7d2d18537a8aabea4576db0c55b356df.ppt

- Количество слайдов: 34

Progress on Solid Breeder Test Program and Needs for TBWG A. Ying/M. Abdou Feb. 24, 2004 UCLA Main contributors for this period of performance: M. Dagher, J. An Outline • Response to questions raised on thermal creep during last meeting • Progress on Solid Breeder Test Program and Needs for TBWG

issues on thermal creep What is thermal creep, why is it important, and what do we know now? (In fact, thermal creep is not the only phenomenon critical to pebble bed dimensional integrity) Background information The temperature window, and the associated design margin, for the solid breeder pebble bed is relatively narrow. Any deviation from its original position, particularly at the interface may increase the interfacial thermal resistance and cause the breeder operating temperature to go beyond its maximum allowable temperature. (Events such as sintering and melting can be the consequences)

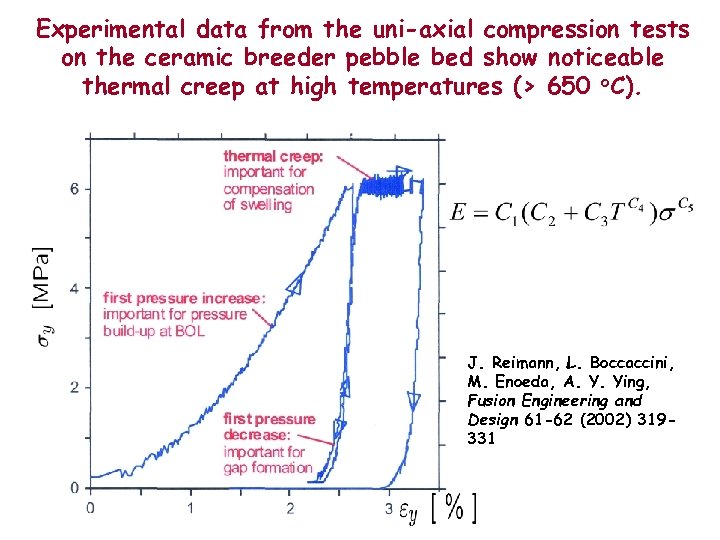

Experimental data from the uni-axial compression tests on the ceramic breeder pebble bed show noticeable thermal creep at high temperatures (> 650 o. C). J. Reimann, L. Boccaccini, M. Enoeda, A. Y. Ying, Fusion Engineering and Design 61 -62 (2002) 319331

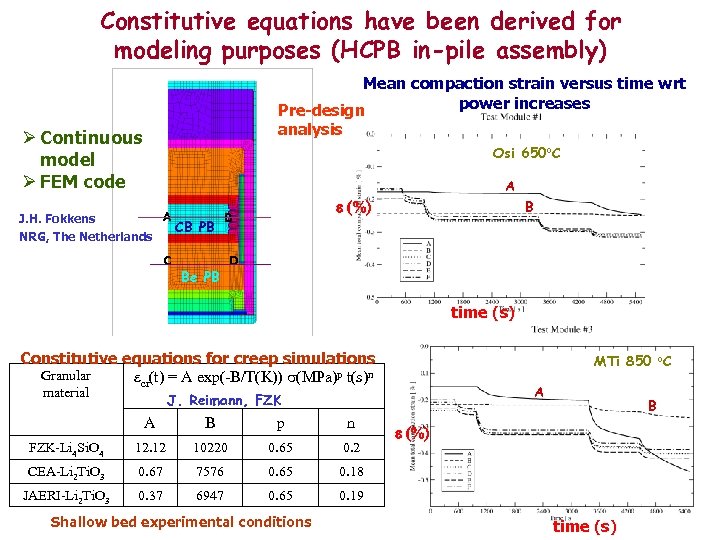

Constitutive equations have been derived for modeling purposes (HCPB in-pile assembly) Mean compaction strain versus time wrt power increases Pre-design analysis Ø Continuous model Ø FEM code Osi 650 o. C A A J. H. Fokkens NRG, The Netherlands C CB PB Be PB B e (%) B D time (s) Constitutive equations for creep simulations Granular ecr(t) = A exp(-B/T(K)) s(MPa)p t(s)n material MTi 850 o. C A J. Reimann, FZK A B p n FZK-Li 4 Si. O 4 12. 12 10220 0. 65 0. 2 CEA-Li 2 Ti. O 3 0. 67 7576 0. 65 0. 18 JAERI-Li 2 Ti. O 3 0. 37 6947 0. 65 B 0. 19 Shallow bed experimental conditions e (%) time (s)

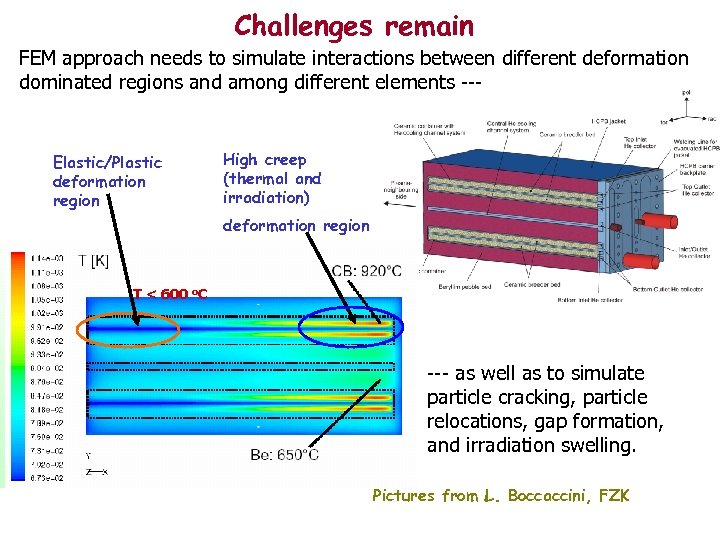

Challenges remain FEM approach needs to simulate interactions between different deformation dominated regions and among different elements --- Elastic/Plastic deformation region High creep (thermal and irradiation) deformation region T < 600 o. C --- as well as to simulate particle cracking, particle relocations, gap formation, and irradiation swelling. Pictures from L. Boccaccini, FZK

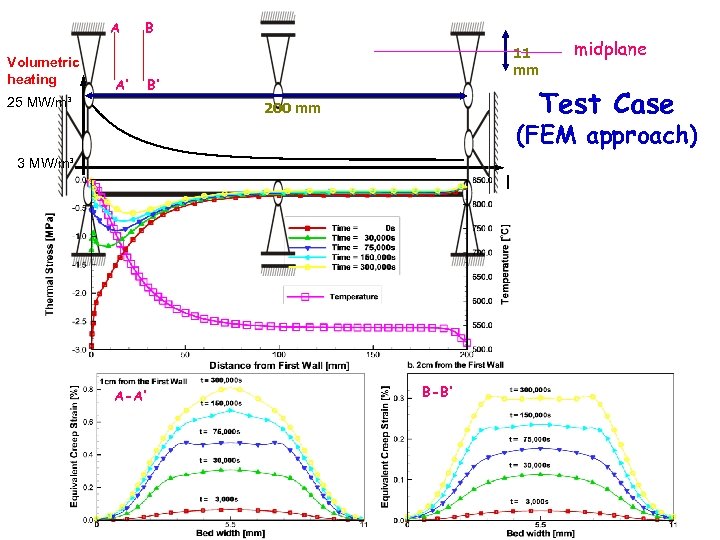

A Volumetric heating B A’ 25 MW/m³ 11 mm B’ midplane Test Case 200 mm (FEM approach) 3 MW/m³ l A-A’ B-B’

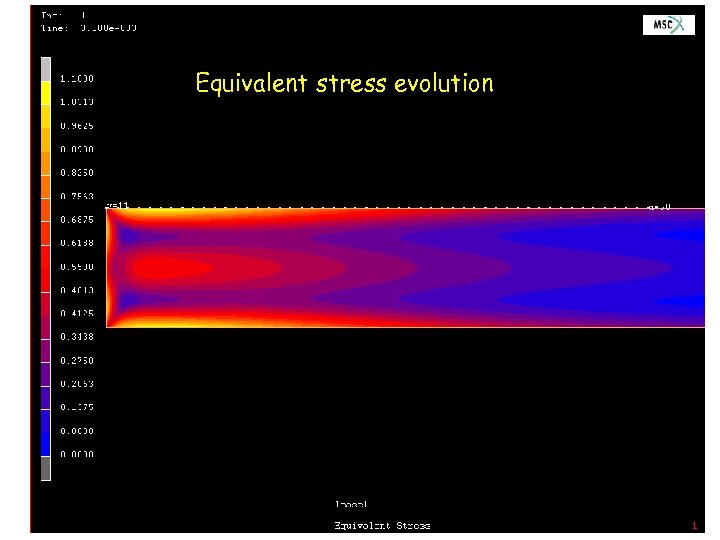

Equivalent stress evolution

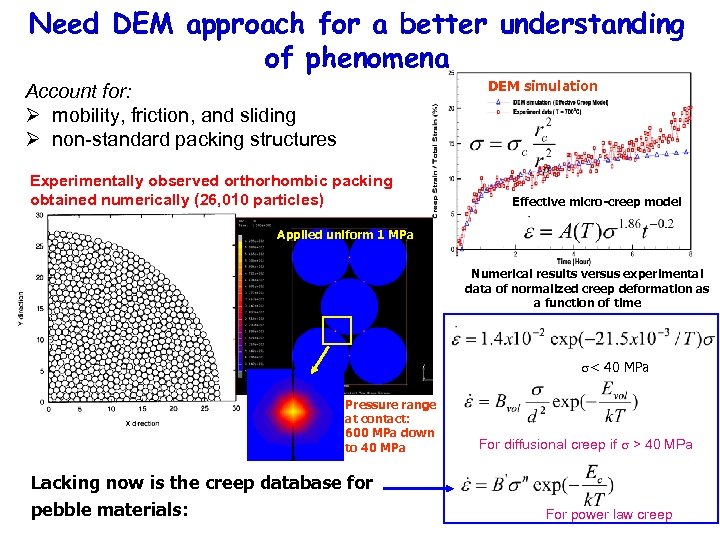

Need DEM approach for a better understanding of phenomena DEM simulation Account for: Ø mobility, friction, and sliding Ø non-standard packing structures Experimentally observed orthorhombic packing obtained numerically (26, 010 particles) Effective micro-creep model Applied uniform 1 MPa Numerical results versus experimental data of normalized creep deformation as a function of time s< 40 MPa Pressure range at contact: 600 MPa down to 40 MPa Lacking now is the creep database for pebble materials: For diffusional creep if s > 40 MPa For power law creep

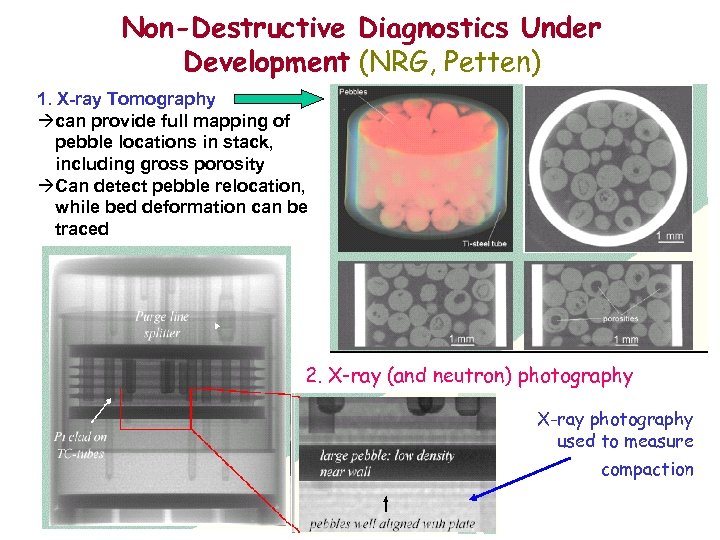

Non-Destructive Diagnostics Under Development (NRG, Petten) 1. X-ray Tomography àcan provide full mapping of pebble locations in stack, including gross porosity àCan detect pebble relocation, while bed deformation can be traced 2. X-ray (and neutron) photography X-ray photography used to measure compaction

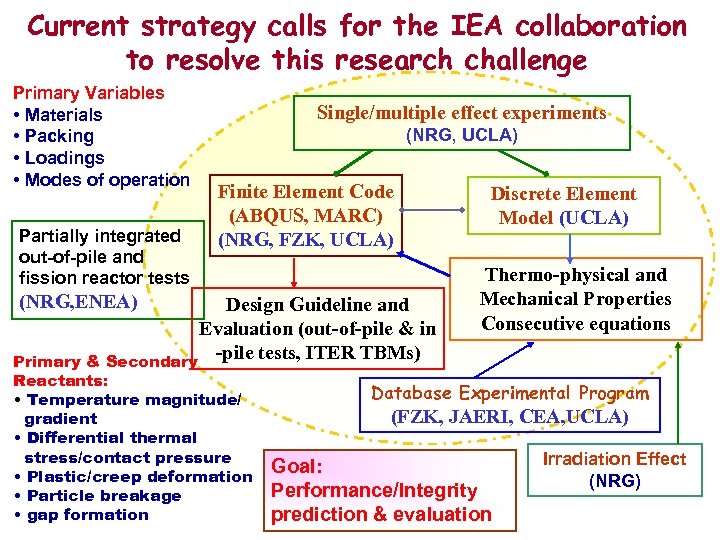

Current strategy calls for the IEA collaboration to resolve this research challenge Primary Variables • Materials • Packing • Loadings • Modes of operation Partially integrated out-of-pile and fission reactor tests Single/multiple effect experiments (NRG, UCLA) Finite Element Code (ABQUS, MARC) (NRG, FZK, UCLA) (NRG, ENEA) Design Guideline and Evaluation (out-of-pile & in Primary & Secondary -pile tests, ITER TBMs) Reactants: • Temperature magnitude/ gradient • Differential thermal stress/contact pressure • Plastic/creep deformation • Particle breakage • gap formation Discrete Element Model (UCLA) Thermo-physical and Mechanical Properties Consecutive equations Database Experimental Program (FZK, JAERI, CEA, UCLA) Goal: Performance/Integrity prediction & evaluation Irradiation Effect (NRG)

Need for TBWG Recall from the last November meeting -During the TBWG-11, emphasis was placed on exploring the possibility of collaboration between the parties, aiming to reduce the number of independent TBMs that should be contemporaneously tested in ITER in order to find a solution to the repartition of the space available in the ITER ports Working Sub-Groups were formed according to blanket concepts

WSG-1: formed by blanket concepts based on ceramic breeder with Helium as coolant and ferritic martensitic steel as structural material Ø Including 6 parties Ø Coordinated by Lorenzo Boccaccini (FZK/EU) Ø First informal meeting held in Tokyo on the 14 th of December, 2003. To examine whether or not reduced test space is possible through collaborative efforts and a more integrated testing approach “The main issue is to check the space necessary for performing meaningful testing and, hence, about the possibility to reduce this space by collaboration and a more integrated approach in the testing programme. This will help the subgroup to define the interfaces with ITER that are the first request from the JCT. ”

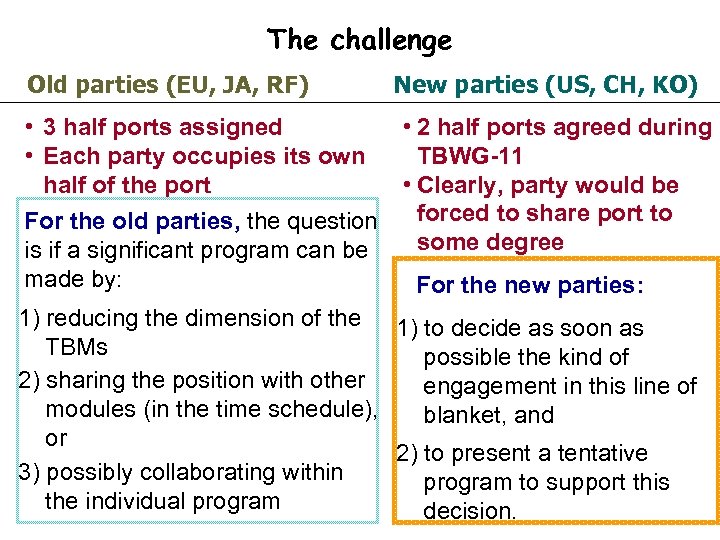

The challenge Old parties (EU, JA, RF) • 3 half ports assigned • Each party occupies its own half of the port For the old parties, the question is if a significant program can be made by: New parties (US, CH, KO) • 2 half ports agreed during TBWG-11 • Clearly, party would be forced to share port to some degree For the new parties: 1) reducing the dimension of the 1) to decide as soon as TBMs possible the kind of 2) sharing the position with other engagement in this line of modules (in the time schedule), blanket, and or 2) to present a tentative 3) possibly collaborating within program to support this the individual program decision.

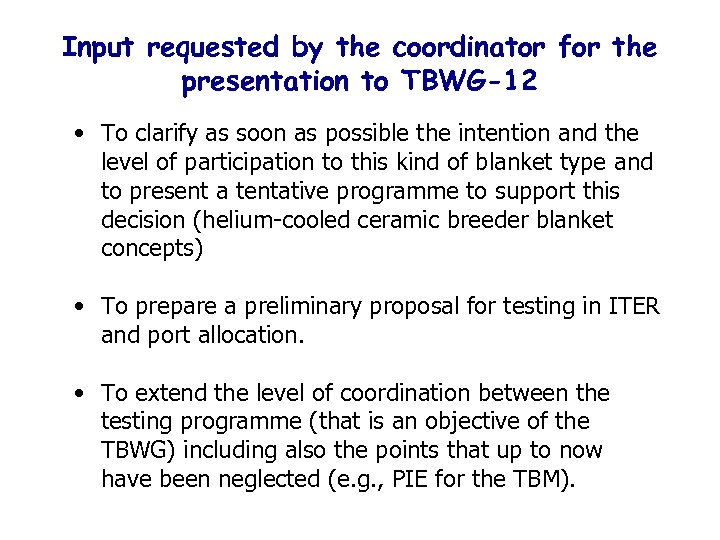

Input requested by the coordinator for the presentation to TBWG-12 • To clarify as soon as possible the intention and the level of participation to this kind of blanket type and to present a tentative programme to support this decision (helium-cooled ceramic breeder blanket concepts) • To prepare a preliminary proposal for testing in ITER and port allocation. • To extend the level of coordination between the testing programme (that is an objective of the TBWG) including also the points that up to now have been neglected (e. g. , PIE for the TBM).

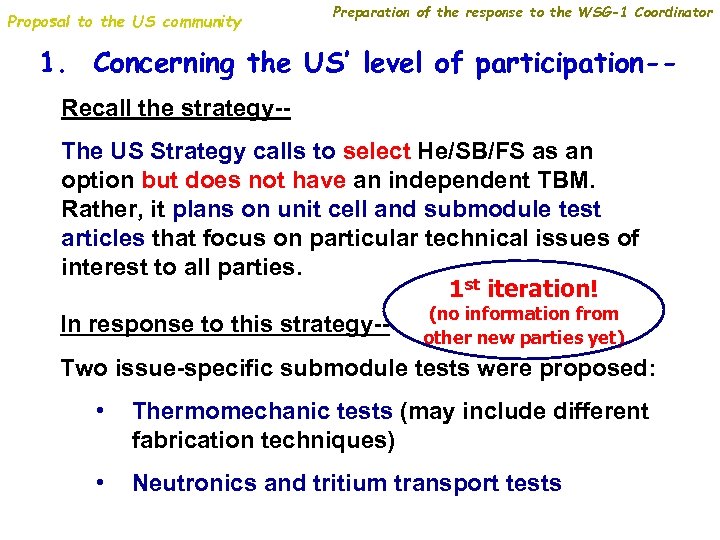

Proposal to the US community Preparation of the response to the WSG-1 Coordinator 1. Concerning the US’ level of participation-Recall the strategy-The US Strategy calls to select He/SB/FS as an option but does not have an independent TBM. Rather, it plans on unit cell and submodule test articles that focus on particular technical issues of interest to all parties. 1 st iteration! (no information from In response to this strategy-- other new parties yet) Two issue-specific submodule tests were proposed: • Thermomechanic tests (may include different fabrication techniques) • Neutronics and tritium transport tests

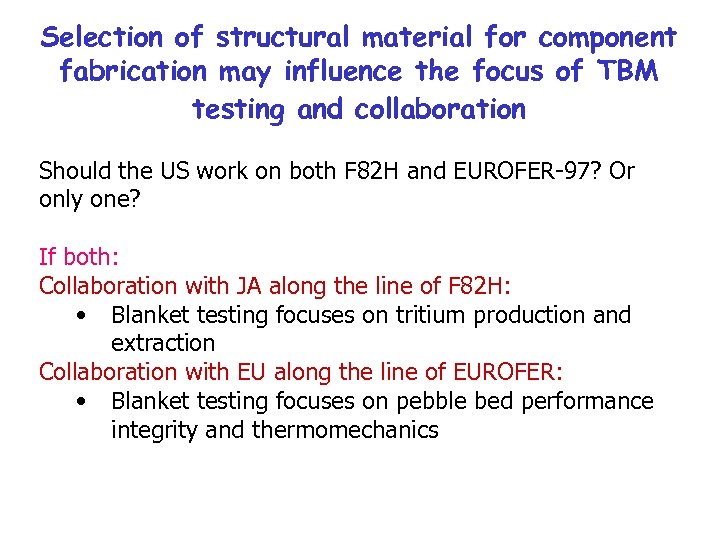

Selection of structural material for component fabrication may influence the focus of TBM testing and collaboration Should the US work on both F 82 H and EUROFER-97? Or only one? If both: Collaboration with JA along the line of F 82 H: • Blanket testing focuses on tritium production and extraction Collaboration with EU along the line of EUROFER: • Blanket testing focuses on pebble bed performance integrity and thermomechanics

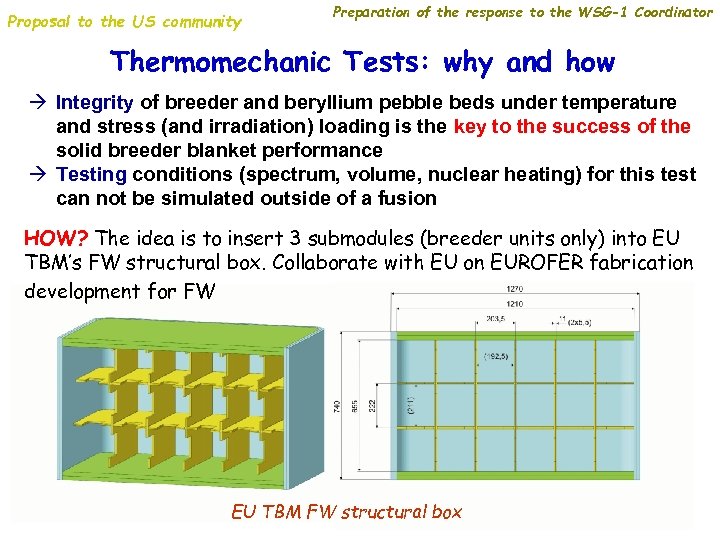

Proposal to the US community Preparation of the response to the WSG-1 Coordinator Thermomechanic Tests: why and how à Integrity of breeder and beryllium pebble beds under temperature and stress (and irradiation) loading is the key to the success of the solid breeder blanket performance à Testing conditions (spectrum, volume, nuclear heating) for this test can not be simulated outside of a fusion HOW? The idea is to insert 3 submodules (breeder units only) into EU TBM’s FW structural box. Collaborate with EU on EUROFER fabrication development for FW EU TBM FW structural box

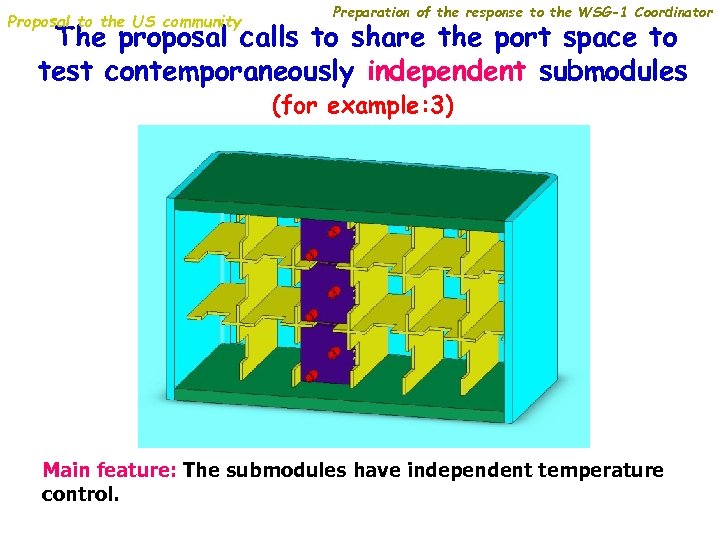

Proposal to the US community Preparation of the response to the WSG-1 Coordinator The proposal calls to share the port space to test contemporaneously independent submodules (for example: 3) Main feature: The submodules have independent temperature control.

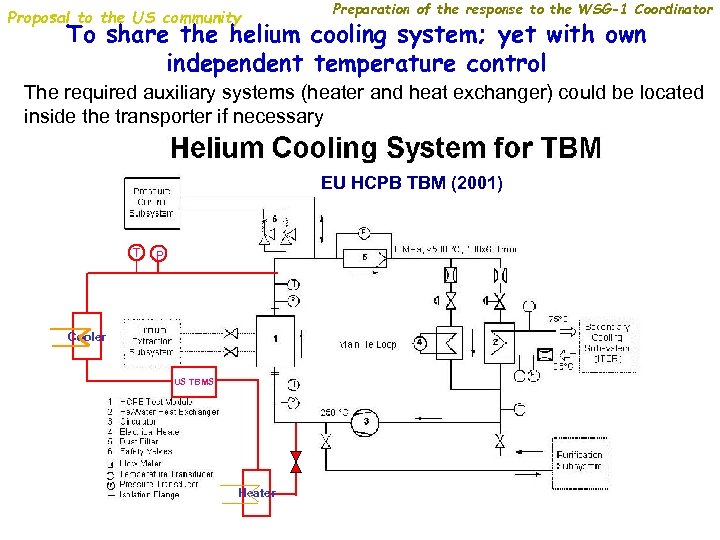

Proposal to the US community Preparation of the response to the WSG-1 Coordinator To share the helium cooling system; yet with own independent temperature control The required auxiliary systems (heater and heat exchanger) could be located inside the transporter if necessary EU HCPB TBM (2001) T P Cooler US TBMS Heater

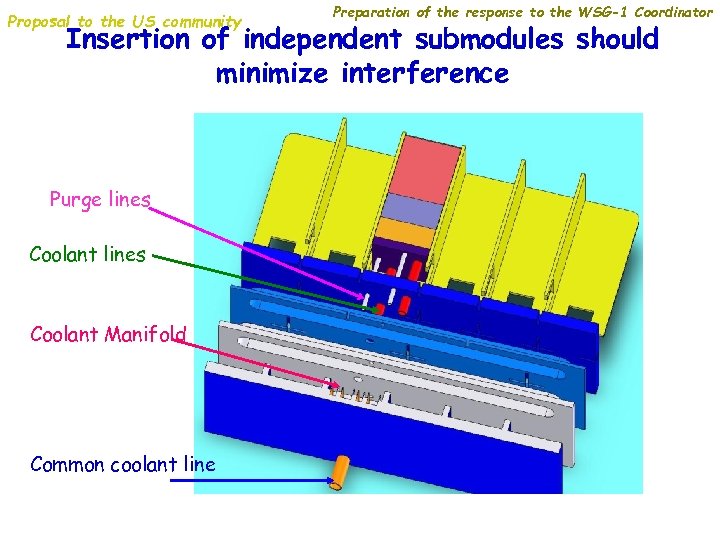

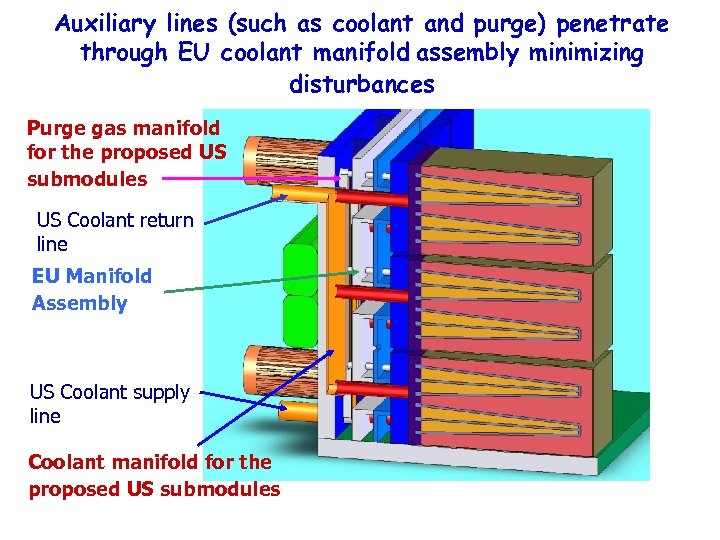

Proposal to the US community Preparation of the response to the WSG-1 Coordinator Insertion of independent submodules should minimize interference Purge lines Coolant Manifold Common coolant line

Auxiliary lines (such as coolant and purge) penetrate through EU coolant manifold assembly minimizing disturbances Purge gas manifold for the proposed US submodules US Coolant return line EU Manifold Assembly US Coolant supply line Coolant manifold for the proposed US submodules

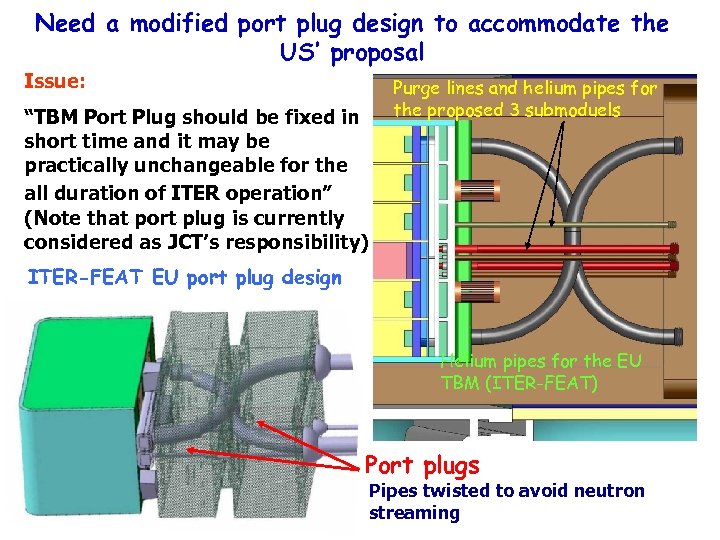

Need a modified port plug design to accommodate the US’ proposal Issue: “TBM Port Plug should be fixed in short time and it may be practically unchangeable for the all duration of ITER operation” (Note that port plug is currently considered as JCT’s responsibility) Purge lines and helium pipes for the proposed 3 submoduels ITER-FEAT EU port plug design Helium pipes for the EU TBM (ITER-FEAT) Port plugs Pipes twisted to avoid neutron streaming

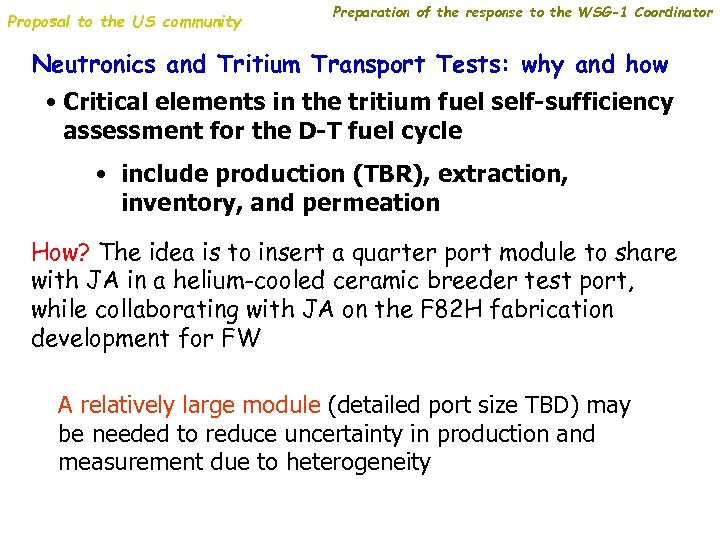

Proposal to the US community Preparation of the response to the WSG-1 Coordinator Neutronics and Tritium Transport Tests: why and how • Critical elements in the tritium fuel self-sufficiency assessment for the D-T fuel cycle • include production (TBR), extraction, inventory, and permeation How? The idea is to insert a quarter port module to share with JA in a helium-cooled ceramic breeder test port, while collaborating with JA on the F 82 H fabrication development for FW A relatively large module (detailed port size TBD) may be needed to reduce uncertainty in production and measurement due to heterogeneity

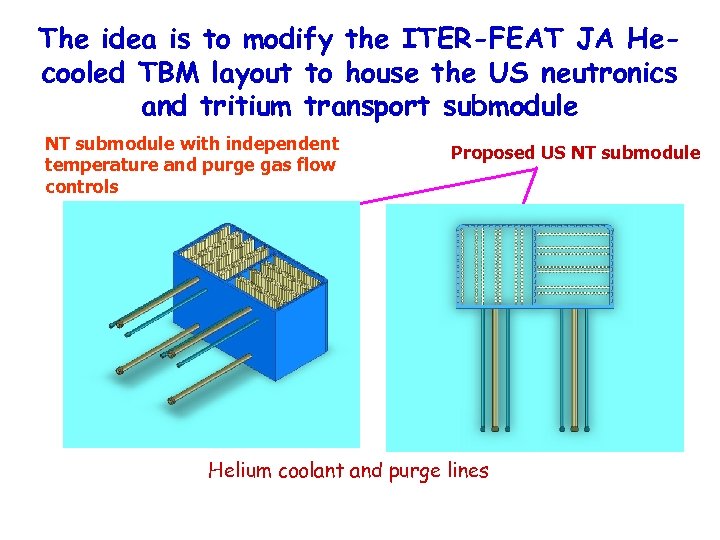

The idea is to modify the ITER-FEAT JA Hecooled TBM layout to house the US neutronics and tritium transport submodule NT submodule with independent temperature and purge gas flow controls Proposed US NT submodule Helium coolant and purge lines

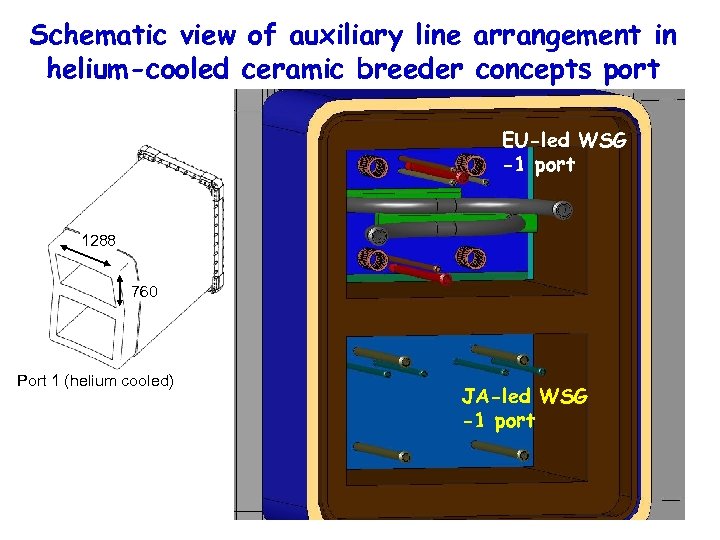

Schematic view of auxiliary line arrangement in helium-cooled ceramic breeder concepts port EU-led WSG -1 port 1288 760 Port 1 (helium cooled) JA-led WSG -1 port

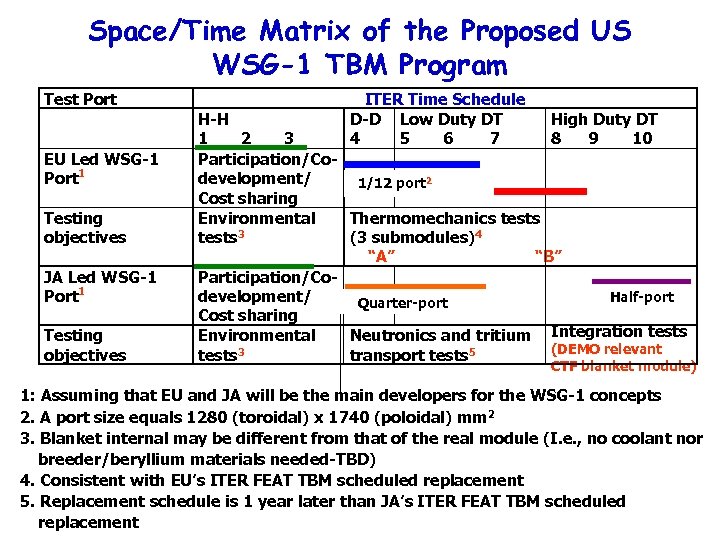

Space/Time Matrix of the Proposed US WSG-1 TBM Program Test Port EU Led WSG-1 Port 1 Testing objectives JA Led WSG-1 Port 1 Testing objectives ITER Time Schedule D-D Low Duty DT 4 5 6 7 H-H High Duty DT 1 2 3 8 9 10 Participation/Codevelopment/ 1/12 port 2 Cost sharing Environmental Thermomechanics tests 3 (3 submodules)4 “A” “B” Participation/Codevelopment/ Half-port Quarter-port Cost sharing Environmental Neutronics and tritium Integration tests (DEMO relevant tests 3 transport tests 5 CTF blanket module) 1: Assuming that EU and JA will be the main developers for the WSG-1 concepts 2. A port size equals 1280 (toroidal) x 1740 (poloidal) mm 2 3. Blanket internal may be different from that of the real module (I. e. , no coolant nor breeder/beryllium materials needed-TBD) 4. Consistent with EU’s ITER FEAT TBM scheduled replacement 5. Replacement schedule is 1 year later than JA’s ITER FEAT TBM scheduled replacement

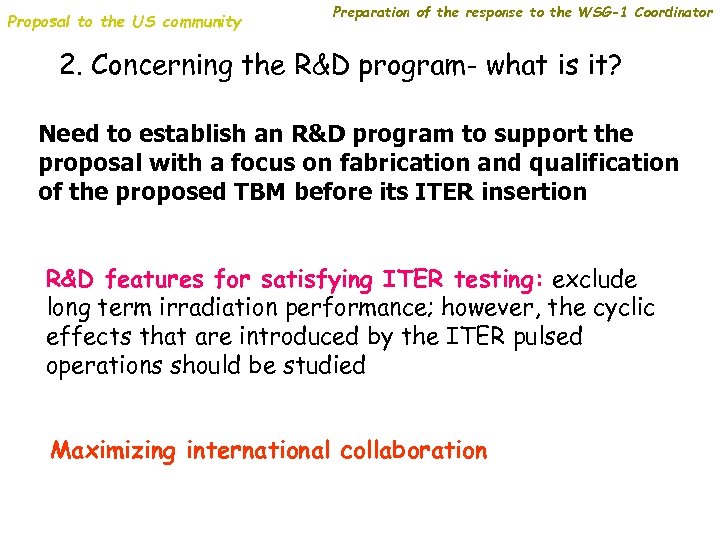

Proposal to the US community Preparation of the response to the WSG-1 Coordinator 2. Concerning the R&D program- what is it? Need to establish an R&D program to support the proposal with a focus on fabrication and qualification of the proposed TBM before its ITER insertion R&D features for satisfying ITER testing: exclude long term irradiation performance; however, the cyclic effects that are introduced by the ITER pulsed operations should be studied Maximizing international collaboration

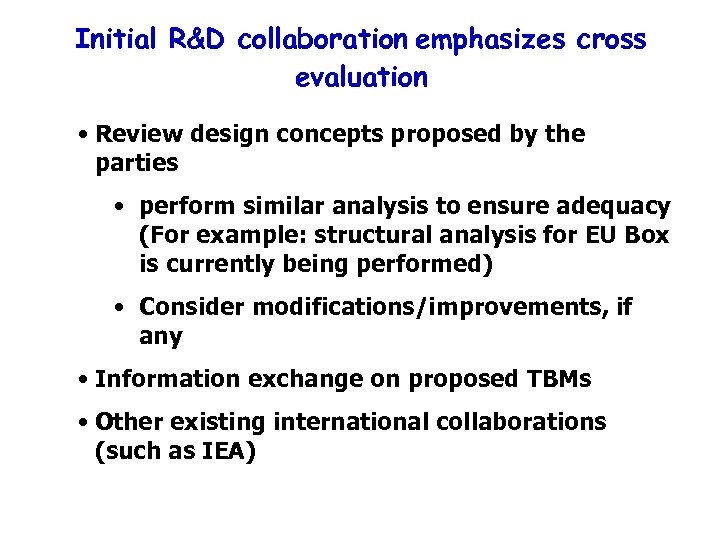

Initial R&D collaboration emphasizes cross evaluation • Review design concepts proposed by the parties • perform similar analysis to ensure adequacy (For example: structural analysis for EU Box is currently being performed) • Consider modifications/improvements, if any • Information exchange on proposed TBMs • Other existing international collaborations (such as IEA)

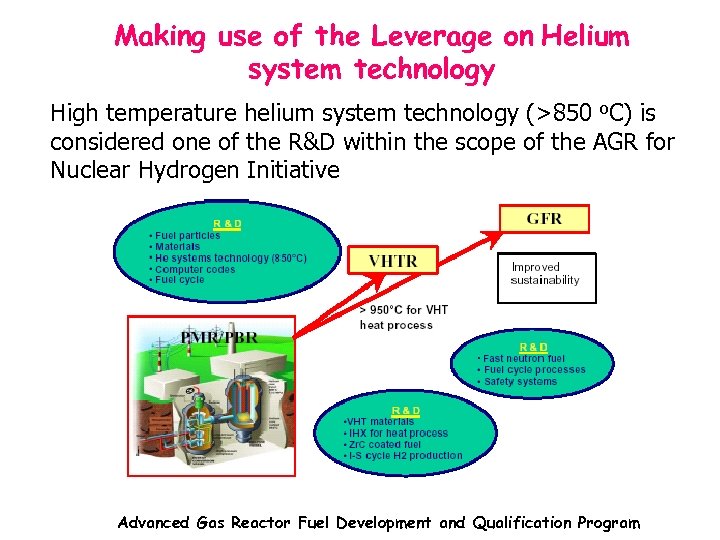

Making use of the Leverage on Helium system technology High temperature helium system technology (>850 o. C) is considered one of the R&D within the scope of the AGR for Nuclear Hydrogen Initiative Advanced Gas Reactor Fuel Development and Qualification Program

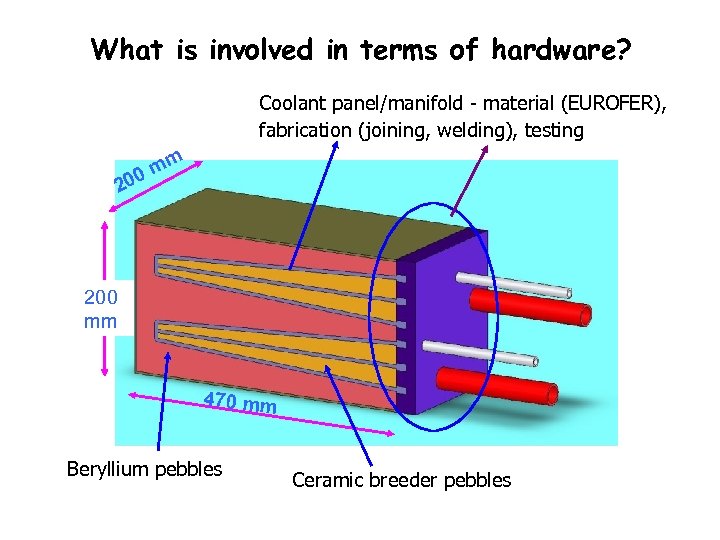

What is involved in terms of hardware? Coolant panel/manifold - material (EUROFER), fabrication (joining, welding), testing mm 0 20 200 mm 470 mm Beryllium pebbles Ceramic breeder pebbles

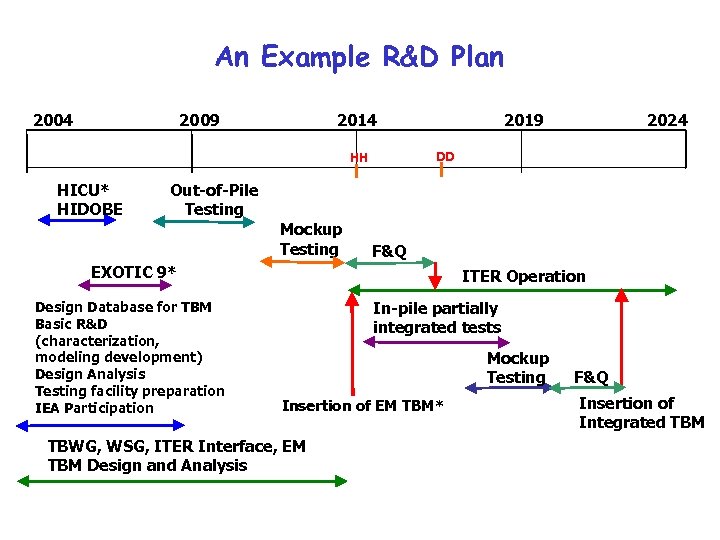

An Example R&D Plan 2004 2009 2014 2024 DD HH HICU* HIDOBE 2019 Out-of-Pile Testing Mockup Testing F&Q EXOTIC 9* Design Database for TBM Basic R&D (characterization, modeling development) Design Analysis Testing facility preparation IEA Participation ITER Operation In-pile partially integrated tests Mockup Testing Insertion of EM TBM* TBWG, WSG, ITER Interface, EM TBM Design and Analysis F&Q Insertion of Integrated TBM

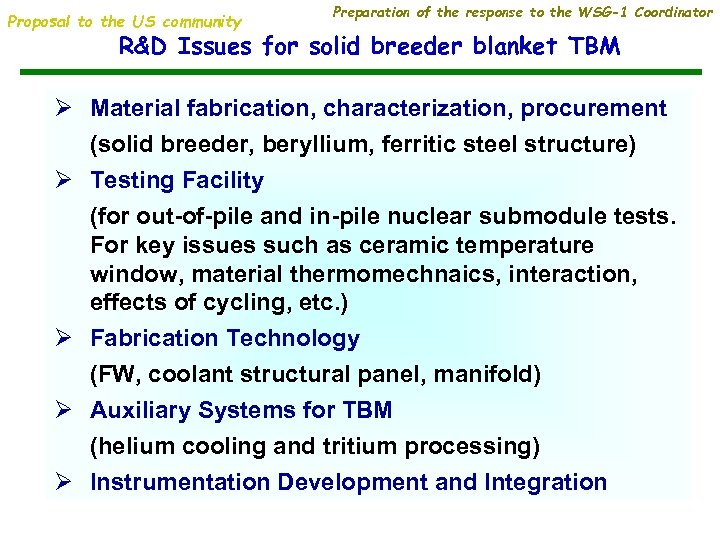

Proposal to the US community Preparation of the response to the WSG-1 Coordinator R&D Issues for solid breeder blanket TBM Ø Material fabrication, characterization, procurement (solid breeder, beryllium, ferritic steel structure) Ø Testing Facility (for out-of-pile and in-pile nuclear submodule tests. For key issues such as ceramic temperature window, material thermomechnaics, interaction, effects of cycling, etc. ) Ø Fabrication Technology (FW, coolant structural panel, manifold) Ø Auxiliary Systems for TBM (helium cooling and tritium processing) Ø Instrumentation Development and Integration

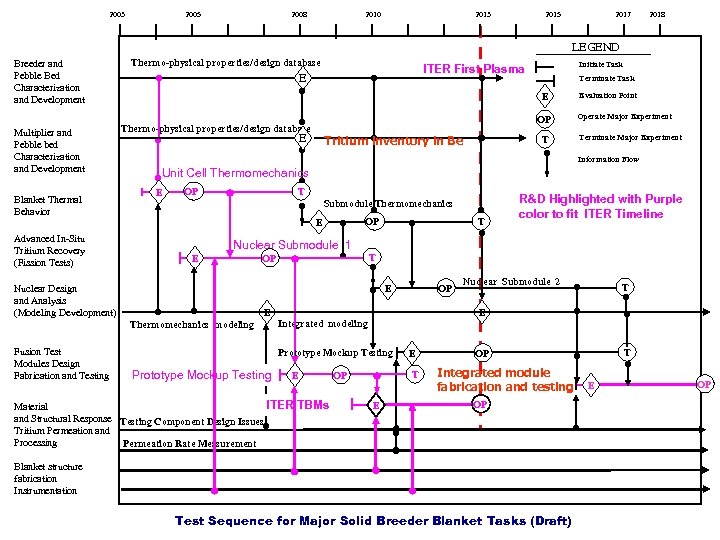

2003 2005 2008 2010 2013 2015 2017 2018 LEGEND Breeder and Pebble Bed Characterization and Development Multiplier and Pebble bed Characterization and Development Blanket Thermal Behavior Advanced In-Situ Tritium Recovery (Fission Tests) Thermo-physical properties/design database E Terminate Task E OP Thermo-physical properties/design database E Tritium inventory in Be T Evaluation Point Operate Major Experiment Terminate Major Experiment Information Flow Unit Cell Thermomechanics E OP T Submodule Thermomechanics OP E T R&D Highlighted with Purple color to fit ITER Timeline Nuclear Submodule 1 E T OP E Nuclear Design and Analysis (Modeling Development) OP E Thermomechanics modeling Fusion Test Modules Design Fabrication and Testing Initiate Task ITER First Plasma T E Integrated modeling Prototype Mockup Testing Nuclear Submodule 2 E ITER Material and Structural Response Testing Component Design Issues Tritium Permeation and Processing Permeation Rate Measurement TBMs E T OP Integrated module fabrication and testing OP Blanket structure fabrication Instrumentation Test Sequence for Major Solid Breeder Blanket Tasks (Draft) E OP

Summary • Need processes to derive a US ITER TBM plan • Two issue-specific submodule tests are proposed for helium-cooled ceramic breeder blanket concepts • Neutronics and tritium transport tests • Thermomechanic tests • Can this proposal be submitted to WSG-1 for initial discussions? • Need inputs to WSG-1 for the preparation of TBWG-12 discussion • the intention and the level of participation to helium-cooled ceramic breeder blanket concepts • a tentative program to support this decision (helium-cooled ceramic breeder blanket concepts) • Proposal can be revised with more inputs from other parties

7d2d18537a8aabea4576db0c55b356df.ppt