91e17b8010110a6fb6e132e716cb7fc5.ppt

- Количество слайдов: 13

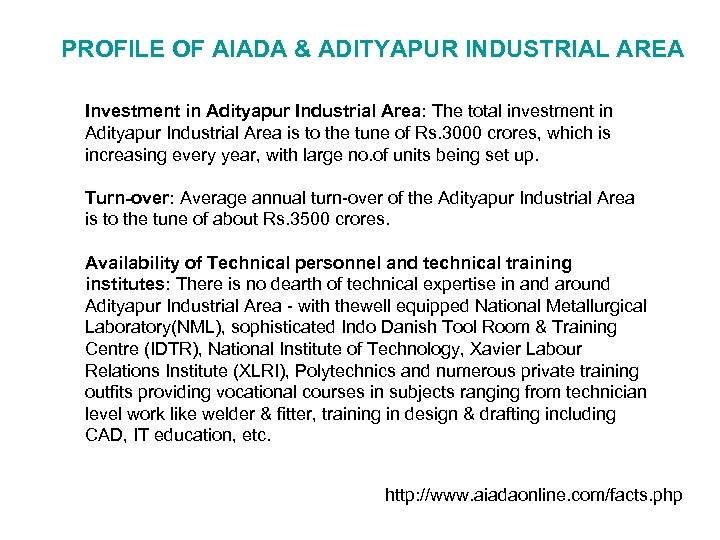

PROFILE OF AIADA & ADITYAPUR INDUSTRIAL AREA Investment in Adityapur Industrial Area: The total investment in Adityapur Industrial Area is to the tune of Rs. 3000 crores, which is increasing every year, with large no. of units being set up. Turn-over: Average annual turn-over of the Adityapur Industrial Area is to the tune of about Rs. 3500 crores. Availability of Technical personnel and technical training institutes: There is no dearth of technical expertise in and around Adityapur Industrial Area - with thewell equipped National Metallurgical Laboratory(NML), sophisticated Indo Danish Tool Room & Training Centre (IDTR), National Institute of Technology, Xavier Labour Relations Institute (XLRI), Polytechnics and numerous private training outfits providing vocational courses in subjects ranging from technician level work like welder & fitter, training in design & drafting including CAD, IT education, etc. http: //www. aiadaonline. com/facts. php

PROFILE OF AIADA & ADITYAPUR INDUSTRIAL AREA Investment in Adityapur Industrial Area: The total investment in Adityapur Industrial Area is to the tune of Rs. 3000 crores, which is increasing every year, with large no. of units being set up. Turn-over: Average annual turn-over of the Adityapur Industrial Area is to the tune of about Rs. 3500 crores. Availability of Technical personnel and technical training institutes: There is no dearth of technical expertise in and around Adityapur Industrial Area - with thewell equipped National Metallurgical Laboratory(NML), sophisticated Indo Danish Tool Room & Training Centre (IDTR), National Institute of Technology, Xavier Labour Relations Institute (XLRI), Polytechnics and numerous private training outfits providing vocational courses in subjects ranging from technician level work like welder & fitter, training in design & drafting including CAD, IT education, etc. http: //www. aiadaonline. com/facts. php

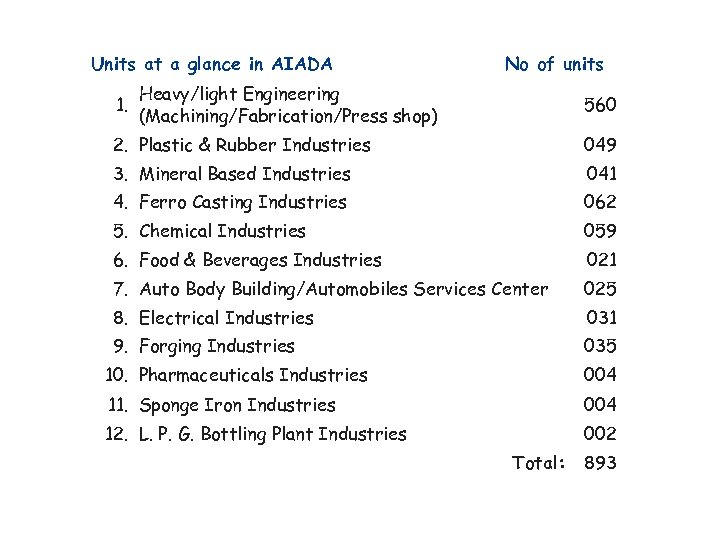

Units at a glance in AIADA 1. No of units Heavy/light Engineering (Machining/Fabrication/Press shop) 560 2. Plastic & Rubber Industries 049 3. Mineral Based Industries 041 4. Ferro Casting Industries 062 5. Chemical Industries 059 6. Food & Beverages Industries 021 7. Auto Body Building/Automobiles Services Center 025 8. Electrical Industries 031 9. Forging Industries 035 10. Pharmaceuticals Industries 004 11. Sponge Iron Industries 004 12. L. P. G. Bottling Plant Industries 002 Total: 893

Units at a glance in AIADA 1. No of units Heavy/light Engineering (Machining/Fabrication/Press shop) 560 2. Plastic & Rubber Industries 049 3. Mineral Based Industries 041 4. Ferro Casting Industries 062 5. Chemical Industries 059 6. Food & Beverages Industries 021 7. Auto Body Building/Automobiles Services Center 025 8. Electrical Industries 031 9. Forging Industries 035 10. Pharmaceuticals Industries 004 11. Sponge Iron Industries 004 12. L. P. G. Bottling Plant Industries 002 Total: 893

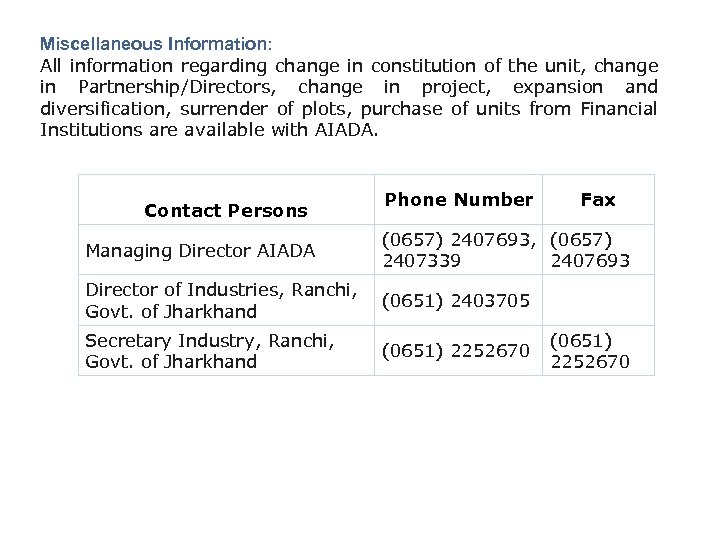

Miscellaneous Information: All information regarding change in constitution of the unit, change in Partnership/Directors, change in project, expansion and diversification, surrender of plots, purchase of units from Financial Institutions are available with AIADA. Contact Persons Managing Director AIADA Phone Number Fax (0657) 2407693, (0657) 2407339 2407693 Director of Industries, Ranchi, (0651) 2403705 Govt. of Jharkhand Secretary Industry, Ranchi, Govt. of Jharkhand (0651) 2252670

Miscellaneous Information: All information regarding change in constitution of the unit, change in Partnership/Directors, change in project, expansion and diversification, surrender of plots, purchase of units from Financial Institutions are available with AIADA. Contact Persons Managing Director AIADA Phone Number Fax (0657) 2407693, (0657) 2407339 2407693 Director of Industries, Ranchi, (0651) 2403705 Govt. of Jharkhand Secretary Industry, Ranchi, Govt. of Jharkhand (0651) 2252670

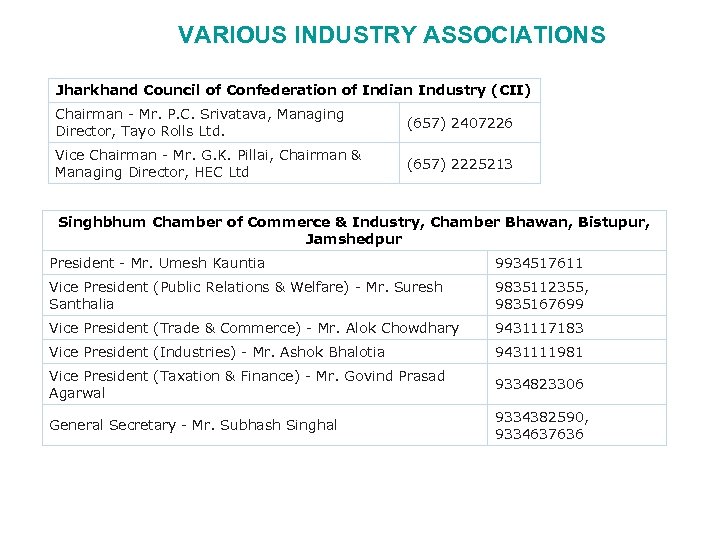

VARIOUS INDUSTRY ASSOCIATIONS Jharkhand Council of Confederation of Indian Industry (CII) Chairman - Mr. P. C. Srivatava, Managing Director, Tayo Rolls Ltd. (657) 2407226 Vice Chairman - Mr. G. K. Pillai, Chairman & Managing Director, HEC Ltd (657) 2225213 Singhbhum Chamber of Commerce & Industry, Chamber Bhawan, Bistupur, Jamshedpur President - Mr. Umesh Kauntia 9934517611 Vice President (Public Relations & Welfare) - Mr. Suresh Santhalia 9835112355, 9835167699 Vice President (Trade & Commerce) - Mr. Alok Chowdhary 9431117183 Vice President (Industries) - Mr. Ashok Bhalotia 9431111981 Vice President (Taxation & Finance) - Mr. Govind Prasad Agarwal 9334823306 General Secretary - Mr. Subhash Singhal 9334382590, 9334637636

VARIOUS INDUSTRY ASSOCIATIONS Jharkhand Council of Confederation of Indian Industry (CII) Chairman - Mr. P. C. Srivatava, Managing Director, Tayo Rolls Ltd. (657) 2407226 Vice Chairman - Mr. G. K. Pillai, Chairman & Managing Director, HEC Ltd (657) 2225213 Singhbhum Chamber of Commerce & Industry, Chamber Bhawan, Bistupur, Jamshedpur President - Mr. Umesh Kauntia 9934517611 Vice President (Public Relations & Welfare) - Mr. Suresh Santhalia 9835112355, 9835167699 Vice President (Trade & Commerce) - Mr. Alok Chowdhary 9431117183 Vice President (Industries) - Mr. Ashok Bhalotia 9431111981 Vice President (Taxation & Finance) - Mr. Govind Prasad Agarwal 9334823306 General Secretary - Mr. Subhash Singhal 9334382590, 9334637636

VARIOUS INDUSTRY ASSOCIATIONS Singhbhum Industries Association (SIA) President - Mr. Ravi Bharadwaj SIA, Tapti Road, Sakchi, Jamshedpur (657) 2200741, (657) 2200742 Adityapur Small Industries Association (ASIA) President - Mr. S N Thakur ASIA, Adityapur, Jamshedpur (657) 2200389, (657) 2407223

VARIOUS INDUSTRY ASSOCIATIONS Singhbhum Industries Association (SIA) President - Mr. Ravi Bharadwaj SIA, Tapti Road, Sakchi, Jamshedpur (657) 2200741, (657) 2200742 Adityapur Small Industries Association (ASIA) President - Mr. S N Thakur ASIA, Adityapur, Jamshedpur (657) 2200389, (657) 2407223

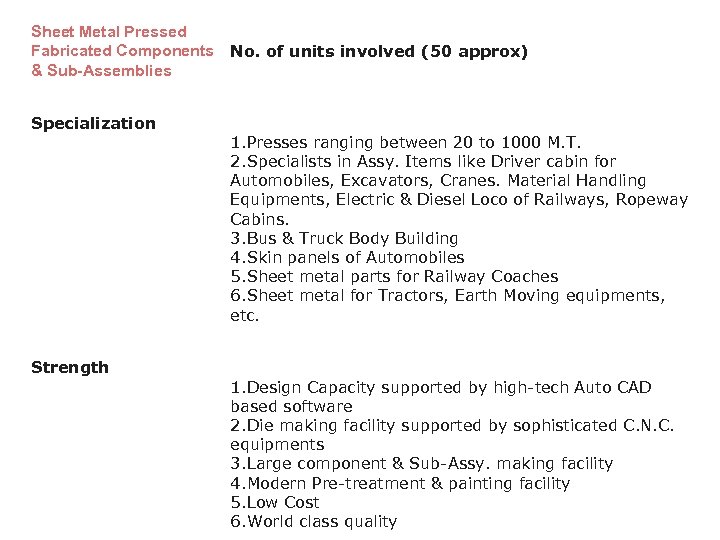

Sheet Metal Pressed Fabricated Components & Sub-Assemblies No. of units involved (50 approx) Specialization Strength 1. Presses ranging between 20 to 1000 M. T. 2. Specialists in Assy. Items like Driver cabin for Automobiles, Excavators, Cranes. Material Handling Equipments, Electric & Diesel Loco of Railways, Ropeway Cabins. 3. Bus & Truck Body Building 4. Skin panels of Automobiles 5. Sheet metal parts for Railway Coaches 6. Sheet metal for Tractors, Earth Moving equipments, etc. 1. Design Capacity supported by high-tech Auto CAD based software 2. Die making facility supported by sophisticated C. N. C. equipments 3. Large component & Sub-Assy. making facility 4. Modern Pre-treatment & painting facility 5. Low Cost 6. World class quality

Sheet Metal Pressed Fabricated Components & Sub-Assemblies No. of units involved (50 approx) Specialization Strength 1. Presses ranging between 20 to 1000 M. T. 2. Specialists in Assy. Items like Driver cabin for Automobiles, Excavators, Cranes. Material Handling Equipments, Electric & Diesel Loco of Railways, Ropeway Cabins. 3. Bus & Truck Body Building 4. Skin panels of Automobiles 5. Sheet metal parts for Railway Coaches 6. Sheet metal for Tractors, Earth Moving equipments, etc. 1. Design Capacity supported by high-tech Auto CAD based software 2. Die making facility supported by sophisticated C. N. C. equipments 3. Large component & Sub-Assy. making facility 4. Modern Pre-treatment & painting facility 5. Low Cost 6. World class quality

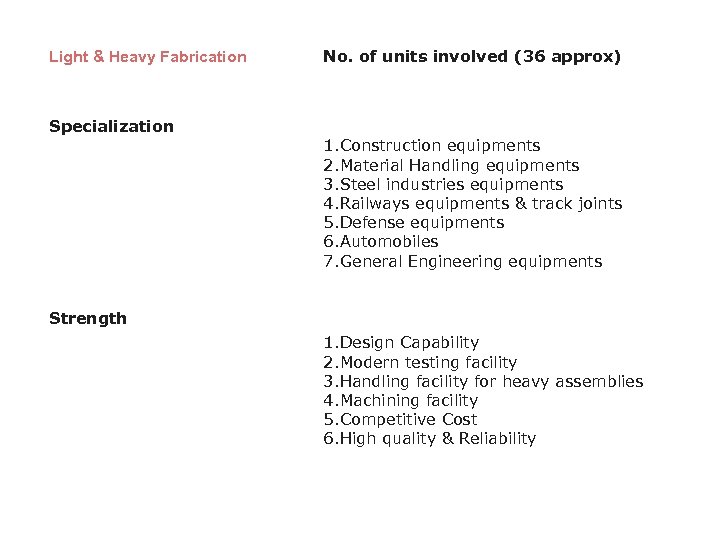

Light & Heavy Fabrication No. of units involved (36 approx) Specialization 1. Construction equipments 2. Material Handling equipments 3. Steel industries equipments 4. Railways equipments & track joints 5. Defense equipments 6. Automobiles 7. General Engineering equipments Strength 1. Design Capability 2. Modern testing facility 3. Handling facility for heavy assemblies 4. Machining facility 5. Competitive Cost 6. High quality & Reliability

Light & Heavy Fabrication No. of units involved (36 approx) Specialization 1. Construction equipments 2. Material Handling equipments 3. Steel industries equipments 4. Railways equipments & track joints 5. Defense equipments 6. Automobiles 7. General Engineering equipments Strength 1. Design Capability 2. Modern testing facility 3. Handling facility for heavy assemblies 4. Machining facility 5. Competitive Cost 6. High quality & Reliability

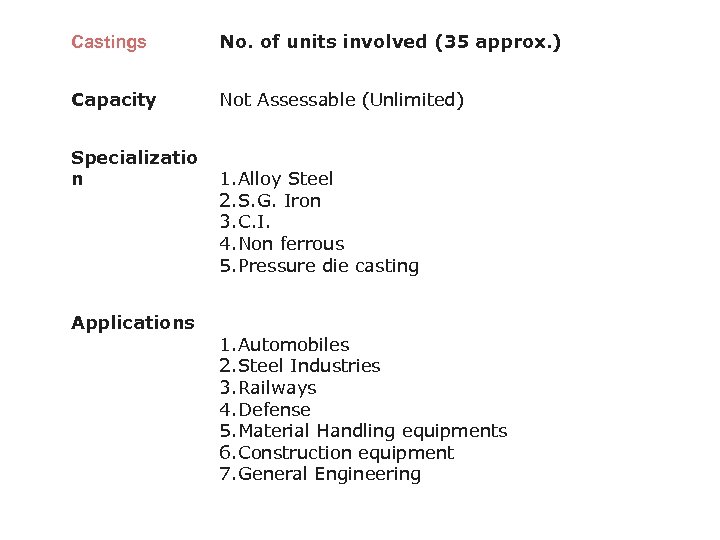

Castings No. of units involved (35 approx. ) Capacity Not Assessable (Unlimited) Specializatio n 1. Alloy Steel 2. S. G. Iron 3. C. I. 4. Non ferrous 5. Pressure die casting Applications 1. Automobiles 2. Steel Industries 3. Railways 4. Defense 5. Material Handling equipments 6. Construction equipment 7. General Engineering

Castings No. of units involved (35 approx. ) Capacity Not Assessable (Unlimited) Specializatio n 1. Alloy Steel 2. S. G. Iron 3. C. I. 4. Non ferrous 5. Pressure die casting Applications 1. Automobiles 2. Steel Industries 3. Railways 4. Defense 5. Material Handling equipments 6. Construction equipment 7. General Engineering

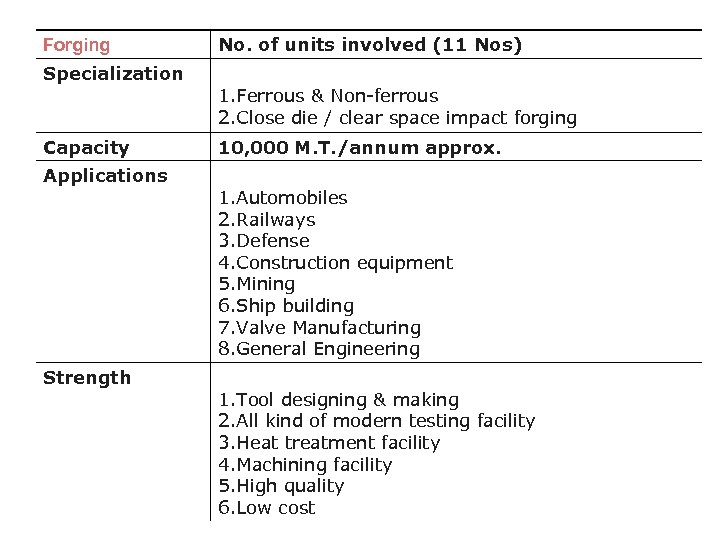

Forging Specialization Capacity Applications Strength No. of units involved (11 Nos) 1. Ferrous & Non-ferrous 2. Close die / clear space impact forging 10, 000 M. T. /annum approx. 1. Automobiles 2. Railways 3. Defense 4. Construction equipment 5. Mining 6. Ship building 7. Valve Manufacturing 8. General Engineering 1. Tool designing & making 2. All kind of modern testing facility 3. Heat treatment facility 4. Machining facility 5. High quality 6. Low cost

Forging Specialization Capacity Applications Strength No. of units involved (11 Nos) 1. Ferrous & Non-ferrous 2. Close die / clear space impact forging 10, 000 M. T. /annum approx. 1. Automobiles 2. Railways 3. Defense 4. Construction equipment 5. Mining 6. Ship building 7. Valve Manufacturing 8. General Engineering 1. Tool designing & making 2. All kind of modern testing facility 3. Heat treatment facility 4. Machining facility 5. High quality 6. Low cost

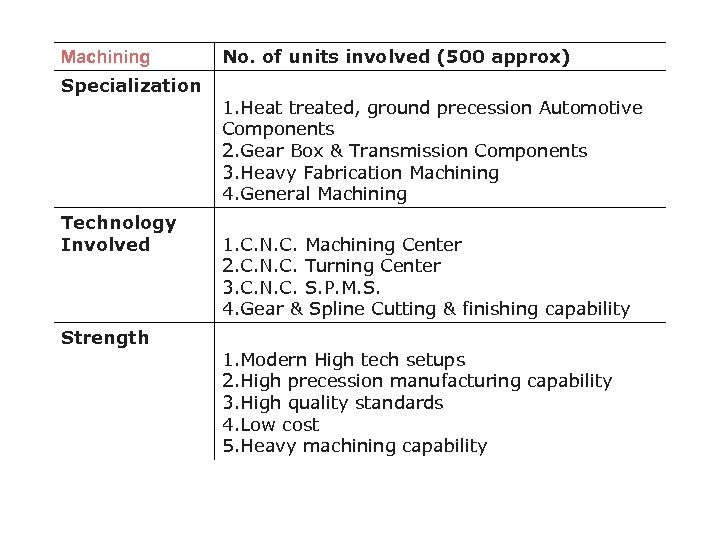

Machining Specialization Technology Involved Strength No. of units involved (500 approx) 1. Heat treated, ground precession Automotive Components 2. Gear Box & Transmission Components 3. Heavy Fabrication Machining 4. General Machining 1. C. N. C. Machining Center 2. C. N. C. Turning Center 3. C. N. C. S. P. M. S. 4. Gear & Spline Cutting & finishing capability 1. Modern High tech setups 2. High precession manufacturing capability 3. High quality standards 4. Low cost 5. Heavy machining capability

Machining Specialization Technology Involved Strength No. of units involved (500 approx) 1. Heat treated, ground precession Automotive Components 2. Gear Box & Transmission Components 3. Heavy Fabrication Machining 4. General Machining 1. C. N. C. Machining Center 2. C. N. C. Turning Center 3. C. N. C. S. P. M. S. 4. Gear & Spline Cutting & finishing capability 1. Modern High tech setups 2. High precession manufacturing capability 3. High quality standards 4. Low cost 5. Heavy machining capability

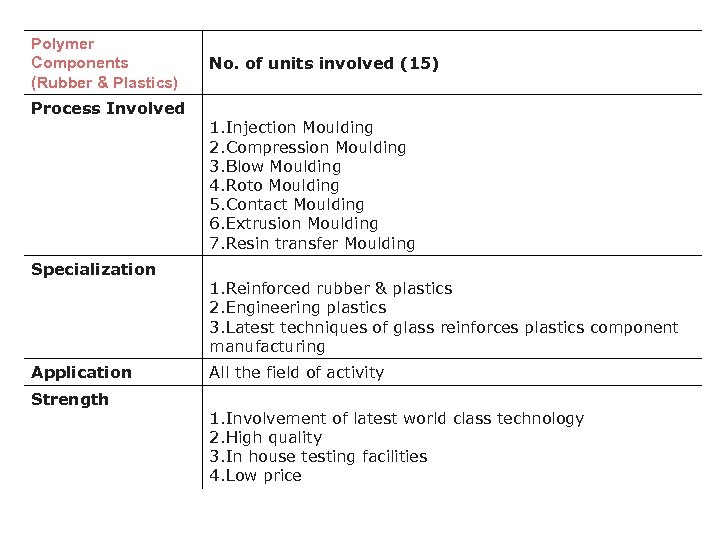

Polymer Components (Rubber & Plastics) Process Involved Specialization Application Strength No. of units involved (15) 1. Injection Moulding 2. Compression Moulding 3. Blow Moulding 4. Roto Moulding 5. Contact Moulding 6. Extrusion Moulding 7. Resin transfer Moulding 1. Reinforced rubber & plastics 2. Engineering plastics 3. Latest techniques of glass reinforces plastics component manufacturing All the field of activity 1. Involvement of latest world class technology 2. High quality 3. In house testing facilities 4. Low price

Polymer Components (Rubber & Plastics) Process Involved Specialization Application Strength No. of units involved (15) 1. Injection Moulding 2. Compression Moulding 3. Blow Moulding 4. Roto Moulding 5. Contact Moulding 6. Extrusion Moulding 7. Resin transfer Moulding 1. Reinforced rubber & plastics 2. Engineering plastics 3. Latest techniques of glass reinforces plastics component manufacturing All the field of activity 1. Involvement of latest world class technology 2. High quality 3. In house testing facilities 4. Low price

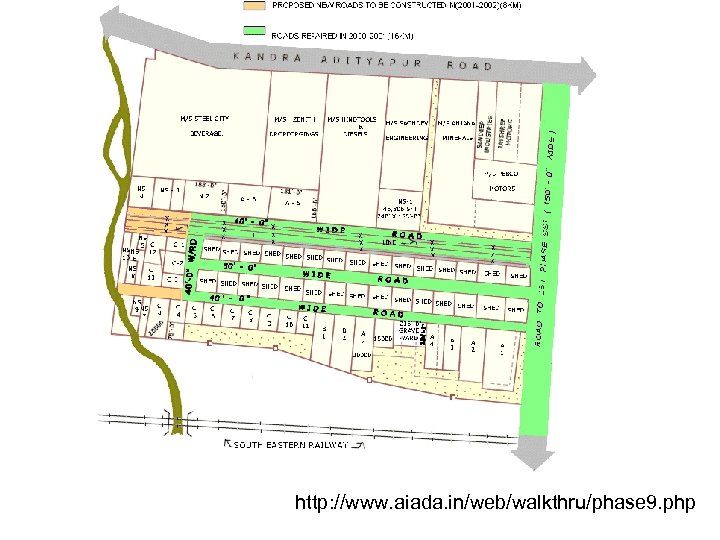

http: //www. aiada. in/web/walkthru/phase 9. php

http: //www. aiada. in/web/walkthru/phase 9. php

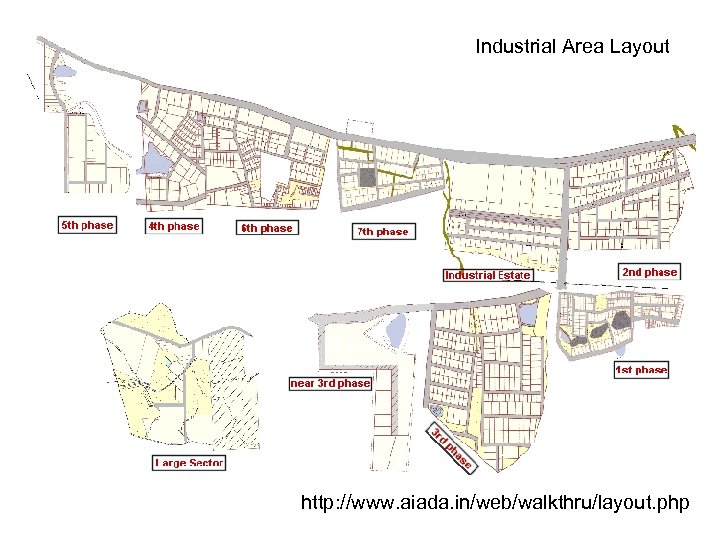

Industrial Area Layout http: //www. aiada. in/web/walkthru/layout. php

Industrial Area Layout http: //www. aiada. in/web/walkthru/layout. php