82c77b16e4e6983b9633ffe72d1440b0.ppt

- Количество слайдов: 47

PRODUCTS PLANNİNG AND PROCESS SELECTİON - II Prepared by Şevkinaz Gümüşoğlu using different references about POM&QM

PRODUCTS PLANNİNG AND PROCESS SELECTİON - II Prepared by Şevkinaz Gümüşoğlu using different references about POM&QM

2 -Simplex Method: Realistic linear programming problems often have several decision variables and many constraints equations. Such problems cannot be solved graphically, so algorithms such as simplex procedure are used. The simplex method is an iterative procedure that progressively approaches and ultimately reaches an optimal solution to LP problems Although the S. M. is especially useful for large-scale problem. But to understand easly we will illustrated for the some problem start was solved graphically. Basic Simplex Concepts We will solve a problem algebraically. Our first step is to acknowledge the existence of slack, The existence of slack represents unused resources. We define the following slack variables: (it represents the unused capacity in the constraints) Si= amount of unused resources. 30 X I+20 X 2<300 30 XI+20 X 2+S I If we have any extra quantity we can express it as surplus resources. 5 -2

2 -Simplex Method: Realistic linear programming problems often have several decision variables and many constraints equations. Such problems cannot be solved graphically, so algorithms such as simplex procedure are used. The simplex method is an iterative procedure that progressively approaches and ultimately reaches an optimal solution to LP problems Although the S. M. is especially useful for large-scale problem. But to understand easly we will illustrated for the some problem start was solved graphically. Basic Simplex Concepts We will solve a problem algebraically. Our first step is to acknowledge the existence of slack, The existence of slack represents unused resources. We define the following slack variables: (it represents the unused capacity in the constraints) Si= amount of unused resources. 30 X I+20 X 2<300 30 XI+20 X 2+S I If we have any extra quantity we can express it as surplus resources. 5 -2

Surplus variables are analogous to slack variables, in that they allow us to express linear programs in the equation form required by simplex. X 1>2 X 1 - S 1=2 S 1 will begin as a negative value, which is not allowed. Thus this constraints cannot serve as a standing simplex row in its present form. (Variables must be non-negative). To begin the simplex procedure we introduce the artificial variable. Artificial variable has no meaningful economic interpretation. X 1 - S 1+Y 1=2 Yi : artificial variable To guarantee that Yi=0 (so that it is not in the final variable mix), we must make it highly unprofitable to do otherwise We use the letter M(relatively 5 -3 big figure than Cj, j, Si, Yi) M = represent a huge number.

Surplus variables are analogous to slack variables, in that they allow us to express linear programs in the equation form required by simplex. X 1>2 X 1 - S 1=2 S 1 will begin as a negative value, which is not allowed. Thus this constraints cannot serve as a standing simplex row in its present form. (Variables must be non-negative). To begin the simplex procedure we introduce the artificial variable. Artificial variable has no meaningful economic interpretation. X 1 - S 1+Y 1=2 Yi : artificial variable To guarantee that Yi=0 (so that it is not in the final variable mix), we must make it highly unprofitable to do otherwise We use the letter M(relatively 5 -3 big figure than Cj, j, Si, Yi) M = represent a huge number.

Simplex Procedure 1. Set up initial simplex table. The simplex method always begins with feasible solution where both X i and X 2 equal zero. This corresponds to the origin of the graphic solution where in only slack is produced, that is, zero profit. 4 Xi + 6 X 2+ Si = 12 Xi =0 X 2=0 Si =12 8 Xi + 4 X 2+ S 2 = 16 S 2 =16 Each simple table is a solution that graphically corresponds to a corner of a feasible region. C; 10 30 0 0 Variable Xi X 2 S i S 2 Solution Values We determine Smalest nonnegative between quantity/ pivot element We call them Ratio We interest maximum greatest Per-unit to select new enter variable 5 -4

Simplex Procedure 1. Set up initial simplex table. The simplex method always begins with feasible solution where both X i and X 2 equal zero. This corresponds to the origin of the graphic solution where in only slack is produced, that is, zero profit. 4 Xi + 6 X 2+ Si = 12 Xi =0 X 2=0 Si =12 8 Xi + 4 X 2+ S 2 = 16 S 2 =16 Each simple table is a solution that graphically corresponds to a corner of a feasible region. C; 10 30 0 0 Variable Xi X 2 S i S 2 Solution Values We determine Smalest nonnegative between quantity/ pivot element We call them Ratio We interest maximum greatest Per-unit to select new enter variable 5 -4

Si =Slack variable CJ = Contribution from the variable CJ- Zj =Net contribution of the variable (unit improvement) aij = Substitution coefficient, exchange coefficient: In the body of the tableau the values represent the original constraint coefficient. Thus, we would increase the value of the objective function by a full $10 for each unit of X 1 produced and by $30 for each unit of X 2 produced. Exchange coefficients indicate how many units of the variable must be given up. 5 -5

Si =Slack variable CJ = Contribution from the variable CJ- Zj =Net contribution of the variable (unit improvement) aij = Substitution coefficient, exchange coefficient: In the body of the tableau the values represent the original constraint coefficient. Thus, we would increase the value of the objective function by a full $10 for each unit of X 1 produced and by $30 for each unit of X 2 produced. Exchange coefficients indicate how many units of the variable must be given up. 5 -5

Repeat step 2 through step 7, until all values in the bottom row are =0 or <0. Since all values are =0 or <0, the optimal solution is already reached. ZJ = Unit sacrifice (opportunity cost) Unit sacrifice = (Unit profit column) *( exchange coefficient column). (Unit profit column) X (X 1 Column) 0 x 4=0 0 x 8=0 Sacrifice for X 1 =0 CJ- Zj =Unit improvement = Unit profit-Unit sacrifice For example ; unit improvement for C 1 =10 -0=10 Apply the entry criterion: Find the current non mix variable that increasing from zero will improve the objective at the greatest rate. This variable is the entering variable. Apply the exit criterion: Use the current tableau’s exchange coefficient values 5 -6 from the column of the entering variable to calculate the following exchange ratio for each row.

Repeat step 2 through step 7, until all values in the bottom row are =0 or <0. Since all values are =0 or <0, the optimal solution is already reached. ZJ = Unit sacrifice (opportunity cost) Unit sacrifice = (Unit profit column) *( exchange coefficient column). (Unit profit column) X (X 1 Column) 0 x 4=0 0 x 8=0 Sacrifice for X 1 =0 CJ- Zj =Unit improvement = Unit profit-Unit sacrifice For example ; unit improvement for C 1 =10 -0=10 Apply the entry criterion: Find the current non mix variable that increasing from zero will improve the objective at the greatest rate. This variable is the entering variable. Apply the exit criterion: Use the current tableau’s exchange coefficient values 5 -6 from the column of the entering variable to calculate the following exchange ratio for each row.

Ignoring ratios with zero or negative denominators, find the smallest non-negative exchange ratio. This ratio represents us leaving variable. The circled value in the greatest per unit improvement column is called pivot element. This value is used to evaluated the new corner point. New entering variable row is calculated by dividing pivot element in this row. The other variables row is calculated : (value of old row) - (value of entering variable row)X(pivot element in this row) There fore, X 1 =not in solution X 1 =2 units Z =$60 We have the slack in solution S 2 =8 and that the constraints is not binding. We have only one (non slack) decision variable in the solution and one binding constraints. Values in the CJ - Zj now 1. (-10) To produce on can of X (cleaner) would reduce profits by $10, because it would take machine A time away from the production of Y. (0) The first zero indicates that Y is in solution (being produced). (-5) Shadow prices, the net effect of increasing (or decreasing) the slack on idle time of machine A by one unit. Conversely, if another hour could be available, say by shifting a current job from A, the time an A could be profitably utilized at a profit rate of $5 per hour. 5 -7 (0) Machine B already has slack time. Increasing B’s available time (or decreasing it) by one unit would have no effect on profits

Ignoring ratios with zero or negative denominators, find the smallest non-negative exchange ratio. This ratio represents us leaving variable. The circled value in the greatest per unit improvement column is called pivot element. This value is used to evaluated the new corner point. New entering variable row is calculated by dividing pivot element in this row. The other variables row is calculated : (value of old row) - (value of entering variable row)X(pivot element in this row) There fore, X 1 =not in solution X 1 =2 units Z =$60 We have the slack in solution S 2 =8 and that the constraints is not binding. We have only one (non slack) decision variable in the solution and one binding constraints. Values in the CJ - Zj now 1. (-10) To produce on can of X (cleaner) would reduce profits by $10, because it would take machine A time away from the production of Y. (0) The first zero indicates that Y is in solution (being produced). (-5) Shadow prices, the net effect of increasing (or decreasing) the slack on idle time of machine A by one unit. Conversely, if another hour could be available, say by shifting a current job from A, the time an A could be profitably utilized at a profit rate of $5 per hour. 5 -7 (0) Machine B already has slack time. Increasing B’s available time (or decreasing it) by one unit would have no effect on profits

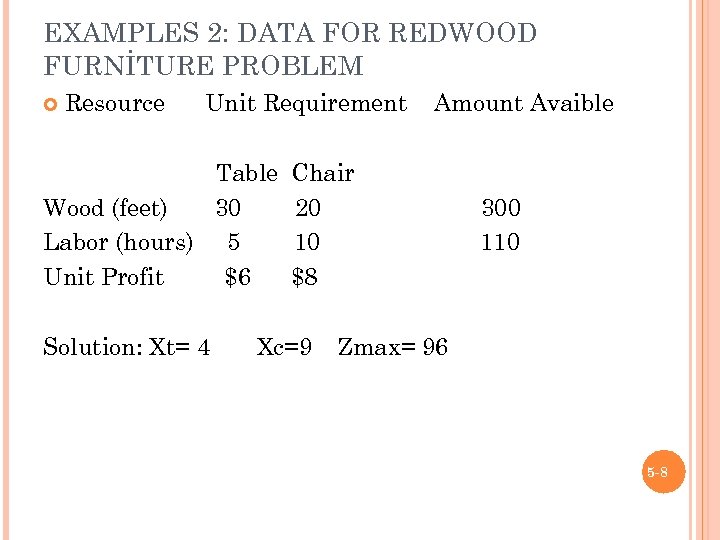

EXAMPLES 2: DATA FOR REDWOOD FURNİTURE PROBLEM Resource Unit Requirement Table Wood (feet) 30 Labor (hours) 5 Unit Profit $6 Solution: Xt= 4 Amount Avaible Chair 20 10 $8 Xc=9 300 110 Zmax= 96 5 -8

EXAMPLES 2: DATA FOR REDWOOD FURNİTURE PROBLEM Resource Unit Requirement Table Wood (feet) 30 Labor (hours) 5 Unit Profit $6 Solution: Xt= 4 Amount Avaible Chair 20 10 $8 Xc=9 300 110 Zmax= 96 5 -8

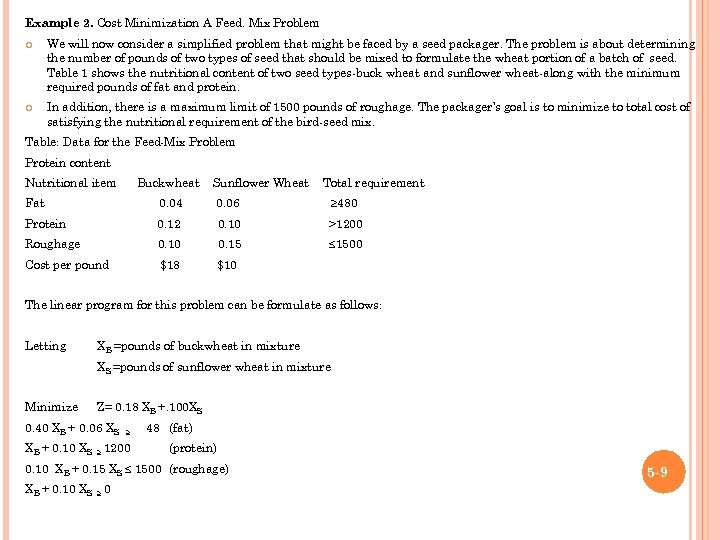

Example 2. Cost Minimization A Feed. Mix Problem We will now consider a simplified problem that might be faced by a seed packager. The problem is about determining the number of pounds of two types of seed that should be mixed to formulate the wheat portion of a batch of seed. Table 1 shows the nutritional content of two seed types-buck wheat and sunflower wheat-along with the minimum required pounds of fat and protein. In addition, there is a maximum limit of 1500 pounds of roughage. The packager’s goal is to minimize to total cost of satisfying the nutritional requirement of the bird-seed mix. Table: Data for the Feed-Mix Problem Protein content Nutritional item Buckwheat Sunflower Wheat Total requirement Fat 0. 04 0. 06 480 Protein 0. 12 0. 10 >1200 Roughage 0. 10 0. 15 1500 Cost per pound $18 $10 The linear program for this problem can be formulate as follows: Letting XB =pounds of buckwheat in mixture XS =pounds of sunflower wheat in mixture Minimize Z= 0. 18 XB +. 100 XS 0. 40 XB + 0. 06 XS XB + 0. 10 XS 1200 48 (fat) (protein) 0. 10 XB + 0. 15 XS 1500 (roughage) XB + 0. 10 XS 0 5 -9

Example 2. Cost Minimization A Feed. Mix Problem We will now consider a simplified problem that might be faced by a seed packager. The problem is about determining the number of pounds of two types of seed that should be mixed to formulate the wheat portion of a batch of seed. Table 1 shows the nutritional content of two seed types-buck wheat and sunflower wheat-along with the minimum required pounds of fat and protein. In addition, there is a maximum limit of 1500 pounds of roughage. The packager’s goal is to minimize to total cost of satisfying the nutritional requirement of the bird-seed mix. Table: Data for the Feed-Mix Problem Protein content Nutritional item Buckwheat Sunflower Wheat Total requirement Fat 0. 04 0. 06 480 Protein 0. 12 0. 10 >1200 Roughage 0. 10 0. 15 1500 Cost per pound $18 $10 The linear program for this problem can be formulate as follows: Letting XB =pounds of buckwheat in mixture XS =pounds of sunflower wheat in mixture Minimize Z= 0. 18 XB +. 100 XS 0. 40 XB + 0. 06 XS XB + 0. 10 XS 1200 48 (fat) (protein) 0. 10 XB + 0. 15 XS 1500 (roughage) XB + 0. 10 XS 0 5 -9

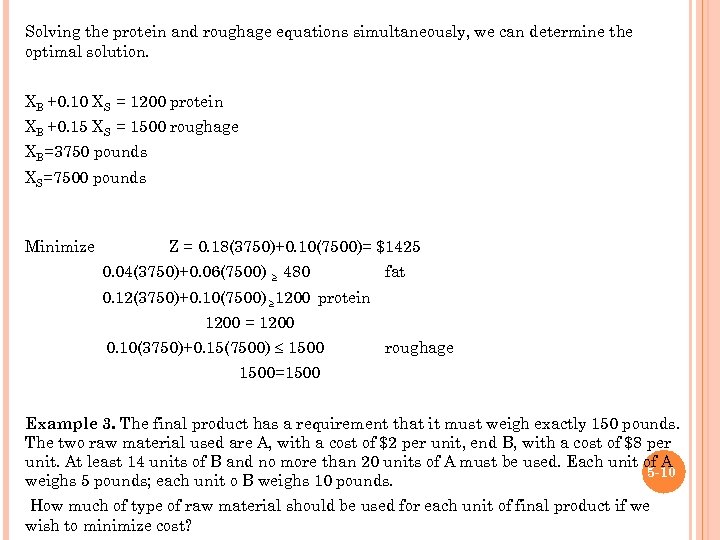

Solving the protein and roughage equations simultaneously, we can determine the optimal solution. XB +0. 10 XS = 1200 protein XB +0. 15 XS = 1500 roughage XB=3750 pounds XS=7500 pounds Minimize Z = 0. 18(3750)+0. 10(7500)= $1425 0. 04(3750)+0. 06(7500) 480 fat 0. 12(3750)+0. 10(7500) 1200 protein 1200 = 1200 0. 10(3750)+0. 15(7500) 1500 roughage 1500=1500 Example 3. The final product has a requirement that it must weigh exactly 150 pounds. The two raw material used are A, with a cost of $2 per unit, end B, with a cost of $8 per unit. At least 14 units of B and no more than 20 units of A must be used. Each unit of A 5 -10 weighs 5 pounds; each unit o B weighs 10 pounds. How much of type of raw material should be used for each unit of final product if we wish to minimize cost?

Solving the protein and roughage equations simultaneously, we can determine the optimal solution. XB +0. 10 XS = 1200 protein XB +0. 15 XS = 1500 roughage XB=3750 pounds XS=7500 pounds Minimize Z = 0. 18(3750)+0. 10(7500)= $1425 0. 04(3750)+0. 06(7500) 480 fat 0. 12(3750)+0. 10(7500) 1200 protein 1200 = 1200 0. 10(3750)+0. 15(7500) 1500 roughage 1500=1500 Example 3. The final product has a requirement that it must weigh exactly 150 pounds. The two raw material used are A, with a cost of $2 per unit, end B, with a cost of $8 per unit. At least 14 units of B and no more than 20 units of A must be used. Each unit of A 5 -10 weighs 5 pounds; each unit o B weighs 10 pounds. How much of type of raw material should be used for each unit of final product if we wish to minimize cost?

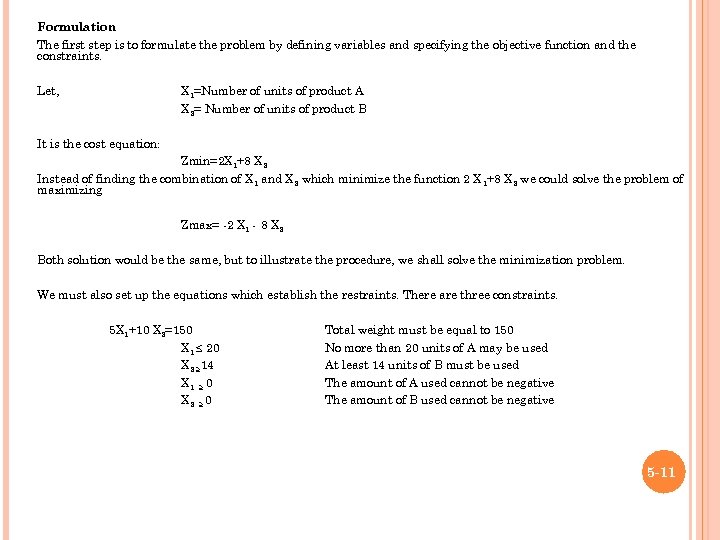

Formulation The first step is to formulate the problem by defining variables and specifying the objective function and the constraints. Let, X 1=Number of units of product A X 2= Number of units of product B It is the cost equation: Zmin=2 X 1+8 X 2 Instead of finding the combination of X 1 and X 2 which minimize the function 2 X 1+8 X 2 we could solve the problem of maximizing Zmax= -2 X 1 - 8 X 2 Both solution would be the same, but to illustrate the procedure, we shall solve the minimization problem. We must also set up the equations which establish the restraints. There are three constraints. 5 X 1+10 X 2=150 Total weight must be equal to 150 X 1 20 No more than 20 units of A may be used X 2 14 At least 14 units of B must be used X 1 0 The amount of A used cannot be negative X 2 0 The amount of B used cannot be negative 5 -11

Formulation The first step is to formulate the problem by defining variables and specifying the objective function and the constraints. Let, X 1=Number of units of product A X 2= Number of units of product B It is the cost equation: Zmin=2 X 1+8 X 2 Instead of finding the combination of X 1 and X 2 which minimize the function 2 X 1+8 X 2 we could solve the problem of maximizing Zmax= -2 X 1 - 8 X 2 Both solution would be the same, but to illustrate the procedure, we shall solve the minimization problem. We must also set up the equations which establish the restraints. There are three constraints. 5 X 1+10 X 2=150 Total weight must be equal to 150 X 1 20 No more than 20 units of A may be used X 2 14 At least 14 units of B must be used X 1 0 The amount of A used cannot be negative X 2 0 The amount of B used cannot be negative 5 -11

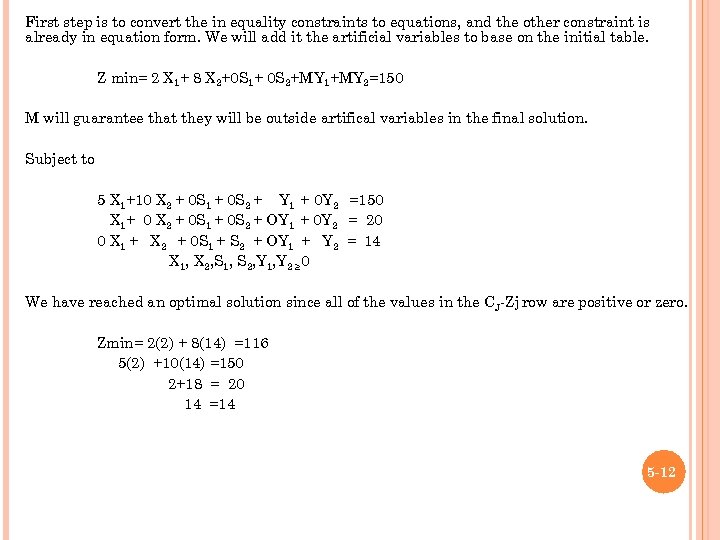

First step is to convert the in equality constraints to equations, and the other constraint is already in equation form. We will add it the artificial variables to base on the initial table. Z min= 2 X 1+ 8 X 2+0 S 1+ 0 S 2+MY 1+MY 2=150 M will guarantee that they will be outside artifical variables in the final solution. Subject to 5 X 1+10 X 2 + 0 S 1 + 0 S 2 + Y 1 + 0 Y 2 =150 X 1+ 0 X 2 + 0 S 1 + 0 S 2 + OY 1 + 0 Y 2 = 20 0 X 1 + X 2 + 0 S 1 + S 2 + OY 1 + Y 2 = 14 X 1, X 2, S 1, S 2, Y 1, Y 2 0 We have reached an optimal solution since all of the values in the CJ-Zj row are positive or zero. Zmin= 2(2) + 8(14) =116 5(2) +10(14) =150 2+18 = 20 14 =14 5 -12

First step is to convert the in equality constraints to equations, and the other constraint is already in equation form. We will add it the artificial variables to base on the initial table. Z min= 2 X 1+ 8 X 2+0 S 1+ 0 S 2+MY 1+MY 2=150 M will guarantee that they will be outside artifical variables in the final solution. Subject to 5 X 1+10 X 2 + 0 S 1 + 0 S 2 + Y 1 + 0 Y 2 =150 X 1+ 0 X 2 + 0 S 1 + 0 S 2 + OY 1 + 0 Y 2 = 20 0 X 1 + X 2 + 0 S 1 + S 2 + OY 1 + Y 2 = 14 X 1, X 2, S 1, S 2, Y 1, Y 2 0 We have reached an optimal solution since all of the values in the CJ-Zj row are positive or zero. Zmin= 2(2) + 8(14) =116 5(2) +10(14) =150 2+18 = 20 14 =14 5 -12

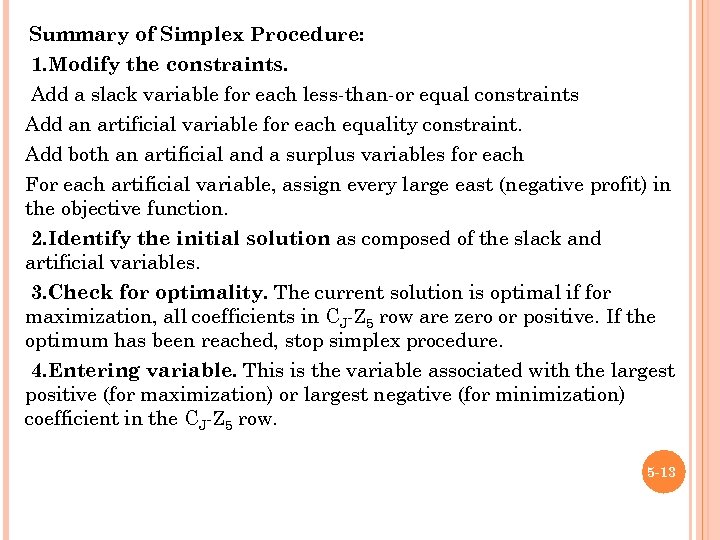

Summary of Simplex Procedure: 1. Modify the constraints. Add a slack variable for each less-than-or equal constraints Add an artificial variable for each equality constraint. Add both an artificial and a surplus variables for each For each artificial variable, assign every large east (negative profit) in the objective function. 2. Identify the initial solution as composed of the slack and artificial variables. 3. Check for optimality. The current solution is optimal if for maximization, all coefficients in CJ-Z 5 row are zero or positive. If the optimum has been reached, stop simplex procedure. 4. Entering variable. This is the variable associated with the largest positive (for maximization) or largest negative (for minimization) coefficient in the CJ-Z 5 row. 5 -13

Summary of Simplex Procedure: 1. Modify the constraints. Add a slack variable for each less-than-or equal constraints Add an artificial variable for each equality constraint. Add both an artificial and a surplus variables for each For each artificial variable, assign every large east (negative profit) in the objective function. 2. Identify the initial solution as composed of the slack and artificial variables. 3. Check for optimality. The current solution is optimal if for maximization, all coefficients in CJ-Z 5 row are zero or positive. If the optimum has been reached, stop simplex procedure. 4. Entering variable. This is the variable associated with the largest positive (for maximization) or largest negative (for minimization) coefficient in the CJ-Z 5 row. 5 -13

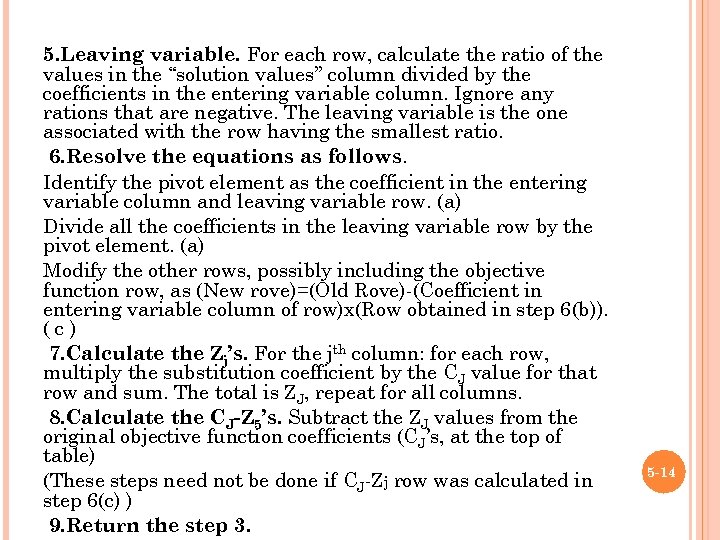

5. Leaving variable. For each row, calculate the ratio of the values in the “solution values” column divided by the coefficients in the entering variable column. Ignore any rations that are negative. The leaving variable is the one associated with the row having the smallest ratio. 6. Resolve the equations as follows. Identify the pivot element as the coefficient in the entering variable column and leaving variable row. (a) Divide all the coefficients in the leaving variable row by the pivot element. (a) Modify the other rows, possibly including the objective function row, as (New rove)=(Old Rove)-(Coefficient in entering variable column of row)x(Row obtained in step 6(b)). (c) 7. Calculate the Zj’s. For the jth column: for each row, multiply the substitution coefficient by the CJ value for that row and sum. The total is ZJ, repeat for all columns. 8. Calculate the CJ-Z 5’s. Subtract the ZJ values from the original objective function coefficients (CJ’s, at the top of table) (These steps need not be done if CJ-Zj row was calculated in step 6(c) ) 9. Return the step 3. 5 -14

5. Leaving variable. For each row, calculate the ratio of the values in the “solution values” column divided by the coefficients in the entering variable column. Ignore any rations that are negative. The leaving variable is the one associated with the row having the smallest ratio. 6. Resolve the equations as follows. Identify the pivot element as the coefficient in the entering variable column and leaving variable row. (a) Divide all the coefficients in the leaving variable row by the pivot element. (a) Modify the other rows, possibly including the objective function row, as (New rove)=(Old Rove)-(Coefficient in entering variable column of row)x(Row obtained in step 6(b)). (c) 7. Calculate the Zj’s. For the jth column: for each row, multiply the substitution coefficient by the CJ value for that row and sum. The total is ZJ, repeat for all columns. 8. Calculate the CJ-Z 5’s. Subtract the ZJ values from the original objective function coefficients (CJ’s, at the top of table) (These steps need not be done if CJ-Zj row was calculated in step 6(c) ) 9. Return the step 3. 5 -14

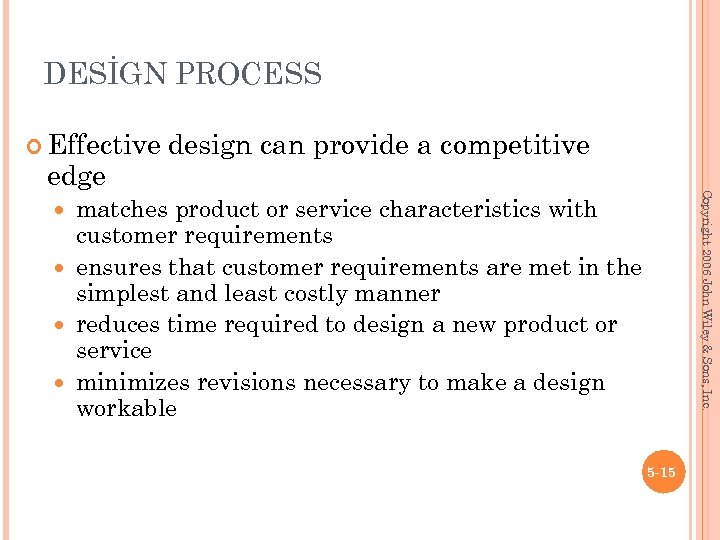

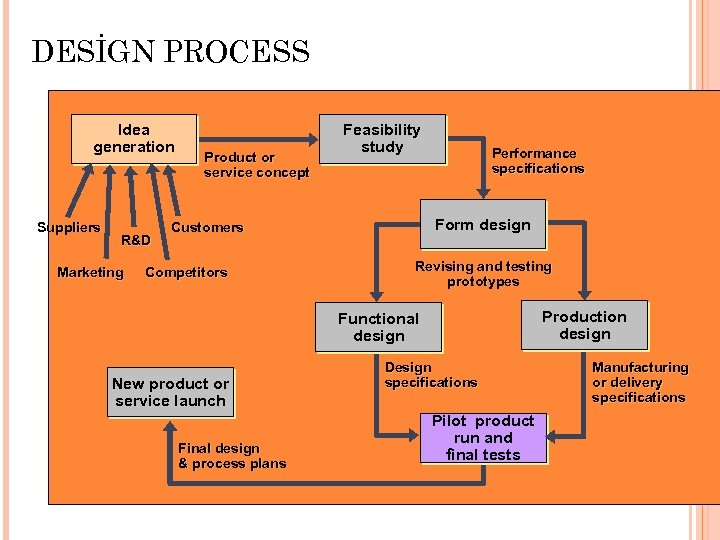

DESİGN PROCESS Effective Copyright 2006 John Wiley & Sons, Inc. edge design can provide a competitive matches product or service characteristics with customer requirements ensures that customer requirements are met in the simplest and least costly manner reduces time required to design a new product or service minimizes revisions necessary to make a design workable 5 -15

DESİGN PROCESS Effective Copyright 2006 John Wiley & Sons, Inc. edge design can provide a competitive matches product or service characteristics with customer requirements ensures that customer requirements are met in the simplest and least costly manner reduces time required to design a new product or service minimizes revisions necessary to make a design workable 5 -15

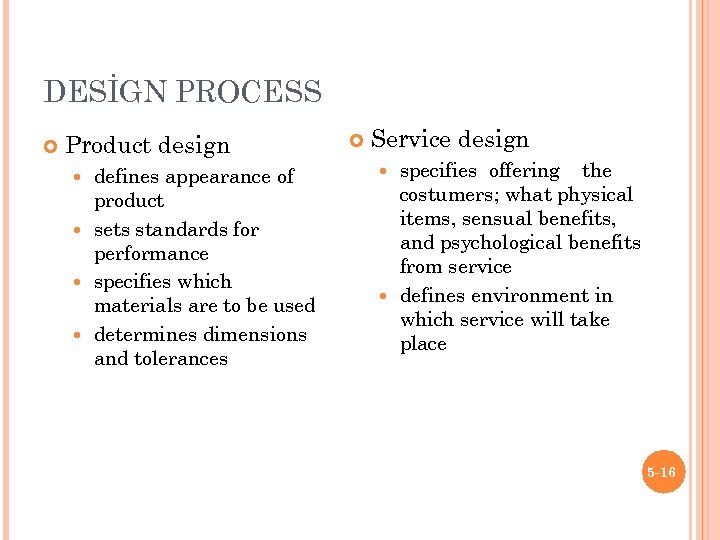

DESİGN PROCESS Product design defines appearance of product sets standards for performance specifies which materials are to be used determines dimensions and tolerances Service design specifies offering the costumers; what physical items, sensual benefits, and psychological benefits from service defines environment in which service will take place 5 -16

DESİGN PROCESS Product design defines appearance of product sets standards for performance specifies which materials are to be used determines dimensions and tolerances Service design specifies offering the costumers; what physical items, sensual benefits, and psychological benefits from service defines environment in which service will take place 5 -16

DESİGN PROCESS Idea generation R&D Marketing Form design Customers Competitors Performance specifications Revising and testing prototypes Production design Functional design New product or service launch Final design & process plans Design specifications Pilot product run and final tests Copyright 2006 John Wiley & Sons, Inc. Suppliers Product or service concept Feasibility study Manufacturing or delivery specifications 5 -17

DESİGN PROCESS Idea generation R&D Marketing Form design Customers Competitors Performance specifications Revising and testing prototypes Production design Functional design New product or service launch Final design & process plans Design specifications Pilot product run and final tests Copyright 2006 John Wiley & Sons, Inc. Suppliers Product or service concept Feasibility study Manufacturing or delivery specifications 5 -17

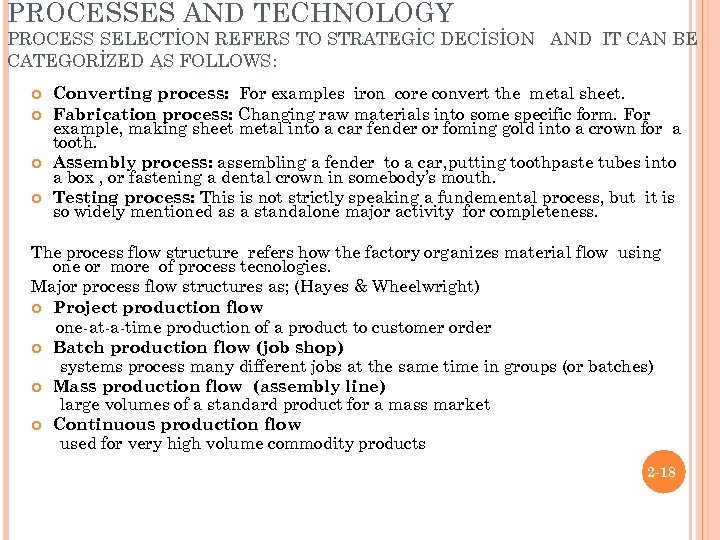

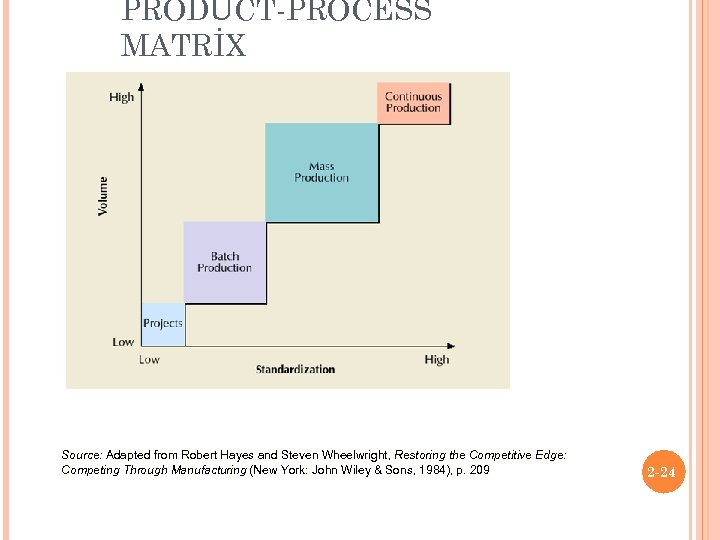

PROCESSES AND TECHNOLOGY PROCESS SELECTİON REFERS TO STRATEGİC DECİSİON AND IT CAN BE CATEGORİZED AS FOLLOWS: Converting process: For examples iron core convert the metal sheet. Fabrication process: Changing raw materials into some specific form. For example, making sheet metal into a car fender or foming gold into a crown for a tooth. Assembly process: assembling a fender to a car, putting toothpaste tubes into a box , or fastening a dental crown in somebody’s mouth. Testing process: This is not strictly speaking a fundemental process, but it is so widely mentioned as a standalone major activity for completeness. The process flow structure refers how the factory organizes material flow using one or more of process tecnologies. Major process flow structures as; (Hayes & Wheelwright) Project production flow one-at-a-time production of a product to customer order Batch production flow (job shop) systems process many different jobs at the same time in groups (or batches) Mass production flow (assembly line) large volumes of a standard product for a mass market Continuous production flow used for very high volume commodity products 2 -18

PROCESSES AND TECHNOLOGY PROCESS SELECTİON REFERS TO STRATEGİC DECİSİON AND IT CAN BE CATEGORİZED AS FOLLOWS: Converting process: For examples iron core convert the metal sheet. Fabrication process: Changing raw materials into some specific form. For example, making sheet metal into a car fender or foming gold into a crown for a tooth. Assembly process: assembling a fender to a car, putting toothpaste tubes into a box , or fastening a dental crown in somebody’s mouth. Testing process: This is not strictly speaking a fundemental process, but it is so widely mentioned as a standalone major activity for completeness. The process flow structure refers how the factory organizes material flow using one or more of process tecnologies. Major process flow structures as; (Hayes & Wheelwright) Project production flow one-at-a-time production of a product to customer order Batch production flow (job shop) systems process many different jobs at the same time in groups (or batches) Mass production flow (assembly line) large volumes of a standard product for a mass market Continuous production flow used for very high volume commodity products 2 -18

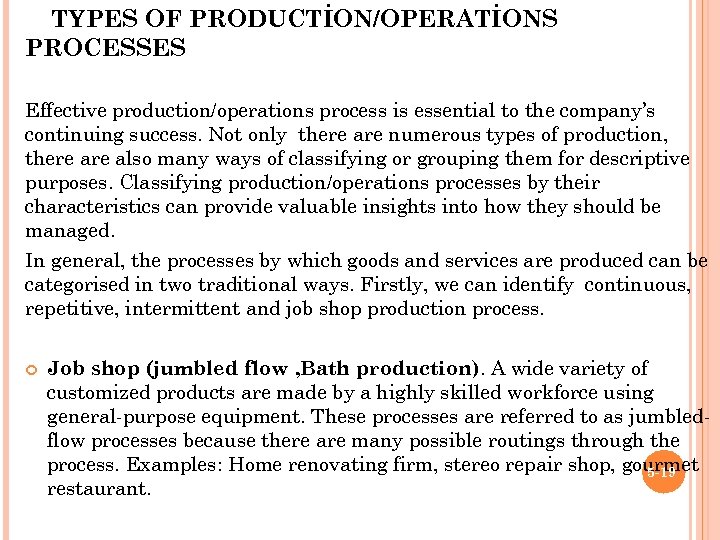

TYPES OF PRODUCTİON/OPERATİONS PROCESSES Effective production/operations process is essential to the company’s continuing success. Not only there are numerous types of production, there also many ways of classifying or grouping them for descriptive purposes. Classifying production/operations processes by their characteristics can provide valuable insights into how they should be managed. In general, the processes by which goods and services are produced can be categorised in two traditional ways. Firstly, we can identify continuous, repetitive, intermittent and job shop production process. Job shop (jumbled flow , Bath production). A wide variety of customized products are made by a highly skilled workforce using general-purpose equipment. These processes are referred to as jumbledflow processes because there are many possible routings through the process. Examples: Home renovating firm, stereo repair shop, gourmet 5 -19 restaurant.

TYPES OF PRODUCTİON/OPERATİONS PROCESSES Effective production/operations process is essential to the company’s continuing success. Not only there are numerous types of production, there also many ways of classifying or grouping them for descriptive purposes. Classifying production/operations processes by their characteristics can provide valuable insights into how they should be managed. In general, the processes by which goods and services are produced can be categorised in two traditional ways. Firstly, we can identify continuous, repetitive, intermittent and job shop production process. Job shop (jumbled flow , Bath production). A wide variety of customized products are made by a highly skilled workforce using general-purpose equipment. These processes are referred to as jumbledflow processes because there are many possible routings through the process. Examples: Home renovating firm, stereo repair shop, gourmet 5 -19 restaurant.

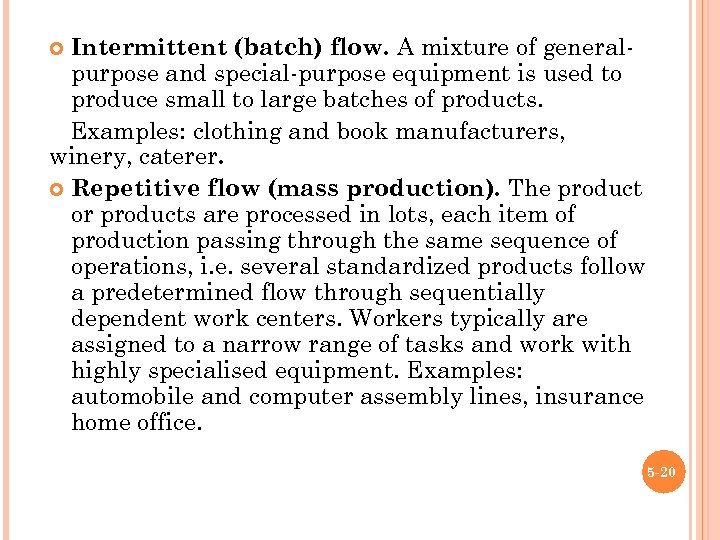

Intermittent (batch) flow. A mixture of generalpurpose and special-purpose equipment is used to produce small to large batches of products. Examples: clothing and book manufacturers, winery, caterer. Repetitive flow (mass production). The product or products are processed in lots, each item of production passing through the same sequence of operations, i. e. several standardized products follow a predetermined flow through sequentially dependent work centers. Workers typically are assigned to a narrow range of tasks and work with highly specialised equipment. Examples: automobile and computer assembly lines, insurance home office. 5 -20

Intermittent (batch) flow. A mixture of generalpurpose and special-purpose equipment is used to produce small to large batches of products. Examples: clothing and book manufacturers, winery, caterer. Repetitive flow (mass production). The product or products are processed in lots, each item of production passing through the same sequence of operations, i. e. several standardized products follow a predetermined flow through sequentially dependent work centers. Workers typically are assigned to a narrow range of tasks and work with highly specialised equipment. Examples: automobile and computer assembly lines, insurance home office. 5 -20

Continuous flow (flow shop). Commodity like products flow continuously through a linear process. This type of process will theoretically run for 24 hrs/day, 7 days/week and 52 weeks/year and, whilst this is often the objective, it is rarely achieved. Examples: chemical, oil, and sugar refineries, power and light utilities. These four categories represent points on continuum of process organisations. Processes that fall within a particular category share many characteristics that fundamentally influence how a process should be managed. The second and similar classification divides production processes into; Process, Mass, Batch, Jobbing Production. Processes that operate continually to produce a very high volume of a standard product are termed “Processes”. This type of process involves the continuous production of a commodity , often by chemical rather than mechanical means, such as oil and gas. Extra examples of a continuous processes oil refinery, electricity production and steel making. 5 -21

Continuous flow (flow shop). Commodity like products flow continuously through a linear process. This type of process will theoretically run for 24 hrs/day, 7 days/week and 52 weeks/year and, whilst this is often the objective, it is rarely achieved. Examples: chemical, oil, and sugar refineries, power and light utilities. These four categories represent points on continuum of process organisations. Processes that fall within a particular category share many characteristics that fundamentally influence how a process should be managed. The second and similar classification divides production processes into; Process, Mass, Batch, Jobbing Production. Processes that operate continually to produce a very high volume of a standard product are termed “Processes”. This type of process involves the continuous production of a commodity , often by chemical rather than mechanical means, such as oil and gas. Extra examples of a continuous processes oil refinery, electricity production and steel making. 5 -21

Mass Production. Is conceptually similar to process production, except that discrete items such as motorcars and domestic appliances are usually involved. A single or a very small range of similar items is produced in very large numbers. In other words, processes that produce high-volume and lowvariety products are termed line or mass processes. Because of the high volumes of product it is costeffective to use specialised labour and equipment. Batch Production. Processes that produce products of medium variety and medium volume are termed “batch processes”. Occurs where the number of discrete items to be manufactured in a period is insufficient to enable mass production to be used. Similar items are manufactured together in batches. In other words, batch processes cover a relatively wide range of volume and variety combination. Products are grouped into batches. 5 -22

Mass Production. Is conceptually similar to process production, except that discrete items such as motorcars and domestic appliances are usually involved. A single or a very small range of similar items is produced in very large numbers. In other words, processes that produce high-volume and lowvariety products are termed line or mass processes. Because of the high volumes of product it is costeffective to use specialised labour and equipment. Batch Production. Processes that produce products of medium variety and medium volume are termed “batch processes”. Occurs where the number of discrete items to be manufactured in a period is insufficient to enable mass production to be used. Similar items are manufactured together in batches. In other words, batch processes cover a relatively wide range of volume and variety combination. Products are grouped into batches. 5 -22

Jobbing Production (Project Type Production). Processes that produce high-variety and low-volume products are termed “jobbing”. Although strictly consisting of the manufacture of different products in unit quantities (in practice corresponds to the intermittent process mentioned above). This type of production assumes a oneof-a-kind production output, such as a new building or developing a new software application. The equipment are typically designed for flexibility and often general purpose, meaning it can be used for many different production requirements 5 -23

Jobbing Production (Project Type Production). Processes that produce high-variety and low-volume products are termed “jobbing”. Although strictly consisting of the manufacture of different products in unit quantities (in practice corresponds to the intermittent process mentioned above). This type of production assumes a oneof-a-kind production output, such as a new building or developing a new software application. The equipment are typically designed for flexibility and often general purpose, meaning it can be used for many different production requirements 5 -23

PRODUCT-PROCESS MATRİX Source: Adapted from Robert Hayes and Steven Wheelwright, Restoring the Competitive Edge: Competing Through Manufacturing (New York: John Wiley & Sons, 1984), p. 209 2 -24

PRODUCT-PROCESS MATRİX Source: Adapted from Robert Hayes and Steven Wheelwright, Restoring the Competitive Edge: Competing Through Manufacturing (New York: John Wiley & Sons, 1984), p. 209 2 -24

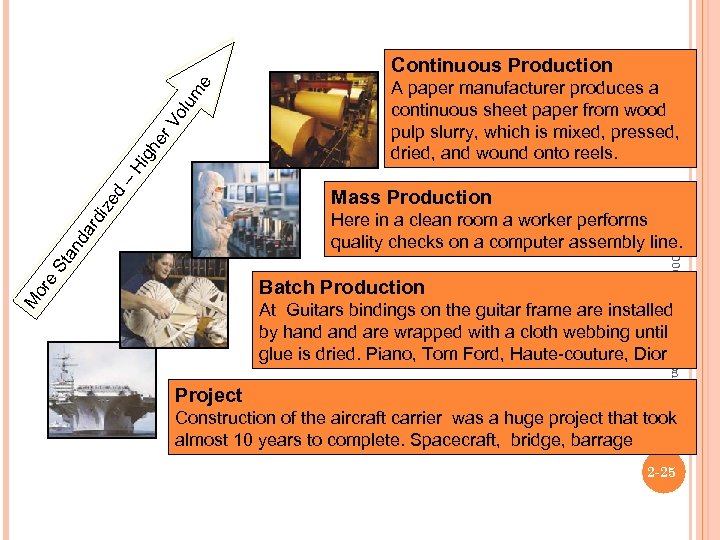

A paper manufacturer produces a continuous sheet paper from wood pulp slurry, which is mixed, pressed, dried, and wound onto reels. Mass Production Copyright 2006 John Wiley & Sons, Inc. St an da rd ize d – Hi gh er Vo lum e Continuous Production Here in a clean room a worker performs quality checks on a computer assembly line. M or e Batch Production At Guitars bindings on the guitar frame are installed by hand are wrapped with a cloth webbing until glue is dried. Piano, Tom Ford, Haute-couture, Dior Project Construction of the aircraft carrier was a huge project that took almost 10 years to complete. Spacecraft, bridge, barrage 2 -25

A paper manufacturer produces a continuous sheet paper from wood pulp slurry, which is mixed, pressed, dried, and wound onto reels. Mass Production Copyright 2006 John Wiley & Sons, Inc. St an da rd ize d – Hi gh er Vo lum e Continuous Production Here in a clean room a worker performs quality checks on a computer assembly line. M or e Batch Production At Guitars bindings on the guitar frame are installed by hand are wrapped with a cloth webbing until glue is dried. Piano, Tom Ford, Haute-couture, Dior Project Construction of the aircraft carrier was a huge project that took almost 10 years to complete. Spacecraft, bridge, barrage 2 -25

SERVİCE STRATEGY: PROCESSES AND TECHNOLOGY service highly customized and very labor intensive Service shop customized and labor intensive Mass service less customized and less labor intensive Service Factory least customized and least labor intensive Copyright 2006 John Wiley & Sons, Inc. Professional 2 -26

SERVİCE STRATEGY: PROCESSES AND TECHNOLOGY service highly customized and very labor intensive Service shop customized and labor intensive Mass service less customized and less labor intensive Service Factory least customized and least labor intensive Copyright 2006 John Wiley & Sons, Inc. Professional 2 -26

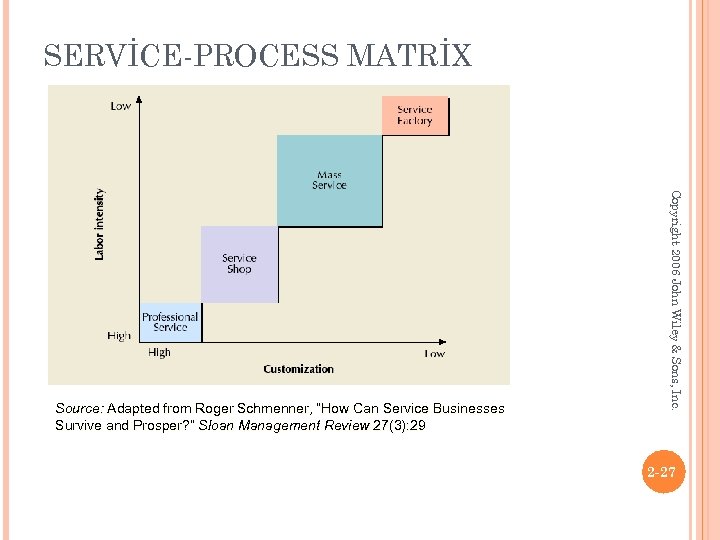

SERVİCE-PROCESS MATRİX Copyright 2006 John Wiley & Sons, Inc. Source: Adapted from Roger Schmenner, “How Can Service Businesses Survive and Prosper? ” Sloan Management Review 27(3): 29 2 -27

SERVİCE-PROCESS MATRİX Copyright 2006 John Wiley & Sons, Inc. Source: Adapted from Roger Schmenner, “How Can Service Businesses Survive and Prosper? ” Sloan Management Review 27(3): 29 2 -27

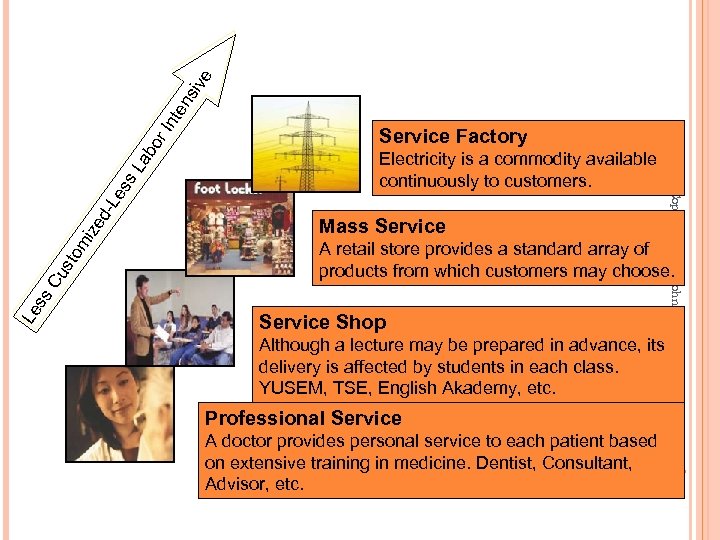

In t en s iv e Electricity is a commodity available continuously to customers. Mass Service Copyright 2006 John Wiley & Sons, Inc. Le ss Cu sto m ize d -L es s. L ab or Service Factory A retail store provides a standard array of products from which customers may choose. Service Shop Although a lecture may be prepared in advance, its delivery is affected by students in each class. YUSEM, TSE, English Akademy, etc. Professional Service A doctor provides personal service to each patient based on extensive training in medicine. Dentist, Consultant, 2 -28 Advisor, etc.

In t en s iv e Electricity is a commodity available continuously to customers. Mass Service Copyright 2006 John Wiley & Sons, Inc. Le ss Cu sto m ize d -L es s. L ab or Service Factory A retail store provides a standard array of products from which customers may choose. Service Shop Although a lecture may be prepared in advance, its delivery is affected by students in each class. YUSEM, TSE, English Akademy, etc. Professional Service A doctor provides personal service to each patient based on extensive training in medicine. Dentist, Consultant, 2 -28 Advisor, etc.

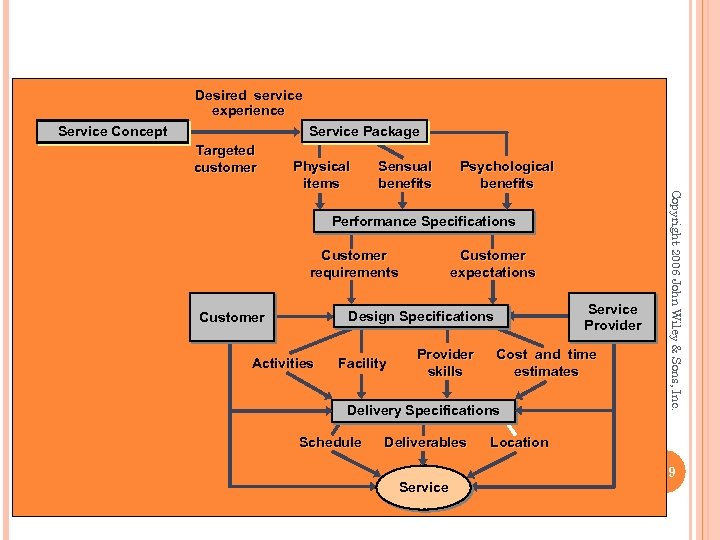

Desired service experience Service Concept Service Package Targeted customer Sensual benefits Psychological benefits Performance Specifications SERVİCE DESİGN PROCES S Customer requirements Customer expectations Service Provider Design Specifications Customer Activities Facility Provider skills Cost and time estimates Delivery Specifications Schedule Deliverables Service Copyright 2006 John Wiley & Sons, Inc. Physical items Location 5 -29

Desired service experience Service Concept Service Package Targeted customer Sensual benefits Psychological benefits Performance Specifications SERVİCE DESİGN PROCES S Customer requirements Customer expectations Service Provider Design Specifications Customer Activities Facility Provider skills Cost and time estimates Delivery Specifications Schedule Deliverables Service Copyright 2006 John Wiley & Sons, Inc. Physical items Location 5 -29

IDEA GENERATİON SOURCES Company’s own R&D department Customer complaints or suggestions Marketing research Suppliers Salespersons in the field Factory workers New technological developments Competitors 5 -30

IDEA GENERATİON SOURCES Company’s own R&D department Customer complaints or suggestions Marketing research Suppliers Salespersons in the field Factory workers New technological developments Competitors 5 -30

FEASİBİLİTY STUDY Market analysis Economic analysis Technical/strategic analysis Performance specifications Copyright 2006 John Wiley & Sons, Inc. 5 -31

FEASİBİLİTY STUDY Market analysis Economic analysis Technical/strategic analysis Performance specifications Copyright 2006 John Wiley & Sons, Inc. 5 -31

FİNAL DESİGN AND PROCESS PLANS Final design Process plans workable instructions necessary equipment and tooling component sourcing recommendations job descriptions and procedures computer programs for automated machines Copyright 2006 John Wiley & Sons, Inc. detailed drawings and specifications for new product or service 5 -32

FİNAL DESİGN AND PROCESS PLANS Final design Process plans workable instructions necessary equipment and tooling component sourcing recommendations job descriptions and procedures computer programs for automated machines Copyright 2006 John Wiley & Sons, Inc. detailed drawings and specifications for new product or service 5 -32

REDUCİNG TİME-TOMARKET Establish multifunctional design teams Make design decisions concurrently rather than sequentially Design for manufacture and assembly Use technology in the design process Engage in collaborative design Copyright 2006 John Wiley & Sons, Inc. 5 -33

REDUCİNG TİME-TOMARKET Establish multifunctional design teams Make design decisions concurrently rather than sequentially Design for manufacture and assembly Use technology in the design process Engage in collaborative design Copyright 2006 John Wiley & Sons, Inc. 5 -33

DESIGN TEAM AND CONCURRENT ENGİNEERİNG DESİGN Improves quality of early design decisions Involves suppliers Incorporates production process Uses a price-minus system Scheduling and management can be complex as tasks are done in parallel Copyright 2006 John Wiley & Sons, Inc. A new approach to design that involves simultaneous design of products and processes by design teams 5 -34

DESIGN TEAM AND CONCURRENT ENGİNEERİNG DESİGN Improves quality of early design decisions Involves suppliers Incorporates production process Uses a price-minus system Scheduling and management can be complex as tasks are done in parallel Copyright 2006 John Wiley & Sons, Inc. A new approach to design that involves simultaneous design of products and processes by design teams 5 -34

DESİGN FOR MANUFACTURE AND ASSEMBLY (DFMA) Design for manufacture Design for assembly a set of procedures for: Copyright 2006 John Wiley & Sons, Inc. design a product for easy and economical production reducing number of parts in an assembly evaluating methods of assembly determining an assembly sequence 5 -35

DESİGN FOR MANUFACTURE AND ASSEMBLY (DFMA) Design for manufacture Design for assembly a set of procedures for: Copyright 2006 John Wiley & Sons, Inc. design a product for easy and economical production reducing number of parts in an assembly evaluating methods of assembly determining an assembly sequence 5 -35

DFM GUİDELİNES Minimize number of parts and subassemblies Use standard parts when possible and repeatable, well-understood processes Design parts for many uses, and modules that can be combined in different ways Design for ease of assembly, minimal handling, and proper presentation 5 -36

DFM GUİDELİNES Minimize number of parts and subassemblies Use standard parts when possible and repeatable, well-understood processes Design parts for many uses, and modules that can be combined in different ways Design for ease of assembly, minimal handling, and proper presentation 5 -36

TECHNOLOGY İN THE DESİGN PROCESS Computer Aided Design (CAD) assists in creation, modification, and analysis of a design includes computer-aided engineering (CAE) tests and analyzes designs on computer screen computer-aided manufacturing (CAM) ultimate design-to-manufacture connection Copyright 2006 John Wiley & Sons, Inc. 5 -37

TECHNOLOGY İN THE DESİGN PROCESS Computer Aided Design (CAD) assists in creation, modification, and analysis of a design includes computer-aided engineering (CAE) tests and analyzes designs on computer screen computer-aided manufacturing (CAM) ultimate design-to-manufacture connection Copyright 2006 John Wiley & Sons, Inc. 5 -37

IMPROVİNG QUALİTY OF DESİGN designs to prevent failures and ensure value Design for environment Measure design quality Use quality function deployment Design for robustness Copyright 2006 John Wiley & Sons, Inc. Review 5 -38

IMPROVİNG QUALİTY OF DESİGN designs to prevent failures and ensure value Design for environment Measure design quality Use quality function deployment Design for robustness Copyright 2006 John Wiley & Sons, Inc. Review 5 -38

DESİGN REVİEW Failure mode and effects analysis (FMEA) Fault tree analysis (FTA) a systematic method of analyzing product failures a visual method for analyzing interrelationships among failures Value analysis (VA) helps eliminate unnecessary features and functions Copyright 2006 John Wiley & Sons, Inc. 5 -39

DESİGN REVİEW Failure mode and effects analysis (FMEA) Fault tree analysis (FTA) a systematic method of analyzing product failures a visual method for analyzing interrelationships among failures Value analysis (VA) helps eliminate unnecessary features and functions Copyright 2006 John Wiley & Sons, Inc. 5 -39

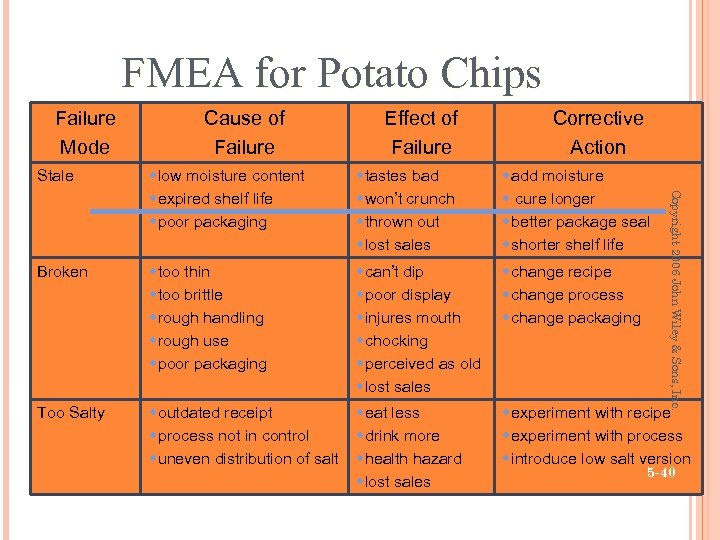

FMEA for Potato Chips Failure Mode Cause of Failure Effect of Failure Corrective Action wlow moisture content wexpired shelf life wpoor packaging wtastes bad wwon’t crunch wthrown out wlost sales wadd moisture w cure longer wbetter package seal wshorter shelf life Broken wtoo thin wtoo brittle wrough handling wrough use wpoor packaging wcan’t dip wpoor display winjures mouth wchocking wperceived as old wlost sales wchange recipe wchange process wchange packaging Too Salty woutdated receipt weat less wprocess not in control wdrink more wuneven distribution of salt whealth hazard wlost sales Copyright 2006 John Wiley & Sons, Inc. Stale wexperiment with recipe wexperiment with process wintroduce low salt version 5 -40

FMEA for Potato Chips Failure Mode Cause of Failure Effect of Failure Corrective Action wlow moisture content wexpired shelf life wpoor packaging wtastes bad wwon’t crunch wthrown out wlost sales wadd moisture w cure longer wbetter package seal wshorter shelf life Broken wtoo thin wtoo brittle wrough handling wrough use wpoor packaging wcan’t dip wpoor display winjures mouth wchocking wperceived as old wlost sales wchange recipe wchange process wchange packaging Too Salty woutdated receipt weat less wprocess not in control wdrink more wuneven distribution of salt whealth hazard wlost sales Copyright 2006 John Wiley & Sons, Inc. Stale wexperiment with recipe wexperiment with process wintroduce low salt version 5 -40

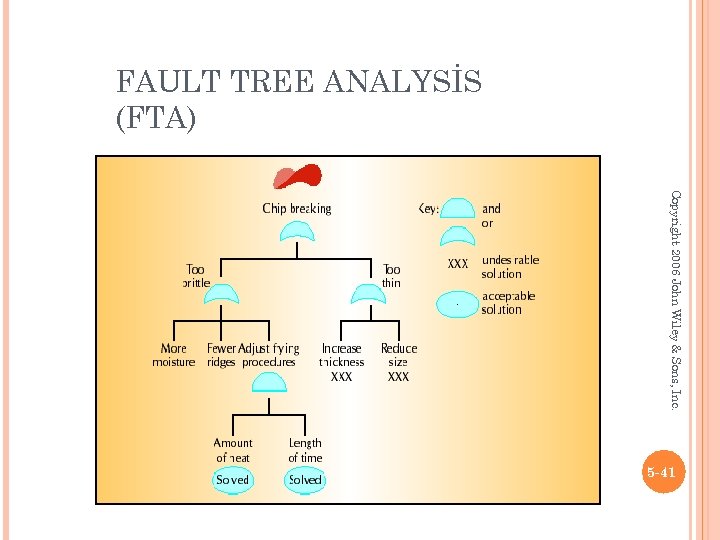

FAULT TREE ANALYSİS (FTA) Copyright 2006 John Wiley & Sons, Inc. 5 -41

FAULT TREE ANALYSİS (FTA) Copyright 2006 John Wiley & Sons, Inc. 5 -41

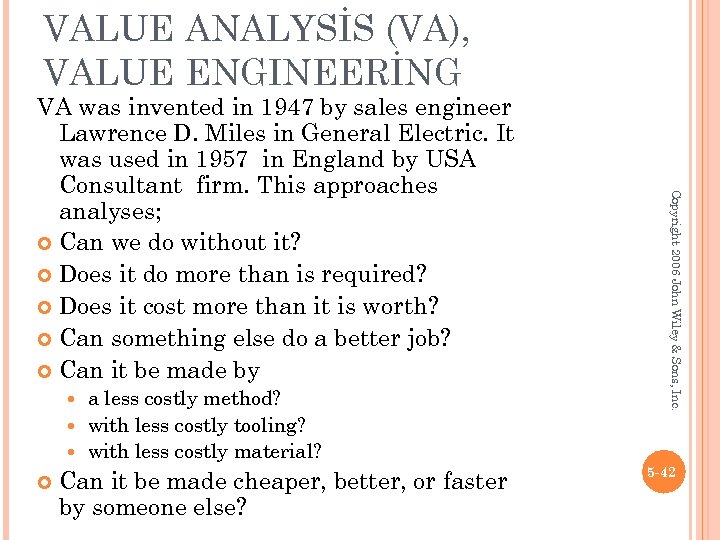

VALUE ANALYSİS (VA), VALUE ENGINEERİNG a less costly method? with less costly tooling? with less costly material? Can it be made cheaper, better, or faster by someone else? Copyright 2006 John Wiley & Sons, Inc. VA was invented in 1947 by sales engineer Lawrence D. Miles in General Electric. It was used in 1957 in England by USA Consultant firm. This approaches analyses; Can we do without it? Does it do more than is required? Does it cost more than it is worth? Can something else do a better job? Can it be made by 5 -42

VALUE ANALYSİS (VA), VALUE ENGINEERİNG a less costly method? with less costly tooling? with less costly material? Can it be made cheaper, better, or faster by someone else? Copyright 2006 John Wiley & Sons, Inc. VA was invented in 1947 by sales engineer Lawrence D. Miles in General Electric. It was used in 1957 in England by USA Consultant firm. This approaches analyses; Can we do without it? Does it do more than is required? Does it cost more than it is worth? Can something else do a better job? Can it be made by 5 -42

DESİGN FOR ENVİRONMENT Design for environment designing a product from material that can be recycled design from recycled material design for ease of repair minimize packaging minimize material and energy used during manufacture, consumption and disposal Extended producer responsibility holds companies responsible for their product even after its useful life Copyright 2006 John Wiley & Sons, Inc. 5 -43

DESİGN FOR ENVİRONMENT Design for environment designing a product from material that can be recycled design from recycled material design for ease of repair minimize packaging minimize material and energy used during manufacture, consumption and disposal Extended producer responsibility holds companies responsible for their product even after its useful life Copyright 2006 John Wiley & Sons, Inc. 5 -43

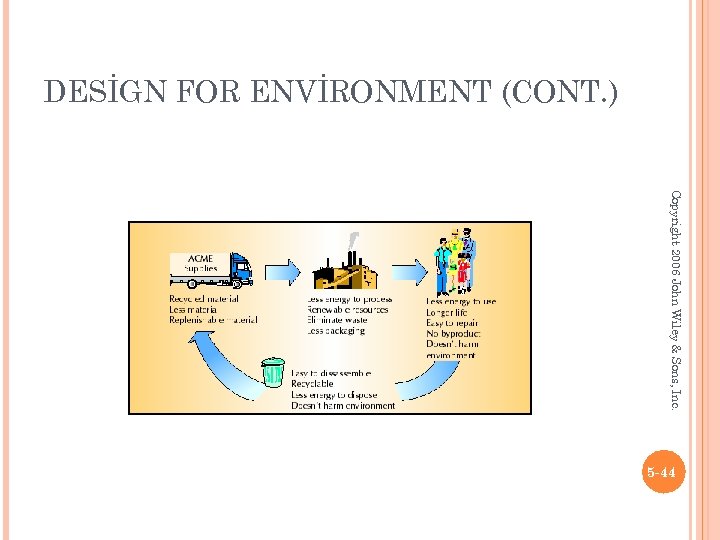

DESİGN FOR ENVİRONMENT (CONT. ) Copyright 2006 John Wiley & Sons, Inc. 5 -44

DESİGN FOR ENVİRONMENT (CONT. ) Copyright 2006 John Wiley & Sons, Inc. 5 -44

• DESİGN FOR ROBUSTNESS Robust product Robust design Controllable factors Uncontrollable factors Six sigma Taguchi Function Lean Production Copyright 2006 John Wiley & Sons, Inc. The other advance topics are; 5 -45

• DESİGN FOR ROBUSTNESS Robust product Robust design Controllable factors Uncontrollable factors Six sigma Taguchi Function Lean Production Copyright 2006 John Wiley & Sons, Inc. The other advance topics are; 5 -45

Stanford Design Thinking Process Video http: //www. youtube. com/watch? v=JZH 70 qhm. Eso Copyright 2006 John Wiley & Sons, Inc. 5 -46

Stanford Design Thinking Process Video http: //www. youtube. com/watch? v=JZH 70 qhm. Eso Copyright 2006 John Wiley & Sons, Inc. 5 -46

THANKS!!! 5 -47

THANKS!!! 5 -47