bac919b65baee46233367a345faea00f.ppt

- Количество слайдов: 47

PRODUCTION/OPERATIONS MAKING THE PRODUCT

PRODUCTION/OPERATIONS MAKING THE PRODUCT

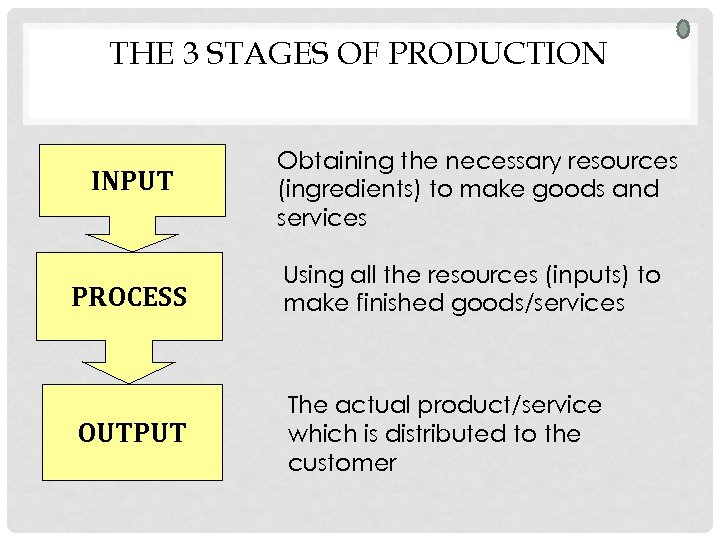

THE 3 STAGES OF PRODUCTION INPUT Obtaining the necessary resources (ingredients) to make goods and services PROCESS Using all the resources (inputs) to make finished goods/services OUTPUT The actual product/service which is distributed to the customer

THE 3 STAGES OF PRODUCTION INPUT Obtaining the necessary resources (ingredients) to make goods and services PROCESS Using all the resources (inputs) to make finished goods/services OUTPUT The actual product/service which is distributed to the customer

For example: Input wool, labour, machinery Process Garment is knitted Output finished product eg jumper Suggest another example

For example: Input wool, labour, machinery Process Garment is knitted Output finished product eg jumper Suggest another example

OPERATIONS - WHAT IS IT? • Changing raw materials into a product which can be sold to customers • The process of using resources to ADD VALUE to a product/service so that it meets the consumers’ needs.

OPERATIONS - WHAT IS IT? • Changing raw materials into a product which can be sold to customers • The process of using resources to ADD VALUE to a product/service so that it meets the consumers’ needs.

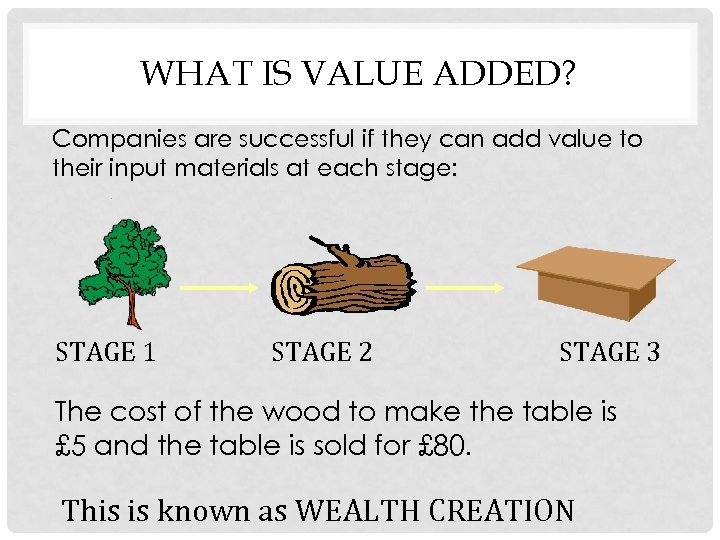

WHAT IS VALUE ADDED? Companies are successful if they can add value to their input materials at each stage: STAGE 1 STAGE 2 STAGE 3 The cost of the wood to make the table is £ 5 and the table is sold for £ 80. This is known as WEALTH CREATION

WHAT IS VALUE ADDED? Companies are successful if they can add value to their input materials at each stage: STAGE 1 STAGE 2 STAGE 3 The cost of the wood to make the table is £ 5 and the table is sold for £ 80. This is known as WEALTH CREATION

QUICK TEST 1. Name a sector of industry which extracts raw materials from the earth. 2. Name the sector of industry which takes the raw materials and makes them into finished goods. 3. What is the other name for the service sector? 4. List 3 inputs in the production of a car. 5. Describe how wealth creation can be measured.

QUICK TEST 1. Name a sector of industry which extracts raw materials from the earth. 2. Name the sector of industry which takes the raw materials and makes them into finished goods. 3. What is the other name for the service sector? 4. List 3 inputs in the production of a car. 5. Describe how wealth creation can be measured.

ANSWERS 1. Name a sector of industry which extracts raw materials from the earth. Primary Sector 2. Name the sector of industry which takes the raw materials and makes them into finished goods. Secondary Sector 3. What is the other name for the service sector? Tertiary Sector

ANSWERS 1. Name a sector of industry which extracts raw materials from the earth. Primary Sector 2. Name the sector of industry which takes the raw materials and makes them into finished goods. Secondary Sector 3. What is the other name for the service sector? Tertiary Sector

4. List 3 inputs in the production of a car. Labour, steel, rubber, plastic, leather 5. Describe how wealth creation can be measured. This is the difference between the value of the inputs and the value of the finished output

4. List 3 inputs in the production of a car. Labour, steel, rubber, plastic, leather 5. Describe how wealth creation can be measured. This is the difference between the value of the inputs and the value of the finished output

WHAT HAS TO BE DONE BEFORE A PRODUCT CAN BE MADE? All new products must go through the Planning Stage to decide: • What is to be produced • How the product is to be made • Where production is to take place • How the product will be packaged

WHAT HAS TO BE DONE BEFORE A PRODUCT CAN BE MADE? All new products must go through the Planning Stage to decide: • What is to be produced • How the product is to be made • Where production is to take place • How the product will be packaged

RESEARCH AND DEVELOPMENT Research • Ensure there is a market • Find best way of meeting demand • Is it efficient • Can it be mass produced • Is it of good quality Development • Design product • Build a prototype • Test and redesign • Trial launch • Test profit generation • Launch the product

RESEARCH AND DEVELOPMENT Research • Ensure there is a market • Find best way of meeting demand • Is it efficient • Can it be mass produced • Is it of good quality Development • Design product • Build a prototype • Test and redesign • Trial launch • Test profit generation • Launch the product

METHODS OF PRODUCTION Click

METHODS OF PRODUCTION Click

PRODUCTION METHODS There are 3 main choices: • JOB Watch me • BATCH Watch me • FLOW Watch me

PRODUCTION METHODS There are 3 main choices: • JOB Watch me • BATCH Watch me • FLOW Watch me

JOB PRODUCTION • Item is specifically designed or built to order (customer requirements). • It is a one-off project • One job is completed from start to finish, then the business moves on to another job. • This type of production uses a lot of workers (labour intensive) who are skilled or specialists in a particular field.

JOB PRODUCTION • Item is specifically designed or built to order (customer requirements). • It is a one-off project • One job is completed from start to finish, then the business moves on to another job. • This type of production uses a lot of workers (labour intensive) who are skilled or specialists in a particular field.

ADVANTAGES • Customer needs are met exactly – the “personal touch” • Changes can be made throughout the job through communication with the customer at all stages • Sense of pride - staff can identify their contribution to the product/service • Motivation – staff enjoy a change of challenge when the next job starts

ADVANTAGES • Customer needs are met exactly – the “personal touch” • Changes can be made throughout the job through communication with the customer at all stages • Sense of pride - staff can identify their contribution to the product/service • Motivation – staff enjoy a change of challenge when the next job starts

DISADVANTAGES • Skilled workers are required – skilled workers normally get higher wage rates than unskilled • Expensive because of uniqueness of product • Less opportunity for automation (use of machines and technology)

DISADVANTAGES • Skilled workers are required – skilled workers normally get higher wage rates than unskilled • Expensive because of uniqueness of product • Less opportunity for automation (use of machines and technology)

BATCH PRODUCTION • Is the process of making several identical products at once • Production stops at the end of each batch before the next batch is started • Can be highly automated but there has to be careful planning

BATCH PRODUCTION • Is the process of making several identical products at once • Production stops at the end of each batch before the next batch is started • Can be highly automated but there has to be careful planning

ADVANTAGES • Flexible production method as each batch can be changed to suit the requirements of the customer • A number of different products can be made using the same production line • Fewer skilled workers are likely to be required so this will cut labour costs

ADVANTAGES • Flexible production method as each batch can be changed to suit the requirements of the customer • A number of different products can be made using the same production line • Fewer skilled workers are likely to be required so this will cut labour costs

DISADVANTAGES • Careful planning is required for the operation to run smoothly • Motivation of workers may be reduced if they are not totally involved in the production process • Time delays – production time is lost resetting machinery for next batch • Good stock management required

DISADVANTAGES • Careful planning is required for the operation to run smoothly • Motivation of workers may be reduced if they are not totally involved in the production process • Time delays – production time is lost resetting machinery for next batch • Good stock management required

FLOW PRODUCTION • This is used when large numbers of identical goods are produced in a continuous process. • It involves large quantities of machinery (automation) often controlled by computers.

FLOW PRODUCTION • This is used when large numbers of identical goods are produced in a continuous process. • It involves large quantities of machinery (automation) often controlled by computers.

ADVANTAGES • Capital-intensive – the use of machines instead of people • Consistency – machines perform the same operation again and again to the same standard • 24 hour production • Speed of production – machines can operate at a faster rate than people • Goods are produced on a large scale (benefits of economies of scale)

ADVANTAGES • Capital-intensive – the use of machines instead of people • Consistency – machines perform the same operation again and again to the same standard • 24 hour production • Speed of production – machines can operate at a faster rate than people • Goods are produced on a large scale (benefits of economies of scale)

DISADVANTAGES • Costs are high – investment in technology and equipment • Identical products – mass produced items have no uniqueness • Lack of motivation for workers – only seeing a small part of the job • If one part of the process breaks down then production must stop

DISADVANTAGES • Costs are high – investment in technology and equipment • Identical products – mass produced items have no uniqueness • Lack of motivation for workers – only seeing a small part of the job • If one part of the process breaks down then production must stop

WHICH METHOD TO CHOOSE? This will depend upon: • Nature of the product – standard or unique • Number of customers • Capital available • Skills and availability of the workforce • Level of technology • Premises/Location Core Notes Operations Unit Page 12

WHICH METHOD TO CHOOSE? This will depend upon: • Nature of the product – standard or unique • Number of customers • Capital available • Skills and availability of the workforce • Level of technology • Premises/Location Core Notes Operations Unit Page 12

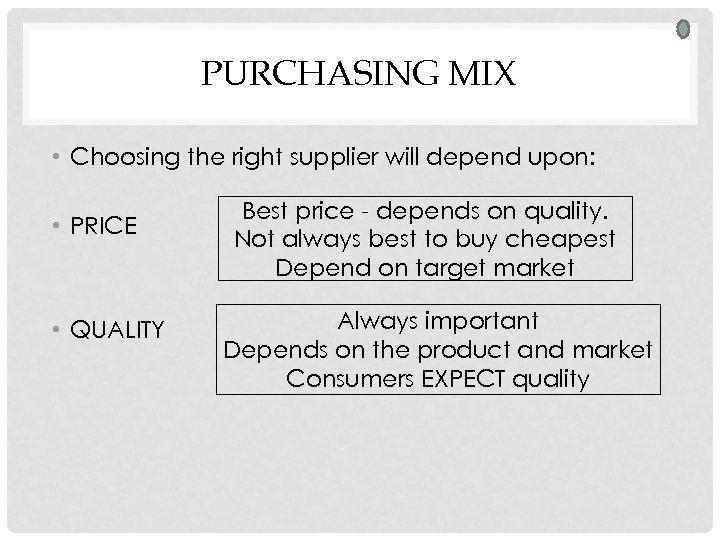

PURCHASING MIX • Choosing the right supplier will depend upon: • PRICE • QUALITY Best price - depends on quality. Not always best to buy cheapest Depend on target market Always important Depends on the product and market Consumers EXPECT quality

PURCHASING MIX • Choosing the right supplier will depend upon: • PRICE • QUALITY Best price - depends on quality. Not always best to buy cheapest Depend on target market Always important Depends on the product and market Consumers EXPECT quality

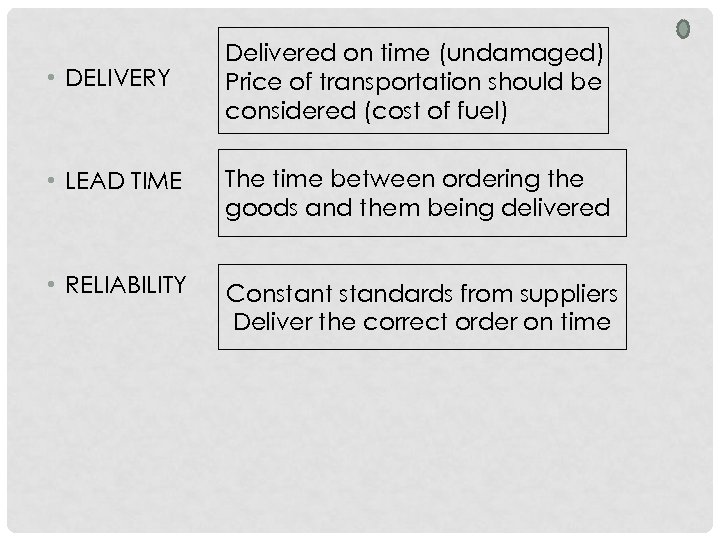

• DELIVERY Delivered on time (undamaged) Price of transportation should be considered (cost of fuel) • LEAD TIME The time between ordering the goods and them being delivered • RELIABILITY Constant standards from suppliers Deliver the correct order on time

• DELIVERY Delivered on time (undamaged) Price of transportation should be considered (cost of fuel) • LEAD TIME The time between ordering the goods and them being delivered • RELIABILITY Constant standards from suppliers Deliver the correct order on time

STOCK – STOCK CONTROL Businesses must keep the correct amount of stock for their needs. What happens if a firm has too much or too little stock?

STOCK – STOCK CONTROL Businesses must keep the correct amount of stock for their needs. What happens if a firm has too much or too little stock?

OVERSTOCKING • Stock can be wasted or go out of date • Too much space is taken up – storage space costs money • Security is required to ensure the stock is not stolen • Money is tied up that could be used in other parts of the business

OVERSTOCKING • Stock can be wasted or go out of date • Too much space is taken up – storage space costs money • Security is required to ensure the stock is not stolen • Money is tied up that could be used in other parts of the business

UNDERSTOCKING • • • Production will have to stop Customer will be let down – order not met Customers may go to another business Business will be lost Reputation will suffer Workers still have to be paid

UNDERSTOCKING • • • Production will have to stop Customer will be let down – order not met Customers may go to another business Business will be lost Reputation will suffer Workers still have to be paid

STOCK MANAGEMENT The following needs to be considered: • The cost of storing stock (warehousing, security and insurance) • Risk of storing stock (theft, out-of-date) • Cash flow problems from overstocking • Loss of profit and reputation from understocking • How to manage stock levels

STOCK MANAGEMENT The following needs to be considered: • The cost of storing stock (warehousing, security and insurance) • Risk of storing stock (theft, out-of-date) • Cash flow problems from overstocking • Loss of profit and reputation from understocking • How to manage stock levels

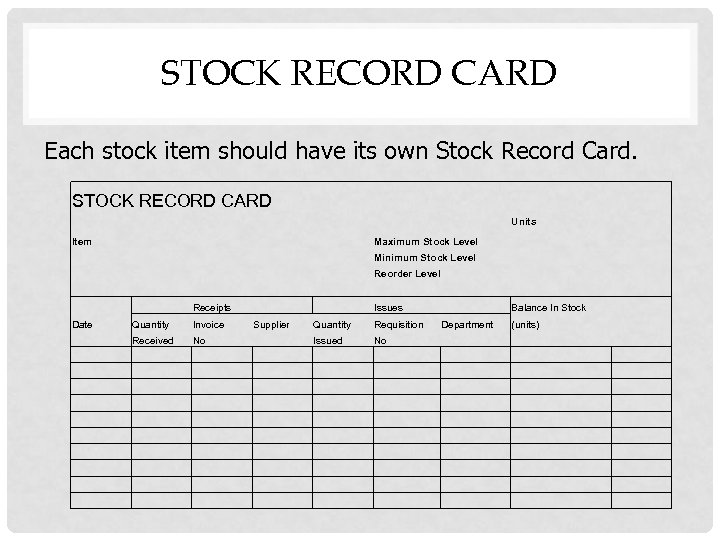

STOCK RECORD CARD Each stock item should have its own Stock Record Card. STOCK RECORD CARD Units Item Maximum Stock Level Minimum Stock Level Reorder Level Receipts Issues Balance In Stock Date Quantity Invoice Supplier Quantity Requisition Department (units) Received No Issued No

STOCK RECORD CARD Each stock item should have its own Stock Record Card. STOCK RECORD CARD Units Item Maximum Stock Level Minimum Stock Level Reorder Level Receipts Issues Balance In Stock Date Quantity Invoice Supplier Quantity Requisition Department (units) Received No Issued No

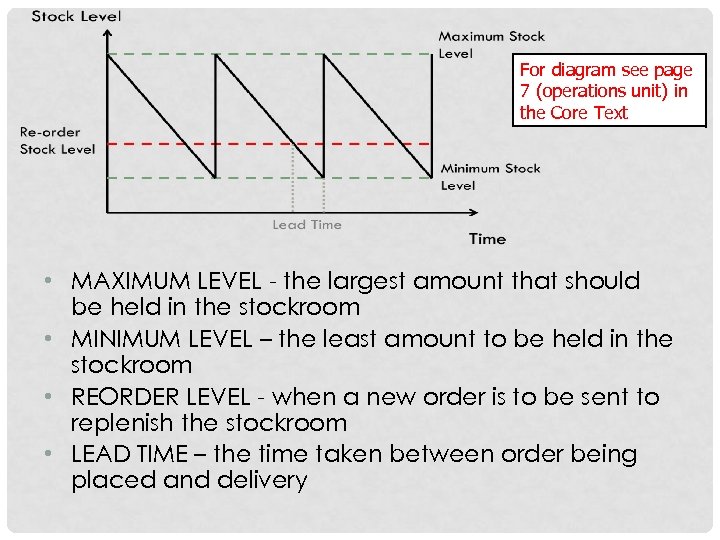

For diagram see page 7 (operations unit) in the Core Text • MAXIMUM LEVEL - the largest amount that should be held in the stockroom • MINIMUM LEVEL – the least amount to be held in the stockroom • REORDER LEVEL - when a new order is to be sent to replenish the stockroom • LEAD TIME – the time taken between order being placed and delivery

For diagram see page 7 (operations unit) in the Core Text • MAXIMUM LEVEL - the largest amount that should be held in the stockroom • MINIMUM LEVEL – the least amount to be held in the stockroom • REORDER LEVEL - when a new order is to be sent to replenish the stockroom • LEAD TIME – the time taken between order being placed and delivery

JUST-IN-TIME STOCK CONTROL • To keep stocks to a minimum, many organisations use just-in-time stock control. • Stock is not stored on the premises • Stocks is delivered straight to the production line when it is needed

JUST-IN-TIME STOCK CONTROL • To keep stocks to a minimum, many organisations use just-in-time stock control. • Stock is not stored on the premises • Stocks is delivered straight to the production line when it is needed

ADVANTAGES • Money is not tied up in stocks • Less costs in holding stocks/warehousing • Less movement/handling of stocks • Workers must be more accurate as there is not a supply of extra materials – wasted materials may stop production

ADVANTAGES • Money is not tied up in stocks • Less costs in holding stocks/warehousing • Less movement/handling of stocks • Workers must be more accurate as there is not a supply of extra materials – wasted materials may stop production

DISADVANTAGES • Complete reliance/dependance on the supplier • Always the chance of running out of stock • Increased costs for ordering and administration • Unable to fulfil last minute orders

DISADVANTAGES • Complete reliance/dependance on the supplier • Always the chance of running out of stock • Increased costs for ordering and administration • Unable to fulfil last minute orders

Examples of companies who use JIT

Examples of companies who use JIT

PEOPLE VERSUS MACHINES MECHANISATION - workers are mostly replaced by machines that they operate AUTOMATION - is one step further and involves replacing workers fully by machines. The machines need minimum supervision. What are the benefits of automation

PEOPLE VERSUS MACHINES MECHANISATION - workers are mostly replaced by machines that they operate AUTOMATION - is one step further and involves replacing workers fully by machines. The machines need minimum supervision. What are the benefits of automation

QUALITY

QUALITY

QUALITY • provides a competitive advantage • keeps customers happy and encourages return purchases • provides customer with information and builds confidence in the brand • reduces costs incurred in solving post sales problems

QUALITY • provides a competitive advantage • keeps customers happy and encourages return purchases • provides customer with information and builds confidence in the brand • reduces costs incurred in solving post sales problems

WAYS TO ENSURE QUALITY OF PRODUCT Use some or all of the following: • • • Quality Management procedures High quality raw materials Highly trained staff Up-to-date technology Well maintained machinery

WAYS TO ENSURE QUALITY OF PRODUCT Use some or all of the following: • • • Quality Management procedures High quality raw materials Highly trained staff Up-to-date technology Well maintained machinery

QUALITY Techniques used by businesses to check the quality of their products: • QUALITY CONTROL • (TOTAL) QUALITY MANAGEMENT • QUALITY CIRCLES • QUALITY ASSURANCE

QUALITY Techniques used by businesses to check the quality of their products: • QUALITY CONTROL • (TOTAL) QUALITY MANAGEMENT • QUALITY CIRCLES • QUALITY ASSURANCE

QUALITY CONTROL • At the end of the production process, products are checked to ensure that they meet agreed quality standards. • Any unacceptable products are then discarded as waste or sent back for reworking.

QUALITY CONTROL • At the end of the production process, products are checked to ensure that they meet agreed quality standards. • Any unacceptable products are then discarded as waste or sent back for reworking.

(TOTAL) QUALITY MANAGEMENT • QM requires everyone in the business to think about quality – not only production teams. • It is a system of doing things right first time and no errors are tolerated. • QM also relies upon good relationships with suppliers – all materials received should be subject to the same high quality standards.

(TOTAL) QUALITY MANAGEMENT • QM requires everyone in the business to think about quality – not only production teams. • It is a system of doing things right first time and no errors are tolerated. • QM also relies upon good relationships with suppliers – all materials received should be subject to the same high quality standards.

QUALITY CIRCLES • Groups of employees meet regularly to discuss areas where improvements can be made. • By involving the employees in the process they can take ownership of the improvements – increasing motivation and productivity.

QUALITY CIRCLES • Groups of employees meet regularly to discuss areas where improvements can be made. • By involving the employees in the process they can take ownership of the improvements – increasing motivation and productivity.

QUALITY ASSURANCE • Products are checked at regular intervals during the production process. • Quality Assurance is provided when a business guarantees the quality of their products. • If a firm reaches certain standards it will be awarded a quality mark. • Customers can buy with confidence

QUALITY ASSURANCE • Products are checked at regular intervals during the production process. • Quality Assurance is provided when a business guarantees the quality of their products. • If a firm reaches certain standards it will be awarded a quality mark. • Customers can buy with confidence

QUALITY • What do these business experts say about the importance of quality? • How does quality impact on workers? Day in the Life of a Toyota production line worker.

QUALITY • What do these business experts say about the importance of quality? • How does quality impact on workers? Day in the Life of a Toyota production line worker.

TECHNOLOGY • We have already seen how important an internal and external influence Technology is on business. • All aspects of Operations are affected by technology – from ordering stock, maintaining stock records, producing the good or service, selling and delivering the finished product.

TECHNOLOGY • We have already seen how important an internal and external influence Technology is on business. • All aspects of Operations are affected by technology – from ordering stock, maintaining stock records, producing the good or service, selling and delivering the finished product.

TECHNOLOGY See how a small bakery used technology to grow… For any firm technology allows: • standardised product(s) to be produced – allows economies of scale • continuous production

TECHNOLOGY See how a small bakery used technology to grow… For any firm technology allows: • standardised product(s) to be produced – allows economies of scale • continuous production

TECHNOLOGY – ALLOWS THE FOLLOWING • processing products in batches — allows many similar standardised products to be made using pre -programmed machinery • online ordering - with quicker timescales between ordering and delivery, meaning higher levels of customer satisfaction.

TECHNOLOGY – ALLOWS THE FOLLOWING • processing products in batches — allows many similar standardised products to be made using pre -programmed machinery • online ordering - with quicker timescales between ordering and delivery, meaning higher levels of customer satisfaction.