da80485024ee40725e2f92ea8652f36b.ppt

- Количество слайдов: 8

Prognosis 2030 – A Vision February 19 2008 T. A. Cruse, DARPA/DSO Consultant Dayton, Ohio 45459 1

The Perfect World for Prognosis Damage progression is deterministic n n Perfect knowledge of microstructural features, chemistry, initial strains, etc. Perfect physics-based damage models appropriate to microstructures Ignorance of any = uncertainty n n n Usually seen as scatter in actual/predicted Processing deviation = new population Design error = major shift in new population Prognosis is more than physics/chemistry 19 February 2008 DCT Workshop 2

Prognosis is a 3 -Legged Stool Leg 1: Physics-based system state models n n n Response to defined/controlled processing Response to defined/recorded environments Prediction of future states, given initial state Leg 2: System state “fingerprint” n Initial state definition and recording Leg 3: State validation – “virtual sensor” n Linking Leg 1 with new NDE characterizations to provide updated system state “fingerprint” 19 February 2008 DCT Workshop 3

What is New NDE? What it is not n n n Finding cracks Finding delaminations Stiffness change What it will include n n n Change detection New signal processing Witness mapping Ping-ring response mode Focus on state awareness What it will be n Integral part of 3 -legs 19 February 2008 DCT Workshop 4

State Awareness Attributes Real-time environmental loads & history n E. g. , loads, thermal loads, humidity, chemistry, etc. Real-time microstructural response n E. g. , strain, temperature, diffusion, oxidation, etc. Initial state “fingerprint” n n Micro/macro state definition at service intro Critical processing history state contributions Current state “fingerprint” 19 February 2008 DCT Workshop 5

Prognosis 2030 – the vision Vast computational power in the system n n n Real-time state assessment updating Real-time integration of initial state and environmental history Real-time forensics (space systems/avionics) Real-time communications to user for prognosing future state capabilities “Columbia safe-return” scenario capability System operates as integrated, virtual sensor n n All three legs are fully integrated State awareness through “new NDE” Analytical system certification revolution n n Fully risk based design/deployment with processing histories Fully adaptive to individual part tracking up to the “tail number” 19 February 2008 DCT Workshop 6

Prognosis 2030 - Challenges Close the “scatter band” n n High fidelity modeling – system response High fidelity damage models w Complex 3 D material systems w High heat flux loading environments/responses Revolutionize material state awareness n n Neural materials and systems Ping-ring state updating Global-local communications within system Remote diagnostics/forensics Future material system complexities n n Hybrids, 3 D and tailored systems, Complete material processing All things to be probabilistically integrated 19 February 2008 DCT Workshop 7

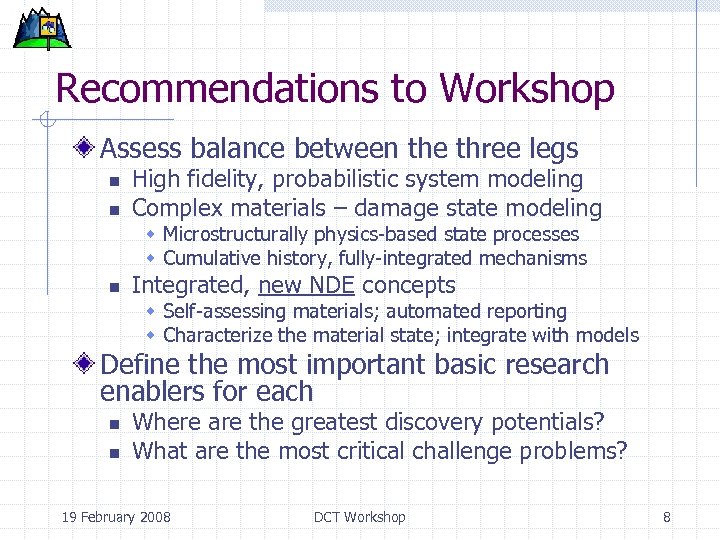

Recommendations to Workshop Assess balance between the three legs n n High fidelity, probabilistic system modeling Complex materials – damage state modeling w Microstructurally physics-based state processes w Cumulative history, fully-integrated mechanisms n Integrated, new NDE concepts w Self-assessing materials; automated reporting w Characterize the material state; integrate with models Define the most important basic research enablers for each n n Where are the greatest discovery potentials? What are the most critical challenge problems? 19 February 2008 DCT Workshop 8

da80485024ee40725e2f92ea8652f36b.ppt