2456b1c8f43ec99b5e9fc19650b7e4e7.ppt

- Количество слайдов: 135

Program for North American Mobility in Higher Education Module 14. “Life Cycle Assessment (LCA)” : 4 steps of LCA, approaches, software, databases, subjectivity, sensitivity analysis, application to a classic example. Created by: École Polytechnique de Montréal, Instituto Mexicano del Petroleo & Universidad Autonoma de San Luis Potosi. Tier II : Case Study Application of Life Cycle Assessment Module 14

REFERENCES ü Salazar E. Munnoch K. Samson R. Stuart P. “Assessment of opportunities for environmental impact reduction from newsprint production using Life Cycle Assessment (LCA)”, Tappi journal ü Salazar E. Munnoch K. Samson R. Stuart P. “Development of a LCA Baseline Model for Newsprint Production”, Int J LCA ü HUIJBREGTS M (1998 a): “Application of Uncertainty and Variability in LCA. Part I: A General Framework for the Analysis of Uncertainty and Variability in Life Cycle Assessment”. Int J LCA 3: 5, 273 -280 ü HUIJBREGTS M (1998 b): “Application of Uncertainty and Variability in LCA. Part II: Dealing with Parameter Uncertainty and Uncertainty due to Choices in Life Cycle Assessment”. Int J LCA 3: 6, 343 -351 ü Maurice B. et al; Uncertainty Analysis in Life Cycle Inventory. “Application to the Production of Electricity with French Coal Power Plants”; J. Cleaner Prod 8 95 - 108 (2000) Tier II : Case Study Application of Life Cycle Assessment Module 14

Tier II : Purpose üCase Study Application of Life Cycle Assessment. Demonstrates the application of LCA to a Pulp & Paper case study including the interpretation stage. Tier II : Case Study Application of Life Cycle Assessment Module 14

T i e r II BACKGROUND INFORMATION Tier II : Case Study Application of Life Cycle Assessment Module 14

Tier II : Contents 1. Case study example of the application of the LCA at an integrated newsprint mill including: * Description of the System Studied * Goal and Scope definition * Life Cycle Inventory (LCI) * Life Cycle Impact Assessment (LCIA) 2. * Model Interpretation including Parameter Sensitivity Analysis “Classical” model application to identify opportunities for environmental improvements. 3. Insight into how this model might be used for “Life Cycle Thinking”: * In EMS to demonstrate continuous environmental improvement. * In EIS to quantify and communicate environmental impacts * For strategic planning. 4. Multiple choice questions Tier II : Case Study Application of Life Cycle Assessment Module 14

Tier II : Contents 1. Case study example of the application of the LCA at an integrated newsprint mill including: * Description of the System Studied * Goal and Scope definition * Life Cycle Inventory (LCI) * Life Cycle Impact Assessment (LCIA) * Model Interpretation including Parameter Sensitivity Analysis 2. “Classical” model application to identify opportunities for environmental improvements. 3. Insight into how this model might be used for “Life Cycle Thinking”: * In EMS to demonstrate continuous environmental improvement. * In EIS to quantify and communicate environmental impacts * For strategic planning. 4. Multiple choice questions Tier II : Case Study Application of Life Cycle Assessment Module 14

Tier II : Contents 1. Case study example of the application of the LCA at an integrated newsprint mill including: * Description of the System Studied * Goal and Scope definition * Life Cycle Inventory (LCI) * Life Cycle Impact Assessment (LCIA) * Model Interpretation including Parameter Sensitivity Analysis 2. “Classical” model application to identify opportunities for environmental improvements. 3. Insight into how this model might be used for “Life Cycle Thinking”: * In EMS to demonstrate continuous environmental improvement. * In EIS to quantify and communicate environmental impacts * For strategic planning. 4. Multiple choice questions Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Introduction Life Cycle Thinking is being promoted among different sectors involved on product chains. This concept implies that the impacts of all life cycle stages are comprehensively considered when taking informed decisions on production and consumption patterns, policies and management strategies. One of the most effective way to apply the Life Cycle Thinking concept in the pulp and paper industry is by using LCA in the assessment of process variants. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Description of the Study Standard newsprint production at a TMP/DIP integrated mill is the system under study. The main production chain (i. e. woodlands, sawmill and newsprint mill) is located in Northern Ontario and managed by the same company. Production of woodlands includes (in volume): 75% spruce and 25% aspen. During winter spruce logs are transported to the integrated mill by trucks, while aspen is sold to plywood; therefore this is not included as part of the system. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Description of the Study Lumber is produced from spruce logs in the on-site sawmill and is sold for the construction industry; this product is also excluded from the system. The onsite sawmill provides around 70% of the chips loaded to TMP and 55% of the hogfuel burnt at the boiler house. Additional chips and hog fuel required to cover the mill needs are purchased from local area sawmills and transported by truck to the integrated mill. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Description of the Study TMP yield is around 95%. Refining consumes 70% of the total electricity at the mill, but part of this energy is recovered as steam, which constitutes 20% of the total amount of steam consumed at the mill. The secondary fiber furnished to the DIP process includes Old Newspaper (ONP) and Coated Groundwood Specialty (CGS); they are purchased mainly from Ontario and USA and transported to the mill by truck or rail. The yield of the DIP by Dissolved Air Floatation process is around 85%. TMP and DIP pulps are furnished to four paper machines in a ratio of 4 to 1, respectively to produce standard newsprint. This newsprint is distributed to Ontario, Quebec and US cities by truck and rail. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Description of the Study The steam required for the process is produced on-site from the following energy sources: hog fuel (44%), natural gas (48%) and sludges (8%). Most of the steam is consumed by the paper machines (70% of the total process steam). The effluents of the integrated mill receive primary and a secondary treatment, the sludges produced in the effluent treatment plant are combined with those from DIP and then dewatered, 50% of the sludge is burnt in the boiler house and the rest is landfilled on-site. Almost all the electricity consumed at the integrated mill (around 98%) is purchased from the grid, where the at-source power mix is the following: 33% fossil (coal), 39% nuclear and 28% hydro. Tier II : Case Study Application of Life Cycle Assessment Module 14

Tier II : Contents 1. Case study example of the application of the LCA at an integrated newsprint mill including: * Description of the System Studied * Goal and Scope definition * Life Cycle Inventory (LCI) * Life Cycle Impact Assessment (LCIA) * Model Interpretation including Parameter Sensitivity Analysis 2. “Classical” model application to identify opportunities for environmental improvements. 3. Insight into how this model might be used for “Life Cycle Thinking”: * In EMS to demonstrate continuous environmental improvement. * In EIS to quantify and communicate environmental impacts * For strategic planning. 4. Multiple choice questions Tier II : Case Study Application of Life Cycle Assessment Module 14

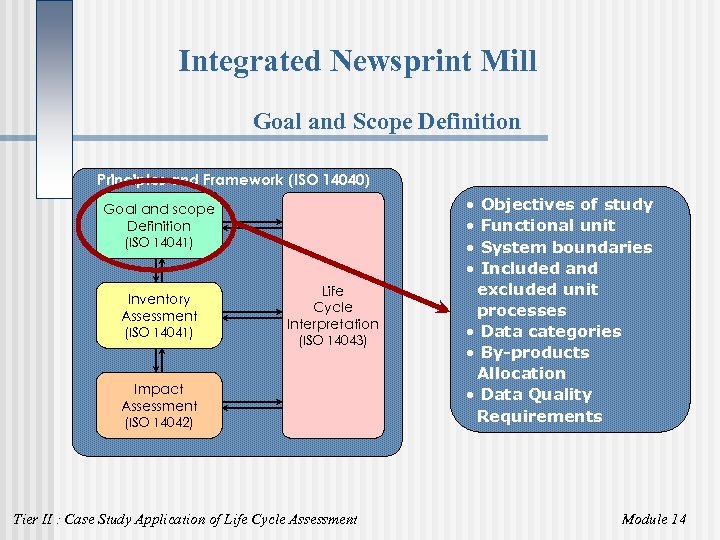

Integrated Newsprint Mill Goal and Scope Definition Principles and Framework (ISO 14040) • • Goal and scope Definition (ISO 14041) Inventory Assessment (ISO 14041) Life Cycle Interpretation (ISO 14043) Impact Assessment (ISO 14042) Tier II : Case Study Application of Life Cycle Assessment Objectives of study Functional unit System boundaries Included and excluded unit processes • Data categories • By-products Allocation • Data Quality Requirements Module 14

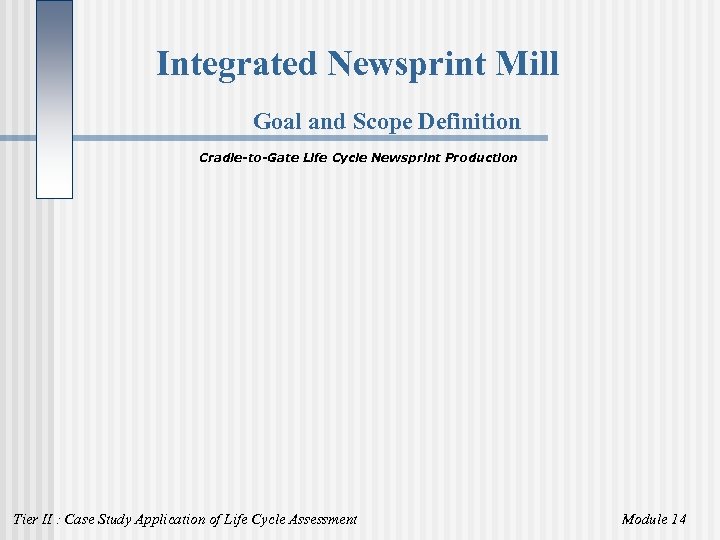

Integrated Newsprint Mill Goal and Scope Definition The objective of the study is to build a baseline model that can be used to demonstrate continuous environmental improvement and to assess future major process modifications. The functional unit was defined as the production an distribution of 1 ton of newsprint with 10% moisture content (air dried metric ton: admt); the system boundaries include the production chain from wood extraction to newsprint distribution (cradle-to-gate). The next figure depicts the system boundaries. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Goal and Scope Definition Cradle-to-Gate Life Cycle Newsprint Production Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Goal and Scope Definition Transportation of waste paper from warehouses and its disposition in municipal landfills as the alternative of recycling at the mill were modeled in order to assess potential changes on the DIP content of the newsprint. Raw materials (i. e. logs, chips, hogfuel and waste paper) transportation is included. Wastepaper transportation from curbside to material recovery facilities as well as chemicals transportation to the newsprint mill are excluded since they are negligible in comparison with the raw material transportation (Terrachoice 1997). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Goal and Scope Definition Newspaper printing, use and disposal are excluded because it is assumed that process variants do not significantly affect the environmental impacts of these stages. For instance, the increase of recycled content of the newsprint affects the printability and appearance properties of newspapers in pressrooms and consequently more ink is required (Smook 1992). However this effects are negligible compared with others involved in this kind of modification (e. g. more wastepaper transportation, less electricity consumption, less wastepaper to landfill, etc). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Goal and Scope Definition Manufacturing, maintenance and disassembly of assets are not included in the system boundaries since these are used for a large number of functional units during their life cycles and their impact for one functional unit is negligible. Data categories used on the study: • By type: measured, calculated, estimated • By source: primary (from the studied site/company) and secondary (from commercial databases) Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Goal and Scope Definition According to ISO, for process with outputs that can be partially co-products and partially wastes, the environmental burdens can be allocated only to the coproducts (ISO 1999). In this case study, the environmental burdens are allocated among lumber, chips and hog fuel because newsprint production depends on the latter two outflows to cover their fiber and energy requirements, respectively, and otherwise they would be substituted by other virgin materials. Nonetheless, the effect of alternative allocation approaches on the results is assessed in the interpretation phase. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Goal and Scope Definition Data Sources and Data Quality Requirements For the inventory analysis, its used primary data for the processes with major contributions (i. e. integrated mill, electricity production) and secondary data for the background systems with less contribution (i. e. fuel and chemical production, industrial landfill) and we modeled the system in the LCA software SIMAPRO 5. 1. Chemicals and fuels production as ell as landfill are modeled using commercial databases. The following data quality requirements were initially set: Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Goal and Scope Definition ü Time : The year of inventory collection is 2001. Data from five years before is desirable. ü Geography : The system under study is located in Northern Ontario. North American data is desirable. ü Technology : Average technology is desirable. However, only for fuels production the available databases matched with these criteria (i. e. Franklin database: American average 1995 -1999). For chemicals production, European databases are used (i. e. IVAM and BUWAL: European averages 1990 -1994; KCLECO: Finnish averages 1992). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Goal and Scope Definition In the case of chemicals for which no specific databases were available (e. g. chelan, coagulants, flocculants and polymers), general databases (e. g. chemicals organic ETH: European averages 1990 -1994) are used instead. Landfill models are as well based on a European database (i. e. KCLECO). The effect of the gaps between the initial data quality requirements and the quality of data actually used on the base line model is assessed on the interpretation phase. Tier II : Case Study Application of Life Cycle Assessment Module 14

Tier II : Contents 1. Case study example of the application of the LCA at an integrated newsprint mill including: * Description of the System Studied * Goal and Scope definition * Life Cycle Inventory (LCI) * Life Cycle Impact Assessment (LCIA) * Model Interpretation including Parameter Sensitivity Analysis 2. “Classical” model application to identify opportunities for environmental improvements. 3. Insight into how this model might be used for “Life Cycle Thinking”: * In EMS to demonstrate continuous environmental improvement. * In EIS to quantify and communicate environmental impacts * For strategic planning. 4. Multiple choice questions Tier II : Case Study Application of Life Cycle Assessment Module 14

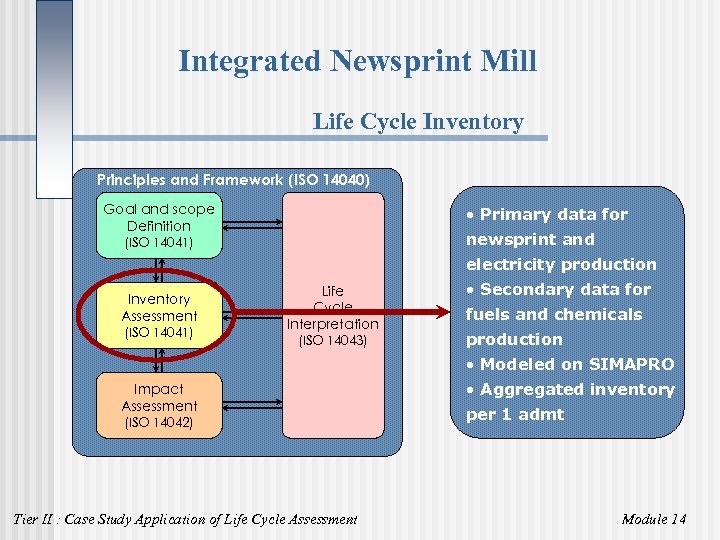

Integrated Newsprint Mill Life Cycle Inventory Principles and Framework (ISO 14040) Goal and scope Definition • Primary data for newsprint and (ISO 14041) electricity production Inventory Assessment (ISO 14041) Life Cycle Interpretation (ISO 14043) • Secondary data for fuels and chemicals production • Modeled on SIMAPRO Impact Assessment (ISO 14042) Tier II : Case Study Application of Life Cycle Assessment • Aggregated inventory per 1 admt Module 14

Integrated Newsprint Mill Life Cycle Inventory The inventory results per 1 admt of newsprint, includes hundreds of substances, from which the most important in terms of mass are presented and discussed in this section. In order to have a better visualization, we have grouped the inventory substances and present the results in graphs, showing the contribution of different system processes to the total amount of substance emitted. Note that in some cases, the scales have been modified in order to show all the substances of a group in the same graph. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Inventory Sawmill Model Around 30% chips and 40% hogfuel consumed by the newsprint mill is supplied by local sawmills, having independent supply systems (i. e. chips and hogfuel usually are not supplied by the same sawmill). In this study, on-site sawmill model is considered as an average for the production of the total amount of chips and hogfuel required per 1 admt of newsprint. In fact, electricity and steam consumptions are similar between involved sawmills, the only difference can be the energy sources, especially for steam because the fuel breakdown in the newsprint mill boiler house might not be representative for all the local sawmills. However, this difference can be considered negligible if we take into account that steam consumption from sawmill is only 5% of the total system consumption. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Inventory Transportation Models Round trip is considered for logs transportation and fuel consumption is based on primary data. One-way trip is considered for chips, hogfuel and wastepaper supply as ell as for newsprint distribution; return is not included because usually cargo from other companies or systems is transported in the round way. Fuel consumption is based on mass transported (t or number of loads) and average distances, using fuel efficiency factors (L/km or L/t-km) for truck and locomotive recommended in EPDS guidelines (Terrachoice 1997). Air emissions are calculated based on fuel consumption using emissions factors from the references recommended by EPDS guidelines (Terrachoice 1997); and from Franklin database, sourced on USEPA AP-42 MOBILE model, in the case of particles. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Inventory CO 2 Emissions from Biomass Combustion There is debate among life cycle practitioners about whether or not include CO 2 emissions from biomass combustion in the inventory analysis, especially when comparing two alternative energy sources (Reijnders et al. 2003). In this case study, it was applied the natural approach recommended by the International Council of Forest and Paper Association which is compatible which most internationals protocols, including that of the IPPC. This approach is based on the assumption that CO 2 emitted from biomass combustion is the atmospheric CO 2 that was sequestered during growth of the tree; hence, there is no net contribution to the atmospheric CO 2 level (NCASI 2001). Tier II : Case Study Application of Life Cycle Assessment Module 14

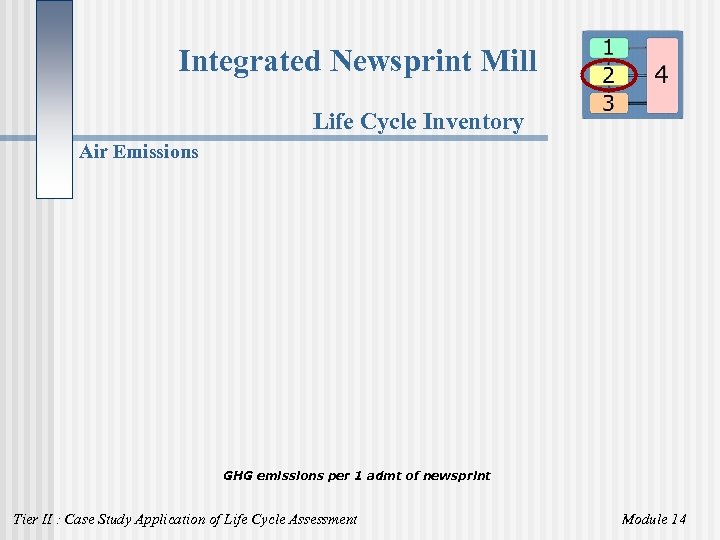

Integrated Newsprint Mill Life Cycle Inventory Air Emissions The following figures present the inventory results for Green House Gases (GHG), gases and particulates, respectively. For all the air emissions, the contribution from chemical production is negligible compared with the other processes (<5%), therefore it is not shown in the graphs. From the next figure: CO 2 is emitted in much higher amounts than methane and N 2 O. Most of the CO 2 (i. e. 79%) is emitted from electricity production; note however that data of GHG emission from electricity production was collected already as CO 2 eq. For methane and N 2 O, the mill direct emissions present more important contributions: 88% of methane is emitted from industrial landfill and 55% of N 2 O from biomass combustion at the boiler house. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Inventory Air Emissions GHG emissions per 1 admt of newsprint Tier II : Case Study Application of Life Cycle Assessment Module 14

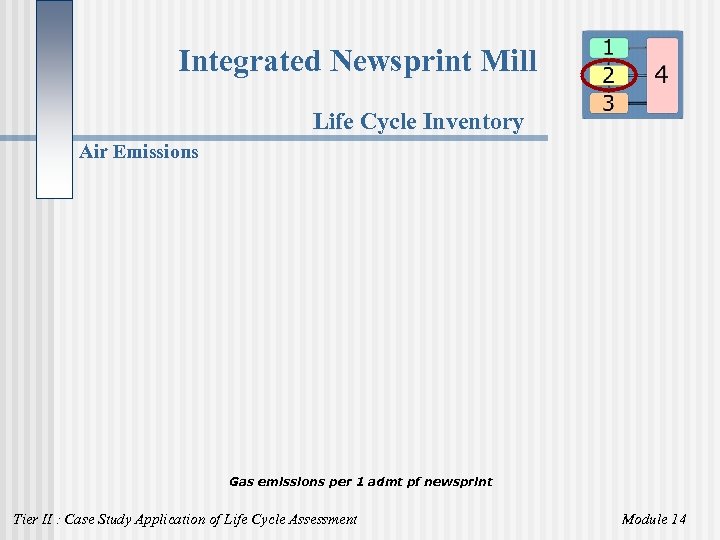

Integrated Newsprint Mill Life Cycle Inventory Air Emissions The next figure shows that there is less variability on the amount of gases emitted compared to the GHG results. SO 2 is the gas emitted in the highest amount, mainly from electricity production (57%) and fuels production (38%). CO and NOX are emitted almost in equal amounts; their main contributors are biomass combustion (43% on CO) and electricity production (45% on NOX). VOC is emitted in the least amount, mainly from fuel production (69%). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Inventory Air Emissions Gas emissions per 1 admt pf newsprint Tier II : Case Study Application of Life Cycle Assessment Module 14

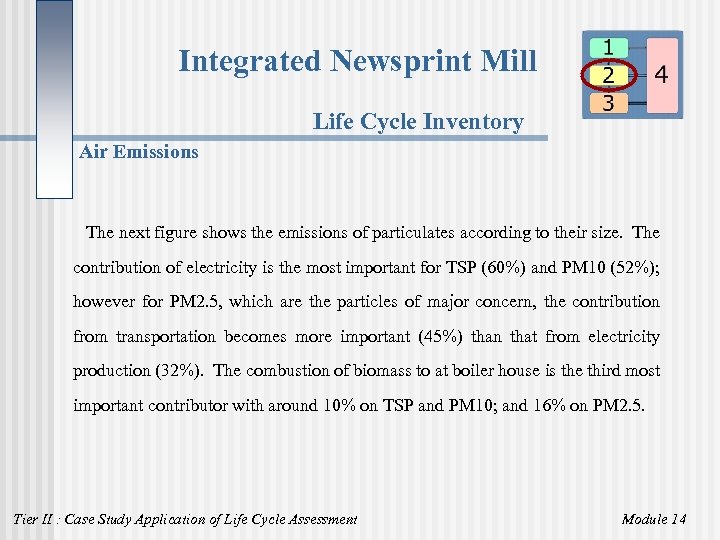

Integrated Newsprint Mill Life Cycle Inventory Air Emissions The next figure shows the emissions of particulates according to their size. The contribution of electricity is the most important for TSP (60%) and PM 10 (52%); however for PM 2. 5, which are the particles of major concern, the contribution from transportation becomes more important (45%) than that from electricity production (32%). The combustion of biomass to at boiler house is the third most important contributor with around 10% on TSP and PM 10; and 16% on PM 2. 5. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Inventory Air Emissions Particulate emissions per 1 admt Tier II : Case Study Application of Life Cycle Assessment Module 14

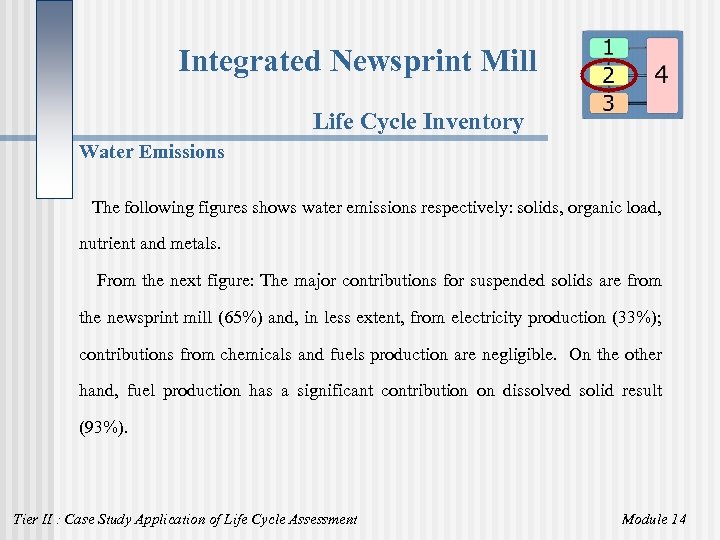

Integrated Newsprint Mill Life Cycle Inventory Water Emissions The following figures shows water emissions respectively: solids, organic load, nutrient and metals. From the next figure: The major contributions for suspended solids are from the newsprint mill (65%) and, in less extent, from electricity production (33%); contributions from chemicals and fuels production are negligible. On the other hand, fuel production has a significant contribution on dissolved solid result (93%). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Inventory Water Emissions Solid emissions to water per 1 admt of newsprint Tier II : Case Study Application of Life Cycle Assessment Module 14

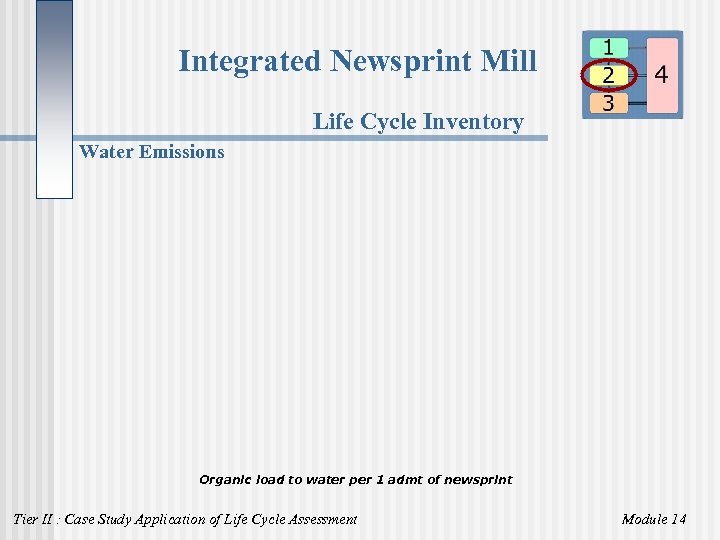

Integrated Newsprint Mill Life Cycle Inventory Water Emissions The next figure shows the results for two organic load indicators: BOD 5 and COD. Around 99% of the organic load (for both indicators) comes from newsprint mill. Indirect emissions are shown separately for a better visualization and it is observed that among the indirect emitters, fuels production has the highest contribution. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Inventory Water Emissions Organic load to water per 1 admt of newsprint Tier II : Case Study Application of Life Cycle Assessment Module 14

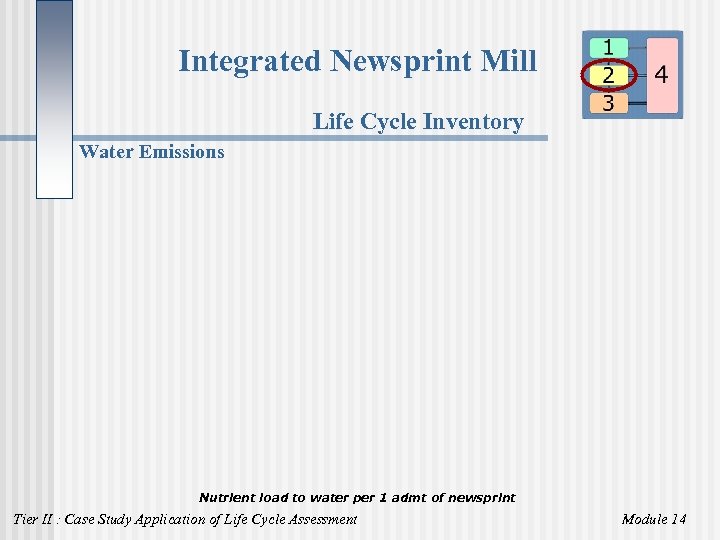

Integrated Newsprint Mill Life Cycle Inventory Water Emissions The next figure shows the nutrient load in two indicators: N-t and P -t. Like in the case of organic load, the major contribution comes from newsprint production: 99% on N-t and 93% on P-t. The second major contributor to P-t emissions is electricity production with 7%. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Inventory Water Emissions Nutrient load to water per 1 admt of newsprint Tier II : Case Study Application of Life Cycle Assessment Module 14

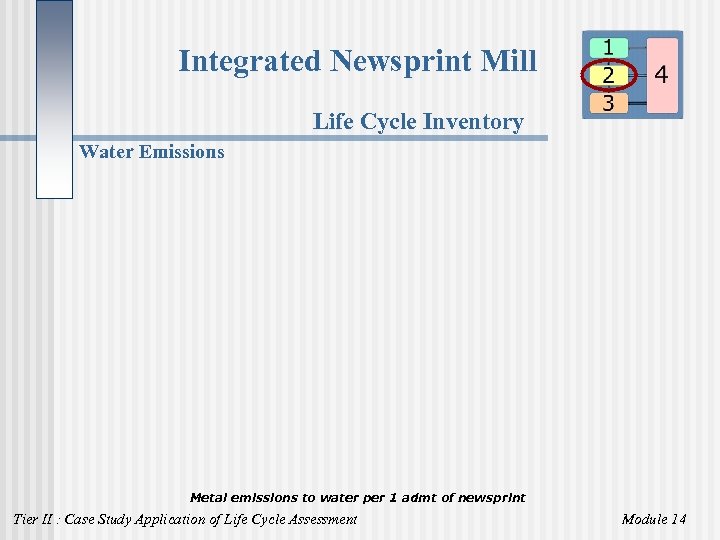

Integrated Newsprint Mill Life Cycle Inventory Water Emissions The next figure shows the most significant metals en terms of mass (i. e. >1 g/admt). Only for Zn and Mn which are natural wood constituents, newsprint production presents the highest contribution (around 98%); while for the rest of the metals, the major contributor is the chemicals production. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Inventory Water Emissions Metal emissions to water per 1 admt of newsprint Tier II : Case Study Application of Life Cycle Assessment Module 14

Tier II : Contents 1. Case study example of the application of the LCA at an integrated newsprint mill including: * Description of the System Studied * Goal and Scope definition * Life Cycle Inventory (LCI) * Life Cycle Impact Assessment (LCIA) * Model Interpretation including Parameter Sensitivity Analysis 2. “Classical” model application to identify opportunities for environmental improvements. 3. Insight into how this model might be used for “Life Cycle Thinking”: * In EMS to demonstrate continuous environmental improvement. * In EIS to quantify and communicate environmental impacts * For strategic planning. 4. Multiple choice questions Tier II : Case Study Application of Life Cycle Assessment Module 14

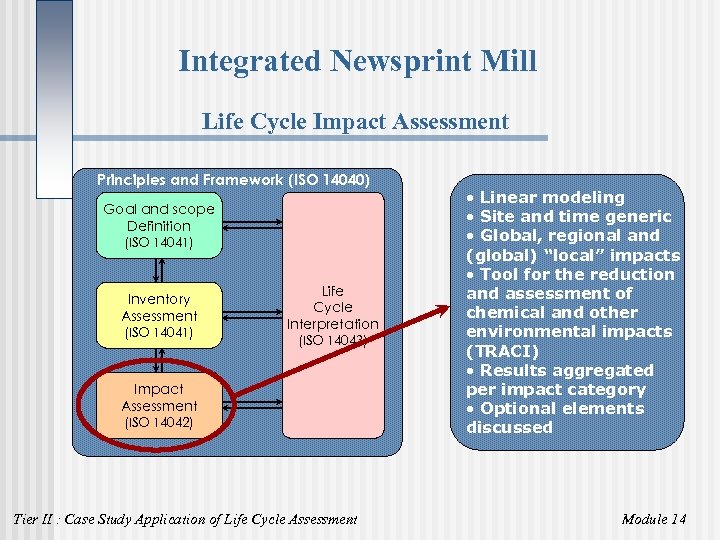

Integrated Newsprint Mill Life Cycle Impact Assessment Principles and Framework (ISO 14040) Goal and scope Definition (ISO 14041) Inventory Assessment (ISO 14041) Life Cycle Interpretation (ISO 14043) Impact Assessment (ISO 14042) Tier II : Case Study Application of Life Cycle Assessment • Linear modeling • Site and time generic • Global, regional and (global) “local” impacts • Tool for the reduction and assessment of chemical and other environmental impacts (TRACI) • Results aggregated per impact category • Optional elements discussed Module 14

Integrated Newsprint Mill Life Cycle Impact Assessment Main Assumptions and Simplifications: For this study, the output related impact categories proposed by SETAC have been included. Most of the category indicators have been chosen at midpoint, except for human health particles which is assessed at endpoint level. TRACI is used for the assessment after verifying that meets the ISO requirements and SETAC recommendations. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Impact Assessment Selection of Impact Categories, Category Indicators and Characterization Models Selection of impact categories, category indicators and characterization models was performed according to the objectives and context of the study and based on SETAC best available practices which are ISO compatibles (Udo de Haes et al. 1999 a). The next table summarizes the results of this process. Input related impact categories (i. e. abiotic resources and land use) are not included on the study mainly because best available methods have not been yet identified (Udo de Haes et al. 2002). Furthermore, the impact of biotic resources is not relevant to this study since the wood resource in the system (i. e. spruce) is from man-controlled cultures and therefore is not depleted (Udo de Haes et al. 2002). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Impact Assessment Selection of Impact Categories, Category Indicators and Characterization Models Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Impact Assessment Selection of Impact Categories, Category Indicators and Characterization Models In the case of land use, available methods were reviewed (Weidema 2001, Lindeijer et al 2002), however the lack of the specific data for the activities related with the system studied was a constraint to characterize this impact. Nonetheless, inventory data is included in the base line model in order to analyze results at inventory level and incorporate the appropriate models when they are available. All the output related impact categories recommended by SETAC are included (Udo de Haes et al. 1999 b). Global impacts are modeled at midpoint level using the International Panel on Climate Change (IPCC, time horizon: 100 y) and World Meteorological Organization (WMO, time horizon: infinite) characterization factors for global warming and ozone depletion, respectively. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Impact Assessment Selection of Impact Categories, Category Indicators and Characterization Models Regional impacts are modeled at midpoint using the Toll for the Reduction and Assessment of Chemicals and Other Environmental Impacts (TRACI) method from the United States Environmental Protection Agency. This method was selected because it includes spatial differentiation in fate and sensitivity recommended by SETAC (Udo de Haes et al. 1999 b) and because it has been demonstrated the potentially important influence of release location upon the strength of expected impact (Norris 2003, Hauschild et al. 2003). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Impact Assessment Selection of Impact Categories, Category Indicators and Characterization Models For local impacts, Traci models were also selected. Ecotoxicity, human health cancer and human health non cancer are modeled at midpoint level using multimedia fate modeling for US average conditions while human health particles is modeled at endpoint level and characterization factors are available per state (Bare et al. 2003). Michigan was selected as reference state in the latter case. Compatibility with SETAC recommendations were as well identified for these impacts including the use of midpoint toxicity indicators for species composition for terrestrial and aquatic ecosystems and the division of human health impacts in disability-type subcategories (Udo de Haes et al. 1999 b). Tier II : Case Study Application of Life Cycle Assessment Module 14

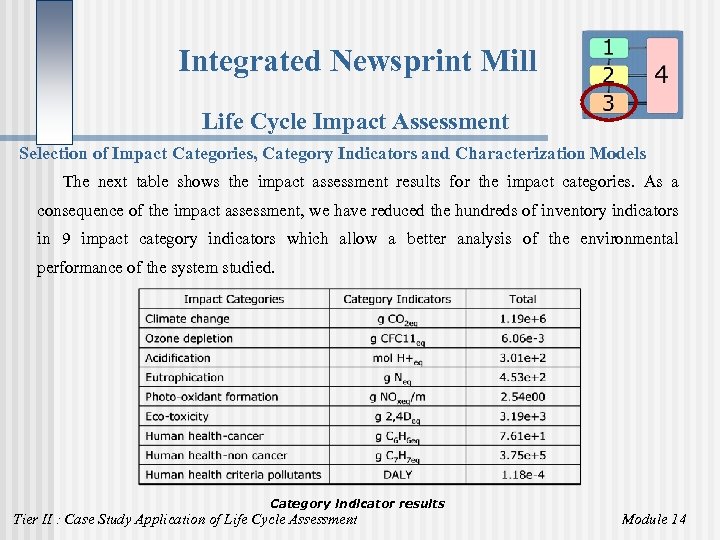

Integrated Newsprint Mill Life Cycle Impact Assessment Selection of Impact Categories, Category Indicators and Characterization Models The next table shows the impact assessment results for the impact categories. As a consequence of the impact assessment, we have reduced the hundreds of inventory indicators in 9 impact category indicators which allow a better analysis of the environmental performance of the system studied. Category indicator results Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Impact Assessment Particle Size Distribution The following assumptions and models were applied in order to calculate the particulates size distribution for these processes: ü Natural gas pre-combustion and combustion: Particulates emitted from natural gas combustion are smaller than 1 micrometer (USEPA 1998). In the natural gas production process, particulates are emitted from compressor engines that fire natural gas (USEPA 1995 a); therefore, the same particulates size distribution is used. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Impact Assessment Particle Size Distribution üDiesel pre-combustion: Size distribution for industrial boilers firing residual oil (USEPA 1995 b) was included on the model. Actually, in the diesel production process there is also particulates emission from the cracking processes; however, due to lack of information about the size distribution of this operation, distribution for industrial boilers is considered as representative for the whole process. ü Transportation road/rail: Size distribution for diesel vehicles (USEPA 2003) was included on the model. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Impact Assessment Particle Size Distribution Emission data from processes with small contribution on the particulate inventory per 1 admt of newsprint were not refined by including size distribution (i. e. chemicals production as well as gasoline, propane and kerosene combustion and pre -combustion). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Impact Assessment Total Suspended Solids (TSS) Characterization TSS refers to the amount of fiber in pulp and paper mill effluents and it is regulated by the Canadian Pulp and Paper Effluent Regulation under the Fisheries Act (Environmental Canada 2003). TSS is not characterized by existent life cycle impact assessment models. However, due to its biological nature, it can be assumed that TSS impacts are already accounted by BOD characterization in eutrophication impact category. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Impact Assessment Organic Load Characterization TRACI eutrophication model includes separate characterization factors for BOD and COD (i. e. Chemical Oxygen Demand) and recommends characterizing only COD when both parameters are available for any unit processes, in order to avoid double counting (Norris 2003). This recommendation has been applied in all the unit processes of the system studied but the newsprint mill because the effluent characteristics (i. e. low biodegradability of the organic suspended solids and nutrient content) correspond to those for which COD is an overestimation of the total environmental oxygen demand (Norris 2003). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Impact Assessment Normalization Two references recommended by ISO (ISO 2001 a) were evaluated for normalizing the characterization results in order to understand better the relative magnitude of the impacts from newsprint production. However, the lack of representative data was a constraint for the quantification. ü Baseline scenario for the system under study: The average cradle-to-gate life cycle of newsprint production in North American context is the best reference scenario for this particular case study. However, it is not yet available. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Impact Assessment Normalization ü Emissions per capita: Data to calculate the normalization factors for this reference is available; however, some data gaps were found referred to significant emissions from the system (e. g. BOD) that did not allow calculating a representative normalization profile. For the intended applications (i. e. assessment of process modifications, demonstration of continuous improvement and design of minimum impact mill configuration), it is recommended to use the characterization results of this baseline model as normalization reference. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Impact Assessment Weighting The question of weighting arises when trade-offs among impacts categories are involved (i. e. when it cannot be unambiguously decided that one option is environmentally preferable to another for all the impact categories included on the study). This optional step is therefore not applied on this descriptive study but it will be most likely necessary to include in the intended applications. Various weighting methods are covered on the literature and it has been showed that they may lead to different results. However, they remain a controversial issue and it does not exist a single favored weighting method for the use in LCA (Udo de Haes et al 2002, Hofstetter 1999, Finnveden 1999). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Impact Assessment Organic Load Characterization For the case studies referred to the intended applications, the definition of weighting factors must be transparent; sensitivity analysis should be performed in order to illustrate the effects of this choice and the weighted profile should be considered as an input to the interpretation phase as opposed to the final answer, as recommended by (Bengtsson et al. 2000). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Life Cycle Impact Assessment Peer Review Process A formal internal peer review of this case study is being carried out by LCA experts from the Interuniversity Reference Centre for the Life Cycle Assessment, Interpretation and Management of Products, Processes and Services (CIRAIG) from the Ecole Polytechnique de Montreal, following ISO protocol (ISO 1997). This peer-review includes the methodology for each of the four LCA phases as well as the calculation procedures, input data and results. Tier II : Case Study Application of Life Cycle Assessment Module 14

Tier II : Contents 1. Case study example of the application of the LCA at an integrated newsprint mill including: * Description of the System Studied * Goal and Scope definition * Life Cycle Inventory (LCI) * Life Cycle Impact Assessment (LCIA) * Model Interpretation including Parameter Sensitivity Analysis 2. “Classical” model application to identify opportunities for environmental improvements. 3. Insight into how this model might be used for “Life Cycle Thinking”: * In EMS to demonstrate continuous environmental improvement. * In EIS to quantify and communicate environmental impacts * For strategic planning. 4. Multiple choice questions Tier II : Case Study Application of Life Cycle Assessment Module 14

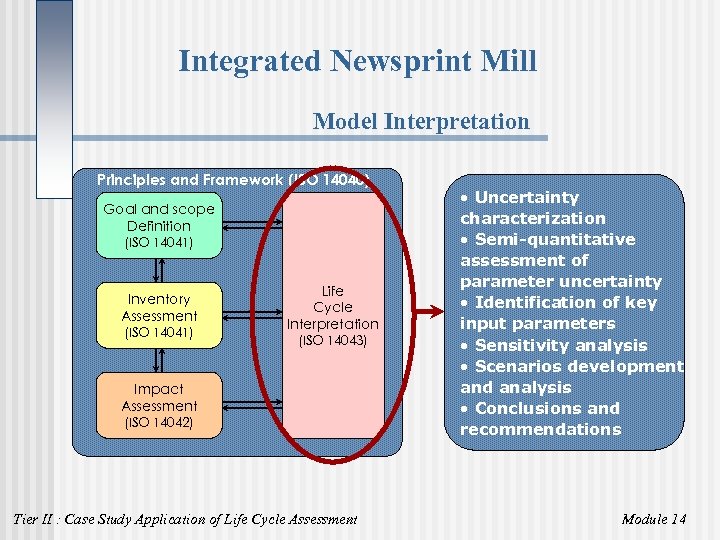

Integrated Newsprint Mill Model Interpretation Principles and Framework (ISO 14040) Goal and scope Definition (ISO 14041) Inventory Assessment (ISO 14041) Life Cycle Interpretation (ISO 14043) Impact Assessment (ISO 14042) Tier II : Case Study Application of Life Cycle Assessment • Uncertainty characterization • Semi-quantitative assessment of parameter uncertainty • Identification of key input parameters • Sensitivity analysis • Scenarios development and analysis • Conclusions and recommendations Module 14

Integrated Newsprint Mill Model Interpretation Discussion Twenty six parameters were selected as “key”. Most of the impact categories showed significant sensitivity (>10%) on energy consumption at the newsprint mill, including electricity and natural gas consumption. Eutrophication showed significant sensitivity only on N-t emissions in the newsprint mill effluent. Among background parameters, sensitivities higher than 20% were found for data on ozone depleting emissions from DTPA (i. e. chelant) production, arsenic emission to water from soda production, mercury and arsenic emissions to air from electricity production and methane emissions from industrial landfill. The impact categories affected for these parameters were global warming, ozone depletion, ecotoxicity and human toxicity. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation Discussion For the assessment of methodological choices, the analysis of two alternative by-product allocation approaches in sawmill operations shows a variation on the category indicator results from 2% to 13% when the total burdens are allocated to the main product (i. e. lumber). It was also found that the exclusion of wastepaper collection from the system does not affect the final results. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation Identification of Key Parameters A large number of parameters are introduced in the life cycle inventory phase, depending on the scope and complexity of the system under study. Therefore, it is important to systematically select the key parameters on which the interpretation analysis will be focused. A broad sensitivity analysis using standard uncertainty estimates has been recommended (Sakai et al. 2002, Heijungs et al. 2001, Heijungs 1996). However, a disadvantage of using a standard sensitivity range is that parameters with a minor contribution to LCA outcomes but with a large unknown uncertainty range are eliminated from the analysis (Huijbregts 1998 b). An alternative approach is to identify the key input parameters based on the contribution of input data to the results and a qualitative assessment of the data uncertainty (Maurice et al 2000). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation Identification of Key Parameters This latter approach is applied on the baseline model, with some modifications. The procedure is performed per impact category and is explained below, illustrating it with the example of Global Warming (GW). Step 1: Calculate the contribution per substance and do a cut off (e. g. 1%) in order to reduce the analysis only for those substances with major contributions to the indicator result. Ex: From thirteen green house gases (GHG) included on the study, 99. 2% of the total GW indicator result represents the contribution of CO 2 (90. 6%) and methane (8. 6%). Tier II : Case Study Application of Life Cycle Assessment Module 14

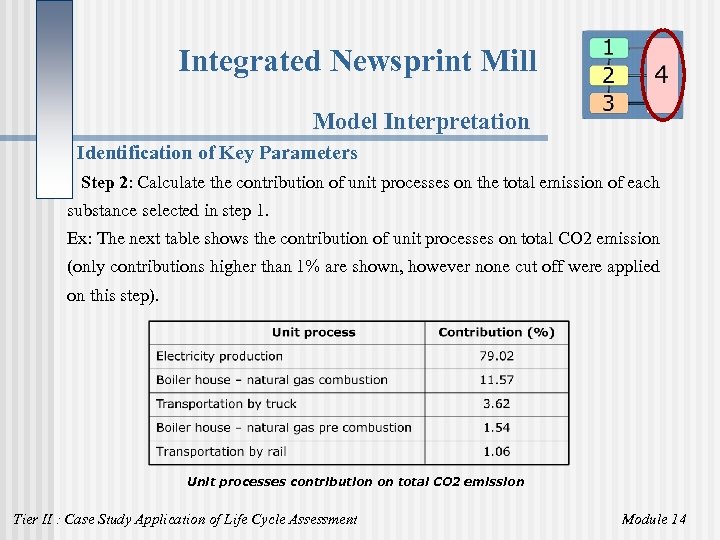

Integrated Newsprint Mill Model Interpretation Identification of Key Parameters Step 2: Calculate the contribution of unit processes on the total emission of each substance selected in step 1. Ex: The next table shows the contribution of unit processes on total CO 2 emission (only contributions higher than 1% are shown, however none cut off were applied on this step). Unit processes contribution on total CO 2 emission Tier II : Case Study Application of Life Cycle Assessment Module 14

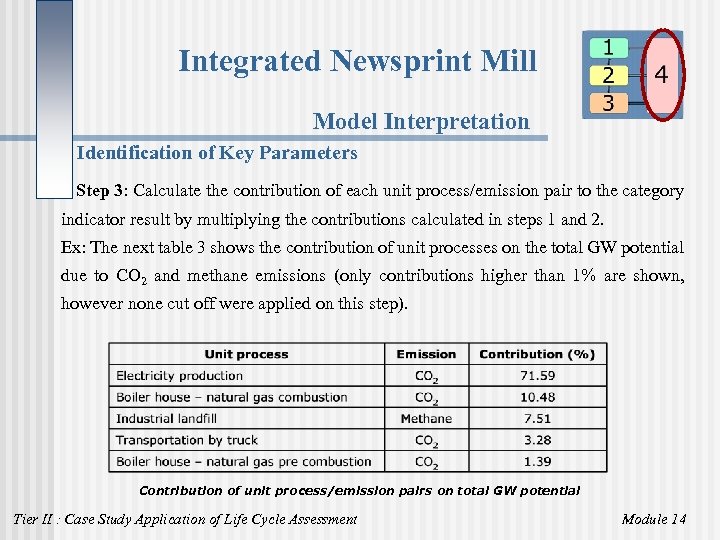

Integrated Newsprint Mill Model Interpretation Identification of Key Parameters Step 3: Calculate the contribution of each unit process/emission pair to the category indicator result by multiplying the contributions calculated in steps 1 and 2. Ex: The next table 3 shows the contribution of unit processes on the total GW potential due to CO 2 and methane emissions (only contributions higher than 1% are shown, however none cut off were applied on this step). Contribution of unit process/emission pairs on total GW potential Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation Identification of Key Parameters Step 4: Define Data Quality Indicators (DQI) appropriate to the study in order to evaluate quantitatively the uncertainty of unit process/emission pairs. Ex: Four DQI were defined for this study: source of data, temporal correlation, geographical correlation and technological correlation. The improved DQI matrix of Weidema (Weidema 1998) were used as reference, however we considered that the reliability of source and completeness indicators were not fully suitable for the study. Reliability indicators involve the evaluation of verification processes which are not informed in the commercial databases used and completeness indicator is more appropriate for data set (i. e. the entire unit process) than for an elementary flow (e. g. CO 2 from electricity production). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation Identification of Key Parameters Therefore, these two latter indicators were replaced by the source of data indicator and descriptions for the scores 1 to 5 were defined as follows, in such a way that represent the different data sources used: ü Score 1: Average of continuous measurements ü Score 2: Average of punctual measurements ü Score 3: Calculated from measured data ü Score 4: Calculated from literature references ü Score 3: Estimated or unknown source Tier II : Case Study Application of Life Cycle Assessment Module 14

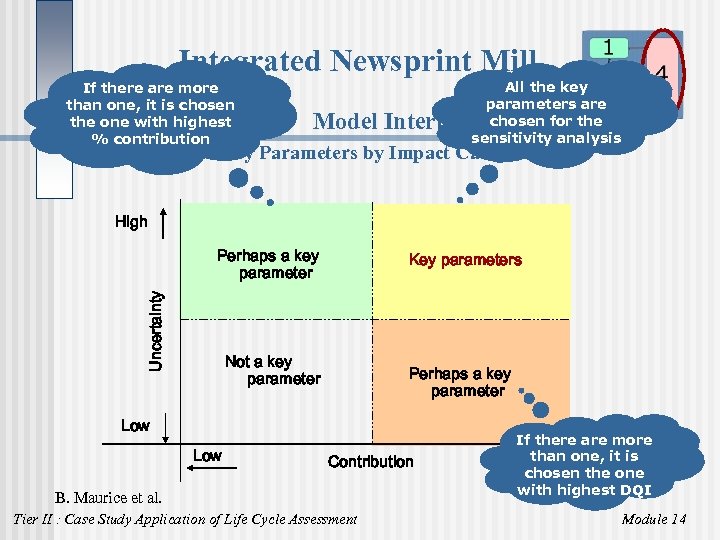

Integrated Newsprint Mill Model Interpretation Identification of Key Parameters Despite Weidema’s recommendation on not to aggregate in any way the DQIs, we applied Maurice approach on calculating an average of them in order to simplify the procedure, taking into account that these are “intermediate indicators” used to select key parameters for which quantitative uncertainty will be calculated afterwards. Step 5: Define the high and low levels for contribution and uncertainty in order to apply the approach proposed by Heijungs (Heijungs 1996) illustrated in this figure. Ex: For this study the limit between low and high contribution was defined as 10% and for low and high uncertainty, a DQI of 2. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill If there are more than one, it is chosen the one with highest % contribution All the key parameters are chosen for the sensitivity analysis Model Interpretation Identification of Key Parameters by Impact Categories High Uncertainty Perhaps a key parameter Key parameters Not a key parameter Perhaps a key parameter Low Contribution B. Maurice et al. Tier II : Case Study Application of Life Cycle Assessment If there are more than High one, it is chosen the one with highest DQI Module 14

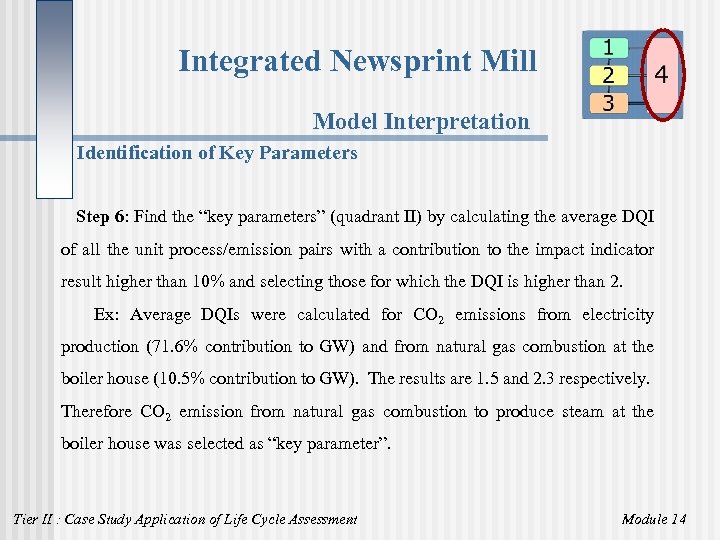

Integrated Newsprint Mill Model Interpretation Identification of Key Parameters Step 6: Find the “key parameters” (quadrant II) by calculating the average DQI of all the unit process/emission pairs with a contribution to the impact indicator result higher than 10% and selecting those for which the DQI is higher than 2. Ex: Average DQIs were calculated for CO 2 emissions from electricity production (71. 6% contribution to GW) and from natural gas combustion at the boiler house (10. 5% contribution to GW). The results are 1. 5 and 2. 3 respectively. Therefore CO 2 emission from natural gas combustion to produce steam at the boiler house was selected as “key parameter”. Tier II : Case Study Application of Life Cycle Assessment Module 14

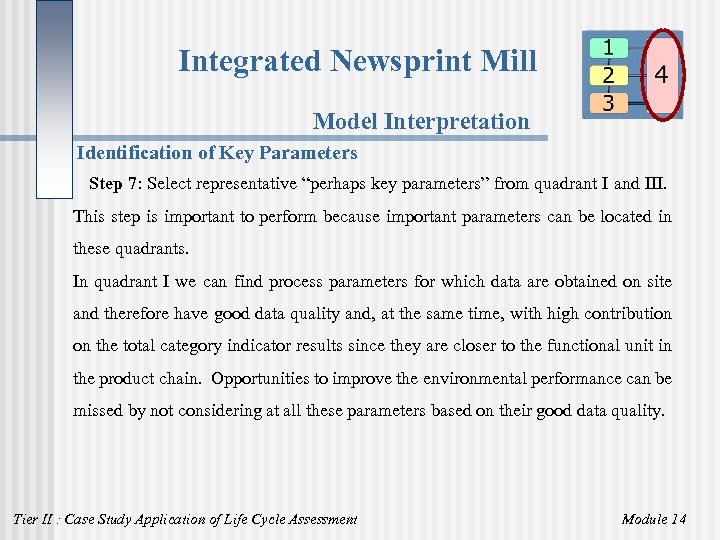

Integrated Newsprint Mill Model Interpretation Identification of Key Parameters Step 7: Select representative “perhaps key parameters” from quadrant I and III. This step is important to perform because important parameters can be located in these quadrants. In quadrant I we can find process parameters for which data are obtained on site and therefore have good data quality and, at the same time, with high contribution on the total category indicator results since they are closer to the functional unit in the product chain. Opportunities to improve the environmental performance can be missed by not considering at all these parameters based on their good data quality. Tier II : Case Study Application of Life Cycle Assessment Module 14

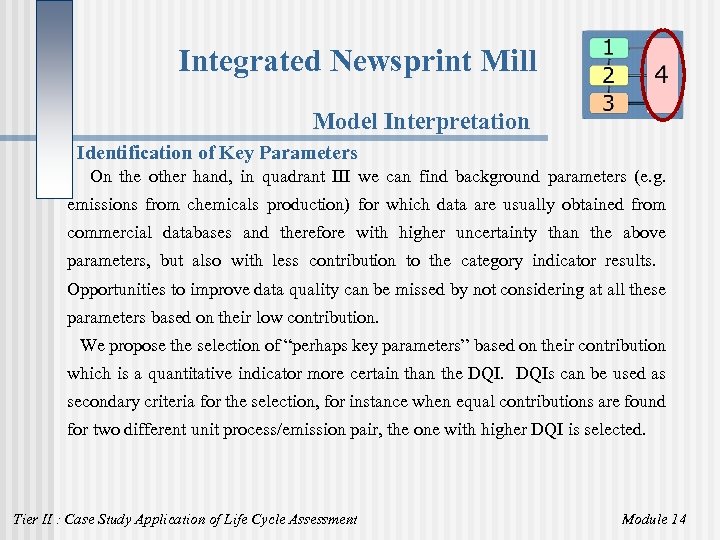

Integrated Newsprint Mill Model Interpretation Identification of Key Parameters On the other hand, in quadrant III we can find background parameters (e. g. emissions from chemicals production) for which data are usually obtained from commercial databases and therefore with higher uncertainty than the above parameters, but also with less contribution to the category indicator results. Opportunities to improve data quality can be missed by not considering at all these parameters based on their low contribution. We propose the selection of “perhaps key parameters” based on their contribution which is a quantitative indicator more certain than the DQIs can be used as secondary criteria for the selection, for instance when equal contributions are found for two different unit process/emission pair, the one with higher DQI is selected. Tier II : Case Study Application of Life Cycle Assessment Module 14

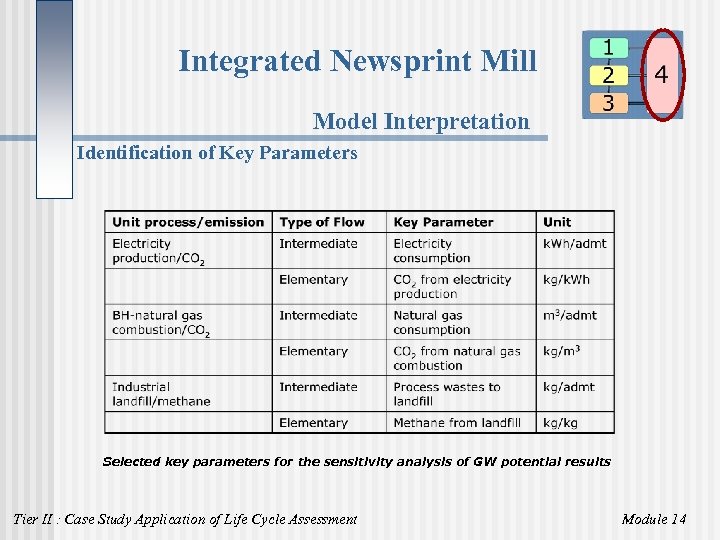

Integrated Newsprint Mill Model Interpretation Identification of Key Parameters Ex: CO 2 emission from electricity production (71. 7% contribution and 1. 5 DQI) is selected from quadrant I. Methane emission from industrial landfill (7. 4% contribution and 3. 5 DQI) is selected from quadrant III. Step 8: For all the selected unit process/emission pairs, identify the elementary and intermediate flows that affect them. These parameters are analyzed in the next step of the interpretation procedure. Ex: The next table 4 shows the list of the selected unit process/emission pairs with the related elementary and intermediate flows (i. e. key parameters) as well as their units. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation Identification of Key Parameters Selected key parameters for the sensitivity analysis of GW potential results Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation Definition of Uncertainty Ranges for Selected Key Parameters Uncertainty ranges for the selected key parameters were calculated in order to perform the sensitivity analyses. The guidelines proposed by Maurice (Maurice et al. 2000) were considered for the calculation or estimation of the uncertainty ranges, as follows: ü For primary data in woodlands, sawmill and newsprint mill, the minimum and maximum values of monthly statistics for the year 2001 defined the uncertainty range. ü For primary data from electricity production, where only averages were available from the production site, the assumption of ± 20% for continuous measurements and ± 50% for punctual measurements was applied based on (Hanssen et al. 1996). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation Definition of Uncertainty Ranges for Selected Key Parameters ü For secondary data from Franklin database: A percentage of variation was applied according to information from the database developers. ü For secondary data from other databases where no information on uncertainty was available, the uncertainty range was based on comparison of similar processes from different databases. ü For secondary data where no information on similar processes from other databases was available, the uncertainty range was based on the large intervals proposed by Finnveden (Finnveden et al. 1998). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation Sensitivity Analysis on Key Foreground and Background Parameters The sensitivity analysis technique was selected from a study where fourteen methods were compared in terms of the required calculation effort, the sensitivity ranking of parameter and the relative method performance (Hamby 1995). The study concludes that the Sensitivity Index (SI) is “the easiest and most reliable method that can be performed without detailed knowledge of the parameter distribution”. The sensitivity index is a one-at-a-time method where one parameter is varied at a time from its minimum to its maximum value (uncertainty range) while the others are holding fixed and the resulting output percent difference is calculated and expressed as SI. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation Sensitivity Analysis on Key Foreground and Background Parameters Sensitivity Indexes were calculated for the selected key parameters and the results are analyzed separately for the foreground and background parameters, in order to identify improvement opportunities on environmental performance and data quality, respectively. The next two figures show the results foreground and background parameters. Twenty six key parameters were analyzed in total, but only those with SI higher than 10% are shown. It can be observed that the background parameters have in general higher sensitivity than the foreground parameters due to their higher uncertainty. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation Sensitivity Analysis on Key Foreground and Background Parameters Results of Sensitivity Analysis on Foreground Parameters Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation Sensitivity Analysis on Key Foreground and Background Parameters From this figure it can be concluded that the mill efforts to improve the life cycle environmental performance of the newsprint production should be focus on the energy issues, especially the consumption of electricity and natural gas to produce steam that have an important sensitivity in most of the impact categories. Also, the eutrophication category results can be significantly reduced by taking actions to reduce N-t emissions from the newsprint mill effluents. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation Sensitivity Analysis on Key Foreground and Background Parameters Results of Sensitivity Analysis on Background Parameters Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation Sensitivity Analysis on Key Foreground and Background Parameters From this figure it can be concluded that efforts to improve the data quality should be focus on the ozone depleting emissions from DTPA (i. e. chelant) production, arsenic emission to water from soda production, mercury and arsenic emissions to air from electricity production and methane emissions from industrial landfill. The actions should be oriented first to improve the estimated uncertainty ranges and then evaluate by a complementary sensitivity analysis if better production data quality is required. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation Assessment of Uncertainties due to Methodological Choices Examples of methodological choices that introduce uncertainty on LCA models are: the selection of functional unit, system boundaries, allocation rules, the choice of using average data or average technology and selection of characterization methods (Bjorklund 2002). In order to reduce this type of uncertainty, it has been recommended to use standardized procedures (i. e. ISO 14040 family), as well as to perform peer review processes when choices are judged (Huijbregts 1998 a). In the development of the baseline model, besides the application of the recommended measures to reduce the uncertainty due to choices, the effects of two methodological choices, for which different approaches are discussed among practitioners, were analyzed. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation By Product Allocation in Sawmill The approaches presented previously were modeled and the impact category results are compared with those from the baseline model in the next figure. The profiles are normalized against the baseline model results. Alternative Approach 1: The environmental burdens are allocated only to lumber and chips. Alternative Approach 2: The environmental burdens are allocated only to lumber. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation By Product Allocation in Sawmill Results of Sensitivity Analysis on Alternative Allocation Approaches for Sawmill Operations Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation By Product Allocation in Sawmill The results show that whether or not we allocate burdens to hog fuel, the results remain the same. But when environmental burdens are exclusively allocated to lumber, the characterization results differ from the baseline model results in 2% to 13%, with higher values for human health particles and photochemical smog where transportation has a significant contribution and because diesel consumption for log transportation and sawmill operations represent around 75% of the total consumption for transportation by truck. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Model Interpretation Exclusion of Wastepaper Collection During the scope definition, transportation of wastepaper from curbsides to material recovery facilities in the cities was considered negligible when comparing with other transportation activities (i. e. log transportation, wastepaper transportation from material recovery facilities to the mill, etc. ) and therefore excluded from the system. On the interpretation phase this assumption was verified by using the municipal waste truck model from IVAM database, which is modeled by hour and distance is not relevant; and average data on rate of old newspaper collection during the year 1998 in the province of Ontario. The results show that the contribution of wastepaper collection is negligible for all the impact categories (<<1%), being the highest one 0. 00435% for human health particles. Tier II : Case Study Application of Life Cycle Assessment Module 14

Tier II : Contents 1. Case study example of the application of the LCA at an integrated newsprint mill including: * Description of the System Studied * Goal and Scope definition * Life Cycle Inventory (LCI) * Life Cycle Impact Assessment (LCIA) * Model Interpretation including Parameter Sensitivity Analysis 2. Assessment of Opportunities to Improve the Environmental Performance of Newsprint Production Using Life Cycle Assessment (LCA) 3. Multiple choice questions Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement This section shows the assessment of improvement opportunities, dividing the proposed alternatives in those related to the energy consumption and those related with the effluent emissions. In the former group, we analyze the increase of DIP production and the implementation of co-generation systems; the results show important benefits for most of the impact categories (e. g. 2040% reduction in Global Warming Potential), except for acidification, photochemical smog and human health particles due to the increase of natural gas consumption per 1 admt. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement In the latter group, we analyze tertiary treatment by coagulation/flocculation as well as zero effluent by membrane filtration; these technologies show significant improvement for eutrophication potential (i. e. 50 -80% reduction), with higher benefits from the membrane technology which completely eliminates the contribution from newsprint mill effluent to eutrophication, optimizes water resource use and has available alternatives to sludge landfilling. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement In this publication we analyze and interpret systematically the baseline model results in order to identify the process and non-process parameters with significant influence on the impacts of whole chain. Finally, we identify and assess the potential improvement on the life cycle environmental performance from different mill configurations. Tier II : Case Study Application of Life Cycle Assessment Module 14

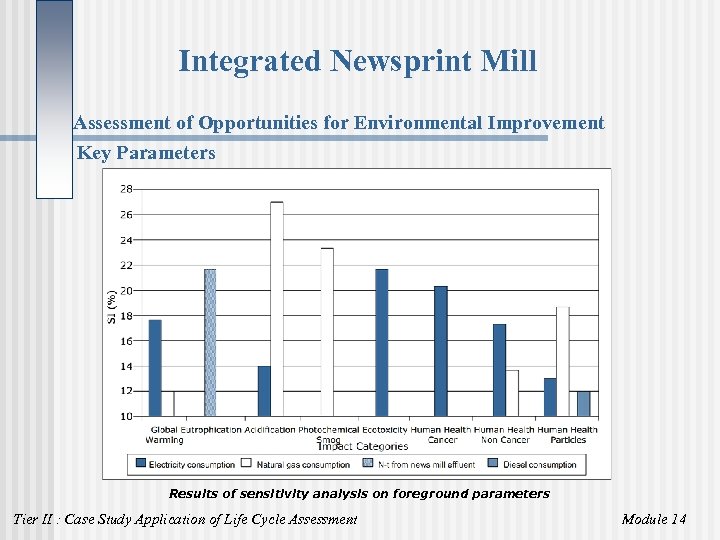

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Key Parameters In this section, the attention is focused on the key mill process or foreground parameters, because they are the starting point for the definition and assessment of opportunities to improve the life cycle environmental performance. The next figure shows the results of the sensitivity analysis for these parameters. Note: SI = Sensitivity Index, defined as: Where Dmin and Dmax represent respectively the minimum and … (1) maximum output values resulting from varying the input over its uncertainty range (Hamby 1994). Tier II : Case Study Application of Life Cycle Assessment Module 14

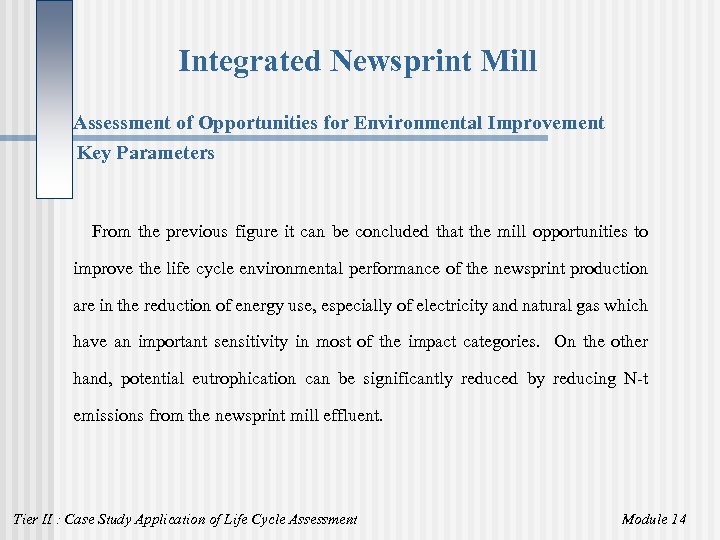

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Key Parameters Results of sensitivity analysis on foreground parameters Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Key Parameters From the previous figure it can be concluded that the mill opportunities to improve the life cycle environmental performance of the newsprint production are in the reduction of energy use, especially of electricity and natural gas which have an important sensitivity in most of the impact categories. On the other hand, potential eutrophication can be significantly reduced by reducing N-t emissions from the newsprint mill effluent. Tier II : Case Study Application of Life Cycle Assessment Module 14

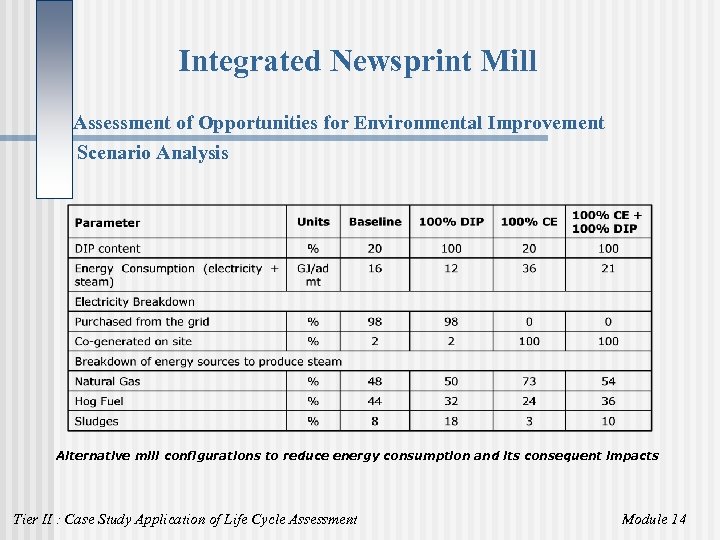

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Energy Oriented Scenarios They are focused on reducing purchased electricity and natural gas consumption. We consider the following strategies: ü Reduce the energy consumption of the mill by increasing the DIP production that is less energy intensive than the TMP process. ü Reduce the amount of energy purchased from the grid by co-generating steam and electricity, preferably from biomass. ü A combination of these two strategies. Based on these strategies, we developed three alternative mill configurations presented in the next table. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Alternative mill configurations to reduce energy consumption and its consequent impacts Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Energy Oriented Scenarios The increase of DIP production (100% DIP) results in a consumption of around one half of the electricity required in the baseline model; and at the same time, an increase of 35% on the steam produced by the boiler house in order to replace the steam recovered from the TMP process in the baseline model. As a consequence, there is an overall decrease in the energy consumption from the mill. The main assumptions we made for the inventory analysis of this configuration are: Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis ü The additional amount of ONP and GGS required is transported from the same places as the baseline model. Furthermore, we consider a credit for recycling this amount of wastepaper which otherwise would be landfilled. ü The entire amount of DIP sludges can be dewatered and burnt in the boiler house. ü The additional energy required in the boiler house to produce steam is covered by natural gas. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis As a consequence of the last assumption, we can observe in the previous table that the breakdown of natural gas and sludges increase comparing to the baseline model. Natural gas consumption increases around 40% and the amount of sludges used as energy source is twice more than in the baseline model. In the 100% CE configuration, we consider that all the electricity consumed by the mill is co-generated on site. We do not include any energy reduction program, but we change the energy source: instead of buying the electricity from the grid, we generate it from steam. However, the required amount of steam for this configuration is around twice more than for the baseline model. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Therefore, the total amount of energy required at the mill also increases. To produce this additional steam entirely from biomass is not feasible due to problems on hog fuel availability where the system is located. Therefore, we assume that we cannot increase the current hog fuel consumption more than 100% and that the rest energy needs are covered by natural gas. Observe the variations on the breakdown of these energy sources in the same table. As a result, natural gas consumption for this configuration is around 4 times more than the consumption for the baseline model. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Electricity consumption is reduced by shutting down TMP, but the steam requirements increase to replace the steam from TMP and to provide the energy required to co-generate 100% of the electricity needs. As a consequence, the total energy requirements increase around 30%. For the additional amount of wastepaper required and sludge generated, we made the same assumptions as for 100% DIP configuration. For the additional hog fuel required, we made the same assumption as for 100% CE. Since there is more sludge that can be used as energy source and there is less electricity required at the mill, natural gas consumption increases in less than twice compared to the baseline model. Tier II : Case Study Application of Life Cycle Assessment Module 14

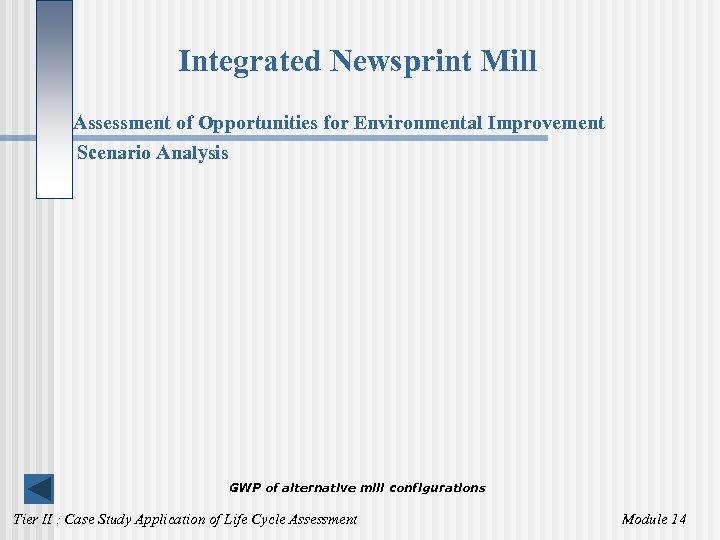

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Using LCA we can identify the benefits and impacts of going from the baseline model to alternative configurations as well as identify the trade-offs and the origins of the impacts. For instance, the next figure shows a comparison of the Global Warming Potential (GWP) for the baseline model and the designed energy-oriented scenarios. All the configurations involve improvements for this performance indicator, with reductions from 20 to 40%, despite of the fact that the overall energy consumption increases for the three scenarios. This result can be explained based on the energy source: we are replacing electricity sourced on coal at 33% with electricity generated from natural gas and biomass (CO 2 neutral). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis GWP of alternative mill configurations Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Regarding the process contributions, we observe a reduction on the CO 2 eq emitted from electricity production along with an increase from the natural gas combustion at the boiler house, in such a way that the combined impact to cover the energy mill needs is reduced in 30% for the scenario 100% CE, 50% for the scenario 100% DIP and 60% for the combined scenario. However, as natural gas consumption increases, the pre-combustion effects (i. e. fuels production) are more significant; see, for example, the increase of the pointy area for the scenario 100%CE. We can also observe the increase of the contribution from chemicals production when more DIP is produced. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Contributions from landfill and transportation remain almost constant. In the case of landfill, we have a balance between the increase of process wastes from DIP plus the amount of ashes from steam production and the credit for recycling more wastepaper which otherwise would be landfilled. In the case of transportation, the balance is between more wastepaper transportation and the avoidance of transportation related to woodlands and sawmills operations. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis The alternative mill configurations have potential benefits to improve the environmental performance on the impact categories that have a significant sensitivity on electricity consumption (see figure *). However, for the impact categories which are more sensitive to natural gas consumption (i. e. acidification, photochemical smog and human health particles), the category indicator results increase as a consequence of the increase on natural gas consumption. For instance, in the next figure we observe that despite of the fact that the contribution from electricity production is reduced or eliminated, the contributions from biomass and natural gas combustion and especially from the natural gas production increase importantly, resulting in a net increase of the photochemical smog indicator. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Photochemical smog potential of alternative mill configurations Tier II : Case Study Application of Life Cycle Assessment Module 14

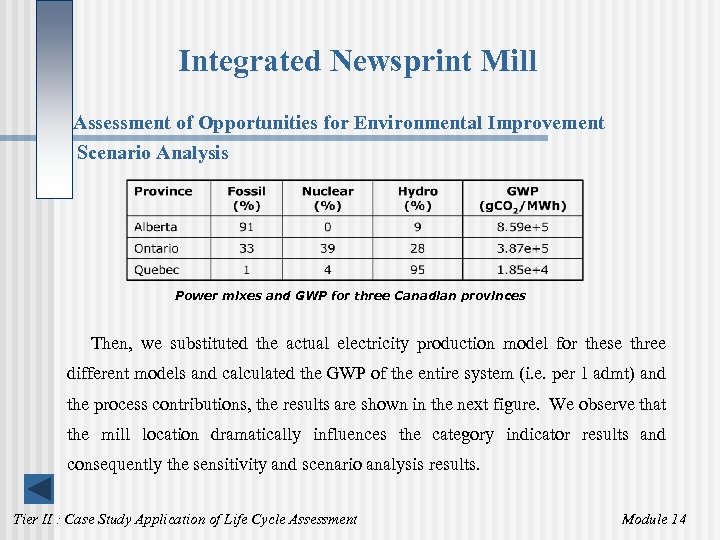

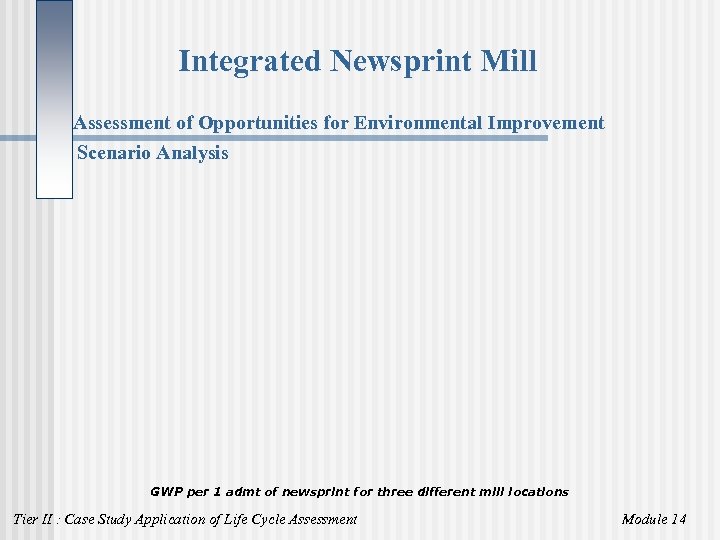

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Another point to highlight is that since these scenarios are mainly oriented towards reducing the purchased electricity consumption, the consequent benefits strongly depend on the at-source power mix, and therefore on the mill location. In order to understand better the significance of this non-process parameter, we took as reference the average power mix of three different Canadian provinces: Ontario, Quebec and Alberta. The next table presents the power mix for each province as well as the correspondent GWP. Note that this latter indicator was calculated using LCA databases for comparative purposes and it does not represent real emissions (e. g. the model for hydropower considers zero emissions). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Power mixes and GWP for three Canadian provinces Then, we substituted the actual electricity production model for these three different models and calculated the GWP of the entire system (i. e. per 1 admt) and the process contributions, the results are shown in the next figure. We observe that the mill location dramatically influences the category indicator results and consequently the sensitivity and scenario analysis results. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis GWP per 1 admt of newsprint for three different mill locations Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Effluent Oriented Scenarios These scenarios are focused on reducing the nutrient emissions from the newsprint mill. We consider the following strategies: ü Tertiary treatment by coagulation/flocculation ü Zero effluent by membrane filtration Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Based on these strategies, we analyzed 3 alternative scenarios: ü Tertiary treatment of the current amount of effluents by coagulation/flocculation. ü Implementation of water conservation programs in order to reduce the amount of effluents to treat; and tertiary treatment of the reduced amount of effluents by coagulation/flocculation. ü Implementation of a membrane filtration technology after the secondary treatment in order to reuse the effluent as fresh water in the process. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis The two first scenarios were developed for the newsprint mill by a consultant company as alternatives to achieve their environmental targets set for the year 2005. They are inspired on a tertiary treatment plant by dissolved air flotation aided by chemical coagulation and flocculation with alum and polymer, applied in a TMP-DIP newsprint mill in Sweden in order to reduce COD and phosphorous discharges (Thoren et al. 1997). However, a constraint of this technology is that the precipitation of TSS and nutrients with inorganic chemicals produces a considerable quantity of sludge that is difficult to dewater and therefore must be landfilled (European Commission 2001). We did not quantify the amount of sludge generated for these scenarios, because reliable data was not available. Tier II : Case Study Application of Life Cycle Assessment Module 14

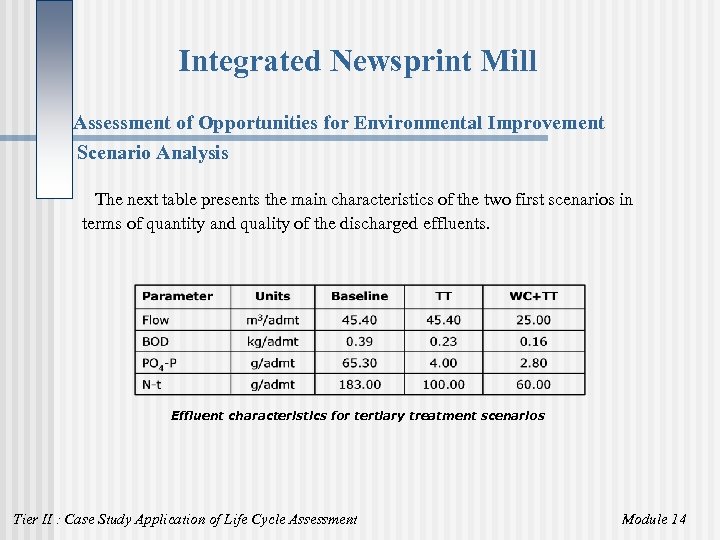

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis The next table presents the main characteristics of the two first scenarios in terms of quantity and quality of the discharged effluents. Effluent characteristics for tertiary treatment scenarios Tier II : Case Study Application of Life Cycle Assessment Module 14

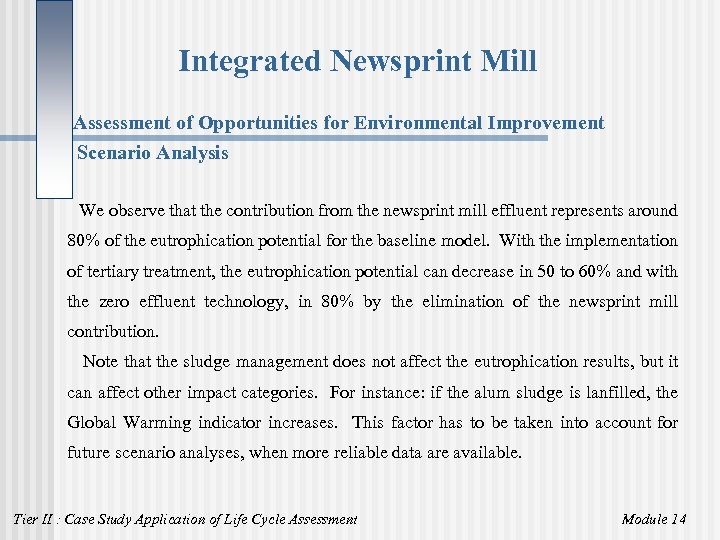

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis For the zero effluent scenario, we selected the membrane technology that depending on the applicable membrane cut-off size and the filtering pressure, can theoretically remove almost 100% of the organic material, producing a filtrate with sufficient quality to replace most of the fresh water used in the process. The sludges generated can be sent to biological treatment or may require further concentration into a solid fuel for disposal by incineration (IPPC 2001). The amount of sludges generated for this scenario has neither been quantified. The next figure shows the comparative results for eutrophication impact category which is the more sensitive to the nutrient emissions from the newsprint mill. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Eutrophication potential for alternative effluent scenarios Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis We observe that the contribution from the newsprint mill effluent represents around 80% of the eutrophication potential for the baseline model. With the implementation of tertiary treatment, the eutrophication potential can decrease in 50 to 60% and with the zero effluent technology, in 80% by the elimination of the newsprint mill contribution. Note that the sludge management does not affect the eutrophication results, but it can affect other impact categories. For instance: if the alum sludge is lanfilled, the Global Warming indicator increases. This factor has to be taken into account for future scenario analyses, when more reliable data are available. Tier II : Case Study Application of Life Cycle Assessment Module 14

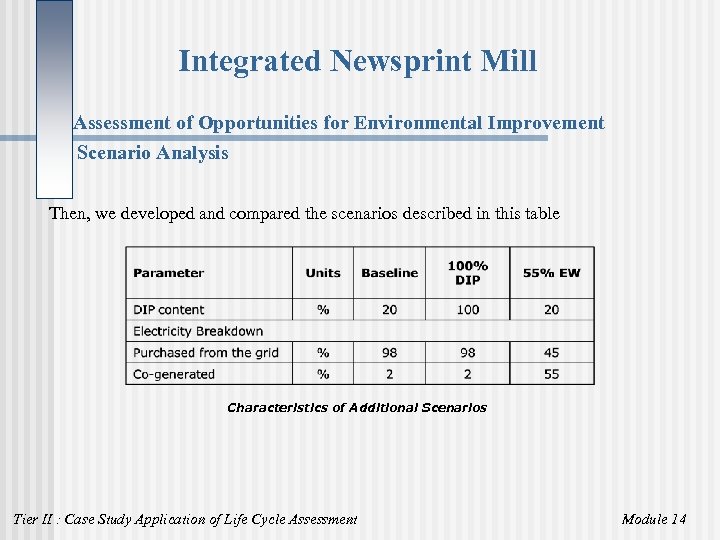

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Additional Scenario Analysis We performed an additional scenario analysis in order to respond to a question often arose during presentations on this research project: what is more environmental friendly, to recycle wastepaper or to incinerate it in the city and recover electricity? . The main concern associated with this question was the impact from wastepaper transportation. In order to assess these alternatives, we firstly included in the baseline model the wastepaper transportation from curbsides to material recovery facilities, initially excluded from the system, and we calculated the contribution of this activity to the category indicators. The results show that the contribution in all impact categories is negligible (<<1%). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Then, we developed and compared the scenarios described in this table Characteristics of Additional Scenarios Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis We designed the scenario 100% DIP under the same criteria used in Energy Oriented Scenarios. For the scenario 55% Electricity from Wastepaper (EW), we considered that the additional amount of wastepaper that is recycled in the scenario 100% DIP, is incinerated in the city and electricity is recovered and sent to the grid. The amount of electricity produced in this way constitutes 55% the total electricity mill consumption. We used an average Finnish wastepaper incineration model; and, since these alternatives are oriented towards reducing the impacts caused by the energy consumption, we run the model for the three power mixes see table * ). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis The next 3 figures present the profiles normalized against the baseline model results. Note that scores lower than 1 mean a decrease in the category indicator results, and therefore an improvement in the environmental performance. Also note that these graphs represent the results for this particular newsprint production system as if it is located in three different provinces as opposed to average newsprint production systems in these provinces. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Results of additional scenario analysis – Ontario power mix Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis A comparison of the results shows that the assessed alternatives have environmental benefits mainly when fossil sources have a high breakdown in the electricity mix (e. g. Ontario and Alberta); the higher the fossil source breakdown, the higher the benefit. However, if the power mix has a negligible breakdown of fossil source, there is no improvement in the environmental performance as a consequence of the 100% DIP scenario; the scenario 55% EW has benefits mainly for global impacts as well as for eco-toxicity and human toxicity, presenting a range of improvement from 7% to 30%. Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Results of additional scenario analysis – Quebec power mix Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis For the power mixes where both alternatives have environmental benefits, the difference in environmental performance improvement is less than 10% for most of the impact categories, except for regional impacts for which 100% DIP represents a better alternative (since the scenario 55%EW produces higher amount of combustion gases that contributes to regional impacts); and for Ozone Depletion, for which 55%EW is a better alternative (since the chemicals consumption is higher for 100%DIP scenario). Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Scenario Analysis Results of additional scenario analysis – Alberta power mix Tier II : Case Study Application of Life Cycle Assessment Module 14

Integrated Newsprint Mill Assessment of Opportunities for Environmental Improvement Conclusions A cradle-to-gate LCA study for the production of 1 admt of newsprint was completed, following rigorously ISO 14040 standards. Sensitivity analyses of the baseline model results show that energy consumption, mainly in the form of electricity and natural gas to produce steam, as well as effluent emissions are process parameters that have a significant sensitivity (>10%) on the category indicator results. We also identified that electricity mix that varies with mill location is a non-process parameter that affect dramatically the LCA results. Therefore, the drawn conclusions are valid only to the system studied and no generalization can be done based on the results obtained. Tier II : Case Study Application of Life Cycle Assessment Module 14