d50ef32f2c42a06fa7cc140f7d4d7853.ppt

- Количество слайдов: 16

Progress on UCLA MTOR Film Flow Experiments for ALIST (Nov. 2002 - April 2003) Presented by Alice Ying M. Abdou, N. Morley, T. Sketchley, J. Burris, M. Narula April 7, 2003 APEX Meeting Grand Canyon, AZ

Progress on UCLA MTOR Film Flow Experiments for ALIST (Nov. 2002 - April 2003) Presented by Alice Ying M. Abdou, N. Morley, T. Sketchley, J. Burris, M. Narula April 7, 2003 APEX Meeting Grand Canyon, AZ

Experimental Investigation now Focused on Film Flow Characteristics with Conducting Walls ØMost likely the electrical insulator coating would not be available in the next few years. In addition, ØFilm in insulated chute appeared feasible passing through the NSTX-like steady state 2 -D field gradients (toroidal and surface normal), except additional MHD pressure drop There was a need to add the 3 rd component field (poloidal field) to complete the exploratory assessment (steady state). However, the field magnitude is relatively low (thus its effect may not be significant) Would revisit this effect if the result of the conducting chute film flow shows unfavorable.

Experimental Investigation now Focused on Film Flow Characteristics with Conducting Walls ØMost likely the electrical insulator coating would not be available in the next few years. In addition, ØFilm in insulated chute appeared feasible passing through the NSTX-like steady state 2 -D field gradients (toroidal and surface normal), except additional MHD pressure drop There was a need to add the 3 rd component field (poloidal field) to complete the exploratory assessment (steady state). However, the field magnitude is relatively low (thus its effect may not be significant) Would revisit this effect if the result of the conducting chute film flow shows unfavorable.

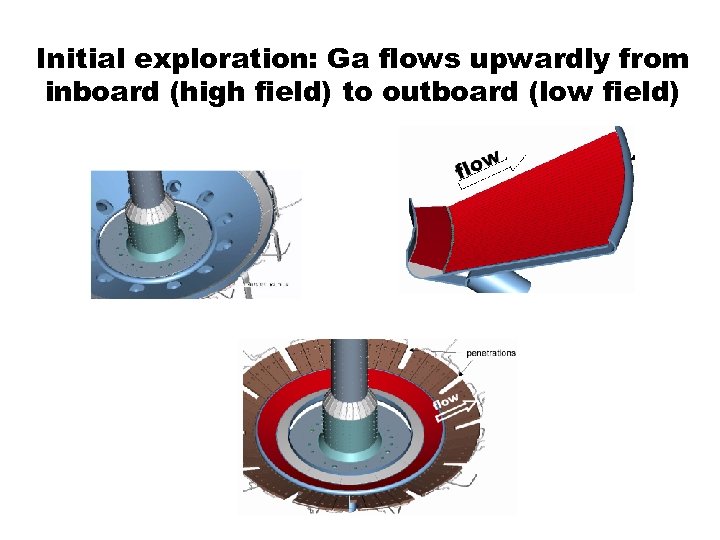

Initial exploration: Ga flows upwardly from inboard (high field) to outboard (low field)

Initial exploration: Ga flows upwardly from inboard (high field) to outboard (low field)

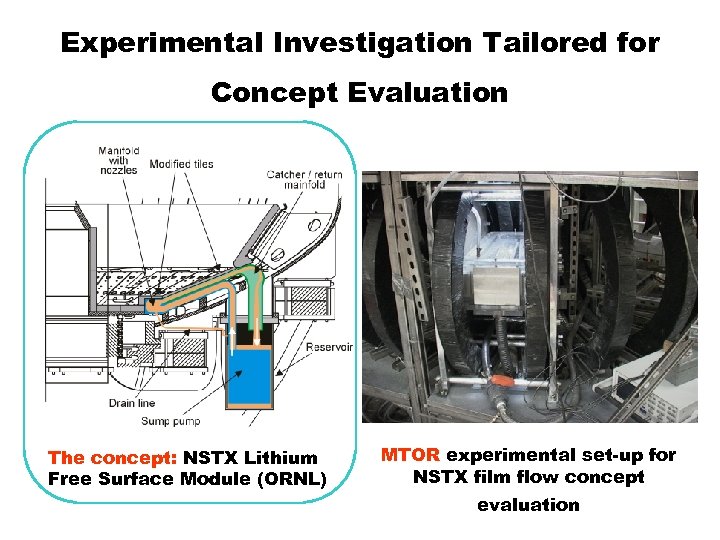

Experimental Investigation Tailored for Concept Evaluation The concept: NSTX Lithium Free Surface Module (ORNL) MTOR experimental set-up for NSTX film flow concept evaluation

Experimental Investigation Tailored for Concept Evaluation The concept: NSTX Lithium Free Surface Module (ORNL) MTOR experimental set-up for NSTX film flow concept evaluation

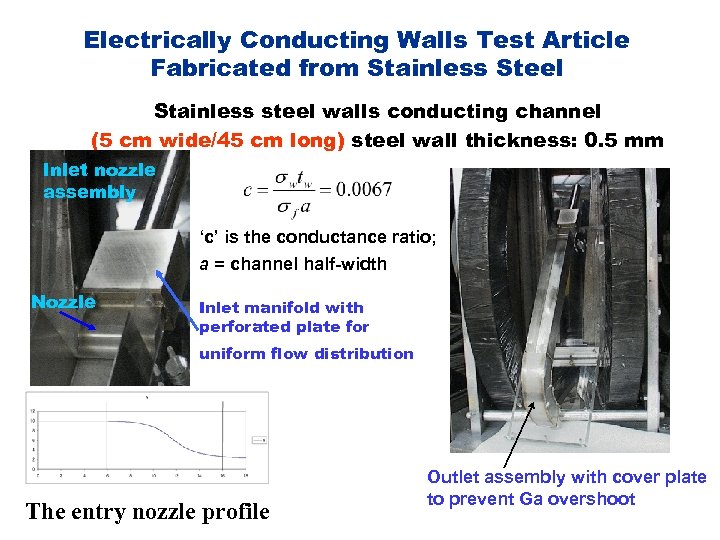

Electrically Conducting Walls Test Article Fabricated from Stainless Steel Stainless steel walls conducting channel (5 cm wide/45 cm long) steel wall thickness: 0. 5 mm Inlet nozzle assembly ‘c’ is the conductance ratio; a = channel half-width Nozzle Inlet manifold with perforated plate for uniform flow distribution The entry nozzle profile Outlet assembly with cover plate to prevent Ga overshoot

Electrically Conducting Walls Test Article Fabricated from Stainless Steel Stainless steel walls conducting channel (5 cm wide/45 cm long) steel wall thickness: 0. 5 mm Inlet nozzle assembly ‘c’ is the conductance ratio; a = channel half-width Nozzle Inlet manifold with perforated plate for uniform flow distribution The entry nozzle profile Outlet assembly with cover plate to prevent Ga overshoot

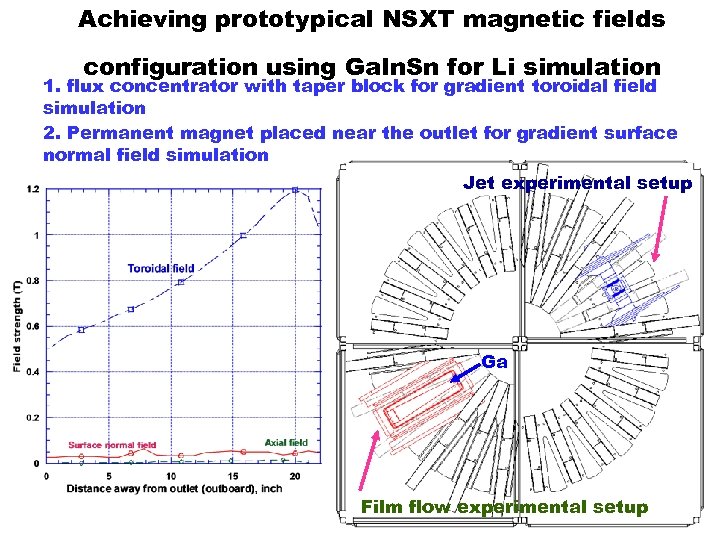

Achieving prototypical NSXT magnetic fields configuration using Ga. In. Sn for Li simulation 1. flux concentrator with taper block for gradient toroidal field simulation 2. Permanent magnet placed near the outlet for gradient surface normal field simulation Jet experimental setup Ga Film flow experimental setup

Achieving prototypical NSXT magnetic fields configuration using Ga. In. Sn for Li simulation 1. flux concentrator with taper block for gradient toroidal field simulation 2. Permanent magnet placed near the outlet for gradient surface normal field simulation Jet experimental setup Ga Film flow experimental setup

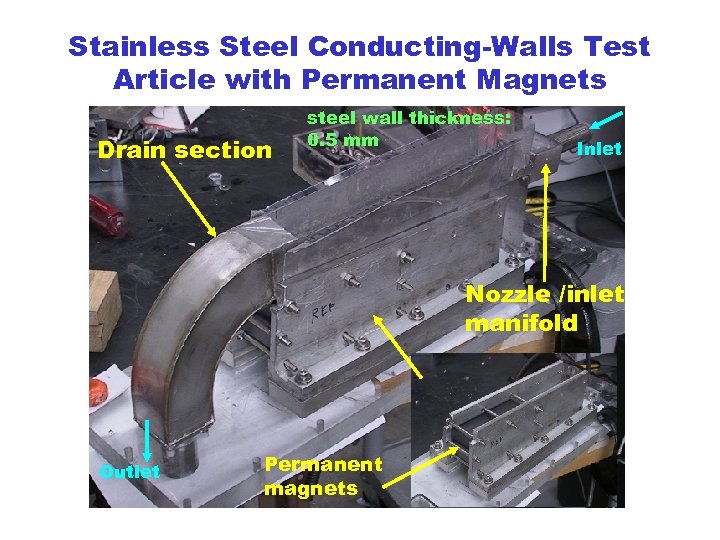

Stainless Steel Conducting-Walls Test Article with Permanent Magnets Drain section steel wall thickness: 0. 5 mm Inlet Nozzle /inlet manifold Outlet Permanent magnets

Stainless Steel Conducting-Walls Test Article with Permanent Magnets Drain section steel wall thickness: 0. 5 mm Inlet Nozzle /inlet manifold Outlet Permanent magnets

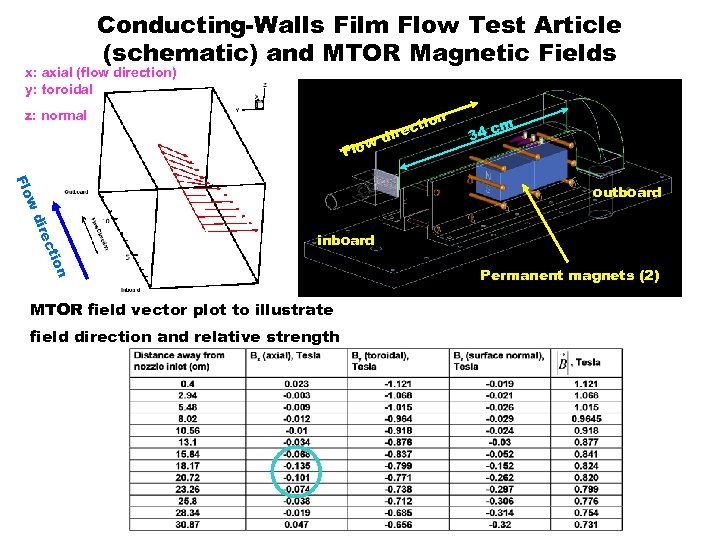

Conducting-Walls Film Flow Test Article (schematic) and MTOR Magnetic Fields x: axial (flow direction) y: toroidal z: normal d low F tio rec i n 34 cm inboard on cti ire wd Flo outboard MTOR field vector plot to illustrate field direction and relative strength Permanent magnets (2)

Conducting-Walls Film Flow Test Article (schematic) and MTOR Magnetic Fields x: axial (flow direction) y: toroidal z: normal d low F tio rec i n 34 cm inboard on cti ire wd Flo outboard MTOR field vector plot to illustrate field direction and relative strength Permanent magnets (2)

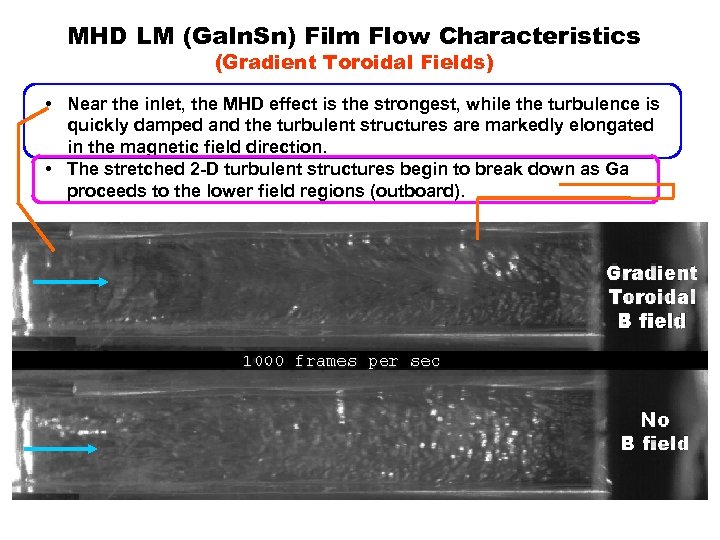

MHD LM (Ga. In. Sn) Film Flow Characteristics (Gradient Toroidal Fields) • Near the inlet, the MHD effect is the strongest, while the turbulence is quickly damped and the turbulent structures are markedly elongated in the magnetic field direction. • The stretched 2 -D turbulent structures begin to break down as Ga proceeds to the lower field regions (outboard).

MHD LM (Ga. In. Sn) Film Flow Characteristics (Gradient Toroidal Fields) • Near the inlet, the MHD effect is the strongest, while the turbulence is quickly damped and the turbulent structures are markedly elongated in the magnetic field direction. • The stretched 2 -D turbulent structures begin to break down as Ga proceeds to the lower field regions (outboard).

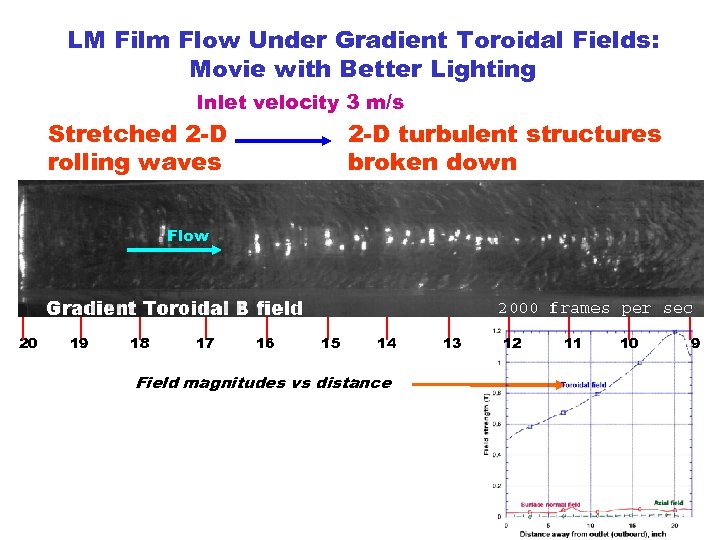

LM Film Flow Under Gradient Toroidal Fields: Movie with Better Lighting Inlet velocity 3 m/s Stretched 2 -D rolling waves 2 -D turbulent structures broken down Flow 20 19 18 17 16 15 14 Field magnitudes vs distance 13 12 11 10 9

LM Film Flow Under Gradient Toroidal Fields: Movie with Better Lighting Inlet velocity 3 m/s Stretched 2 -D rolling waves 2 -D turbulent structures broken down Flow 20 19 18 17 16 15 14 Field magnitudes vs distance 13 12 11 10 9

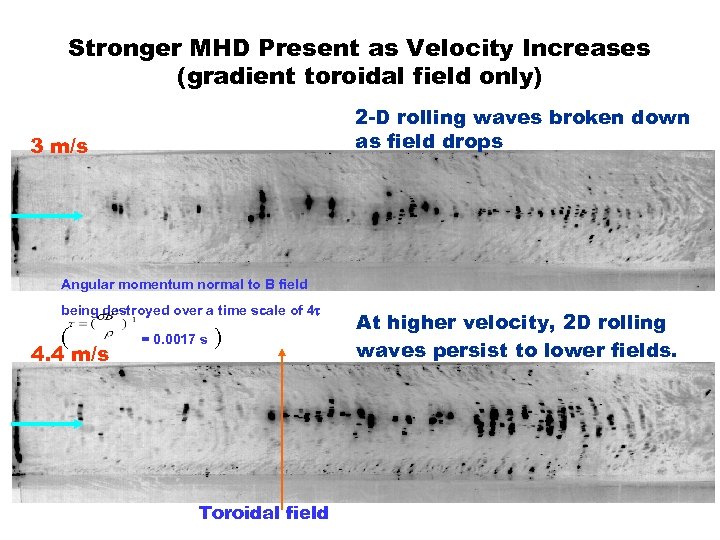

Stronger MHD Present as Velocity Increases (gradient toroidal field only) 2 -D rolling waves broken down as field drops 3 m/s Angular momentum normal to B field being destroyed over a time scale of 4 ( 4. 4 m/s = 0. 0017 s ) Toroidal field At higher velocity, 2 D rolling waves persist to lower fields.

Stronger MHD Present as Velocity Increases (gradient toroidal field only) 2 -D rolling waves broken down as field drops 3 m/s Angular momentum normal to B field being destroyed over a time scale of 4 ( 4. 4 m/s = 0. 0017 s ) Toroidal field At higher velocity, 2 D rolling waves persist to lower fields.

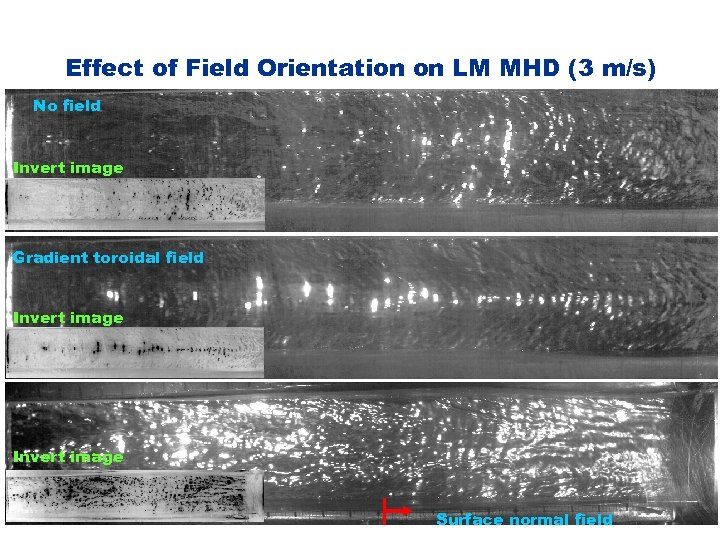

Effect of Field Orientation on LM MHD (3 m/s) No field Invert image Gradient toroidal field Invert image Surface normal field

Effect of Field Orientation on LM MHD (3 m/s) No field Invert image Gradient toroidal field Invert image Surface normal field

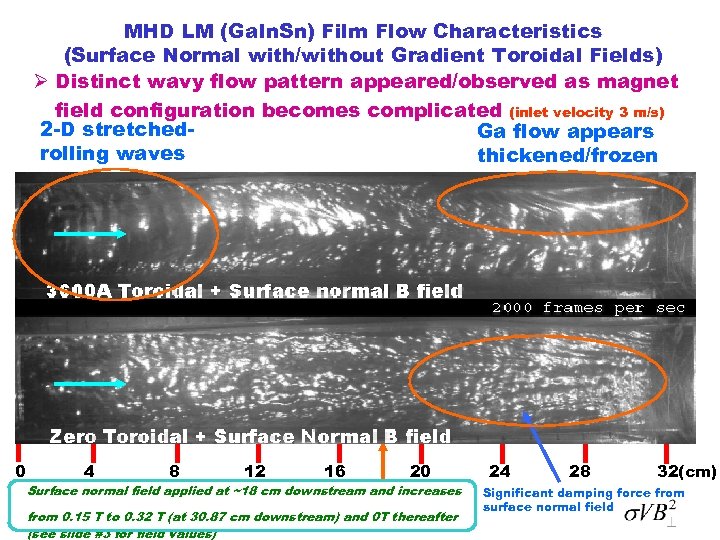

MHD LM (Ga. In. Sn) Film Flow Characteristics (Surface Normal with/without Gradient Toroidal Fields) Ø Distinct wavy flow pattern appeared/observed as magnet field configuration becomes complicated (inlet velocity 3 m/s) 2 -D stretched. Ga flow appears rolling waves thickened/frozen inboard 0 4 Outboard 8 12 16 20 Surface normal field applied at ~18 cm downstream and increases from 0. 15 T to 0. 32 T (at 30. 87 cm downstream) and 0 T thereafter (see slide #3 for field values) 24 28 32(cm) Significant damping force from surface normal field

MHD LM (Ga. In. Sn) Film Flow Characteristics (Surface Normal with/without Gradient Toroidal Fields) Ø Distinct wavy flow pattern appeared/observed as magnet field configuration becomes complicated (inlet velocity 3 m/s) 2 -D stretched. Ga flow appears rolling waves thickened/frozen inboard 0 4 Outboard 8 12 16 20 Surface normal field applied at ~18 cm downstream and increases from 0. 15 T to 0. 32 T (at 30. 87 cm downstream) and 0 T thereafter (see slide #3 for field values) 24 28 32(cm) Significant damping force from surface normal field

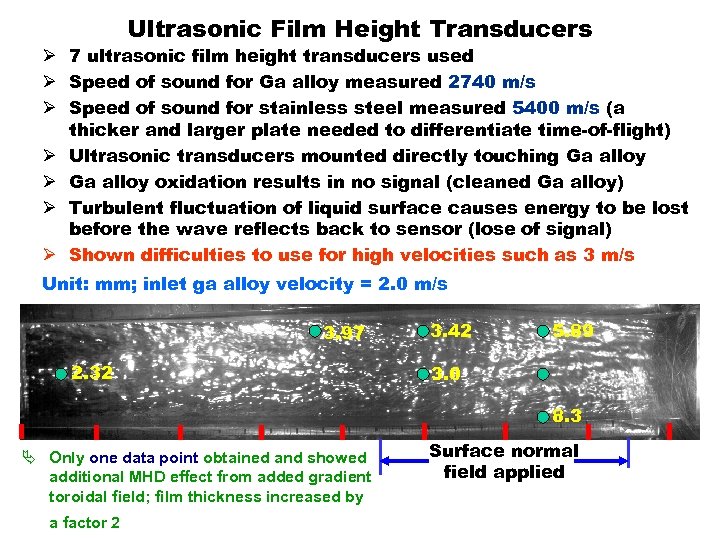

Ultrasonic Film Height Transducers Ø 7 ultrasonic film height transducers used Ø Speed of sound for Ga alloy measured 2740 m/s Ø Speed of sound for stainless steel measured 5400 m/s (a thicker and larger plate needed to differentiate time-of-flight) Ø Ultrasonic transducers mounted directly touching Ga alloy Ø Ga alloy oxidation results in no signal (cleaned Ga alloy) Ø Turbulent fluctuation of liquid surface causes energy to be lost before the wave reflects back to sensor (lose of signal) Ø Shown difficulties to use for high velocities such as 3 m/s Unit: mm; inlet ga alloy velocity = 2. 0 m/s 3. 97 2. 32 3. 42 5. 89 3. 0 8. 3 Ä Only one data point obtained and showed additional MHD effect from added gradient toroidal field; film thickness increased by a factor 2 Surface normal field applied

Ultrasonic Film Height Transducers Ø 7 ultrasonic film height transducers used Ø Speed of sound for Ga alloy measured 2740 m/s Ø Speed of sound for stainless steel measured 5400 m/s (a thicker and larger plate needed to differentiate time-of-flight) Ø Ultrasonic transducers mounted directly touching Ga alloy Ø Ga alloy oxidation results in no signal (cleaned Ga alloy) Ø Turbulent fluctuation of liquid surface causes energy to be lost before the wave reflects back to sensor (lose of signal) Ø Shown difficulties to use for high velocities such as 3 m/s Unit: mm; inlet ga alloy velocity = 2. 0 m/s 3. 97 2. 32 3. 42 5. 89 3. 0 8. 3 Ä Only one data point obtained and showed additional MHD effect from added gradient toroidal field; film thickness increased by a factor 2 Surface normal field applied

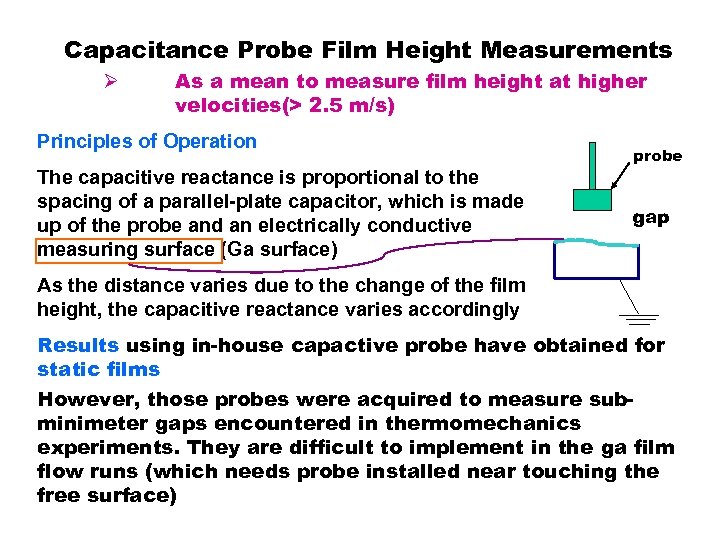

Capacitance Probe Film Height Measurements Ø As a mean to measure film height at higher velocities(> 2. 5 m/s) Principles of Operation The capacitive reactance is proportional to the spacing of a parallel-plate capacitor, which is made up of the probe and an electrically conductive measuring surface (Ga surface) probe gap As the distance varies due to the change of the film height, the capacitive reactance varies accordingly Results using in-house capactive probe have obtained for static films However, those probes were acquired to measure subminimeter gaps encountered in thermomechanics experiments. They are difficult to implement in the ga film flow runs (which needs probe installed near touching the free surface)

Capacitance Probe Film Height Measurements Ø As a mean to measure film height at higher velocities(> 2. 5 m/s) Principles of Operation The capacitive reactance is proportional to the spacing of a parallel-plate capacitor, which is made up of the probe and an electrically conductive measuring surface (Ga surface) probe gap As the distance varies due to the change of the film height, the capacitive reactance varies accordingly Results using in-house capactive probe have obtained for static films However, those probes were acquired to measure subminimeter gaps encountered in thermomechanics experiments. They are difficult to implement in the ga film flow runs (which needs probe installed near touching the free surface)

Exploratory studies for flowing liquid metal divertor options for ALIST NSTX in MTOR facility- A. Ying et al. Contents 0. Introduction I. Background Information (FLOW 3 D Numerical Simulation results to show why experimental study is critical) II. MTOR Facility- Flux concentrator/Engineering Scaling and Stage-one Objectives of MTOR Experiments III. Characterization of Liquid Metal Jets Under Gradient Transverse Fields III. 1 Introduction /Typical Jet Behavior without MHD, Literature Review of MHD-Jet Studies III. 2 Experimental Studies in MTOR III. 3 Experimental Results IV. Film Flow Characteristics Under Complex Gradient Fields IV. 1 Introduction /Typical Film Behavior without MHD, Literature Review of MHD-Film Studies IV. 2 Experimental Studies in MTOR IV. 3 Experimental Results and Analysis V. Summary and Next-step Plan

Exploratory studies for flowing liquid metal divertor options for ALIST NSTX in MTOR facility- A. Ying et al. Contents 0. Introduction I. Background Information (FLOW 3 D Numerical Simulation results to show why experimental study is critical) II. MTOR Facility- Flux concentrator/Engineering Scaling and Stage-one Objectives of MTOR Experiments III. Characterization of Liquid Metal Jets Under Gradient Transverse Fields III. 1 Introduction /Typical Jet Behavior without MHD, Literature Review of MHD-Jet Studies III. 2 Experimental Studies in MTOR III. 3 Experimental Results IV. Film Flow Characteristics Under Complex Gradient Fields IV. 1 Introduction /Typical Film Behavior without MHD, Literature Review of MHD-Film Studies IV. 2 Experimental Studies in MTOR IV. 3 Experimental Results and Analysis V. Summary and Next-step Plan