layer uniformity of 1. 2% • Experimental spin rates lead to – 10 Hz capsule spin rate – Gas varies 2 m. K across capsule (local gradient; bed expansion 2) – Thermal impedance mis-match at surface predicts surface temperature variation will be 0. 006 m. K – 1 -D layering analysis predicts that 0. 006 m. K top to bottom on fuel layer will produce layer uniformity of 0. 026% • 0. 1µm thickess difference This is less than layer spec of 5 µm rms IFTP 2006 -071

Summary • MPLX Cryostat has been delivered to GA – It is currently being outfitted for layering using a fluidized bed (subsystems designed and in fab) – Mass layering is a significant project, made possible by our previous experience with ICF community designing cryotarget systems • Prototype frit produced good fluidization of capsules – Polonium continues to control static ‘cling’ issue • RT tests indicate fast capsule rotation – Indicates high average thermal symmetry necessary for uniform fuel layers is achievable IFTP 2006 -071

Backup and old slides follow IFTP 2006 -071

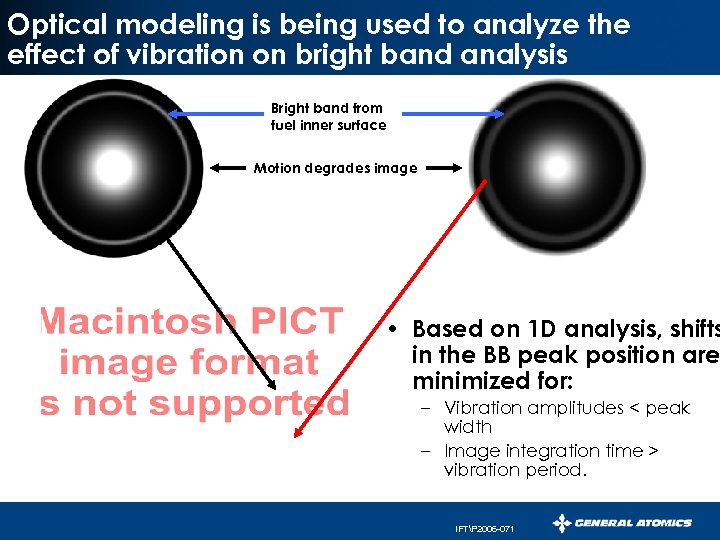

Optical modeling is being used to analyze the effect of vibration on bright band analysis Bright band from fuel inner surface Motion degrades image • Based on 1 D analysis, shifts in the BB peak position are minimized for: – Vibration amplitudes < peak width – Image integration time > vibration period. IFTP 2006 -071

The ~0. 26 m. K temperature variation should lead to ≤ 1. 2% layer non-uniformity • Temperature difference produced by offset void (from UR/LLE) Ro Ri 1 Ri 2 Ri 1. 2% non-uniformity is sufficient IFTP 2006 -071

At 3. 7 Hz, the surface of the capsule varies ~0. 26 m. K 0. 054 K is temperature variation in bed helium, top to bottom Model shell as semi-infinite slab with a fluid at the surface whose temperature is varying sinusoidally sin( t) 0. 5 atm Helium Thermal impedance of the film coefficient causes less variation on the surface of the slab than of the fluid itself IFTP 2006 -071

We have begun to port/adapt bright band analysis algorithms into Labview • LNLL bright band analysis routines are being adapted into LANL sphlinder analysis code that is already Labview based – Save porting time Add Bright band picture Add Labview VI picture Add sphlinder picture IFTP 2006 -071

IFTP 2006 -071

c166641800ea50fa2f116739ce4123d9.ppt