45c6b104b07f9a4dcfc61e3057d3799f.ppt

- Количество слайдов: 41

Programmable Automation Controllers (PAC) Reduce Cost, Size, and Weight July 21, 2005 © 2005 Fairmount Automation, Inc. All Rights Reserved.

About Fairmount Automation Product Development q Founded q Located q OEM Engineering Services in 1996 in Suburban Philadelphia, PA of Programmable Automation Controllers q Products Installed on Over 30% of U. S. Navy Fleet q Leadership Role in Design and Development of Automated Damage Control Systems for DD(X) © 2005 Fairmount Automation, Inc. All Rights Reserved. 2

DD(X) AFSS q q q q Designed and implemented leading-edge Autonomic Fire Suppression System (AFSS) Based on embedded smart-valve technology Distributed device-level control (Lon. Talk protocol) Successful Weapon Effect Test (WET) on ex. USS Peterson (first ever) Successful live-fire tests on ex-USS Shadwell Anticipate central role in DD(x) Flight I ADCS design Process improvement initiative underway to achieve CMMi Level 3 assessment (sponsored by Raytheon) © 2005 Fairmount Automation, Inc. All Rights Reserved. 3

First Generation FAC-2000 MIL-SPEC Grade A Shock, MIL-SPEC Vibration q Programmable Digital Multi-Loop Controller q User-Friendly, Hardened Integral Operator Interface q Initially Installed in 1997 to Overhaul Legacy Controls q ü ü ü Reactor Secondary Steam Plant Controls Catapult Accumulators Primary Boiler Controls Main Feed Pumps Distilling Plants Evaporators USS John F Kennedy © 2005 Fairmount Automation, Inc. All Rights Reserved. 4

Current Installed Base Over 1500 Loops of Control q q q q Aircraft Carriers Amphibious Assault Amphibious Transport Destroyers Cruisers Frigates Combat Support Ships Submarine Supply Ships USS Boone © 2005 Fairmount Automation, Inc. All Rights Reserved. 5

Installed Applications q q q q q Propulsion Boilers Feed Pumps Distilling Plants Waste Heat Boilers Condensers Evaporators Oil and Fuel Heaters Steam Turbine Aux. Diesel Generator Aux. q q q q Force Draft Blowers Deaereating Feed Tanks Chilled Water Plants Catapult Accumulators Compressors Purifiers Compressors Shaft Speed Indication USS Ticonderoga © 2005 Fairmount Automation, Inc. All Rights Reserved. 6

Chameleon: New Controller Platform © 2005 Fairmount Automation, Inc. All Rights Reserved. 7

Key Characteristics q MIL-SPEC qualified “out-of-the-box” q Eliminates need for costly, bulky, and heavy enclosures q Distributed processor architecture enhances survivability q Open connectivity to industry standard protocols and networks q Flexible and modular architecture with versatile I/O suite q Easy to assemble, install, and maintain q Integrated user-interface with prominent displays and buttons q Wireless device configuration and data retrieval © 2005 Fairmount Automation, Inc. All Rights Reserved. 8

© 2005 Fairmount Automation, Inc. All Rights Reserved. 9

Chameleon PAC Installations q 350+ Chameleon Modules In Service (U. S. Navy) q Currently Installed on 20 U. S. Navy Ships: USS IWO JIMA USS VANDERGRIFT USS DUBUQUE USS BOONE USS JOHN HALL USS WASP USS DOYLE USS UNDERWOOD USS PONCE USS DEWERT USS KAUFFMAN USS FORD USS GARY USS ESSEX USS SIMPSON USS BRADLEY USS CLEVELAND USS PELELIU USS NASHVILLE USS MCINERNY © 2005 Fairmount Automation, Inc. All Rights Reserved. 10

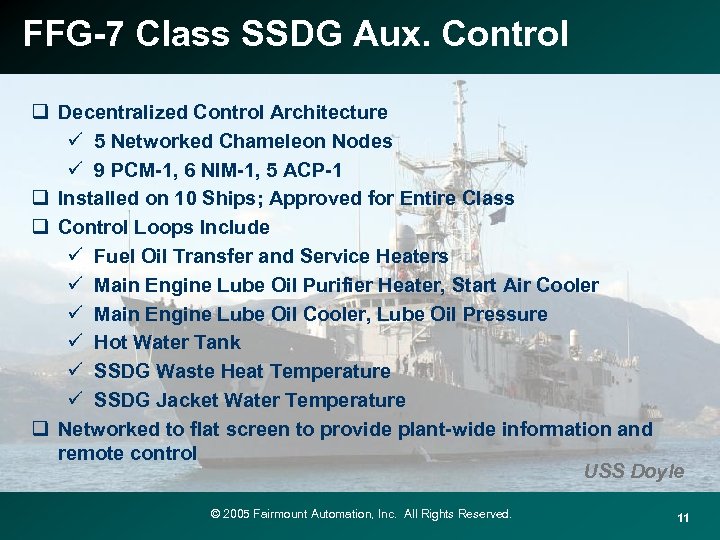

FFG-7 Class SSDG Aux. Control q Decentralized Control Architecture ü 5 Networked Chameleon Nodes ü 9 PCM-1, 6 NIM-1, 5 ACP-1 q Installed on 10 Ships; Approved for Entire Class q Control Loops Include ü Fuel Oil Transfer and Service Heaters ü Main Engine Lube Oil Purifier Heater, Start Air Cooler ü Main Engine Lube Oil Cooler, Lube Oil Pressure ü Hot Water Tank ü SSDG Waste Heat Temperature ü SSDG Jacket Water Temperature q Networked to flat screen to provide plant-wide information and remote control USS Doyle © 2005 Fairmount Automation, Inc. All Rights Reserved. 11

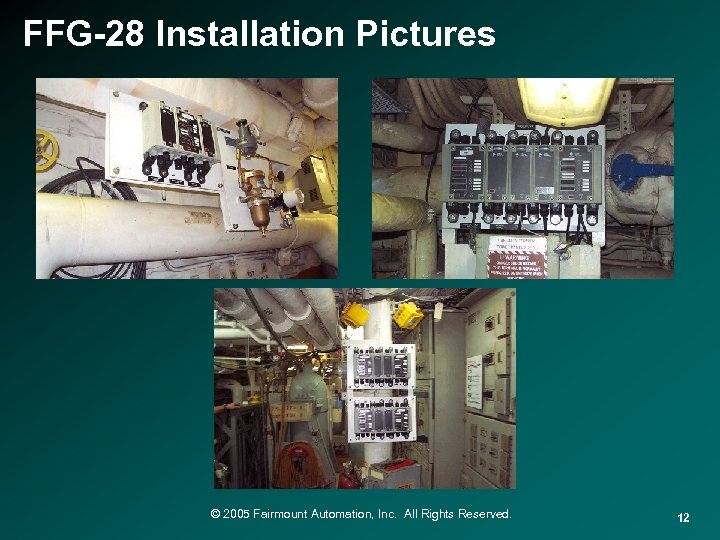

FFG-28 Installation Pictures © 2005 Fairmount Automation, Inc. All Rights Reserved. 12

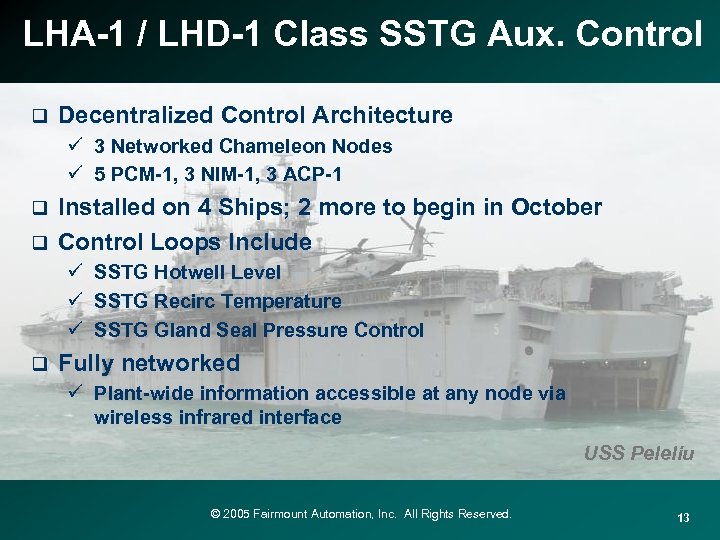

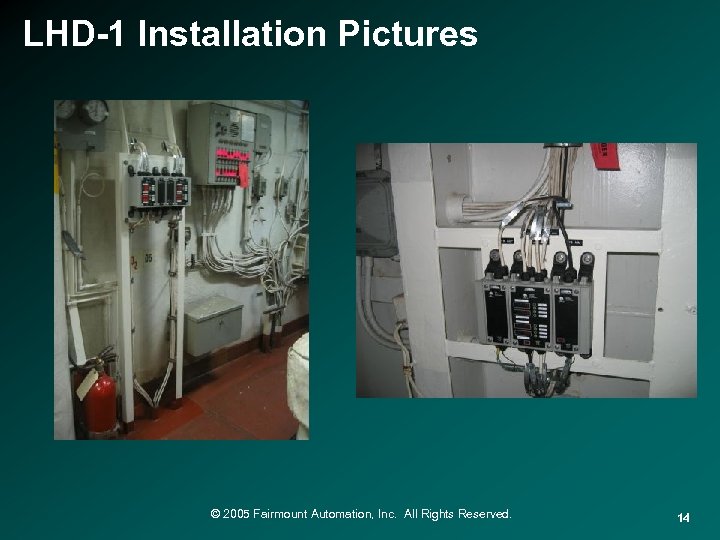

LHA-1 / LHD-1 Class SSTG Aux. Control q Decentralized Control Architecture ü 3 Networked Chameleon Nodes ü 5 PCM-1, 3 NIM-1, 3 ACP-1 Installed on 4 Ships; 2 more to begin in October q Control Loops Include q ü SSTG Hotwell Level ü SSTG Recirc Temperature ü SSTG Gland Seal Pressure Control q Fully networked ü Plant-wide information accessible at any node via wireless infrared interface USS Peleliu © 2005 Fairmount Automation, Inc. All Rights Reserved. 13

LHD-1 Installation Pictures © 2005 Fairmount Automation, Inc. All Rights Reserved. 14

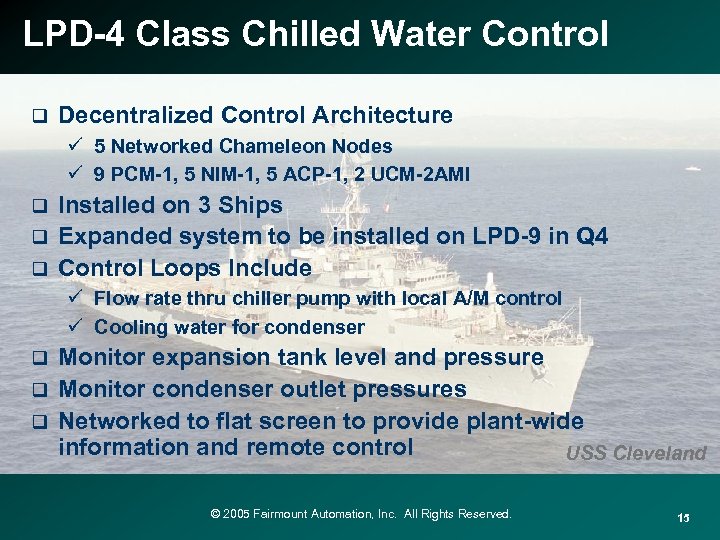

LPD-4 Class Chilled Water Control q Decentralized Control Architecture ü 5 Networked Chameleon Nodes ü 9 PCM-1, 5 NIM-1, 5 ACP-1, 2 UCM-2 AMI Installed on 3 Ships q Expanded system to be installed on LPD-9 in Q 4 q Control Loops Include q ü Flow rate thru chiller pump with local A/M control ü Cooling water for condenser Monitor expansion tank level and pressure q Monitor condenser outlet pressures q Networked to flat screen to provide plant-wide information and remote control USS Cleveland q © 2005 Fairmount Automation, Inc. All Rights Reserved. 15

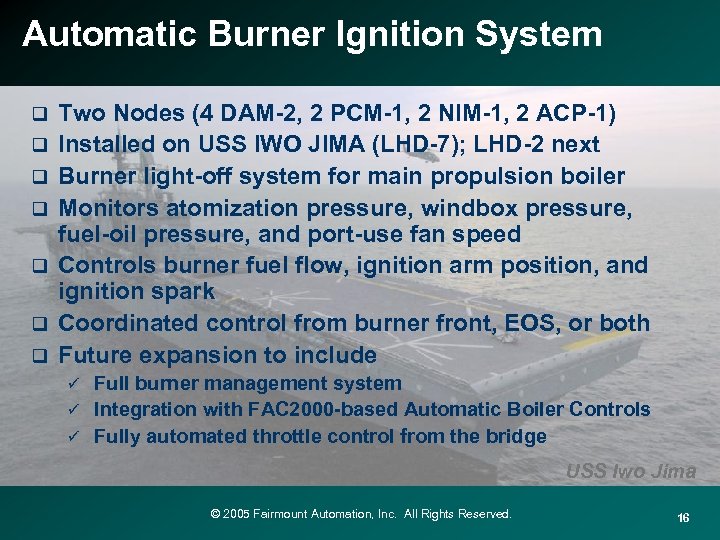

Automatic Burner Ignition System q q q q Two Nodes (4 DAM-2, 2 PCM-1, 2 NIM-1, 2 ACP-1) Installed on USS IWO JIMA (LHD-7); LHD-2 next Burner light-off system for main propulsion boiler Monitors atomization pressure, windbox pressure, fuel-oil pressure, and port-use fan speed Controls burner fuel flow, ignition arm position, and ignition spark Coordinated control from burner front, EOS, or both Future expansion to include Full burner management system ü Integration with FAC 2000 -based Automatic Boiler Controls ü Fully automated throttle control from the bridge ü USS Iwo Jima © 2005 Fairmount Automation, Inc. All Rights Reserved. 16

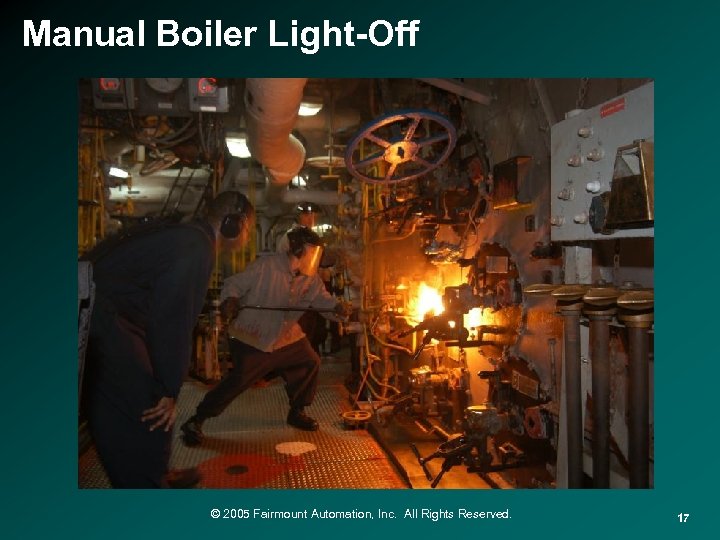

Manual Boiler Light-Off © 2005 Fairmount Automation, Inc. All Rights Reserved. 17

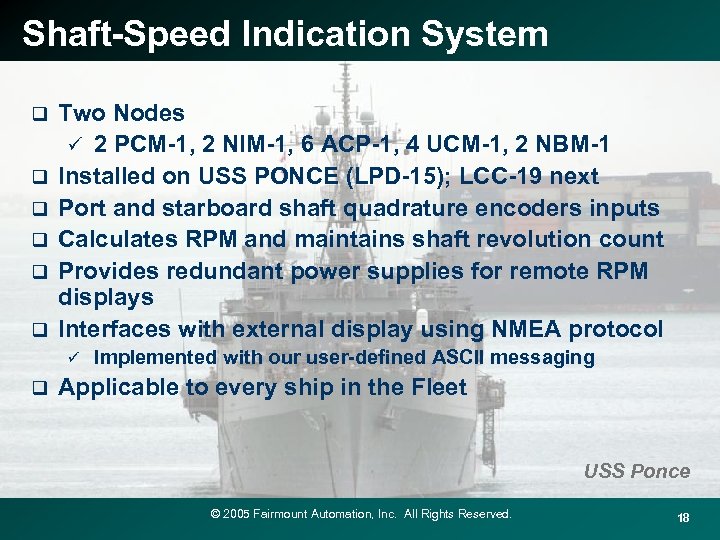

Shaft-Speed Indication System q q q Two Nodes ü 2 PCM-1, 2 NIM-1, 6 ACP-1, 4 UCM-1, 2 NBM-1 Installed on USS PONCE (LPD-15); LCC-19 next Port and starboard shaft quadrature encoders inputs Calculates RPM and maintains shaft revolution count Provides redundant power supplies for remote RPM displays Interfaces with external display using NMEA protocol ü q Implemented with our user-defined ASCII messaging Applicable to every ship in the Fleet USS Ponce © 2005 Fairmount Automation, Inc. All Rights Reserved. 18

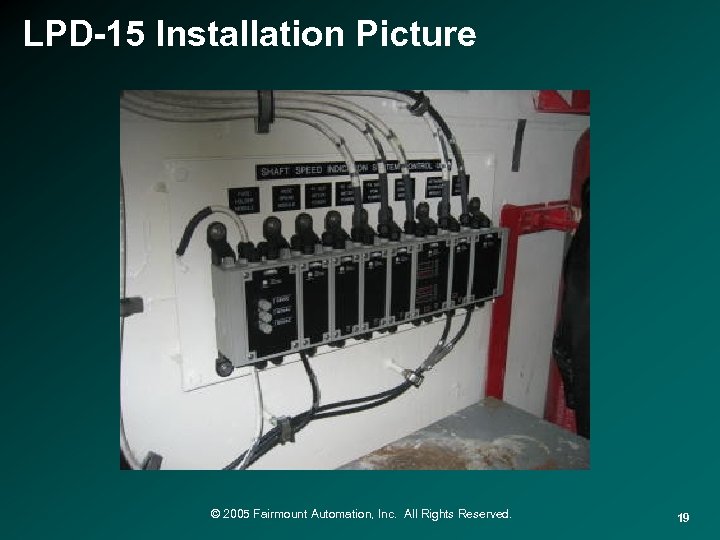

LPD-15 Installation Picture © 2005 Fairmount Automation, Inc. All Rights Reserved. 19

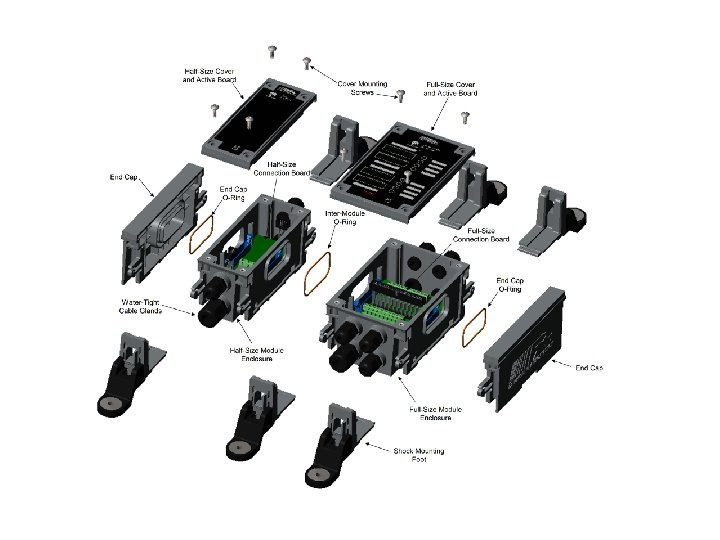

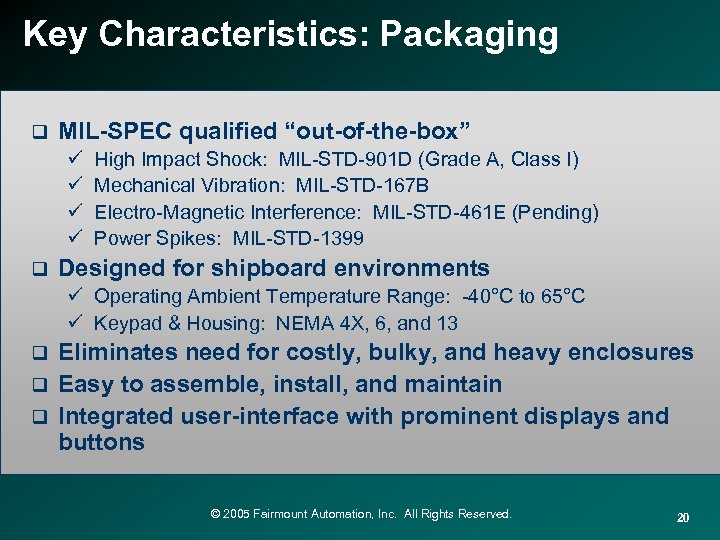

Key Characteristics: Packaging q MIL-SPEC qualified “out-of-the-box” ü ü q High Impact Shock: MIL-STD-901 D (Grade A, Class I) Mechanical Vibration: MIL-STD-167 B Electro-Magnetic Interference: MIL-STD-461 E (Pending) Power Spikes: MIL-STD-1399 Designed for shipboard environments ü Operating Ambient Temperature Range: -40°C to 65°C ü Keypad & Housing: NEMA 4 X, 6, and 13 Eliminates need for costly, bulky, and heavy enclosures q Easy to assemble, install, and maintain q Integrated user-interface with prominent displays and buttons q © 2005 Fairmount Automation, Inc. All Rights Reserved. 20

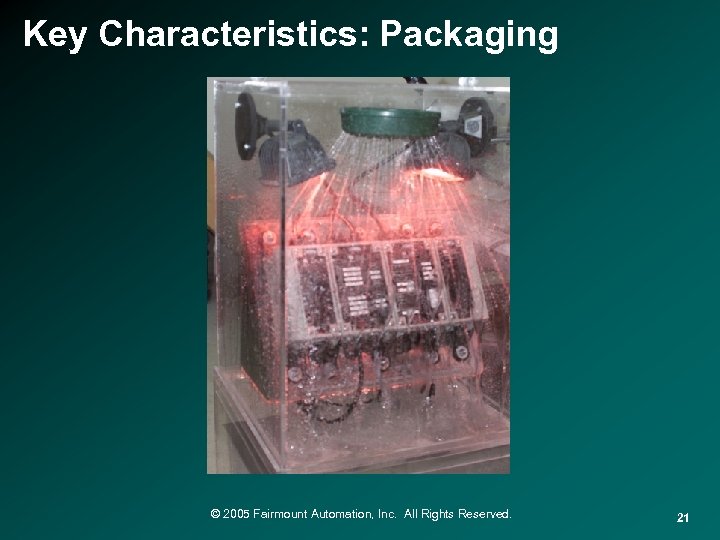

Key Characteristics: Packaging © 2005 Fairmount Automation, Inc. All Rights Reserved. 21

Key Characteristics: Modular Design q Multi-Processor architecture enhances survivability Each module is self-contained controller ü Deterministic performance (sub 10 ms) ü q q q Facilitates future technology insertion Open connectivity to standard protocols and networks Versatile I/O suite All modules are hot-swappable Highly granular redundancy I/O connections ü Control execution ü Power sources ü Network connections ü © 2005 Fairmount Automation, Inc. All Rights Reserved. 22

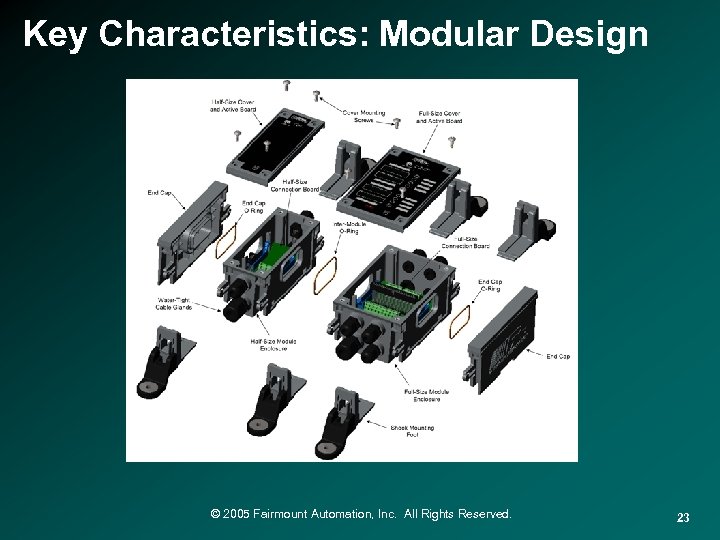

Key Characteristics: Modular Design © 2005 Fairmount Automation, Inc. All Rights Reserved. 23

Key Characteristics: Design Flexibility q Local controller for OEM equipment ü ü ü q Strainers Chillers Pumps Generators Valves Remote I/O drop Connectivity to central PLC ü Potential integration with Smart Carrier program ü q Decentralized and highly-survivable ship-wide machinery control and monitoring system © 2005 Fairmount Automation, Inc. All Rights Reserved. 24

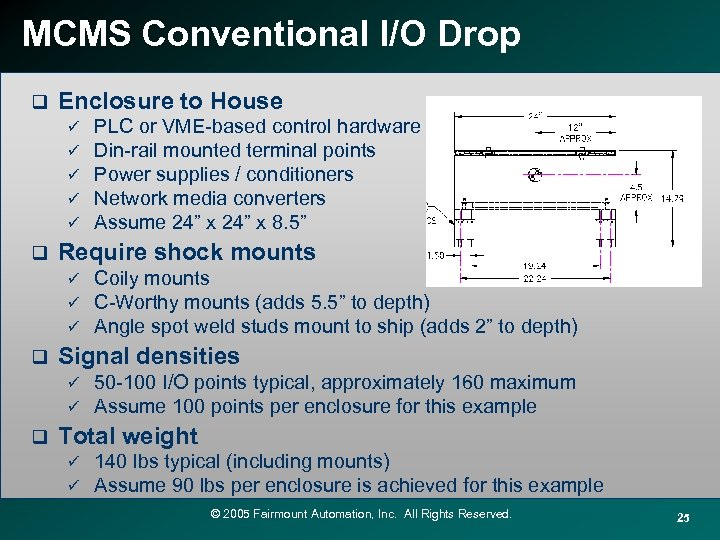

MCMS Conventional I/O Drop q Enclosure to House ü ü ü q Require shock mounts ü ü ü q Coily mounts C-Worthy mounts (adds 5. 5” to depth) Angle spot weld studs mount to ship (adds 2” to depth) Signal densities ü ü q PLC or VME-based control hardware Din-rail mounted terminal points Power supplies / conditioners Network media converters Assume 24” x 8. 5” 50 -100 I/O points typical, approximately 160 maximum Assume 100 points per enclosure for this example Total weight ü ü 140 lbs typical (including mounts) Assume 90 lbs per enclosure is achieved for this example © 2005 Fairmount Automation, Inc. All Rights Reserved. 25

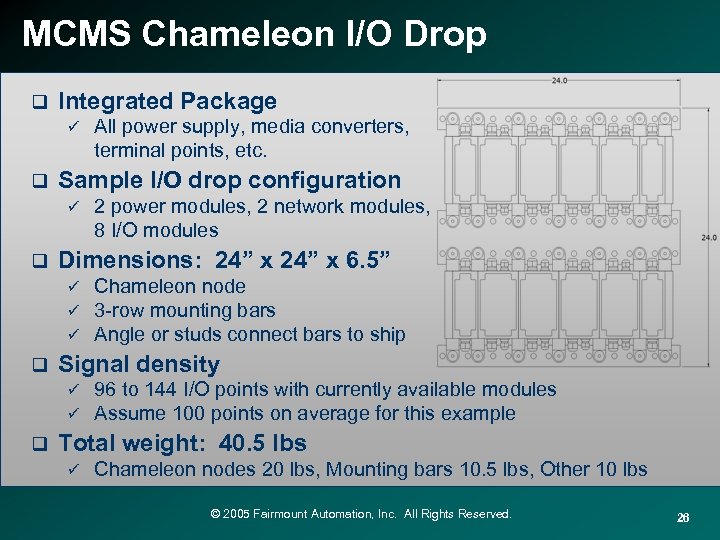

MCMS Chameleon I/O Drop q Integrated Package ü q Sample I/O drop configuration ü q Chameleon node 3 -row mounting bars Angle or studs connect bars to ship Signal density ü ü q 2 power modules, 2 network modules, 8 I/O modules Dimensions: 24” x 6. 5” ü ü ü q All power supply, media converters, terminal points, etc. 96 to 144 I/O points with currently available modules Assume 100 points on average for this example Total weight: 40. 5 lbs ü Chameleon nodes 20 lbs, Mounting bars 10. 5 lbs, Other 10 lbs © 2005 Fairmount Automation, Inc. All Rights Reserved. 26

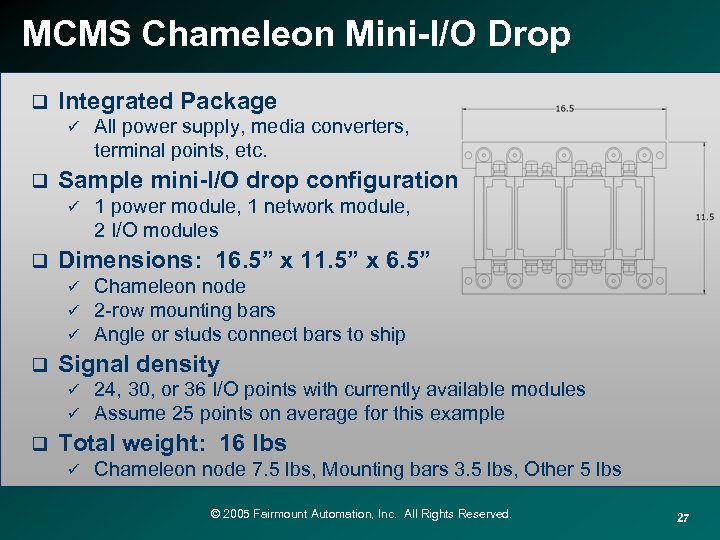

MCMS Chameleon Mini-I/O Drop q Integrated Package ü q Sample mini-I/O drop configuration ü q Chameleon node 2 -row mounting bars Angle or studs connect bars to ship Signal density ü ü q 1 power module, 1 network module, 2 I/O modules Dimensions: 16. 5” x 11. 5” x 6. 5” ü ü ü q All power supply, media converters, terminal points, etc. 24, 30, or 36 I/O points with currently available modules Assume 25 points on average for this example Total weight: 16 lbs ü Chameleon node 7. 5 lbs, Mounting bars 3. 5 lbs, Other 5 lbs © 2005 Fairmount Automation, Inc. All Rights Reserved. 27

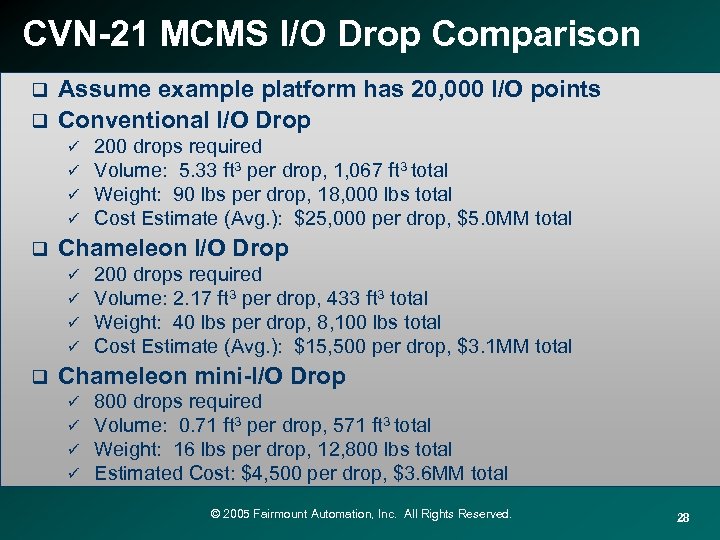

CVN-21 MCMS I/O Drop Comparison Assume example platform has 20, 000 I/O points q Conventional I/O Drop q ü ü q Chameleon I/O Drop ü ü q 200 drops required Volume: 5. 33 ft 3 per drop, 1, 067 ft 3 total Weight: 90 lbs per drop, 18, 000 lbs total Cost Estimate (Avg. ): $25, 000 per drop, $5. 0 MM total 200 drops required Volume: 2. 17 ft 3 per drop, 433 ft 3 total Weight: 40 lbs per drop, 8, 100 lbs total Cost Estimate (Avg. ): $15, 500 per drop, $3. 1 MM total Chameleon mini-I/O Drop ü ü 800 drops required Volume: 0. 71 ft 3 per drop, 571 ft 3 total Weight: 16 lbs per drop, 12, 800 lbs total Estimated Cost: $4, 500 per drop, $3. 6 MM total © 2005 Fairmount Automation, Inc. All Rights Reserved. 28

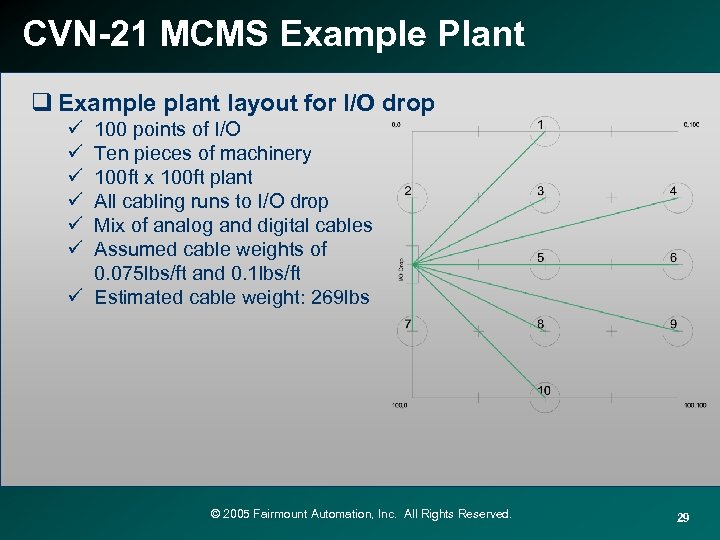

CVN-21 MCMS Example Plant q Example plant layout for I/O drop ü ü ü 100 points of I/O Ten pieces of machinery 100 ft x 100 ft plant All cabling runs to I/O drop Mix of analog and digital cables Assumed cable weights of 0. 075 lbs/ft and 0. 1 lbs/ft ü Estimated cable weight: 269 lbs © 2005 Fairmount Automation, Inc. All Rights Reserved. 29

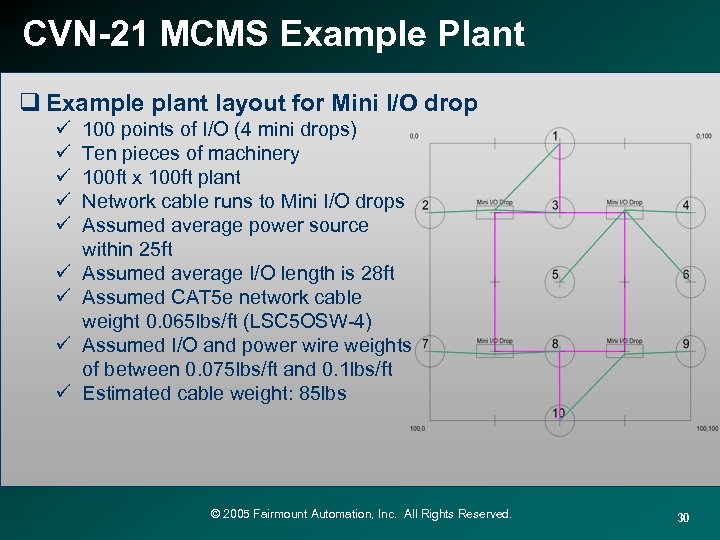

CVN-21 MCMS Example Plant q Example plant layout for Mini I/O drop ü ü ü ü ü 100 points of I/O (4 mini drops) Ten pieces of machinery 100 ft x 100 ft plant Network cable runs to Mini I/O drops Assumed average power source within 25 ft Assumed average I/O length is 28 ft Assumed CAT 5 e network cable weight 0. 065 lbs/ft (LSC 5 OSW-4) Assumed I/O and power wire weights of between 0. 075 lbs/ft and 0. 1 lbs/ft Estimated cable weight: 85 lbs © 2005 Fairmount Automation, Inc. All Rights Reserved. 30

CVN-21 MCMS Mini I/O Benefits q Assume example platform has 200 plants similar to example plant (i. e. 20, 000 points of I/O on platform) q Total Weight Comparison ü I/O drop weight • Cable: 53, 800 lbs • I/O Drops: 18, 000 lbs • Total: 71, 800 lbs ü Mini I/O drop weight • Cable: 17, 000 lbs • Mini I/O Drops: 12, 800 lbs • Total: 29, 800 lbs ü Weight Savings: 42, 000 lbs (over 18 tons or the 1. 4 times the weight of one empty F/A-18 F jet fighter!) © 2005 Fairmount Automation, Inc. All Rights Reserved. 31

CVN-21 MCMS Mini I/O Benefits q Significant cabling reduction ü ü q Cable cost savings Installation labor cost savings Design engineering cost savings (simplified drawings) Weight savings: 42, 000 lbs Simplified troubleshooting Easier to isolate wiring problems ü Can operate systems in isolation ü Don’t need to bring up all systems at once ü Improved survivability q Move towards decentralizing control q Heartbeat control ü Mode shedding ü © 2005 Fairmount Automation, Inc. All Rights Reserved. 32

Chameleon Modules q q q AC Power Module (ACP-1, ACP-1 PA) DC Power Module (DCP-1) Process Control Module (PCM-1) Discrete Automation Module (DAM-1, DAM-2) Network Interface Modules (NIM-1, NIM-3, NIM-4, NIM-6) ü ü ü q RS-485, RS-422, RS-232 Modbus Lon. Talk Fair. NET User-defined ASCII / Binary messaging User Configurable Modules (UCM-1, UCM-2 NB, UCM-2 AMI) © 2005 Fairmount Automation, Inc. All Rights Reserved. 33

AC/DC Power Modules q q q q Single or Multi Power Source Redundant Power with Automatic Switch-over Rugged packaging Spike Tolerance per MIL-STD 1399 Over-current Shut-off Input Circuit Fused ACP-1 PA Standalone Power Source © 2005 Fairmount Automation, Inc. All Rights Reserved. 34

Process Control Module (PCM-1) Process and Motion Control q Four Analog Inputs q ü q Four Analog Outputs ü q Current, Voltage Two Digital Inputs ü ü ü q Current, Voltage, Resistance, RTD On/Off, pulse counting Frequency meter, event timing Pulse width, quadrature decoding Two Digital Outputs ü On/Off, PWM, square-wave generator Four 4 -digit numeric displays q Eight 3 -color LED indicators q © 2005 Fairmount Automation, Inc. All Rights Reserved. 35

Discrete Automation Module (DAM-2) Discrete logic, sequence, batch q Ten Digital Inputs q ü ü q Broad range of AC or DC signals Configured in software Eight Digital Outputs AC or DC Individually Soft-Configured ü Hybrid Mechanical / Solid-State Relays ü Dramatically improved endurance ü Drastically reduce conducted and radiated EMI produced when switching inductive loads by maintaining zero voltage crossing turn on and zero current crossing turn off ü Four Push-Buttons q Eight 3 -color LED indicators q © 2005 Fairmount Automation, Inc. All Rights Reserved. 36

Network Interface Modules q Network Media Available Today: ü ü q NIM-1: RS-485, NIM-3: RS-422 NIM-4: RS-232, NIM-6: TP/FT 10 Network Protocols Available Today: ü ü ü Modbus (Master/Slave, RTU/ASCII) Lon. Talk Fair. NET (FAC 2000 Integration) OPC Server (ICAS Integration) Custom ASCII / Binary Protocols § § q NMEA Implementation Adaptable to custom TCP/IP messaging Currently In Development ü ü ü NIM-2: Ethernet w/ 6 -Port Switch NIM-5: Ethernet (TCP/IP, Ethernet/IP) NIM-7: Profi. BUS DP (Master/Slave) © 2005 Fairmount Automation, Inc. All Rights Reserved. 37

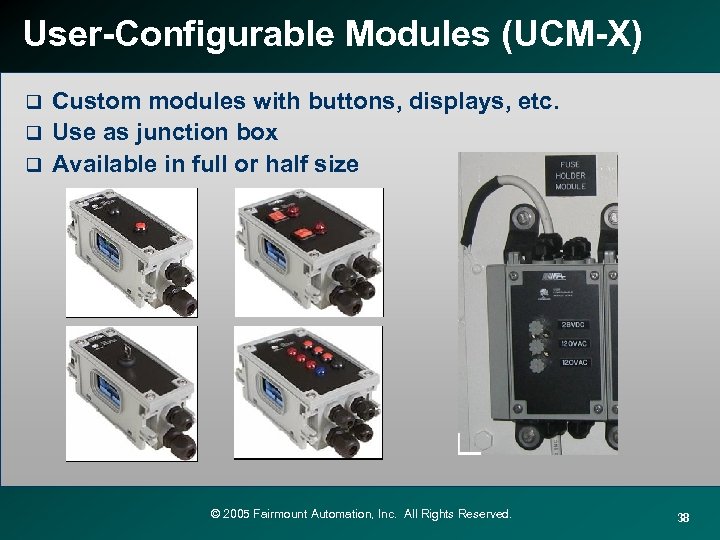

User-Configurable Modules (UCM-X) Custom modules with buttons, displays, etc. q Use as junction box q Available in full or half size q © 2005 Fairmount Automation, Inc. All Rights Reserved. 38

Development Roadmap q q q q q Networking Modules in Development: ü NIM-2: Ethernet with built-in 6 -Port Switch ü NIM-5: Ethernet (support TCP/IP, Ethernet/IP, Profi. NET) ü NIM-7: Profi. BUS DP (Master/Slave) ü NRM-1: Multi-port RS-485 Repeater Module Wireless Access Point Module ü Joint Development Program with 3 e Technologies (SBIR) ü FIPS 140. 2 Certified Wireless Security ü 802. 11 a/b/g, Zigbee Continue to Expand I/O Module Offering Touch-Screen Interface Module Motor Drive Module Battery Backup Module Direct connectivity to TSCE (DDS Protocol) Integrate C/C++ Programming with Function Blocks Plant-wide Configuration Management © 2005 Fairmount Automation, Inc. All Rights Reserved. 39

PAC Programming: Design Pad G 3 Easy to Use Graphical Programming q Intuitive Function Block Diagrams q ü Requires Little or No Training q State-Transition Diagrams ü ü q Clear and Concise Method of Programming Reduced Program Size and Complexity Organizes Complex Control into Easy to Program Nuggets Eliminates Multiple Use of Interlocks and Transition Logic Typical Using Ladder Logic Integrated Simulation Platform All signal values continuously displayed during simulation run ü Simplifies Diagnostics and Check-out by Highlighting Active States ü q Wireless Device Configuration © 2005 Fairmount Automation, Inc. All Rights Reserved. 40

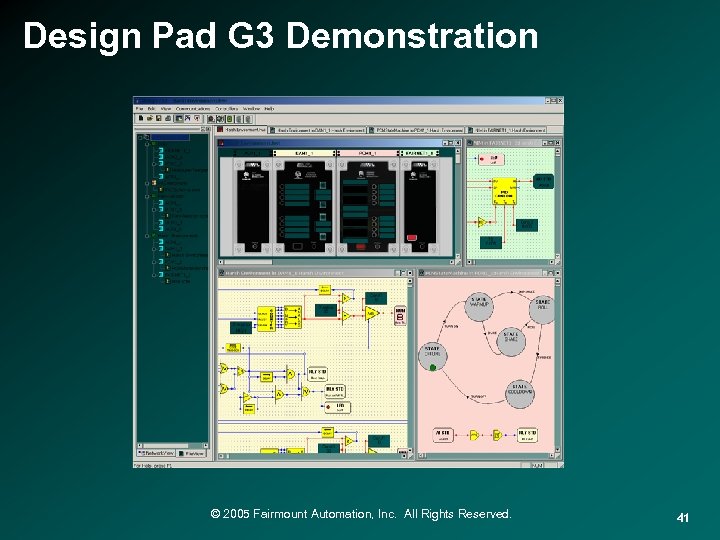

Design Pad G 3 Demonstration © 2005 Fairmount Automation, Inc. All Rights Reserved. 41

45c6b104b07f9a4dcfc61e3057d3799f.ppt