1ce36a537665dd12d23360d9ade6883e.ppt

- Количество слайдов: 13

Profile Adalbert Ney NEYCONSULT

Consulting Profile: Sucessfull track story since 2003 in the areas of procurement and supply chain management. Adalbert Ney Dipl. -Betriebswirt Purchasing and Supply Chain Management In der Tränk 36 D-63075 Offenbach Phone: +49 -69 -977 69 260 Cell: 0171/93 79 287 Mail: neyconsult@web. de Education Masters degree in economics and law Professional Profile Logistics officer Head of purchasing and Supply Chain by several german mid size companies ( sales 60 -100 Mio €) Industries Machine Tool Microprozessor Electronical Automotive Supply Chain Manager of Swedisch, British and American companies ( sales 80 - 200 Mio €) NEYCONSULT

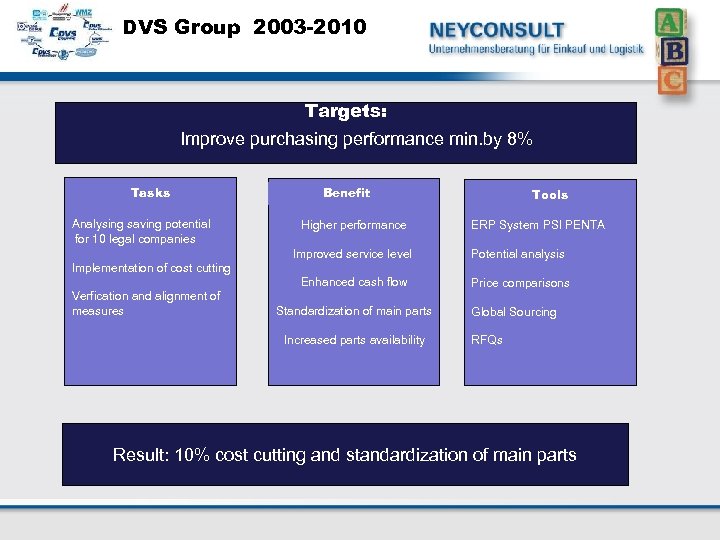

DVS Group 2003 -2010 Targets: Improve purchasing performance min. by 8% Lower main stock Tasks Analysing saving potential for 10 legal companies Benefit Higher performance Tools ERP System PSI PENTA Improved service level Potential analysis Enhanced cash flow Price comparisons Implementation of cost cutting Verfication and alignment of measures Standardization of main parts Increased parts availability Global Sourcing RFQs Result: 10% cost cutting and standardization of main parts

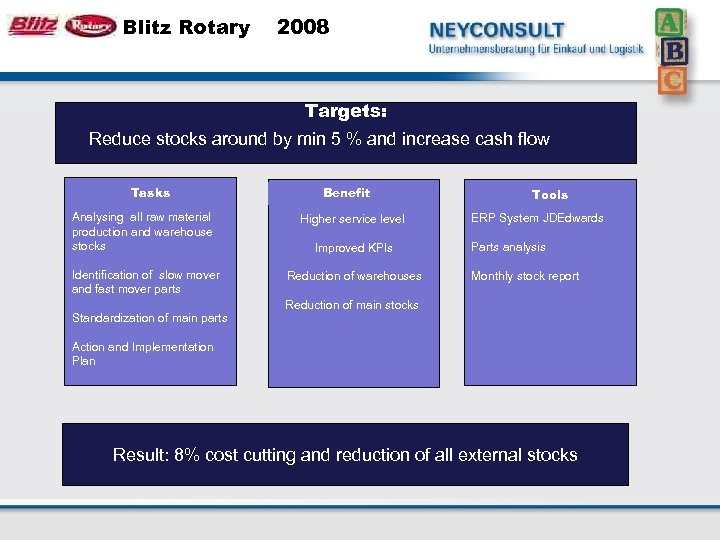

Blitz Rotary 2008 Targets: Reduce stocks around by min 5 % and increase cash flow Tasks Lower main stock Benefit Analysing all raw material production and warehouse stocks Higher service level Identification of slow mover and fast mover parts Reduction of warehouses Standardization of main parts Improved KPIs Tools ERP System JDEdwards Parts analysis Monthly stock report Reduction of main stocks Action and Implementation Plan Result: 8% cost cutting and reduction of all external stocks

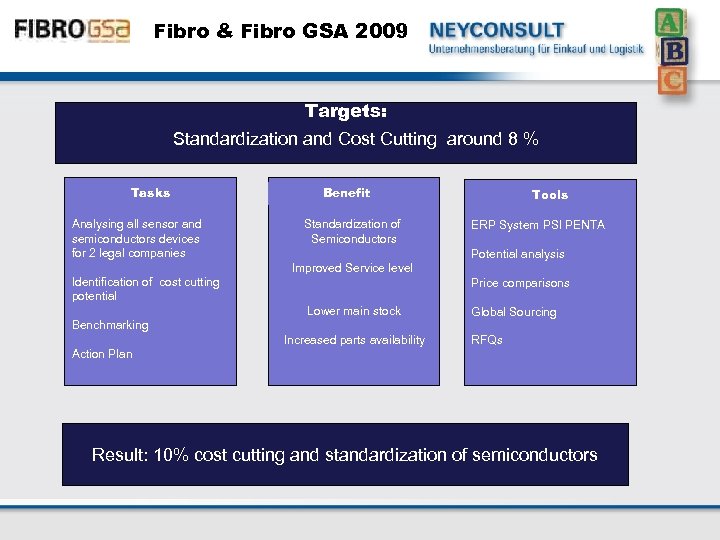

Fibro & Fibro GSA 2009 Targets: Standardization and Cost Cutting around 8 % Lower main stock Tasks Analysing all sensor and semiconductors devices for 2 legal companies Benefit Standardization of Semiconductors Tools ERP System PSI PENTA Potential analysis Improved Service level Identification of cost cutting potential Price comparisons Lower main stock Global Sourcing Benchmarking Increased parts availability RFQs Action Plan Result: 10% cost cutting and standardization of semiconductors

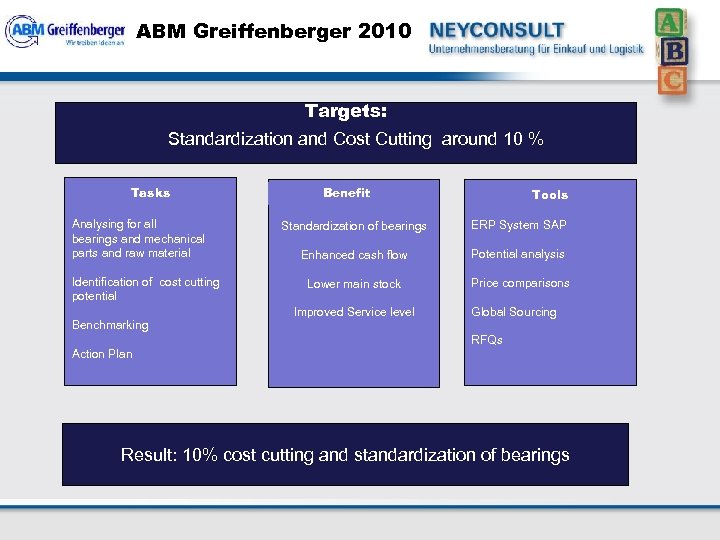

ABM Greiffenberger 2010 Targets: Standardization and Cost Cutting around 10 % Tasks Analysing for all bearings and mechanical parts and raw material Identification of cost cutting potential Benchmarking Benefit Tools Standardization of bearings ERP System SAP Enhanced cash flow Potential analysis Lower main stock Price comparisons Improved Service level Global Sourcing RFQs Action Plan Result: 10% cost cutting and standardization of bearings

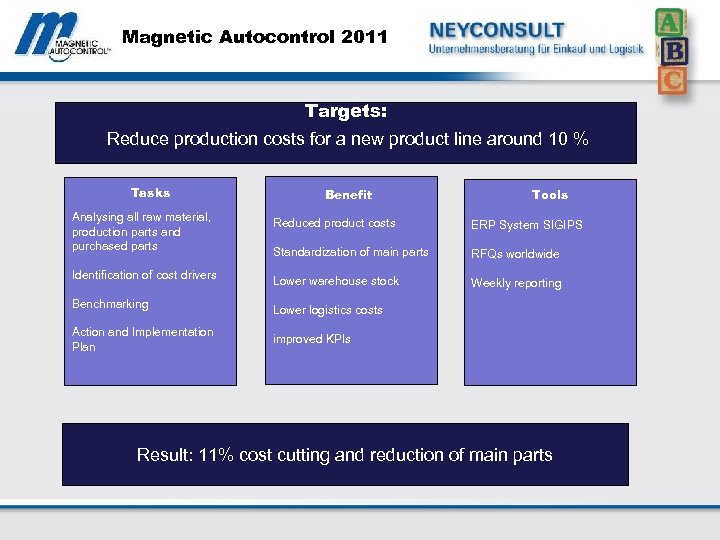

Magnetic Autocontrol 2011 Targets: Reduce production costs for a new product line around 10 % Tasks Analysing all raw material, production parts and purchased parts Identification of cost drivers Benchmarking Action and Implementation Plan Benefit Tools Reduced product costs ERP System SIGIPS Standardization of main parts RFQs worldwide Lower warehouse stock Weekly reporting Lower logistics costs improved KPIs Result: 11% cost cutting and reduction of main parts

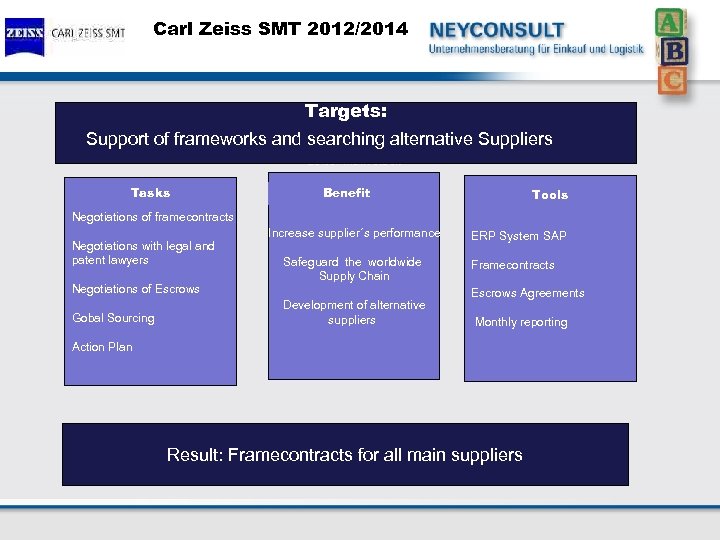

Carl Zeiss SMT 2012/2014 Targets: Support of frameworks and searching alternative Suppliers Lower main stock Tasks Benefit Tools Negotiations of framecontracts Negotiations with legal and patent lawyers Negotiations of Escrows Gobal Sourcing Increase supplier´s performance Safeguard the worldwide Supply Chain Development of alternative suppliers ERP System SAP Framecontracts Escrows Agreements Monthly reporting Action Plan Result: Framecontracts for all main suppliers

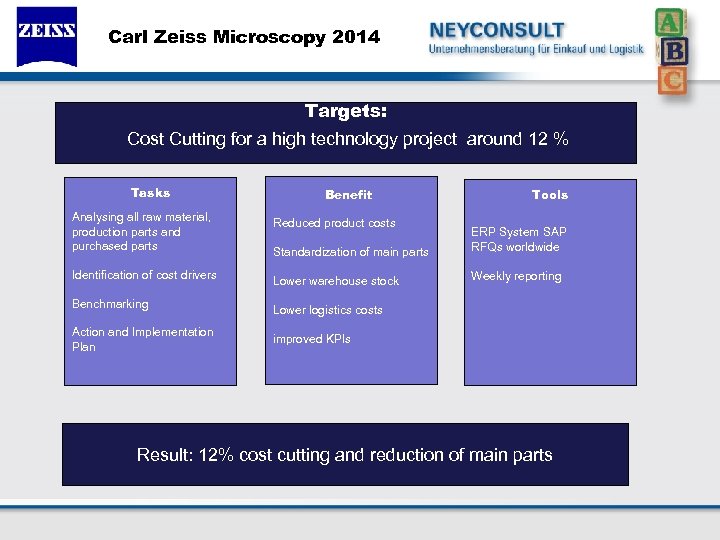

Carl Zeiss Microscopy 2014 Targets: Cost Cutting for a high technology project around 12 % Tasks Analysing all raw material, production parts and purchased parts Identification of cost drivers Benchmarking Action and Implementation Plan Benefit Reduced product costs Tools Standardization of main parts ERP System SAP RFQs worldwide Lower warehouse stock Weekly reporting Lower logistics costs improved KPIs Result: 12% cost cutting and reduction of main parts

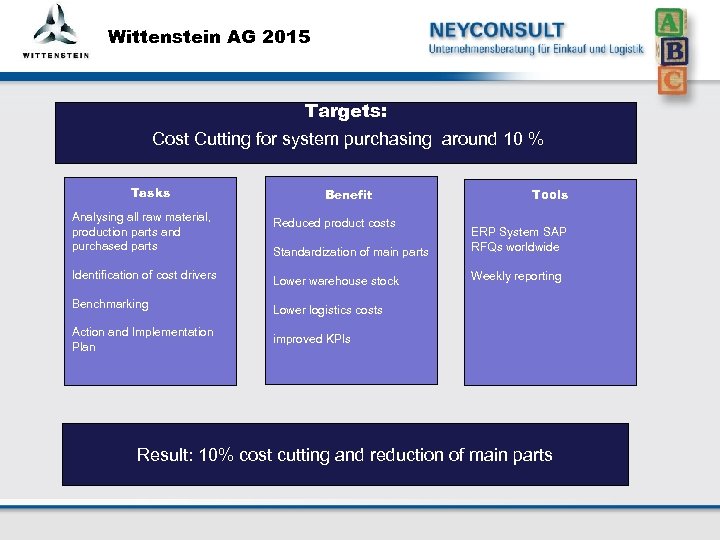

Wittenstein AG 2015 Targets: Cost Cutting for system purchasing around 10 % Tasks Analysing all raw material, production parts and purchased parts Identification of cost drivers Benchmarking Action and Implementation Plan Benefit Reduced product costs Tools Standardization of main parts ERP System SAP RFQs worldwide Lower warehouse stock Weekly reporting Lower logistics costs improved KPIs Result: 10% cost cutting and reduction of main parts

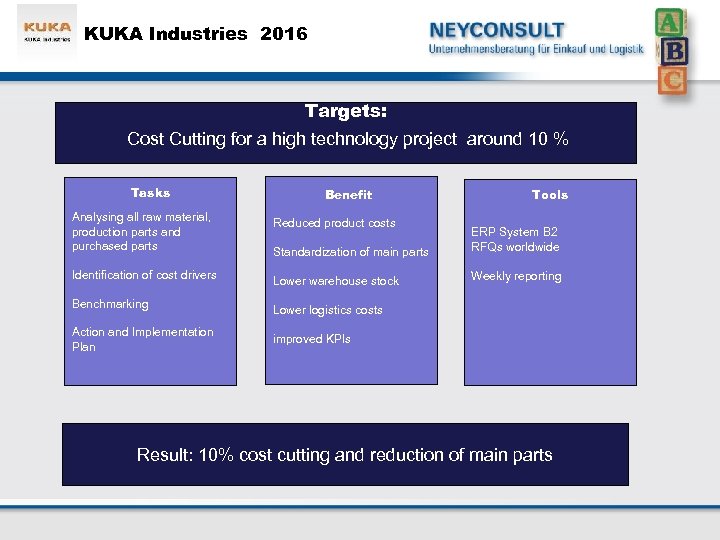

KUKA Industries 2016 Targets: Cost Cutting for a high technology project around 10 % Tasks Analysing all raw material, production parts and purchased parts Identification of cost drivers Benchmarking Action and Implementation Plan Benefit Reduced product costs Tools Standardization of main parts ERP System B 2 RFQs worldwide Lower warehouse stock Weekly reporting Lower logistics costs improved KPIs Result: 10% cost cutting and reduction of main parts

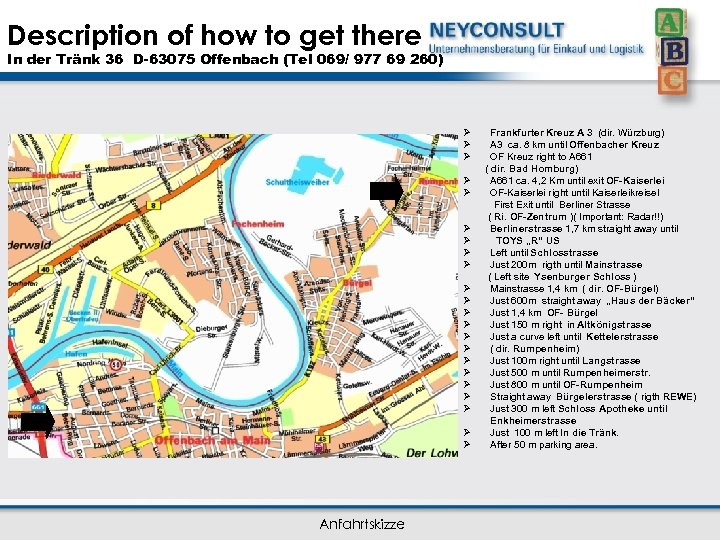

Description of how to get there In der Tränk 36 D-63075 Offenbach (Tel 069/ 977 69 260) Ø Ø Ø Ø Ø Ø Anfahrtskizze Frankfurter Kreuz A 3 (dir. Würzburg) A 3 ca. 8 km until Offenbacher Kreuz OF Kreuz right to A 661 ( dir. Bad Homburg) A 661 ca. 4, 2 Km until exit OF-Kaiserlei right until Kaiserleikreisel First Exit until Berliner Strasse ( Ri. OF-Zentrum )( Important: Radar!!) Berlinerstrasse 1, 7 km straight away until TOYS „R“ US Left until Schlosstrasse Just 200 m rigth until Mainstrasse ( Left site Ysenburger Schloss ) Mainstrasse 1, 4 km ( dir. OF-Bürgel) Just 600 m straight away „Haus der Bäcker“ Just 1, 4 km OF- Bürgel Just 150 m right in Altkönigstrasse Just a curve left until Kettelerstrasse ( dir. Rumpenheim) Just 100 m right until Langstrasse Just 500 m until Rumpenheimerstr. Just 800 m until OF-Rumpenheim Straight away Bürgelerstrasse ( rigth REWE) Just 300 m left Schloss Apotheke until Enkheimerstrasse Just 100 m left In die Tränk. After 50 m parking area.

References

1ce36a537665dd12d23360d9ade6883e.ppt