76e7193a6c2be26fe97fc477707fbd92.ppt

- Количество слайдов: 62

Production Planning and Control

The Objectives of Operations Planning Allocate the company’s ressources Taking into account : Strategic and operational objectives (quantity, quality, lead time, costs) Existing constraints Forecasted demand

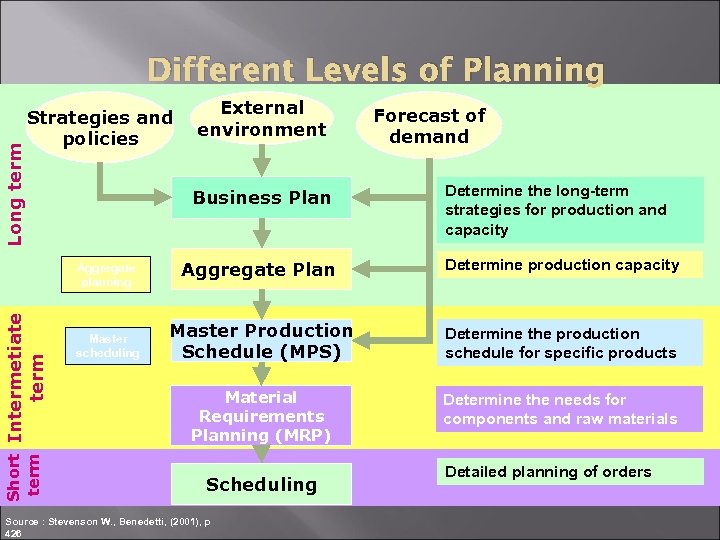

Long term Different Levels of Planning Strategies and policies External environment Business Plan Forecast of demand Determine the long-term strategies for production and capacity Short Intermetiate term Aggregate planning Aggregate Plan Determine production capacity Master scheduling Master Production Schedule (MPS) Determine the production schedule for specific products Material Requirements Planning (MRP) Determine the needs for components and raw materials Scheduling Source : Stevenson W. , Benedetti, (2001), p 426 Detailed planning of orders

is Aggregate production planning medium-term capacity planning over a two to eighteen month planning horizon. It involves determining the lowest-cost method of providing the adjustable capacity for meeting production requirements. Slide 11. 4

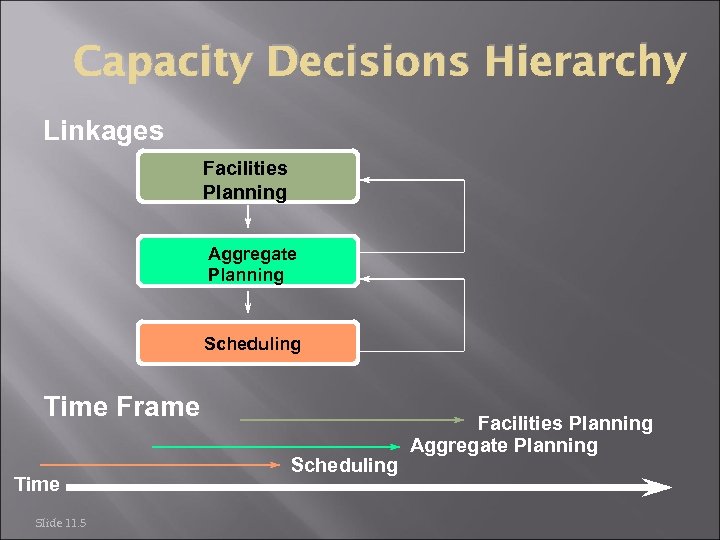

Capacity Decisions Hierarchy Linkages Facilities Planning Aggregate Planning Scheduling Time Frame Time Slide 11. 5 Scheduling Facilities Planning Aggregate Planning

Aggregation? ? ? ? Aggregationrefers to the idea of focusing on overall capacity, rather than individual products or services. Aggregation is done according to: Products Labor Time Slide 11. 6

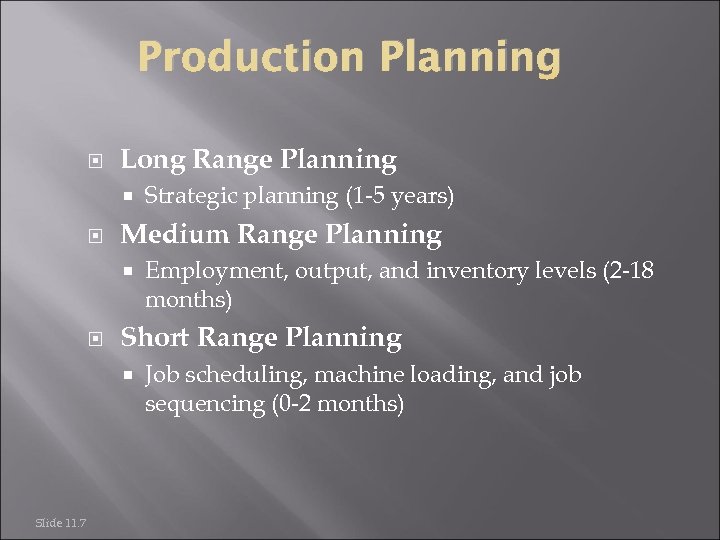

Production Planning Long Range Planning Medium Range Planning Employment, output, and inventory levels (2 -18 months) Short Range Planning Slide 11. 7 Strategic planning (1 -5 years) Job scheduling, machine loading, and job sequencing (0 -2 months)

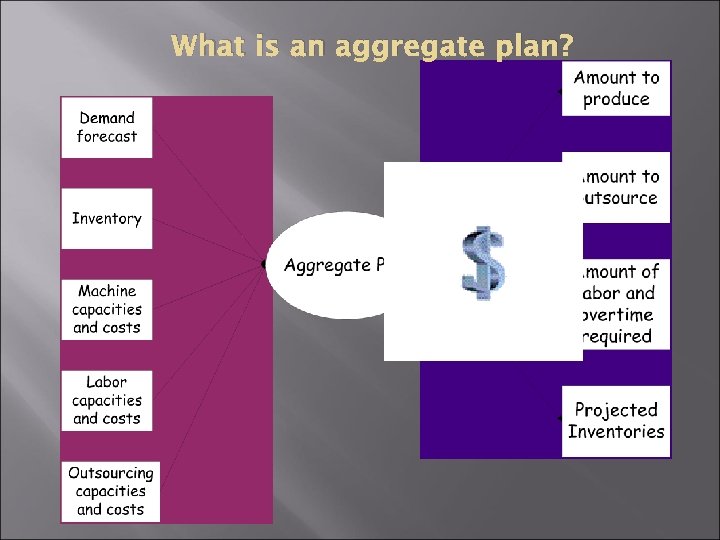

What is an aggregate plan?

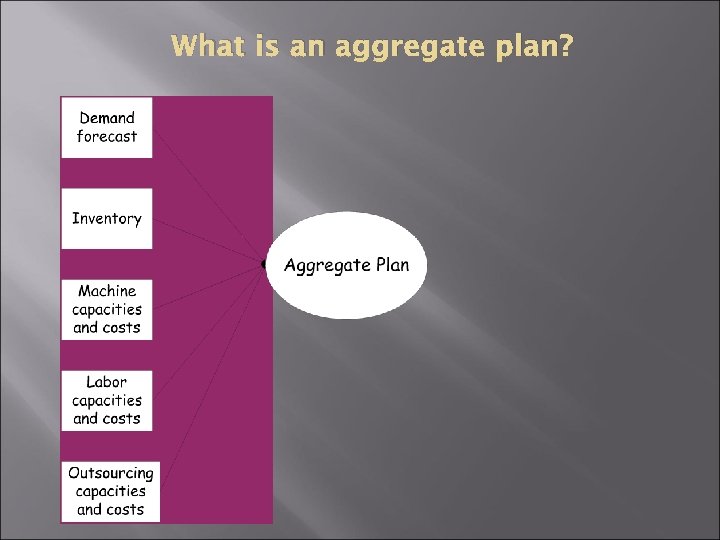

What is an aggregate plan?

What is an aggregate plan?

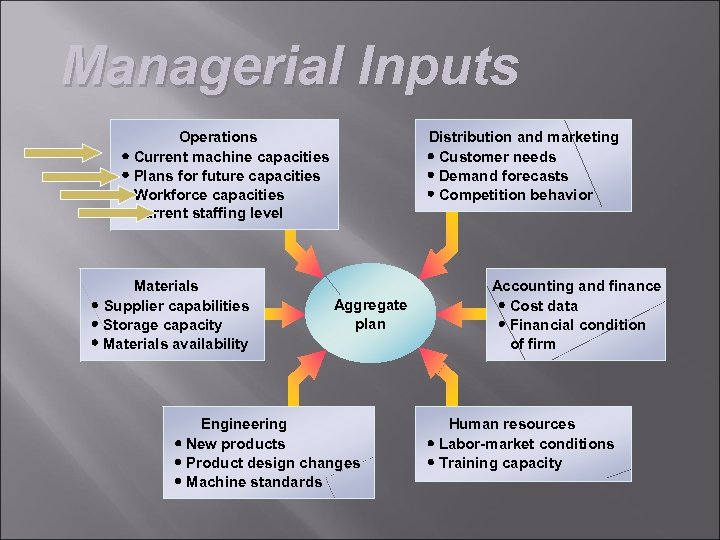

Managerial Inputs Operations Current machine capacities Plans for future capacities Workforce capacities Current staffing level Materials Supplier capabilities Storage capacity Materials availability Distribution and marketing Customer needs Demand forecasts Competition behavior Aggregate plan Engineering New products Product design changes Machine standards Accounting and finance Cost data Financial condition of firm Human resources Labor-market conditions Training capacity

Aggregate Planning Objectives · Minimize Costs/Maximize Profits · Maximize Customer Service · Minimize Inventory Investment · Minimize Changes in Production Rates · Minimize Changes in Workforce Levels · Maximize Utilization of Plant and Equipment

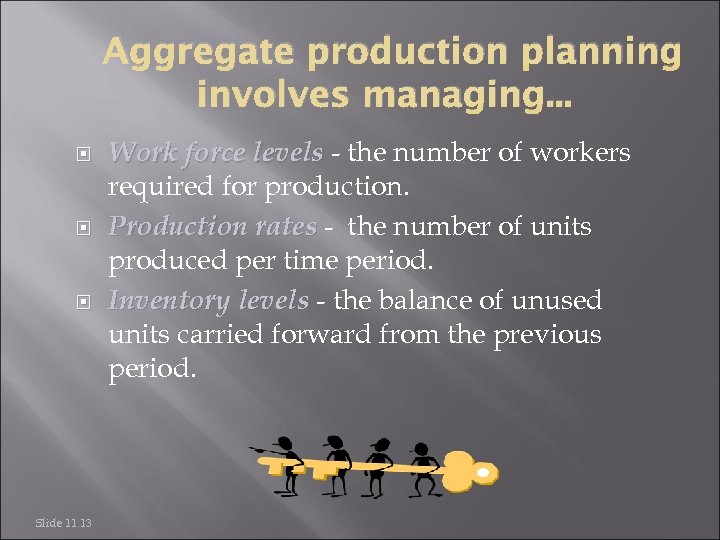

Aggregate production planning involves managing. . . Slide 11. 13 Work force levels - the number of workers required for production. Production rates - the number of units produced per time period. Inventory levels - the balance of unused units carried forward from the previous period.

Common objectives of production planning. . . MINIMIZE: cost, inventory levels, changes in work force levels, use of overtime, use of subcontracting, changes in production rates, plant/personnel idle time MAXIMIZE: profits, customer service

Methods of Influencing Demand Price Incentives Reservations Backlogs Complementary Products or Services Advertising/promotion

Methods of Influencing Supply Hiring/firing workers Overtime/slack time Part time/temporary labor Subcontracting Cooperative arrangements Inventories

Aggregate Production Planning Variable Costs Slide 11. 17 Hiring/firing costs Overtime/slack time costs Part time/temporary labor costs Subcontracting costs Cooperative arrangements costs Inventory carrying costs Backorder or stock out costs

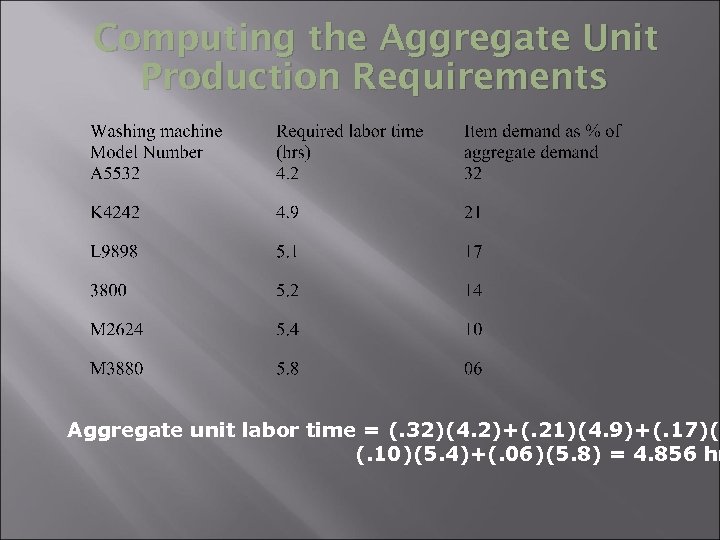

Computing the Aggregate Unit Production Requirements Aggregate unit labor time = (. 32)(4. 2)+(. 21)(4. 9)+(. 17)(5 (. 10)(5. 4)+(. 06)(5. 8) = 4. 856 hr

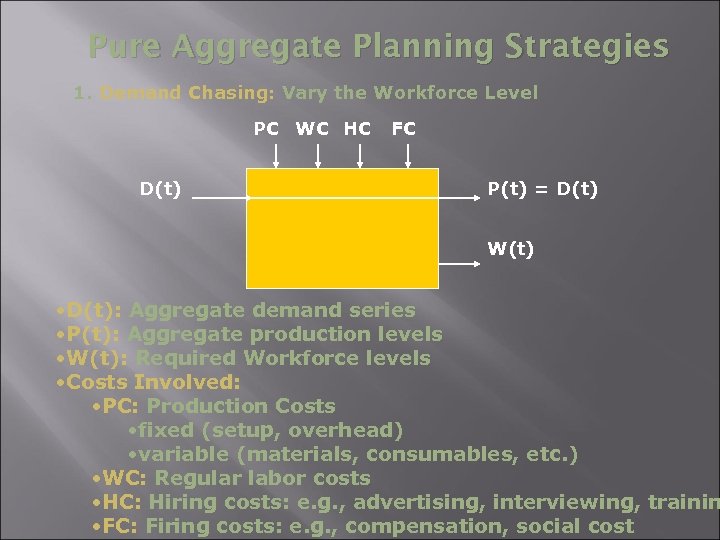

Pure Aggregate Planning Strategies 1. Demand Chasing: Vary the Workforce Level PC WC HC D(t) FC P(t) = D(t) W(t) • D(t): Aggregate demand series • P(t): Aggregate production levels • W(t): Required Workforce levels • Costs Involved: • PC: Production Costs • fixed (setup, overhead) • variable (materials, consumables, etc. ) • WC: Regular labor costs • HC: Hiring costs: e. g. , advertising, interviewing, trainin • FC: Firing costs: e. g. , compensation, social cost

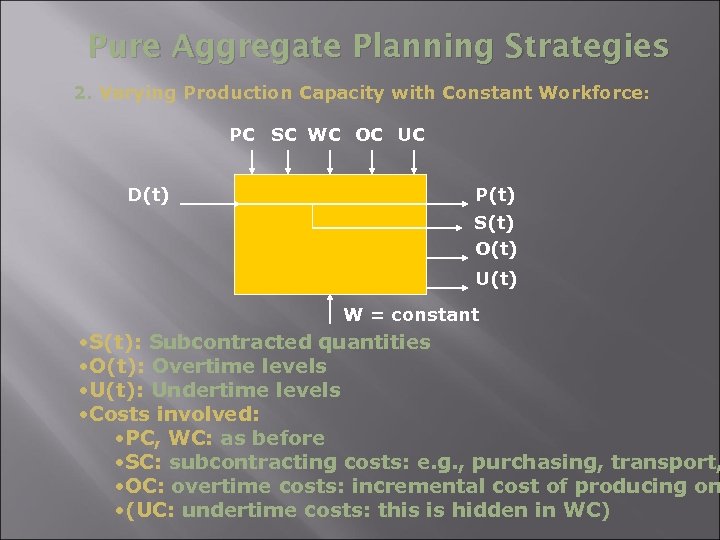

Pure Aggregate Planning Strategies 2. Varying Production Capacity with Constant Workforce: PC SC WC OC UC D(t) P(t) S(t) O(t) U(t) W = constant • S(t): Subcontracted quantities • O(t): Overtime levels • U(t): Undertime levels • Costs involved: • PC, WC: as before • SC: subcontracting costs: e. g. , purchasing, transport, • OC: overtime costs: incremental cost of producing on • (UC: undertime costs: this is hidden in WC)

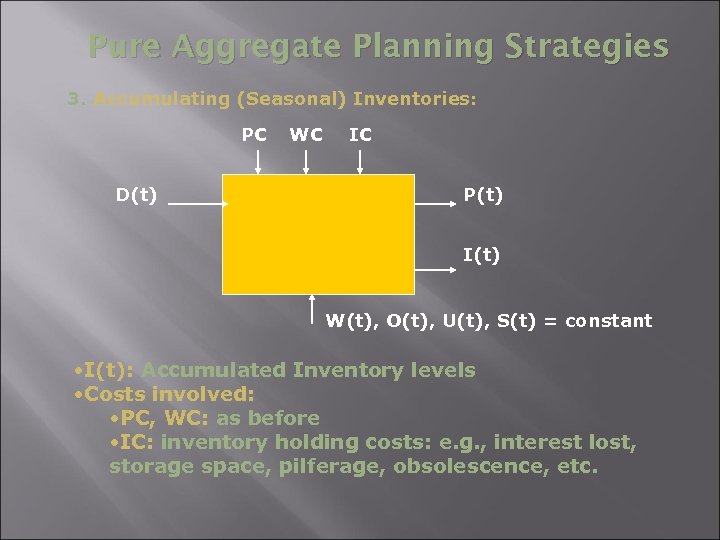

Pure Aggregate Planning Strategies 3. Accumulating (Seasonal) Inventories: PC D(t) WC IC P(t) I(t) W(t), O(t), U(t), S(t) = constant • I(t): Accumulated Inventory levels • Costs involved: • PC, WC: as before • IC: inventory holding costs: e. g. , interest lost, storage space, pilferage, obsolescence, etc.

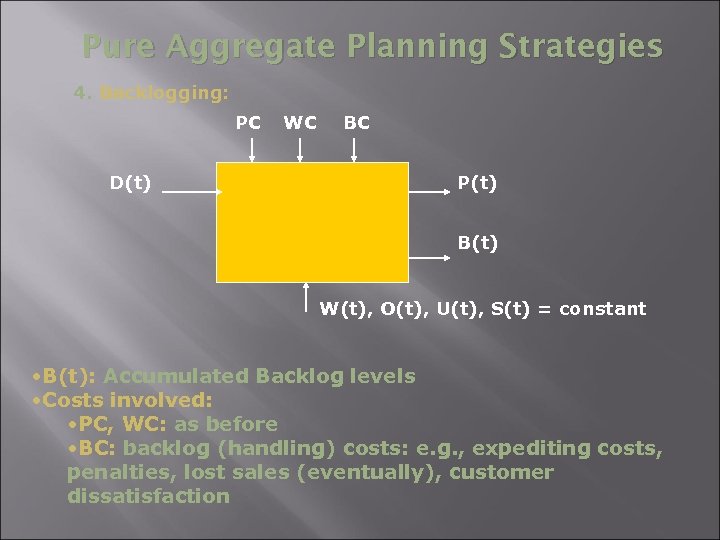

Pure Aggregate Planning Strategies 4. Backlogging: PC D(t) WC BC P(t) B(t) W(t), O(t), U(t), S(t) = constant • B(t): Accumulated Backlog levels • Costs involved: • PC, WC: as before • BC: backlog (handling) costs: e. g. , expediting costs, penalties, lost sales (eventually), customer dissatisfaction

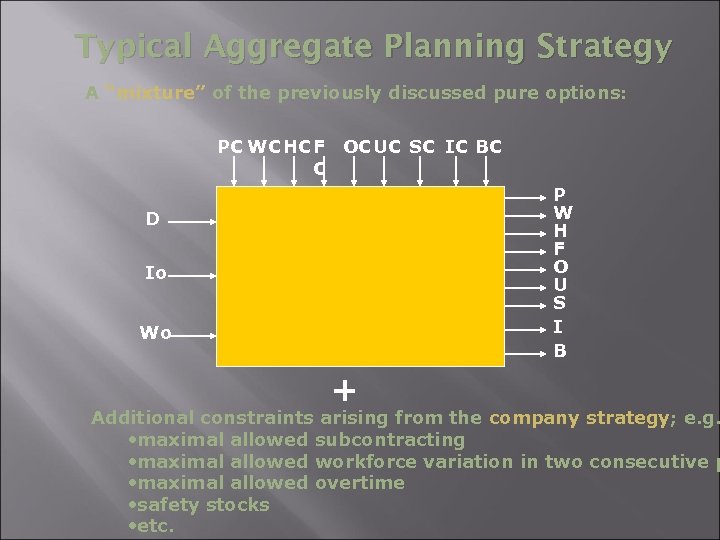

Typical Aggregate Planning Strategy A “mixture” of the previously discussed pure options: PC WC HC F OCUC SC IC BC C P W H F O U S I B D Io Wo + Additional constraints arising from the company strategy; e. g. • maximal allowed subcontracting • maximal allowed workforce variation in two consecutive p • maximal allowed overtime • safety stocks • etc.

Aggregate Production Planning Techniques Trial-and-error method Mathematical techniques Slide 11. 24

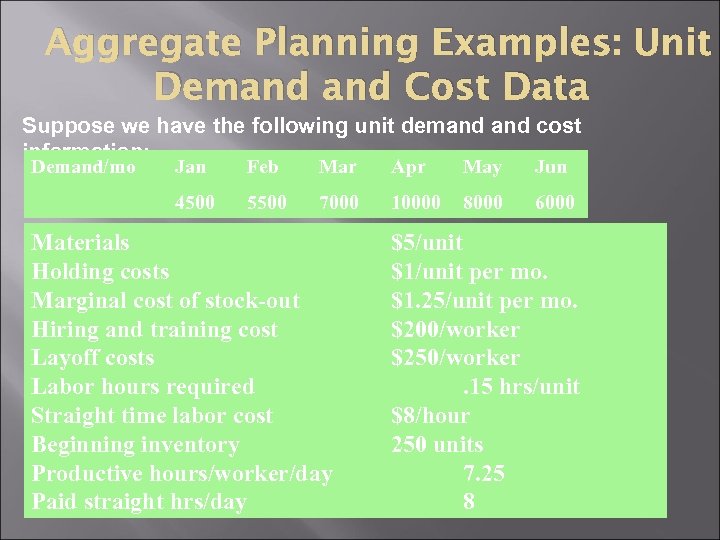

Aggregate Planning Examples: Unit Demand Cost Data Suppose we have the following unit demand cost information: Demand/mo Jan Feb Mar Apr May Jun 4500 5500 7000 10000 8000 6000 Materials Holding costs Marginal cost of stock-out Hiring and training cost Layoff costs Labor hours required Straight time labor cost Beginning inventory Productive hours/worker/day Paid straight hrs/day $5/unit $1/unit per mo. $1. 25/unit per mo. $200/worker $250/worker. 15 hrs/unit $8/hour 250 units 7. 25 8

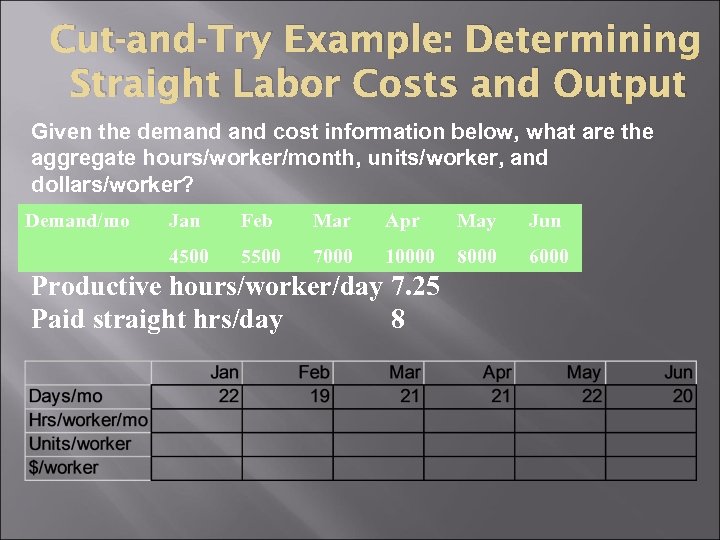

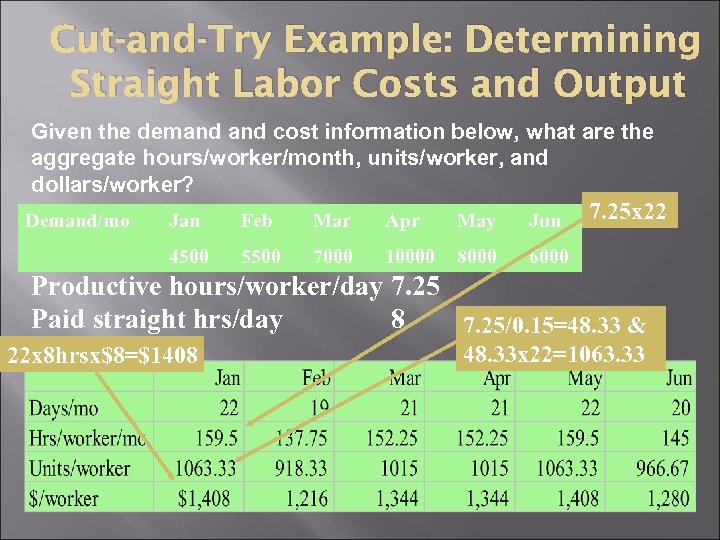

Cut-and-Try Example: Determining Straight Labor Costs and Output Given the demand cost information below, what are the aggregate hours/worker/month, units/worker, and dollars/worker? Demand/mo Jan Feb Mar Apr May Jun 4500 5500 7000 10000 8000 6000 Productive hours/worker/day 7. 25 Paid straight hrs/day 8

Cut-and-Try Example: Determining Straight Labor Costs and Output Given the demand cost information below, what are the aggregate hours/worker/month, units/worker, and dollars/worker? Demand/mo Jan Feb Mar Apr May Jun 4500 5500 7000 10000 8000 7. 25 x 22 6000 Productive hours/worker/day 7. 25 Paid straight hrs/day 8 7. 25/0. 15=48. 33 & 22 x 8 hrsx$8=$1408 48. 33 x 22=1063. 33

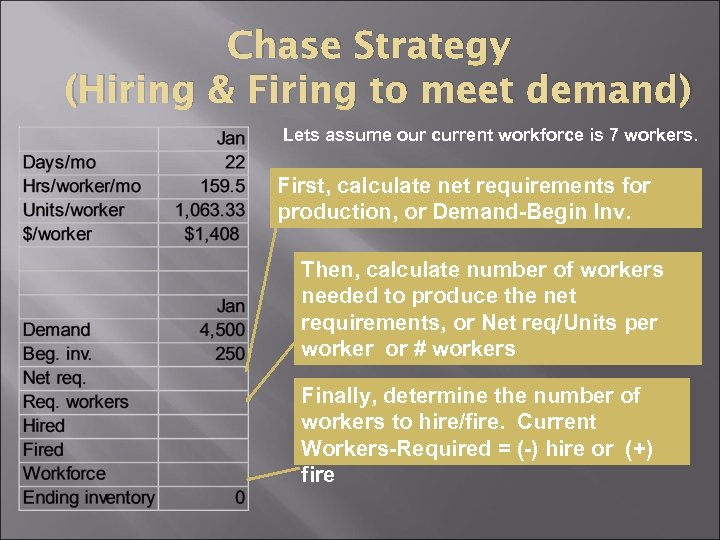

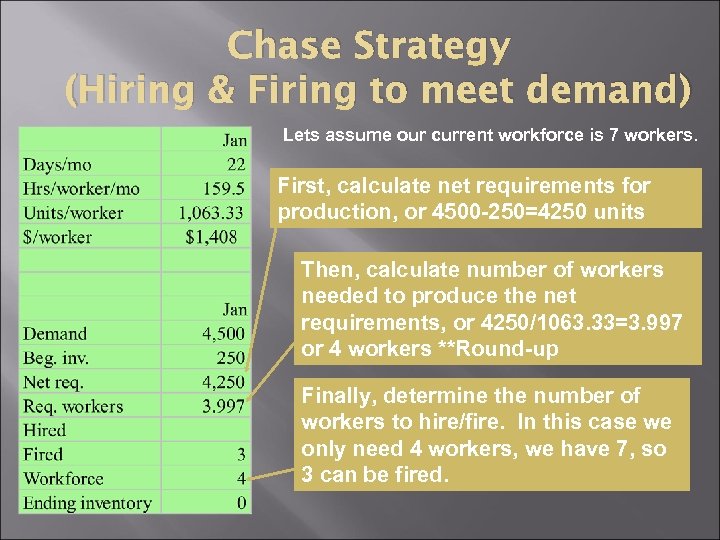

Chase Strategy (Hiring & Firing to meet demand) Lets assume our current workforce is 7 workers. First, calculate net requirements for production, or Demand-Begin Inv. Then, calculate number of workers needed to produce the net requirements, or Net req/Units per worker or # workers Finally, determine the number of workers to hire/fire. Current Workers-Required = (-) hire or (+) fire

Chase Strategy (Hiring & Firing to meet demand) Lets assume our current workforce is 7 workers. First, calculate net requirements for production, or 4500 -250=4250 units Then, calculate number of workers needed to produce the net requirements, or 4250/1063. 33=3. 997 or 4 workers **Round-up Finally, determine the number of workers to hire/fire. In this case we only need 4 workers, we have 7, so 3 can be fired.

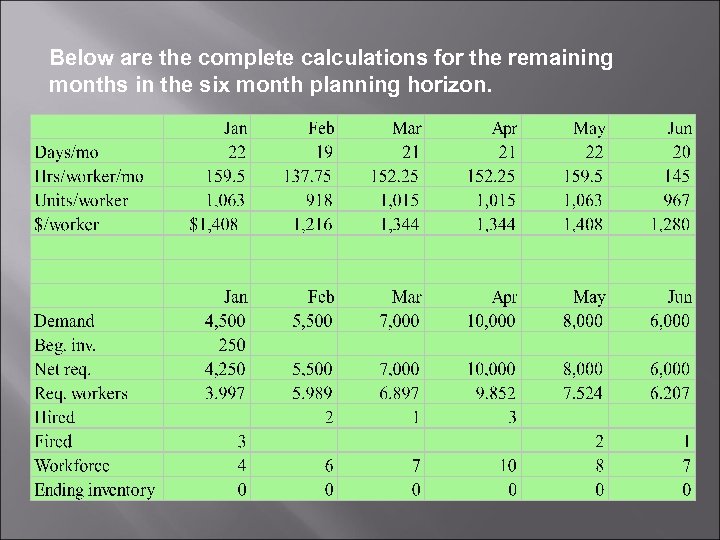

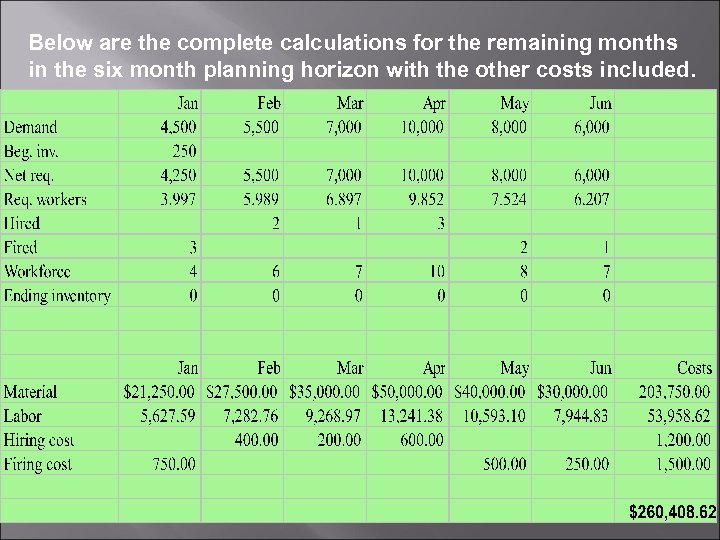

Below are the complete calculations for the remaining months in the six month planning horizon.

Below are the complete calculations for the remaining months in the six month planning horizon with the other costs included.

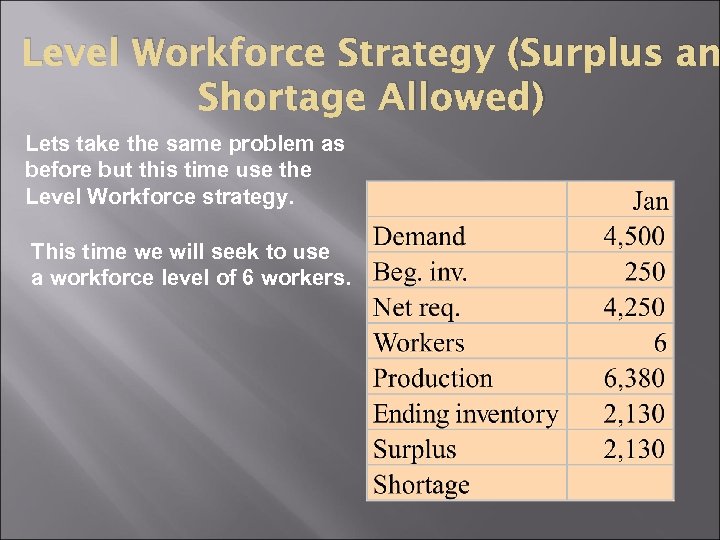

Level Workforce Strategy (Surplus an Shortage Allowed) Lets take the same problem as before but this time use the Level Workforce strategy. This time we will seek to use a workforce level of 6 workers.

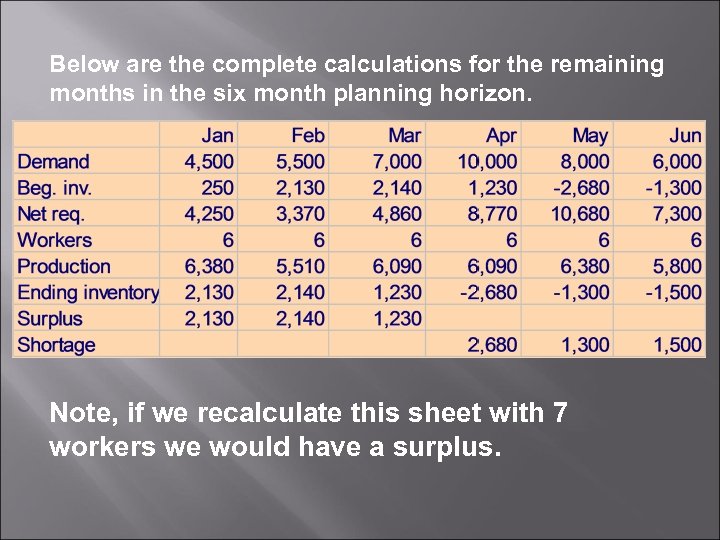

Below are the complete calculations for the remaining months in the six month planning horizon. Note, if we recalculate this sheet with 7 workers we would have a surplus.

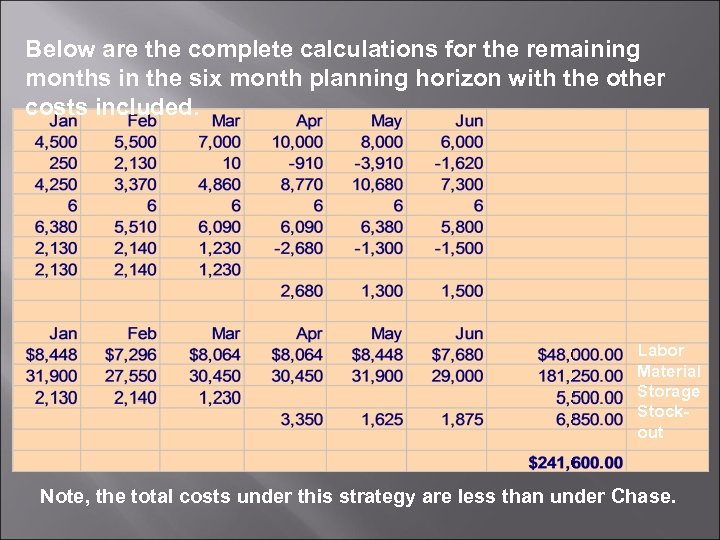

Below are the complete calculations for the remaining months in the six month planning horizon with the other costs included. Labor Material Storage Stockout Note, the total costs under this strategy are less than under Chase.

Mixing Options to Develop a Plan þ Chase strategy þ Match output rates to demand forecast for each period þ Vary workforce levels or vary production rate þ Favored by many service organizations

Mixing Options to Develop a Plan þ Level strategy þ Daily production is uniform þ Use inventory or idle time as buffer þ Stable production leads to better quality and productivity þ Some combination of capacity options, a mixed strategy, might be the best solution

Graphical Methods þ Popular techniques þ Easy to understand use þ Trial-and-error approaches that do not guarantee an optimal solution þ Require only limited computations

Graphical Methods 1. Determine the demand for each period 2. Determine the capacity for regular time, overtime, and subcontracting each period 3. Find labor costs, hiring and layoff costs, and inventory holding costs 4. Consider company policy on workers and stock levels 5. Develop alternative plans and

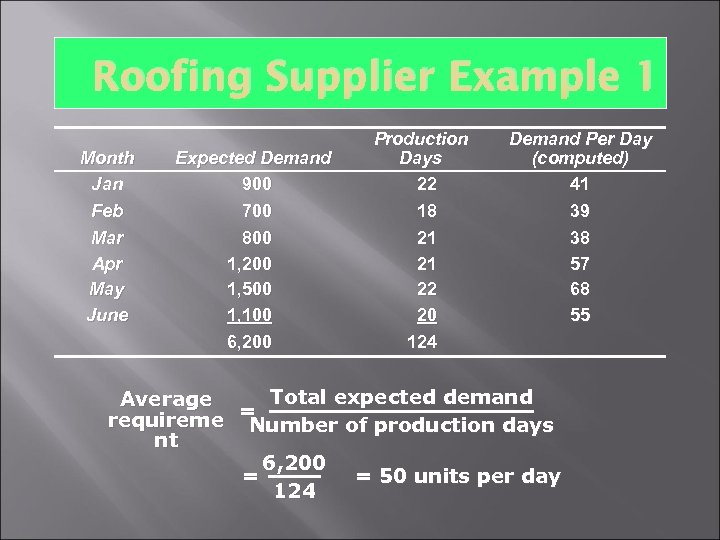

Roofing Supplier Example 1 Month Jan Feb Expected Demand 900 700 Production Days 22 18 Mar Apr May June 800 1, 200 1, 500 1, 100 6, 200 Demand Per Day (computed) 41 39 21 21 22 20 124 38 57 68 55 Total expected demand Average requireme = Number of production days nt 6, 200 = = 50 units per day 124

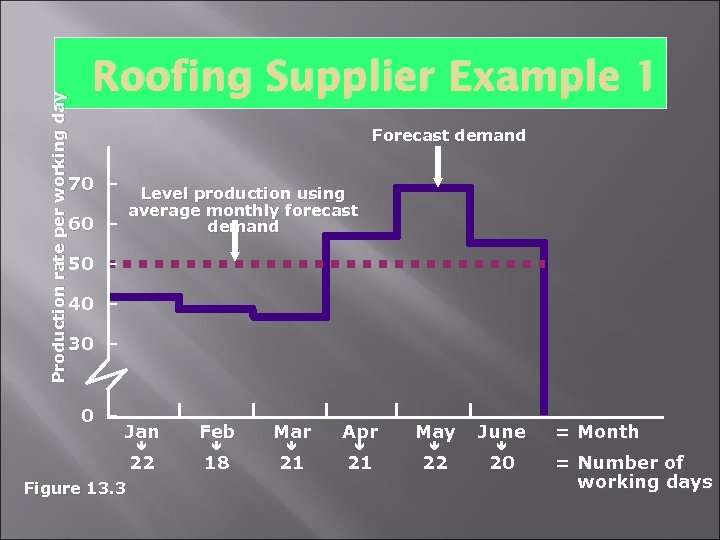

Production rate per working day Roofing Supplier Example 1 Forecast demand 70 – Level production using average monthly forecast 60 – demand 50 – 40 – 30 – Jan Feb Mar Apr May June 22 18 21 21 22 20 Figure 13. 3 = Month = Number of working days

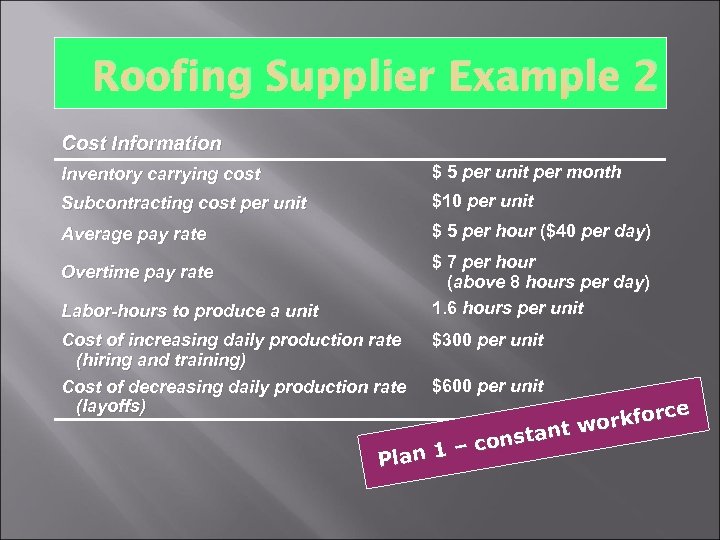

Roofing Supplier Example 2 Cost Information Inventory carrying cost $ 5 per unit per month Subcontracting cost per unit $10 per unit Average pay rate $ 5 per hour ($40 per day) $ 7 per hour (above 8 hours per day) 1. 6 hours per unit Overtime pay rate Labor-hours to produce a unit Cost of increasing daily production rate (hiring and training) Cost of decreasing daily production rate (layoffs) $300 per unit $600 per unit ce orkfor tw nstan co an 1 – Pl

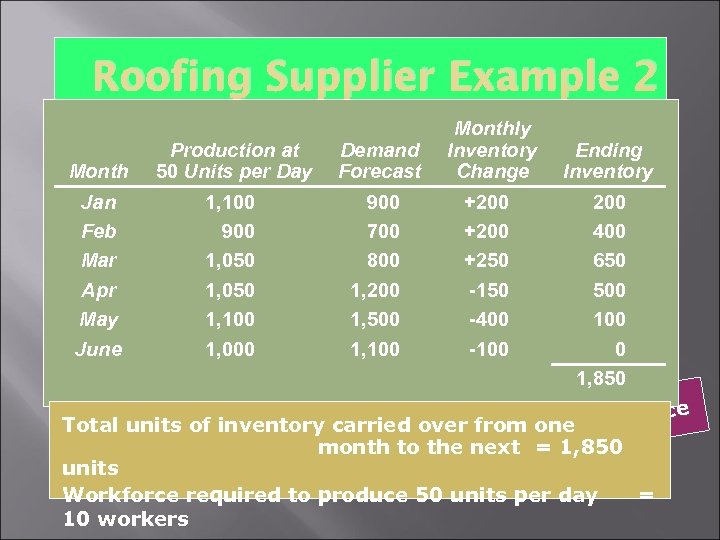

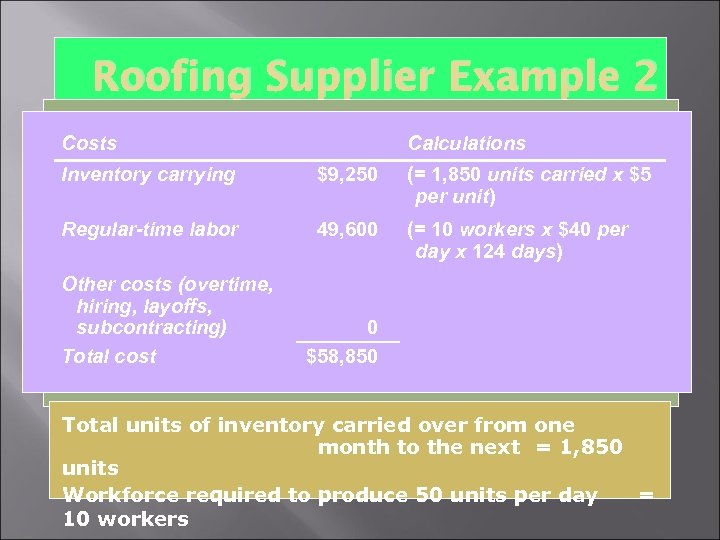

Roofing Supplier Example 2 Cost Information Production at Month 50 Units Inventory carry cost per Day Subcontracting cost per unit Jan 1, 100 Feb Average pay rate 900 Mar 1, 050 Overtime pay rate Monthly Demand Inventory Ending Forecast $ 5 Change per Inventory per unit month 900 700 800 Apr 1, 050 1, 200 Labor-hours to produce a unit May 1, 100 1, 500 Cost of increasing daily production rate June and training) 1, 000 1, 100 (hiring and training) Cost of decreasing daily production rate (layoffs) $10 +200 per unit 200 $ 5 per hour ($40 per day) +200 400 +250 650 $ 7 per hour (above 8 hours per day) -150 500 1. 6 hours per unit -400 $300 per unit -100 $600 per unit 100 0 1, 850 rce Total units of inventory carried over from one workfo t nstan 1, 850 co Table 13. 3 month to the next = an 1 – Pl units Workforce required to produce 50 units per day = 10 workers

Roofing Supplier Example 2 Monthly Costs Calculations Cost Information Production at Demand Inventory Ending Month carrying Forecast 1, 850 unitsper Inventory per unit month Inventory carry cost per Day $9, 250 Inventory 50 Units (= $ 5 Change carried x $5 $10 +200 per Subcontracting cost per unit Jan 1, 100 900 per unit) unit 200 Regular-time labor 49, 600 (= 10 workers ($40 per day) per $ 5 per hour x $40 400 Feb 700 +200 Average pay rate 900 124 Mar 1, 050 800 day x+250 days) 650 Overtime pay rate Other costs (overtime, Apr 1, 050 1, 200 hiring, layoffs, Labor-hours to produce a unit May 1, 100 1, 500 subcontracting) 0 Cost of increasing daily production rate June and 1, 000 1, 100 Total cost training) $58, 850 (hiring Cost of decreasing daily production rate (layoffs) $ 7 per hour (above 8 hours per day) -150 500 1. 6 hours per unit -400 $300 per unit -100 $600 per unit 100 0 1, 850 Total units of inventory carried over from one Table 13. 3 month to the next = 1, 850 units Workforce required to produce 50 units per day = 10 workers

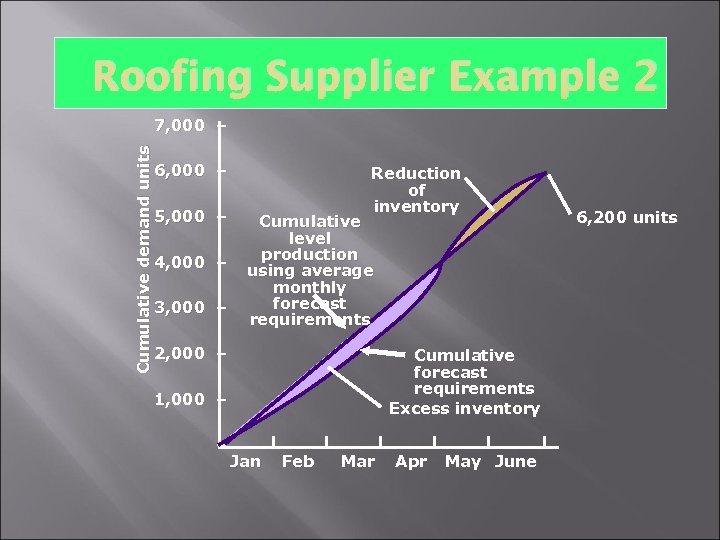

Roofing Supplier Example 2 Cumulative demand units 7, 000 – 6, 000 – 5, 000 – 4, 000 – 3, 000 – Reduction of inventory Cumulative level production using average monthly forecast requirements 2, 000 – Cumulative forecast requirements Excess inventory 1, 000 – – Jan Feb Mar Apr May June 6, 200 units

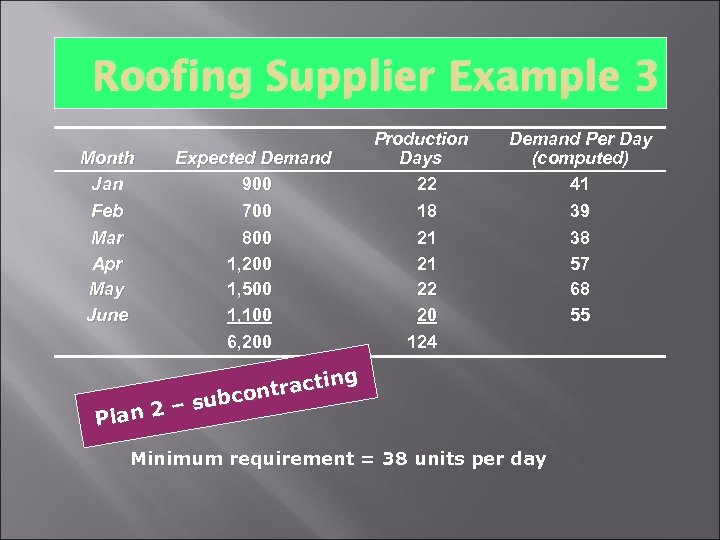

Roofing Supplier Example 3 Month Jan Feb Expected Demand 900 700 Production Days 22 18 Mar Apr May June 800 1, 200 1, 500 1, 100 6, 200 Demand Per Day (computed) 41 39 21 21 22 20 124 38 57 68 55 g ractin nt subco – Plan 2 Minimum requirement = 38 units per day

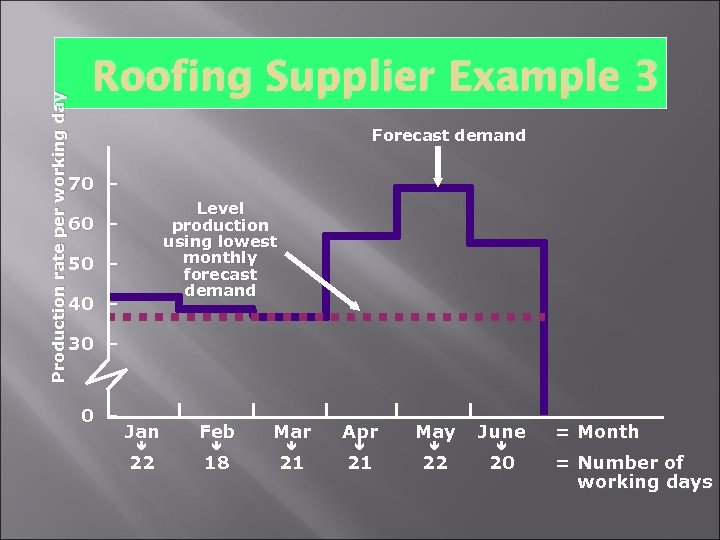

Production rate per working day Roofing Supplier Example 3 Forecast demand 70 – Level production using lowest monthly forecast demand 60 – 50 – 40 – 30 – Jan Feb Mar Apr May June 22 18 21 21 22 20 = Month = Number of working days

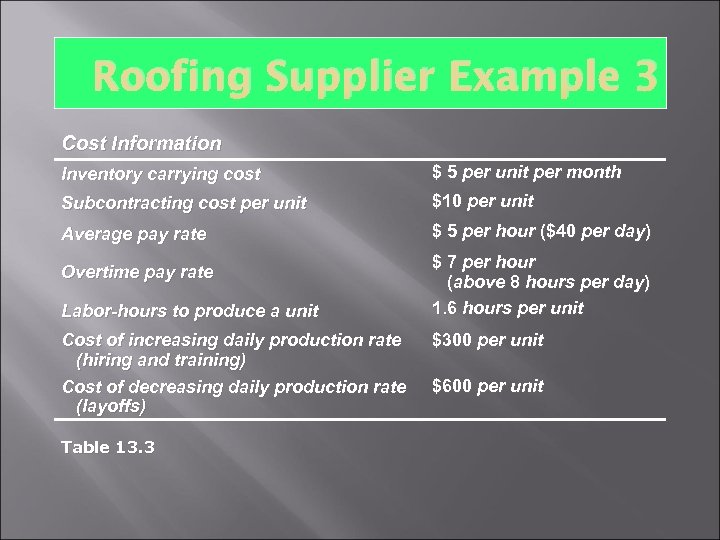

Roofing Supplier Example 3 Cost Information Inventory carrying cost $ 5 per unit per month Subcontracting cost per unit $10 per unit Average pay rate $ 5 per hour ($40 per day) Overtime pay rate Labor-hours to produce a unit Cost of increasing daily production rate (hiring and training) Cost of decreasing daily production rate (layoffs) Table 13. 3 $ 7 per hour (above 8 hours per day) 1. 6 hours per unit $300 per unit $600 per unit

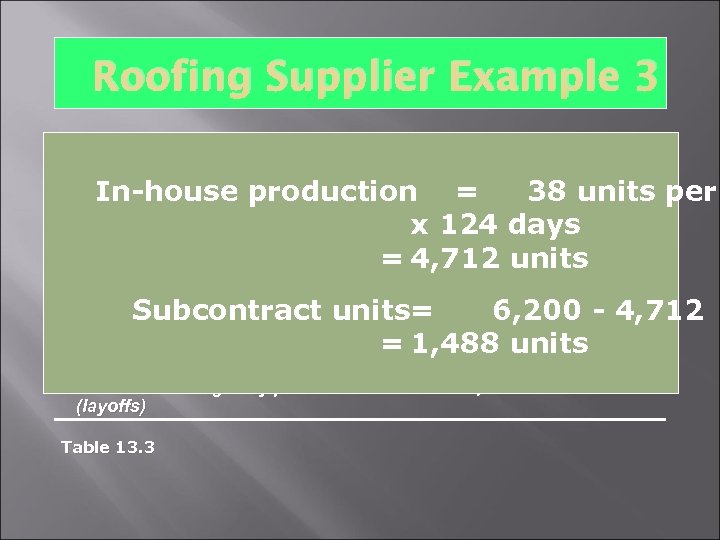

Roofing Supplier Example 3 Cost Information Inventory carry cost $ 5 per unit per month In-house production $10 per unit = 38 Subcontracting cost per unit Average pay rate Overtime pay rate units per x $124 hour ($40 per day) 5 per days = 4, 712 hour $ 7 per units (above 8 hours per day) Labor-hours to produce a units=1. 6 hours per unit - 4, 712 Subcontract 6, 200 Cost of increasing daily production rate 1, 488 units = $300 per unit (hiring and training) Cost of decreasing daily production rate $600 per unit (layoffs) Table 13. 3

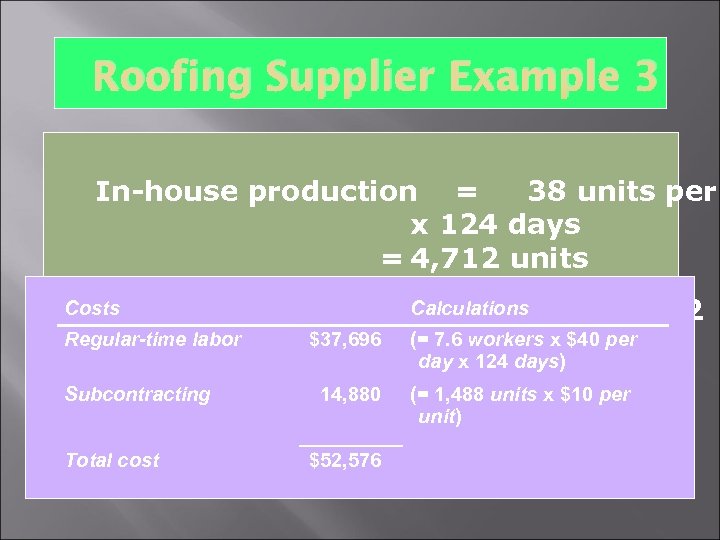

Roofing Supplier Example 3 Cost Information Inventory carry cost $ 5 per unit per month In-house production $10 per unit = 38 Subcontracting cost per unit Average pay rate Overtime pay rate units per x $124 hour ($40 per day) 5 per days = 4, 712 hour $ 7 per units (above 8 hours per day) Costs Subcontract Calculations Labor-hours to produce a units=1. 6 hours per unit - 4, 712 6, 200 Regular-time labor $37, 696= 1, 488 unit x $40 7. 6 workers Cost of increasing daily production rate (= $300 per units per (hiring and training) day x 124 days) Cost of decreasing daily production rate (= $600 per unitx $10 per Subcontracting 14, 880 1, 488 units (layoffs) unit) Table 13. 3 Total cost $52, 576

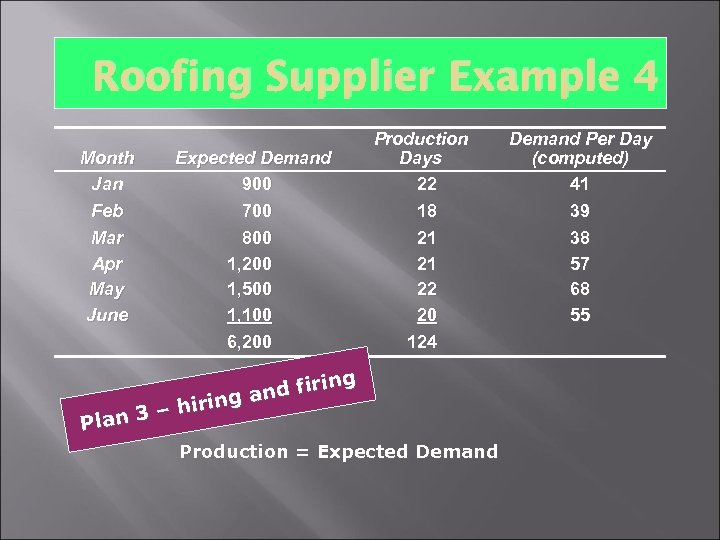

Roofing Supplier Example 4 Month Jan Feb Expected Demand 900 700 Production Days 22 18 Mar Apr May June 800 1, 200 1, 500 1, 100 6, 200 21 21 22 20 124 ing nd fir a hiring – Plan 3 Production = Expected Demand Per Day (computed) 41 39 38 57 68 55

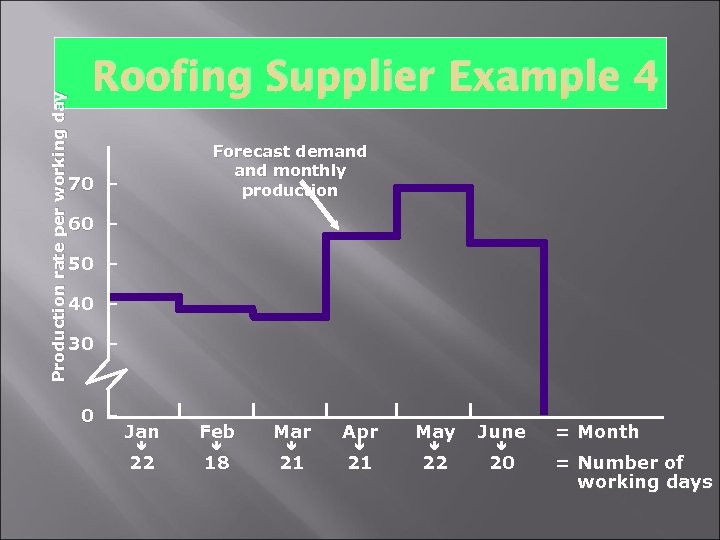

Production rate per working day Roofing Supplier Example 4 Forecast demand monthly production 70 – 60 – 50 – 40 – 30 – Jan Feb Mar Apr May June 22 18 21 21 22 20 = Month = Number of working days

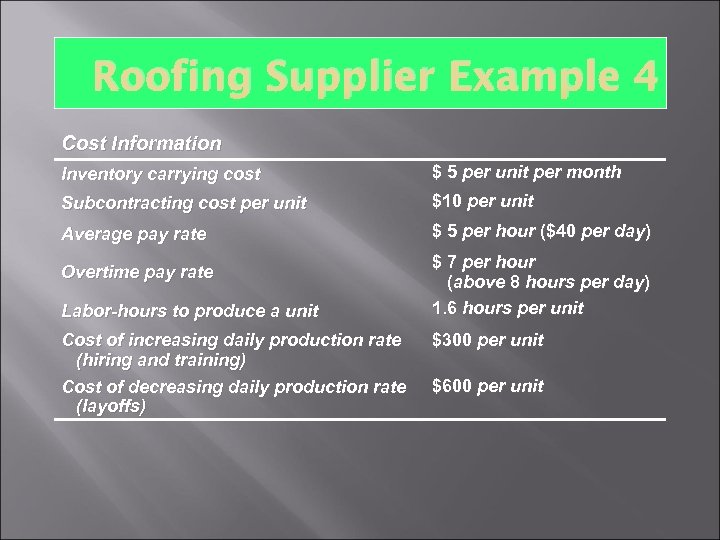

Roofing Supplier Example 4 Cost Information Inventory carrying cost $ 5 per unit per month Subcontracting cost per unit $10 per unit Average pay rate $ 5 per hour ($40 per day) Overtime pay rate Labor-hours to produce a unit Cost of increasing daily production rate (hiring and training) Cost of decreasing daily production rate (layoffs) $ 7 per hour (above 8 hours per day) 1. 6 hours per unit $300 per unit $600 per unit

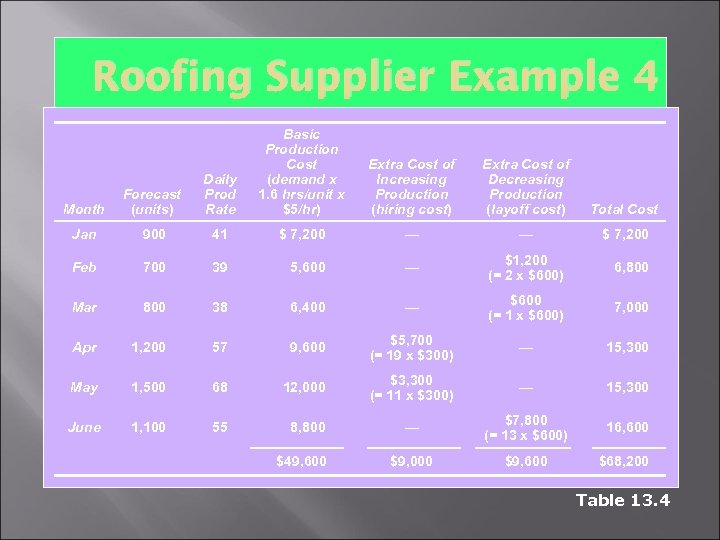

Roofing Supplier Example 4 Basic Production Cost Inventory carrying cost (demand x Daily Forecast Prod 1. 6 hrs/unit x Subcontracting cost per unit Month (units) Rate $5/hr) Cost Information Jan 900 Average pay rate Extra Cost of $ unit per Increasing 5 per. Decreasing month Production $10 per unitcost) Total Cost (hiring cost) (layoff 41 $ 7, 200 — Feb Overtime 700 rate 39 pay 5, 600 — Mar 800 38 6, 400 Labor-hours to produce a unit — $ 5 per hour ($40 per 7, 200 — $ day) $1, 200 $ 7 per hour 6, 800 (= x $600) (above 28 hours per day) $600 7, 000 1. 6 hours x $600) (= 1 per unit $5, 700$300 per unit Cost of increasing daily production rate Apr 1, 200 57 9, 600 — (= 19 x $300) (hiring and training) $3, 300 May 1, 500 68 12, 000 — Cost of decreasing daily production (= 11 x $300) per unit rate $600 (layoffs) June 1, 100 Table 13. 3 55 8, 800 $49, 600 15, 300 — $7, 800 (= 13 x $600) 16, 600 $9, 000 $9, 600 $68, 200 Table 13. 4

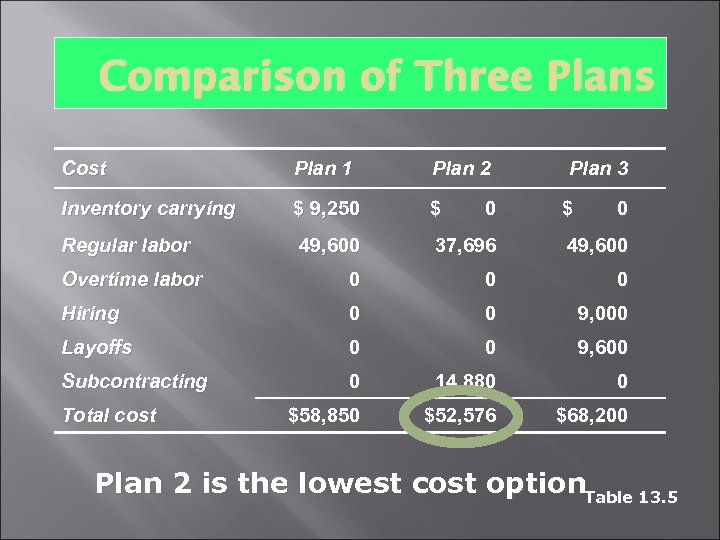

Comparison of Three Plans Cost Plan 1 Plan 2 Inventory carrying $ 9, 250 $ Regular labor 49, 600 37, 696 49, 600 Overtime labor 0 0 0 Hiring 0 0 9, 000 Layoffs 0 0 9, 600 Subcontracting 0 14, 880 0 $58, 850 $52, 576 $68, 200 Total cost 0 Plan 3 $ 0 Plan 2 is the lowest cost option. Table 13. 5

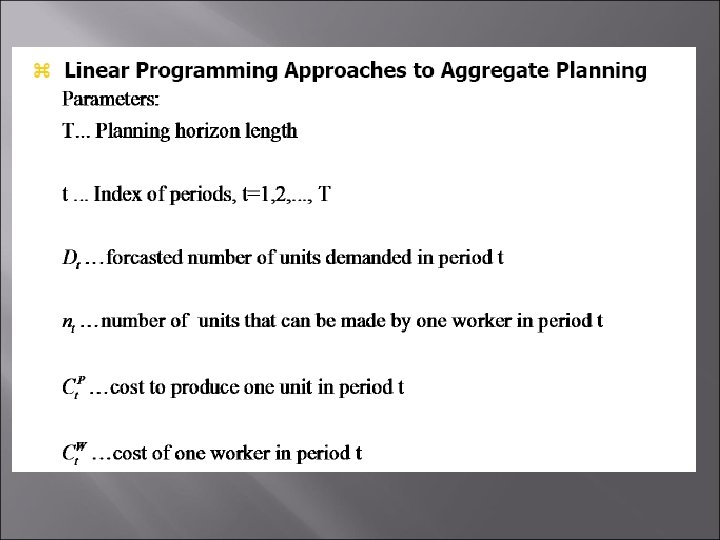

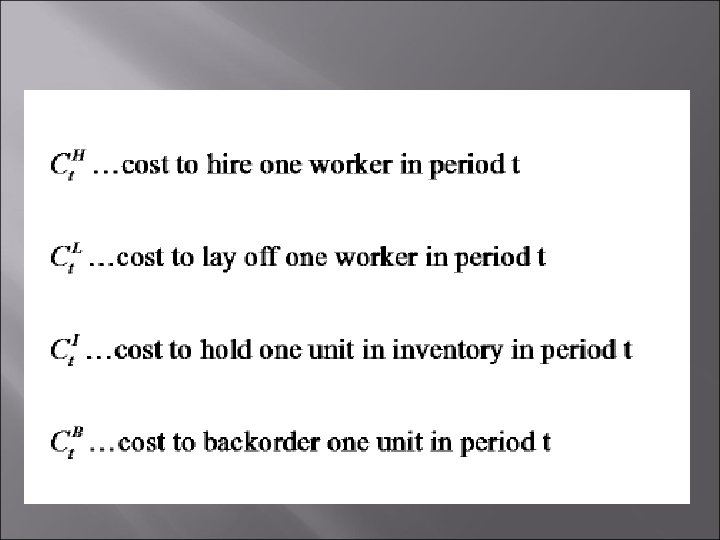

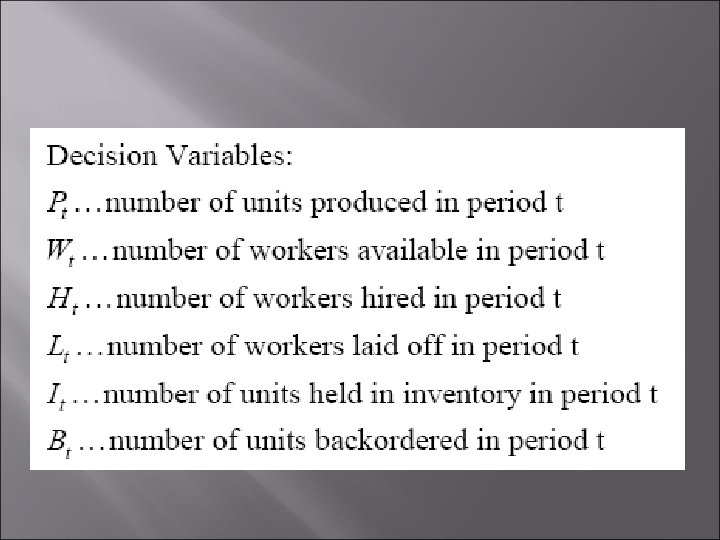

Mathematical Approaches þ Useful for generating strategies þ Transportation Method of Linear Programming þ Produces an optimal plan þ Management Coefficients Model þ Model built around manager’s experience and performance þ Other Models þ þ Linear Decision Rule Simulation

76e7193a6c2be26fe97fc477707fbd92.ppt